oSIST prEN 13240:2011

(Main)Room heaters fired by solid fuel - Requirements and test methods

Room heaters fired by solid fuel - Requirements and test methods

This European Standard specifies requirements relating to the design, manufacture, construction, safety and performance (efficiency and emission) instructions and marking together with associated test methods and test fuels for type testing residential roomheaters fired by solid fuel.

This Standard is applicable to non-mechanically fired appliances which are listed under categories 1a and 2a of Table 1. These appliances provide heat into the space where they are installed. Additionally, where fitted with a boiler, they also provide domestic hot water and/or central heating. These appliances may burn either solid mineral fuels, peat briquettes, natural or manufactured wood logs or be multi-fuel in accordance with the appliance manufacturer’s instructions.

This standard is not applicable to appliances with fan assisted combustion air.

Raumheizer für feste Brennstoffe - Anforderungen und Prüfungen

Diese Europäische Norm gilt für freistehende oder eingebaute Raumheizer für feste Brennstoffe, ohne funktionalen Änderungen, die mit Feuerraumtüren entweder geschlossen oder geschlossen und offen betrieben werden können und die in den Kategorien 1a und 2a in Tabelle 1 aufgeführt sind. Diese Europäische Norm ist nur für nicht mechanisch beschickte Feuerstätten der Kategorien 1a und 2a von Tabelle 1 anwendbar. Diese Europäische Norm beschreibt Anforderungen an Auslegung, Herstellung, Ausführung, Sicherheit und Leistungsvermögen (Wirkungsgrad und Emission) von Raumheizer für feste Brennstoffe (im Folgenden als "Feuerstätte(n)" bezeichnet) und deren Anleitungen. Weiterhin enthält diese Norm Festlegungen für die Konformitätsbewertung, das heißt Typprüfung (ITT) und werkseigene Produktionskontrolle (FCP) und die Kennzeichnung der Feuerstätten. Diese Feuerstätten beheizen den Aufstellungsraum. Sofern sie mit wasserführenden Bauteilen ausgestattet sind, liefern sie Heizwasser und/oder dienen der Zentralbeheizung. Diese Feuerstätten können entsprechend der Bedienungsanleitung des Herstellers entweder feste mineralische Brennstoffe, Torfbriketts, Holzscheite, Holzbriketts oder mehrere dieser Brennstoffe verfeuern. Diese Norm gilt nicht für Feuerstätten mit Verbrennungsluftgebläse oder mechanisch beschickte Feuerstätten.

Poêles à combustible solide - Exigences et méthodes d'essai

La présente Norme européenne est applicable aux poêles à combustible solide, indépendants ou encastrés, sans modification fonctionnelle, qui fonctionnent avec des portes foyères uniquement fermées, ou ouvertes et fermées, et qui sont énumérés sous les catégories 1a et 2a du Tableau 1. D'autre part, la présente Norme européenne n'est applicable qu'aux poêles dépourvus d’alimentation mécanique qui sont énumérés sous les catégories 1a et 2a du Tableau 1. La présente Norme européenne spécifie les exigences relatives à la conception, la fabrication, la construction, la sécurité et la performance (en termes de rendement et d'émission) des poêles à combustible solide (appelés ci-après « appareils ») et fournit des instructions les concernant. En outre, elle fournit des dispositions pour l'évaluation de la conformité, c'est-à-dire l'essai de type initial (ITT) et le contrôle de fabrication en usine (FPC) ainsi que pour le marquage de ces appareils. Ces appareils produisent de la chaleur dans l’espace où ils sont installés. De plus, lorsqu’ils sont équipés d’un bouilleur, ils produisent également de l’eau chaude à usage domestique et/ou du chauffage central. Ces appareils peuvent utiliser soit des combustibles minéraux solides, des briquettes de tourbe, des bûches de bois naturel ou reconstitué, soit plusieurs combustibles conformément aux instructions du fabricant. Cette norme ne s’applique pas aux appareils équipés d'un ventilateur pour l'alimentation en air de combustion ou aux appareils à alimentation mécanique.

Grelniki prostorov na trdna goriva - Zahteve in preskusne metode

General Information

- Status

- Not Published

- Public Enquiry End Date

- 29-May-2011

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 07-Oct-2013

- Due Date

- 12-Oct-2013

- Completion Date

- 07-Oct-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 04-Jul-2009

Overview

oSIST prEN 13240:2011 is a comprehensive European Standard developed by CEN, titled "Room heaters fired by solid fuel - Requirements and test methods." This standard sets out mandatory conditions related to the design, manufacture, construction, safety, and performance of residential room heaters fueled by solid fuels such as wood logs, mineral fuels, peat briquettes, or multi-fuel types. It also includes instructions for marking, test methods, and suitable test fuels for type testing these appliances.

Applicability focuses on non-mechanically fired appliances categorized under 1a and 2a-freestanding or inset room heaters without fan assisted combustion air. The heaters targeted by this standard are designed to provide heat directly into the installation space and may also supply domestic hot water or central heating if fitted with a boiler.

This standard supersedes EN 13240:2001 and supports compliance with essential EU directives, ensuring safety, efficiency, and emission control requirements are met for solid fuel room heaters in Europe.

