ISO 16904:2016

(Main)Petroleum and natural gas industries — Design and testing of LNG marine transfer arms for conventional onshore terminals

Petroleum and natural gas industries — Design and testing of LNG marine transfer arms for conventional onshore terminals

ISO 16904:2016 specifies the design, minimum safety requirements and inspection and testing procedures for liquefied natural gas (LNG) marine transfer arms intended for use on conventional onshore LNG terminals, handling LNG carriers engaged in international trade. It can provide guidance for offshore and coastal operations. It also covers the minimum requirements for safe LNG transfer between ship and shore. Although the requirements for power/control systems are covered, this International Standard does not include all the details for the design and fabrication of standard parts and fittings associated with transfer arms. ISO 16904:2016 is supplementary to local or national standards and regulations and is additional to the requirements of ISO 28460. ISO 16904:2016 needs not be applied to existing facilities.

Industries du pétrole et du gaz naturel — Conception et essais des bras de transfert de GNL sur des terminaux terrestres conventionnels

L'ISO 16904:2016 spécifie les règles de conception, les spécifications minimales de sécurité ainsi que les procédures de contrôle et d'essais relatifs aux bras de transfert de gaz naturel liquéfié (GNL) marins destinés à être utilisés sur des terminaux terrestres conventionnels, recevant des méthaniers engagés dans le commerce international. Elle peut fournir des lignes directrices pour des opérations côtières et au large. Elle fixe également les spécifications minimales permettant de garantir que le transfert de GNL entre le navire et le terminal s'effectue en toute sécurité. Bien que les spécifications relatives aux systèmes d'alimentation/télécommande soient couvertes, l'ISO 16904:2016 ne fixe pas tous les détails relatifs à la conception et à la fabrication des pièces normalisées et des raccords des bras de transfert. L'ISO 16904:2016 vient compléter les normes et règlements locaux ou nationaux, et s'ajoute aux spécifications de l'ISO 28460. Il n'est pas nécessaire d'appliquer l'ISO 16904:2016 aux installations existantes.

General Information

- Status

- Published

- Publication Date

- 11-Feb-2016

- Technical Committee

- ISO/TC 67/SC 9 - Liquefied natural gas installations and equipment

- Drafting Committee

- ISO/TC 67/SC 9 - Liquefied natural gas installations and equipment

- Parallel Committee

- ISO/TC 60/SC 2 - Gear capacity calculation

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 07-Jun-2021

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 12-Feb-2026

Overview

ISO 16904:2016 - Petroleum and natural gas industries - Design and testing of LNG marine transfer arms for conventional onshore terminals - defines the design, minimum safety requirements, inspection and testing procedures for LNG marine transfer arms used at conventional onshore LNG terminals handling carriers in international trade. It also provides guidance for coastal and offshore operations and sets minimum requirements for safe LNG transfer between ship and shore. The standard is supplementary to local or national regulations and to ISO 28460, and does not have to be applied retroactively to existing facilities.

Key topics

ISO 16904:2016 covers technical and procedural subjects including:

- Design of transfer arms: length, configuration, counterweights, pipework, welding, corrosion/embrittlement protection and maintenance.

- Mechanical components: swivel joints (apex/bottom), structural bearings and brinelling considerations.

- Safety systems: two-stage alarm and shutdown (ESD), monitoring and alarm systems, emergency release system (ERS) and other safety devices.

- Ship connection: design and operation of QCDC (quick connection/disconnection) systems, presentation flange and flange covers.

- Hydraulic & electrical controls: arm operation, hydraulic/electric components, remote control, jetty control consoles and control-system testing.

- Inspection and testing: prototype tests, manufacturing inspection, factory acceptance tests (FAT) and site acceptance tests (SAT).

- Quality assurance: quality system requirements, quality plans and required documentation.

- Supporting material: design data sheets, reference figures and documentation checklists (informative annexes).

Applications

ISO 16904:2016 is practical for:

- Terminal designers and engineering firms specifying LNG marine transfer arms.

- OEMs/manufacturers developing transfer arms, swivel joints and QCDC hardware.

- Project managers and procurement teams for FAT/SAT criteria and supplier evaluation.

- Port operators, safety and operations teams for risk assessments, emergency planning and procedures.

- Inspection bodies and regulators performing compliance, testing and certification.

Use cases:

- Preparing design briefs and technical specifications for new onshore LNG jetties.

- Developing safety and testing programs (prototype, factory and site acceptance tests).

- Establishing maintenance and inspection schedules aligned with minimum safety requirements.

Related standards

ISO 16904 is supplementary to and referenced alongside:

- ISO 28460 (ship-to-shore interface and port operations)

- IEC 60079 series (explosive atmospheres)

- IEC 61508 (functional safety)

- ASME B16.5 (flanges) and ASME welding codes

- ISO 9001/9000 (quality management) These referenced documents address detailed electrical, explosive-atmosphere and pressure equipment requirements not exhaustively covered in ISO 16904.

Keywords: ISO 16904:2016, LNG marine transfer arms, design and testing, onshore LNG terminal, ERS, QCDC, emergency shut down, prototype test, FAT, SAT.

Buy Documents

ISO 16904:2016 - Petroleum and natural gas industries -- Design and testing of LNG marine transfer arms for conventional onshore terminals

ISO 16904:2016 - Industries du pétrole et du gaz naturel -- Conception et essais des bras de transfert de GNL sur des terminaux terrestres conventionnels

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 16904:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Design and testing of LNG marine transfer arms for conventional onshore terminals". This standard covers: ISO 16904:2016 specifies the design, minimum safety requirements and inspection and testing procedures for liquefied natural gas (LNG) marine transfer arms intended for use on conventional onshore LNG terminals, handling LNG carriers engaged in international trade. It can provide guidance for offshore and coastal operations. It also covers the minimum requirements for safe LNG transfer between ship and shore. Although the requirements for power/control systems are covered, this International Standard does not include all the details for the design and fabrication of standard parts and fittings associated with transfer arms. ISO 16904:2016 is supplementary to local or national standards and regulations and is additional to the requirements of ISO 28460. ISO 16904:2016 needs not be applied to existing facilities.

ISO 16904:2016 specifies the design, minimum safety requirements and inspection and testing procedures for liquefied natural gas (LNG) marine transfer arms intended for use on conventional onshore LNG terminals, handling LNG carriers engaged in international trade. It can provide guidance for offshore and coastal operations. It also covers the minimum requirements for safe LNG transfer between ship and shore. Although the requirements for power/control systems are covered, this International Standard does not include all the details for the design and fabrication of standard parts and fittings associated with transfer arms. ISO 16904:2016 is supplementary to local or national standards and regulations and is additional to the requirements of ISO 28460. ISO 16904:2016 needs not be applied to existing facilities.

