SIST EN 12716:2019

(Main)Execution of special geotechnical work - Jet grouting

Execution of special geotechnical work - Jet grouting

This document establishes general principles for the execution of jet grouting works.

NOTE The jet grouting processes is distinguished from the grouting processes covered by EN 12715.

Ausführung von Arbeiten im Spezialtiefbau - Düsenstrahlverfahren

Diese Europäische Norm legt allgemeine Grundsätze für die Ausführung von Düsenstrahlarbeiten fest.

ANMERKUNG Das Düsenstrahlverfahren unterscheidet sich von den in EN 12715 erfassten Injektionsverfahren.

Exécution des travaux géotechniques spéciaux - Jet-grouting

La présente Norme européenne établit des principes généraux en vue de l’exécution des travaux de jet-grouting.

NOTE Il convient de distinguer les procédés d’exécution de jet-grouting des procédés d’injection (« grouting ») couverts par l’EN 12715.

Izvedba posebnih geotehničnih del - Injektiranje pod visokimi pritiski

Ta evropski standard določa splošna načela za izvedbo injektiranja pod visokimi pritiski.

Postopki injektiranja pod visokimi pritiski se razlikujejo od postopkov injektiranja, ki jih obravnava standard EN 12715.

General Information

- Status

- Published

- Public Enquiry End Date

- 09-Jun-2017

- Publication Date

- 12-Feb-2019

- Technical Committee

- KON.007 - Geotechnics

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 15-Jan-2019

- Due Date

- 22-Mar-2019

- Completion Date

- 13-Feb-2019

Relations

- Effective Date

- 01-Mar-2019

Overview

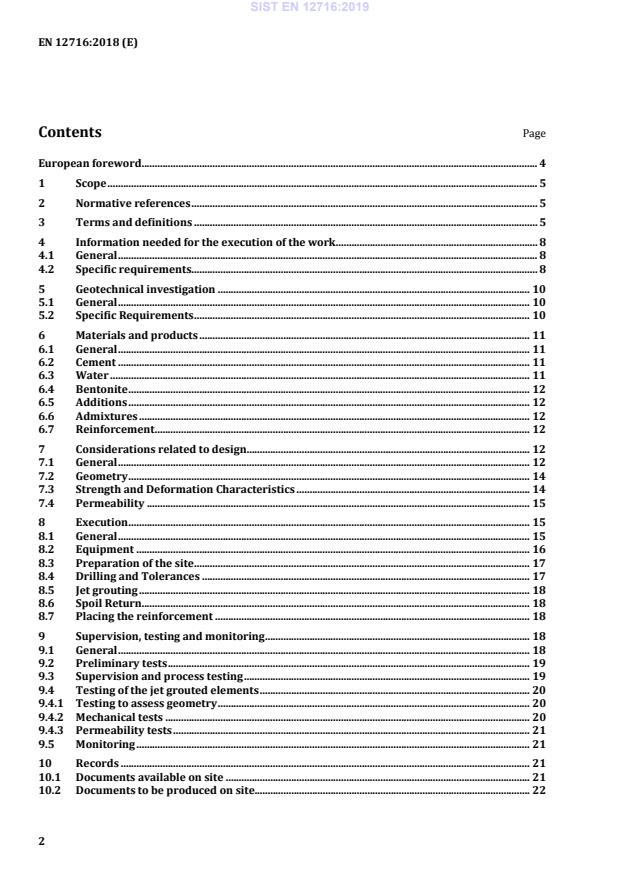

EN 12716:2018 - Execution of special geotechnical work: Jet grouting (CEN) sets out general principles for planning, executing and controlling jet grouting works. It explains terminology (e.g. jet grouted element, rig, monitor, nozzle, spoil return, radius of influence), defines jet-grouting systems (single, double, triple) and distinguishes this process from other grouting standards (notably EN 12715). The standard complements Eurocode 7 (EN 1997‑1 / EN 1997‑2) and includes construction, material and quality requirements needed on site.

Key topics and technical requirements

- Scope and terminology: Definitions for jet grouting processes, element types (sub‑vertical, sub‑horizontal, inclined), and system classifications (single/double/triple).

- Information & planning: Required pre‑execution information such as legal restrictions, site geometry, adjacent structures, access, spoil handling and environmental constraints.

- Geotechnical investigation: Requirements for ground investigation and identification of geotechnical equivalent zones to select uniform jetting parameters.

- Materials and products: Requirements and references for hydraulic binders, cement, water, bentonite, admixtures and reinforcement; complements EN 197‑1 and EN 1008 for cement-related provisions.