Key Topics

Scope and Applicability

- Freestanding and inset room heaters using solid fuel without functional modifications

- Non-mechanically fired appliances - excludes fan assisted combustion air systems

- Appliances burning solid mineral fuels, peat briquettes, wood logs (natural and manufactured), or multi-fuel

Design, Materials, and Construction

- Use of grey cast iron, spheroidal graphite cast iron, non-alloy structural steels, and stainless steel based on referenced EN and ISO standards

- Construction requirements ensuring durability, strength, and leaktightness

Safety Requirements

- Natural draught operation, firedoor operation, temperature control of adjacent combustible materials, and electrical safety

- Prevention of overheating in fuel storage and operating components

Performance Requirements

- Efficiency and emissions testing to minimize environmental impact

- Flue gas temperature and flue draught controls

- Space heating and water heating outputs, refuelling intervals, and combustion stability

Testing and Evaluation

- Initial type testing (ITT) involving emissions, efficiency, and safety performance

- Factory production control (FPC) for ongoing compliance

- Normative test methods and selection of standard test fuels

Marking and Instructions

- Clear, compliant marking to aid identification and safe use

- Installation and user operating instructions ensuring correct appliance handling and maintenance

Applications

oSIST prEN 13240:2011 is essential for manufacturers, testing laboratories, and regulatory bodies involved with the production, certification, and installation of residential solid fuel room heaters. Its practical value extends to:

- Manufacturers who design and produce solid fuel room heaters ensuring compliance with European safety and environmental standards.

- Test facilities conducting type testing and factory production control to validate product performance, emissions, and safety.

- Installers and distributors needing authoritative instructions to install and safely operate solid fuel heaters in residential settings.

- Regulatory agencies referencing the standard for market surveillance and enforcement of EU construction product directives.

By adhering to oSIST prEN 13240:2011, stakeholders can guarantee appliances that deliver efficient heating, comply with environmental regulations, and maintain occupant safety within homes or small buildings.

Related Standards

oSIST prEN 13240:2011 references multiple relevant European and International standards to ensure material quality, safety, and reliable test procedures:

- EN 13229: Covers inset appliances with and without firedoors

- EN 1561 & EN 1563: Standards for grey cast iron and spheroidal graphite cast iron used in construction

- EN 10025 & EN 10028: Specifications on structural steel materials

- EN 60335-2-102: Safety requirements for household solid fuel burning appliances with electrical connections

- ISO 7 & ISO 228: Pipe thread standards relevant for appliance connections

- ISO 1171 & ISO 1928: Test methods for ash content and calorific values of solid fuels

- CEN/TS 15883: Emission test methods tailored to residential solid fuel burning appliances

These interlinked standards form a robust framework ensuring solid fuel heaters meet rigorous safety, material, and environmental specifications for the European market.

Keywords: oSIST prEN 13240:2011, solid fuel room heaters, residential heaters, European standard, solid fuel appliances, type testing, safety requirements, emission testing, efficiency requirements, solid mineral fuels, peat briquettes, wood logs, non-mechanically fired appliances, CEN standards, heating appliance conformity

Frequently Asked Questions

oSIST prEN 13240:2011 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Room heaters fired by solid fuel - Requirements and test methods". This standard covers: This European Standard specifies requirements relating to the design, manufacture, construction, safety and performance (efficiency and emission) instructions and marking together with associated test methods and test fuels for type testing residential roomheaters fired by solid fuel. This Standard is applicable to non-mechanically fired appliances which are listed under categories 1a and 2a of Table 1. These appliances provide heat into the space where they are installed. Additionally, where fitted with a boiler, they also provide domestic hot water and/or central heating. These appliances may burn either solid mineral fuels, peat briquettes, natural or manufactured wood logs or be multi-fuel in accordance with the appliance manufacturer’s instructions. This standard is not applicable to appliances with fan assisted combustion air.

This European Standard specifies requirements relating to the design, manufacture, construction, safety and performance (efficiency and emission) instructions and marking together with associated test methods and test fuels for type testing residential roomheaters fired by solid fuel. This Standard is applicable to non-mechanically fired appliances which are listed under categories 1a and 2a of Table 1. These appliances provide heat into the space where they are installed. Additionally, where fitted with a boiler, they also provide domestic hot water and/or central heating. These appliances may burn either solid mineral fuels, peat briquettes, natural or manufactured wood logs or be multi-fuel in accordance with the appliance manufacturer’s instructions. This standard is not applicable to appliances with fan assisted combustion air.

oSIST prEN 13240:2011 is classified under the following ICS (International Classification for Standards) categories: 97.100.30 - Solid fuel heaters. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 13240:2011 has the following relationships with other standards: It is inter standard links to SIST EN 13240:2003, SIST EN 13240:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 13240:2011 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/129. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN 13240:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2011

Grelniki prostorov na trdna goriva - Zahteve in preskusne metode

Room heaters fired by solid fuel - Requirements and test methods

Raumheizer für feste Brennstoffe - Anforderungen und Prüfungen

Poêles à combustible solide - Exigences et méthodes d'essai

Ta slovenski standard je istoveten z: prEN 13240

ICS:

97.100.30 Grelniki na trdo gorivo Solid fuel heaters

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

March 2011

ICS 97.100.30 Will supersede EN 13240:2001

English Version

Room heaters fired by solid fuel - Requirements and test

methods

Poêles à combustible solide - Exigences et méthodes Raumheizer für feste Brennstoffe - Anforderungen und

d'essai Prüfungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 295.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2011 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13240:2011: E

worldwide for CEN national Members.

