ISO/IEC Guide 77-3:2008

(Main)Guide for specification of product properties and classes — Part 3: Experience gained

Guide for specification of product properties and classes — Part 3: Experience gained

ISO/IEC Guide 77-3:2008 provides general advice and guidance for the description of products and their characteristics by the use of ISO 13584 and IEC 61360 for the creation of computer processable product libraries, catalogues and reference dictionaries. This description will provide the details of the products and their properties in an unambiguous manner, capable of computer communication in a form that is independent of any proprietary application software. The term “product” is taken to include devices, processes, systems, installations, etc. ISO/IEC Guide 77-3:2008 is intended to assist in the objective of enabling the flow of technical information between internal and external business partners in a cost effective and timely manner. The guidance in ISO/IEC Guide 77-3:2008 is intended to assist the following groups: convenors and members of ISO technical committees; technical experts contributing their knowledge to the development of reference dictionaries, data bases and product libraries; information experts responsible for the generation of applications of ISO 13584, particularly related to standardized reference dictionaries; managers and technical experts in the manufacturing industry. ISO/IEC Guide 77-3:2008 is intended to provide practical information of the experience gained in the creation of product reference dictionaries within ISO and IEC. ISO/IEC Guide 77-3:2008 is intended for information only, in areas such as education. The following are within the scope of ISO/IEC Guide 77-3:2008: experience of developing a reference dictionary for cutting tools; experience of developing a reference dictionary for electronic components; experience of creating a system for the maintenance of a reference dictionary for measuring instruments; experience of developing a reference dictionary for fasteners. The following are outside the scope of ISO/IEC Guide 77-3:2008: an overview for ISO technical committees and industrial managers for the development of computer-processable product libraries, reference dictionaries and catalogues; technical guidance for the creation of product libraries and dictionaries.

Guide pour la spécification des classes et des propriétés du produit — Partie 3: Expérience acquise

General Information

- Status

- Published

- Publication Date

- 26-Feb-2008

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 18-Mar-2022

- Completion Date

- 14-Feb-2026

Overview

ISO/IEC Guide 77-3:2008 - Guide for specification of product properties and classes, Part 3: Experience gained documents practical experience from ISO and IEC projects that used the common ISO 13584 / IEC 61360 information model to build computer-processable product libraries, catalogues and reference dictionaries. Rather than prescribing technical rules, this part collects lessons learned from real projects (cutting tools, electronic components, measuring instruments, fasteners) to help teams plan, build and maintain unambiguous, software‑independent product descriptions.

Key topics

- Experience reports from reference-dictionary projects (ISO 13399, IEC 61360, ISO 13584-501, ISO 13584-511).

- Use of ISO 13584 / IEC 61360 data model for property and class specification (PLIB model references).

- Project setup and team roles: scope definition, project teams, liaisons, and governance.

- Information modelling and classification strategies, including property specification and visible properties.

- Tools, supporting software and publication practices for dictionary creation and maintenance.

- Maintenance and registration procedures, including planned maintenance, publication workflows and unique identification.

- Lessons learned and conclusions on effort, modelling issues, training needs, and practical maintenance/use.

Note: ISO/IEC Guide 77-3 is informational. It reports on what worked and what did not; it does not replace the technical guidance provided in Guide 77-2.

Applications

ISO/IEC Guide 77-3 is valuable when you need to:

- Create or evaluate computer-processable product libraries, catalogues and reference dictionaries that are interoperable across systems.

- Understand practical implications of applying ISO 13584 and IEC 61360 for product metadata and classification.

- Plan resource needs, team structure and tooling for a standards-based dictionary project.

- Learn best practices for maintenance, publication and unique identification of dictionary entries.

Typical use cases: manufacturing data exchange, CAD/CAM parts libraries, component catalogues, procurement data, PLM integration, and semantic interoperability projects.

Who should use this standard

- Convenors and members of ISO/IEC technical committees

- Technical experts building reference dictionaries and product libraries

- Information architects and data managers implementing ISO 13584 / IEC 61360-based systems

- Managers and technical leads in manufacturing, instrumentation and electronics sectors

Related standards

- ISO 13584 (PLIB / parts library standards)

- IEC 61360 (electrotechnical component dictionary)

- ISO/IEC Guide 77-1 (Fundamental benefits) and Guide 77-2 (Technical principles and guidance)

- ISO 13399, ISO 13584-501, ISO 13584-511 (examples covered in Guide 77-3)

Keywords: product properties, reference dictionary, ISO 13584, IEC 61360, PLIB, product libraries, product classification, metadata, catalogues, maintenance.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

