SIST EN 12957:2002+A1:2009

(Main)Machine tools - Safety - Electro discharge machines

Machine tools - Safety - Electro discharge machines

1.1 This standard specifies technical safety requirements and measures, applicable to EDM equipment and EDM system (e.g. for spark erosion-sinking, spark erosion-wire cutting), to be adopted by persons undertaking the design, construction, installation and/or supply of such equipment. This standard also includes information to be provided by the manufacturer to the user.

1.2 The design requirements of this standard shall not apply to arc eroding and electro chemical machining equipment.

1.3 This standard takes account of the intended use in normal workshop environment and non explosive atmospheres including installation, setting, maintenance, repair and dismantling for removal or disposal of EDM equipment.

1.4 This standard also applies to auxiliary devices essential for EDM processing.

1.5 This standard deals with specific hazards defined in clause 4, Table 1, and the measures of prevention in clause 5, Table 2.

1.6 This standard applies to machines built after its date of issue.

NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

Werkzeugmaschinen - Sicherheit - Funkenerodiermaschinen

1.1 Diese Norm legt technische Sicherheitsanforderungen und -maßnahmen für die EDM-Einrichtung und

die EDM-Anlage (z. B. Senkerodieren oder Drahterodieren) fest, die von Konstrukteuren, Herstellern,

Inbetriebnehmern und/oder Lieferanten von diesen Einrichtungen anzuwenden sind. Diese Norm enthält auch

Informationen, die dem Anwender durch den Hersteller zur Verfügung gestellt werden müssen.

1.2 Diese Norm gilt nicht für Maschinen zur Lichtbogenerosion oder elektrochemischen Bearbeitung.

1.3 Die in dieser Norm enthaltenen Anforderungen beziehen die bestimmungsgemäße Verwendung unter

üblichen Werkstattbedingungen in nicht explosionsfähiger Atmosphäre einschließlich Installation, Einrichten,

Wartung, Reparatur und Demontage zur Standortänderung oder Entsorgung von EDM-Einrichtungen mit ein.

1.4 Diese Norm gilt auch für Zusatzeinrichtungen, die für die EDM-Bearbeitung erforderlich sind.

1.5 Diese Norm behandelt spezifische Gefährdungen, die in Abschnitt 4, Tabelle 1, und die Schutzmaßnahmen,

die in Abschnitt 5, Tabelle 2, aufgelistet sind.

1.6 Diese Norm gilt für Maschinen, die nach dem Erscheinungsdatum der Norm hergestellt werden.

ANMERKUNG Die Richtlinie 94/9/EG bezüglich Geräte und Schutzsysteme zur bestimmungsgemäßen Verwendung in

explosionsgefährdeten Bereichen kann bei Maschinen oder Bauteilen nach dieser Europäischen Norm zur Anwendung

kommen. Die vorliegende Norm ist nicht als Mittel zum Nachweis der Übereinstimmung mit den grundlegenden

Gesundheits- und Sicherheitsanforderungen der Richtlinie 94/9/EG vorgesehen.

Machine-outils - Sécurité - Machines d'électroérosion

1.1 La présente Norme européenne fixe les prescriptions techniques de sécurité et les mesures applicables aux équipements d'usinage par électroérosion et les systèmes d'usinage par électroérosion, par exemple forage par étincelage de coupage, par électroérosion à l'aide d'un fil, qui doivent être adoptées par les personnes se chargeant de la conception, de la construction, de l'installation et/ou de la fourniture de tels équipements. La présente norme contient aussi les informations que le fabricant doit fournir à l’utilisateur.

1.2 Les prescriptions de conception de la présente norme ne s'appliquent pas aux machines d'érosion à l'arc électrique et aux machines d'usinage électrochimique.

1.3 La présente norme tient compte de l'utilisation normale, en environnement industriel normal et sans atmosphère explosive y compris l'installation, le réglage, la maintenance, la réparation et le démontage pour évacuation ou mise au rebut des équipements d'électroérosion.