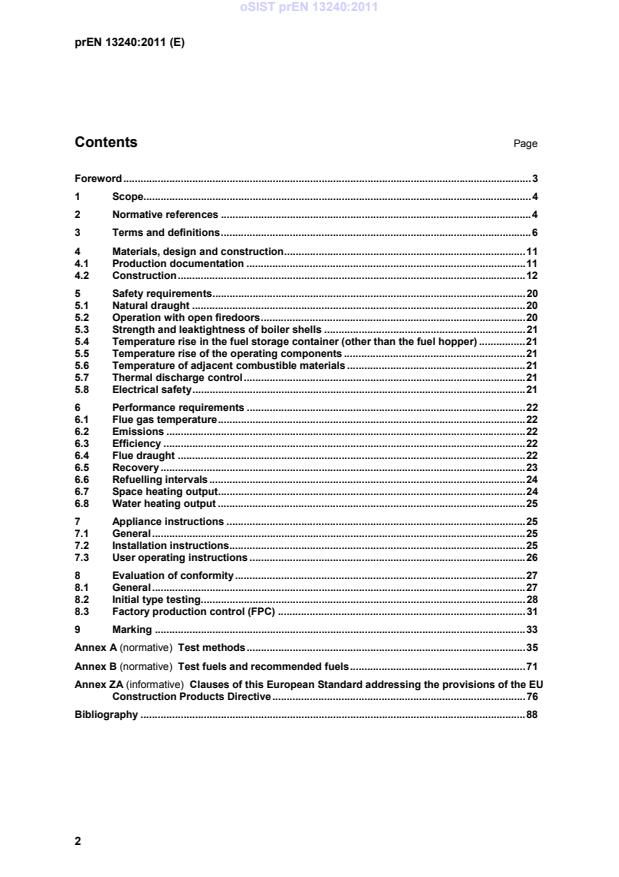

Contents Page

Foreword . 3

1 Scope. 4

2 Normative references . 4

3 Terms and definitions . 6

4 Materials, design and construction . 11

4.1 Production documentation . 11

4.2 Construction . 12

5 Safety requirements . 20

5.1 Natural draught . 20

5.2 Operation with open firedoors . 20

5.3 Strength and leaktightness of boiler shells . 21

5.4 Temperature rise in the fuel storage container (other than the fuel hopper) . 21

5.5 Temperature rise of the operating components . 21

5.6 Temperature of adjacent combustible materials . 21

5.7 Thermal discharge control . 21

5.8 Electrical safety . 21

6 Performance requirements . 22

6.1 Flue gas temperature . 22

6.2 Emissions . 22

6.3 Efficiency . 22

6.4 Flue draught . 22

6.5 Recovery . 23

6.6 Refuelling intervals . 24

6.7 Space heating output . 24

6.8 Water heating output . 25

7 Appliance instructions . 25

7.1 General . 25

7.2 Installation instructions. 25

7.3 User operating instructions . 26

8 Evaluation of conformity . 27

8.1 General . 27

8.2 Initial type testing . 28

8.3 Factory production control (FPC) . 31

9 Marking . 33

Annex A (normative) Test methods . 35

Annex B (normative) Test fuels and recommended fuels . 71

Annex ZA (informative) Clauses of this European Standard addressing the provisions of the EU

Construction Products Directive . 76

Bibliography . 88

Foreword

This document (prEN 13240:2011) has been prepared by Technical Committee CEN/TC 295

“Residential solid fuel burning appliances”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 13240:2001.

This document has been prepared under the mandate M/129 given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

This document is a revision of the published standard EN 13240:2001 following comments received at

its 5 year review.

1 Scope

This European Standard is applicable to freestanding or inset roomheaters fired by solid fuel, without

functional modification, that operate with fire doors either as closed only or as closed or open and

which are listed under categories 1a and 2a of Table 1. This European Standard is also only

applicable to non-mechanically fired roomheaters as listed under categories 1a and 2a of Table 1.

This European Standard specifies requirements relating to the design, manufacture, construction,

safety and performance (efficiency and emission) of roomheaters fired by solid fuel (hereafter referred

to as “appliance(s)”) and provides instructions for them. Furthermore, it also gives provisions for

evaluation of conformity i.e. initial type testing (ITT) and factory production control (FPC) and marking

of these appliances.

These appliances provide heat into the space where they are installed. Additionally, where fitted with

a boiler, they also provide domestic hot water and/or central heating. These appliances may burn

either solid mineral fuels, peat briquettes, natural or manufactured wood logs or be multi-fuel in

accordance with the appliance manufacturer’s instructions.

This standard is not applicable to appliances with fan assisted combustion air or appliances that are

mechanically fired.

Table 1 — Categorisation of appliances

a) b) c)

Freestanding or Freestanding or inset Inset appliances

inset appliances appliances which have for fireplace recess

without functional functional modification and enclosure

modification

1)

Appliances operating EN 13240 EN 13229 EN 13229

with firedoors closed

2)

Appliances operating EN 13240 EN 13229 EN 13229

with firedoors closed or open

3)

EN 13229 EN 13229 EN 13229

Open fires without firedoors

NOTE Without functional modification means “conversion of a free standing appliance into an insert appliance

by modifications that do not affect combustion”.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other

publications. These normative references are cited at the appropriate places in the text and the

publications are listed hereafter. For dated references, subsequent amendments to or revisions of any

of these publications apply to this European Standard only when incorporated in it by amendment or

revision. For undated references the latest edition of the publication referred to applies (including

amendments).