ISO/IEC Guide 77-3:2008 is a guide published by the International Organization for Standardization (ISO). Its full title is "Guide for specification of product properties and classes — Part 3: Experience gained". This standard covers: ISO/IEC Guide 77-3:2008 provides general advice and guidance for the description of products and their characteristics by the use of ISO 13584 and IEC 61360 for the creation of computer processable product libraries, catalogues and reference dictionaries. This description will provide the details of the products and their properties in an unambiguous manner, capable of computer communication in a form that is independent of any proprietary application software. The term “product” is taken to include devices, processes, systems, installations, etc. ISO/IEC Guide 77-3:2008 is intended to assist in the objective of enabling the flow of technical information between internal and external business partners in a cost effective and timely manner. The guidance in ISO/IEC Guide 77-3:2008 is intended to assist the following groups: convenors and members of ISO technical committees; technical experts contributing their knowledge to the development of reference dictionaries, data bases and product libraries; information experts responsible for the generation of applications of ISO 13584, particularly related to standardized reference dictionaries; managers and technical experts in the manufacturing industry. ISO/IEC Guide 77-3:2008 is intended to provide practical information of the experience gained in the creation of product reference dictionaries within ISO and IEC. ISO/IEC Guide 77-3:2008 is intended for information only, in areas such as education. The following are within the scope of ISO/IEC Guide 77-3:2008: experience of developing a reference dictionary for cutting tools; experience of developing a reference dictionary for electronic components; experience of creating a system for the maintenance of a reference dictionary for measuring instruments; experience of developing a reference dictionary for fasteners. The following are outside the scope of ISO/IEC Guide 77-3:2008: an overview for ISO technical committees and industrial managers for the development of computer-processable product libraries, reference dictionaries and catalogues; technical guidance for the creation of product libraries and dictionaries.

ISO/IEC Guide 77-3:2008 provides general advice and guidance for the description of products and their characteristics by the use of ISO 13584 and IEC 61360 for the creation of computer processable product libraries, catalogues and reference dictionaries. This description will provide the details of the products and their properties in an unambiguous manner, capable of computer communication in a form that is independent of any proprietary application software. The term “product” is taken to include devices, processes, systems, installations, etc. ISO/IEC Guide 77-3:2008 is intended to assist in the objective of enabling the flow of technical information between internal and external business partners in a cost effective and timely manner. The guidance in ISO/IEC Guide 77-3:2008 is intended to assist the following groups: convenors and members of ISO technical committees; technical experts contributing their knowledge to the development of reference dictionaries, data bases and product libraries; information experts responsible for the generation of applications of ISO 13584, particularly related to standardized reference dictionaries; managers and technical experts in the manufacturing industry. ISO/IEC Guide 77-3:2008 is intended to provide practical information of the experience gained in the creation of product reference dictionaries within ISO and IEC. ISO/IEC Guide 77-3:2008 is intended for information only, in areas such as education. The following are within the scope of ISO/IEC Guide 77-3:2008: experience of developing a reference dictionary for cutting tools; experience of developing a reference dictionary for electronic components; experience of creating a system for the maintenance of a reference dictionary for measuring instruments; experience of developing a reference dictionary for fasteners. The following are outside the scope of ISO/IEC Guide 77-3:2008: an overview for ISO technical committees and industrial managers for the development of computer-processable product libraries, reference dictionaries and catalogues; technical guidance for the creation of product libraries and dictionaries.

ISO/IEC Guide 77-3:2008 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.240.50 - IT applications in industry. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC Guide 77-3:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

GUIDE 77-3

Guide for specification

of product properties

and classes —

Part 3:

Experience gained

First edition 2008

©

ISO/IEC 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2008 – All rights reserved

