SIST EN 12839:2012

(Main)Precast concrete products - Elements for fences

Precast concrete products - Elements for fences

This European standard specifies precast products in reinforced or pre-stressed concrete with or without fibres, to be used together or in combination with other elements to erect fences e.g. boundary fences.

This European standard covers both mechanical resistance determined by calculation and load bearing capacity determined by testing.

Normal weight concrete or light weight concrete elements include posts, solid or open panels, slabs, rails, spurs, struts and base panels.

The intended uses may be nonstructural or lightly structural.

It provides for the evaluation of conformity of elements to this European Standard. Marking conditions are included.

Betonfertigteile - Betonelemente für Zäune

Diese Europäische Norm legt die Anforderungen an vorgefertigte Erzeugnisse aus Stahl- oder Spannbeton mit oder ohne Fasern fest, die zusammen oder in Verbindung mit anderen Bauteilen zur Errichtung von Zäunen, z. B. Einfriedungen, verwendet werden können.

In dieser Europäischen Norm wird sowohl die rechnerisch bestimmte Widerstandsfähigkeit gegen mechanische Einwirkungen als auch die in Prüfungen ermittelte Tragfähigkeit behandelt.

Normale oder leichte Betonbauteile umfassen Pfähle, Voll- oder durchbrochene Tafeln, Platten, Riegel, Stützpfeiler, Abstützungen und Sockelplatten.

Der vorgesehene Verwendungszweck kann nicht tragende oder unerheblich tragende Funktionen einschließen.

Die Norm legt die Bewertung der Konformität der von dieser Europäischen Norm erfassten Produkte fest. Die Bedingungen für die Kennzeichnung sind ebenfalls behandelt.

Produits préfabriqués en béton - Eléments pour clôtures

La présente Norme européenne spécifie les éléments préfabriqués en béton armé ou précontraint, avec ou sans fibres, destinés à être utilisés ensemble ou en combinaison avec d’autres éléments pour ériger des clôtures, par exemple des clôtures séparatives.

La présente Norme européenne traite de la résistance mécanique déterminée par calcul et de la résistance mécanique déterminée par des essais.

Les éléments en béton de masse volumique normale ou en béton léger comprennent les poteaux, les dalles pleines et les panneaux ajourés, les plaques, les lisses, les poteaux d’embase, les jambes de force et les dalles de soubassement.

Les emplois prévus peuvent être non structurels ou légèrement structurels.

Elle précise l’évaluation de la conformité des éléments à la présente Norme européenne. Les conditions de marquage sont incluses.

Betonski izdelki - Elementi za ograje

Ta evropski standard določa izdelke iz armiranega ali prednapetega betona z vlakni ali brez njih, ki se uporabljajo skupaj ali v kombinaciji z drugimi elementi za postavljanje ograj, kot so zunanje ograje.

Ta evropski standard zajema mehansko odpornost, ki se določi z izračuni, in nosilnost, ki se določi s preskušanjem.

Med elemente iz normalno težkega ali lahkega betona spadajo stebri, zaprti ali odprti paneli, plošče, nosilci, palice, oporniki in osnovni paneli.

Predvidene uporabe so lahko nekonstrukcijske ali lahke konstrukcijske.

Omogoča vrednotenje skladnosti elementov s tem evropskim standardom. Vključeni so pogoji za označevanje.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Sep-2011

- Publication Date

- 04-Apr-2012

- Technical Committee

- BBB - Concrete, reinforced concrete and prestressed concrete

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Jan-2012

- Due Date

- 02-Apr-2012

- Completion Date

- 05-Apr-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-May-2012

Overview

EN 12839:2012 - Precast concrete products: Elements for fences is a CEN European standard that specifies requirements for precast concrete fence elements. It applies to reinforced or pre‑stressed concrete, with or without fibres, using normal weight or light weight concrete. Covered products include posts, solid and open panels, slabs, rails, spurs, struts and base panels intended for boundary fences and similar enclosures. The standard addresses both mechanical resistance (by calculation) and load‑bearing capacity (by testing), and defines procedures for conformity assessment and marking.

Key topics and technical requirements

- Materials and production: Requirements for concrete production and hardened concrete, including use of reinforced or pre‑stressed elements and optional fibre reinforcement.

- Product types: Dimensions and geometric tolerances for posts, panels, rails and base elements; surface characteristics and finishes (as cast or treated).