ISO 16904:2016 is classified under the following ICS (International Classification for Standards) categories: 75.180.01 - Equipment for petroleum and natural gas industries in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16904:2016 has the following relationships with other standards: It is inter standard links to EN ISO 20519:2017, EN ISO 20519:2022, EN ISO 20257-1:2020, EN ISO 16904:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 16904:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16904

First edition

2016-02-15

Petroleum and natural gas

industries — Design and testing

of LNG marine transfer arms for

conventional onshore terminals

Industries du pétrole et du gaz naturel — Conception et essais des

bras de transfert de GNL sur des terminaux terrestres conventionnels

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Abbreviated terms . 9

5 Design of the arms .10

5.1 Definition of the length and the configuration of the arms, arms description .10

5.1.1 General.10

5.1.2 Balancing .10

5.1.3 Arms dimensions and clearances .11

5.2 Design basis .11

5.2.1 Product line diameter and product data .11

5.2.2 Material and grades .11

5.2.3 Stress analysis .12

5.3 Swivel joints .15

5.3.1 General.15

5.3.2 Product sealing arrangement .16

5.3.3 Bearing system .16

5.3.4 External sealing arrangement .16

5.3.5 Design .16

5.4 Structural bearings .17

5.4.1 Design .17

5.4.2 Protection of structural bearings.18

5.4.3 Grease sampling point .18

5.5 Accessories .18

5.5.1 Adjustable support (jack) .18

5.5.2 Nitrogen injection line .18

5.5.3 Stowing locking device .18

5.5.4 Ladders and platforms . .19

5.5.5 Vapour recovery lines .19

5.5.6 Liquid nitrogen line .19

5.5.7 Thermal insulation .19

5.5.8 Ice fall protection .19

5.6 Pipework and fitting .19

5.6.1 Process connections . .19

5.6.2 Drain connection.19

5.6.3 Plugged connection .20

5.6.4 Valve .20

5.6.5 Connection flange.20

5.6.6 Gasket .20

5.7 Welding .20

5.8 Corrosion protection and embrittlement protection .20

5.8.1 Corrosion protection .20

5.8.2 Embrittlement protection .20

5.9 Maintenance .21

6 Safety systems .21

6.1 General .21

6.2 Two stage alarm and shutdown system .22

6.2.1 First stage .22

6.2.2 Second stage .22

6.3 Monitoring and alarm systems .22

6.3.1 Alarm envelopes .22

6.3.2 Arm positioning alarms system .22

6.3.3 Arm constant position monitoring system (CPMS) .23

6.3.4 Pressure and hydraulic level alarm .23

6.4 ERS .23

6.4.1 General.23

6.4.2 Design of ERS .23

6.4.3 Safety devices on ERS .24

6.5 Safety devices .24

6.5.1 Fire safety requirements .24

6.5.2 Electrical safety requirements .25

6.5.3 Failure of electrical power supply.25

6.5.4 Stray current protectors .26

6.5.5 Bonding .26

7 Connection with the ship .26

7.1 General .26

7.2 Design of QCDC .26

7.3 QCDC system .27

7.4 Flange cover.27

8 Hydraulic and electric control systems .28

8.1 General .28

8.2 Arms operations .28

8.3 Hydraulic components .29

8.4 Electric components .30

8.5 Testing of control systems .30

8.6 Remote control .30

8.7 Transfer arms jetty control console .30

9 Inspection and tests .31

9.1 General .31

9.2 Prototype test .31

9.2.1 General.31

9.2.2 Swivel joint .31

9.2.3 ERS .34

9.2.4 QCDC .35

9.3 Manufacturing inspection and tests .37

9.3.1 General.37

9.3.2 Materials .37

9.3.3 Welding .37

9.3.4 Non-destructive test .37

9.3.5 Dimensional inspection .37

9.3.6 Pressure test .37

9.3.7 ERS .38

9.3.8 QCDC .38

9.3.9 Insulating flange (stray current protector) .39

9.3.10 Hydraulic circuit test .39

9.4 Factory acceptance tests .39

9.5 Site acceptance tests .40

9.5.1 General.40

9.5.2 Transfer arm assembly .41

9.5.3 Hydraulic circuit .42

10 Quality assurance and control.42

10.1 Quality system .42

10.2 Quality plan .42

11 Required documentation .43

Annex A (informative) Design data sheets .44

Annex B (informative) Reference table and figures .58

iv © ISO 2016 – All rights reserved

Annex C (informative) Documentation requirements.62

Bibliography .67

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 16904:2016(E)

Petroleum and natural gas industries — Design and

testing of LNG marine transfer arms for conventional

onshore terminals

1 Scope

This International Standard specifies the design, minimum safety requirements and inspection

and testing procedures for liquefied natural gas (LNG) marine transfer arms intended for use on

conventional onshore LNG terminals, handling LNG carriers engaged in international trade. It can

provide guidance for offshore and coastal operations. It also covers the minimum requirements for safe

LNG transfer between ship and shore.

Although the requirements for power/control systems are covered, this International Standard does

not include all the details for the design and fabrication of standard parts and fittings associated with

transfer arms.

This International Standard is supplementary to local or national standards and regulations and is

additional to the requirements of ISO 28460.

This International Standard needs not be applied to existing facilities.

2 Normative references

The following referenced documents, in whole or in part, are normatively referenced in this document

and are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3452-1, Non-destructive testing — Penetrant testing — Part 1: General principles

ISO 4406, Hydraulic fluid power — Fluids — Method for coding the level of contamination by solid particles

ISO 9934-1, Non-destructive testing — Magnetic particle testing — Part1: General principles

ISO 10474:2013, Steel and steel products — Inspection documents

ISO 10497, Testing of valves — Fire type-testing requirements

ISO 17636-1, Non-destructive testing of welds — Radiographic testing — Part 1: X- and gamma-ray

techniques with film

ISO 17636-2, Non-destructive testing of welds — Radiographic testing — Part 2: X- and gamma-ray

techniques with digital detectors

ISO 28460:2010, Petroleum and natural gas industries — Installation and equipment for liquefied natural

gas — Ship-to-shore interface and port operations

IEC 60034-5, Rotating electrical machines — Part 5: Degrees of protection provided by the integral design

of rotating electrical machines (IP code) — Classification

IEC 60079-0, Explosive atmospheres — Part 0: Equipment — General requirements

IEC 60079-1, Explosive atmospheres — Part 1: Equipment protection by flameproof enclosures “d”

IEC 60079-2, Explosive atmospheres — Part 2: Equipment protection by pressurized enclosures “p”

IEC 60079-5, Explosive atmospheres — Part 5: Equipment protection by powder filling “q”

IEC 60079-6, Explosive atmospheres — Part 6: Equipment protection by oil immersion “o”

IEC 60079-7, Explosive atmospheres — Part 7: Equipment protection by increased safety “e”

IEC 60079-10-1, Explosive atmospheres — Part 10-1: Classification of areas — Explosive gas atmospheres

IEC 60079-11, Explosive atmospheres — Part 11: Equipment protection by intrinsic safety “i”

IEC 60079-14, Explosive atmospheres — Part 14: Electrical installations design, selection and erection

IEC 60079-18, Explosive atmospheres — Part 18: Equipment protection by encapsulation “m”

IEC 60079-25, Explosive atmospheres — Part 25: Intrinsically safe electrical systems

IEC 60529, Degrees of protection provided by enclosures (IP Code) and IEC 60529/A1&A2, Amendment 1&2

IEC 61508 (all parts), Functional safety of electrical/electronic/programmable electronic safety-

related systems

IEC 62305-3, Protection against lightning — Part 3: Physical damage to structures and life hazard

ASME B16.5, Pipe Flanges and Flanged Fittings

ASMEBoiler and Pressure Vessel Code Section IX: Welding and Brazing Qualifications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

apex swivel

articulated, fluid-carrying joint located between the inboard arm (3.20) and outboard arm (3.32)

Note 1 to entry: See Figure B.2.