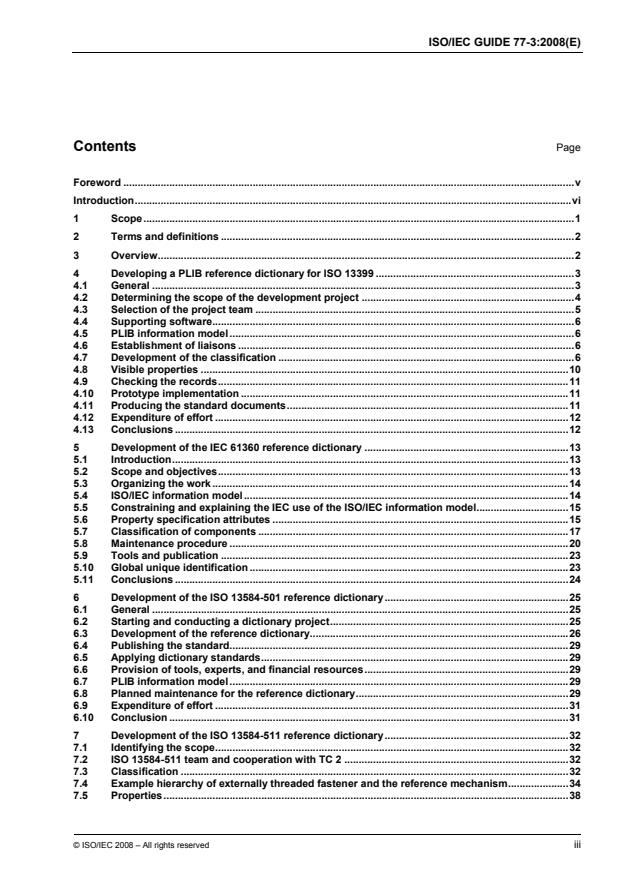

Contents Page

Foreword .v

Introduction.vi

1 Scope.1

2 Terms and definitions .2

3 Overview.2

4 Developing a PLIB reference dictionary for ISO 13399 .3

4.1 General .3

4.2 Determining the scope of the development project .4

4.3 Selection of the project team .5

4.4 Supporting software.6

4.5 PLIB information model.6

4.6 Establishment of liaisons .6

4.7 Development of the classification .6

4.8 Visible properties .10

4.9 Checking the records.11

4.10 Prototype implementation .11

4.11 Producing the standard documents.11

4.12 Expenditure of effort .12

4.13 Conclusions .12

5 Development of the IEC 61360 reference dictionary .13

5.1 Introduction.13

5.2 Scope and objectives.13

5.3 Organizing the work.14

5.4 ISO/IEC information model.14

5.5 Constraining and explaining the IEC use of the ISO/IEC information model.15

5.6 Property specification attributes .15

5.7 Classification of components .17

5.8 Maintenance procedure .20

5.9 Tools and publication .23

5.10 Global unique identification .23

5.11 Conclusions .24

6 Development of the ISO 13584-501 reference dictionary.25

6.1 General .25

6.2 Starting and conducting a dictionary project.25

6.3 Development of the reference dictionary.26

6.4 Publishing the standard.29

6.5 Applying dictionary standards.29

6.6 Provision of tools, experts, and financial resources.29

6.7 PLIB information model.29

6.8 Planned maintenance for the reference dictionary.29

6.9 Expenditure of effort .31

6.10 Conclusion .31

7 Development of the ISO 13584-511 reference dictionary.32

7.1 Identifying the scope.32

7.2 ISO 13584-511 team and cooperation with TC 2 .32

7.3 Classification .32

7.4 Example hierarchy of externally threaded fastener and the reference mechanism.34

7.5 Properties.38

© ISO/IEC 2008 – All rights reserved iii

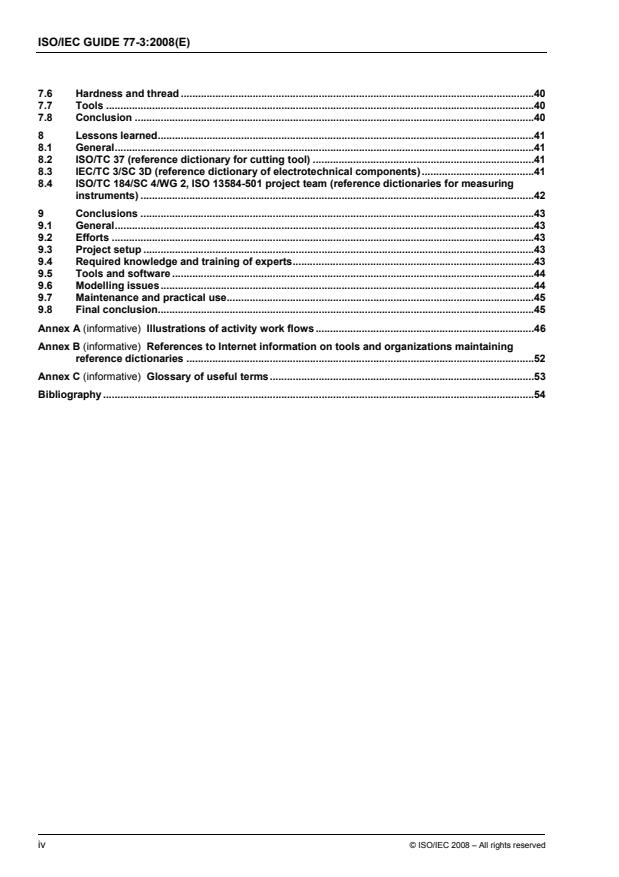

7.6 Hardness and thread .40

7.7 Tools .40

7.8 Conclusion .40

8 Lessons learned.41

8.1 General.41

8.2 ISO/TC 37 (reference dictionary for cutting tool) .41

8.3 IEC/TC 3/SC 3D (reference dictionary of electrotechnical components).41

8.4 ISO/TC 184/SC 4/WG 2, ISO 13584-501 project team (reference dictionaries for measuring

instruments) .42

9 Conclusions .43

9.1 General.43

9.2 Efforts .43

9.3 Project setup .43

9.4 Required knowledge and training of experts.43

9.5 Tools and software .44

9.6 Modelling issues.44

9.7 Maintenance and practical use.45

9.8 Final conclusion.45

Annex A (informative) Illustrations of activity work flows .46

Annex B (informative) References to Internet information on tools and organizations maintaining

reference dictionaries .52

Annex C (informative) Glossary of useful terms.53

Bibliography .54

iv © ISO/IEC 2008 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

Draft Guides adopted by the responsible Committee or Group are circulated to the member bodies for voting.

