SIST EN 13803-1:2010

(Main)Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line

Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line

This European Standard specifies the rules and limits that determine permissible speed for a given track alignment. Alternatively, for a specified permissible speed, it defines limits for track alignment design parameters.

More restrictive requirements of the High Speed TSI Infrastructure and the Conventional Rail TSI Infrastructure, as well as other (national, company, etc.) rules will apply.

This European Standard applies to main lines with track gauges 1435 mm and wider with permissible speeds between 80 km/h and 300 km/h. Annex C (informative) describes the conversion rules which can be applied for tracks with gauges wider than 1435 mm. Normative Annex D is applied for track gauges wider than 1435 mm.

However, the values and conditions stated for this speed range can also be applied to lines where permissible speeds are less than 80 km/h, but in this case, more or less restrictive values may need to be used and should be defined in the contract.

This European Standard need not be applicable to certain urban and suburban lines.

This European Standard also takes account of vehicles that have been approved for high cant deficiencies.

For the operation of tilting trains, specific requirements are defined within this European Standard.

Bahnanwendungen - Oberbau - Linienführung in Gleisen - Spurweiten 1435 mm und grösser - Teil 1: Durchgehendes Hauptgleis

Diese Europäische Norm legt die Regeln und Grenzen fest, welche die zulässige Geschwindigkeit für die

vorhandene Trassierung bestimmen. Alternativ legt sie, für eine festgelegte zulässige Geschwindigkeit,

Grenzen zur Linienführung von Gleisen fest.

Weitere einschränkende Anforderungen der TSI Infrastruktur für Hochgeschwindigkeit und konventionelle

Strecken, so wie weitere (nationale, firmeninterne usw.) Regeln, können zutreffen.

Diese Europäische Norm gilt für Hauptgleise mit Spurweiten von 1 435 mm und größer mit zulässigen

Geschwindigkeiten zwischen 80 km/h und 300 km/h. Anhang C (informativ) beschreibt die Umrechnungsregeln,

die für Gleise mit Spurweiten größer als 1 435 mm angewendet werden können. Der normative

Anhang D wird für Spurweiten größer als 1 435 mm angewendet.

Die für diesen Geschwindigkeitsbereich genannten Werte und Regeln können auch für Strecken angewandt

werden, die mit einer Geschwindigkeit von weniger als 80 km/h betrieben werden. In diesem Fall kann es

notwendig sein, mehr oder weniger einschränkende Werte anzuwenden; diese sollten in dem Vertrag

festgelegt werden.

Diese Europäische Norm braucht nicht für innerstädtische und Vorortbahnstrecken angewendet werden.

Diese Europäische Norm berücksichtigt Fahrzeuge, die für höhere Überhöhungsfehlbeträge zugelassen sind..

Für den Betrieb von Neigetechnik-Zügen sind in dieser Europäischen Norm spezifische Anforderungen

festgelegt.

Applications ferroviaires - Voies - Paramètres de conception du tracé de la voie - Écartement 1435 mm et plus large - Partie 1: Voie courante

La présente Norme européenne définit les règles et limites qui déterminent la vitesse admissible pour un tracé

de voie donnée. Réciproquement, elle définit les paramètres de conception du tracé de la voie pour une vitesse

admissible donnée.

Des prescriptions plus restrictives faisant l’objet de Spécification Technique d’Interopérabilité – Grande

Vitesse – Infrastructure, de Spécification Technique d’Interopérabilité – Rail conventionnel- Infrastructure ou

d’autres règles (règles nationales, règles d’entreprise, etc.) s’appliqueront.

La présente Norme européenne est applicable aux voies principales d'écartement 1435 mm et plus large, dont

les vitesses admissibles sont comprises entre 80 km/h et 300 km/h. L'Annexe C (informative) décrit les règles

de conversion qui peuvent être appliquées pour les voies d'écartement supérieur à 1435 mm. L'Annexe D,

normative, est appliquée pour des écartements de voie 1435 mm et plus larges.

Cependant, les valeurs et les conditions requises pour cette gamme de vitesse peuvent également être

appliquées aux lignes dont les vitesses admissibles sont inférieures à 80 km/h, mais dans ce cas, il peut être

nécessaire d’utiliser des valeurs plus ou moins restrictives, selon les indications du document contractuel.

Il n’est pas nécessaire d’appliquer la présente Norme européenne à certaines lignes de banlieue et de métro.

La présente Norme européenne prend également en considération les véhicules ayant été homologuées pour

des insuffisances de dévers élevées.

