ISO 12405-4:2018

(Main)Electrically propelled road vehicles —Test specification for lithium-ion traction battery packs and systems — Part 4: Performance testing

Electrically propelled road vehicles —Test specification for lithium-ion traction battery packs and systems — Part 4: Performance testing

This document specifies test procedures for the basic characteristics of performance, reliability and electrical functionality for the battery packs and systems for either high-power or high-energy application. Unless otherwise stated, the test applies to both applications. NOTE 1 Typical applications for high-power battery packs and systems are hybrid electric vehicles (HEVs) and some type of fuel cell vehicles (FCVs). NOTE 2 Typical applications for high-energy battery packs and systems are battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs) and some type of fuel cell vehicles (FCVs). NOTE 3 Testing on cell level is specified in IEC 62660 series.

Véhicules routiers à propulsion électrique — Spécifications d'essai pour packs et systèmes de batterie de traction aux ions lithium — Partie 4: Essais de performance

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12405-4

First edition

2018-07

Electrically propelled road vehicles —

Test specification for lithium-ion

traction battery packs and systems —

Part 4:

Performance testing

Véhicules routiers à propulsion électrique — Spécifications d'essai

pour packs et systèmes de batterie de traction aux ions lithium —

Partie 4: Essais de performance

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

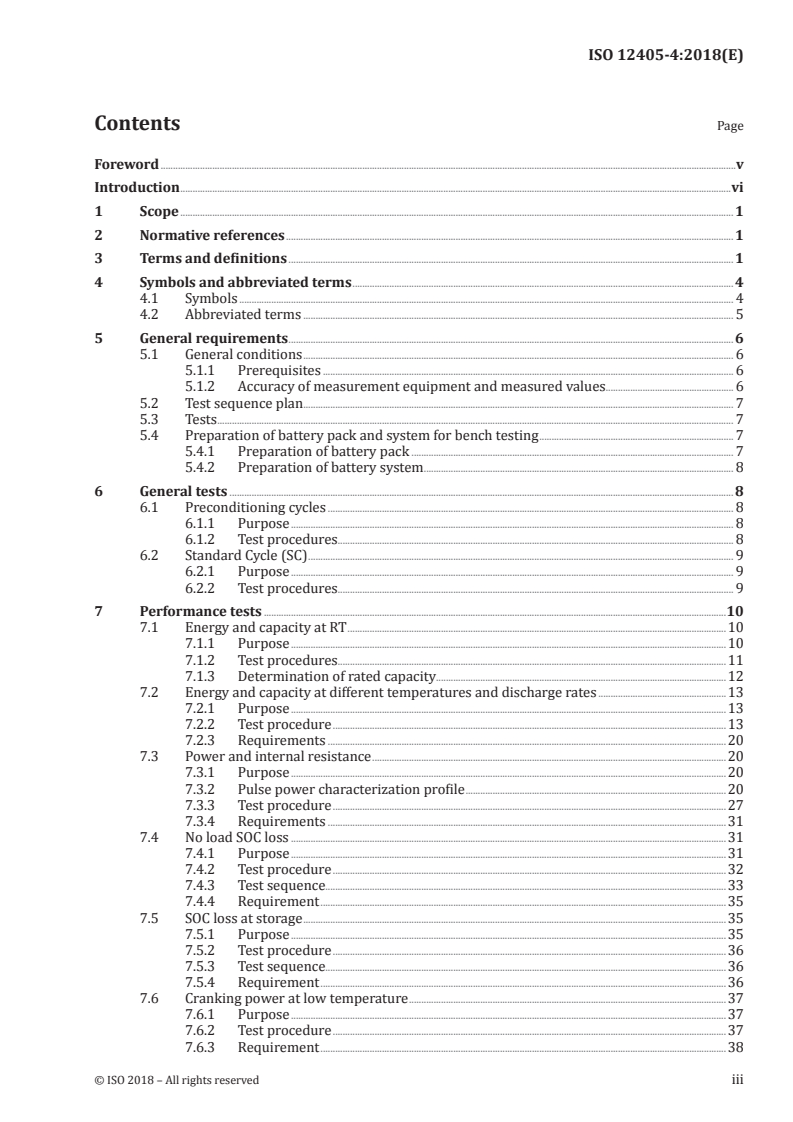

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 4

4.1 Symbols . 4

4.2 Abbreviated terms . 5

5 General requirements . 6

5.1 General conditions . 6

5.1.1 Prerequisites . 6

5.1.2 Accuracy of measurement equipment and measured values. 6

5.2 Test sequence plan . 7

5.3 Tests . 7

5.4 Preparation of battery pack and system for bench testing . 7

5.4.1 Preparation of battery pack . 7

5.4.2 Preparation of battery system . 8

6 General tests . 8

6.1 Preconditioning cycles . 8

6.1.1 Purpose . 8

6.1.2 Test procedures. 8

6.2 Standard Cycle (SC) . 9

6.2.1 Purpose . 9

6.2.2 Test procedures. 9

7 Performance tests .10

7.1 Energy and capacity at RT .10

7.1.1 Purpose .10

7.1.2 Test procedures.11

7.1.3 Determination of rated capacity .12

7.2 Energy and capacity at different temperatures and discharge rates .13

7.2.1 Purpose .13

7.2.2 Test procedure .13

7.2.3 Requirements .20

7.3 Power and internal resistance .20

7.3.1 Purpose .20

7.3.2 Pulse power characterization profile .20

7.3.3 Test procedure .27

7.3.4 Requirements .31

7.4 No load SOC loss .31

7.4.1 Purpose .31

7.4.2 Test procedure .32

7.4.3 Test sequence . . .33

7.4.4 Requirement .35

7.5 SOC loss at storage .35

7.5.1 Purpose .35

7.5.2 Test procedure .36

7.5.3 Test sequence . . .36

7.5.4 Requirement .36

7.6 Cranking power at low temperature .37

7.6.1 Purpose .37