- Design considerations: Geometry, strength/deformation characteristics, permeability and detailing of reinforcement where applicable; guidance focuses on construction and supervision aspects.

- Execution: Equipment and rig requirements, drilling and tolerance controls, jetting operations (monitor/nozzle control), spoil management and installation tolerances.

- Quality control & testing: Preliminary tests, supervision and process testing, tests to assess element geometry, mechanical tests (e.g. strength), permeability tests, sampling and sample quality classes.

- Records & documentation: Documents required on site and records to be produced; examples provided in annexes.

- Safety & environment: Site safety, environmental protection and compliance with national/European rules.

Applications and users

Practical uses of the standard include: ground improvement, underpinning, formation of cut‑off walls or seepage barriers, stabilization around excavations, tunnelling and foundation support where jet grouting is appropriate. Primary users:

- Geotechnical and civil engineers (designers)

- Specialist jet‑grouting contractors and site supervisors

- Quality managers and testing/monitoring teams

- Project owners and regulators overseeing ground improvement works

Related standards

- EN 1997‑1 / EN 1997‑2 (Eurocode 7 - geotechnical design)

- EN 12715 (other grouting processes)

- EN 197‑1, EN 1008 (cement and mixing water)

- EN 206, EN 480‑4, EN 934‑4 (concrete and admixtures)

- EN 16228 series (drilling/foundation equipment safety)

Keywords: EN 12716:2018, jet grouting, geotechnical standard, CEN, jet grouted element, ground improvement, quality control, Eurocode 7.

Frequently Asked Questions

SIST EN 12716:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Execution of special geotechnical work - Jet grouting". This standard covers: This document establishes general principles for the execution of jet grouting works. NOTE The jet grouting processes is distinguished from the grouting processes covered by EN 12715.

This document establishes general principles for the execution of jet grouting works. NOTE The jet grouting processes is distinguished from the grouting processes covered by EN 12715.

SIST EN 12716:2019 is classified under the following ICS (International Classification for Standards) categories: 93.020 - Earthworks. Excavations. Foundation construction. Underground works. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12716:2019 has the following relationships with other standards: It is inter standard links to SIST EN 12716:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12716:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.WLVNLAusführung von Arbeiten im Spezialtiefbau - DüsenstrahlverfahrenExécution des travaux géotechniques spéciaux - Jet-groutingExecution of special geotechnical work - Jet grouting93.020Zemeljska dela. Izkopavanja. Gradnja temeljev. Dela pod zemljoEarthworks. Excavations. Foundation construction. Underground worksICS:Ta slovenski standard je istoveten z:EN 12716:2018SIST EN 12716:2019en,fr,de01-marec-2019SIST EN 12716:2019SLOVENSKI

STANDARDSIST EN 12716:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12716

December

t r s z ICS

{ uä r t r Supersedes EN

s t y s xã t r r sEnglish Version

Execution of special geotechnical work æ Jet grouting Exécution des travaux géotechniques spéciaux æ Jetægrouting

Ausführung von Arbeiten im Spezialtiefbau æ Düsenstrahlverfahren This European Standard was approved by CEN on

t z September

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s t y s xã t r s z ESIST EN 12716:2019

Determination of the material strength . 24 Annex B (informative)

Sample Quality. 26 Annex C (normative)

Direct and indirect tests and quality controls . 29 Annex D (informative)

Examples of site records of jet grouting works . 31 Annex E (informative)

Degree of obligation of the provisions . 34 Bibliography . 37

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp SIST EN 12716:2019

0,10 m; b) deviation from the element’s axis 1) for vertical jet grouting elements

2 % of the maximum drilling length, 2) for sub-vertical jet grouting elements

4 % of the maximum drilling length, 3) for inclined and sub-horizontal jet grouting elements

6 % of the maximum drilling length. 7.2.3 The following shall be clearly shown on design drawings: — minimum cross sectional dimensions of jet grouted elements to be achieved in the different soil layers that will be encountered; — tolerances on the position and inclination of the element axes if different from 7.2.2. 7.2.4 Maximum cross sectional dimensions should also be considered and related to the element spacing to ensure the integrity of a jet grouted structure. 7.2.5 If any unexpected underground obstruction cannot be removed, the relevant area shall be marked on the printed or electronic design drawings and/or models, and the adjacent jet grouting treatment shall be redesigned so as to achieve the intended purpose. 7.3 Strength and Deformation Characteristics 7.3.1 The strength of a jet grouted material depends on the jet grouting system selected, the parameters employed and on the soil type an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...