- Mechanical resistance: Design by calculation (reference to Eurocodes where applicable) and verification by load testing-Annex B specifies test methods for load bearing capacity.

- Durability and performance tests: Tests and criteria for compressive strength, water absorption, density and concrete cover; surface and thermal/acoustic considerations.

- Factory production control (FPC): Procedures for ongoing quality control in manufacture (Annex C) and independent acceptance/testing at delivery (Annex D).

- Conformity and marking: Evaluation of conformity, marking and labelling requirements, and guidance for CE marking and relationship to EU construction product requirements (informative Annex ZA).

- Types of fences: Informative Annex A describes common fence types - solid, open‑work, mesh/wire, mixed, rail and anti‑intruder systems.

Applications and who uses this standard

EN 12839 is practical for anyone involved with precast fence elements:

- Manufacturers of precast fence posts, panels and rails - for product design, production control and CE marking.

- Structural and civil engineers - to verify mechanical resistance and specify appropriate load testing or calculation methods.

- Specifiers and procurement teams - to write performance‑based specifications for boundary fences, public works and private developments.

- Contractors and installers - to understand dimensional tolerances, handling safety and on‑site acceptance testing.

- Authorities and certifiers - for conformity assessment, acceptance sampling and regulatory compliance.

Related standards

- EN 13369 - Common rules for precast concrete products (referenced for shared requirements).

- EN 206-1 - Concrete specification and conformity.

- EN 1991-1-4 (Eurocode 1) - Actions on structures (wind actions) when relevant.

- EN 12390-4 - Testing hardened concrete (compressive strength).

EN 12839:2012 is the key reference when specifying or producing precast concrete fence elements to ensure consistent quality, structural performance and regulatory compliance.

Frequently Asked Questions

SIST EN 12839:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Precast concrete products - Elements for fences". This standard covers: This European standard specifies precast products in reinforced or pre-stressed concrete with or without fibres, to be used together or in combination with other elements to erect fences e.g. boundary fences. This European standard covers both mechanical resistance determined by calculation and load bearing capacity determined by testing. Normal weight concrete or light weight concrete elements include posts, solid or open panels, slabs, rails, spurs, struts and base panels. The intended uses may be nonstructural or lightly structural. It provides for the evaluation of conformity of elements to this European Standard. Marking conditions are included.

This European standard specifies precast products in reinforced or pre-stressed concrete with or without fibres, to be used together or in combination with other elements to erect fences e.g. boundary fences. This European standard covers both mechanical resistance determined by calculation and load bearing capacity determined by testing. Normal weight concrete or light weight concrete elements include posts, solid or open panels, slabs, rails, spurs, struts and base panels. The intended uses may be nonstructural or lightly structural. It provides for the evaluation of conformity of elements to this European Standard. Marking conditions are included.

SIST EN 12839:2012 is classified under the following ICS (International Classification for Standards) categories: 91.090 - External structures; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12839:2012 has the following relationships with other standards: It is inter standard links to SIST EN 12839:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12839:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/100. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12839:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Betonski izdelki - Elementi za ograjeBetonfertigteile - Betonelemente für ZäuneProduits préfabriqués en béton - Eléments pour clôturesPrecast concrete products - Elements for fences91.100.30Beton in betonski izdelkiConcrete and concrete products91.090Konstrukcije zunaj stavbExternal structuresICS:Ta slovenski standard je istoveten z:EN 12839:2012SIST EN 12839:2012en,fr,de01-maj-2012SIST EN 12839:2012SLOVENSKI

STANDARDSIST EN 12839:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12839

January 2012 ICS 91.100.30 Supersedes EN 12839:2001English Version

Precast concrete products - Elements for fences

Produits préfabriqués en béton - Eléments pour clôtures

Betonfertigteile - Betonelemente für Zäune This European Standard was approved by CEN on 13 November 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12839:2012: ESIST EN 12839:2012