7.6.2 Test procedure .37

7.6.3 Requirement .38

7.7 Cranking power at high temperature .38

7.7.1 Purpose .38

7.7.2 Test procedure .38

7.7.3 Requirement .39

7.8 Energy efficiency .40

7.8.1 Purpose .40

7.8.2 Test description .40

7.8.3 Test procedure .40

7.8.4 Requirement .42

7.8.5 Calculation example for energy efficiency test .42

7.9 Energy efficiency at fast charging .42

7.9.1 Purpose .42

7.9.2 Test procedure .42

7.9.3 Requirement .44

7.10 Cycle life .44

7.10.1 Purpose .44

7.10.2 Test procedure .45

7.10.3 Requirement .60

7.10.4 Calculation example for cycle life test for high-power battery system .61

Annex A (informative) Battery pack and system and overview on tests .62

Annex B (informative) Examples of data sheets for battery pack and system testing .67

Annex C (informative) Example of test conditions .71

Bibliography .72

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www .iso .org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www .iso .org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the WTO

principles in the Technical Barriers to Trade (TBT) see the following URL: Foreword - Supplementary

information

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 37,

Electrically propelled vehicles.

This document cancels and replaces ISO 12405-1:2011 and ISO 12405-2:2012 by summarizing the test

specifications.

Introduction

Lithium-ion-based battery systems are an efficient alternative energy storage system for electrically

propelled vehicles. The requirements for lithium-ion based battery systems for use as a power source

for the propulsion of electric road vehicles are significantly different from those batteries used for

consumer electronics or stationary usage.

This document provides specific test procedures for lithium-ion battery packs and systems specially

developed for propulsion of road vehicles. This document specifies such tests and related requirements

to ensure that a battery pack or system is able to meet the specific needs of the automobile industry.

It enables vehicle manufactures to choose test procedures to evaluate the characteristics of a battery

pack or system for their specific requirements.

ISO 12405 specifies test procedures for lithium-ion battery packs and systems which are connected to

the electric propulsion system of electrically propelled vehicles.

The objective of ISO 12405 is to specify standard test procedures for the basic characteristics of

performance, reliability and electrical functionality of lithium-ion battery packs and systems and to

assist the user in comparing the test results achieved for different battery packs or systems.

1)

NOTE 1 The general safety relevant tests and requirements are given in ISO 6469-1 .

2)

NOTE 2 Environmental conditions and testing will be given in the future ISO 19453-6 .

For specifications for battery cells, see IEC 62660-1 to 3.

1) Under preparation. Stage at the time of publication: ISO/DIS 6469-1.