Pour l’exploitation des trains pendulaires, des exigences particulières sont définies dans la présente Norme

européenne.

Železniške naprave - Zgornji ustroj - Parametri za projektiranje prog - Tirne širine 1435 mm in več - 1. del: Odprta proga

Ta evropski standard določa pravila in mejne vrednosti, ki določajo dovoljeno hitrost za določeno tirno traso. Druga možnost je, da za določeno dovoljeno hitrost opredeljuje mejne vrednosti parametrov za projektiranje prog. Veljajo bolj omejujoče zahteve za infrastrukturo TSI za visoke hitrosti in infrastrukturo TSI za konvencionalne hitrosti ter druga pravila (nacionalna pravila, pravila podjetja, itd.). Ta evropski standard velja za glavne proge s tirno širino 1435 mm in več z dovoljenimi hitrostmi med 80 km/h in 300 km/h. Dodatek C (informativni) opisuje pravila za pretvorbo, ki se lahko uporabijo za tirne širine, ki presegajo 1435 mm. Za tirne širine, ki presegajo 1435 mm, velja normativni Dodatek D. Vrednosti in pogoji, navedeni za ta razpon hitrosti, pa lahko veljajo tudi za proge, kjer so dovoljene hitrosti pod 80 km/h, vendar je treba v tem primeru uporabiti bolj ali manj omejujoče vrednosti, ki jih je treba opredeliti v pogodbi. Tega evropskega standarda ni treba uporabljati za določene mestne in primestne proge. Ta evropski standard upošteva tudi vozila, odobrena za velika pomanjkanja nadvišanja. Za delovanje nagibnih vlakov so v okviru tega evropskega standarda opredeljene posebne zahteve.

General Information

- Status

- Withdrawn

- Publication Date

- 12-Jul-2010

- Withdrawal Date

- 10-May-2017

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 09-May-2017

- Due Date

- 01-Jun-2017

- Completion Date

- 11-May-2017

Relations

- Effective Date

- 01-Sep-2010

- Effective Date

- 03-May-2017

- Effective Date

- 01-Jul-2014

Frequently Asked Questions

SIST EN 13803-1:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line". This standard covers: This European Standard specifies the rules and limits that determine permissible speed for a given track alignment. Alternatively, for a specified permissible speed, it defines limits for track alignment design parameters. More restrictive requirements of the High Speed TSI Infrastructure and the Conventional Rail TSI Infrastructure, as well as other (national, company, etc.) rules will apply. This European Standard applies to main lines with track gauges 1435 mm and wider with permissible speeds between 80 km/h and 300 km/h. Annex C (informative) describes the conversion rules which can be applied for tracks with gauges wider than 1435 mm. Normative Annex D is applied for track gauges wider than 1435 mm. However, the values and conditions stated for this speed range can also be applied to lines where permissible speeds are less than 80 km/h, but in this case, more or less restrictive values may need to be used and should be defined in the contract. This European Standard need not be applicable to certain urban and suburban lines. This European Standard also takes account of vehicles that have been approved for high cant deficiencies. For the operation of tilting trains, specific requirements are defined within this European Standard.

This European Standard specifies the rules and limits that determine permissible speed for a given track alignment. Alternatively, for a specified permissible speed, it defines limits for track alignment design parameters. More restrictive requirements of the High Speed TSI Infrastructure and the Conventional Rail TSI Infrastructure, as well as other (national, company, etc.) rules will apply. This European Standard applies to main lines with track gauges 1435 mm and wider with permissible speeds between 80 km/h and 300 km/h. Annex C (informative) describes the conversion rules which can be applied for tracks with gauges wider than 1435 mm. Normative Annex D is applied for track gauges wider than 1435 mm. However, the values and conditions stated for this speed range can also be applied to lines where permissible speeds are less than 80 km/h, but in this case, more or less restrictive values may need to be used and should be defined in the contract. This European Standard need not be applicable to certain urban and suburban lines. This European Standard also takes account of vehicles that have been approved for high cant deficiencies. For the operation of tilting trains, specific requirements are defined within this European Standard.