Note 2 to entry: It provides luffing (3.26) of the outboard arm relative to the inboard arm.

3.2

attitude

various modes of use and/or location of the transfer arm (3.59) (i.e. manoeuvring, stowed, connected,

hydrostatic test, and maintenance)

Note 1 to entry: The transfer arm can take several positions for each attitude.

3.3

base riser

riser

vertical assembly which bolts to the loading platform and supports the articulated assembly of the

transfer arm (3.59)

Note 1 to entry: See Figure B.2.

Note 2 to entry: Sometimes referred to as “standpost”.

3.4

bottom swivel

accommodates pitching (3.35) motion of LNG carrier (3.25) and is located adjacent to presentation flange

(3.37) in horizontal part of TSA (3.60)

Note 1 to entry: See Figure B.2.

2 © ISO 2016 – All rights reserved

3.5

brinelling

any permanent indentation in swivel (3.55) or structural bearing (3.50) raceways caused by excessive

loading of balls or rollers

3.6

cargo manifold

pipe assembly mounted onboard LNG carrier (3.25) to which the presentation flange (3.37) or QCDC

(3.39) of the transfer arm (3.59) is connected

Note 1 to entry: See Figure B.2.

3.7

cavitation

formation and collapse of bubbles in a liquid when the pressure falls to or below the liquid vapour

pressure; the collapse releases energy, sometimes with an audible sound and vibration

Note 1 to entry: Such low pressures occur in high velocity zones such as the inner radius of elbows, or at places

with variations of diameters.

3.8

clash

any contact during design operational conditions, or as a result of an emergency separation, between

any part of a transfer arm (3.59) and:

— adjacent transfer arm while both arms are operating or one arm is operating and the other arm is

stowed [e.g. the counterweights (3.11)];

— adjacent section of the same transfer arm [e.g. triple swivel assembly (3.60) and outboard arm (3.32)];

— loading platform equipment [e.g. counterweight (3.11) and piping or valves]

3.9

contact angle

α

angle between the plane of the swivel joint (3.55) or structural bearing (3.50) balls or rollers and the

centre of contact at the ball or roller raceway interface

3.10

conventional onshore LNG terminal

LNG exporting or receiving terminal that is located on-shore and that has a marine transfer arms for

the loading or unloading of LNG carriers (3.25) in a harbour or other sheltered coastal location

3.11

counterweight

system of weights used to balance the inboard arm (3.20) and outboard arm (3.32) assemblies

Note 1 to entry: Some transfer arms (3.59) have a single counterweight for this function and others have multiple

counterweights.

3.12

design pressure

pressure for which the transfer arm (3.59) is designed

Note 1 to entry: See Table A.1.

3.13

design temperature

range of temperatures for which the transfer arm (3.59) is designed

Note 1 to entry: See Table A.1.

3.14

drift

longitudinal and/or lateral displacement of the LNG carrier (3.25) under the influence of

environmental forces

Note 1 to entry: See also surge fore (3.52) or aft (3.51) and sway (3.54).

3.15

emergency release system

ERS

system that provides a positive means of quick release of transfer arms (3.59) and safe isolation

between the LNG carrier (3.25) and shore, following a predefined procedure including an emergency

shutdown (ESD) (3.16)

Note 1 to entry: See Figure B.2.

3.16

emergency shutdown

ESD

method that safely and effectively stops the transfer of LNG and vapour between the LNG carrier

(3.25) and shore

3.17

freeboard

vertical distance between the ship’s deck and the water level at the manifold location

Note 1 to entry: See Table A.3 and Figure A.1.

3.18

free wheel

ability of a hydraulically operated transfer arm (3.59) when connected to a LNG carrier (3.25) to follow

freely without hydraulic restraint the vertical and horizontal motions of the LNG carrier’s manifold

(draft changes and sway (3.54) and surge motions)

3.19

heave

vertical motion of the LNG carrier (3.25) due to wave action

Note 1 to entry: See Table A.4 and Figure A.2.

3.20

inboard arm

product-carrying pipe and any structural members contained between the apex swivel (3.1) and the

trunnion swivel (3.61)

Note 1 to entry: See Figure B.2.

3.21

included angle

angle formed between inboard arm (3.20) and outboard arm (3.32)

Note 1 to entry: See Figure B.2.

Note 2 to entry: The maximum and minimum included angles are left to the transfer arm manufacturer.

Note 3 to entry: The included angle in the stowed position of the transfer arms (3.59) is such, that the arms are

parked with the triple swivel assembly (3.60) behind the berthing line.

4 © ISO 2016 – All rights reserved

3.22

insulating flange

electrical insulating system, usually dedicated, which is installed in the lower end of the outboard arm

(3.32) or in the vertical part of the triple swivel assembly (3.60)

Note 1 to entry: Its purpose is to prevent stray currents from causing an arc at the LNG carrier’s (3.25) flange as

the transfer arm (3.59) is connected or disconnected.

3.23

jack

permanent, adjustable load-carrying mechanism potentially installed in the triple swivel assembly (3.60)

to transfer a portion of the arm (3.59) fluid weight to the deck instead of the LNG carrier’s (3.25) manifold

Note 1 to entry: See Figure B.2.

3.24

jetty control centre

control centre situated on or adjacent to the jetty primarily to control and/or monitor the transfer arms

(3.59)

Note 1 to entry: Sometimes referred to as “jetty control room” or “local control room”.

3.25

LNG carrier

LNGC

tank ship designed for the carriage of LNG

3.26

luffing

rotary motions of the inboard arm (3.20) and outboard arm (3.32) in the vertical plane

Note 1 to entry: See Figure B.2.

3.27

main hydraulic unit

MHU

hydraulic unit that generates hydraulic power to ensure the normal operation and emergency release

sequence of the arms

3.28

manifold setback

horizontal distance between the board side of LNG carrier (3.25) and the face of cargo manifold (3.6)

Note 1 to entry: See Table A.3 and Figure A.1.

3.29

manifold spacing

horizontal distance between two adjacent cargo manifold (3.6) flange axes

Note 1 to entry: See Table A.3 and Figure A.1.

3.30

middle swivel

accommodates yawing (3.63) and surge of LNG carrier (3.25) and is located between top swivel (3.57)

and bottom swivel (3.4) in vertical part of TSA (3.60)

Note 1 to entry: See Figure B.2.

3.31

operating envelope

volume in which presentation flange(s) (3.37) of a (group of) transfer arm(s) (3.59) is (are) required to

operate

3.32

outboard arm

product-carrying pipe and any structural members contained between the apex swivel (3.1) and the

triple swivel assembly (3.60)

Note 1 to entry: See Figure B.2.

3.33

owner

designated agent

company or group of companies for whose use the transfer arms (3.59) are installed, responsible for the

safe design and construction of the installation

3.34

pantograph system

system for transmitting balancing loads from the outboard arm (3.32) to the counterweight(s) (3.11)

Note 1 to entry: The system comprises an assembly of linkages and pinned connections, or a cable and sheaves

system (respectively, “rigid link pantograph” and “cables and sheaves pantograph”).

3.35

pitch

rotation of the LNG carrier (3.25) around transversal horizontal axis

Note 1 to entry: See Table A.4 and Figure A.2.

