SIST EN 840-5:2020

(Main)Mobile waste and recycling containers - Part 5: Performance requirements and test methods

Mobile waste and recycling containers - Part 5: Performance requirements and test methods

This European Standard gives the test methods for mobile waste and recycling containers according to EN 840-1 to EN 840-4. It also gives the levels to be reached during the tests or after they have been done.

This European Standard is applicable to mobile waste and recycling containers with capacities up to 1 700 l.

Fahrbare Abfall- und Wertstoffbehälter - Teil 5: Anforderungen an die Ausführung und Prüfverfahren

Dieses Dokument legt die Prüfverfahren für fahrbare Abfall- und Wertstoffbehälter nach EN 840 1 bis EN 840 4 fest. Es legt auch die Anforderungsstufen fest, die während oder nach der Prüfung erreicht werden müssen.

Dieses Dokument gilt für fahrbare Abfall- und Wertstoffbehälter mit einem Nennvolumen bis 1 700 l.

Conteneurs roulants à déchets et de recyclage - Partie 5 : Exigences de performance et méthodes d’essais

Le présent document spécifie les méthodes d’essais applicables aux conteneurs roulants à déchets et de recyclage conformes aux EN 840 1 à EN 840 4. Elle indique également le niveau des exigences à atteindre lors des essais ou à l’issue des essais.

Le présent document s’applique aux conteneurs roulants à déchets et de recyclage de capacité inférieure ou égale à 1 700 l.

Premični zabojniki za odpadke in za recikliranje - 5. del: Zahtevane lastnosti in preskusne metode

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Sep-2018

- Publication Date

- 22-Apr-2020

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 16-Apr-2020

- Due Date

- 21-Jun-2020

- Completion Date

- 23-Apr-2020

Relations

- Effective Date

- 15-Apr-2020

- Effective Date

- 28-Feb-2018

Overview

EN 840-5:2020 (CEN) specifies performance requirements and test methods for mobile waste and recycling containers covered by EN 840‑1 to EN 840‑4. It applies to containers with capacities up to 1 700 l and defines how to verify structural integrity, functionality and safety after standardized mechanical and environmental tests. The 2020 edition supersedes EN 840‑5:2012 and is part of the EN 840 series for mobile waste and recycling containers.

Key topics and technical requirements

- Scope and applicability: Tests apply to containers up to 1 700 l; components must conform to EN 840‑1 to EN 840‑4.

- Pre‑ and post‑test checks: Visual inspection for defects, dimensional checks, marking, colour agreement and mass tolerances (plastic ±5 %, metal ±10 %).

- Conditioning and temperatures: Tests conducted at T = (23 ± 5) °C and T = −18 °C with minimum conditioning of 12 h; limited exposure windows (5 min) and re‑conditioning rules.

- Test load: Ballast bags of HDPE granules (density 0.5 kg/dm3). Load = 0.4 kg/dm3 × nominal volume, maximum 440 kg.

- Mechanical tests:

- Impact (ball drop): Low‑temperature impact tests on sensitive points (lid, hinges, handles, body bottom) using a defined 5 kg steel cylinder apparatus.

- Lateral impacts on inclined plane: Sequence of controlled face and corner impacts for 4‑wheel containers at defined velocities and a 10° incline.

- Kerb travel / kerb fall and wheel tests (annexed apparatus and procedures).

- Pulling and rolling tests, stability tests, lifting/tilting tests, and miscellaneous tests (e.g., handle tests).

- Leakage and functionality criteria: After impacts, containers may deform but must remain functional and, where tested, waterproof (e.g., 10 % body fill leak check).

- Test reporting: Defined content for test reports and informative annexes for apparatus (kerb stop, wheel test, weathering).

Applications and users

Who uses EN 840‑5:2020:

- Manufacturers of mobile waste and recycling containers - to validate design, production quality and compliance.

- Independent test laboratories - to perform standardized performance testing and certification.

- Municipalities, waste management companies and procurement teams - to specify durability, safety and warranty conditions in tenders.