SIST EN 13803-1:2010 is classified under the following ICS (International Classification for Standards) categories: 45.080 - Rails and railway components; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13803-1:2010 has the following relationships with other standards: It is inter standard links to SIST ENV 13803-1:2004, SIST EN 13803:2017, SIST EN 13803:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13803-1:2010 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU, 96/48/EC; Standardization Mandates: M/275, M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13803-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Oberbau - Linienführung in Gleisen - Spurweiten 1435 mm und grösser - Teil 1: Durchgehendes HauptgleisApplications ferroviaires - Voies - Paramètres de conception du tracé de la voie - Écartement 1435 mm et plus large - Partie 1: Voie couranteRailway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line93.100Gradnja železnicConstruction of railways45.080Rails and railway componentsICS:Ta slovenski standard je istoveten z:EN 13803-1:2010SIST EN 13803-1:2010en,de01-september-2010SIST EN 13803-1:2010SLOVENSKI

STANDARDSIST ENV 13803-1:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13803-1

June 2010 ICS 93.100 Supersedes ENV 13803-1:2002English Version

Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line

Applications ferroviaires - Voies - Paramètres de conception du tracé de la voie - Écartement 1435 mm et plus large - Partie 1: Voie courante

Bahnanwendungen - Oberbau - Linienführung in Gleisen - Spurweiten 1 435 mm und größer - Teil 1: Durchgehendes Hauptgleis This European Standard was approved by CEN on 20 May 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13803-1:2010: ESIST EN 13803-1:2010

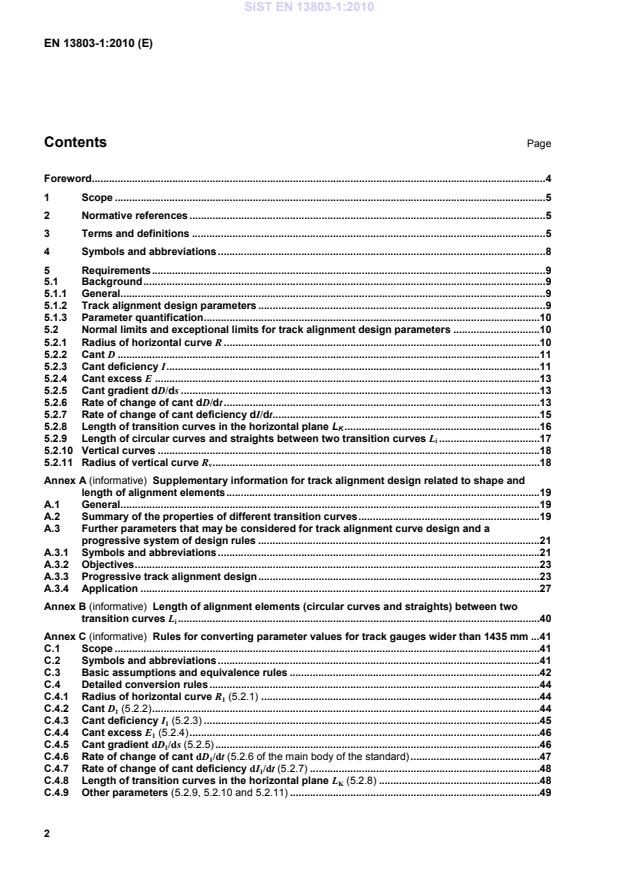

Supplementary information for track alignment design related to shape and length of alignment elements . 19A.1General . 19A.2Summary of the properties of different transition curves . 19A.3Further parameters that may be considered for track alignment curve design and a progressive system of design rules . 21A.3.1Symbols and abbreviations . 21A.3.2Objectives . 23A.3.3Progressive track alignment design . 23A.3.4Application . 27Annex B (informative)

Length of alignment elements (circular curves and straights) between two transition curves Li . 40Annex C (informative)

Rules for converting parameter values for track gauges wider than 1435 mm . 41C.1Scope . 41C.2Symbols and abbreviations . 41C.3Basic assumptions and equivalence rules . 42C.4Detailed conversion rules . 44C.4.1Radius of horizontal curve R1 (5.2.1) . 44C.4.2Cant D1 (5.2.2) . 44C.4.3Cant deficiency I1 (5.2.3) . 45C.4.4Cant excess E1 (5.2.4) . 46C.4.5Cant gradient dD1/ds (5.2.5) . 46C.4.6Rate of change of cant dD1/dt (5.2.6 of the main body of the standard) . 47C.4.7Rate of change of cant deficiency dI1/dt (5.2.7) . 48C.4.8Length of transition curves in the horizontal plane LK (5.2.8) . 48C.4.9Other parameters (5.2.9, 5.2.10 and 5.2.11) . 49SIST EN 13803-1:2010