3.36

powered emergency release coupling

PERC

powered device to provide a means of quick release of the transfer arms (3.59) when such action is

required only as an emergency measure

3.37

presentation flange

transfer arm (3.59) flange for connection to either the cargo manifold (3.6) or spool piece (3.47)

Note 1 to entry: See Figure B.2.

3.38

product

fluid transferred using transfer arms (3.59)

Note 1 to entry: Fluids are LNG, NG or LN .

3.39

quick connect disconnect coupler

QCDC

coupler

manual or hydraulic mechanical device used to connect the transfer arm (3.59) to the cargo manifold

(3.6) without employing bolts

Note 1 to entry: See Figure B.2.

3.40

remote pendant control

remote control

device to facilitate the fine manoeuvring operation of the transfer arms (3.59) from a remote location

(e.g. LNG carrier’s (3.25) cargo manifold (3.6) area)

Note 1 to entry: The system can use a trailing wire or radio-controlled system.

6 © ISO 2016 – All rights reserved

3.41

riser and trunnion swivel assembly

fluid carrying system consists of riser swivel (3.43), trunnion swivel (3.61) and elbows and mounted on

top of the base riser (3.3)

Note 1 to entry: See Figure B.2.

3.42

riser flange

transfer arm (3.59) flange for connection to LNG piping

Note 1 to entry: See Figure B.2.

3.43

riser swivel

swing joint in the riser and trunnion swivel assembly (3.41) which permits slewing (3.46) of the

transfer arm (3.59)

Note 1 to entry: See Figure B.2.

3.44

roll

rotation of LNG carrier (3.25) around longitudinal horizontal axis

Note 1 to entry: See Table A.4 and Figure A.2.

3.45

safety integrity level

SIL

statistical representations of the integrity of the safety instrumented system when a process

demand occurs

Note 1 to entry: See Clause 6.

3.46

slew

horizontal, rotary motion of the transfer arm (3.59) around the base riser (3.3)

Note 1 to entry: See Figure B.2.

3.47

spool piece

short length of pipe for the purpose of matching the cargo manifold (3.6) to the presentation flange

(3.37) or QCDC (3.39)

Note 1 to entry: Sometimes referred to as “adaptor” or “short distance piece”.

3.48

spotting line

pre-determined location on the jetty used by the LNG carrier (3.25) when berthing to align with the

LNG carrier vapour manifold

Note 1 to entry: See Figure A.4.

3.49

stress analysis

detailed calculation of the structural loading in the transfer arm (3.59) and cargo manifold (3.6) for

various positions and attitudes to check the integrity of the transfer arm for the service intended

3.50

structural bearing

bearing in the load carrying components supporting the product line that, in combination, allow the

transfer arm (3.59) to follow freely the motion of the LNG carrier (3.25)

3.51

surge aft

longitudinal LNG carrier (3.25) afterward motion

Note 1 to entry: See Table A.4 and Figure A.2.

3.52

surge fore

longitudinal LNG carrier (3.25) forward motion

Note 1 to entry: See Table A.4 and Figure A.2.

3.53

surge pressure

rapid change in pressure as a consequence of a change in flow rate in a pipeline and/or piping systems

(including transfer arms (3.59))

3.54

sway

transverse LNG carrier (3.25) motion

Note 1 to entry: See Table A.4 and Figure A.2.

3.55

swivel joint

swivel

swing joint contained in the transfer arm (3.59) to permit the arm to follow freely the motion of the LNG

carrier (3.25)

3.56

terminal

LNG producing/receiving plant with loading/unloading facilities

3.57

top swivel

accommodates rolling (3.44), heave and sway motion of LNG carrier (3.25) and is located between

outboard arm (3.32) and middle swivel (3.30) in horizontal part of TSA (3.60)

Note 1 to entry: See Figure B.2.

3.58

transfer

loading or unloading operation

3.59

transfer arm

arm

articulated metal transfer system used for transferring product (3.38) to or from LNG carrier (3.25)

with the capability of accommodating differences in tides, freeboard (3.17) and LNG carrier’s motions

Note 1 to entry: See Figure B.2.

Note 2 to entry: It can be referred to as a “loading arm” or “unloading arm”.

8 © ISO 2016 – All rights reserved

3.60

triple swivel assembly

TSA

group of three swivels (3.55) and elbows located at the end of the outboard arm (3.32)

Note 1 to entry: See Figure B.2.

3.61

trunnion swivel

swing joint in the riser and trunnion swivel assembly (3.41) which permits the inboard arm (3.20) to

rotate around the horizontal axis

Note 1 to entry: See Figure B.2.

3.62

uninterrupted power supply

UPS

back-up of the electrical supply system providing power to critical control and safety systems so that

the plant can be kept in safe conditions

3.63

yaw

rotation of the LNG carrier (3.25) around vertical axis

Note 1 to entry: See Table A.4 and Figure A.2.

4 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

CPMS constant position monitoring system

ERS emergency release system

ESD emergency shutdown

FL fluid load

LNG liquefied natural gas

LNGC liquefied natural gas carrier

LN liquefied nitrogen gas

MHU main hydraulic unit

NDE non destruction examination

NG natural gas

N nitrogen gas

OBE operating basis earthquake

PERC powered emergency release coupling

PL pressure load

PQR performance quality records

QCDC quick connect disconnect coupler

SIL safety integrity level

SSE safe shutdown earthquake

TL thermal load

TSA triple swivel assembly

UPS uninterrupted power supply

WL wind load

WPS welding procedure specifications

5 Design of the arms

5.1 Definition of the length and the configuration of the arms, arms description

5.1.1 General

The transfer arm general arrangement is given in Figure B.2.

The length and the configuration of the transfer arms shall allow for the connection of the on-shore piping

to the ship’s cargo manifold. The connection shall allow for free movement within the operating envelope.

The transfer arms are normally composed of the following (see definitions in Clause 3):

— triple swivel assembly (TSA) including emergency release system (ERS) and quick connect

disconnect coupler (QCDC), if specified;

— outboard arm;

— apex swivel assembly between the outboard and inboard arm;

— pantograph system;

— inboard arm;

— riser and trunnion swivel assembly between the inboard arm and the base riser;

— base riser.

The product piping subject to low temperature shall be free to expand or contract within the structure.

The structure itself shall not be subjected to low temperature.

All piping supports shall be adequately designed so that stresses in the piping and the structure are

within allowable limits for all attitudes and positions.

Any parts of transfer arm, e.g. seals, bolts and nuts, shall not come off or unfasten and drop into product

piping due to product flow, vibration, negative pressure and cryogenic condition.

5.1.2 Balancing

The complete TSA and outboard arm shall be balanced in the empty condition without ice. It shall be

balanced with pantograph system about the apex swivel.

The complete, articulated assembly shall be balanced in empty condition without ice. It shall be

balanced about the trunnion swivel.

10 © ISO 2016 – All rights reserved

The design of the transfer arms shall consider, in addition to the normal operation, the emergency

release of the arms in both the empty and full condition. There should be no clash of the arms with the

ship or the jetty.

5.1.3 Arms dimensions and clearances

5.1.3.1 Arms dimensions

Transfer arm dimensions, based on the design data in Tables A.1 to A.15 and Figures A.1 to A.4 attached,

shall be determined by the transfer arm manufacturer to ensure that the transfer arm satisfies all

specified requirements.