2) Under preparation. Stage at the time of publication: ISO/CD 19453-6.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 12405-4:2018(E)

Electrically propelled road vehicles — Test specification

for lithium-ion traction battery packs and systems —

Part 4:

Performance testing

1 Scope

This document specifies test procedures for the basic characteristics of performance, reliability

and electrical functionality for the battery packs and systems for either high-power or high-energy

application. Unless otherwise stated, the test applies to both applications.

NOTE 1 Typical applications for high-power battery packs and systems are hybrid electric vehicles (HEVs) and

some type of fuel cell vehicles (FCVs).

NOTE 2 Typical applications for high-energy battery packs and systems are battery electric vehicles (BEVs),

plug-in hybrid electric vehicles (PHEVs) and some type of fuel cell vehicles (FCVs).

NOTE 3 Testing on cell level is specified in IEC 62660 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

3)

ISO 6469-1 , Electrically propelled road vehicles — Safety specifications — Part 1: On-board rechargeable

energy storage system (RESS)

4)

ISO 6469-3 , Electrically propelled road vehicles — Safety specifications — Part 3: Protection of persons

against electric shock

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

3.1

battery control unit

BCU

electronic device that controls, manages, detects or calculates electric and thermal functions of the

battery system (3.3) and that provides communication between the battery system and other vehicle

controllers

Note 1 to entry: See A.3.1 for further explanations.

3) Under preparation. Stage at the time of publication: ISO/DIS 6469-1.

4) Under preparation. Stage at the time of publication: ISO/DIS 6469-3.

3.2

battery pack

energy storage device that includes cells or cell assemblies normally connected with cell electronics

(3.5), power supply circuits and overcurrent shut-off device, including electrical interconnections,

interfaces for external systems

Note 1 to entry: See A.2 for further explanations.

Note 2 to entry: Examples of external systems are cooling, voltage class B, auxiliary voltage class A and

communication.

3.3

battery system

energy storage device that includes cells or cell assemblies or battery pack(s) (3.2) as well as electrical

circuits and electronics

Note 1 to entry: See A.3.2 and A.3.3 for further explanations. Battery system components can also be distributed

in different devices within the vehicle.

Note 2 to entry: Examples of electronics are the BCU and contactors.

3.4

capacity

total number of ampere hours that can be withdrawn from a fully charged battery pack (3.2) under

specified conditions

3.5

cell electronics

electronic device that collects and possibly monitors thermal or electric data of cells or cell assemblies

and contains electronics for cell balancing, if necessary

Note 1 to entry: The cell electronics can include a cell controller. The functionality of cell balancing can be

controlled by the cell electronics or by the BCU.

3.6

customer

party that is interested in using the battery pack or system and therefore orders or performs the test

EXAMPLE A vehicle manufacturer.

3.7

device under test

DUT

battery pack or battery system

3.8

electric drive

combination of a traction motor, power electronics and their associated controls for the conversion of

electric to mechanical power and vice versa

3.9

electrically propelled vehicle

vehicle with one or more electric drive(s) (3.8) for vehicle propulsion

3.10

energy density

amount of stored energy related to the battery pack (3.2) or system (3.3) volume

Note 1 to entry: The battery pack or system includes the cooling system, if any, to the point of a reversible

attachment of the coolant lines or air ducts, respectively.

Note 2 to entry: Energy density is expressed in watt hours per litre (Wh/l).

2 © ISO 2018 – All rights reserved

3.11

energy round trip efficiency

ratio of the net d.c. energy delivered by a DUT during a discharge test to the total d.c. energy required to

restore the initial SOC by a standard charge

Note 1 to entry: The net d.c. energy is expressed as watt hours (Wh) discharge and the total d.c. energy is

expressed as watt hours (Wh) charge.

3.12

high-energy battery pack and system

battery pack (3.2) and system (3.3) using cells, which have the numerical ratio between maximum

allowed electric power output and electric energy output at a 1C discharge rate at RT lower than 10

Note 1 to entry: Typically high-energy battery packs and systems are designed for applications in BEVs and PHEVs.

Note 2 to entry: The allowed electric power output is expressed as power in watts (W) and the electric energy

output is expressed as energy in watt hours (Wh).