EN 1561:1997, Founding — Grey cast irons

EN 1563:1997, Founding — Spheroidal graphite cast iron

EN 10025:1993, Hot rolled products of non-alloy structural steels — Technical delivery conditions

EN 10027-2:1992, Designation systems for steels — Part 2: Numerical system

EN 10028-2:1992, Flat products made of steels for pressure purposes — Part 2: Non-alloy and alloy

steels with specified elevated temperature properties

EN 10029:1991, Hot rolled steel plates 3 mm thick or above — Tolerances on dimensions, shape and

mass

EN 10088-2:1995, Stainless steels — Part 2: Technical delivery conditions for sheet/plate and strip for

general purposes

EN 10111:1998, Continuously hot-rolled low carbon steel sheet and strip for cold forming — Technical

delivery conditions

EN 10120:1996, Steel sheet and strip for welded gas cylinders

EN 60335-2-102, Household and similar electrical appliances — Safety — Part 2-102: Particular

requirements for gas, oil and solid-fuel burning appliances having electrical connections

ISO 7-1:1994, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 7-2:2000, Pipe threads where pressure-tight joints are made on the threads — Part 2: Verification

by means of limit gauges

ISO 228-1:2000, Pipe threads where pressure-tight joints are not made on the threads —

Part 1: Dimensions, tolerances and designation

ISO 228-2:1987, Pipe threads where pressure-tight joints are not made on the threads —

Part 2: Verification by means of limit gauges

ISO 331:1983, Coal — Determination of moisture in the analysis sample — Direct gravimetric method

ISO 334:1992, Solid mineral fuels — Determination of total sulfur — Eschka method

ISO 351:1996, Solid mineral fuels — Determination of total sulfur — High temperature combustion

method

ISO 501:1981, Coal — Determination of the crucible swelling number

ISO 562:1998, Hard coal and coke — Determination of volatile matter

ISO 609:1996, Solid mineral fuels — Determination of carbon and hydrogen — High temperature

combustion method

ISO 687:1974, Coke — Determination of moisture in the analysis sample

ISO 1171:1997, Solid mineral fuels — Determination of ash content

ISO 1928:1995, Solid mineral fuels — Determination of gross calorific value by the bomb calorimetric

method, and calculation of net calorific value

ISO 2859 (all parts), Sampling procedures for inspection by attributes

CEN/TS 15883:2009, Residential solid fuel burning appliances — Emission test methods

3 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1

air grilles

components in the inlet and outlet openings to distribute and direct convection air flow

3.2

air inlet control

manual or automatic device which controls the quantity of air supplied for combustion

3.3

appliance with boiler

heat generator consisting of a room heating component and a water heating component in one unit

3.4

ash content of the fuel

solid matter remaining after the complete combustion of solid fuel

3.5

ashpan

removable receptacle shaped to receive the residue falling from the firebed

3.6

ashpit

enclosed chamber designed to receive the residue or the ashpan

3.7

ashpit loss

part of the residue which is combustible

3.8

basic firebed

quantity of glowing embers which ensures ignition of the test fuel to be charged

NOTE The basic firebed may be specified by the manufacturer.

3.9

boiler

vessel in which water is heated, intended for fitting in or forming an integral part of a solid fuel

appliance

3.10

boiler flueway

portion of the flueway formed wholly or in part by the surfaces of the boiler

3.11

bottomgrate

part of the appliance at the base of the firebox which supports the firebed through which the residue

falls into the ashpan or ashpit and through which combustion air and/or combustion gases may be

drawn

3.12

bottomgrate bars; firebars

bars supporting the fuelbed, separate or integral with a surrounding frame

3.13

charging door

door which covers the refuelling opening

3.14

combustion air

air supplied to the firebox which is entirely or partially used to burn the fuel

3.15

combustion gases

compounds in gaseous form produced inside an appliance when fuel is burned

3.16

continuous burning appliance

heating appliance designed for slow burning over an extended period of time (e.g. overnight) and

meeting the requirements of the slow combustion test

3.17

de-ashing

process of clearing a fuelbed and discharging the residue into the collecting receptacle

3.18

de-ashing mechanism

device to agitate or disturb the ash to facilitate its removal from the firebed

NOTE It may also be used to change the bottomgrate operating position on some appliances.

3.19

direct water system

hot water system in which stored domestic hot water is heated directly by hot water circulating from

the boiler

3.20

draught regulator

inlet device for admission of air downstream of the firebed, enabling the flue draught to be controlled

3.21

efficiency

ratio of total heat output to total heat input during the test period expressed as a percentage during the

test period

3.22

firebox; combustion chamber

that part of the appliance in which the fuel is burned

3.23

firebox opening

aperture in the firebox through which an appliance may be fuelled

3.24

firedoor

door through which the fire may be viewed and which may be opened to allow refuelling of the firebed

3.25

fireplace enclosure

assembly consisting of walls and ceiling of non combustible materials which is built on site to surround

a heat generator and heat exchanger and to form a space from which hot convection air is emitted

into the living space, e.g. by air grilles

3.26

fireplace recess

space formed in a wall or chimney breast constructed from non combustible materials and into which

a heating appliance may be installed and from which a chimney flue leads

3.27

flue by-pass device

device which in the open position allows flue gases to pass directly to the flue spigot/socket

NOTE This can be used as a preheating aid to overcome chimney condensation.