5.1.3.2 Clearance study

The design shall cater for the following minimum clearances unless otherwise specified in Table A.6:

— 0,15 m minimum clearance between any part of an operating arm and a stowed arm;

— 0,3 m minimum clearance between any part of an operating arm and any adjacent structures,

piping, equipment;

— 0,3 m minimum clearance between any part of adjacent operating arms;

— 0,15 m minimum clearance between counterweights of operating arms.

Table B.1 shows the location of main clearance checkpoints.

Transfer arm manufacturer’s clearance study shall include all cases including emergency release

positions and retracting attitude following emergency release.

The study shall identify all check points, based on a drawing of the jetty layout in elevation and plan.

Consideration should be given for any future expansion.

In the stowed position, no part of the transfer arm shall extend beyond the jetty face or berthing line

with compressed fenders plus the additional safety margin c

...

NORME ISO

INTERNATIONALE 16904

Première édition

2016-02-15

Industries du pétrole et du gaz

naturel — Conception et essais des

bras de transfert de GNL sur des

terminaux terrestres conventionnels

Petroleum and natural gas industries — Design and testing of LNG

marine transfer arms for conventional onshore terminals

Numéro de référence

©

ISO 2016

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2016, Publié en Suisse

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni utilisée

sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur

l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à

l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – Tous droits réservés

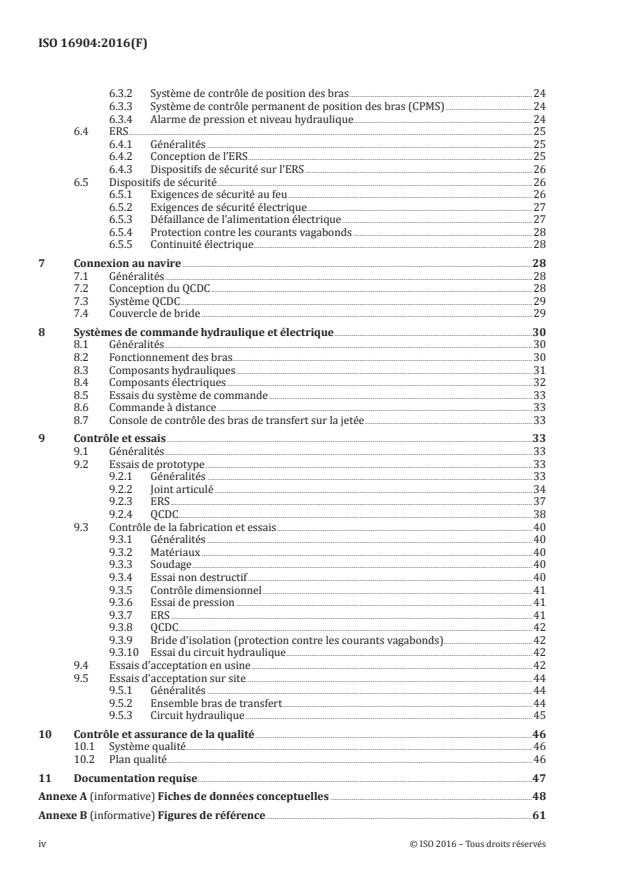

Sommaire Page

Avant-propos .vi

1 Domaine d’application . 1

2 Références normatives . 1

3 Termes et définitions . 2

4 Abréviations . 9

5 Conception des bras .10

5.1 Définition de la longueur et de la configuration des bras, description des bras .10

5.1.1 Généralités .10

5.1.2 Équilibrage .11

5.1.3 Dimensions et dégagements des bras .11

5.2 Principes de conception .12

5.2.1 Diamètre de la tuyauterie produit et caractéristiques du produit .12

5.2.2 Matériaux et nuances .12

5.2.3 Analyse des contraintes .12

5.3 Joints articulés .16

5.3.1 Généralités .16

5.3.2 Dispositif d’étanchéité du produit .16

5.3.3 Système de roulement .17

5.3.4 Dispositif d’étanchéité externe .17

5.3.5 Conception .17

5.4 Articulations de structure .18

5.4.1 Conception .18

5.4.2 Protection des articulations de structure .19

5.4.3 Prise d’échantillons de graisse.19

5.5 Accessoires .19

5.5.1 Support ajustable (vérin) .19

5.5.2 Tuyauterie d’injection d’azote .20

5.5.3 Dispositif de verrouillage en position de stockage .20

5.5.4 Échelles et plates-formes .20

5.5.5 Tuyauteries de récupération de vapeur .20

5.5.6 Tuyauterie d’azote liquide .20

5.5.7 Isolation thermique .21

5.5.8 Protection contre les chutes de glace .21

5.6 Canalisations et robinetterie .21

5.6.1 Raccordements .21

5.6.2 Raccord de vidange . .21

5.6.3 Prise de connexion .21

5.6.4 Vanne .21

5.6.5 Bride de connexion .21

5.6.6 Joint d’étanchéité .21

5.7 Soudage .21

5.8 Protection contre la corrosion et contre la fragilisation .22

5.8.1 Protection contre la corrosion .22

5.8.2 Protection contre la fragilisation .22

5.9 Maintenance .22

6 Systèmes de sécurité .23

6.1 Généralités .23

6.2 Système d’arrêt et d’alarme à deux niveaux .23

6.2.1 Premier niveau .23

6.2.2 Second niveau .24

6.3 Systèmes de contrôle et d’alarme .24

6.3.1 Enveloppes des alarmes .24

6.3.2 Système de contrôle de position des bras .24

6.3.3 Système de contrôle permanent de position des bras (CPMS) .24

6.3.4 Alarme de pression et niveau hydraulique.24

6.4 ERS .25

6.4.1 Généralités .25

6.4.2 Conception de l’ERS . .25

6.4.3 Dispositifs de sécurité sur l’ERS .26

6.5 Dispositifs de sécurité .26

6.5.1 Exigences de sécurité au feu .26

6.5.2 Exigences de sécurité électrique .27

6.5.3 Défaillance de l’alimentation électrique .27

6.5.4 Protection contre les courants vagabonds .28

6.5.5 Continuité électrique . . .28

7 Connexion au navire .28

7.1 Généralités .28

7.2 Conception du QCDC .28

7.3 Système QCDC .29

7.4 Couvercle de bride .29

8 Systèmes de commande hydraulique et électrique .30

8.1 Généralités .30

8.2 Fonctionnement des bras.30

8.3 Composants hydrauliques .31

8.4 Composants électriques .32

8.5 Essais du système de commande .33

8.6 Commande à distance .33

8.7 Console de contrôle des bras de transfert sur la jetée .33

9 Contrôle et essais .33

9.1 Généralités .33

9.2 Essais de prototype .33

9.2.1 Généralités .33

9.2.2 Joint articulé .34

9.2.3 ERS .37

9.2.4 QCDC .38

9.3 Contrôle de la fabrication et essais .40

9.3.1 Généralités .40

9.3.2 Matériaux .40

9.3.3 Soudage .40

9.3.4 Essai non destructif .40

9.3.5 Contrôle dimensionnel .41

9.3.6 Essai de pression .41

9.3.7 ERS .41

9.3.8 QCDC .42

9.3.9 Bride d’isolation (protection contre les courants vagabonds) .42

9.3.10 Essai du circuit hydraulique .42

9.4 Essais d’acceptation en usine .42

9.5 Essais d’acceptation sur site .44

9.5.1 Généralités .44

9.5.2 Ensemble bras de transfert .44

9.5.3 Circuit hydraulique .45

10 Contrôle et assurance de la qualité .46

10.1 Système qualité .46

10.2 Plan qualité.46

11 Documentation requise .47

Annexe A (informative) Fiches de données conceptuelles .48

Annexe B (informative) Figures de référence .61

iv © ISO 2016 – Tous droits réservés

Annexe C (informative) Exigences en matière de documentation .66

Bibliographie .71

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1 Il convient, en particulier, de prendre note des différents

critères d’approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www.

iso.org/directives).

