ISO/IEC 80079-49:2024

(Main)Explosive atmospheres — Part 49: Flame arresters — Performance requirements, test methods and limits for use

Explosive atmospheres — Part 49: Flame arresters — Performance requirements, test methods and limits for use

This document specifies the requirements for flame arresters that prevent flame transmission when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for the classification, basic construction and information for use, including the marking of flame arresters, and specifies test methods to verify the safety requirements and determine safe limits of use. This document is applicable to pressures ranging from 80 kPa to 160 kPa and temperatures ranging from -20 °C to +200 °C. This document does not apply to the following: - external safety-related measurement and control equipment that might be required to keep the operational conditions within the established safe limits; - flame arresters used for explosive mixtures of vapours and gases, which tend to self-decompose (for example, acetylene) or which are chemically unstable; - flame arresters used for carbon disulfide, due to its special properties; - flame arresters whose intended use is for mixtures other than gas-air or vapour-air mixtures (for example, higher oxygen-nitrogen ratio, chlorine as oxidant); - flame arrester test procedures for reciprocating internal combustion engines; - fast acting valves, extinguishing systems and other explosion isolating systems; - Flame arresters used in gas detectors (those being covered for example, by IEC 60079‑29‑1 and IEC 62990‑1). This edition cancels and replaces ISO 16852:2016, which has been technically revised. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to ISO 16852:2016: a) adaptation of the relevant IEC TC 31 requirements on standards; b) modification of the upper limit of the temperature range from 150 °C to 200 °C under the condition that T0 shall be not larger than 80 % of the auto ignition temperature of the gas-air-mixture; c) change of the term "explosion group" to "equipment group" due to editorial requirements in IEC/TC 31; d) clarification of the conditions and requirements for flame arresters whose intended operating conditions are outside the atmospheric conditions in 7.3.4 and 7.3.5; e) clarification of the requirements on the information for use in Clause 12 f) concerning the burn time; f) addition of a permission to the construction requirements both in 7.1 and 14.1 to substitute visual inspection by performing a flow test; g) addition of a flow chart for the evaluation of test results as Annex D

Atmosphères explosives — Partie 49: Arrête flammes — Exigences de performance, méthodes d’essai et limites d’utilisation

ISO/IEC 80079-49:2024 spécifie les exigences applicables aux arrête-flammes qui empêchent la transmission d’une flamme lorsqu’un mélange explosible gaz-air ou vapeur-air est présent. Il établit des principes homogènes pour la classification, la construction de base et les informations pour l’utilisation, y compris le marquage des arrête-flammes, et spécifie des méthodes d’essai permettant de vérifier les exigences de sécurité et de déterminer les limites de sécurité d’utilisation. Le présent document s’applique pour des pressions comprises entre 80 kPa et 160 kPa et des températures comprises entre –20 °C et +200 °C. Le présent document ne s’applique pas aux cas suivants: – appareils externes de contrôle et de mesure qui peuvent être exigés pour le maintien des conditions opérationnelles dans les limites de sécurité établies; – arrête-flammes utilisés pour des mélanges explosibles de vapeurs et de gaz qui ont tendance à s’autodécomposer (par exemple l’acétylène) ou qui sont chimiquement instables; – arrête-flammes utilisés pour le disulfure de carbone, du fait de ses propriétés spécifiques; – arrête-flammes destinés à être utilisés pour des mélanges autres que des mélanges gaz air ou vapeur-air (par exemple avec un rapport oxygène-azote plus élevé, avec présence de chlore en tant qu’oxydant); – procédures d’essai d’arrête-flammes pour moteurs à pistons à combustion interne; – vannes à fermeture rapide, barrières d’extinction ou autres systèmes d’isolation d’explosion; – arrête-flammes utilisés dans les détecteurs de gaz (ceux qui sont couverts, par exemple par l’IEC 60079‑29‑1 et l’IEC 62990‑1). Cette deuxième édition annule et remplace l’ISO 16852:2016, qui a fait l’objet d’une révision technique. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’ISO 16852:2016: a) adaptation des exigences pertinentes du CE 31 de l’IEC relatives aux normes; b) modification de la limite supérieure du domaine de températures de 150 °C à 200 °C à condition que T0 ne soit pas supérieure à 80 % de la température d’auto-inflammation du mélange air-gaz; c) modification du terme "groupe d’explosion" en "groupe d’appareils" en raison des exigences rédactionnelles du CE 31 de l’IEC; d) clarification des conditions et des exigences relatives aux arrête-flammes dont les conditions d’utilisation prévues sont en dehors des conditions atmosphériques en 7.3.4 et 7.3.5; e) clarification des exigences relatives aux instructions d’utilisation à l’Article 12, f), concernant le temps de brûlage; f) ajout d’une autorisation aux exigences de construction en 7.1 et 14.1 pour remplacer l’examen visuel par la réalisation d’un essai d’écoulement; g) ajout d’une Annexe D qui fournit un organigramme pour l’évaluation des résultats d’essai. La présente version bilingue (2024-12) correspond à la version anglaise monolingue publiée en 2024-05. La version française de cette norme n'a pas été soumise au vote

General Information

- Status

- Published

- Publication Date

- 06-May-2024

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 6060 - International Standard published

- Start Date

- 07-May-2024

- Due Date

- 05-Jul-2023

- Completion Date

- 07-May-2024

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

Overview - ISO/IEC 80079-49:2024 (Flame arresters, performance & tests)

ISO/IEC 80079-49:2024 specifies performance requirements, test methods and limits for use of flame arresters intended to prevent flame transmission in explosive gas‑air or vapour‑air mixtures. The standard sets uniform principles for classification, basic construction, marking and information for use. It applies to pressures from 80 kPa to 160 kPa and temperatures from −20 °C to +200 °C (with T0 ≤ 80% of the mixture auto‑ignition temperature). This edition cancels ISO 16852:2016 and includes significant technical revisions and alignment with IEC TC 31 requirements.

Key topics and technical requirements

- Scope and exclusions: applies only to gas‑air and vapour‑air mixtures; excludes chemically unstable gases (e.g., acetylene), carbon disulfide, non‑air oxidants, gas detectors (covered by IEC 60079‑29‑1 / IEC 62990‑1), fast‑acting valves and some external control equipment.

- Classification: flame transmission categories covering deflagration, stable and unstable detonation, and stabilized burning behavior.

- Construction & marking: requirements for prototype and production units, housing, joints, pressure/leak testing, and mandatory user information and warning markings.

- Test methods: standardized tests including deflagration, detonation (stable/unstable), short‑time burning, endurance burning, and specific procedures for static, dynamic (high‑velocity vent valves), hydraulic and liquid product detonation arresters.

- Limits for use: clear criteria and annexed guidance for determining safe operating envelopes (Annex E), including pressure/temperature limits and burn ratings.

- New/clarified items (2024 edition): higher upper temperature limit (150 → 200 °C under defined condition), terminology change from “explosion group” to “equipment group”, allowance to substitute visual inspection with flow testing, and a flow chart for test result evaluation (Annex D).

Practical applications and users

ISO/IEC 80079-49 is essential for:

- Manufacturers of flame arresters and venting equipment to design and certify compliant products.

- Test laboratories and notified bodies performing conformity and safety verification.

- Plant safety & design engineers in petrochemical, refining, storage, process industries, and gas handling systems selecting or specifying flame arresters.

- Maintenance and inspection teams ensuring installed arresters remain within safe limits of use.