3.28

flue damper

mechanism to change the flow of the combustion gases

3.29

flue draught

differential between the static pressure in the place of installation and the static pressure at the flue

gas measurement point

3.30

flue gases

gaseous compounds leaving the appliance flue spigot or socket and entering the flue gas connector

3.31

flue gas connector

duct through which flue gases are conveyed from the flue spigot of the appliance into the chimney flue

3.32

flue gas mass flow

mass of flue gas drawn off from the appliance per unit of time

3.33

flue gas temperature

temperature of the flue gas at the specified point in the measurement section

3.34

flue spigot; flue socket

integral part of the appliance for connecting the flue gas connector thus permitting the deliberate

escape of products of combustion into the chimney flue

3.35

flueway

that part of an appliance designed to convey combustion gases from the firebox to the flue

spigot/socket

3.36

freestanding appliance

appliance designed to operate without needing to be built into a fireplace recess or fireplace

enclosure and which is not connected to the building except by the flue gas connector

3.37

front firebars

grating or plate fitted at the front of the firebox opening to prevent spillage of fuel and ash or to

change the firebox capacity, or both

3.38

fuel hopper

fuel store integral with the appliance from which fuel is fed to the firebox

3.39

heat input

quantity of energy which the fuel provides to the appliance

3.40

heat output

quantity of useful heat released by the appliance

3.41

indirect water system

hot water system in which stored domestic hot water is heated by a primary heater through which hot

water from the boiler is circulated without mixing of the primary (heating) water and the stored

domestic hot water

3.42

inset appliance

appliance with or without doors designed to be installed into a fireplace recess or an enclosure, or into

a firebox of an open fire

3.43

integral fuel storage container

enclosed area forming part of the appliance, but not connected directly to the fuel charging area, in

which fuel is stored prior to it being physically transferred by the user to the fuel charging position

3.44

intermittent burning appliance

heating appliance designed for unrestricted burning at nominal heat output and which is not intended

for operating at reduced combustion for any specified period of time unless this is clearly stated by the

manufacturer

NOTE An appliance may be either a continuous burning appliance or an intermittent burning appliance

according to the fuel used.

3.45

maximum water operating pressure

limiting water pressure at which the boiler of an appliance can be safely operated

3.46

nominal heat output

total heat output of the appliance quoted by the manufacturer and achieved under defined test

conditions when burning the specified test fuel

3.47

open fire

appliance which is built as an inset and designed to be connected to the building and surrounded by

non combustible materials

3.48

operating tool

device supplied with the appliance for handling movable and/or hot components

3.49

primary air

combustion air which passes through the fuel bed

NOTE Primary air does not necessarily have separate inlets neither does it necessarily pass through a

bottomgrate.

3.50

recommended fuel

fuel of commercial quality, listed in the appliance manufacturer’s instructions, and shown to achieve

the claimed performance when tested in accordance with this European Standard

3.51

recovery capability

ability of the fire to re-ignite existing or newly charged fuel after a defined burning period without external

assistance

3.52

reduced combustion capability

ability of an intermittent burning appliance to continue burning for a minimum period, dependent on

appliance type and fuel burned, without any input of fuel and without any external interference with

the combustion process, in such a manner that at the end of this period, the firebed can be recovered

3.53

refuelling interval

period of time for which the combustion may be maintained in the appliance with a single load of fuel,

without intervention by the user

3.54

residue

ashes, including combustibles, which collect in the ashpit

3.55

roomheater

appliance having a fully enclosed firebox with firedoor(s) which are normally closed, that distributes

heat by radiation and/or convection and also provides hot water when fitted with a boiler

3.56

safety heat exchanger

device which allows excess heat to be released from an appliance

3.57

slow combustion capability

ability of an appliance to continue operating at a low burning rate for a specified minimum period

without any input of fuel and without any interference with the combustion process, in such a manner

that the basic firebed can be recovered at the end of this period

3.58

solid fuel

naturally occurring or manufactured solid mineral fuels, natural or manufactured wood logs and peat

briquettes

3.59

solid mineral fuel

coal, lignite, coke and fuels derived from these

3.60

space heating output

heat output provided by convection and radiation to the room

3.61

steady-state condition

stage at which values to be measured in successive equal periods of time do not exhibit significant

change

3.62

surround

outside components or assembly enclosing the appliance or parts of it

3.63

test fuel

fuel of commercial quality being characteristic of its type to be used for testing appliances

3.64

thermal discharge control

mechanical device controlled by the water flow temperature which opens a drain in the water circuit of

a safety heat exchanger when a specified flow temperature is attained

3.65

thermostat

temperature sensitive device which automatically changes the air inlet cross-sectional area

3.66

water heating output

heat output to water, averaged during the test period

3.67

working surfaces

all surfaces of an appliance designed to transmit heat to the surrounding atmosphere

NOTE All external surfaces of a roomheater including the flue gas connector in accordance with this

standard are classified as working surfaces because they are designed to transmit heat into the room in which

they are installed.

4 Materials, design and construction

4.1 Production documentation

The type of appliance in accordance with Table 1 submitted for testing shall be stated and the

appliance shall be tested using the standard appropriate to that claim.

The parameters and characteristics considered in making the decisions in relation to either the family

or range of appliances to be submitted for initial type testing (see 8.2.1) shall be recorded. Where

changes are made to an appliance in the design, the raw material, the supplier of the components, or

in the production process, which would significantly alter the performance characteristics of the

appliance, especially in respect of one or more of the list of characteristics detailed in Table 9 and

Table 10, (see 8.2.2) these shall be recorded. A copy of the parameters and characteristics

considered in making the decisions shall be included in the production documentation for each

appliance.

To identify the appliance, related documents and/or scaled assembly drawings shall be available

showing the basic design and construction of the appliance. The documentation and/or the drawings

shall include at least the following information:

the specification of the materials used in the construction of the appliance;

the manufacturer’s declared nominal heat output in kW using fuels recommended by the

manufacturer together with the declared minimum refuelling intervals for these fuels.