L’attention est appelée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets reçues par l’ISO (voir www.iso.org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la signification des termes et expressions spécifiques de l’ISO liés à l’évaluation

de la conformité, ou pour toute information au sujet de l’adhésion de l’ISO aux principes de l’Organisation

mondiale du commerce (OMC) concernant les obstacles techniques au commerce (OTC), voir le lien

suivant: www.iso.org/iso/fr/avant-propos.html.

Le comité chargé de l’élaboration du présent document est l’ISO/TC 67, Matériel, équipement et structures

en mer pour les industries pétrolière, pétrochimique et du gaz naturel.

vi © ISO 2016 – Tous droits réservés

NORME INTERNATIONALE ISO 16904:2016(F)

Industries du pétrole et du gaz naturel — Conception et

essais des bras de transfert de GNL sur des terminaux

terrestres conventionnels

1 Domaine d’application

La présente Norme internationale spécifie les règles de conception, les spécifications minimales de

sécurité ainsi que les procédures de contrôle et d’essais relatifs aux bras de transfert de gaz naturel

liquéfié (GNL) marins destinés à être utilisés sur des terminaux terrestres conventionnels, recevant des

méthaniers engagés dans le commerce international. Elle peut fournir des lignes directrices pour des

opérations côtières et au large. Elle fixe également les spécifications minimales permettant de garantir

que le transfert de GNL entre le navire et le terminal s’effectue en toute sécurité.

Bien que les spécifications relatives aux systèmes d’alimentation/télécommande soient couvertes, la

présente Norme internationale ne fixe pas tous les détails relatifs à la conception et à la fabrication des

pièces normalisées et des raccords des bras de transfert.

La présente Norme internationale vient compléter les normes et règlements locaux ou nationaux, et

s’ajoute aux spécifications de l’ISO 28460.

Il n’est pas nécessaire d’appliquer la présente Norme internationale aux installations existantes.

2 Références normatives

Les documents ci-après, dans leur intégralité ou non, sont des références normatives indispensables à

l’application du présent document. Pour les références datées, seule l’édition citée s’applique. Pour les

références non datées, la dernière édition du document de référence s’applique (y compris les éventuels

amendements).

ISO 3452-1, Essais non destructifs — Examen par ressuage — Partie 1: Principes généraux

ISO 4406, Transmissions hydrauliques — Fluides — Méthode de codification du niveau de pollution

particulaire solide

ISO 9934-1, Essais non destructifs — Magnétoscopie — Partie 1: principes généraux du contrôle

ISO 10474:2013, Aciers et produits sidérurgiques — Documents de contrôle

ISO 10497, Essais des appareils de robinetterie — Exigences de l’essai au feu

ISO 17636-1, Contrôle non destructif des assemblages soudés — Contrôle par radiographie — Partie 1:

Techniques par rayons X ou gamma à l’aide de film

ISO 17636-2, Contrôle non destructif des assemblages soudés — Contrôle par radiographie — Partie 2:

Techniques par rayons X ou gamma à l’aide de détecteurs numériques

ISO 28460:2010, Industries du pétrole et du gaz naturel — Installations et équipements relatifs au gaz

naturel liquéfié — Interface terre-navire et opérations portuaires

IEC 60034-5, Machines électriques tournantes — Partie 5: Degrés de protection procurés par la conception

intégrale des machines électriques tournantes (code IP) — Classification

IEC 60079-0, Atmosphères explosives — Partie 0: Exigences générales

IEC 60079-1, Atmosphères explosives — Partie 1: Protection du matériel par enveloppes antidéflagrantes «d»

IEC 60079-2, Atmosphères explosives — Partie 2: Protection du matériel par enveloppe à surpression

interne «p»

IEC 60079-5, Atmosphères explosives — Partie 5: Protection du matériel par remplissage pulvérulent «q»

IEC 60079-6, Atmosphères explosives — Partie 6: Protection du matériel par immersion dans l’huile «o»

IEC 60079-7, Atmosphères explosives — Partie 7: Protection du matériel par sécurité augmentée «e»

IEC 60079-10-1, Atmosphères explosives — Partie 10-1: classement des emplacements — Atmosphères

explosives gazeuses

IEC 60079-11, Atmosphères explosives — Partie 11: Protection de l’équipement par sécurité intrinsèque «i»

IEC 60079-18, Atmosphères explosives — Partie 18: Protection du matériel par encapsulage «m»

IEC 60079-14, Atmosphères explosives — Partie 18: conception, sélection et construction des installations

électriques

IEC 60079-25, Atmosphères explosives — Partie 25: Systèmes de sécurité intrinsèque

IEC 60529, Degrés de protection procurés par les enveloppes (code IP) et IEC 60529/A1, Amendement 1

IEC 61508 (toutes les parties), Sécurité fonctionnelle des systèmes électriques/électroniques/ électroniques

programmables relatifs à la sécurité

IEC 62305-3, Protection contre la foudre — Partie 3: Dommages physiques sur les structures et risques

humains

ASME B16.5, Pipe Flanges and Flanged Fittings

ASMEBoiler and Pressure Vessel Code IX: Welding and Brazing Qualifications

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

3.1

rotation d’ouverture du compas (rotation médiane)

raccord articulé, conçu pour le transfert des liquides et situé entre le bras interne (3.20) et le bras

externe (3.32)

Note 1 à l’article: Voir la Figure B.2.

Note 2 à l’article: Il permet le relevage (3.26) du bras externe par rapport au bras interne.

3.2

position de travail

divers modes d’utilisation et/ou de positionnement du bras de transfert (3.59) (manœuvre, stockage,

connexion, essai hydrostatique et maintenance)

Note 1 à l’article: Le bras de transfert peut avoir différentes positions pour chaque position de travail.

3.3

embase

fût du bras qui est assemblé à la plate-forme de chargement et qui supporte l’ensemble articulé du bras

de transfert (3.59)

Note 1 à l’article: Voir la Figure B.2.

Note 2 à l’article: Cet ensemble est parfois désigné par le terme ‘colonne support’.

2 © ISO 2016 – Tous droits réservés

3.4

rotation inférieure

supporte le mouvement de tangage (3.35) du méthanier (3.25) et est située de façon contiguë à la bride

de présentation (3.37) dans la partie horizontale du TSA (3.60)

Note 1 à l’article: Voir la Figure B.2.

3.5

marquage (des chemins de roulement)

toute empreinte permanente située sur les chemins de roulement (3.55) ou les articulations de structure

(3.50) provoquée par le chargement excessif des billes ou des galets

3.6

traverse du navire

ensemble de tuyauteries à brides à bord du méthanier (3.25) sur lesquelles sont connectées la bride de

présentation (3.37) ou le QCDC (3.39) du bras de transfert (3.59)

Note 1 à l’article: Voir la Figure B.2.