Benefits: improved safety against flame propagation, harmonized test methods, and clear marking/instruction requirements to support regulatory compliance and equipment selection.

Related standards

- ISO 16852:2016 (replaced)

- IEC/TC 31 publications (alignment)

- IEC 60079‑29‑1, IEC 62990‑1 (gas detector flame arrester considerations)

ISO/IEC 80079-49:2024 - Explosive atmospheres — Part 49: Flame arresters — Performance requirements, test methods and limits for use Released:7. 05. 2024

ISO/IEC 80079-49:2024 - Atmospheres explosives — Partie 49: Arrete flammes — Exigences de performance, méthodes d’essai et limites d’utilisation Released:12/6/2024

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO/IEC 80079-49:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Explosive atmospheres — Part 49: Flame arresters — Performance requirements, test methods and limits for use". This standard covers: This document specifies the requirements for flame arresters that prevent flame transmission when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for the classification, basic construction and information for use, including the marking of flame arresters, and specifies test methods to verify the safety requirements and determine safe limits of use. This document is applicable to pressures ranging from 80 kPa to 160 kPa and temperatures ranging from -20 °C to +200 °C. This document does not apply to the following: - external safety-related measurement and control equipment that might be required to keep the operational conditions within the established safe limits; - flame arresters used for explosive mixtures of vapours and gases, which tend to self-decompose (for example, acetylene) or which are chemically unstable; - flame arresters used for carbon disulfide, due to its special properties; - flame arresters whose intended use is for mixtures other than gas-air or vapour-air mixtures (for example, higher oxygen-nitrogen ratio, chlorine as oxidant); - flame arrester test procedures for reciprocating internal combustion engines; - fast acting valves, extinguishing systems and other explosion isolating systems; - Flame arresters used in gas detectors (those being covered for example, by IEC 60079‑29‑1 and IEC 62990‑1). This edition cancels and replaces ISO 16852:2016, which has been technically revised. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to ISO 16852:2016: a) adaptation of the relevant IEC TC 31 requirements on standards; b) modification of the upper limit of the temperature range from 150 °C to 200 °C under the condition that T0 shall be not larger than 80 % of the auto ignition temperature of the gas-air-mixture; c) change of the term "explosion group" to "equipment group" due to editorial requirements in IEC/TC 31; d) clarification of the conditions and requirements for flame arresters whose intended operating conditions are outside the atmospheric conditions in 7.3.4 and 7.3.5; e) clarification of the requirements on the information for use in Clause 12 f) concerning the burn time; f) addition of a permission to the construction requirements both in 7.1 and 14.1 to substitute visual inspection by performing a flow test; g) addition of a flow chart for the evaluation of test results as Annex D

This document specifies the requirements for flame arresters that prevent flame transmission when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for the classification, basic construction and information for use, including the marking of flame arresters, and specifies test methods to verify the safety requirements and determine safe limits of use. This document is applicable to pressures ranging from 80 kPa to 160 kPa and temperatures ranging from -20 °C to +200 °C. This document does not apply to the following: - external safety-related measurement and control equipment that might be required to keep the operational conditions within the established safe limits; - flame arresters used for explosive mixtures of vapours and gases, which tend to self-decompose (for example, acetylene) or which are chemically unstable; - flame arresters used for carbon disulfide, due to its special properties; - flame arresters whose intended use is for mixtures other than gas-air or vapour-air mixtures (for example, higher oxygen-nitrogen ratio, chlorine as oxidant); - flame arrester test procedures for reciprocating internal combustion engines; - fast acting valves, extinguishing systems and other explosion isolating systems; - Flame arresters used in gas detectors (those being covered for example, by IEC 60079‑29‑1 and IEC 62990‑1). This edition cancels and replaces ISO 16852:2016, which has been technically revised. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to ISO 16852:2016: a) adaptation of the relevant IEC TC 31 requirements on standards; b) modification of the upper limit of the temperature range from 150 °C to 200 °C under the condition that T0 shall be not larger than 80 % of the auto ignition temperature of the gas-air-mixture; c) change of the term "explosion group" to "equipment group" due to editorial requirements in IEC/TC 31; d) clarification of the conditions and requirements for flame arresters whose intended operating conditions are outside the atmospheric conditions in 7.3.4 and 7.3.5; e) clarification of the requirements on the information for use in Clause 12 f) concerning the burn time; f) addition of a permission to the construction requirements both in 7.1 and 14.1 to substitute visual inspection by performing a flow test; g) addition of a flow chart for the evaluation of test results as Annex D

ISO/IEC 80079-49:2024 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 80079-49:2024 has the following relationships with other standards: It is inter standard links to EN 14983:2024, EN ISO/IEC 80079-49:2024, ISO 16852:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 80079-49:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

ISO/IEC 80079-49

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

Explosive atmospheres –

Part 49: Flame arresters – Performance requirements, test methods and limits

for use

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about ISO/IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

ISO/IEC 80079-49

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

Explosive atmospheres –

Part 49: Flame arresters – Performance requirements, test methods and limits

for use

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.220.10 ISBN 978-2-8322-8716-3