Track alignment design parameter limits for track gauges wider than 1435 mm . 50D.1Scope . 50D.2Requirements for a gauge of 1668 mm . 50D.2.1General . 50D.2.2Cant D1 . 50D.2.3Cant deficiency I1 . 50D.2.4Cant excess E1 . 51D.2.5Cant gradient dD1/ds . 51D.2.6Rate of change of cant dD1/dt . 51D.2.7Rate of change of cant deficiency dI1/dt . 52D.2.8Length of circular curves and straights between two transition curves Li1 . 52D.2.9Vertical curves . 53D.2.10Radius of vertical curve . 53D.3Requirements for a gauge of 1524 mm . 53D.3.1General . 53D.3.2Cant D1 . 53D.3.3Cant deficiency I1 . 54D.3.4Cant excess E1 . 54D.3.5Cant gradient dD1/ds . 55D.3.6Rate of change of cant dD1/dt . 55D.3.7Rate of change of cant deficiency dI1/dt . 55D.3.8Length of circular curves and straights between two transition curves Li1 . 56D.3.9Vertical curves . 56D.3.10Radius of vertical curve . 56Annex E (informative)

Track resistance to lateral forces generated by the rolling stock . 57E.1Introduction . 57E.2The effect of alignment design parameters on lateral forces generated by the rolling stock . 57E.2.1Cant deficiency . 57E.2.2Cant excess . 58E.2.3The lateral strength limit of a track under loading (Prud'homme limit) . 58E.2.4Factors influencing the resistance to track lateral displacement . 58Annex F (informative)

Consequences on track resistance, stress and fatigue resulting from tilting body train systems . 59F.1General . 59F.2Basic principles applying to tilting body techniques . 59F.3Safety requirements . 59F.3.1Lateral axle force and track lateral resistance (track lateral shift) . 59F.3.2Vehicle overturning . 60F.3.3Comfort requirements . 61Annex G (informative)

Constraints and risks associated with the use of exceptional limits . 62Annex H (informative)

Recapitulation of the work carried out by the ORE B 55 Committee – Maximum permissible cant . 63H.1Introduction . 63H.2Criteria for safety against derailment at low speed through wheel-climbing . 63H.3Limits for track twist. 64H.4Rules applicable to the design of and checks performed on new vehicles with regard to their capability of coping with track twist values . 65H.5List of reports published by the ORE B 55 Committee . 65Annex I (informative)

A-deviation Switzerland . 66Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2008/57/EC of the European Parliament and of the council of 17 June 2008 on the interoperability of the rail system within the Community . 67Bibliography . 70 SIST EN 13803-1:2010

1 Official Journal of the European Communities N° L 235 of 1996-09-17 2 Official Journal of the European Communities N° L 134 of 2004-04-30 3 Official Journal of the European Communities N° L 237 of 1991-08-24 SIST EN 13803-1:2010

More restrictive requirements of the High Speed TSI Infrastructure and the Conventional Rail TSI Infrastructure, as well as other (national, company, etc.) rules will apply. This European Standard applies to main lines with track gauges 1435 mm and wider with permissible speeds between 80 km/h and 300 km/h. Annex C (informative) describes the conversion rules which can be applied for tracks with gauges wider than 1435 mm. Normative Annex D is applied for track gauges wider than 1435 mm. However, the values and conditions stated for this speed range can also be applied to lines where permissible speeds are less than 80 km/h, but in this case, more or less restrictive values may need to be used and should be defined in the contract.

This European Standard need not be applicable to certain urban and suburban lines.

This European Standard also takes account of vehicles that have been approved for high cant deficiencies.

For the operation of tilting trains, specific requirements are defined within this European Standard.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13803-2, Railway applications — Track — Track alignment design parameters — Track gauges 1435 mm and wider — Part 2: Switches and crossings and comparable alignment design situations with abrupt changes of curvature EN 14363, Railway applications — Testing for the acceptance of running characteristics of railway vehicles —Testing of running behaviour and stationary tests EN 15686, Railway applications — Testing for the acceptance of running characteristics of railway vehicles with cant deficiency compensation system and/or vehicles intended to operate with higher cant deficiency than stated in EN 14363:2005, Annex G EN 15687, Railway applications — Testing for the acceptance of running characteristics of freight vehicles with static wheel axle higher than 225 kN and up to 250 kN ISO 80000-3, Quantities and units — Part 3: Space and time 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 alignment element segment of the track with either vertical direction, horizontal direction or cant obeying a unique mathematical description as function of longitudinal distance NOTE Unless otherwise stated, the appertaining track alignment design parameters are defined for the track centre line and the longitudinal distance for the track centre line is defined in a projection in a horizontal plane. SIST EN 13803-1:2010