3.7

cavitation

formation et écrasement de bulles dans un liquide lorsque la pression atteint ou chute en-dessous de

la pression de vapeur du liquide. L’écrasement libère de l’énergie, quelquefois accompagnée d’un bruit

audible et de vibrations

Note 1 à l’article: Ces basses pressions apparaissent dans des zones de grande vitesse telles que les rayons

internes des coudes ou à des endroits où il existe des variations de diamètre.

3.8

interférence

tout contact, dans des conditions opérationnelles de conception ou suite à une déconnexion d’urgence,

entre tout ou partie d’un bras de transfert (3.59) et:

— bras de transfert contigu, alors que tous deux sont en service, ou lorsque l’un est en service et l’autre

en position de stockage [par exemple les contrepoids (3.11)];

— section contiguë du même bras de transfert [par exemple l’ensemble articulé triple (3.60) et le bras

externe (3.32)];

— équipement de la plate-forme de chargement [par exemple le contrepoids (3.11) ou les vannes]

3.9

angle de contact α

angle entre le plan du chemin des billes ou des galets du joint articulé (3.55) ou de l’articulation de

structure (3.50) et le point de contact de la bille ou du galet sur le chemin de roulement

3.10

terminal terrestre conventionnel de GNL

terminal de réception ou d’exportation de GNL situé à terre et doté d’un bras de transfert marin pour le

chargement ou le déchargement des méthaniers (3.25) dans un port ou un autre emplacement côtier abrité

3.11

contrepoids

système de poids utilisés pour équilibrer les ensembles bras interne (3.20) et bras externe (3.32)

Note 1 à l’article: Certains bras de transfert (3.59) sont munis d’un simple contrepoids pour cette fonction,

d’autres en ont plusieurs.

3.12

pression de calcul

pression pour laquelle est conçu le bras de transfert (3.59)

Note 1 à l’article: Voir le Tableau A.1.

3.13

température de calcul

plage des températures pour lesquelles le bras de transfert (3.59) est conçu

Note 1 à l’article: Voir le Tableau A.1.

3.14

dérive

déplacement longitudinal et/ou latéral du méthanier (3.25) sous l’influence des facteurs

environnementaux

Note 1 à l’article: Voir également cavalement avant (3.51) ou arrière (3.52) et balancement (3.54).

3.15

système de déconnexion d’urgence

ERS

système permettant la déconnexion positive rapide des bras de transfert (3.59) et garantissant une

isolation sûre entre le méthanier (3.25) et la terre, selon une procédure prédéfinie comprenant un arrêt

d’urgence (ESD) (3.16)

Note 1 à l’article: Voir la Figure B.2.

3.16

arrêt d’urgence

ESD

méthode permettant d’interrompre de manière sûre et efficace le transfert de GNL et de gaz entre le

méthanier (3.25) et la terre

3.17

franc-bord

élévation du pont du navire au-dessus du niveau de la mer à l’endroit des traverses

Note 1 à l’article: Voir le Tableau A.3 et la Figure A.1.

3.18

roue libre

capacité d’un bras de transfert (3.59) à fonctionnement hydraulique et sans retenue par le système

hydraulique, à suivre librement les mouvements verticaux et horizontaux des traverses du méthanier

(changements de tirant d’eau, ainsi que balancement (3.54) et cavalement)

3.19

pilonnement

mouvement vertical du méthanier (3.25) provoqué par l’action des vagues

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.20

bras interne

tuyauterie transportant le produit et toute structure porteuse située entre la rotation d’ouverture du

compas (3.1) et la rotation horizontale d’embase (3.61)

Note 1 à l’article: Voir la Figure B.2.

4 © ISO 2016 – Tous droits réservés

3.21

angle d’ouverture

angle formé entre le bras interne (3.20) et le bras externe (3.32)

Note 1 à l’article: Voir la Figure B.2.

Note 2 à l’article: Les angles d’ouverture minimaux et maximaux sont laissés à la discrétion du fabricant du bras

de transfert.

Note 3 à l’article: Lorsque les bras de transfert (3.59) sont en position de stockage, il est nécessaire que l’angle

d’ouverture soit tel que l’ensemble articulé triple (3.60) se trouve derrière la ligne d’accostage.

3.22

bride d’isolation

système d’isolation électrique, généralement dédié, installé sur l’extrémité inférieure du bras externe

(3.32) ou ensemble triple de rotation (3.60)

Note 1 à l’article: Ce système permet d’éviter que les courants vagabonds ne créent un arc électrique au niveau de

la bride du méthanier (3.25) lors de la connexion ou de la déconnexion du bras de transfert (3.59).

3.23

support

mécanisme de reprise de charge, permanent et ajustable, potentiellement installé sur l’ensemble articulé

triple (3.60). Il permet de transférer une partie du poids du liquide contenu dans le bras (3.59) sur le

pont et non sur la traverse du méthanier (3.25)

Note 1 à l’article: Voir la Figure B.2.

3.24

cabine de commande de la jetée

cabine de commande située sur la jetée ou à proximité, essentiellement pour diriger et/ou contrôler les

bras de transfert (3.59)

Note 1 à l’article: Parfois appelée «salle de contrôle de la jetée» ou «salle de contrôle locale».

3.25

méthanier

LNGC

navire-citerne conçu pour le transport de GNL

3.26

relevage

mouvements rotatifs des bras interne (3.20) et externe (3.32) dans le plan vertical

Note 1 à l’article: Voir la Figure B.2.

3.27

centrale hydraulique

MHU

centrale hydraulique qui génère la puissance hydraulique pour assurer le fonctionnement normal et la

séquence de déconnexion d’urgence des bras

3.28

recul de la traverse

distance horizontale entre la muraille plane du méthanier (3.25) et la face de la traverse du navire (3.6)

Note 1 à l’article: Voir le Tableau A.3 et la Figure A.1.

3.29

espacement des traverses

distance horizontale qui sépare les axes de deux traverses du navire (3.6) contiguës

Note 1 à l’article: Voir le Tableau A.3 et la Figure A.1.

3.30

rotation moyenne

supporte le lacet et le cavalement du lacet (3.63) méthanier (3.25) et est située entre la rotation

supérieure (3.57) et la rotation inférieure (3.4) dans la partie verticale du TSA (3.60)

Note 1 à l’article: Voir la Figure B.2.

3.31

enveloppe de fonctionnement

volume dans lequel doit ou doivent fonctionner la ou les brides de présentation (3.37) d’un bras de

transfert individuel ou d’un groupe de bras de transfert (3.59)

3.32

bras externe

tuyauterie de transport du produit et toute structure porteuse située entre la rotation d’ouverture du

compas (3.1)et l’ensemble articulé triple (3.60)

Note 1 à l’article: Voir la Figure B.2.

3.33

propriétaire

son représentant

société ou groupe de sociétés pour lesquels les bras de transfert (3.59) sont installés pour utilisation. Le

propriétaire est responsable de la conception de la sécurité et de la construction de l’installation

3.34

système de pantographe

système utilisé pour transmettre au(x) contrepoids (3.11) les charges d’équilibrage du bras externe (3.32)

Note 1 à l’article: Le système est constitué d’un ensemble de tringleries et de connexions articulées, ou bien

d’un système de câbles et de poulies (respectivement «pantographe par liaison rigide» et «câbles et poulies

pantographes»).