If the appliance is fitted with a boiler, then the following additional details shall also be specified:

the welding process used in the manufacture of the boiler shell;

NOTE The symbol for the type of weld used is sufficient.

the permissible maximum operating water temperature, in °C;

the permissible maximum operating pressure, in bar;

the type test pressure, in bar;

the water heating output, in kW.

4.2 Construction

4.2.1 General construction

4.2.1.1 Design, manufacture and assembly

The shape and dimensions of the components and equipment and the method of design and

manufacture and, if assembled on site, the method of assembly and installation, shall ensure that,

when operated as specified in accordance with the test procedures of this standard and exposed to

the associated mechanical, chemical and thermal stresses, the appliance shall operate reliably and

safely such that during normal operation no combustion gas posing a hazard can escape into the

room in which the appliance is installed nor can embers fall out. Non-combustible materials shall be

used, except that it shall be permissible to use combustible materials for the following applications:

components or accessories fitted outside the appliance;

internal components of controls and safety equipment;

operating handles;

electrical equipment.

No part of the appliance shall comprise any material known to be harmful.

When fired with solid mineral fuels, the appliance shall have a bottomgrate and an ashpan.

Component parts, which require periodic replacement and/or removal shall be either so designed or

marked for identification to ensure correct fitting.

NOTE 1 Because the entire heat dissipating surfaces of the appliance including the flue spigot/socket and the

flue gas connector are working surfaces, there is no requirement for limiting the surface temperature of the

appliance.

NOTE 2 All operations which the user carries out, including loading and emptying of the appliance, adjusting

controls and de-ashing should be easy, safe and effective.

4.2.1.2 Durability

The durability aspects of the appliance shall be deemed to be satisfied if it is shown to meet

the constructional requirements specified in 4.2.2 to 4.2.13, the safety requirements specified

in Clause 5 and the performance requirements specified in Clause 6.

NOTE The long practice with these products shows that such an approach for dealing with durability is

sufficient.

4.2.2 Integral boiler

4.2.2.1 General

The boiler shell shall be constructed from cast iron and/or steel and shall be capable of operating at

the maximum operating pressure declared by the manufacturer. The integral boiler shall meet the

requirements of A.4.7.

The materials and dimensions for the integral boiler construction shall be in accordance with the

specifications given in Tables 2 to 7. If alternative materials are used, then written evidence of similar

performance is required.

Provision shall be made for parts, which form a seal, to be located securely by means of bolts,

gaskets or welding to prevent the leakage of air/water or combustion products. Adjacent surfaces

between metal components in the firebox or the flueways shall be gastight. Where a seal is made with

fire-cement, cement shall be well supported by adjacent metal surfaces.

4.2.2.2 Boilers constructed of steel

4.2.2.2.1 Welding and welding materials

The materials used shall be suitable for welding.

NOTE The materials listed in Table 3, are suitable and do not require any additional heat treatment after

welding.

4.2.2.2.2 Nominal minimum wall thicknesses (steel)

Boilers constructed of steel shall have the appropriate wall thicknesses set out in Table 2.

Table 2 — Steel - Nominal minimum wall thicknesses

Application Non- Stainless Non-alloy steels for

alloy and appliances burning wood

steels corrosion only and having maximum

resistant water operating pressures of

steels up to and including 2 bar

mm mm mm

Walls of both the boiler shell and the 5 2 3

combustion chamber which are in

contact with either burning fuel or

products of combustion and/or water

Walls of convection heating surfaces 4 2 3

outside combustion chamber (except

circular tubes)

Circular tubes used in convection part of 3,2 1,5 3,2

heat exchanger

Water cooled grate tubes 4 3 3

Surfaces not in contact with burning fuel 3 2 3

or products of combustion and/or water

NOTE 1 The nominal minimum wall thicknesses apply to pressure loaded sheets and tubes other

than immersion coils, safety heat exchangers.

NOTE 2 Thinner wall thicknesses are only permissible with proof of equivalent corrosion

resistance, heat resistance and strength.

NOTE 3 The nominal minimum wall thicknesses listed have been specified taking into

consideration:

- the maximum water operating pressure (4 bar),

- the material properties,

- the heat transfer location.

The tolerances on the nominal minimum wall thicknesses for non-alloyed steels given in Table 2 shall

be as specified in EN 10029:1991.

Table 3 — Steel material types

1)

References Material type Material numbers

EN 10111:1998 DD 11 1.0332

DD12 1.0398

DD13 1.0335

DD14 1.0389

EN 10025:2004 S235JR 1.0037

S235JRG2 1.0038

S235J0 1.0114

S235J2G3 1.0116

S275JR 1.0044

S275J0 1.0143

S275J2G3 1.0144

S355JR 1.0045

S355J0 1.0553

S355J2G3 1.0570

S355K2G3 1.0595

EN 10028-2:2004 P195TR1 1.0107

P235GH 1.0345

P285QH 1.0478

P265GH 1.0425

P355NL1 1.0566

P295GH 1.0481

P355QH1 1.0571

P355GH 1.0473

16Mo3 1.5415

15NiCuMoNb5 1.6368

13CrMo4-5 1.7335

10CrMo9-10 1.7380

11CrMo9-10 1.7383

EN 10120:2008 P245NB 1.0111

P265NB 1.0423

P310NB 1.0437

P355NB 1.0557

EN 10088-2:2006 X5CrNi18-10 1.4301

X5CrNi17-12-2 1.4401

X2CrNiM017-13-2 1.4404

X6CrNiTi18-10 1.4541

X6CrNiNb18-10 1.4550

X2 CrMnNiN 22-5-2 1.4162

X2 CrNiN 23-4 1.4362

X2 CrNiMoN 22-5-3 1.4462

X1 NiCrMoCuN 25-20-7 1.4529

X1 NiCrMoCu 25-20-5 1.4539

X6CrNiMoTi17-12-2 1.4571

X6CrNiMoNb17-12-2 1.4580

X3CrNiMo17-3-3 1.4436

1) In accordance with EN 10027-2:1992.