NOTE 2 It is possible to use other forms of transition curve, which show a non-linear variation of curvature. Informative Annex A gives a detailed account of certain alternative types of transitions that may be used in track alignment design. NOTE 3 Normally, a transition curve is not used for the vertical alignment. 3.4 compound curve sequence of curved alignment elements, including two or more circular curves in the same direction NOTE The compound curve may include transition curves between the circular curves and / or the circular curves and the straight tracks

3.5 reverse curve sequence of curved alignment elements, containing alignment elements which curve in the opposite directions NOTE A sequence of curved alignment elements, may be both a compound curve and a reverse curve. 3.6 cant amount by which one running rail is raised above the other running rail NOTE Cant is positive when the outer rail on curved track is raised above the inner rail and is negative when the inner rail on curved track is raised above the outer rail. Negative cant is unavoidable at switches and crossings on a canted main line where the turnout is curving in the opposite direction to the main line and, in certain cases, on the plain line immediately adjoining a turnout (see EN 13803-2).

3.7 equilibrium cant cant at a particular speed at which the vehicle will have a resultant force perpendicular to the running plane 3.8 cant excess difference between applied cant and a lower equilibrium cant NOTE 1 When there is cant excess, there will be an unbalanced lateral force in the running plane. The resultant force will move towards the inner rail of the curve.

NOTE 2 Cant on a straight track results in cant excess, generating a lateral force towards the low rail.

3.9 cant deficiency difference between applied cant and a higher equilibrium cant NOTE When there is cant deficiency, there will be an unbalanced lateral force in the running plane. The resultant force will move towards the outer rail of the curve.

3.10 cant transition alignment element where cant changes with respect to longitudinal distance SIST EN 13803-1:2010

NOTE 2 Cant transitions giving a linear variation of cant are usually used. In some cases, cant is smoothed at the ends of the transition.

NOTE 3 It is possible to use other forms of cant transition, which show a non-linear variation of cant. Informative Annex A gives a detailed account of certain alternative types of transitions that may be used in track alignment design.

3.11 cant gradient absolute value of the derivative (with respect to longitudinal distance) of cant 3.12 rate of change of cant absolute value of the time derivative of cant 3.13 rate of change of cant deficiency absolute value of the time derivative of cant deficiency (and/or cant excess) 3.14 maximum permissible speed maximum speed resulting from the application of track alignment limits given in this standard 3.15 normal limit limit not normally exceeded NOTE The actual design values for new lines should normally have a margin to the normal limits. These values ensure maintenance costs of the track are kept at a reasonable level, except where particular conditions of poor track stability may occur, without compromising passenger comfort. To optimize the performance of existing lines it may be useful to go beyond the normal limits.

3.16 exceptional limit extreme limit not to be exceeded NOTE As exceptional limits are extreme, it is essential that their use is as infrequent as possible and subject to further consideration. Informative Annex H describes the constraints and risks associated with the use of exceptional limits. SIST EN 13803-1:2010

m/s3 5 daq/dt rate of change of non-compensated lateral acceleration m/s3 6 dD/ds cant gradient

mm/m 7 dD/dt rate of change of cant mm/s 8 dI/dt rate of change of cant deficiency (and/or cant excess)

mm/s 9 D Cant mm 10 DEQ equilibrium cant mm 11 e distance between the nominal centre points of the two contact patches of a wheelset (e.g. about 1500 mm for track gauge 1435 mm) mm 12 E cant excess mm 13 g acceleration due to gravity: 9,81 m/s2 m/s2 14 hg height of the centre of gravity mm 15 I cant deficiency mm 16 LD length of cant transition

m 17 LK length of transition curve

m 18 Li length of alignment elements (circular curves and straights) between two transition curves

m 19 lim limit (index) - 20 max maximum value (index) - 21 min minimum value (index) - 22 qD factor for calculation of length of cant transition

m·h/(km·mm)23 qI factor for calculation of length of transition curve

m·h/(km·mm)24 qN factor for calculation of length of cant transition or transition curve with non-constant gradient of cant and curvature, respectively

- 25 qR factor for calculation of vertical radius m·h2/km2 26 qV factor for conversion of the units for vehicle speed: 3,6 km·s/(h·m) km·s/(h·m) 27 R radius of horizontal curve m 28 Rv radius of vertical curve m 29 s longitudinal distance

m 30 sr roll flexibility coefficient, equivalent to flexibility coefficient s in EN 15273-1 - 31 st tilt compensation factor of a tilt system