Publication as a Guide requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/IEC Guide 77-3 was prepared by the Joint Technical Advisory Group of the ISO Technical Management

Board and the IEC Standardization Management Board on product properties and families.

ISO/IEC Guide 77 consists of the following parts, under the general title Guide for specification of product

properties and classes:

⎯ Part 1: Fundamental benefits

⎯ Part 2: Technical principles and guidance

⎯ Part 3: Experience gained

© ISO/IEC 2008 – All rights reserved v

Introduction

This part of ISO/IEC Guide 77 contains a number of experience reports about the development of reference

dictionaries. It contains examples from ISO/TC 29 (on cutting tools), ISO/TC 184/SC 4 (on instrumentation

and fasteners), and IEC/SC 3D (on the IEC reference dictionary).

The common ISO 13584/IEC 61360 dictionary model (2.1) and the methodology as described in

ISO/IEC Guide 77-1 and ISO/IEC Guide 77-2 have been used and are being used as the basis for the

development of reference dictionaries. To support future developers of reference dictionaries, this part of

ISO/IEC Guide 77 describes the experiences gained in some projects over the last few years. The

experiences reported are based on work from different standardization committees. The aim of this part of

ISO/IEC Guide 77 is to give practical information, such as the following:

a) Which kind of procedures have been adopted for the creation of the different reference dictionaries?

b) What basic decisions have been taken in the creation process?

c) How much effort has been spent on these projects?

d) How have the resources of the common ISO/IEC data model been used?

e) How will the reference dictionaries be maintained?

The following International Standards are used as examples:

⎯ ISO 13399, a reference dictionary for cutting tools developed by ISO/TC 29/WG 34;

⎯ IEC 61360, the reference dictionary of components within the electrotechnical domain developed by

IEC/SC 3D;

⎯ ISO 13584-501, an initial reference dictionary content of laboratory and environment measuring

instruments to be registered into ISO 13584-501RA (Registration Authority), developed by

ISO/TC 184/SC 4/WG 2;

⎯ ISO 13584-511, a reference dictionary of fasteners developed by ISO/TC 184/SC 4/WG 2 with support

from ISO/TC 2.

The examples provided contain a variety of different approaches, based on different starting points and goals.

Due to these different approaches, the clauses in this part of ISO/IEC Guide 77 describing each of the

individual projects are not structured in the same way. Rather than following a uniform structure, they

emphasize those aspects which were important for their specific development process. To give an initial

overview, key points and common and differentiating aspects have been summarized in Clause 3. Clauses 4

to 7 contain the detailed reports about the development projects.

NOTE In the context of this part of ISO/IEC Guide 77, the term “reference dictionary” is used to refer to the data

dictionaries that have been built in the above-mentioned technical standardization committees on the basis of the data

model defined in ISO 13584 and IEC 61360. In other communities (e.g. in the semantic Web world), such a reference

dictionary would be seen as a special case of an ontology.

vi © ISO/IEC 2008 – All rights reserved

Guide for specification of product properties and classes —

Part 3:

Experience gained

1 Scope

This part of ISO/IEC Guide 77 provides general advice and guidance for the description of products and their

characteristics by the use of ISO 13584 and IEC 61360 for the creation of computer processable product

libraries, catalogues and reference dictionaries. This description will provide the details of the products and

their properties in an unambiguous manner, capable of computer communication in a form that is independent

of any proprietary application software. The term “product” is taken to include devices, processes, systems,

installations, etc. This part of ISO/IEC Guide 77 is intended to assist in the objective of enabling the flow of

technical information between internal and external business partners in a cost effective and timely manner.

The guidance in this part of ISO/IEC Guide 77 is intended to assist the following groups:

⎯ convenors and members of ISO technical committees;

⎯ technical experts contributing their knowledge to the development of reference dictionaries, data bases

and product libraries;

⎯ information experts responsible for the generation of applications of ISO 13584, particularly related to

standardized reference dictionaries;

⎯ managers and technical experts in the manufacturing industry.

This part of ISO/IEC Guide 77 is intended to provide practical information of the experience gained in the

creation of product reference dictionaries within ISO and IEC. This part of ISO/IEC Guide 77 is intended for

information only, in areas such as education.