3.13

high-power battery pack and system

battery pack (3.2) and system (3.3) using cells, for which the numerical ratio between maximum allowed

electric power output and electric energy output at a 1C discharge rate at RT equal to or higher than 10

Note 1 to entry: Typically high-power battery packs and systems are designed for applications in HEVs and FCVs.

Note 2 to entry: The allowed electric power output is expressed as power in watts (W) and the electric energy

output is expressed as energy in watt hours (Wh).

3.14

maximum working voltage

highest value of a.c. voltage (rms) or of d.c. voltage which may occur in an electric system under any

normal operating conditions according to the supplier's specifications, disregarding transients

3.15

overcurrent protection

protection intended to operate when the current is in excess of a predetermined value

3.16

rated capacity

supplier's specification of the total number of ampere hours that can be withdrawn from a fully charged

battery pack or system for a specified set of test conditions such as discharge rate, temperature and

discharge cut-off voltage

3.17

room temperature

RT

temperature of (25 ± 2) °C

3.18

sign of battery current

discharge current is specified as positive and the charge current as negative

3.19

specific energy

amount of stored energy related to the battery pack (3.2) or system (3.3) mass

Note 1 to entry: The mass of battery pack or system includes the mass of the temperature conditioning system if

any up to the point of a reversible attachment of the coolant lines or air ducts and the coolant mass.

Note 2 to entry: Specific energy is expressed in watt hours per kilogram (Wh/kg).

3.20

state of charge

SOC

available capacity in a battery pack or system expressed as a percentage of rated capacity (3.15)

3.21

top off charge

additional charge which eliminates possible SOC reduction after SCH at RT followed by thermal

equilibration at a different temperature

3.22

supplier

party that provides battery systems and packs

EXAMPLE A battery manufacturer.

3.23

voltage class A

classification of an electric component or circuit with a maximum working voltage (3.14) of ≤30 V a.c.

(rms) or ≤60 V d.c., respectively

Note 1 to entry: See ISO 6469-3.

3.24

voltage class B

classification of an electric component or circuit with a maximum working voltage (3.14) of (>30 and

≤1 000) V a.c. (rms) or (>60 and ≤1 500) V d.c., respectively

Note 1 to entry: See ISO 6469-3.

4 Symbols and abbreviated terms

4.1 Symbols

C Capacity fade

fade

C Rated 1 C capacity at BOL

rt,t0

I maximum continuous charge current specified by the supplier for energy efficiency at

c,max

fast charging testing

I maximum continuous discharge current specified by the supplier for energy and ca-

d,max

pacity testing

I maximum discharge pulse current specified by the supplier for power, internal resistance

dp,max

and energy efficiency testing

T maximum temperature

max

T minimum temperature

min

T Time

4 © ISO 2018 – All rights reserved

4.2 Abbreviated terms

a.c. alternating current

BCU battery control unit

BEV battery electric vehicle

BOL beginning of life

C capacity, expressed in ampere hours (Ah)

nC current rate equal to n times the one hour discharge capacity expressed in ampere (e.g.

3C is equal to three times the 1 h current discharge rate, expressed in ampere)

d.c. direct current

DUT device under test

EODV End-of-discharge-voltage

EUCAR European Council for Automotive Research

FCV fuel cell vehicle

HEV hybrid electric vehicle

IEC International Electrotechnical Commission

ISO International Organization for Standardization

Li lithium

Li-ion lithium-ion

OCV Open Circuit Voltage

PHEV plug-in hybrid electric vehicle

PSD power spectral density

RESS rechargeable energy storage system

rms root mean square

RT room temperature (25 ± 2) °C

SC standard cycle

SCH standard charge

SDCH standard discharge

SOC state of charge

USABC United States Advanced Battery Consortium

5 General requirements

5.1 General conditions

5.1.1 Prerequisites

A battery pack or system to be tested according to this document shall fulfil the following requirements:

— The electrical safety design and safety requirements shall comply with the requirements given in

5) 6)

ISO 6469-1 and ISO 6469-3 .

— The necessary documentation for operation and needed interface parts for connection to the test

equipment (i.e. connectors, plugs including cooling, communication) shall be delivered together

with the DUT.

A battery system shall enable the specified tests, i.e. via specified test modes implemented in the BCU,

and shall be able to communicate with the test bench via common communication buses.

The battery pack subsystem as a DUT shall comprise all parts specified by the customer (e.g. including

mechanical and electrical connecting points for mechanical test).