- 32 t time s 33 V speed

km/h 34 Vmax maximum speed of fast trains

km/h 35 Vmin minimum speed of slow trains

km/h 36 ∆aq overall variation of non-compensated lateral acceleration m/s2 37 ∆D overall variation of cant along a cant transition

mm 38 ∆I overall variation of cant deficiency (and/or cant excess) mm

Unnecessary use of the exceptional limits specified in this European Standard should be avoided. A substantial margin to them should be provided, either by complying with the normal limits or by applying a margin with respect to permissible speed. For further details, see informative Annex G. 5.1.2 Track alignment design parameters The following parameters are specified in 5.2: radius of horizontal curve R (m) (*S); cant D (mm) (*S); cant deficiency I (mm) (*S); cant excess E (mm); cant gradient dD/ds (mm/m) (*S); rate of change of cant dD/dt (mm/s); rate of change of cant deficiency (and/or cant excess) dI/dt (mm/s); length of cant transitions LD (m) (*S);

length of transition curves in the horizontal plane LK (m); length of alignment elements (circular curves and straights) between two transition curves Li (m);

radius of vertical curve Rv (m); speed V (km/h) (*S). Parameters followed by the (*S) note indicate safety-related parameters. SIST EN 13803-1:2010

NOTE 1 The exceptional limits are safety-related and may (for most parameters) induce a reduced comfort level. These limits are extreme and should be used only under special circumstances or after specific safety-case analysis.

NOTE 2 The limits are defined for normal service operations. If and when running trials are conducted, for example to ascertain the vehicle dynamic behaviour (by continually monitoring of the vehicle responses), exceeding the limits (particularly in terms of cant deficiency) should be permitted and it is up to the infrastructure manager to decide any appropriate arrangement. In this context, safety margins are generally reinforced by taking additional steps such as ballast consolidation, monitoring of track geometric quality, etc.

b) For non-safety related parameters, the limits shall be considered as the limit above which passenger comfort may be affected and the need for track maintenance increased; however, to cope with special situations, values in excess of the limits may be used, but they shall not exceed any safety limit.

The use of exceptional limits should be avoided, especially use of exceptional limits for several parameters at the same location along the track.

For cant deficiency, not all vehicles are approved for the normal or exceptional limits. For such vehicles, the operational limit shall be consistent with the approved maximum cant deficiency. 5.2 Normal limits and exceptional limits for track alignment design parameters 5.2.1 Radius of horizontal curve R The largest curve radii and transition permitted by track design constraints should be used where possible. Normal limit for radius is 190 m and exceptional limit is 150 m. Note that these small radii will result in a permissible speed less than 80 km/h. Hence, normal and exceptional limits for the radius shall also be derived from the requirements below.

The parameters that shall be considered in the determination of the minimum curve radius are: the maximum and minimum speeds;

the applied cant; the limits for cant deficiency and cant excess. For every combination of maximum speed Vmax and maximum cant deficiency Ilim, the minimum permissible curve radius shall be calculated using the following equation: 2maxlimminVIDCR⋅+=

[m] where C = 11,8 mm·m·h2/km2

Where D > Elim, the maximum permissible curve radius for the minimum speed Vmin shall be calculated using the following equation:

[m] where C = 11,8 mm·m·h2/km2, and D > Elim

NOTE 1 It is recommended that the radius of tracks alongside platforms should not be less than 500 m. This is to restrict the gap between platform and vehicles to facilitate safe vehicle access and egress by passengers. NOTE 2 Small radius curves may require gauge widening in order to improve vehicle curving. 5.2.2 Cant D Cant shall be determined in relation to the following considerations:

high cant on small-radius curves increases the risk of low-speed freight wagons derailing. Under these conditions, vertical wheel loading applied to the outer rail is much reduced, especially when track twist (defined in EN 13848-1) causes additional reductions;

cant exceeding 160 mm may cause freight load displacement and the deterioration of passenger comfort when a train makes a stop or runs with low speed (high value of cant excess). Works vehicles and special loads with a high centre of gravity may become unstable;

high cant increases cant excess values on curves where there are large differences between the speeds of fast trains and slow trains. Normal limit for cant is 160 mm.

NOTE It is recommended that cant should be restricted to 110 mm for tracks adjacent to passenger platforms. Some other track features, such as level crossings, bridges and tunnels may also, in certain local circumstances, impose cant restrictions.

Exceptional limit for cant is 180 mm.