3.35

tangage

rotation du méthanier (3.25) autour de l’axe horizontal transversal

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.36

déconnecteur d’urgence énergisé

PERC

dispositif énergisé permettant de déconnecter rapidement les bras de transfert (3.59) lorsqu’une telle

action est requise uniquement en cas d’urgence

3.37

bride de présentation

bride d’un bras de transfert (3.59) pour connexion à la traverse du navire (3.6) ou à la manchette de

raccordement (3.47)

Note 1 à l’article: Voir la Figure B.2.

3.38

produit

fluide transféré par les bras de transfert (3.59)

Note 1 à l’article: Les fluides sont: , ou .

6 © ISO 2016 – Tous droits réservés

3.39

coupleur de connexion et de déconnexion rapide

QCDC

coupleur

dispositif mécanique manuel ou hydraulique utilisé pour connecter le bras de chargement (3.59) à la

traverse du navire (3.6) sans utiliser de boulons

Note 1 à l’article: Voir la Figure B.2.

3.40

dispositif de commande à distance

commande à distance

dispositif destiné à faciliter les opérations délicates de connexion et/ou de déconnexion des brides des

bras de transfert (3.59) à distance (par exemple zone de traverse (3.25) du méthanier (3.6))

Note 1 à l’article: La commande peut être à fil ou radiocommandée.

3.41

ensemble embase et rotation horizontale d’embase

système de transport du produit, composé de la rotation de l’embase (3.43), la rotation horizontale

d’embase (3.61) et de coudes et monté au sommet de l’embase (3.3)

Note 1 à l’article: Voir la Figure B.2.

3.42

bride d’embase

bride d’un bras de transfert (3.59) pour le raccordement aux tuyauteries de GNL

Note 1 à l’article: Voir la Figure B.2.

3.43

rotation de l’embase

joint articulé de l’ensemble embase et rotation horizontale d’embase (3.41) qui permet le pivotement

(3.46) du bras de transfert (3.59)

Note 1 à l’article: Voir la Figure B.2.

3.44

roulis

rotation du méthanier (3.25) autour de l’axe horizontal longitudinal

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.45

niveau d’intégrité de sécurité

SIL

représentations statistiques de l’intégrité du système instrumenté de sécurité lorsqu’une demande de

processus a lieu

Note 1 à l’article: Voir l’Article 5.

3.46

pivotement

mouvement de rotation horizontal du bras de chargement (3.59) autour de l’embase (3.3)

Note 1 à l’article: Voir la Figure B.2.

3.47

manchette de raccordement

courte longueur de tuyauterie destinée à faire concorder la traverse du navire (3.6) et la bride de

présentation (3.37) ou le QCDC (3.39)

Note 1 à l’article: Ces dispositifs sont parfois appelés «adaptateurs» ou «réductions».

3.48

repère d’alignement du navire

marquage utilisé par le méthanier (3.25) au moment de l’accostage pour aligner les axes des bras de

transfert

Note 1 à l’article: Voir la Figure A.4.

3.49

analyse des contraintes

calcul détaillé des charges structurelles exercées sur le bras de transfert (3.59) et la traverse du navire

(3.6) en fonction des différentes conditions et positions, permettant de vérifier l’intégrité du bras de

transfert pour les différents modes d’utilisation prévus

3.50

articulations de structure

roulements des organes porteurs qui soutiennent la canalisation de produit et qui, associés à d’autres

éléments, permettent au bras de transfert (3.59) de suivre librement le mouvement du méthanier (3.25)

3.51

cavalement arrière

déplacement longitudinal du méthanier (3.25) vers l’arrière

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.52

cavalement avant

déplacement longitudinal du méthanier (3.25) vers l’avant

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.53

coup de bélier

modification rapide de la pression provoquée par un changement du débit dans une canalisation et/ou

dans des systèmes de canalisations (ce qui inclut les bras de transfert (3.59))

3.54

balancement

mouvement transversal du méthanier (3.25)

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

3.55

joint articulé

rotation

joint articulé contenu dans le bras de transfert (3.59) qui permet au bras de suivre librement le

mouvement du méthanier (3.25)

3.56

terminal

installation de production/réception de GNL doté d’une installation de chargement et/ou de

déchargement

8 © ISO 2016 – Tous droits réservés

3.57

rotation supérieure

supporte le mouvement de roulis (3.44), de pilonnement et de balancement du méthanier et est située

entre le bras externe et la rotation moyenne dans la partie horizontale du TSA

Note 1 à l’article: Voir la Figure B.2.

3.58

transfert

opération de chargement et/ou de déchargement

3.59

bras de transfert

bras

système de transfert articulé en métal utilisé pour transférer un produit (3.38) vers ou depuis le

méthanier avec la capacité de supporter des différences de marées, le franc-bord et les mouvements du

méthanier

Note 1 à l’article: Voir la Figure B.2.

Note 2 à l’article: Il peut aussi être appelé «bras de chargement» ou «bras de déchargement»

3.60

ensemble articulé triple

TSA

ensemble de trois rotations et coudes situé à l’extrémité du bras externe (3.32)

Note 1 à l’article: Voir la Figure B.2.

3.61

rotation horizontale d’embase

joint articulé dans l’ensemble embase et rotation horizontale d’embase qui permet la rotation du bras

interne autour de l’axe horizontal

Note 1 à l’article: Voir la Figure B.2.

3.62

dispositif d’alimentation continue

UPS

source de secours du système principal d’alimentation électrique fournissant l’énergie nécessaire aux

commandes critiques et aux systèmes de sécurité afin de maintenir les installations dans des conditions

de sécurité

3.63

lacet

rotation du méthanier (3.25) autour d’un axe vertical

Note 1 à l’article: Voir le Tableau A.4 et la Figure A.2.

4 Abréviations

Pour les besoins du présent document, les abréviations suivantes s’appliquent:

CND contrôle non destructif

CPMS système de contrôle permanent de position des bras;

ERS système de déconnexion d’urgence;

ESD arrêt d’urgence;

FL charge due à la masse du fluide;

GNL gaz naturel liquéfié;

LNGC navire transporteur de gaz naturel liquéfié;

LN azote liquide;

MHU centrale hydraulique;

GN gaz naturel;

N azote gazeux;

OBE séisme de maintien en exploitation;

PERC déconnecteur d’urgence énergisé;

PL charge due à la pression;

PQR enregistrements relatifs à la qualité des performances;

QCDC coupleur de connexion et de déconnexion rapide;

SIL niveau d’intégrité de sécurité;

SSE séisme d’arrêt de sécurité;

TL charge thermique;

TSA ensemble articulé triple;

UPS dispositif d’alimentation continue;

WL charge due au vent;

MOS spécifications du mode opératoire de soudage.

5 Conception des bras

5.1 Définition de la longueur et de la configuration des bras, description des bras

5.1.1 Généralités

La disposition générale des bras de transfert est illustrée en Figure B.2.

La longueur et la configuration des bras de transfert doivent permettre la connexion entre la traverse

du navire et la tuyauterie terrestre. Cette connexion ne doit pas entraver la liberté de mouvement des

bras au sein de l’enveloppe de fonctionnement.

Les bras de transfert sont normalement composés (voir les définitions à l’Article 3):

— d’un ensemble articulé triple (TSA) comportant un système de déconnexion d’urgence (ERS) et un

coupleur de connexion et de déconnexion rapide (QCDC) si cela est spéc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...