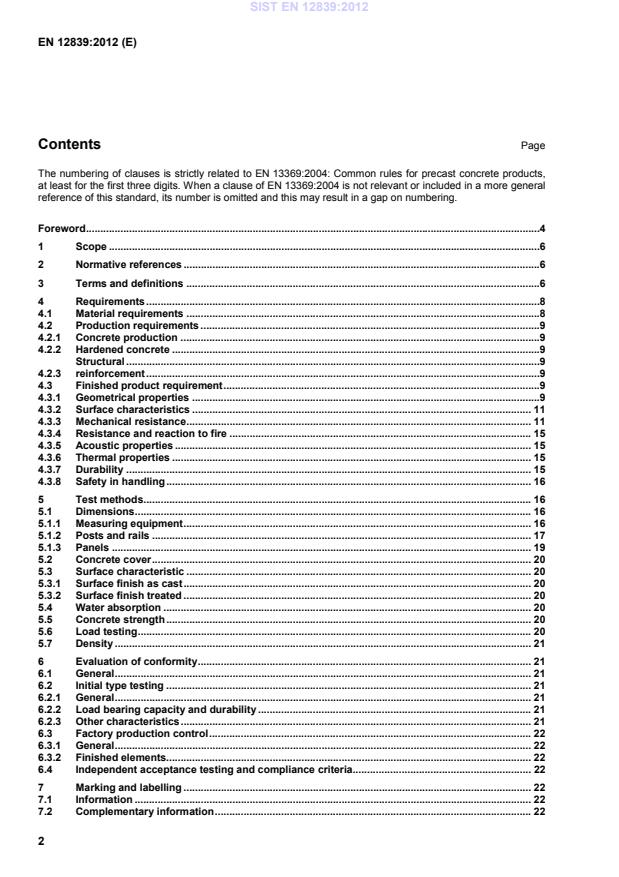

Page The numbering of clauses is strictly related to EN 13369:2004: Common rules for precast concrete products, at least for the first three digits. When a clause of EN 13369:2004 is not relevant or included in a more general reference of this standard, its number is omitted and this may result in a gap on numbering. Foreword .41Scope .62Normative references .63Terms and definitions .64Requirements .84.1Material requirements .84.2Production requirements .94.2.1Concrete production .94.2.2Hardened concrete .9Structural .94.2.3reinforcement .94.3Finished product requirement .94.3.1Geometrical properties .94.3.2Surface characteristics . 114.3.3Mechanical resistance . 114.3.4Resistance and reaction to fire . 154.3.5Acoustic properties . 154.3.6Thermal properties . 154.3.7Durability . 154.3.8Safety in handling . 165Test methods . 165.1Dimensions . 165.1.1Measuring equipment . 165.1.2Posts and rails . 175.1.3Panels . 195.2Concrete cover . 205.3Surface characteristic . 205.3.1Surface finish as cast . 205.3.2Surface finish treated . 205.4Water absorption . 205.5Concrete strength . 205.6Load testing . 205.7Density . 216Evaluation of conformity . 216.1General . 216.2Initial type testing . 216.2.1General . 216.2.2Load bearing capacity and durability . 216.2.3Other characteristics . 216.3Factory production control . 226.3.1General . 226.3.2Finished elements. 226.4Independent acceptance testing and compliance criteria. 227Marking and labelling . 227.1Information . 227.2Complementary information . 22SIST EN 12839:2012

Basic types of fences . 24A.1General . 24A.2Solid fence . 24A.3Open-work fence . 25A.4Mesh or wire fence . 25A.5Mixed fence . 26A.6Rail fence . 28A.7Anti-intruder fence . 29Annex B (normative)

Test method for the determination of the load bearing capacity and the complementary load bearing capacity . 32B.1Load testing . 32Annex C (normative)

Factory production control procedures . 38Annex D (informative)

Acceptance testing of a consignment at delivery . 39D.1General . 39D.2Sampling. 39D.3Places and dates of inspection and acceptance testing . 39D.4Compliance . 39Annex ZA (informative)

Relationship between this European Standard and the essential requirements of EU Directive 89/106/EEC, EU Construction Products Directive . 41ZA.1Scope and relevant characteristics . 41ZA.2Procedure for attestation of conformity of precast concrete elements for boundary fences . 42ZA.3CE marking and labelling. 44Bibliography . 52 SIST EN 12839:2012