– 2 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

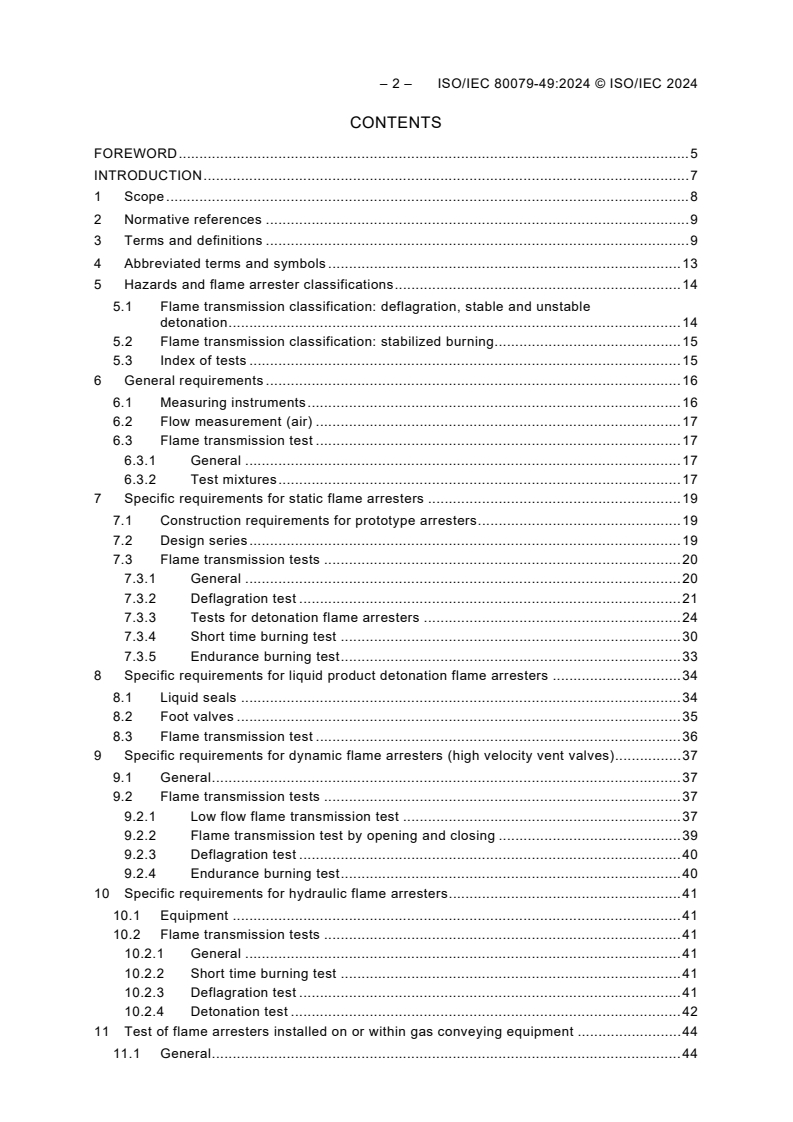

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 9

4 Abbreviated terms and symbols . 13

5 Hazards and flame arrester classifications . 14

5.1 Flame transmission classification: deflagration, stable and unstable

detonation . 14

5.2 Flame transmission classification: stabilized burning . 15

5.3 Index of tests . 15

6 General requirements . 16

6.1 Measuring instruments . 16

6.2 Flow measurement (air) . 17

6.3 Flame transmission test . 17

6.3.1 General . 17

6.3.2 Test mixtures . 17

7 Specific requirements for static flame arresters . 19

7.1 Construction requirements for prototype arresters . 19

7.2 Design series . 19

7.3 Flame transmission tests . 20

7.3.1 General . 20

7.3.2 Deflagration test . 21

7.3.3 Tests for detonation flame arresters . 24

7.3.4 Short time burning test . 30

7.3.5 Endurance burning test . 33

8 Specific requirements for liquid product detonation flame arresters . 34

8.1 Liquid seals . 34

8.2 Foot valves . 35

8.3 Flame transmission test . 36

9 Specific requirements for dynamic flame arresters (high velocity vent valves) . 37

9.1 General . 37

9.2 Flame transmission tests . 37

9.2.1 Low flow flame transmission test . 37

9.2.2 Flame transmission test by opening and closing . 39

9.2.3 Deflagration test . 40

9.2.4 Endurance burning test . 40

10 Specific requirements for hydraulic flame arresters . 41

10.1 Equipment . 41

10.2 Flame transmission tests . 41

10.2.1 General . 41

10.2.2 Short time burning test . 41

10.2.3 Deflagration test . 41

10.2.4 Detonation test . 42

11 Test of flame arresters installed on or within gas conveying equipment . 44

11.1 General . 44

11.2 Flame transmission tests . 44

11.2.1 General . 44

11.2.2 Test procedure for gas conveying equipment with inlet pressure

> 600 hPa . 46

11.2.3 Test procedure for gas conveying equipment with inlet pressure

≤ 600 hPa . 47

12 Instructions . 47

13 Marking . 48

13.1 Location . 48

13.2 Flame arrester housing . 49

13.2.1 General information . 49

13.2.2 Warning markings . 49

13.2.3 Examples of marking . 50

13.3 Flame arrester element . 51

14 Manufacturing and production . 51

14.1 Construction . 51

14.2 Housing . 51

14.3 Joints . 51

14.4 Pressure test . 51

14.5 Leak test . 52

Annex A (normative) Flow measurement . 53

A.1 General . 53

A.2 In-line flame arresters . 54

A.3 End-of-line flame arrester . 54

A.3.1 General . 54

A.3.2 Special flow measurement for dynamic flame arresters . 55

A.4 Undamped oscillation tests of dynamic flame arrester (High velocity vent

valves) . 56

Annex B (informative) Information for selecting flame arresters . 58

Annex C (informative) Recommended practice . 59

Annex D (informative) Evaluation of test results . 60

Annex E (normative) Application . 62

E.1 General . 62

E.2 Limits for use for static flame arresters . 63

E.2.1 In-line flame arrester . 63

E.2.2 Pre-volume flame arrester . 63

E.2.3 Detonation flame arrester . 63

E.2.4 Short time burn flame arrester . 63

E.3 Limits for use for liquid detonation flame arresters . 64

E.4 Limits for use for dynamic flame arresters (high velocity vent valves) . 64

E.5 Limits for use for hydraulic flame arresters . 64

Annex F (informative) Significant changes between this document and EN ISO

16852:2016 . 67

Bibliography . 69

Figure 1 – Test apparatus for end-of-line flame arrester for deflagration test . 21

Figure 2 – Test apparatus for in-line flame arrester for deflagration test . 22

Figure 3 – Test apparatus for pre-volume flame arrester for deflagration test . 24

– 4 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

Figure 4 – Test apparatus for detonation flame arrester for detonation without

restriction. 26

Figure 5 – Test apparatus for detonation flame arrester for detonation with restriction . 28

Figure 6 – Test apparatus for short time burning test . 31

Figure 7 – Test apparatus for endurance burning test . 33

Figure 8 – Liquid product detonation flame arrester . 35

Figure 9 – End-of-line flame arrester incorporating a non-return valve (foot valve) . 35

Figure 10 – Test apparatus for liquid product detonation flame arresters . 36

Figure 11 – Test apparatus for determining the non-hammering conditions for dynamic

flame arresters. 39

Figure 12 – Test apparatus for hydraulic flame arresters. 43

Figure 13 – Test apparatus for the flame transmission test of flame arresters installed

on or within gas conveying equipment . 45

Figure 14 – Example of marking plate, burn rating "a" . 50

Figure 15 – Example of marking plate, burn rating "b" . 50

Figure A.1 – Test apparatus for recording the pressure drop/flow rate curve for in-line

flame arresters. 54

Figure A.2 – Test apparatus for recording the pressure drop/flow rate curve for end-of-

line flame arresters with or without integrated pressure/vacuum valve . 56

Figure A.3 – Test apparatus for determining the non-oscillating conditions for dynamic

flame arresters. 57

Figure D.1 – Decision process for stable detonation arrester (DET3 and DET4) . 60

Figure D.2 – Decision process for unstable detonation arrester (DET1 and DET2) . 61

Figure E.1 – Test apparatus for hydraulic flame arresters . 66

Table 1 – Flame arrester classification for deflagration, stable and unstable detonation . 15

Table 2 – Summary of tests to be conducted . 16

Table 3 – Specification of gas-air mixtures for deflagration and detonation tests . 18

Table 4 – Specification of gas-air mixtures for short time burning tests and burning

tests of dynamic flame arresters . 18

Table 5 – Specification of gas-air or vapour-air mixtures for endurance burning tests of

static flame arresters . 19

Table 6 – Design series . 20

Table 7 – Ratio p /p . 27

md TB

Table 8 – Number of the individual tests and test parameters for the flame

transmission test of flame arresters installed on or within gas conveying equipment

with inlet pressures > 600 hPa . 46

Table 9 – Number of the individual tests and test parameters for the flame

transmission test of flame arresters installed on or within gas conveying equipment

with inlet pressures ≤ 600 hPa . 47

Table B.1 – Information for selecting flame arresters . 58

Table F.1 – Significant changes with respect to EN ISO 16852:2016 . 67

EXPLOSIVE ATMOSPHERES –

Part 49: Flame arresters –

Performance requirements, test methods and limits for use

FOREWORD

1) ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission)

form the specialized system for worldwide standardization. National bodies that are members of ISO or IEC

participate in the development of International Standards through technical committees established by the

respective organization to deal with particular fields of technical activity. ISO and IEC technical committees

collaborate in fields of mutual interest. Other international organizations, governmental and non-governmental,

in liaison with ISO and IEC, also take part in the work.