NOTE Materials and wall thicknesses other than those specified may only be used on production of appropriate

evidence as regards at least their equivalent corrosion resistance, heat resistance and strength to non-alloy steel

at the material thicknesses specified in 4.2.2.2.2 for the particular application/usage.

4.2.2.3 Boilers constructed of cast iron

4.2.2.3.1 Cast iron parts subject to water pressure

The mechanical properties of cast iron used for parts subject to water pressure shall, as a minimum,

correspond to the values listed in Table 4.

Table 4 — Minimum mechanical requirements for cast irons

1)

Grey cast iron

- Tensile strength R

> 150 N/mm

m

- Brinell hardness 160 HB to 220 HB

2)

Spheroidal graphite iron

- Tensile strength R > 400 N/mm

m

- Elongation 18 % A

1) In accordance with EN 1561:1997.

2) In accordance with EN 1563:1997.

4.2.2.3.2 Minimum wall thicknesses (cast iron)

The wall thickness of the casting section shall be not less than the minimum thicknesses listed in

Table 5.

Table 5 — Cast iron - Minimum wall thicknesses

Nominal heat output Grey cast iron Spheroidal graphite

cast iron

kW mm mm

3,5 3,0

< 30

4,0 3,5

≥ 30 and < 50

4.2.2.4 Boiler shell tappings

The threads of boiler shell tappings, for flow and return pipes, shall be not less than the minimum

thread size designation given in Table 6.

Where tapered threads are used, they shall be in accordance with the requirements of ISO 7-1:1994

and ISO 7-2:2000. Where parallel threads are used, they shall be in accordance with ISO 228-1:2000

and ISO 228-2:1987. The design and position of flow tappings shall be such that air is not retained

within the boiler shell.

Table 6 — Minimum thread size designation of flow and return tappings

Nominal heat output Gravity circulation Pumped circulation

thread size thread size

1) 1)

designation designation

kW

1 ½

≤ 22

> 22 ≤ 35 1¼ 1

> 35 < 50 1½ 1

1)

Designation in accordance with ISO 7-1:1994 and ISO 7-2:2000 or

ISO 228-1:2000 and ISO 228-2:1987.

If boilers are supplied with reducing bushes in horizontal flow tappings, these shall be eccentric and

fixed so that the reduced outlet is uppermost. The minimum depth of tapping or length of thread shall

conform to Table 7.

Table 7 — Minimum depth of tapping or length of thread

1)

Thread size designation Minimum depth or length of

thread

mm

½ to 1¼ 16

1½ 19

1)

Designation in accordance with ISO 7-1:1994 and ISO 7-

2:2000 or ISO 228-1:2000 and ISO 228-2:1987.

Where a drain socket is provided in the boiler shell, it shall be a minimum thread size designation of ½

and shall be in accordance with ISO 7-1:1994 and ISO 7-2:2000 or ISO 228-1:2000 and ISO 228-

2:1987.

4.2.2.5 Boiler waterways

4.2.2.5.1 Design of all boiler waterways

The design of the boiler shall ensure a free flow of water through all parts. To minimize the build up of

sediments, sharp or wedge-shaped waterways with a taper towards the bottom shall be avoided.

Where inspection holes are provided in the boiler to give access for inspection and cleaning of the

waterways, they shall be a minimum of (70 × 40) mm or have a minimum diameter of 70 mm and be

sealed with a gasket and cap.

4.2.2.5.2 Boiler waterways used with indirect water systems

The minimum internal dimension of waterways throughout the main body of the appliance shall be not

less than 20 mm except where waterways have to be locally reduced to facilitate manufacture or are

in areas not in direct contact with burning fuel. In these cases the width of the waterways shall not be

less than 15 mm.

4.2.2.5.3 Boiler waterways used with direct water systems

The minimum internal dimensions of waterways in boilers designed for direct water systems shall be

not less than 25 mm.

4.2.2.5.4 Venting of the water sections

The boiler and its components shall be designed in such a way that their respective water sections

can be vented.

The boiler shall be so designed that under normal operation in accordance with the manufacturer's

installation instructions, no undue boiling noises occur.

4.2.2.5.5 Water tightness

Holes, for screws and similar components, which are used for the attachment or removal of parts,

shall not open into waterways or spaces through which water flows.

NOTE This does not apply to pockets for measuring, control and safety equipment.

4.2.3 Cleaning of heating surfaces

All heating surfaces shall be accessible from the flue gas side for inspection and cleaning with

brushes, scrapers or chemical agents by means of sufficient cleaning openings. Where cleaning and

servicing of the boiler and its components require the use of special tools (e.g. special brushes), these

shall be supplied by the appliance manufacturer.

4.2.4 Flue spigot or socket

For horizontal flue connection, the flue spigot/socket shall be designed to allow fitting, internal or

external, over a length of at least 40 mm, of a flue gas connector.

For vertical flue connection, the fitting shall overlap by at least 25 mm.

