SIST EN 12715:2021

(Main)Execution of special geotechnical work - Grouting

Execution of special geotechnical work - Grouting

This document is applicable to the execution, testing and monitoring of geotechnical grouting work.

Grouting for geotechnical purposes (geotechnical grouting) is a process in which the remote placement of a pumpable material in the ground is indirectly controlled by adjusting its rheological characteristics and by the manipulation of the placement parameters (pressure, volume and the flow rate).

The following principles and methods of geotechnical grouting are covered by this document:

- displacement grouting (compaction and compensation grouting);

- grouting without displacement of the host material (permeation, fissure/contact grouting, bulk filling).

Figure 1 illustrates the various injection methods associated with these two principles.

NOTE The term consolidation grouting is sometimes used to emphasize an improvement in the strength or deformation characteristics of a soil or rock mass, with the aim that it does not undergo any unacceptable deformation. The term compensation grouting is used when the objective of grouting is to concurrently compensate for ground loss.

The principal objectives of geotechnical grouting are:

- the modification of the hydraulic/hydrogeological characteristics of the ground;

- the modification of the mechanical properties of the ground;

- the filling of natural cavities, mine workings, voids adjacent to structures;

- inducing displacement to compensate for ground loss or to stabilize and lift footings, slabs and pavements.

Specialized grouting activities, generally associated with structural and/or emergency works, are not covered by this document.

The execution, testing and monitoring of jet grouting work is not covered by this document and is covered by EN 12716.

Ausführung von Arbeiten im Spezialtiefbau - Injektionen

Dieses Dokument ist anzuwenden für die Ausführung, Prüfung und Überwachung von geotechnischen Injektionsarbeiten.

Die Injektion mit geotechnischer Zielsetzung (geotechnische Injektion) ist ein Vorgang, bei dem die Ein-bringung eines pumpbaren Materials in den Baugrund indirekt kontrolliert wird, indem die rheologischen Kennwerte des Materials entsprechend angepasst und die Einbringparameter (Druck, Volumen und Durch-flussrate) gesteuert werden.

Dieses Dokument behandelt die folgenden Grundsätze und Verfahren für geotechnische Injektionen:

- Injektion mit Baugrundverdrängung (Verdichtungs- und Kompensationsinjektion);

- Injektion ohne Baugrundverdrängung (Poreninjektion, Kluft /Kontaktinjektion, Hohlraumverfüllung).

Bild 1 veranschaulicht die verschiedenen Injektionsverfahren, die mit diesen beiden Prinzipien verbunden sind.

ANMERKUNG Der Begriff Verfestigungsinjektion wird manchmal verwendet, um eine Verbesserung der Festigkeit oder Verformungseigenschaften eines Locker- oder Festgesteins zu betonen, die darauf abzielt, unzulässige Verformung zu vermeiden. Der Begriff Kompensationsinjektion wird verwendet, wenn während der Injektion ein Baugrundverlust zu kompensieren ist.

Die Hauptziele der geotechnischen Injektion sind:

- die Änderung der hydraulischen/hydrogeologischen Eigenschaften des Baugrunds;

- die Änderung der mechanischen Eigenschaften des Baugrunds;

- das Verfüllen von natürlichen Hohlräumen, Grubenbauten, Hohlräumen im Untergrund im Übergang zu angrenzenden Bauwerken;

- induzierende Verdrängung zum Ausgleich von fehlendem Baugrund oder zum Stabilisieren und Anheben von Fundamenten, Platten und Oberflächenbefestigungen.

Spezielle Injektionsarbeiten, die im Allgemeinen mit Bau- und/oder Arbeiten nach Katastrophenfällen verbunden sind, werden in diesem Dokument nicht behandelt.

Dieses Dokument ist nicht anzuwenden für die Ausführung, Prüfung und Überwachung mittels Düsenstrahl¬verfahren. Dies wird in EN 12716 behandelt.

Exécution des travaux géotechniques spéciaux - Injection

Le présent document s’applique à l’exécution, aux essais et au contrôle des travaux d’injection géotechnique.

L’injection à des fins géotechniques (injection géotechnique) est un procédé qui consiste à introduire à distance dans le terrain un matériau pouvant être pompé, cette introduction étant contrôlée indirectement en ajustant les caractéristiques rhéologiques du matériau pompé et en intervenant sur les paramètres de mise en place (pression, volume et débit).

Le présent document s’applique aux principes et méthodes d’injection géotechnique suivants :

- injection avec déplacement (injection solide et de compensation) ;

- injection sans déplacement des terrains (imprégnation, injection de fissure/roche, comblement en masse).

La Figure 1 illustre les différentes méthodes d’injection selon ces deux principes.

NOTE L’expression « injection de consolidation » est parfois employée pour mettre en avant une amélioration des caractéristiques de résistance ou de déformation d’un sol ou d’une masse rocheuse dans le but que ce sol ou cette masse ne subissent pas de déformations inacceptables. L’expression « injection de compensation » est utilisée lorsque l’objectif de l’injection est de compenser simultanément la perte de sol.