2) The formal decisions or agreements of IEC and ISO on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC and ISO National bodies.

3) IEC and ISO documents have the form of recommendations for international use and are accepted by IEC and

ISO National bodies in that sense. While all reasonable efforts are made to ensure that the technical content of

IEC and ISO documents is accurate, IEC and ISO cannot be held responsible for the way in which they are used

or for any misinterpretation by any end user.

4) In order to promote international uniformity, IEC and ISO National bodies undertake to apply IEC and ISO

documents transparently to the maximum extent possible in their national and regional publications. Any

divergence between any IEC and ISO document and the corresponding national or regional publication shall be

clearly indicated in the latter.

5) IEC and ISO do not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC and ISO marks of conformity. IEC and ISO are not

responsible for any services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this document.

7) No liability shall attach to IEC and ISO or their directors, employees, servants or agents including individual

experts and members of its technical committees and IEC and ISO National bodies for any personal injury,

property damage or other damage of any nature whatsoever, whether direct or indirect, or for costs (including

legal fees) and expenses arising out of the publication, use of, or reliance upon, this ISO/IEC document or any

other IEC and ISO documents.

8) Attention is drawn to the Normative references cited in this document. Use of the referenced publications is

indispensable for the correct application of this document.

9) IEC and ISO draw attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC and ISO take no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, IEC and ISO had not received notice of

(a) patent(s), which may be required to implement this document. However, implementers are cautioned that this

may not represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch and www.iso.org/patents. IEC and ISO shall not be held responsible for identifying any or

all such patent rights.

ISO/IEC 80079-49 has been prepared by subcommittee 31M: Non-electrical equipment and

protective systems for explosive atmospheres, of ISO/IEC joint technical committee 1:

Information technology.

This edition cancels and replaces ISO 16852:2016, which has been technically revised. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to

ISO 16852:2016:

a) adaptation of the relevant IEC TC 31 requirements on standards;

b) modification of the upper limit of the temperature range from 150 °C to 200 °C under the

condition that T shall be not larger than 80 % of the auto ignition temperature of the gas-

air-mixture;

c) change of the term "explosion group" to "equipment group" due to editorial requirements in

IEC/TC 31;

d) clarification of the conditions and requirements for flame arresters whose intended operating

conditions are outside the atmospheric conditions in 7.3.4 and 7.3.5;

– 6 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

e) clarification of the requirements on the information for use in Clause 12 f) concerning the

burn time;

f) addition of a permission to the construction requirements both in 7.1 and 14.1 to substitute

visual inspection by performing a flow test;

g) addition of a flow chart for the evaluation of test results as Annex D.

The text of this International Standard is based on the following documents:

Draft Report on voting

31M/212/FDIS 31M/223/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

A list of all parts in the ISO/IEC 80079 series, published under the general title Explosive

atmospheres, can be found on the IEC website.

NOTE The following print types are used:

• Words in italic font in the text are defined in Clause 3.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1, available at www.iec.ch/members_experts/refdocs

and www.iso.org/directives.

INTRODUCTION

Flame arresters are protective systems fitted to openings of enclosures or to pipe work and are

intended to allow fluid flow but prevent flame transmission if a flammable mixture is ignited.

They have widely been used for decades in the chemical and oil industry, and a variety of

national standards is available. This document was prepared with an aim to establish an

international basis by harmonizing and incorporating recent national developments and

standards as far as reasonable.

This document addresses performance requirements and test methods, as well as limits for use

for flame arresters.

Only the minimum safety requirements for flame arresters to prevent flame transmission are

specified.

The hazard identification of common applications found in industry leads to the specification of

the test methods. These test methods reflect standard practical situations and, as such, form

the heart of this document because they also allow classification of the various types of flame

arresters and then determination of the limits of use.

A considerable number of test methods and test conditions had to be taken into account for two

main reasons.

a) Different types of flame arresters are covered with respect to the operating principle (static,

hydraulic, liquid, dynamic) and each type clearly needs its specific test set-up and test

procedure.

b) It is necessary to adapt flame arresters to the special conditions of application (gas,

installation) because of the conflicting demands of high flame quenching capability and low

pressure loss. This situation is completely different from the otherwise similar principle of

protection by flameproof enclosure, for example for electrical equipment, where the

importance of process gas flow through any gaps is negligible and importance is placed on

the flame quenching effect of the gap.

Consequently, in this document, the testing and classification related to Equipment Groups and

installation conditions have been subdivided more than is usually the case in other parts of the

ISO/IEC 80079 and IEC 60079 series of standards. In particular,

– Equipment Group IIA is subdivided into sub-groups IIA1 and IIA,

– Equipment Group IIB is subdivided into sub-groups IIB1, IIB2, IIB3 and IIB, and

– the type "detonation arrester" is divided into four sub-types, which take into account specific

installation situations.

The test conditions lead to the limits for use which are most important for the user. This

document specifies this safety relevant information and its dissemination through the

manufacturer's written instructions for use and the marking of the flame arresters.

The limits for use are also a link to more general (operational) safety considerations and

regulations, which remain the responsibility the user and regulators. Annex B and Annex C offer

some guidance on these aspects.

– 8 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

EXPLOSIVE ATMOSPHERES –

Part 49: Flame arresters –

Performance requirements, test methods and limits for use

1 Scope

This document specifies the requirements for flame arresters that prevent flame transmission

when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for

the classification, basic construction and information for use, including the marking of flame

arresters, and specifies test methods to verify the safety requirements and determine safe limits

of use.

This document is applicable to pressures ranging from 80 kPa to 160 kPa and temperatures

ranging from −20 °C to +200 °C.

NOTE 1 For flame arresters with operational conditions inside the scope, but outside atmospheric conditions,

see Annex E.

NOTE 2 In designing and testing flame arresters for operation under conditions other than those specified above,

this document can be used as a guide. This document can also be used to design any additional testing related to

the specific conditions of use. This is particularly important when high temperatures and pressures are applied. The

test mixtures might need to be modified in these cases.

This document does not apply to the following:

– external safety-related measurement and control equipment that might be required to keep

the operational conditions within the established safe limits;

NOTE 3 Integrated measurement and control equipment, such as integrated temperature and flame sensors as

well as parts which, for example, intentionally melt (retaining pin), burn away (weather hoods) or bend (bimetallic

strips), are within the scope of this document.

– flame arresters used for explosive mixtures of vapours and gases, which tend to self-

decompose (for example, acetylene) or which are chemically unstable;

– flame arresters used for carbon disulfide, due to its special properties;

– flame arresters whose intended use is for mixtures other than gas-air or vapour-air mixtures

(for example, higher oxygen-nitrogen ratio, chlorine as oxidant);

– flame arrester test procedures for reciprocating internal combustion engines;

NOTE 4 Flame arresters for specific applications (e.g. reciprocating internal combustion engines) can use this

document as a guide for design but be subject to testing related to their specific use.