If not otherwise specified, before each test the DUT shall be equilibrated at the test temperature. The

thermal equilibration is reached if during a period of 1 h without active cooling the deviations between

test temperature and temperature of all cell temperature measuring points are lower than ±2 K.

If not otherwise specified, each charge and each SOC change shall be followed by a rest period of 30 min.

5.1.2 Accuracy of measurement equipment and measured values

The accuracy of external measurement equipment shall be at least within the following tolerances:

— voltage ±0,5 %

— current ±0,5 %

— temperature ±1 K

The overall accuracy of externally controlled or measured values, relative to the specified or actual

values, shall be at least within the following tolerances:

— voltage ±1 %

— current ±1 %

— temperature ±2 K

— time ±0,1 %

— mass ±0,1 %

— dimensions ±0,1 %

All values (time, temperature, current and voltage) shall be noted at least every 5 % of the estimated

discharge and charge time, except if it is noted otherwise in the individual test procedure.

5) Under preparation. Stage at the time of publication: ISO/DIS 6469-1.

6) Under preparation. Stage at the time of publication: ISO/DIS 6469-3.

6 © ISO 2018 – All rights reserved

5.2 Test sequence plan

The test sequence for an individual battery pack or system, or a battery pack subsystem shall be based

on agreement between the customer and supplier with consideration of tests in 5.3.

An example for a list of test conditions to be agreed between customer and supplier is provided in

Table C.1 for high-power battery packs and systems or in Table C.2 for high-energy battery packs and

systems.

5.3 Tests

An overview of the tests is given in Figure 1 where the references to the specific subclauses are also

given. Annex B provides examples for collection of test data.

Key

a

The test applies only to high-power battery packs and systems.

b

The test applies only to high-energy battery packs and systems.

Figure 1 — Test sequence

5.4 Preparation of battery pack and system for bench testing

5.4.1 Preparation of battery pack

If not otherwise specified, the battery pack shall be connected with voltage class B if any, and voltage

class A connections to the test bench equipment. Contactors, available voltage, current and temperature

data shall be controlled according to the supplier’s requirements and according to the given test

specification by the test bench equipment. The passive overcurrent protection shall be operational in

the battery pack. Active overcurrent protection shall be maintained by the test bench equipment, if

necessary, via disconnection of the battery pack main contactors. The cooling device may be connected

to the test bench equipment and operated according to the supplier's requirements.

5.4.2 Preparation of battery system

If not otherwise specified, the battery system shall be connected with voltage class B, if any, and

voltage class A and cooling connections to the test bench equipment. The battery system shall be

controlled by the BCU, the test bench equipment shall follow the operational limits provided by the

BCU via bus communication. The test bench equipment shall maintain the on/off requirements for

the main contactors and the voltage, current and temperature profiles according to the requested

requirements of the given test procedure. The battery system cooling device and the corresponding

cooling loop at the test bench equipment shall be operational according to the controls by the BCU,

unless otherwise specified in the given test procedure. The BCU shall enable the test bench equipment

to perform the requested test procedure within the battery system operational limits. If necessary, the

BCU program shall be adapted by the supplier for the requested test procedure. The active and passive

overcurrent protection shall be operational by the battery system. Active overcurrent protection shall

be maintained by the test bench equipment, too, if necessary via request of disconnection of the battery

system main contactors.

6 General tests

6.1 Preconditioning cycles

6.1.1 Purpose

The DUT shall be conditioned by performing some electrical cycles, before starting the real testing

sequence, in order to ensure an adequate stabilization of the battery pack or system performance.

This test applies to battery packs and systems.

6.1.2 Test procedures

6.1.2.1 High-power battery pack and system

For high-power battery packs and systems the procedure shall be the following:

— The test shall be performed at RT.

— The discharges shall be performed at 2 C or at a different current if suggested and/or used

by the supplier in testing before delivery. The charging shall be performed according to the

recommendations of the supplier.

— Five consecutive preconditioning cycles shall be performed. Fewer cycles may be agreed between

the customer and supplier.

— At the end of discharge, the battery pack or system voltage shall not go below the minimum voltage

recommended by the supplier.