Les principaux objectifs de l’injection géotechnique sont :

- la modification des propriétés hydrauliques/hydrogéologiques des terrains ;

- la modification des propriétés mécaniques des terrains ;

- le comblement des cavités naturelles, des exploitations minières, des vides au contact des structures ;

- la création de mouvements pour compenser des tassements, stabiliser et redresser des semelles, radiers ou dallages.

Le présent document ne s’applique pas aux activités d’injection spécialisées, qui sont en général associées aux travaux effectués sur les structures, ou en urgence.

Le présent document ne couvre pas l’exécution, les essais et le contrôle des travaux de jet-grouting qui sont traités dans l’EN 12716.

Izvedba posebnih geotehničnih del - Injektiranje

General Information

- Status

- Published

- Public Enquiry End Date

- 19-May-2019

- Publication Date

- 10-Dec-2020

- Technical Committee

- KON.007 - Geotechnics

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 30-Nov-2020

- Due Date

- 04-Feb-2021

- Completion Date

- 11-Dec-2020

Relations

- Effective Date

- 01-Jan-2021

Overview

EN 12715:2020 - Execution of special geotechnical work - Grouting (CEN) is the European standard that provides requirements for the execution, testing and monitoring of geotechnical grouting works. It defines geotechnical grouting as the remote placement of a pumpable material in the ground controlled through rheology and placement parameters (pressure, volume, flow rate). The standard updates and supersedes earlier editions and complements EN 1997 (geotechnical design). Note: jet grouting is excluded (see EN 12716) and some specialised structural/emergency grouting activities are not covered.

Key topics and requirements

- Scope and definitions: Covers both displacement and non-displacement grouting methods (e.g., compaction/compensation grouting, permeation, fissure/contact grouting, bulk filling).

- Information & ground investigation: Specifies the information required for execution and the role of field grouting trials and ground investigation in planning works.

- Materials and grouts: Requirements for grout materials (cements, clays, fillers, water, chemical admixtures) and categories of grouts (suspensions, solutions, mortars).

- Execution design: Execution design basis, objectives and selection of grouting principles and methods aligned with EN 1997 guidance.

- Grout placement & drilling: Guidance on drilling layouts, borehole design, packers, grouting sequences and pressure/volume control.

- Testing, monitoring and control: On-site testing, monitoring of grout performance and ground response (including displacement monitoring), environmental impact control and validation of works.

- Records and documentation: Site records, test reports and documentation requirements to demonstrate compliance.

- Health, safety and environmental protection: Site safety and environmental constraints are addressed.

- Informative annexes: Glossary, grout type characterisation and measurement of grout parameters.

Practical applications

EN 12715:2020 is used to plan, execute and verify grouting works for geotechnical objectives such as:

- Reducing permeability and modifying hydrogeological conditions (sealing beneath structures, cut-off walls).

- Improving mechanical properties of soils and rock (consolidation grouting).

- Filling voids, natural cavities or mine workings adjacent to structures.

- Inducing controlled displacement to compensate ground loss or lift/stabilize slabs and pavements (compensation grouting).

Who should use this standard

- Geotechnical and civil engineers, site supervisors and specialist grouting contractors

- Design offices preparing execution designs that interact with EN 1997

- Project owners, site inspectors and testing laboratories specifying or verifying grouting works

- Regulators and clients requiring harmonised European practice for grouting execution and monitoring

Related standards

- EN 12716 (jet grouting)

- EN 1997 series (geotechnical design)

- Relevant material and testing standards referenced within EN 12715:2020

Keywords: EN 12715:2020, geotechnical grouting, grouting standard, grouting methods, permeation grouting, compensation grouting, execution design, grout materials, CEN.

Frequently Asked Questions

SIST EN 12715:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Execution of special geotechnical work - Grouting". This standard covers: This document is applicable to the execution, testing and monitoring of geotechnical grouting work. Grouting for geotechnical purposes (geotechnical grouting) is a process in which the remote placement of a pumpable material in the ground is indirectly controlled by adjusting its rheological characteristics and by the manipulation of the placement parameters (pressure, volume and the flow rate). The following principles and methods of geotechnical grouting are covered by this document: - displacement grouting (compaction and compensation grouting); - grouting without displacement of the host material (permeation, fissure/contact grouting, bulk filling). Figure 1 illustrates the various injection methods associated with these two principles. NOTE The term consolidation grouting is sometimes used to emphasize an improvement in the strength or deformation characteristics of a soil or rock mass, with the aim that it does not undergo any unacceptable deformation. The term compensation grouting is used when the objective of grouting is to concurrently compensate for ground loss. The principal objectives of geotechnical grouting are: - the modification of the hydraulic/hydrogeological characteristics of the ground; - the modification of the mechanical properties of the ground; - the filling of natural cavities, mine workings, voids adjacent to structures; - inducing displacement to compensate for ground loss or to stabilize and lift footings, slabs and pavements. Specialized grouting activities, generally associated with structural and/or emergency works, are not covered by this document. The execution, testing and monitoring of jet grouting work is not covered by this document and is covered by EN 12716.