– fast acting valves, extinguishing systems and other explosion isolating systems;

– Flame arresters used in gas detectors (those being covered for example, by IEC 60079‑29‑1

and IEC 62990‑1).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-0, Explosive atmospheres – Part 0: Equipment – General requirements

IEC 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures

"d"

ISO/IEC 80079-34, Explosive atmospheres – Part 34: Application of quality management

systems for Ex Product manufacture

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60079-0 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

flame arrester

device fitted to the opening of an enclosure, or to the connecting pipe work of a system of

enclosures, and whose intended function is to allow flow but prevent the transmission of flame

3.2

housing

portion of a flame arrester (3.1) whose principal function is to provide a suitable enclosure for

the flame arrester element (3.3) and allow mechanical connections to other systems

3.3

flame arrester element

portion of a flame arrester (3.1) whose principal function is to prevent flame transmission

3.4

stabilized burning

steady burning of a flame stabilized at, or close to, the flame arrester element (3.3)

3.5

short time burning

stabilized burning (3.4) for a specified time

3.6

endurance burning

stabilized burning (3.4) for an unlimited time

– 10 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

3.7

explosion

abrupt oxidation or decomposition reaction producing an increase in temperature, pressure, or

both simultaneously

[SOURCE: ISO 8421-1:1987, 1.13]

3.8

deflagration

explosion (3.7) propagating at subsonic velocity

[SOURCE: ISO 8421-1:1987, 1.11]

3.9

detonation

explosion (3.7) propagating at supersonic velocity and characterized by a shock wave

[SOURCE: ISO 8421-1:1987, 1.12]

3.10

stable detonation

detonation (3.9) progressing through a confined system without significant variation of velocity

and pressure characteristics

Note 1 to entry: For the atmospheric conditions, test mixtures and test procedures of this document, typical

velocities range between 1 600 m/s and 2 200 m/s.

3.11

unstable detonation

detonation (3.9) during the transition of a combustion process from a deflagration (3.8) into a

stable detonation (3.10)

Note 1 to entry: The transition occurs in a limited spatial zone, where the velocity of the combustion wave is not

constant and where the explosion pressure is significantly higher than in a stable detonation. The position of this

transition zone depends, amongst other factors, on pipe diameter, pipe configuration, test gas and explosion group.

Note 2 to entry: An unstable detonation presents a higher level of hazard than a stable detonation due to higher

flame speeds and pressures.

3.12

characteristic safety data of explosive mixtures

3.12.1

maximum experimental safe gap

MESG

maximum gap of a joint of 25 mm in width which prevents any transmission of an explosion

during tests made under the conditions specified in ISO/IEC 80079-20-1

[SOURCE: ISO/IEC 80079-20-1:2017, 3.4, modified – "in ISO/IEC 80079-20-1" added and

Note 1 to entry deleted.]

3.12.2

safe gap

maximum gap of a joint of 25 mm in width which prevents any transmission of an explosion

during tests made under the conditions specified in ISO/IEC 80079-20-1 for the specified

vapour/gas mixture

3.12.3

equipment grouping

classification system of equipment related to the explosive atmosphere for which they are

intended to be used

Note 1 to entry: In a large part of the safety equipment industry "explosion group" is used as an alternative term.

[SOURCE: ISO/IEC 80079-20-1:2017, 3.7, modified – Note 1 to entry replaced.]

3.13

bi-directional flame arrester

flame arrester (3.1) that prevents flame transmission from both sides

3.14

deflagration flame arrester

DEF

flame arrester (3.1) designed to prevent the transmission of a deflagration (3.8)

Note 1 to entry: It can be an end-of-line flame arrester (3.21) or an in-line flame arrester (3.22).

3.15

detonation flame arrester

DET

flame arrester (3.1) designed to prevent the transmission of a detonation

Note 1 to entry: It can be an end-of-line flame arrester (3.21) or an in-line flame arrester (3.22), and can be used

for both stable detonations (3.10) and unstable detonations (3.11).

3.16

endurance flame arrester

flame arrester (3.1) that prevents flame transmission during and after endurance burning (3.6)

3.17

static flame arrester

flame arrester (3.1) designed to prevent flame transmission by quenching gaps

3.17.1

measurable type

flame arrester (3.1) where the quenching gaps of the flame arrester element (3.3) can be

technically drawn, measured and controlled

3.17.2

non-measurable type

flame arrester (3.1) where the quenching gaps of the flame arrester element (3.3) cannot be

technically drawn, measured or controlled

EXAMPLE Random structures such as knitted mesh, sintered materials and gravel beds.

3.18

dynamic flame arrester

high velocity vent valve

deflagration proof (see 3.14) pressure relief valve designed always to have efflux velocities that

prevent the flame propagation against the flow direction

Note 1 to entry: It can be endurance burn proof (see 3.16).

– 12 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

3.19

liquid product detonation flame arrester

flame arrester (3.1) in which the liquid product is used to form a liquid seal as a flame arrester

medium, in order to prevent flame transmission of a stable or unstable detonation without

restriction (type 4 or type 2)

Note 1 to entry: There are two types of liquid product detonation flame arrester for use in liquid product lines: liquid

seals and foot valves.

3.19.1

liquid seal flame arrester

flame arrester (3.1) designed to use the liquid product to form a barrier to flame transmission

3.19.2

foot valve flame arrester

flame arrester (3.1) designed to use the liquid product combined with a non-return valve to form

a barrier to flame transmission

3.20

hydraulic flame arrester

flame arrester (3.1) designed to break the flow of an explosive mixture into discrete bubbles in

a water column, thus preventing flame transmission

3.21

end-of-line flame arrester

flame arrester (3.1) that is fitted with one pipe connection only

3.22

in-line flame arrester

flame arrester (3.1) that is fitted with two pipe connections, one on each side of the flame

arrester

3.23

pre-volume flame arrester

VDEF

flame arrester (3.1) that, after ignition by an internal ignition source, prevents flame

transmission from inside an explosion-pressure-resistant containment (for example, a vessel or

closed pipe work) to the outside, or into the connecting pipe work

Note 1 to entry: Explosion-pressure resistance is a property of vessels and equipment designed to withstand the

expected explosion pressure without becoming permanently deformed.

3.24

integrated temperature sensor

temperature sensor integrated into the flame arrester, as specified by the manufacturer of the

flame arrester, in order to provide a signal suitable to activate counter measures

4 Abbreviated terms and symbols

A free area of a static flame arrester element

A nominal cross sectional area of the flame arrester connection

p

A cross sectional area on the unprotected side of the flame arrester element

t

A effective open area of the flame arrester element on the protected side

u

D pipe diameter

D minimum diameter of the pipe on the protected side of a dynamic flame arrester

M

L maximum length without undamped oscillations

M

L pipe length upstream of the dynamic flame arrester used in flame transmission test

m

L pipe length on the protected side

p

L pipe length between flame arrester and restriction

r

L pipe length on the unprotected side, maximum allowable run-up length for

u

installation

L , L ,

1 2

L , L

3 4 pipe lengths in the flow test

p time average value of the detonation pressure in the time interval of 200 μs after

md

arrival of the detonation shock wave

p maximum time average value of the transient pressure of an unstable detonation

mu

over a time interval of 200 μs

p pressure in the pressure test

t

p pressure in the flow test of an end-of-line flame arrester

T

p pressure before ignition

TB

p maximum operational pressure

Δ pressure drop in the flow test of an in-line flame arrester

p

p maximum pressure for the endurance burning test of dynamic flame arresters

E

p pressure which can cause the maximum temperature at endurance burning test

m

R ratio of the effective open area of the flame arrester element to pipe cross sectional

A

area

R ratio of the free volume of the flame arrester element to the whole volume

U

t burning time

BT

t time at which the peak pressure correlating to the leading shock front is achieved in