1.4 La présente norme s'applique également aux dispositifs auxiliaires essentiels au procédé d'usinage par électroérosion.

1.5 La présente norme traite des phénomènes dangereux spécifiques définis à l’Article 4 au Tableau 1 et des mesures de prévention à l’Article 5 au Tableau 2.

1.6 La présente norme s'applique aux machines construites après sa date de publication.

NOTE La Directive 94/9/CE relative aux appareils et systèmes de protection destinés à être utilisés en atmosphères explosibles peut s’appliquer au type de machine ou équipement couverts par la présente Norme européenne. La présente norme n’est pas destinée à fournir un moyen de satisfaire aux exigences essentielles de Santé et de Sécurité de la Directive 94/9/CE.

Obdelovalni stroji - Varnost - Stroji EDM

General Information

- Status

- Withdrawn

- Publication Date

- 25-Mar-2009

- Withdrawal Date

- 20-Oct-2013

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 21-Oct-2013

- Due Date

- 13-Nov-2013

- Completion Date

- 21-Oct-2013

- Directive

- 98/37/EC - Machinery

Relations

- Replaced By

SIST EN ISO 28881:2013 - Machine tools - Safety - Electro discharge machines (ISO 28881:2013) - Effective Date

- 01-Nov-2013

- Effective Date

- 01-May-2009

Frequently Asked Questions

SIST EN 12957:2002+A1:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Machine tools - Safety - Electro discharge machines". This standard covers: 1.1 This standard specifies technical safety requirements and measures, applicable to EDM equipment and EDM system (e.g. for spark erosion-sinking, spark erosion-wire cutting), to be adopted by persons undertaking the design, construction, installation and/or supply of such equipment. This standard also includes information to be provided by the manufacturer to the user. 1.2 The design requirements of this standard shall not apply to arc eroding and electro chemical machining equipment. 1.3 This standard takes account of the intended use in normal workshop environment and non explosive atmospheres including installation, setting, maintenance, repair and dismantling for removal or disposal of EDM equipment. 1.4 This standard also applies to auxiliary devices essential for EDM processing. 1.5 This standard deals with specific hazards defined in clause 4, Table 1, and the measures of prevention in clause 5, Table 2. 1.6 This standard applies to machines built after its date of issue. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

1.1 This standard specifies technical safety requirements and measures, applicable to EDM equipment and EDM system (e.g. for spark erosion-sinking, spark erosion-wire cutting), to be adopted by persons undertaking the design, construction, installation and/or supply of such equipment. This standard also includes information to be provided by the manufacturer to the user. 1.2 The design requirements of this standard shall not apply to arc eroding and electro chemical machining equipment. 1.3 This standard takes account of the intended use in normal workshop environment and non explosive atmospheres including installation, setting, maintenance, repair and dismantling for removal or disposal of EDM equipment. 1.4 This standard also applies to auxiliary devices essential for EDM processing. 1.5 This standard deals with specific hazards defined in clause 4, Table 1, and the measures of prevention in clause 5, Table 2. 1.6 This standard applies to machines built after its date of issue. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

SIST EN 12957:2002+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 25.120.40 - Electrochemical machines. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12957:2002+A1:2009 has the following relationships with other standards: It is inter standard links to SIST EN ISO 28881:2013, SIST EN 12957:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12957:2002+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12957:2002+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Obdelovalni stroji - Varnost - Stroji EDMWerkzeugmaschinen - Sicherheit - FunkenerodiermaschinenMachine-outils - Sécurité - Machines d'électroérosionMachine tools - Safety - Electro discharge machines25.120.40Elektrokemijski strojiElectrochemical machinesICS:Ta slovenski standard je istoveten z:EN 12957:2001+A1:2009SIST EN 12957:2002+A1:2009en,fr01-maj-2009SIST EN 12957:2002+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12957:2001+A1