This document is applicable to the execution, testing and monitoring of geotechnical grouting work. Grouting for geotechnical purposes (geotechnical grouting) is a process in which the remote placement of a pumpable material in the ground is indirectly controlled by adjusting its rheological characteristics and by the manipulation of the placement parameters (pressure, volume and the flow rate). The following principles and methods of geotechnical grouting are covered by this document: - displacement grouting (compaction and compensation grouting); - grouting without displacement of the host material (permeation, fissure/contact grouting, bulk filling). Figure 1 illustrates the various injection methods associated with these two principles. NOTE The term consolidation grouting is sometimes used to emphasize an improvement in the strength or deformation characteristics of a soil or rock mass, with the aim that it does not undergo any unacceptable deformation. The term compensation grouting is used when the objective of grouting is to concurrently compensate for ground loss. The principal objectives of geotechnical grouting are: - the modification of the hydraulic/hydrogeological characteristics of the ground; - the modification of the mechanical properties of the ground; - the filling of natural cavities, mine workings, voids adjacent to structures; - inducing displacement to compensate for ground loss or to stabilize and lift footings, slabs and pavements. Specialized grouting activities, generally associated with structural and/or emergency works, are not covered by this document. The execution, testing and monitoring of jet grouting work is not covered by this document and is covered by EN 12716.

SIST EN 12715:2021 is classified under the following ICS (International Classification for Standards) categories: 93.020 - Earthworks. Excavations. Foundation construction. Underground works. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12715:2021 has the following relationships with other standards: It is inter standard links to SIST EN 12715:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12715:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Nadomešča:

SIST EN 12715:2002

Izvedba posebnih geotehničnih del - Injektiranje

Execution of special geotechnical work - Grouting

Ausführung von Arbeiten im Spezialtiefbau - Injektionen

Exécution des travaux géotechniques spéciaux - Injection

Ta slovenski standard je istoveten z: EN 12715:2020

ICS:

93.020 Zemeljska dela. Izkopavanja. Earthworks. Excavations.

Gradnja temeljev. Dela pod Foundation construction.

zemljo Underground works

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12715

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2020

EUROPÄISCHE NORM

ICS 93.020 Supersedes EN 12715:2000

English Version

Execution of special geotechnical work - Grouting

Exécution des travaux géotechniques spéciaux - Ausführung von Arbeiten im Spezialtiefbau -

Injection Injektionen

This European Standard was approved by CEN on 14 September 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12715:2020 E

worldwide for CEN national Members.

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 8

4 Information needed for the execution of work . 10

4.1 General. 10

4.2 Specific information . 11

5 Ground investigation . 12

5.1 General. 12

5.2 Specific requirements . 12

5.3 Field grouting trials and field tests . 13

6 Materials and products . 13

6.1 General. 13

6.2 Grout materials . 13

6.2.1 Cement and hydraulic binders . 13

6.2.2 Clay materials . 13

6.2.3 Sands, gravels and fillers . 14

6.2.4 Water . 14

6.2.5 Chemical products and admixtures . 14

6.3 Grouts . 14

6.3.1 General. 14

6.3.2 Suspensions . 15

6.3.3 Solutions . 15

6.3.4 Mortars . 16

7 Execution design . 16

7.1 General. 16

7.2 Execution design basis and objectives . 16

7.3 Grouting principles and methods . 17

7.3.1 Grouting without ground displacement (non-displacement grouting) . 17

7.3.2 Grouting with ground displacement (displacement grouting) . 18

7.4 Grout . 20

7.4.1 Type and composition . 20

7.4.2 General considerations . 20

7.4.3 Parameters and criteria . 21

7.4.4 Applicability . 21

7.5 Grout placement . 21

7.5.1 General. 21

7.5.2 Drilling layout and borehole design . 22

7.5.3 Grouting sequence . 23

7.5.4 Grouting pressure . 23

7.6 Monitoring and control criteria . 23

8 Execution . 24

8.1 General . 24

8.2 Drilling . 24

8.3 Grout preparation . 25

8.3.1 Storage . 25

8.3.2 Batching and mixing . 25

8.3.3 Pumping and delivery . 25

8.4 Grout placement. 26

8.4.1 General . 26

8.4.2 Packers . 27

8.4.3 Special conditions . 27

8.5 Grouting sequences. 27

9 Supervision, testing and monitoring . 28

9.1 General . 28

9.2 Testing . 28

9.3 Monitoring and control . 29

9.3.1 General . 29

9.3.2 Environmental impact . 29

9.3.3 Validation of the grouting works . 29

9.3.4 Monitoring of displacement . 30

9.3.5 Drilling . 30

9.3.6 Grout . 30

10 Records . 30

10.1 General . 30

10.2 Documents produced on site . 31

11 Special requirements (environment, site safety) . 32

11.1 General . 32

11.2 Health and safety . 32

11.3 Environmental protection . 33

Annex A (informative) Glossary . 34

Annex B (informative) Grout types — Processes and their characterizing . 43

Annex C (informative) Measurement of grout parameters . 46

Bibliography . 51

European foreword

This document (EN 12715:2020) has been prepared by Technical Committee CEN/TC 288 “Execution of

special geotechnical works”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2021, and conflicting national standards shall be

withdrawn at the latest by month year May 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12715:2000. The main changes compared to the previous edition are

listed below:

— generally, the text has been checked and brought up to date;

— the Scope now includes Figure 1 to describe the various forms of grouting covered in this document;

— normative references updated and now include reference to EN 1997 for design;

— definitions updated and extended;

— “site investigation” now changed to “ground investigation” in line with EN1997;

— “design considerations” changed to “execution design” in line with EN1997;

— Table 3 moved to Annex B;

— Table 1 included in Clause 8 relating to revised grouting strategies;

— Table B.2 added to characterise grouts;

— Table 5 and A.1 replaced by Annex C with more types of testing included and standards referenced;

— Glossary reviewed and updated;

— Bibliography updated.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The general scope of TC 288 is the standardization of the execution procedures for geotechnical works

(including testing and control methods) and of the required material properties. WG18 has been charged

to revise EN 12715:2000, with the subject area of grouting.

The design, planning and execution of grouting call for experience and knowledge in this specialized field.

The execution phase requires skilled and qualified personnel and the present document cannot replace

the expertise of specialist contractor.

This document has been prepared to complement EN 1997-1, and EN 1997-2.

Until EN 1997-3 is published, the design of grouting works is not clearly defined. In particular, the

boundary between design under the proposed EN 1997-3 and design as part of the execution of grouting

works has not been determined. This document has therefore adopted a distinction between execution

design, i.e. the design of grouting methodology and the other phases of design.

Clause 7 “Execution Design” of this document expands on design only where necessary for the execution.

This document provides coverage of the construction and supervision requirements for grouting works.

Under preparation. Stage at the time of publication: prEN 1997-3.

1 Scope

This document is applicable to the execution, testing and monitoring of geotechnical grouting work.

Grouting for geotechnical purposes (geotechnical grouting) is a process in which the remote placement

of a pumpable material in the ground is indirectly controlled by adjusting its rheological characteristics

and by the manipulation of the placement parameters (pressure, volume and the flow rate).

The following principles and methods of geotechnical grouting are covered by this document:

— displacement grouting (compaction and compensation grouting);

— grouting without displacement of the host material (permeation, fissure/contact grouting, bulk

filling).

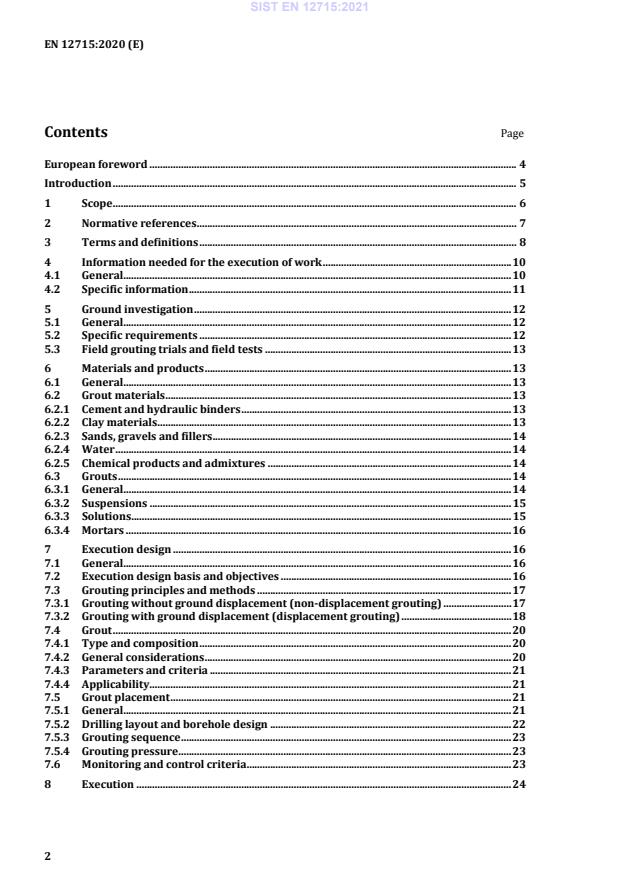

Figure 1 illustrates the various injection methods associated with these two principles.

NOTE The term consolidation grouting is sometimes used to emphasize an improvement in the strength or

deformation characteristics of a soil or rock mass, with the aim that it does not undergo any unacceptable

deformation. The term compensation grouting is used when the objective of grouting is to concurrently compensate

for ground loss.

Figure 1 — Grouting principles and methods

The principal objectives of geotechnical grouting are:

— the modification of the hydraulic/hydrogeological characteristics of the ground;

— the modification of the mechanical properties of the ground;

— the filling of natural cavities, mine workings, voids adjacent to structures;

— inducing displacement to compensate for ground loss or to stabilize and lift footings, slabs and

pavements.