- Designers and material suppliers - for component selection (wheels, hinges, coatings) and conformity with lifecycle requirements.

Practical benefits:

- Ensures consistent, reproducible evaluation of container durability and safety.

- Supports procurement decisions with objective performance data.

- Reduces operational failures and maintenance costs through validated designs.

Related standards

- EN 840‑1 to EN 840‑4 (dimensions and design)

- EN 10142; EN ISO 1461; EN ISO 2081 (metal/coating specifications)

- Refer to annexes in EN 840‑5 for specific test apparatus and weathering procedures.

Keywords: EN 840‑5:2020, mobile waste and recycling containers, performance requirements, test methods, impact test, kerb travel test, lifting‑tilting test, container testing, CEN.

Frequently Asked Questions

SIST EN 840-5:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Mobile waste and recycling containers - Part 5: Performance requirements and test methods". This standard covers: This European Standard gives the test methods for mobile waste and recycling containers according to EN 840-1 to EN 840-4. It also gives the levels to be reached during the tests or after they have been done. This European Standard is applicable to mobile waste and recycling containers with capacities up to 1 700 l.

This European Standard gives the test methods for mobile waste and recycling containers according to EN 840-1 to EN 840-4. It also gives the levels to be reached during the tests or after they have been done. This European Standard is applicable to mobile waste and recycling containers with capacities up to 1 700 l.

SIST EN 840-5:2020 is classified under the following ICS (International Classification for Standards) categories: 13.030.40 - Installations and equipment for waste disposal and treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 840-5:2020 has the following relationships with other standards: It is inter standard links to SIST EN 840-5:2014, SIST EN 840-5:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 840-5:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2020

Nadomešča:

SIST EN 840-5:2014

Premični zabojniki za odpadke in za recikliranje - 5. del: Zahtevane lastnosti in

preskusne metode

Mobile waste and recycling containers - Part 5: Performance requirements and test

methods

Fahrbare Abfall- und Wertstoffbehälter - Teil 5: Anforderungen an die Ausführung und

Prüfverfahren

Conteneurs roulants à déchets et de recyclage - Partie 5 : Exigences de performance et

méthodes d’essais

Ta slovenski standard je istoveten z: EN 840-5:2020

ICS:

13.030.40 Naprave in oprema za Installations and equipment

odstranjevanje in obdelavo for waste disposal and

odpadkov treatment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 840-5

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2020

EUROPÄISCHE NORM

ICS 13.030.40 Supersedes EN 840-5:2012

English Version

Mobile waste and recycling containers - Part 5:

Performance requirements and test methods

Conteneurs roulants à déchets et de recyclage - Partie 5 Fahrbare Abfall- und Wertstoffbehälter - Teil 5:

: Exigences de performance et méthodes d'essais Anforderungen an die Ausführung und Prüfverfahren

This European Standard was approved by CEN on 7 October 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 840-5:2020 E

worldwide for CEN national Members.