February 2009 ICS 25.120.40 Supersedes EN 12957:2001English Version

Machine tools - Safety - Electro discharge machines

Machine-outils - Sécurité - Machines d'électroérosion

Werkzeugmaschinen - Sicherheit - Funkenerodiermaschinen This European Standard was approved by CEN on 9 May 2001 and includes Amendment 1 approved by CEN on 29 December 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12957:2001+A1:2009: ESIST EN 12957:2002+A1:2009

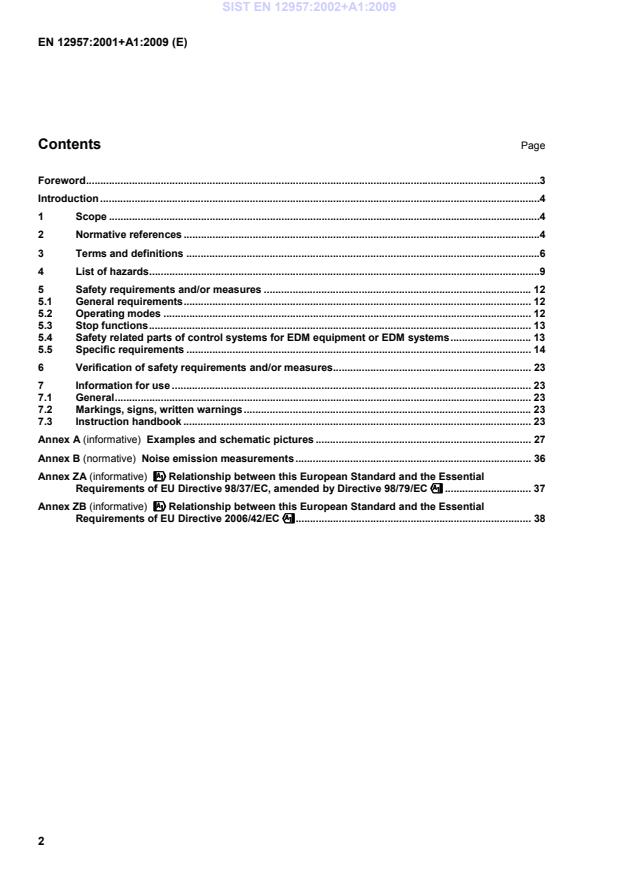

Examples and schematic pictures . 27 Annex B (normative)

Noise emission measurements . 36 Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC, amended by Directive 98/79/EC"""" . 37 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 38

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this standard.

Complementary guidance is given in type A and B Standards to which reference is made in the text. When provisions of this type C Standard are different from those which are stated in type A or B Standards, the provisions of this type C Standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C Standard. It provides one means of conforming with the Essential Health and Safety Requirements (EHSR’s) of the "Machinery Directive" (98/37/EC). 1 Scope 1.1 This standard specifies technical safety requirements and measures, applicable to EDM equipment and EDM system (e.g. for spark erosion-sinking, spark erosion-wire cutting), to be adopted by persons undertaking the design, construction, installation and/or supply of such equipment. This standard also includes information to be provided by the manufacturer to the user. 1.2 The design requirements of this standard shall not apply to arc eroding and electro chemical machining equipment. 1.3 This standard takes account of the intended use in normal workshop environment and non explosive atmospheres including installation, setting, maintenance, repair and dismantling for removal or disposal of EDM equipment. 1.4 This standard also applies to auxiliary devices essential for EDM processing. 1.5 This standard deals with specific hazards defined in clause 4, Table 1, and the measures of prevention in clause 5, Table 2. 1.6 This standard applies to machines built after its date of issue. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC. 2 Normative references This European Standard contains dated or not dated references on provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). SIST EN 12957:2002+A1:2009

EN 811:1996, Safety of machinery - Safety distances to prevent danger zones being reached by the lower limbs

EN 953:1997, Safety of machinery - Guards - General requirements for the design and construction of fixed and movable guards

EN 954-1:1996, Safety of machinery - Safety related parts of control systems – Part 1: General principles for design EN 982:1996, Safety of machinery - Safety requirements for fluid power systems and their components - Hydraulics EN 983:1996, Safety of machinery - Safety requirements for fluid power systems and their components - Pneumatics EN 999:1998, Safety of machinery - The positioning of protective equipment in respect of approach speeds of parts of the human body