Specialized grouting activities, generally associated with structural and/or emergency works, are not

covered by this document.

The execution, testing and monitoring of jet grouting work is not covered by this document and is covered

by EN 12716.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 197-1, Cement - Part 1: Composition, specifications and conformity criteria for common cements

EN 197-2, Cement - Part 2: Assessment and verification of constancy of performance

EN 480-1, Admixtures for concrete, mortar and grout - Test methods - Part 1: Reference concrete and

reference mortar for testing

EN 480-2, Admixtures for concrete, mortar and grout - Test methods - Part 2: Determination of setting time

EN 480-4, Admixtures for concrete, mortar and grout - Test methods - Part 4: Determination of bleeding of

concrete

EN 480-5, Admixtures for concrete, mortar and grout - Test methods - Part 5: Determination of capillary

absorption

EN 480-6, Admixtures for concrete, mortar and grout - Test methods - Part 6: Infrared analysis

EN 480-8, Admixtures for concrete, mortar and grout - Test methods - Part 8: Determination of the

conventional dry material content

EN 480-10, Admixtures for concrete, mortar and grout - Test methods - Part 10: Determination of water

soluble chloride content

EN 480-11, Admixtures for concrete, mortar and grout - Test methods - Part 11: Determination of air void

characteristics in hardened concrete

EN 480-12, Admixtures for concrete, mortar and grout - Test methods - Part 12: Determination of the alkali

content of admixtures

EN 934-1, Admixtures for concrete, mortar and grout - Part 1: Common requirements

EN 934-3, Admixtures for concrete, mortar and grout - Part 3: Admixtures for masonry mortar - Definitions,

requirements, conformity and marking and labelling

EN 934-4, Admixtures for concrete, mortar and grout - Part 4: Admixtures for grout for prestressing tendons

- Definitions, requirements, conformity, marking and labelling

EN 934-6, Admixtures for concrete, mortar and grout - Part 6: Sampling, assessment and verification of the

constancy of performance

EN 1997-1, Eurocode 7: Geotechnical design - Part 1: General rules

EN 1997-2, Eurocode 7 - Geotechnical design - Part 2: Ground investigation and testing

EN 16228-6, Drilling and foundation equipment - Safety - Part 6: Jetting, grouting and injection equipment

EN ISO 22282 (series), Geotechnical investigation and testing - Geohydraulic testing (ISO 22282 series)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

NOTE The definitions given in this chapter cover only the most important terms involved in geotechnical

grouting. Further definitions are given in the glossary in Annex A.

3.1

bulk filling

placement of grout to fill subterranean cavities

3.2

compaction grouting

injection of a low slump mortar or comparatively stiff (viscous and cohesive) particulate grout into the

soil to compact/densify it by expansion alone

Note 1 to entry: Expanding grouts can be used to cause compaction but may also permeate the ground.

3.3

contact grouting

injection of grout into the interface between man-made structures and the ground

3.4

displacement grouting

injection of grout into a host medium in such a manner as to deform, compress, or displace the ground

3.5

effective pressure

pressure governing the flow in the ground, estimated from the grouting pressure considering the sum of

all head losses and head gains in the injection system and the ground

3.6

fissure grouting

injection of grout into fissures, joints, fractures and discontinuities in rock

3.7

grout

pumpable material (suspension, solution or resins, emulsion or mortar), introduced into soil or rock,

which stiffens and sets with time

3.8

grouting pressure

working pressure

pressure applied during the grouting process and measured at defined locations, usually at the pump or

the borehole collar

3.9

hydraulic fracturing

injection of water or grout that creates a new localized fracture in the ground

3.10

hydraulic jacking

hydrojacking

injection of water or grout within existing fractures in the ground to enhance the grout spread and

penetrability

3.11

penetration grouting

grout injection of joints or fractures in rock, or pore spaces in soil, without displacing the ground

Note 1 to entry: The term includes permeation (impregnation), fissure and contact grouting.

3.12

permeation grouting

impregnation grouting

replacement of interstitial water or gas of a porous medium with a grout

3.13

non-displacement grouting

injection of grout into a host medium in such a manner as not to deform, compress, or displace the ground

Note 1 to entry: The term includes penetration grouting and bulk filling.

3.14

bleed

process by which water forms a separate segregation phase from the grout under gravity or pressure

3.15

stable suspension

ability of a suspension to minimise bleed and segregation and retain its original properties under

pressure

3.16

field grouting trial

trial executed in order to define or validate a grouting methodology

3.17

hydraulic binder

all cements and similar products used in aqueous suspensions to produce grout

3.18

fine

hydraulic binders or cements that are characterized by a particle size d of less than 40 µm

3.19

microfine

hydraulic binders or cements that are characterized by a particle size d of less than 20 µm

3.20

ultrafine

hydraulic binders or cements that are characterized by a particle size d of less than 10 µm

3.21

additive

any grout ingredient other than the basic components of a grout mix (water,

aggregates, or cementitious material), which is used to modify the properties of the fluid and the

hardened grout

3.22

mortars

highly particulate grout containing sand and fine aggregates, commonly a concrete with an aggregate size

of less than 4 mm

3.23

split spacing

procedure by which additional grout injection holes are located midway between previously grouted

holes

3.24

sleeved pipe

TAM

injection pipe perforated at regular intervals where the perforations are covered externally by sleeves

acting as non-return valves

Note 1 to entry: TAM is the abbreviation for tube á manchette.