The following are within the scope of this part of ISO/IEC Guide 77:

⎯ experience of developing a reference dictionary for cutting tools;

⎯ experience of developing a reference dictionary for electronic components;

⎯ experience of creating a system for the maintenance of a reference dictionary for measuring instruments;

⎯ experience of developing a reference dictionary for fasteners.

The following are outside the scope of this part of ISO/IEC Guide 77:

⎯ an overview for ISO technical committees and industrial managers for the development of computer-

processable product libraries, reference dictionaries and catalogues;

NOTE 1 An overview of the development of computer-processable product libraries, reference dictionaries and

catalogues is provided in ISO/IEC Guide 77-1.

⎯ technical guidance for the creation of product libraries and dictionaries.

© ISO/IEC 2008 – All rights reserved 1

NOTE 2 Technical guidance for the creation of product libraries and dictionaries is provided in ISO/IEC Guide 77-2.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

common ISO 13584/IEC 61360 dictionary model

data model for product ontology, using the information modelling language EXPRESS, resulting from a joint

effort between ISO/TC 184/SC 4/WG 2 and IEC/SC 3D

[ISO/IEC Guide 77-2:—, 2.6]

2.2

is-a relationship

class inclusion relationship associated with inheritance

[ISO/IEC Guide 77-2:—, 2.9]

2.3

reference dictionary

product ontology compliant with the common ISO 13584/IEC 61360 dictionary model (2.1)

[ISO/IEC Guide 77-2:—, 2.21]

3 Overview

The initiators and drivers of the selected projects are quite different groups, as outlined below.

⎯ ISO 13399 was developed by the leading manufacturers of cutting tools (AB Sandvik Coromant and

Kennametal, Inc.).

⎯ The IEC reference dictionary (IEC 61360) was initially based on the internal Philips model. Since 1989,

the work has been handed over and further developed by the horizontal committee IEC/SC 3D in the IEC

organization.

⎯ ISO 13584-501 was developed in cooperation between an industrial association in Japan (JEMIMA,

Japan Electric Measuring Instruments Manufacturers' Association) and a PLIB software provider

(TOSHIBA Corporation).

⎯ The fastener reference dictionary (ISO 13584-511) was developed by the Chinese National Institute of

Standards with support of technical experts from China and from ISO/TC 2.

The reference dictionary of cutting tools supports an entity-relationship information model, which describes the

assembly of the components of a modern cutting tool with defined cutting edges, whereas the other

dictionaries are stand-alone reference dictionaries, which are not linked to an additional model.

The examples show different approaches to maintenance: ISO 13584-511 relies on the normal maintenance

mechanisms defined for paper-based International Standards, whereas ISO 13399 and IEC 61360 have

installed or will install a maintenance agency to maintain the reference dictionary (2.3) as a standard. The

reference dictionary related to the maintenance procedure of ISO 13584-501 itself is not standardized. It is

instead registered on behalf of ISO by a registration authority in accordance with maintenance procedures

defined in ISO 13584-501. These procedures are similar to the procedures defined by IEC.

2 © ISO/IEC 2008 – All rights reserved

All projects were truly interdisciplinary efforts, in which experts of the modelling methodology were involved

alongside the technical experts. In addition, software engineers have developed various tools to support the

development process, and they also implemented prototype applications to ensure the usability of the

reference dictionaries in actual applications. It was even suggested to involve marketing experts, in order to

ensure that information about new products and new applications are considered in the reference dictionary.

All projects reported the importance of software tools to support the development process. This includes

editors for capturing information, tools for checking the correctness of data, means for distributing information,

etc. Three reference dictionaries are published in the STEP file format (ISO 10303-21). IEC has decided to

make IEC 61360 available in this format as well in the near future.

For the reference dictionary of cutting tools, a specific convention for the creation of names and definitions

was defined. Some of the standards use conventions for the generation of identifiers (e.g. to distinguish

between identifiers for classes and properties.

Some interesting aspects concerning the use of the underlying data model are outlined below.

a) Reuse of properties across reference dictionaries: the use of the is-case-of mechanism for this purpose is

illustrated in Clause 4 in the context of the reference dictionary for cutting tools which uses entries for

some nuts and bolts from ISO 13584-511.

b) Visible and applicable properties: the reference dictionary of cutting tools and the IEC reference dictionary

make all properties visible at the root class and apply them to different classes in their class hierarchies.

This has the advantage that a property can be applied to multiple classes in the hierarchy in various

branches. The properties defined in the IEC reference dictionary include in their definition the classes for

which the property is defined – this concept was used already before the concept of visible properties was

introduced into the PLIB data model. The reference dictionaries developed under ISO 13584 use the

visible properties to define the property domain, i.e. the definition of the property is linked to the definition

class for which it is visible. This makes it possible to tailor the property definition to its domain and to take

special aspects of the domain into account.

c) The reference dictionary for fasteners clusters various properties in the form of features. Such a feature

can be associated as a whole to a class (in the sense of a complex property). This allows for structuring

the set of properties and for a special organization of the characterization class hierarchy.