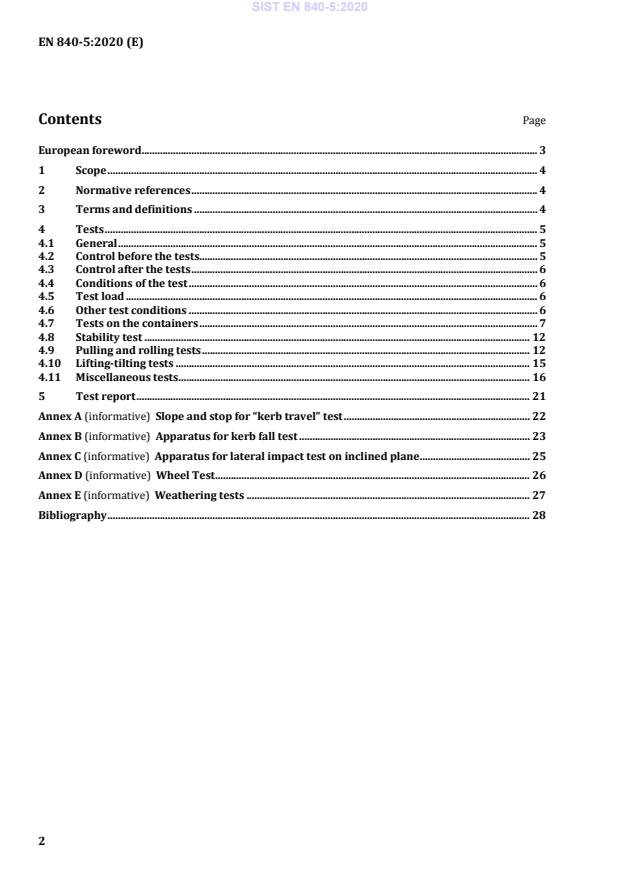

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Tests . 5

4.1 General . 5

4.2 Control before the tests. 5

4.3 Control after the tests . 6

4.4 Conditions of the test . 6

4.5 Test load . 6

4.6 Other test conditions . 6

4.7 Tests on the containers . 7

4.8 Stability test . 12

4.9 Pulling and rolling tests . 12

4.10 Lifting-tilting tests . 15

4.11 Miscellaneous tests . 16

5 Test report . 21

Annex A (informative) Slope and stop for “kerb travel” test . 22

Annex B (informative) Apparatus for kerb fall test . 23

Annex C (informative) Apparatus for lateral impact test on inclined plane . 25

Annex D (informative) Wheel Test . 26

Annex E (informative) Weathering tests . 27

Bibliography . 28

European foreword

This document (EN 840-5:2020) has been prepared by Technical Committee CEN/TC 183 “Waste

management”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2020, and conflicting national standards shall

be withdrawn at the latest by October 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 840-5:2012.

The main changes compared to the previous edition are listed below:

a) 4.11.2 "Handle test" has been updated;

b) Table 4 "Sequence of tests" has been corrected;

c) the document has been editorially revised and adapted to the new design rules.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document gives the test methods for mobile waste and recycling containers according to EN 840-1

to EN 840-4. It also gives the levels to be reached during the tests or after they have been done.

This document is applicable to mobile waste and recycling containers with capacities up to 1 700 l.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 840-1, Mobile waste and recycling containers — Part 1: Containers with 2 wheels with a capacity up to

400 l for comb lifting devices — Dimensions and design

EN 840-2, Mobile waste and recycling containers — Part 2: Containers with 4 wheels with a capacity up to

1 300 l with flat lid(s), for trunnion and/or comb lifting devices — Dimensions and design

EN 840-3, Mobile waste and recycling containers — Part 3: Containers with 4 wheels with a capacity up to

1 300 l with dome lid(s), for trunnion and/or comb lifting devices — Dimensions and design

EN 840-4, Mobile waste and recycling containers — Part 4: Containers with 4 wheels with a capacity up to

1 700 l with flat lid(s), for wide trunnion or BG- and/or wide comb lifting device — Dimensions and design

EN 10142, Continuously hot-dip zinc coated low carbon steels strip and sheet for cold forming —

Technical delivery conditions

EN ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test

methods (ISO 1461)

EN ISO 2081, Metallic and other inorganic coatings - Electroplated coatings of zinc with supplementary

treatments on iron or steel (ISO 2081)

3 Terms and definitions

For the purposes of this document, the terms and definitions according to EN 840-1, EN 840-2,

EN 840-3 and EN 840-4 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

NOTE Terms for components of mobile waste and recycling containers and lifting devices in three languages

are given in Annex A of EN 840-1:2020.

4 Tests

4.1 General

Before and after the tests a visual inspection of the container shall be done for the purpose of:

a) checking that the container is not damaged and has no visual defect;

b) checking that the manufacturing characteristics of the container to be tested are those specified in

the standards applying to the container according to EN 840-1 to EN 840-4;

c) comparing the condition of the container before and after the sequence of the tests.