Normal weight concrete or light weight concrete elements include posts, solid or open panels, slabs, rails, spurs, struts and base panels. The intended uses may be nonstructural or lightly structural. It provides for the evaluation of conformity of elements to this European Standard. Marking conditions are included. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 206-1:2000, Concrete Part 1: Specification, performance, production and conformity EN 1991-1-4:2005, Eurocode 1: Actions on structures Part 1-4: General actions Wind actions EN 12390-4:2000, Testing hardened concrete Part 4: Compressive strength Specification for testing machines EN 13369:2004, Common rules for precast concrete products 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 13369:2004 and the following apply. 3.1 types of fences NOTE Annex A intends to provide information on the possible types of fences in which these elements may be part of. 3.1.1 solid fence fence made of posts and solid panels or cladding 3.1.2 open-work fence fence made of posts and open-work panels possibly including solid panels 3.1.3 mesh or wire fence fence made of posts and woven or welded wire mesh, and/or wires SIST EN 12839:2012

1) This means that statistical interpretation of the tests results demonstrate that 95 % of the corresponding production are at least equal to the values defined above. SIST EN 12839:2012

4.3.1.2 Minimum dimensions For pre-stressing wires of diameter d expressed in mm the minimum concrete cover to the surface of any wire shall be 2,5 d or 10 mm whichever is the greater. The minimum spacing between wires shall be 4 d centre to centre.

4.3.2 Surface characteristics 4.3.2.1 Surface finish as cast The maximum total surface area of blowholes is declared by the manufacturer. NOTE Reference images to identify the severity of blow holes in concrete surfaces could be referred to the guidelines CEN/TR 15739. 4.3.2.2 Instant demoulded product The surface finish of instant demoulded product shall be defined and agreed between the producer and the purchaser. 4.3.2.3 Ends of the elements For pre-stressed elements the ends of the wires shall be flushed with the visible parts of the elements, then coated with a waterproofing product provided there is adequate data on its durability. Top ends of reinforced posts shall be shaped to allow water run-off. 4.3.2.4 Interlocking surfaces Interlocking surfaces shall have no flaw or burr which could hinder the assembly of the elements. For interlocking units in particular, tolerances shall be declared by the manufacturer and shall be such as to permit interlocking. 4.3.3 Mechanical resistance 4.3.3.1 General

For elements for fences either the mechanical resistance determined by calculation following 4.3.3.2 of EN 13369:2004 or the load bearing capacity determined by testing following Annex B of this standard shall be declared. 4.3.3.2 Complementary load bearing capacity 4.3.3.2.1 General For elements designed by testing, the complementary load bearing capacity is the ability of an element to resist a defined load under service conditions and a defined failure load. SIST EN 12839:2012

Vb,0a m/s 80 22 87 24 95 26 100 28 120 33 140 39 a According to § 4.2 of EN 1991-1-4:2005.

4.3.3.2.3 Mechanical resistance of posts Under the test conditions defined in Annex B, posts shall meet the following requirements: a) at the limit of working conditions: after release of the normal service load (Tables 3 to 7) the deflection shall not exceed 1 % of the element's above-ground length, and any cracks shall be closed; b) at the ultimate limit state: the failure load shall be at least equal to the value of the normal failure load (Tables 3 to 7) for the fractile 0,05 2).

2) This means that statistical interpretation of the tests results demonstrates that 95 % of the corresponding production are at least equal to the specification. SIST EN 12839:2012

Normal failure load N Above-ground height of the slabs m 1,00 1,50 2,00 2,50 Class of posta

A 1 400 1 400 1 800 2 200 B 1 400 1 800 2 500 3 100 C 1 400 2 300 3 200 4 000 a In relation with wind pressures (see EN 1991-1-4).

Table 4 - Intermediate posts for solid slabs fences (failure load)

Normal failure load N Above-ground height of the slabs m 1,00 1,50 2,00 2,50 Class of posta

A 2 300 2 300 3 200 4 000 B 2 300 3 200 4 500 5 600 C 2 600 4 100 5 700 7 200 a In relation with wind pressures (see EN 1991-1-4).