— The battery pack or system shall be considered “preconditioned” if the discharged capacity during

two consecutive discharges does not change by a value greater than 3 % of the rated capacity (30 min

discharge or other discharge process adopted during test according to supplier indications). If the

discharge process is equal to that used by the supplier on the same battery pack or system during

factory tests, the data from the second cycle may be compared directly with the data from the

supplier.

— If the precondition requirements cannot be fulfilled, the customer and supplier shall agree on

further procedure.

NOTE The discharge rate of 2 C is used in order to shorten the preconditioning.

8 © ISO 2018 – All rights reserved

6.1.2.2 High-energy battery pack and system

For high-energy battery packs and systems the procedure shall be the following:

— The test shall be performed at RT.

— The discharges shall be performed at C/3 or at a different current if suggested and/or used

by the supplier in testing before delivery. The charging shall be performed according to the

recommendations of the supplier.

— Three consecutive preconditioning cycles shall be performed. If agreed between customer and

supplier, only two cycles shall be performed.

— At end of discharge, the battery pack or system voltage shall not go below the minimum voltage

recommended by the supplier (the minimum voltage is the lowest voltage under discharge without

irreversible damage).

— The battery pack or system shall be considered as “preconditioned” if the discharged capacity during

two consecutive discharges does not change by a value greater than 3 % of the rated capacity. If

the discharge process is equal to that used by the supplier on the same battery pack or system

during factory tests, the data from the second cycle can be compared directly with the data from

the supplier.

— If the preconditioning requirements cannot be fulfilled, customer and supplier shall agree on further

procedure.

6.2 Standard Cycle (SC)

6.2.1 Purpose

The purpose of the standard cycle (SC) is to ensure the same initial condition for each test of a battery

pack or system. A standard cycle (SC), as described below, shall be performed prior to each test.

This test applies to battery packs and systems.

6.2.2 Test procedures

6.2.2.1 General

The standard cycle (SC) shall be performed at RT. The SC shall comprise a standard discharge (SDCH),

see 6.2.2.2, followed by a standard charge (SCH), see 6.2.2.3.

If, for any reason, the time interval between the end of the SC and the start of a new test is longer than

3 h, the SC shall be repeated.

6.2.2.2 Standard discharge (SDCH)

6.2.2.2.1 High-power battery pack and system

Discharge rate:

— 1 C or other specific discharge rate according to the specifications given by the supplier.

Discharge limit:

— According to the specifications given by the supplier.

Rest period after discharge to reach a stable condition:

— 30 min or a thermal equilibration at RT of the DUT is reached.

6.2.2.2.2 High-energy battery pack and system

Discharge rate:

— C/3 or other specific discharge rate according to the specifications given by the supplier.

Discharge limit:

— According to the specifications given by the supplier.

Rest period after discharge to reach a stable condition:

— 30 min or a thermal equilibration at RT of the DUT is reached.

6.2.2.3 Standard charge (SCH)

6.2.2.3.1 High-power battery pack and system

Charge procedure and end of charge criteria:

— According to the specifications given by the supplier. The specifications shall cover end of charge

criteria and time limits for the overall charging procedure.

Rest period after charge:

— 30 min.

6.2.2.3.2 High-energy battery pack and system

Charge procedure and end of charge criteria:

— C/3 or another specific charge rate according to the specifications given by the supplier. The

specifications shall cover end of charge criteria and time limits for the overall charging procedure.

— In any case, the total charge procedure shall be completed within 8 h.

Rest period after charge:

— 60 min.

7 Performance tests

7.1 Energy and capacity at RT

7.1.1 Purpose

This test measures DUT capacity in A·h at constant current discharge rates.

For high-power battery packs and systems, the constant current discharge rates shall be corresponding

to the suppliers rated 1 C capacity in A·h (e.g., if the rated one hour discharge capacity is 10 A·h, the

discharge rate is 10 A). The one hour rate (1 C) is used as reference for static capacity and energy

measurement and as a standard rate for high-power battery pack and system level testing. In addition,

if applicable, the 10 C and the maximum permitted C rate shall be performed for capacity determination

to meet the high-power system requirements. Discharge shall be terminated on supplier-specified

discharge voltage limits depending on discharge rates and temperature.