Ppeak

the test

T temperature of the flame arrester before ignition

TB

T maximum operational temperature of the flame arrester

v maximum flow velocity during the volume flow-pressure drop measurement (flow

max

test)

v minimum flow velocity during the volume flow-pressure drop measurement (flow test)

min

volume flow rate

V

critical volume flow rate

V

c

flow rate at closing point of dynamic flame arresters

V

CL

– 14 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

minimum volume flow rate for endurance burning on dynamic flame arresters

V

maximum volume flow rate for endurance burning on dynamic flame arresters

V

E

maximum volume flow rate for dynamic flame arresters at the set pressure

V

K

volume flow rate leading to maximum temperature

V

m

V

minimum volume in the protected tank

M

safe volume flow rate

V

max

safe volume flow rate including a safety margin

V

s

maximum volume flow rate leading to flame transmission

V

t

Z minimum water seal immersion depth at rest above the outlet openings of the

Rmin

immersion tubes

Z immersion depth at rest, corresponding to Z plus the manufacturer's

R Rmin

recommended safety margin

Z minimum operational water seal immersion depth when the mixture flow displaces

0min

the water from the immersion tubes, where Z > Z

0min Rmin

Z operational immersion depth, corresponding to Z plus the manufacturer's

0 0min

recommended safety margin

All pressure values are absolute pressures.

NOTE Symbols in the figures for the flame arrester are in line with ISO 14617-7.

5 Hazards and flame arrester classifications

5.1 Flame transmission classification: deflagration, stable and unstable detonation

The ignition of an explosive mixture will initiate a deflagration. A flame arrester covering only

this hazard is classified as a deflagration flame arrester.

NOTE 1 A deflagration when confined in a pipe will usually accelerate and can undergo transition through an

unstable to a stable detonation provided sufficient pipe length is available. This pipe length will vary depending upon

the initial conditions of the mixture and the pipe work configuration.

A flame arrester tested in accordance with 7.3.3.2 or 7.3.3.3 is classified as a stable detonation

flame arrester and is suitable for deflagrations and stable detonations.

NOTE 2 Unstable detonations are a specific hazard requiring higher performance flame arresters than for stable

detonations.

A flame arrester tested in accordance with 7.3.3.4 or 7.3.3.5 is classified as an unstable

detonation flame arrester and is suitable for deflagrations, stable detonations and unstable

detonations.

The specific hazards covered by this document, the classification and the testing required for

the appropriate flame arrester are listed in Table 1.

Table 1 – Flame arrester classification for deflagration, stable and unstable detonation

Application Flame arrester classification

a) unconfined deflagration into an enclosure or vessel end-of-line deflagration

b) confined deflagration propagating along a pipe into connecting pipe work in-line deflagration

c) deflagration confined by an enclosure or pipe work to the outside pre-volume deflagration

atmosphere or into connecting apparatus

d) stable detonation propagating along a pipe into connecting pipe work in-line stable detonation

e) unstable detonation propagating along a pipe into connecting pipe work in-line unstable detonation

f) stable detonation at the end of a pipe propagating into an enclosure or

end-of-line stable detonation

vessel

5.2 Flame transmission classification: stabilized burning

Stabilized burning after ignition creates additional hazards in applications where there could be

a continuous flow of the explosive mixture towards the unprotected side of the flame arrester.

The following situations shall be taken into account:

– if the flow of the explosive mixture can be stopped within a specific time that is between

1 min and 30 min, flame arresters which, when tested in accordance with 7.3.4, prevent

flame transmission during that period of stabilized burning are suitable for that hazard, and

they are classified as safe against short time burning;

NOTE Bypassing, sufficient diluting or inerting are measures equivalent to stopping the flow.

– if the flow of the explosive mixture cannot be stopped or, for operational reasons, is not

intended to be stopped within 30 min, flame arresters which, when tested in accordance

with 7.3.5, prevent flame transmission for this type of stabilized burning are suitable for that

hazard, and they are classified as safe

...

ISO/IEC 80079-49

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 49: Flame arresters – Performance requirements, test methods and limits

for use

Atmosphères explosives –

Partie 49: Arrête-flammes – Exigences de performance, méthodes d’essai et

limites d’utilisation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about ISO/IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'ISO/IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication,

utilisez les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications, symboles

La recherche avancée permet de trouver des publications IEC graphiques et le glossaire. Avec un abonnement, vous aurez

en utilisant différents critères (numéro de référence, texte, toujours accès à un contenu à jour adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 500 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 25 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

ISO/IEC 80079-49

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 49: Flame arresters – Performance requirements, test methods and limits

for use

Atmosphères explosives –

Partie 49: Arrête-flammes – Exigences de performance, méthodes d’essai et

limites d’utilisation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.220.10 ISBN 978-2-8327-0077-8