Table 5 — Intermediate posts for open-work fences and posts for mixed fences with a height of the solid part longer than 900 mm Above-ground height of panels m < 1,20 1,50 2,00 2,50 Normal service load N 1 400 1 400 1 800 2 200 Normal failure load N 2 300 2 300 3 200 4 000

Table 6 — Intermediate posts for mesh or wire fences and posts for mixed fences with a height of the solid part lower or equal to 900 mm Above-ground height of posts m < 1,20 1,50 2,00 2,50 Normal service load N 1 400 1 400 1 400 1 400 Normal failure load N 2 100 2 100 2 100 2 100

2,00 2,50 Normal service load N 4 000 3 200 Normal failure load N 5 900 4 800

4.3.3.2.4 Mechanical resistance of base or solid or open-work panels and rails Under the test conditions defined in Annex B, base, solid or open-work panels and rails shall meet the following requirements: a) the failure load shall be at least equal to the normal failure load for the fractile 0,05 3); b) moreover, no element shall have a failure load less than 0,8 times the normal failure load. Values of minimum failure loads are given in Tables 8 to 11. Table 8 — Solid panels Length of panels m 1,90 ≤ L ≤ 2,05 Height of panels m 0,25 < H ≤ 0,50 ≤ 0,25 Minimum failure load N class A 800 600 class B 1 000 750 NOTE It is recommended that panels of at least class B should be used on the sea front or in exposed areas. Local provisions valid in the place where the fence is to be erected should be considered.

Table 9 — Open-work panels Length of panels m 1,90 ≤ L ≤ 2,05 Height of panels m ≤ 0,90 0,90 < H ≤ 1,10 1,10 < H ≤ 1,25 Minimum failure load N 800 1 500 1 900

Table 10 — Base panels Centre to centre distance between posts m 2,00 2,50 Height of panels m ≤ 0,25 0,25 < H ≤ 0,50 ≤ 0,25 0,25 < H ≤ 0,50 Minimum failure load N 600 800 750 1 000

3) This means that statistical interpretation of the tests results demonstrates that 95 % of the corresponding production are at least equal to the specification. SIST EN 12839:2012

4.3.3.3 Transient situations 4.3.3.6 of EN 13369:2004 shall apply. 4.3.4 Resistance and reaction to fire Not relevant. 4.3.5 Acoustic properties Not relevant. 4.3.6 Thermal properties Not relevant. 4.3.7 Durability

4.3.7.1 Class 1 The durability of the load bearing capacity of elements for fences in normal serviceability conditions is ensured by the characteristic compressive strength of concrete, concrete cover and water absorption of concrete. Concrete cover relates to the main external faces of elements. Under the test conditions defined in 5.2 the actual concrete cover shall be at least: either 15 mm, reduced to 10 mm when the thickness of the element section is ≤ 10 cm with a steel wire diameter ≤ 10 mm or reduced to 7 mm when the compressive strength of concrete is at least C55/67 with a steel wire diameter ≤ 5 mm and water/(cement + k x addition) ratio is ≤ 0,40; or the maximum aggregate size; whichever is the greatest. Moreover: for pre-stressed elements 4.3.3.2 applies; for reinforced posts, the actual concrete cover of the surface remaining exposed to the bad weather after implementation of the products measured at top and base shall be at least 15 mm. SIST EN 12839:2012

4) This means that statistical interpretation of the tests results demonstrates that 95 % of the corresponding production are at least equal to the specification. SIST EN 12839:2012

a) Post

b) Rails Lt = 221LtLt+ S = 44321SSSS+++ Figure 1 — Measurement of length and section of post and rail SIST EN 12839:2012

Key 1 Aluminium straight edge 2 Post or rail 3 Maximum deviation recorded with an adjusting wedge (∆) 4 Plane surface 100or×=LTûpf

in % Figure 2 — Measurement of straightness of post and rail SIST EN 12839:2012

Key L Length e Thickness Sq Squareness H Height L = 221LL+ e = 44321eeee+++ H = 221hh+ Sq = 100)(22121×+−DDDD in % Figure 3 — Measurement of length, height, thickness and squareness of panels 5.1.3.2 Flatness The maximum deviation between the surface and the rule, which is measured by the sweep of the slip gauge, is the flatness deviation. SIST EN 12839:2012

Key 1 Final position 2 Gauge 3 Initial position 4 Direction of rotation Figure 4 — Measurement of flatness of panels 5.2 Concrete cover The concrete cover shall be measured on whole elements with a covermeter or on elements which have been tested to failure adjacent to the fracture. Where a covermeter is used, its calibration shall be checked before by using concrete samples containing steel reinforcement with known covers. 5.3 Surface characteristic 5.3.1 Surface finish as cast The surface finish shall be assessed against the reference photographs in (on the 1/1 scale). NOTE It could be useful to refer to CEN/TR 15739. 5.3.2 Surface finish treated NOTE Possible efflorescences due to lime or water migrations have no effect on the performances of the elements; they reduce progressively with time. 5.4 Water absorption The test method given in Annex G of EN 13369:2004 shall apply. 5.5 Concrete strength Test specimens for assessing concrete strength at transfer of pre-stress shall be cured in a manner similar to that of the elements concerned. 5.1.1 of EN 13369:2004 shall apply.