An important aspect for quality assurance is the possibility to formally validate exchange files. In view of the

use of reference dictionaries in computer-to-computer communication, e.g. as database schemas, it is of the

utmost importance to ensure the correctness of data. Dictionary providers may be made liable for the

correctness of their data.

Lastly, the reports show that the development of formal reference dictionaries requires a significant effort.

Some of the projects took several years and involved a number of man years. It is important to plan such a

project accordingly, i.e. to establish the necessary environment with respect to resources, liaisons and

cooperation with relevant technical committees. In addition, the maintenance process should be considered

from the start.

NOTE Annex C contains a Web site address providing links to organizations responsible for the maintenance of

reference dictionaries. Another address points to a Web site with links to various tools that are useful for the development

of reference dictionaries, including those tools that have been used by the projects described in this part of

ISO/IEC Guide 77.

4 Developing a PLIB reference dictionary for ISO 13399

4.1 General

ISO 13399 provides a reference dictionary for cutting tools data representation and exchange. The

development of ISO 13399 was carried out by cooperation between the world's largest manufacturers of

machine cutting tools in a project that lasted for more than 5 years (see 4.12).

© ISO/IEC 2008 – All rights reserved 3

The reasons for the development of ISO 13399 were:

⎯ cutting tools with defined cutting edges have become more complex with multiple replaceable inserts to

perform the cutting operation;

⎯ the use of cutting tools has become more adaptable following the changes in design of machine tools

able to use the same tool for many different operations;

⎯ the existing standard, ISO 3002, only defined cutting tools with brazed cutting items for single operations;

⎯ the reference system in ISO 3002 was not adequate to define all the properties of all the components of a

modern cutting tool (see Figure 1);

⎯ customers increasingly require that cutting tool data should be supplied in computer processable form

and the suppliers need to have one method for supplying this data to reduce their costs and complexity;

⎯ the main method of supplying data for modern cutting tool components and assemblies is intended to be

the information model of ISO 13399-1;

⎯ the reference dictionary of classes and properties for cutting tools was therefore developed as a separate

part of ISO 13399 to allow for the incorporation of new developments and new requirements without the

need to change the information model. In this case, just an update of the reference dictionary would be

required.

4.2 Determining the scope of the development project

The development project was to produce a new reference dictionary for ISO 13399. The main role of the

reference dictionary is to support the entity relationship information model (the information model) specified in

ISO 13399-1. The information model provides the resources to represent component parts of a modern cutting

tool and the assembly of parts to form a complete tool. The information model also enables parts to be

identified by using standardized labels from the reference dictionary, or to be referred to by their aliases using

the labels used by particular companies.

The main activities in the development of the reference dictionary were therefore to develop the class

hierarchy of items within the domain of machine cutting tools and to define the properties of these classes.

The scope of the domain is indicated in Figure 1. A modern cutting tool is an assembly of four main parts, as

follows:

⎯ cutting item: removes material from the work piece by a shearing action at defined cutting edges;

⎯ tool item: supports the cutting item or items in the cutting operation;

⎯ adaptive item: provides the connection between the tool item and the machine tool;

⎯ assembly item: provides the forces to hold the cutting item on the tool item.

These four parts were the starting basis for the class hierarchy. The cutting item may be a detachable insert

capable of being repositioned to bring different cutting edges into use, or permanently attached by means of a

brazed joint, or part of a solid tool.

The convention adapted for the scope was that the classes and their properties applied to the “tool in the

hand”. The alternative convention is for the “tool in use”. The “tool in use” convention will require additional

classes and properties which will be the subject of a subsequent project.

4 © ISO/IEC 2008 – All rights reserved

Figure 1 — Scope of the domain of cutting tools

4.3 Selection of the project team

The selection of the project team is an important component of the development and depends on the scope of

the project. It should always include domain experts and information modellers. However, the ISO 13399

project did not include marketing experts or software developers. While these omissions could be justified in

the earlier phases, once the development reached the point where the technical outcome was clear, the

extension of the scope of the project team to include marketing and software experts would have been

valuable.

The role of the domain experts was to input their knowledge from their companies' products, as well as to

generalize them to a neutral representation that could be applicable to all products in the cutting tool industry.

The domain experts were also familiar with both the existing standard (ISO 3002) in this domain and what was

now needed as a result of new developments in the technology of cutting tools.

The role of the information modellers was to interpret the ISO 13584 standard model and ensure that the

requirements of the domain experts could be met by the provisions of the standard. It is important that the

information modellers are conversant with the development of ISO 13584 and aware of any changes that have

occurred or are planned. This requires an active liaison between the project and the WG 2 of

ISO/TC 184/SC 4.

If software developers are included in the project team, then their role would be to anticipate what the

implementation issues could be and to input new ideas in the functionality of software that would use

ISO 13399.