After completing the tests some deformation of the container is permissible, however, it shall remain

entirely functional.

4.2 Control before the tests

4.2.1 Visual aspects

No obvious damage, cracks, bubbles, large flashes or sharp edges shall be present. No surface defects

(unsmooth areas; trails in colour) perceivable from a distance of 1 m by the naked eye shall be visible.

4.2.2 Compatibility with EN 840-1 to EN 840-4

4.2.2.1 Components

Body, lid, wheels and other fittings shall conform to the relevant container standard.

4.2.2.2 Sizes and dimensions

Functional and safety dimensions for the container and its components shall be checked according to

the figures and the relevant tables of EN 840-1 to EN 840-4.

4.2.2.3 Volumes

The volumes of container shall be measured:

a) for the body, by tank method;

b) for the lid, by tank method;

c) volume results in a) and b) minus any duplicated volumes.

The volumes shall be within the tolerances according to EN 840-1 to EN 840-4.

For containers according to EN 840-3 volume measurement by means of calculation is allowed.

4.2.2.4 Tank method

The test equipment shall consist of a tank with sufficient capacity to receive the container to be tested.

The test procedure is as follows:

— place the empty container in a tank, the container shall not be inclined;

— simultaneously fill the tank and the container with water at a temperature of (15 ± 5) °C;

— measure the quantity of water inside the container.

Accuracy of measurement shall be ± 1 % of the measured capacity of the container.

4.2.3 Deflection for comb lifting system

The frontal receiver shall have a horizontal deflection of no more than:

a) 1,5 % of the length of the frontal receiver for plastic;

b) 0,6 % of the length for steel.

For other systems the values are to be defined when the systems are standardized.

4.2.4 Masses

The tolerances on the container mass claimed are as follows: for plastic containers ± 5 % and for metal

containers ± 10 %.

4.2.5 Colour

The colour shall be defined and agreed between customer and supplier. For colour measurement,

differences and tolerances refer to existing International Standards.

4.2.6 Marking

Marking of the container shall correspond to EN 840-1 to EN 840-4.

4.3 Control after the tests

Not withstanding variations in deflection and sizes, it shall be possible to lift and tilt the container

loaded according to 4.5 with nominal load safely on the designated lifting equipment and to move the

container on its wheels.

4.4 Conditions of the test

The tests shall be carried out at the following temperatures:

— T = (23 ± 5) °C

— T = ( -18 ) °C.

-2

The minimum duration of conditioning before testing at a test temperature T shall be 12 h. If the test

shall be carried out outside the room conditioned at T it shall be carried out within 5 min after taking

the test pieces from the conditioned room. If the duration of the tests is more than 5 min, then the

container shall be kept in the conditioned room for at least 15 min before a new 5 min period of testing.

For special purposes a temperature lower than −18 °C or higher than 23 °C can be agreed; in this case it

shall be indicated in the test report.

4.5 Test load

For the test the containers are to be filled with ballast bags of HDPE granules of 4 kg max., with granules

having a density of 0,5 kg/dm .

The test load shall be 0,4 kg/dm multiplied by nominal volume, but not more than 440 kg.

4.6 Other test conditions

Any other test conditions shall be defined within the tests involved.

4.7 Tests on the containers

4.7.1 General

All tests shall be carried out on new containers.

4.7.2 Impact tests by ball drop

The ball drop test is not compulsory for steel containers.

The ability of sensitive points of the container to resist impacts at low temperature shall be tested

under conditions in 4.4.

The 2-wheeled containers shall be placed on a concrete or steel surface in the normal position.

There shall be a steel frame between the concrete surface or the steel surface and the container so that

the complete area of the bottom of the container can be deflected during the test.

The 4-wheeled containers shall stand on their wheels.

Ball drop tests shall be carried out using a 5 kg steel cylinder, diameter 65 mm, with hemispheric end

radius of 32,5 mm. The steel cylinder is guided in a vertical pipe with a slot or with holes in order to

allow the air to escape during the drop.