To avoid the risk of derailment of torsionally-stiff freight wagons on small radius curve (R < 320 m), cant should be restricted to the following limit: m/mm5,1m50lim−=RD [mm] The application of this limit assumes a high maintenance standard of the track, especially regarding twist. For further information, see informative Annex H. 5.2.3 Cant deficiency I For given values of local radius R and cant D, the cant deficiency I shall determine the maximum permissible speed through a full curve such that:

lim2IDDDRVCIEQ≤−=−⋅=

[mm] where C = 11,8 mm·m·h2/km2 NOTE 1 Ilim can be replaced with the value (aq)lim:

()eIgaeIgeDgRqVaVlimlimq2q1⋅=≤⋅=⋅−= [m/s2]

Normal limits Exceptional limits Non-tilting trains 80 km/h < V ≤ 200 km/h 130 mm 183 mm 200 km/h < V ≤ 230 km/h 130 mm 168 mmab 230 km/h < V ≤ 250 km/h 130 mm 153 mmab 250 km/h < V ≤ 300 km/h 100 mm 130 mmabc Tilting trains 80 km/h ≤ V ≤ 260 km/hd 275 mmb 306 mmb a Trains complying with EN 14363, equipped with a cant deficiency compensation system other than tilt, may be permitted by the Infrastructure Manager to run with higher cant deficiency values.

b The Infrastructure Manager may require qualification of a part of a line for the introduction of trains running at these or higher cant deficiencies, taking into account the required track quality and other conditions. c The limit may be raised to 153 mm for non ballasted track. d Currently, there are no lines used or planned where maximum speed for tilting trains exceeds 260 km/h.

NOTE 1 The European signalling system ERTMS includes vehicle limits of cant deficiency Ilim of 92 mm, 100 mm, 115 mm, 122 mm, 130 mm, 153 mm, 168 mm, 183 mm, 245 mm, 275 mm and 306 mm. These values reflect the current practice of operating different train categories in Europe.

NOTE 2 Freight vehicles are normally approved for a cant deficiency in the range 92 mm to 130 mm. NOTE 3 Non-tilting passenger vehicles are normally approved for a cant deficiency of 130 mm to 168 mm. NOTE 4 Depending on the characteristics of certain special features in track, such as certain switches and crossings in curves, bridges carrying direct-laid ballastless track, tracks with jointed rails, certain sections of line exposed to very strong cross winds, etc., it may be necessary to restrict the permissible cant deficiency. Rules in respect of these restrictions cannot be formulated beforehand since they will be dictated by the design of the special features; definition of such a frame of reference can only be left to the initiative of the Infrastructure Manager. NOTE 5 For further considerations of rolling stock required to operate at high cant deficiencies, passenger comfort with respect to lateral acceleration may be analysed as follows: The quasi-static lateral acceleration ai (at track level, but parallel to the vehicle floor) is a measure of the acceleration felt by passengers inside the vehicle; For a non-tilting train ai is greater than the lateral non-compensated acceleration in the track plane aq: ()()qrrasgeIsa⋅+=⋅⋅+=11i [m/s2];

For a tilting train this can be expressed approximately by ()()geIssatr⋅⋅−⋅+=11i [m/s2]; The roll flexibility coefficient sr is positive for non-tilting vehicles, as the longitudinal rotation axis of the coach body is low (around the top of the suspension plane), hence the lateral acceleration felt by passengers due to cant deficiency is greater than that applied to the running plane. This coefficient can be reduced by choosing a dedicated suspension SIST EN 13803-1:2010

[mm] where C = 11,8 mm·m·h2/km2 Normal limit for cant excess Elim is 110 mm.

The value of E affects inner-rail stresses induced by slow trains, since the quasi-static vertical wheel/rail force of an inner wheel is increased.

5.2.5 Cant gradient dD/ds

The following limits apply everywhere along the track where cant is varying: limmaxdddd≤sDsD

[mm/m] Normal limit: mm/m25,2ddlim=sD Exceptional limit: mm/m50,2ddlim=sD NOTE For permissible speed lower than 80 km/h, a higher cant gradient may be used after a safety-case analysis, see Annex H.

For cant transitions with constant cant gradient, maxddsDcan be calculated from the overall cant variation ∆D and the length LD: limdddd≤∆=sDLDsDD

[mm/m] There are no further special limits for the tilting trains. 5.2.6 Rate of change of cant dD/dt

5.2.6.1 Rate of change of cant dD/dt for non-tilting trains Cant transitions are normally found in transition curves. However, it may be necessary to provide cant transitions in circular curves and straights. SIST EN 13803-1:2010

limdddd≤⋅∆=tDqVLDtDVD

[mm/s] where DL is the length of the cant transition in metres, V is vehicle speed in km/h andVq = 3,6 km·s/(h·m) Normal and exceptional limits for rate of change of cant are given in Table 2. Table 2 — Rate of change of cant (dD/dt)lim for constant cant gradients

Normal limits Exceptional limits Non-tilting trains V<200 km/h I<168 mm 50 mm/s 70 mm/sa 168

50 mm/s 60 mm/s a Where I<153 mm and dI/dt<70 mm/s, the exceptional limit for dD/dt may be raised to 85 mm/s.