EN 1037:1995, Safety of machinery - Prevention of unexpected start-up EN 1050:1996, Safety of machinery - Principles for risk assessment EN 1070:1998, Safety of machinery - Terminology EN 1088:1995, Safety of machinery - Interlocking devices associated with guards - Principles for design and selection prEN 12437-1:1996, Safety of machinery - Permanent means of access to machines and industrial plants – Part 1: Choice of a fixed means of access between two levels

prEN 12437-2:1996, Safety of machinery - Permanent means of access to machines and industrial plants – Part 2: Working platforms and gangways SIST EN 12957:2002+A1:2009

arc erosion; arc eroding; arc machining the removal of material by constant (non pulsed) electro discharges, performed in a dielectric medium. The discharges are initiated by periodical contact of the electrode with the work piece interrupted by axial movement of the electrode

3.2 arc erosion equipment all the necessary units for the process of arc machining 3.3 SIST EN 12957:2002+A1:2009

shielding of EDM equipment mechanical barrier or enclosure of conductive material intended to attenuate the emission/penetration of a varying electromagnetic field into an assigned region 3.21 spark erosion; spark eroding; spark machining; EDM process removal of material in a dielectric fluid by electro discharges, which are separated in time and randomly distributed in space, between two electrically conductive electrodes (the tool electrode and the work piece electrode), and where the energy in the discharge is controlled 3.22 spark erosion-sinking removal of material by spark erosion to produce various shapes in the work piece e.g. concave, convex and prismatic holes 3.23 spark erosion-wire cutting removal of material by spark erosion with a wire electrode to produce prismatic shapes in the work piece 3.24 tool changer (for EDM equipment); electrode changing device mechanism integrated with the machine to supply a previously loaded electrode in exchange for another electrode. The electrode changing device is expected to enable an operator to load/unload electrodes from outside the work area. 3.25 work area (on EDM equipment) space within the envelope of the machine where the EDM process can take place 3.26 work piece changing device (for EDM equipment) mechanism integrated with the machine to supply a previously loaded work piece in exchange for another work piece. The work piece changing device is designed to enable an operator to load/unload work pieces from outside the work area. 3.27 work tank (for EDM equipment) unit surrounding the work area to contain the dielectric fluid for EDM processes SIST EN 12957:2002+A1:2009

Particular attention is given to hazards dealing with: Electrical hazards (electrode voltage); Flammable dielectric fluid (level, temperature, fire detection); Hazardous substances (waste disposal, filters, used dielectric fluid, fume extraction, electrodes and sludges); Electromagnetic emissions (radiated and conducted). NOTE The designer’s attention is focused on hazards which can occur during the life of the machine to both operator and other persons who have access to the danger zone/s for conditions of intended use including reasonably foreseeable misuse of the machine (see EN 292-1:1991, 3.12) for both spark erosion with automatic mode and operations requiring intervention (e.g. setting, maintenance, repair).Although acoustic noise is not considered to be a significant hazard for EDM equipment, the manufacturer of the equipment is not absolved from reducing noise and making noise declaration. The designer is cautioned to verify whether the list of hazards in Table 1 is exhaustive and applicable and, if there are other hazardous situations, not listed in Table 1, which are related to the specific equipment in question. SIST EN 12957:2002+A1:2009

work piece clamping

automatic work piece/electrode changing

moving parts (e.g. axes, rolling elements)

loading/unloading, reorienting

power operated, work piece/ electrode change manual operation/work piece/electrode change between clamps and work piece

envelope of work piece/electrode motion

between work piece/electrode and machine parts A1, A2, A3

A1, A2, A3

A1, A2, A3

1.4 Entanglement

manual or automatic work piece/electrode changing, spindle rotation and wire rollers manual or power operated work piece/electrode changing and spindle rotation between work piece/electrode and machine parts A1, A2, A3 1.9 High pressure fluid injection or ejection

hydraulic/pneumatic systems ejection, leakage and

flushing setting, machining and maintenance at and near the machine A4

(continued)