4 Information needed for the execution of work

4.1 General

4.1.1 All information required to execute the works shall be provided in advance.

4.1.2 This information should include the following, where relevant:

— any legal or statutory restrictions;

— the location of main grid lines for setting out;

— the conditions of structures, roads, services, etc. adjacent to the work, including any necessary

surveys;

— a suitable quality management system, including supervision, monitoring and testing;

— the geometry of the site (boundary conditions, topography, access, slopes, headroom restrictions,

etc.);

— the existing underground structures, services, known contaminations, and archaeological

constraints;

— the environmental restrictions, including noise, vibration, pollution; and

— the future or ongoing activities such as dewatering, tunnelling, deep excavations on or adjacent to

the worksite.

4.2 Specific information

4.2.1 The specific information shall cover, where relevant:

— execution specifications;

— previous use of the site;

— adjacent foundations (types, loads and geometry);

— geotechnical information and data as specified in Clause 5;

— presence of obstructions in the ground (old masonry, anchors, concrete, blocks and boulders, etc.);

— presence of headroom restrictions;

— presence of archaeological remains;

— presence of natural and/or manmade cavities (mines, etc.);

— presence of polluted ground and type, extent and degree of pollution;

— any specific requirements for the grouting works, in particular those pertaining to tolerances, quality

of materials, methods and frequency of testing;

— where available, previous experience with grouting works on or adjacent to the site;

— proposed adjacent enabling or advance works that could affect the grouting works;

— functional requirements for instrumentation and monitoring of potentially affected structures;

— necessity, extent, procedure and content for any survey on the conditions of structures, roads,

services, etc. adjacent to the works area.

4.2.2 Required site surveys shall be carried out and be available prior to the commencement of the

works.

NOTE The results are useful to define the threshold values for any movement which affect adjacent structures

by the works area construction.

4.2.3 Any additional or deviating requirements to this document shall be established and agreed with

the relevant parties or authorities before the commencement of the works and the quality control system

shall be suitably amended.

5 Ground investigation

5.1 General

Any ground investigation shall fulfil the requirements of EN 1997-2 and the relevant national documents.

5.2 Specific requirements

5.2.1 Relevant experience of the execution of comparable grouting works under similar conditions

and/or in the vicinity of the site should be taken into account when determining the extent of the ground

investigation (reference to relevant experience is permitted if appropriate means of verification were

taken).

5.2.2 The ground investigation report shall be sufficient for the execution of the grouting works.

5.2.3 If during grouting the ground conditions differ from those in the ground investigation report this

shall be reported.

5.2.4 For the execution of grouting works, the ground investigation report should contain the following

specific information:

— the relevant physical and chemical characteristics of the ground and groundwater;

— the presence of any anisotropies or permeable horizons which could influence the grouting works;

— the orientation, frequency, and aperture of rock joints and the composition and nature of any infill

material;

— the location and nature of filled or open cavities;

— the presence of obstructions that require special drilling and grouting methods or equipment;

— the presence and characteristics of ground that is likely to loosen, soften or become unstable,

dissolve, collapse or swell as a result of drilling or grouting;

— the presence of strata with high groundwater velocities and/or permeabilities.

5.2.5 Where relevant, the following specific drilling information should be recorded:

— location and cause of core losses;

— unstable zones and stabilization measures taken;

— water level at the beginning and end of a run, zones of water loss and gain, measurements of return

water, water colour and changes in colour;

— recording of drill parameters in the case of destructive boreholes;

— rate of advance.

5.2.6 Permeability testing shall be done in accordance with EN ISO 22282 series.

5.3 Field grouting trials and field tests

5.3.1 Field grouting trials should be executed where ground investigations and local or comparable

experience is insufficient to support or justify the effectiveness of the grouting project.

NOTE Some indication of in situ groutability can be obtained by permeating reconstituted soil samples with

trial grouts, under laboratory conditions.

5.3.2 The trials should provide information on borehole spacing, grout type, procedure and

parameters.

5.3.3 Detailed records shall be kept of each operation performed during the grouting trials.

6 Materials and products

6.1 General

6.1.1 All grout components and grouts shall comply with the specifications for the works.

6.1.2 The suitability of the grout constituents and their combination with the ground shall be

considered and investigated if necessary.

6.1.3 Once established, the sources of grout materials shall not be changed without prior compliance

verification or testing.

6.2 Grout materials

6.2.1 Cement and hydraulic binders

6.2.1.1 Cements shall comply with EN 197-1 and EN 197-2. Cements that do not comply with

EN 197-1 may be used if considered acceptable for the grouting purpose envisaged.