For high-energy battery packs and systems the constant current discharge rates shall be corresponding

to the suppliers rated C/3 capacity in A·h (e.g., if the rated three hour discharge capacity is 45 A·h, the

discharge rate is 15 A). The three hour rate (C/3) is used as reference for static capacity and energy

measurement and as a standard rate for pack and high-energy system level testing. In addition, if

10 © ISO 2018 – All rights reserved

applicable, the 1C, 2C and the maximum permitted C rate shall be performed for capacity determination

to meet the high-energy system requirements. Discharge shall be terminated on supplier specified

discharge voltage limits depending on discharge rates and temperature.

This test applies to battery packs and systems.

7.1.2 Test procedures

7.1.2.1 High-power battery pack and system

The test shall be performed at RT with the discharge rates of 1 C, 10 C and the maximum C rate as

permitted by the supplier (the maximum C rate corresponds to I ).

d,max

The test sequence shall be performed as specified in Table 1.

Table 1 — Test sequence energy and capacity test at RT for high-power battery packs and systems

Step Procedure Test temperature

1.1 Thermal equilibration RT

1.2 Standard charge (SCH) RT

1.3 Standard cycle (SC) RT

2.1 Discharge at 1 C RT

2.2 Standard charge (SCH) RT

2.3 Discharge at 1 C RT

2.4 Standard charge (SCH) RT

2.5 Discharge at 10 C RT

2.6 Standard charge (SCH) RT

2.7 Discharge at 10 C RT

2.8 Standard charge (SCH) RT

2.9 Discharge at I RT

d,max

2.10 Standard charge (SCH) RT

2.11 Discharge at I RT

d,max

2.12 Standard charge (SCH) RT

3.1 Standard cycle (SC) RT

The SCH procedure shall follow 6.2.2.3.1.

The SC procedure shall follow 6.2.

All discharge tests shall be terminated at the supplier's discharge voltage limits.

After discharge, the DUT shall rest at least for 30 min or shall be thermally equilibrated at the required

ambient temperature or a fixed time period shall be used to allow for thermal equilibration before

starting the next step in the test sequence.

7.1.2.2 High-energy battery pack and system

The test shall be performed at RT with the discharge rates C/3, 1C, 2C (if 2C is less than I ) and the

d,max

maximum C rate as permitted by the supplier.

The test sequence shall be performed as specified in Table 2.

Table 2 — Test sequence energy and capacity test at RT for high-energy battery packs and

systems

Step Procedure Ambient temperature

1.1 Thermal equilibration RT

1.2 Standard charge (SCH) RT

1.3 Standard cycle (SC) RT

2.1 Discharge at C/3 RT

2.2 Standard charge (SCH) RT

2.3 Discharge at C/3 RT

2.4 Standard charge (SCH) RT

2.5 Discharge at 1C RT

2.6 Standard charge (SCH) RT

2.7 Discharge at 1C RT

2.8 Standard charge (SCH) RT

2.9 Discharge at 2C RT

2.10 Standard charge (SCH) RT

2.11 Discharge at 2C RT

2.12 Standard charge (SCH) RT

2.13 Discharge at I RT

d,max

2.14 Standard charge (SCH) RT

2.15 Discharge at I RT

d,max

2.16 Standard charge (SCH) RT

3.1 Standard cycle (SC) RT

The standard charge (SCH) procedure shall follow 6.2.2.3.2.

The standard cycle (SC) procedure shall follow 6.2.

All discharge tests shall be terminated at the supplier's discharge voltage limits.

After discharge, the DUT shall rest at least for 30 min or shall be thermally equilibrated at the requested

ambient temperature or a fixed time period shall be used to allow for thermal equilibration before

starting the next step in the test sequence.

7.1.3 Determination of rated capacity

7.1.3.1 High-power battery pack and system

If the 1 C capacity obtained during testing at 7.1.2.1 step no. 2.3 in Table 1 differs more than 5 % from

the suppliers 1 C specification, this measured 1 C capacity shall be used as rated capacity and shall

be the basis value for all further discharge current requirements, i.e. the value for C in each discharge

current calculation, nC, shall be based on the measured 1 C capacity.

The following data shall be reported:

— current, voltage, DUT temperature and ambient temperature versus time at each discharge test and

the following standard charge;

— discharged capacity, in A·h, energy in Wh and average power in W at each discharge test;

— charged capacity in A·h, energy in Wh and average power in W following each discharge test;

— energy round-trip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...