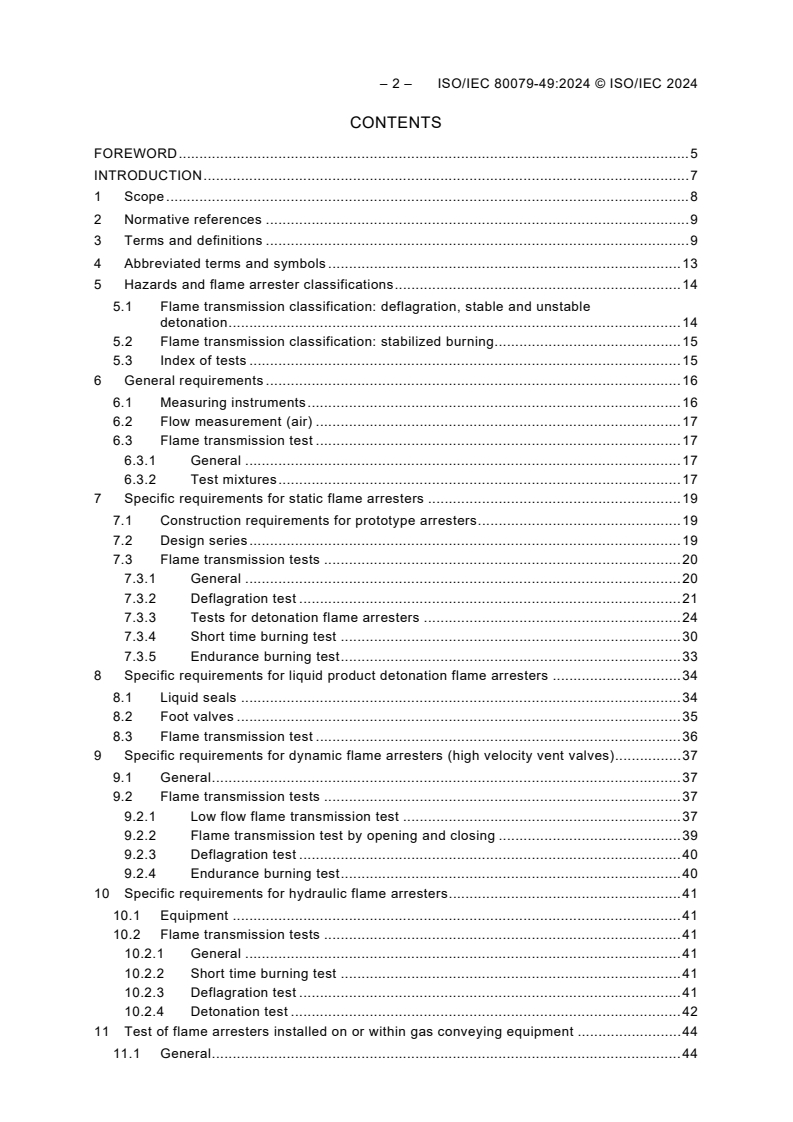

– 2 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 9

4 Abbreviated terms and symbols . 13

5 Hazards and flame arrester classifications . 14

5.1 Flame transmission classification: deflagration, stable and unstable

detonation . 14

5.2 Flame transmission classification: stabilized burning . 15

5.3 Index of tests . 15

6 General requirements . 16

6.1 Measuring instruments . 16

6.2 Flow measurement (air) . 17

6.3 Flame transmission test . 17

6.3.1 General . 17

6.3.2 Test mixtures . 17

7 Specific requirements for static flame arresters . 19

7.1 Construction requirements for prototype arresters . 19

7.2 Design series . 19

7.3 Flame transmission tests . 20

7.3.1 General . 20

7.3.2 Deflagration test . 21

7.3.3 Tests for detonation flame arresters . 24

7.3.4 Short time burning test . 30

7.3.5 Endurance burning test . 33

8 Specific requirements for liquid product detonation flame arresters . 34

8.1 Liquid seals . 34

8.2 Foot valves . 35

8.3 Flame transmission test . 36

9 Specific requirements for dynamic flame arresters (high velocity vent valves) . 37

9.1 General . 37

9.2 Flame transmission tests . 37

9.2.1 Low flow flame transmission test . 37

9.2.2 Flame transmission test by opening and closing . 39

9.2.3 Deflagration test . 40

9.2.4 Endurance burning test . 40

10 Specific requirements for hydraulic flame arresters . 41

10.1 Equipment . 41

10.2 Flame transmission tests . 41

10.2.1 General . 41

10.2.2 Short time burning test . 41

10.2.3 Deflagration test . 41

10.2.4 Detonation test . 42

11 Test of flame arresters installed on or within gas conveying equipment . 44

11.1 General . 44

11.2 Flame transmission tests . 44

11.2.1 General . 44

11.2.2 Test procedure for gas conveying equipment with inlet pressure

> 600 hPa . 46

11.2.3 Test procedure for gas conveying equipment with inlet pressure

≤ 600 hPa . 47

12 Instructions . 47

13 Marking . 48

13.1 Location . 48

13.2 Flame arrester housing . 49

13.2.1 General information . 49

13.2.2 Warning markings . 49

13.2.3 Examples of marking . 50

13.3 Flame arrester element . 51

14 Manufacturing and production . 51

14.1 Construction . 51

14.2 Housing . 51

14.3 Joints . 51

14.4 Pressure test . 51

14.5 Leak test . 52

Annex A (normative) Flow measurement . 53

A.1 General . 53

A.2 In-line flame arresters . 54

A.3 End-of-line flame arrester . 54

A.3.1 General . 54

A.3.2 Special flow measurement for dynamic flame arresters . 55

A.4 Undamped oscillation tests of dynamic flame arrester (High velocity vent

valves) . 56

Annex B (informative) Information for selecting flame arresters . 58

Annex C (informative) Recommended practice . 59

Annex D (informative) Evaluation of test results . 60

Annex E (normative) Application . 62

E.1 General . 62

E.2 Limits for use for static flame arresters . 63

E.2.1 In-line flame arrester . 63

E.2.2 Pre-volume flame arrester . 63

E.2.3 Detonation flame arrester . 63

E.2.4 Short time burn flame arrester . 63

E.3 Limits for use for liquid detonation flame arresters . 64

E.4 Limits for use for dynamic flame arresters (high velocity vent valves) . 64

E.5 Limits for use for hydraulic flame arresters . 64

Annex F (informative) Significant changes between this document and EN ISO

16852:2016 . 67

Bibliography . 69

Figure 1 – Test apparatus for end-of-line flame arrester for deflagration test . 21

Figure 2 – Test apparatus for in-line flame arrester for deflagration test . 22

Figure 3 – Test apparatus for pre-volume flame arrester for deflagration test . 24

– 4 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

Figure 4 – Test apparatus for detonation flame arrester for detonation without

restriction. 26

Figure 5 – Test apparatus for detonation flame arrester for detonation with restriction . 28

Figure 6 – Test apparatus for short time burning test . 31

Figure 7 – Test apparatus for endurance burning test . 33

Figure 8 – Liquid product detonation flame arrester . 35

Figure 9 – End-of-line flame arrester incorporating a non-return valve (foot valve) . 35

Figure 10 – Test apparatus for liquid product detonation flame arresters . 36

Figure 11 – Test apparatus for determining the non-hammering conditions for dynamic

flame arresters. 39

Figure 12 – Test apparatus for hydraulic flame arresters. 43

Figure 13 – Test apparatus for the flame transmission test of flame arresters installed

on or within gas conveying equipment . 45

Figure 14 – Example of marking plate, burn rating "a" . 50

Figure 15 – Example of marking plate, burn rating "b" . 50

Figure A.1 – Test apparatus for recording the pressure drop/flow rate curve for in-line

flame arresters. 54

Figure A.2 – Test apparatus for recording the pressure drop/flow rate curve for end-of-

line flame arresters with or without integrated pressure/vacuum valve . 56

Figure A.3 – Test apparatus for determining the non-oscillating conditions for dynamic

flame arresters. 57

Figure D.1 – Decision process for stable detonation arrester (DET3 and DET4) . 60

Figure D.2 – Decision process for unstable detonation arrester (DET1 and DET2) . 61

Figure E.1 – Test apparatus for hydraulic flame arresters . 66

Table 1 – Flame arrester classification for deflagration, stable and unstable detonation . 15

Table 2 – Summary of tests to be conducted . 16

Table 3 – Specification of gas-air mixtures for deflagration and detonation tests . 18

Table 4 – Specification of gas-air mixtures for short time burning tests and burning

tests of dynamic flame arresters . 18

Table 5 – Specification of gas-air or vapour-air mixtures for endurance burning tests of

static flame arresters . 19

Table 6 – Design series . 20

Table 7 – Ratio p /p . 27

md TB

Table 8 – Number of the individual tests and test parameters for the flame

transmission test of flame arresters installed on or within gas conveying equipment

with inlet pressures > 600 hPa . 46

Table 9 – Number of the individual tests and test parameters for the flame

transmission test of flame arresters installed on or within gas conveying equipment

with inlet pressures ≤ 600 hPa . 47

Table B.1 – Information for selecting flame arresters . 58

Table F.1 – Significant changes with respect to EN ISO 16852:2016 . 67

EXPLOSIVE ATMOSPHERES –

Part 49: Flame arresters –

Performance requirements, test methods and limits for use

FOREWORD

1) ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission)

form the specialized system for worldwide standardization. National bodies that are members of ISO or IEC

participate in the development of International Standards through technical committees established by the

respective organization to deal with particular fields of technical activity. ISO and IEC technical committees

collaborate in fields of mutual interest. Other international organizations, governmental and non-governmental,

in liaison with ISO and IEC, also take part in the work.

2) The formal decisions or agreements of IEC and ISO on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC and ISO National bodies.

3) IEC and ISO documents have the form of recommendations for international use and are accepted by IEC and

ISO National bodies in that sense. While all reasonable efforts are made to ensure that the technical content of

IEC and ISO documents is accurate, IEC and ISO cannot be held responsible for the way in which they are used

or for any misinterpretation by any end user.