The role of marketing experts would be to provide a bridge between the needs of customers and the

developers of ISO 13399, and to input information on new product types and new applications to extend its

scope.

© ISO/IEC 2008 – All rights reserved 5

4.4 Supporting software

The development of a reference dictionary requires software to support the activities. The software needed to

support the development of the reference dictionary for ISO 13399 was:

⎯ an editor for the compilation of the reference dictionary;

⎯ ISO STD2 Template for the production of the standard documents;

⎯ software to convert the reference dictionary file to a printable version;

⎯ CAD software to create the diagrams to support the definitions of properties;

⎯ a database to provide a searchable record of the content and provide checks against duplication of

names, etc.;

⎯ spreadsheet software to provide complete lists of classes and properties.

It was necessary to train the members of the project team in the use of the software that was appropriate to

their roles.

4.5 PLIB information model

The PLIB information model used for this project was ISO 13584-25. This model was further constrained to

limit the meaning of the data types used in the reference dictionary:

⎯ the classes used were item classes and feature classes only;

NOTE In ISO 13584-42, only these kinds of classes exist.

⎯ some of the data types were constrained to use only a limited number of data formats.

The scope and constraints on the model were described in ISO/TS 13399-100 by adopting the diagrammatic

presentation methods used in IEC 61360-2.

The domain experts were provided with some training in the use of ISO 13584 by using the editor software. It

was not necessary to refer directly to the information model for the reference dictionary. The domain experts

soon understood the principles of the development and were very comfortable with compiling the reference

dictionary by using the editor software.

4.6 Establishment of liaisons

ISO/TC 29 was the technical committee responsible for ISO 13399 and an official liaison was established

between ISO/TC 29 and ISO/TC 184/SC 4. This relationship was essential to provide access to the latest

development in the technology and standards for product data representation.

4.7 Development of the classification

4.7.1 Main classes

The main sections of the class hierarchy were initially identified as:

a) cutting items: the portion of the cutting tool in contact with the workpiece;

b) tool items: the assembly that is the support for the cutting item;

c) adaptive items: the components that connect the tool item to the machine tool;

6 © ISO/IEC 2008 – All rights reserved

d) accessory items: items that hold the cutting item to the tool item and items that are used to create the

assembly.

The root class was an item class and the main classes were either item classes or feature classes, where a

feature was an aspect of an item class that could not exist in isolation.

As the development of the reference dictionary proceeded, changes to this initial division needed to be made:

⎯ accessory items were restricted to assembly items to hold the cutting item in place on the tool item;

⎯ further main classes were identified as:

⎯ reference systems to provide a coordinate axis system for the definition of angles and lengths;

⎯ classes that were common to several of the original sections;

⎯ classes of connection systems.

The classes were either item classes or feature classes. Every effort was made to keep the class hierarchy

with as few subsidiary levels as possible and to avoid information modelling in the class hierarchy.

4.7.2 References to other dictionaries

As the reference dictionary neared to completion, it was realized that two of the classes in ISO 13399 were

the same concepts as classes in ISO 13584-511:

⎯ threaded fasteners as a subclass in the assembly item class;

⎯ thread as a common feature of several classes.

The class of externally threaded item was copied from ISO 13584-511 and was defined as an

item_class_case_of in ISO 13399. Then a reference was made from ISO 13399 to the class with the same

name in ISO 13584-511. The properties for this class in ISO 13399 were imported from ISO 13584-511 (by

use of the “Add dictionary” function in the dictionary editor). By this means, the contents of the externally

threaded item class from ISO 13584-511 are known to the reference dictionary in ISO 13399. There are some

special threaded fasteners particular to the assembly of cutting tools that are not standardized in the sources

from which ISO 13584-511 is derived. These special items were created in ISO 13399 as subclasses of

externally threaded item. The illustration of the reference to externally threaded item is shown in Figure 4.

Thread, as a feature of an object, is a common feature of several items in the domain of ISO 13399 and so it

was made a feature class with no superclass, other the root class. Care was taken to ensure that the

properties of thread did not include any properties related to the cutting of the thread, which are properties of

some types of cutting item. The feature class of thread in ISO 13584-511 did not include all the types of thread

and all the properties of a thread that were thought to be necessary for ISO 13399. Cooperation with the

developers of ISO 13584-511 was therefore established to extend ISO 13584-511 to meet the requirements of

ISO 13399 and when this is completed the reference can be made from ISO 13399 to ISO 13584-511 in the

same manner as for the externally threaded item.

4.7.3 Feature classes

ISO 13584 makes it possible to organize features into a class hierarchy, where a feature is defined as a class

of objects that cannot exist in isolation, e.g. a cutting edge is a feature of a cutting item. This aspect of the

class hierarchy is needed to avoid repetition, e.g. to avoid having to define a subclass of cutting edge for

every class of cutting item. It is also necessary to be able to assign properties to a feature as a class.