6.2.1.2 Testing of cements and other binders shall be in accordance with their appropriate standard.

6.2.1.3 When selecting the type of hydraulic binder for grout, its grain size distribution shall be

evaluated in relation to the dimensions of the rock apertures or interstitial voids of the ground to be

treated.

6.2.1.4 Pozzolans, blast furnace slag, silica fume and fly ash from thermal power plants or any other

reactive material may be used in grouts.

6.2.2 Clay materials

6.2.2.1 Natural clays, activated or modified bentonites can be added to cement-based grouts in order

to reduce bleeding and/or filtration under pressure, to vary the viscosity and cohesion (yield) of the

grout, or to improve the pumpability and/or penetrability of the grout.

6.2.2.2 The mineralogy, particle size, water content, and Atterberg limits of the clay should be known.

6.2.2.3 The effect of the clay materials on the grout properties should be evaluated if it has not been

established by comparable experience.

6.2.3 Sands, gravels and fillers

6.2.3.1 Sands, gravels and inert fillers may be added to cement grouts or clay suspensions as bulking

agents or as a means of varying the consistency of the grout, its resistance to wash-out, or its mechanical

strength and deformability.

6.2.3.2 The grain size distribution of sands, gravels and fillers shall be known.

6.2.4 Water

6.2.4.1 Unless potable water is used for grouting, its chemical suitability shall be verified.

6.2.4.2 Sea water or saline groundwater can be used provided that the properties of the grout mix

are not impaired.

6.2.5 Chemical products and admixtures

6.2.5.1 The effects of all chemical products and their by-products, including the effect of time,

resulting from the reaction of the chemical products with other components of the grout or with the

surrounding ground shall be considered.

6.2.5.2 Admixtures may be added to the grout to modify its properties and to control its parameters

such as viscosity, setting time, stability, strength, resistance, cohesion and permeability after placement.

6.2.5.3 Admixtures to grout such as superplasticizers, water retaining agents, air entrainers and

others shall be subject to EN 934-1, EN 934-3, EN 934-4, EN 934-6 and EN 480-1, EN 480-2, EN 480-4,

EN 480-5, EN 480-6, EN 480-8, EN 480-10, EN 480-11, and EN 480-12.

6.3 Grouts

6.3.1 General

6.3.1.1 Grouts are classified as:

— suspensions: either particulate or colloidal (nano-particles);

— solutions: either true or colloidal (large molecules);

— mortars.

6.3.1.2 The following intrinsic properties shall be considered when choosing a grout:

— rheology (viscosity, cohesion, etc.), setting time, stability;

— particle size, if applicable;

— strength and durability; and

— toxicity and environmental impact.

6.3.2 Suspensions

6.3.2.1 Suspensions are characterized by the following properties:

— water/solid and/or binder ratio;

— grain size distribution;

— rate of segregation and bleeding;

— stability under pressure filtration;

— rheology and its evolution with time.

6.3.2.2 The tendency of suspended solids to flocculate shall be taken into account, particularly when

using fine, microfine or ultrafine cements.

6.3.2.3 The tendency of solids in suspension to settle in water due to gravity forces, and the tendency

of the suspensions to bleed under pressure, shall be considered in relation with the nature and properties

of the host medium.

6.3.2.4 Clay suspensions should be prepared so that the clay particles are deflocculated and hydrated

before injecting.

6.3.3 Solutions

6.3.3.1 After setting, some types of grouts are not stable with time and their use should be assessed.

6.3.3.2 The effect of syneresis on the properties of the treated ground and on the environment,

particularly their long-term effect, shall be evaluated prior to treatment.

6.3.3.3 The effect of temperature on the grout behaviour during production and placement shall be

taken into account.

6.3.3.4 Special attention shall be paid to:

— the toxicity of individual grout components;

— the risk of dilution of the grout mixture in the groundwater leading to prolongation of the setting

time;

— inhibition of the chemical reaction;

— the toxicity and environmental impact of any substance released into the groundwater if the chemical

reaction is not fully achieved or modified by the host medium.

6.3.4 Mortars

6.3.4.1 Mortars flowing under their own weight can be used for filling cavities, large cracks, open

fissures and voids in the ground.

6.3.4.2 When used for compaction grouting, the mortar should:

— contain a minimum of 15 % of fines passing 0,1 mm;

— have high internal friction;

— have a slump of 9cm ± 3cm tested according to EN 12350-2;

— remain pumpable for grouting.

7 Execution design

7.1 General

7.1.1 The basic standard for the design of ground improvement is EN 1997-1.

7.1.2 This present standard only covers the execution design e.g. grout materials, pressures, flow rates,

sequence, spacing, etc. for the planning and implementation of geotechnical grouting applications.

7.2 Execution design basis and objectives

7.2.1 The execution design and planning of a grouting application shall consider the objectives, impact

of varying ground conditions or variations in the behaviour of the host materials.