5.6 Load testing For elements verified by testing the test method given in Annex B shall apply. SIST EN 12839:2012

6.2.3 Other characteristics Table 13 — Number of elements to be tested in initial type tests Requirements Number of test pieces Dimensions (see 5.1) 3 elements Reinforcement and concrete cover (see 5.2) 3 elements Finish (see 5.3) 3 elements Durability class 1: Water absorption of concrete (see 5.4) 1 element (and 3 specimens cut in this element) Design by testing: Load bearing capacity for specific intended uses (see 4.3.3) 3 specimens SIST EN 12839:2012

Basic types of fences A.1 General There are six basic types of fences: solid fences; open-work fences; mesh or wire fences; mixed fences; rail fences; anti-intruder fences. Elements may be made of concrete or not. A.2 Solid fence Solid fences are made of posts and solid panels or cladding for the purpose of providing a screen with a height of at least 900 mm.

Key 1 Post 2 Solid pane Figure A.1 — Example of solid fence SIST EN 12839:2012

Key 1 Open work panel Figure A.2 — Example of open-work fence A.4 Mesh or wire fence Mesh or wire fences are made of posts and mesh or wires. The number of wires may vary. SIST EN 12839:2012

Key 1 Post and wire a) wire fence

Key 1 Posts and mesh and wire 2 Posts and mesh b) mesh or mesh and wire fences Figure A.3 — Examples of mesh or wire fences A.5 Mixed fence Mixed fences are made of posts, base panels and rails or wires or mesh. SIST EN 12839:2012

Key 1 Rails 2 Mesh 3 Post 4 Base panel a) with rails, post, base panel and wire or mesh

Key 1 Post 2 Base panel b) with posts, base panels and wires or mesh SIST EN 12839:2012

Key 1 Base enclosure walls 2 Mesh 3 Steel pipe c) with self-bearing base enclosure walls Figure A.4 — Examples of mixed fences A.6 Rail fence Rail fences are made of posts and rails, with or without infill. SIST EN 12839:2012

Key 1 Rail a) with one rail

b) with two rails Key 1 Rails Figure A.5 — Examples of rail fences A.7 Anti-intruder fence Anti-intruder fences are made of solid slab fences, mixed fences or mesh fences. SIST EN 12839:2012

a) with posts, wire and mesh

b) with posts, base panels, wire and mesh SIST EN 12839:2012

c) with posts, solid panels and wire Figure A.6 — Examples of anti-intruder fences SIST EN 12839:2012

Test method for the determination of the load bearing capacity and the complementary load bearing capacity

B.1 Load testing B.1.1 Test method for load bearing capacity B.1.1.1 Apparatus B.1.1.1.1 A testing machine complying with EN 12390-4:2000, Class 3. B.1.1.2 Test piece A test piece shall consist of one complete element. B.1.1.3 Testing of posts B.1.1.3.1 Principle Each element is tested in horizontal position. The test load is applied at the midpoint of the above-ground length and in the direction of wind loading, as shown in Figure B.1. The weight of the post shall be taken into consideration. B.1.1.3.2 Procedure Each element shall undergo the following operations: measure the appropriate distance 2hseLL= for the application of loads; clamp the post horizontally at its lower end so that the free length of the posts equals its above-ground length Lhs when in service; apply the load at the distance Le ± 20 mm from the clamped end; increase the load at a rate of 100 N/s ± 20 N/s; record the failure load R. SIST EN 12839:2012

a) Positioning of the load application Dimensions in millimetres

b) Support parts Key 1 Raising Figure B.1 — Testing of post SIST EN 12839:2012

Key 1 Packing piece (wood) 2 Load Figure B.2 — Testing of panels NOTE For the base panel with a coping, the load is applied by interposing a hard piece of wood having a thickness equal to the one of the coping (tests for factory production control can be carried out on solid panel). B.1.1.5 Testing of rails Lay the element horizontally over two supports which are separated by a distance d which is the total length Lt o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...