© ISO/IEC 2008 – All rights reserved 7

In ISO 13399, the association between an object and a feature was made by assigning a property to the item

class that indicates by its value whether the object possesses the feature. The data type for this kind of

property was Boolean, e.g. a cutting item may or may not have a chip breaker as part of its design. The

Boolean property “chip breaker property” was made applicable to the cutting item class and the value of the

property will indicate whether or not an instance of a cutting item has a chip breaker. The properties of the

chip breaker itself are then made applicable to the chip breaker feature class.

However, ISO 13584 does not provide the means to identify the item class of which the feature class is a part:

Only the forward association can be identified by the method described above. The correct association

between a feature and the object of which it is a part would have to be achieved in a software implementation

of the reference dictionary.

4.7.4 Assigning class names

Class names were devised by the domain experts based on common industrial practice, where possible.

Differences between the class names used for the same concept in the companies that participated in the

project team were resolved by choosing either one of the alternatives, or by devising independent names for

use in ISO 13399. The convention adopted for long names was to use only lower case letters with no joining

character between multiple words. Where groups of classes were associated with an aspect of a cutting tool,

the names were devised with common elements to identify the association.

The convention adopted for short names was to use lower case letters in a truncated form of the long name.

The compilation of the classes in a data base was used to verify that there was no repetition of names or short

names.

4.7.5 Assigning definitions

Definitions were derived from other International Standards, wherever possible, and in these cases the source

was identified. However, much of the content of the reference dictionary was new material that needed

original definitions. Whenever it was possible, a diagram was produced to support the definition.

4.7.6 Assigning identification codes

The assignation of an identification code to a class is a fundamental feature of the PLIB method. For

ISO 13399, each identification code was a random number that was generated by the editor software. The

benefit was to assign no meaning to the code so that the position of a class could be changed if it was

necessary to change the class hierarchy as the reference dictionary developed.

4.7.7 Assigning applicable properties

Properties were selected from the list of visible properties (see 4.8) to be applicable to the appropriate level of

the class hierarchy. This was the important contribution from the domain experts and also resulted in changes

to the class hierarchy to reflect the grouping of classes and their properties.

4.7.8 Examples of the classification

A high level view of the class hierarchy in ISO 13399 is shown in Figure 2. Note that there is an additional

library from ISO 13584-511.

8 © ISO/IEC 2008 – All rights reserved

Figure 2 — The main classes in the ISO 13399 reference dictionary

An expanded section of the classification that defines the cutting item feature class is shown in Figure 3,

together with the definition of cutting edge major and its applicable properties.

Figure 3 — Part of the classification of cutting item features

© ISO/IEC 2008 – All rights reserved 9

An example of the use of another reference dictionary as a reference is provided in Figure 4. This example

shows the properties from ISO 13584-511 applied to the externally threaded fastener component in

ISO 13399. Note that the identification of the class is “Item case of”, signifying that it is defined in another

dictionary.

Figure 4 — Example of the references to ISO 13584-511 for the applicable properties of the externally

threaded fastener component

4.8 Visible properties

4.8.1 Choice of visible properties

The development of the list of visible properties was the largest part of the development process. The

companies in the development team provided lists of properties from their company data bases and a great

effort was made either to harmonize the names or to create independent names and derive rigorous

definitions. The concepts enshrined in the definitions were regarded as the most import aspects of the

properties with the names acting as labels for the definitions. The properties chosen for representation in the

reference dictionary were restricted to the properties that are commonly described in the tool company

catalogues. There were no properties defined in the reference dictionary that related to the design or

manufacture of the tools. This restriction was to protect the intellectual property of the manufacturers.

4.8.2 Name scope of identification codes

All the visible properties were created at the root level of the reference dictionary and used identification codes

that were generated at random by the editor software. This had the advantage that the assignment of

applicable properties could be made at any level in the class hierarchy.

10 © ISO/IEC 2008 – All rights reserved

4.8.3 Assignment of property names

The convention adopted for long names of properties was to use only lower case letters with no joining

character between multiple words. Where groups of properties were associated with an aspect of a cutting

tool, the names were devised with common elements to identify the association.

The usual convention adopted for short names was to use lower case letters in a truncated form of the long

name. In some cases, the short name was derived from the common industry symbol for the property. A

compilation of the properties names in a data base was used to verify that there was no repetition of short

names.

4.8.4 Assignment of property symbols

Property symbols were copies, in upper case symbols, of the short name. The data base was used to ensure

that there was no repetition of symbols.

4.8.5 Development of property definitions

The development of definitions was a joint effort between the domain experts and the information modellers.

All the definitions were in British English, so it was helpful to have a native British English speaker as part of

the development team. Definitions were derived from existing International Standards wh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...