7.2.2 The execution design might need to be adapted as the work progresses.

7.2.3 To formulate a grouting execution design, the following information shall be made available:

— a definition of the grouting objectives, its required performance and the control criteria as set out in

the detailed design;

— relevant ground information, in particular geological, geotechnical and hydrogeological data

(including water chemistry) (see Clause 5);

— limitations imposed by environmental restrictions, allowable deformations and displacements, the

influence of or on adjoining structures (buildings and foundations, etc.) or any other parameters

which could affect the choice of grout mix and placement technique;

— references to other grouting projects executed in the same area or under comparable circumstances,

if available.

7.2.4 Based on the ground investigation, the grouting trials and the detailed design, the following

aspects shall be considered and addressed by the execution design:

— the geometry and extent of the ground to be treated;

— the measurable properties required to be achieved by the detailed design;

— the drilling method, layout and sequence;

— the grouting techniques and methods to be applied;

— the spacing of injection points;

— the sequencing of the injections with respect to time, grout composition and injection point;

— the grouting values and any specified limits (injection pressure, flowrate and quantity of grout to be

injected and time);

— the composition and characteristic of grouts to be used;

— the required tests and field controls to be adopted before, during and after grouting;

— the required instrumentation for monitoring, control and data logging.

7.2.5 The following aspects should be considered for grouting:

— the required grout properties;

— potential changes of the in situ state of stress and pore pressures as a result of the grouting work, the

existing groundwater conditions as well as expected post construction conditions;

— the toxicity of the grouting products;

— the working environment in which the grouting materials shall be stored, mixed and injected;

— the availability and reliable supply of grouting materials;

— environmental and safety restrictions;

7.2.6 The time period between the completion of a phase of grouting and the start of the follow-on

works shall be specified.

7.3 Grouting principles and methods

7.3.1 Grouting without ground displacement (non-displacement grouting)

7.3.1.1 General Considerations

To avoid displacement grouting shall be carried out at controlled pressures and flow rates, using

appropriate grouts.

7.3.1.2 Penetration grouting

7.3.1.2.1 Penetration grouting comprises permeation, fissure and contact grouting.

7.3.1.2.2 The function of penetration grouting is to reduce the permeability of the soil or rock and/or

increase the strength and density.

7.3.1.2.3 The flow (injection) rate Q shall be controlled to ensure that the effective pressure remains

lower than the ground fracturing pressure.

7.3.1.2.4 Grouting with microfine, ultrafine or chemical grouts in the presence of coarse grained soils

could require preliminary grouting e.g. with cement based grouts.

7.3.1.2.5 The function of fissure or contact grouting of rock is the filling of cavities, open fissures,

fractures or joints in a rock mass with grout without creating new fractures or displacement, in order to

reduce the permeability and/or increase the strength of the grouted mass.

7.3.1.2.6 The frequency, orientation, extent, aperture, roughness and infilling of the discontinuities of

the rock shall be considered in order to formulate the design and the borehole arrangement.

7.3.1.2.7 The drilling method shall be governed by the requirements set out in the execution design

and/or specifications.

7.3.1.2.8 For pre- and post- tunnel excavation grouting the applied pressures and materials shall be

chosen based on the geometrical and ground conditions.

NOTE 1 Pre-grouting is typically done to reduce groundwater inflows into the tunnel to allow the excavation to

proceed and/or to achieve the inflow performance requirements.

NOTE 2 Post-grouting is done to attain the performance requirements or further reduce local inflows.

7.3.1.2.9 The design of any rock grouting shall take into account the presence or extent of any

excavation damage zone.

7.3.1.3 Bulk filling

7.3.1.3.1 Bulk filling is generally applied to the placement of large volumes of grout under gravity or at

low pressures.

7.3.1.3.2 If a large volume of cementitious grout is placed in an enclosed space, the effect of high local

temperatures and induced stresses shall be taken into account.

7.3.1.3.3 Bulk filling may be followed by a phase of grouting under pressure to fill the remaining voids.

7.3.2 Grouting with ground displacement (displacement grouting)

7.3.2.1 General considerations

7.3.2.1.1 The function of displacement grouting is the injection of grout under pressure with the

deliberate intent of spatially displacing the ground.

7.3.2.1.2 Displacement grouting can be employed to produce controlled movements, to reduce

permeability, to reinforce or stabilize the ground and/or to increase the stiffness under a structure or

foundation.

7.3.2.2 Hydraulic fracture grouting

The function of hydraulic fracture grouting is the creation of fractures within soil or rock in order to

create additional total volume thereby mitigating or producing controlled movements, e.g. uplift of

structures.

7.3.2.3 Hydraulic jacking grouting

7.3.2.3.1 The function of hydraulic jacking grouting of rock masses is to enhance the grout spread and

penetrability.

7.3.2.3.2 The propagation of hydraulic fractures should be controlled to reduce the risk of

unacceptable displacement.

NOTE This is usually done by applying an incremental series of limited volume injections over a period of time.

7.3.2.4 Compensation grouting

7.3.2.4.1 The function of compensation grouting is to inject grout into the ground that is undergoing

volume loss either due to the result of engineering works such as deep excavations or tunnelling or

consolidation of compressible material such that the volume loss is reversed or reduced.

7.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...