For cant transitions with variable cant gradient, the value of dD/dt is not constant. limmaxdddd≤tDtD

[mm/s] Normal limit: mm/s55ddlim=tD

Exceptional limit mm/s76ddlim=tD NOTE 1 Due to limited experience with transitions with variable gradients, the limits for rate of change of cant are indicative. They may be replaced by limits for second derivative of cant with respect to time (d2D/dt2), see A.3. NOTE 2 Informative Annex A gives further information on linear cant transitions and alternative types of cant transitions.

5.2.6.2 Rate of change of cant dD/dt for tilting trains Both active and the passive tilt systems need certain time to adapt the angle of tilt to the curve radius and it is for this reason that curves shall include transition sections of sufficient length. The transition curves should coincide with the cant transitions. If they do not, then special running tests are recommended to determine to what extent the maximum cant deficiency may need to be reduced. The clothoid is normally used for transition curves, giving a linear variation of curvature. Where using transition curves with non-constant gradients, the function of the tilt system shall be taken into account for the analysis of the complex interaction between the vehicle and the track. SIST EN 13803-1:2010

[mm/s] NOTE 1 The variation of non-compensated lateral acceleration in the running plane may be determined as limmax≤tataddddqq [m/s3] NOTE 2 The rate of change of the quasi-static lateral acceleration, at track level, but parallel to the vehicle floor (dai/dt), which is a measure of the rate of change of acceleration felt by the passenger inside the vehicle, is greater than the rate of change of non-compensated acceleration in the track plane (daq/dt): ()tastardd1ddqi⋅+= [m/s3]. NOTE 3 The influence of rate of change of lateral acceleration on passenger comfort is described in EN 12299.

Normal and exceptional limits for rate of change of cant deficiency are given in Table 3. Table 3 — Rate of change of cant deficiency (dI/dt)lim

Normal limits Exceptional limits Non-tilting trains V<200 km/h I<168 mm 55 mm/s 100 mm/s 168

55 mm/s 75 mm/s

In case of using tilting trains on given alignment, the values of dI/dt are higher. The tilt control system creates transient states at the entry to curves, which may give rise to even more pronounced jerks. Both active and the passive tilt systems need certain time to adapt the angle of tilt to the curve radius and it is for this reason that curves shall include transition sections of sufficient length. Normal limit: mm/s100ddlim=tI For transitions with constant gradients of curvature and cant with ∆I the overall cant deficiency variation along the whole transition it follows: SIST EN 13803-1:2010

[mm/s] where KL is the length of the transition in metres, V is vehicle speed in km/h andVq = 3,6 km·s/(h·m) NOTE 4 For transitions with constant gradients of curvature and cant with ∆aq the overall variation of non-compensated lateral acceleration along the whole transition it follows: limÄ=tdadqVLtdadqVKqq∆[m/s3]. The values of dI/dt and daq/dt are not constant for transitions with non-linear curvature variation and non-linear cant application, see informative Annex A for further information.

5.2.8 Length of transition curves in the horizontal plane LK For transition curves coinciding with cant transitions, LK = LD, with a constant gradient of curvature and cant, the minimum length shall be determined using the parameters from 5.2.5, 5.2.6 and 5.2.7 in the following manner: cant gradient sDdd; rate of change of cant tDdd; rate of change of cant deficiency tIdd; and by the following formulae: 1dd−⋅∆≥limsDDLD [m] 1dd−⋅∆⋅≥limtDDqVLVD[m] 1dd−⋅∆⋅≥limtIIqVLVK[m] NOTE 1 Certain local standards present the requirement for dD/dt in the form ()1000DVqLDD∆⋅⋅≥lim [m], where the limit for Dq is defined from 1dd1000−⋅=tDqqVD [m·h/(km·mm)]. NOTE 2 Certain local standards present the requirement for dI/dt in the form ()1000IVqLIK∆⋅⋅≥lim [m], where the limit for Iq is defined from 1dd1000−⋅=tIqqVI [m·h/(km·mm)]. For transition curves coinciding with cant transitions, LK = LD

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...