* Description Hazardous situation action Activity Danger zone Reference to Table 2 2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) contact with work piece/electrode, wire/wire-path and contact with unprotected circuits process control, setting and maintenance work piece, electrode, tooling fixture, generator and electrical enclosure B1, B2 2.2 Contact of per-sons with parts which have be-come live under faulty conditions (indirect contact) contact with parts of the machine which are not live during normal operation maintenance and service of the machine at and near the machine, insulation of electrical cables and equipment B1, B3 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Contact with or inhalation of harmful fluids, gases, mists, fumes, and dust conditions near the machine caused by ejection of dielectric fluid, droplets or evaporation, mists, fumes, etc. during the EDM process, setting, maintenance and disposal of the machine at and near the machine D1 - D5 7.2 Fire or explosion

fire hazard originated by flammable mist generation, long lasting arcing condition, loss of dielectric fluid, fault of electrical or hydraulic power supply, etc.

during the EDM process near the machine and the work tank D5 - D12 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction) from:10.2 Restoration of the energy supply after an interruption malfunction of the ma-chine itself and/or elec-trical/pneumatic equip-ment due to restoration of the energy supply after energy restoration at the machine E3 10.3 External influences on electrical equipment malfunction of the machine itself or electrical equipment due to electromagnetic disturbances machine in operation, setting and maintenance at and in the vicinity of the machine C1 13 Failure of the power supply malfunction resulting from power loss, powered clamping failures and machine elements moving under residual forces (e.g. inertia, gravity) all activities at the machine at all moving elements of the machine E1, E2 (continued)

* Description Hazardous situation action Activity Danger zone Reference to Table 2 14 Failure of the control circuit mechanical hazards associated with ma-chine movements, elec-trical hazard and/or fire during operation, setting, cleaning, maintenance and repair activities at the machine F1 Other hazards 19 Slip, trip and fall of persons (related to machinery) ejection or spillage of fluids and lubricants; trailing floor-mounted or loose connection cables during and after machining and maintenance large work tanks, slippery floor and high working positions; area surrounding the machine G1 20 Hearing loss or other physiological disturbances emission of hazardous noise from the EDM equipment or its auxiliary devices during operation, setting, cleaning, maintenance and repair activities at and in the vicinity of the machine or the auxiliary devices H1 * This list is derived from EN 1050:1996, annex A

5 Safety requirements and/or measures 5.1 General requirements Machinery shall comply with the safety requirements and/or protective measures as indicated in Table 2 of this clause. In addition the equipment shall be designed according to the principles of EN 292 for hazards relevant, but not significant, which are not dealt with by this standard (e.g. sharp edges).

5.2 Operating modes 5.2.1 Operating mode selection Based on 1.2.5 of EN 292-2:1991/A1:1995 and 9.2.3 of EN 60204-1:1997, the selection of the mode shall be either a key operated switch, or equally lockable means. Mode selection shall be permitted only from outside the work area and shall not initiate start-up. The indication of the selected operating mode shall be provided (e.g. the position of the selector, the provision of an indicating light or visual display indication). Mode changes shall ensure, that only one mode is active at any one time.

Mode selection shall be category 1 according to EN 954-1:1996. 5.2.2 Protecting measures relating to operating modes 5.2.2.1 Automatic mode Starting the automatic mode shall be possible only if guards are closed and other safety devices are in protective condition (e.g. guard lock, fire detection device ready when flammable dielectric fluids are used and fume extraction activated). SIST EN 12957:2002+A1:2009

An operational stop-function which is initiated by a stop device shall be provided for each mode of operation. When the operational stop function is activated, the energy supply to axes drive motors, work piece holding device and NC equipment, need not be cut off, see A.1.2.4 of EN 292-2:1991/A1:1995 and annex A, Figure A.5 of this standard.