The flue spigot or socket is a fixed and indispensable part of the appliance as tested and sold and

shall not be extended for type test purposes. It is not part of the test rig and shall not be confused with

the un-insulated flue gas connector (see A.2.1). However if an extended flue spigot, socket or fluepipe

is part of the appliance design it shall be included for the type test provided that it is supplied as part

of the appliance for fitting whenever the appliance is marketed.

NOTE For inset appliances (made for fireplace recesses) with a vertical chimney flue connection and where

the manufacturer`s installation instructions specify, in addition to the flue gas connector, that an insulating mortar

infill should be added around the connector to seal the appliance to the chimney flue, then in this case it is

permissible for the flue spigot/socket overlap to be reduced to a minimum of 6 mm.

4.2.5 Flueways

The size of the flueway in its minimum dimension shall be not less than 30 mm except it shall be

permissible to reduce it to not less than 15 mm for appliances designed only to burn fuels other than

bituminous coals and peat briquettes, and where an access door(s) is provided for cleaning the

flueway. It shall be possible to clean the flueways of the appliance completely using commercially

available tools or brushes, unless special tools or brushes are provided by the appliance manufacturer.

4.2.6 Ashpan and ash removal

A means for the removal of the ash residue from the appliance shall be provided. When an ashpan is

provided, it shall be capable of containing the combustion residue from two full charges of fuel whilst

retaining sufficient space above to allow adequate primary air flow through the bottomgrate or firebed.

If the ashpan resides in the appliance it shall locate in the ashpit in such a way that it allows the free

passage of primary air and in such a position that it does not obstruct any primary air inlet control.

NOTE 1: The ashpan should be designed and constructed to ensure that:

a) it effectively collects the residue from beneath the bottomgrate;

b) it can be easily and safely withdrawn, carried and emptied when hot, using the tool(s) provided,

without undue spillage of residue material.

NOTE 2: The ashpan can be shovel shaped.

4.2.7 Bottomgrate

Where the bottomgrate is removable it shall be so designed or marked as to ensure correct fitting. If a

de-ashing mechanism is fitted it shall be capable of effectively de-ashing the fuelbed.

NOTE 1 The preferred design with the firedoor(s) and ashpit door(s) closed should allow de-ashing to be

carried out. The de-ashing should be possible without undue effort.

NOTE 2 If it is necessary to remove the ashpit door to de-ash the fire, the appliance should be designed to

minimise ash or fuel spillage during the de-ashing operation.

4.2.8 Combustion air supply

4.2.8.1 Primary air inlet control

The appliance shall be fitted with either a thermostatically controlled primary air inlet control or a

manual primary air inlet control. For appliances with a boiler, a manual primary air inlet control shall

only be allowed for boiler outputs up to 7,5 kW. The adjusting control shall be clearly visible or shall

be permanently marked so that its operation is readily understandable.

The design shall be such that during operation of the appliance, neither ash nor unburned fuel can

prevent the movement or closure of the air inlet control.

The ‘cold’ setting of the air inlet control shall be clearly marked and the method of adjustment shall be

described in the user instructions.

The thermostat shall have a variable temperature range and be of the immersion or dry pocket type.

The pocket shall be positioned so that the thermostat senses the temperature of the flow water from

the appliance.

4.2.8.2 Secondary air inlet control

Where a secondary air inlet control is provided, the position of air entry shall be so designed that the

passage of air is not restricted when the firebox is filled to the manufacturer's recommended capacity.

4.2.9 Control of flue gas

If a flue damper is fitted it shall be of a type, which does not block the flue totally. The damper shall be

easy to operate and incorporate an aperture within the blade, which in a continuous area occupies at

least 20 cm or 3 % of the cross-sectional area of the blade, whichever is greater.

The position of the damper shall be recognizable from the setting of the device.

If a draught regulator is fitted the minimum cross sectional area requirement shall not be applicable

but the device shall be easily accessible for cleaning.

4.2.10 Firedoors and charging doors

When the appliance is equipped with a charging door, that door shall be large enough to allow the

appliance to be filled with the commercial fuels recommended by the manufacturer. Firedoors and

charging doors shall be designed to prevent accidental opening and to facilitate positive closure.

4.2.11 Flue bypass device

Any flue bypass device shall be easily operable. The extreme positions corresponding to full opening

and closing shall be stable and easily identifiable.

4.2.12 Front firebars and/or deepening plate

Front firebars shall be designed to retain the fuel or ash such that there is no undue spillage of ash or

burning fuel from the roomheater during normal operations, particularly during refuelling or de-ashing.

If the appliance is fitted with removable front firebars and/or deepening plate, they shall be of a design

such that they can neither be incorrectly fitted nor accidentally dislodged.

4.2.13 Solid mineral fuel and peat briquettes burning appliances

When the recommended fuels are solid mineral fuel and peat briquettes, the appliances shall have a

bottomgrate and an ashpan.

5 Safety requirements

5.1 Natural draught

Where the appliance manufacturer claims that a continuous burning appliance can be connected to a

chimney serving more than one appliance, and can be operated with solid mineral fuel and peat

briquettes as suitable fuels, then when tested in accordance with A.4.9.3 either the flue draught

throughout the test period shall be not less than 3 Pa or where the flue draught falls below 3 Pa then

over a further 10 h period from when the draught falls below 3 Pa the total quantity of carbon

monoxide in the flue gas, calculated to NTP as detailed in A.6.2.8 shall not be greater than 250 dm³.

Such an appliance shall be clearly labelled to indicate whether or not it can be installed into a shared

flue (see 7.2).

5.2 Operation with open firedoors

The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...