The device shall be according to Figure 1.

Dimensions in millimetres

Key

1 vertical (plastic) pipe (inside diameter: 70 mm) 5 container bottom

2 steel cylinder (diameter: 65 mm; 1 hemispheric end; mass: 5 kg) 6 free room

3 height fall (0,80 m) 7 concrete or steel surface

4 steel frame (see 4.7.2)

Figure 1 — Device for ball drop test

The following areas of containers shall be tested by impact tests:

a) on the body bottom (see Figure 2d) there shall be 3 successive impacts for each impact point

defined below:

1) the injection point(s),

2) A and D or C and B.

after the test the container shall be waterproof in the tested points;

b) there shall be 2 successive impacts for each impact point defined below (see Figures 2a), 2b), 2c))

1) the centre of the lid (E),

2) one corner of the lid (cylinder to be tangent to the lid) (F),

3) the corner diametrically opposite (cylinder to be tangent to the lid) (G),

4) each hinge (H),

5) the centre of the front face of the top rim (J),

6) the centre of a lateral face of the top rim (I),

7) the back corner opposite the lateral face previously tested of the top rim (K),

8) centre of any handle (L, see Figure 2c) key 2).

Dimensions in millimetres

a) Top view of the body/top rim b) Lid

c) Handles, hinges d) Body bottom

Key

1 injection point (if one injection point only, impact on it and on A - D or B - C)

2 middle of handle

Figure 2 — Impact points for ball drop test

Outside of the conditioning room (see 4.4), the test shall not last more than 5 min. After this time the

container shall be reconditioned for at least 15 min.

After the test the following procedure shall be applied, if there is any doubt about the result:

— fill the body with a water volume equal to 10 % of the maximum capacity of the body;

— wait for 10 min.

After 10 min, if the container leaks, it is declared to be non-conforming.

4.7.3 Impacts on an inclined plane

Only 4-wheeled containers shall be tested with impact on each wall of the body and on each corner to

check the resistance to straining and breaking of sensitive areas, including protruding areas and fittings.

The test conditions shall be:

— test temperature T = room temperature;

— test load according to 4.5;

— inclination of 10° (ten degrees) to the horizontal;

— impact against a wall perpendicular to the moving direction;

— a total of 16 impacts according to the sequence in Table 1.

During the procedure the lid shall be closed. The loaded container shall be placed on a trolley with an

inclination of 10° (ten degrees) (relative to the horizontal). Precautions shall be taken to avoid

accidental tipping of the container during the test (see Figure C.1).

Other apparatus than shown in Figure C.1 may be used if it allows the same impact and velocity

conditions.

The impact velocity shall be (1,85 ± 0,05) m/s when a face is tested and (1,3 ± 0,05) m/s when a corner

is tested.

The vertical faces of the container will be numbered from 1 to 4 and the face marked 1 being the large

face fitted for the (comb) lifting system. Corners are marked 1.2, 2.3, 3.4 and 4.1.

Table 1 — Sequence of the lateral impacts

Impact n° Face or corner tested No of impacts

1 to 2 Face 1 2

3 to 4 Corner 1.2 2

5 to 6 Face 2 2

7 to 8 Corner 2.3 2

9 to 10 Face 3 2

11 to 12 Corner 3.4 2

13 to 14 Face 4 2

15 to 16 Corner 4.1 2

After completing the test some deformation of the container is permissible, however, it shall remain

entirely functional.

4.7.4 Kerb travel (run)

Only 4-wheeled containers shall be tested for kerb travel using run tests under the following conditions:

— test shall be carried out at room temperature T ;

— test load according to 4.5;

— apparatus shall comply with Annex A;

— kerb height shall be 140 mm orthogonal to the moving direction and located at the end of the run;

— wheels are to be guided in order to be orthogonal to the kerb at the time of the impact;

— impact velocity shall be (1,85 ± 0,05) m/s;

— there shall be 4 impacts for each of the shorter ends of the container (8 in total).

After the test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...