5.3.2 Emergency stop

The EDM equipment or system shall be provided with one or more emergency stop control devices according to EN 418:1992 and 6.1.1 of EN 292-2:1991. The emergency stop function/s shall be category 1 according to 9.2.2 of EN 60204-1:1997.

For EDM equipment or systems without NC controlled axes (e.g. EDM equipment with single working axis including electromechanical planetary motion devices or Electro Discharge Drilling machines), stop function category 0 according to 9.2.2 of EN 60204-1:1997, may be applied.

Emergency stop shall be category 3 according to EN 954-1:1996. Emergency stop device/s shall be provided at each working station but at least at: the main control panel, the portable control panel, if quick access to another emergency stop device is not possible, the work piece/electrode loading and unloading station if separated from the main operator’s position, a location quickly accessible from inside of an enclosure and/or work tank where whole body access is possible.

5.4 Safety related parts of control systems for EDM equipment or EDM systems Safety related parts of control systems comprise parts concerning the following functions and shall fulfil the requirements of the categories given below according to EN 954-1:1996. SIST EN 12957:2002+A1:2009

Functions EN 954-1:1996 category see ref. Table 2• Machining voltage and electrical sensing for positioning of electrode/work piece 2 B2 • Monitoring of level and temperature of flammable dielectric fluid 3 D7, D8, D9 • Fire detection 2 D11 • Fume extraction shutter 2 D11, D12 • Fume extraction air flow sensing B D4 • Start, stop and automatic restart of machining B E3 • Hold-to-run control B A3 • Interlocking of movable guards 2 A1, A2, A3, B2 • Enabling device 3 A3

The function of safety related parts as specified above shall be verified by examination of circuit diagrams and practical checks.

5.5 Specific requirements Specific safety measures as needed for EDM equipment and/or EDM systems to prevent hazards identified in clause 4 of this standard, are described in Table 2.

Access to work area: crushing, shearing and entanglement

EDM equipment shall be designed as to avoid foreseeable mechanical hazards during intended use and reasonable foreseeable misuse.

Where hazardous situations cannot be prevented, fixed guards shall be used where no access to danger zones is necessary during intended use.

Where access to wire transportation system (rollers) is required, crushing or entanglement prevention devices shall be provided, preventing access by hand. As a schematic example, see annex A, Figure A.9.

Where frequent (more than once per day) access to the work area is required, hazardous situations shall be prevented with interlocking guards.

In automatic mode opening of interlocking guards shall stop all current operations in order to remove all risks within the area under protection.

As long as the interlocking guards remain open, unexpected start-up shall be prevented in all modes.

No other hazardous machine movements shall arise from the actuation of any sensor.

By visual inspection and/or practical checks

By visual inspection and/or practical checks

By visual inspection and/or practical checks

By visual inspection and/or practical checks

By visual inspection and practical checks, examination of circuit diagrams

By visual inspection and practical checks, examination of circuit diagrams

By visual inspection and practical checks, examination of circuit diagrams EN 292-1:1991, 4.2.1 EN 294:1992 EN 349:1993 EN 811:1996 EN 292-1:1991, 3.10

EN 953:1997, 3.2 EN 1070:1998, 3

EN 294:1992 EN 349:1993

EN 292-2:1991, 4.1.3 EN 349:1993 EN 811:1996 EN 953:1997, 3.3, 3.5 EN 1088:1995, 3.2

EN 292-1:1991, 3.22.4

EN 60204-1:1997, 9.2.4 EN 1037:1995

EN 1037:1995, 3.2 A2

Mechanical hazards within the work area

On EDM equipment or systems, where whole body access to the safeguarded space (work area) through an interlocking door is foreseen (e.g. for work piece/electrode cleaning, inspection of work progress) a device which prevents inadvertent closing of the door/s, shall be provided in order to inhibit any hazardous movements and/or actions (e.g. filling of work tank). By examination of circuit diagrams and practical checks EN 1088:1995, 3.2 EN 60204-1:1997, 5.4, 9.3.1 EN 775:1992, 7.3.1.2a (continued) SIST EN 12957:2002+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...