4) In order to promote international uniformity, IEC and ISO National bodies undertake to apply IEC and ISO

documents transparently to the maximum extent possible in their national and regional publications. Any

divergence between any IEC and ISO document and the corresponding national or regional publication shall be

clearly indicated in the latter.

5) IEC and ISO do not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC and ISO marks of conformity. IEC and ISO are not

responsible for any services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this document.

7) No liability shall attach to IEC and ISO or their directors, employees, servants or agents including individual

experts and members of its technical committees and IEC and ISO National bodies for any personal injury,

property damage or other damage of any nature whatsoever, whether direct or indirect, or for costs (including

legal fees) and expenses arising out of the publication, use of, or reliance upon, this ISO/IEC document or any

other IEC and ISO documents.

8) Attention is drawn to the Normative references cited in this document. Use of the referenced publications is

indispensable for the correct application of this document.

9) IEC and ISO draw attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC and ISO take no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, IEC and ISO had not received notice of

(a) patent(s), which may be required to implement this document. However, implementers are cautioned that this

may not represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch and www.iso.org/patents. IEC and ISO shall not be held responsible for identifying any or

all such patent rights.

ISO/IEC 80079-49 has been prepared by subcommittee 31M: Non-electrical equipment and

protective systems for explosive atmospheres, of ISO/IEC joint technical committee 1:

Information technology.

This edition cancels and replaces ISO 16852:2016, which has been technically revised. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to

ISO 16852:2016:

a) adaptation of the relevant IEC TC 31 requirements on standards;

b) modification of the upper limit of the temperature range from 150 °C to 200 °C under the

condition that T shall be not larger than 80 % of the auto ignition temperature of the gas-

air-mixture;

c) change of the term "explosion group" to "equipment group" due to editorial requirements in

IEC/TC 31;

d) clarification of the conditions and requirements for flame arresters whose intended operating

conditions are outside the atmospheric conditions in 7.3.4 and 7.3.5;

– 6 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

e) clarification of the requirements on the information for use in Clause 12 f) concerning the

burn time;

f) addition of a permission to the construction requirements both in 7.1 and 14.1 to substitute

visual inspection by performing a flow test;

g) addition of a flow chart for the evaluation of test results as Annex D.

The text of this International Standard is based on the following documents:

Draft Report on voting

31M/212/FDIS 31M/223/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

A list of all parts in the ISO/IEC 80079 series, published under the general title Explosive

atmospheres, can be found on the IEC website.

NOTE The following print types are used:

• Words in italic font in the text are defined in Clause 3.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1, available at www.iec.ch/members_experts/refdocs

and www.iso.org/directives.

INTRODUCTION

Flame arresters are protective systems fitted to openings of enclosures or to pipe work and are

intended to allow fluid flow but prevent flame transmission if a flammable mixture is ignited.

They have widely been used for decades in the chemical and oil industry, and a variety of

national standards is available. This document was prepared with an aim to establish an

international basis by harmonizing and incorporating recent national developments and

standards as far as reasonable.

This document addresses performance requirements and test methods, as well as limits for use

for flame arresters.

Only the minimum safety requirements for flame arresters to prevent flame transmission are

specified.

The hazard identification of common applications found in industry leads to the specification of

the test methods. These test methods reflect standard practical situations and, as such, form

the heart of this document because they also allow classification of the various types of flame

arresters and then determination of the limits of use.

A considerable number of test methods and test conditions had to be taken into account for two

main reasons.

a) Different types of flame arresters are covered with respect to the operating principle (static,

hydraulic, liquid, dynamic) and each type clearly needs its specific test set-up and test

procedure.

b) It is necessary to adapt flame arresters to the special conditions of application (gas,

installation) because of the conflicting demands of high flame quenching capability and low

pressure loss. This situation is completely different from the otherwise similar principle of

protection by flameproof enclosure, for example for electrical equipment, where the

importance of process gas flow through any gaps is negligible and importance is placed on

the flame quenching effect of the gap.

Consequently, in this document, the testing and classification related to Equipment Groups and

installation conditions have been subdivided more than is usually the case in other parts of the

ISO/IEC 80079 and IEC 60079 series of standards. In particular,

– Equipment Group IIA is subdivided into sub-groups IIA1 and IIA,

– Equipment Group IIB is subdivided into sub-groups IIB1, IIB2, IIB3 and IIB, and

– the type "detonation arrester" is divided into four sub-types, which take into account specific

installation situations.

The test conditions lead to the limits for use which are most important for the user. This

document specifies this safety relevant information and its dissemination through the

manufacturer's written instructions for use and the marking of the flame arresters.

The limits for use are also a link to more general (operational) safety considerations and

regulations, which remain the responsibility the user and regulators. Annex B and Annex C offer

some guidance on these aspects.

– 8 – ISO/IEC 80079-49:2024 © ISO/IEC 2024

EXPLOSIVE ATMOSPHERES –

Part 49: Flame arresters –

Performance requirements, test methods and limits for use

1 Scope

This document specifies the requirements for flame arresters that prevent flame transmission

when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for

the classification, basic construction and information for use, including the marking of flame

arresters, and specifies test methods to verify the safety requirements and determine safe limits

of use.

This document is applicable to pressures ranging from 80 kPa to 160 kPa and temperatures

ranging from −20 °C to +200 °C.

NOTE 1 For flame arresters with operational conditions inside the scope, but outside atmospheric conditions,

see Annex E.

NOTE 2 In designing and testing flame arresters for operation under conditions other than those specified above,

this document can be used as a guide. This document can also be used to design any additional testing related to

the specific conditions of use. This is particularly important when high temperatures and pressures are applied. The

test mixtures might need to be modified in these cases.

This document does not apply to the following:

– external safety-related measurement and control equipment that might be required to keep

the operational conditions within the established safe limits;

NOTE 3 Integrated measurement and control equipment, such as integrated temperature and flame sensors as

well as parts which, for example, intentionally melt (retaining pin), burn away (weather hoods) or bend (bimetallic

strips), are within the scope of this document.

– flame arresters used for explosive mixtures of vapours and gases, which tend to self-

decompose (for example, acetylene) or which are chemically unstable;

– flame arresters used for carbon disulfide, due to its special properties;

– flame arresters whose intended use is for mixtures other than gas-air or vapour-air mixtures

(for example, higher oxygen-nitrogen ratio, chlorine as oxidant);

– flame arrester test procedures for reciprocating internal combustion engines;

NOTE 4 Flame arresters for specific applications (e.g. reciprocating internal combustion engines) can use this

document as a guide for design but be subject to testing related to their specific use.

– fast acting valves, extinguishing systems and other explosion isolating systems;

– Flame arresters used in gas detectors (those being covered for example, by IEC 60079‑29‑1

and IEC 62990‑1).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-0, Explosive atmospheres – Part 0: Equipment – General requirements

IEC 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures

"d"

ISO/IEC 80079-34, Explosive atmospheres – Part 34: Application of quality management

systems for Ex Product manufacture

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60079-0 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

flame arrester

device fitted to the opening of an enclosure, or to the connecting pipe work of a system of

enclosures, and whose intended function is to allow flow but prevent the transmission of flame

3.2

housing

portion of a flame arrester (3.1) whose principal function is to provide a suitable enclosure for

the flame arrester element (3.3) and allow mechanical connections to other systems

3.3

flame arrester element

portion of a flame arrester (3.1) whose principal function is to prevent flame transmission

3.4

stabilized burning