ISO/TS 19700:2007

(Main)Controlled equivalence ratio method for the determination of hazardous components of fire effluents

Controlled equivalence ratio method for the determination of hazardous components of fire effluents

ISO/TS 19700:2007 describes a tube-furnace method for the generation of fire effluent for the identification and measurement of its constituent combustion products, in particular, the yields of toxic products under a range of fire decomposition conditions. The test method described in ISO/TS 19700:2007 can be used solely to measure and describe the properties of materials, products or systems in response to heat or flame under controlled laboratory conditions. It is not suitable to be used by itself for describing or appraising the fire hazard of materials, products or systems under actual fire conditions, or as the sole source on which regulations pertaining to toxicity can be based.

Méthode du rapport d'équivalence contrôlée pour la détermination des substances dangereuses des effluents du feu

General Information

- Status

- Withdrawn

- Publication Date

- 05-Mar-2007

- Withdrawal Date

- 05-Mar-2007

- Technical Committee

- ISO/TC 92/SC 3 - Fire threat to people and environment

- Drafting Committee

- ISO/TC 92/SC 3 - Fire threat to people and environment

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 16-Sep-2016

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 23-Jan-2016

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO/TS 19700:2007 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Controlled equivalence ratio method for the determination of hazardous components of fire effluents". This standard covers: ISO/TS 19700:2007 describes a tube-furnace method for the generation of fire effluent for the identification and measurement of its constituent combustion products, in particular, the yields of toxic products under a range of fire decomposition conditions. The test method described in ISO/TS 19700:2007 can be used solely to measure and describe the properties of materials, products or systems in response to heat or flame under controlled laboratory conditions. It is not suitable to be used by itself for describing or appraising the fire hazard of materials, products or systems under actual fire conditions, or as the sole source on which regulations pertaining to toxicity can be based.

ISO/TS 19700:2007 describes a tube-furnace method for the generation of fire effluent for the identification and measurement of its constituent combustion products, in particular, the yields of toxic products under a range of fire decomposition conditions. The test method described in ISO/TS 19700:2007 can be used solely to measure and describe the properties of materials, products or systems in response to heat or flame under controlled laboratory conditions. It is not suitable to be used by itself for describing or appraising the fire hazard of materials, products or systems under actual fire conditions, or as the sole source on which regulations pertaining to toxicity can be based.

ISO/TS 19700:2007 is classified under the following ICS (International Classification for Standards) categories: 13.220.01 - Protection against fire in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TS 19700:2007 has the following relationships with other standards: It is inter standard links to ISO/TS 19700:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TS 19700:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 19700

First edition

2007-03-15

Controlled equivalence ratio method for

the determination of hazardous

components of fire effluents

Méthode du rapport d'équivalence contrôlée pour la détermination des

substances dangereuses des effluents du feu

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

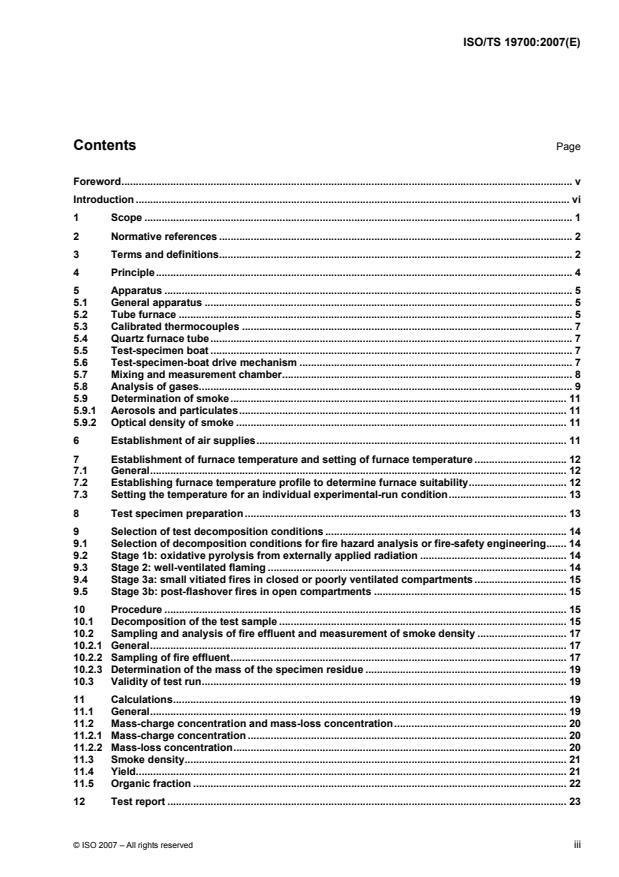

Contents Page

Foreword. v

Introduction . vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions. 2

4 Principle. 4

5 Apparatus . 5

5.1 General apparatus . 5

5.2 Tube furnace . 5

5.3 Calibrated thermocouples . 7

5.4 Quartz furnace tube. 7

5.5 Test-specimen boat . 7

5.6 Test-specimen-boat drive mechanism . 7

5.7 Mixing and measurement chamber. 8

5.8 Analysis of gases. 9

5.9 Determination of smoke. 11

5.9.1 Aerosols and particulates. 11

5.9.2 Optical density of smoke . 11

6 Establishment of air supplies. 11

7 Establishment of furnace temperature and setting of furnace temperature . 12

7.1 General. 12

7.2 Establishing furnace temperature profile to determine furnace suitability. 12

7.3 Setting the temperature for an individual experimental-run condition. 13

8 Test specimen preparation . 13

9 Selection of test decomposition conditions . 14

9.1 Selection of decomposition conditions for fire hazard analysis or fire-safety engineering. 14

9.2 Stage 1b: oxidative pyrolysis from externally applied radiation . 14

9.3 Stage 2: well-ventilated flaming . 14

9.4 Stage 3a: small vitiated fires in closed or poorly ventilated compartments . 15

9.5 Stage 3b: post-flashover fires in open compartments . 15

10 Procedure . 15

10.1 Decomposition of the test sample . 15

10.2 Sampling and analysis of fire effluent and measurement of smoke density . 17

10.2.1 General. 17

10.2.2 Sampling of fire effluent. 17

10.2.3 Determination of the mass of the specimen residue . 19

10.3 Validity of test run. 19

11 Calculations. 19

11.1 General. 19

11.2 Mass-charge concentration and mass-loss concentration. 20

11.2.1 Mass-charge concentration . 20

11.2.2 Mass-loss concentration. 20

11.3 Smoke density. 21

11.4 Yield. 21

11.5 Organic fraction . 22

12 Test report . 23

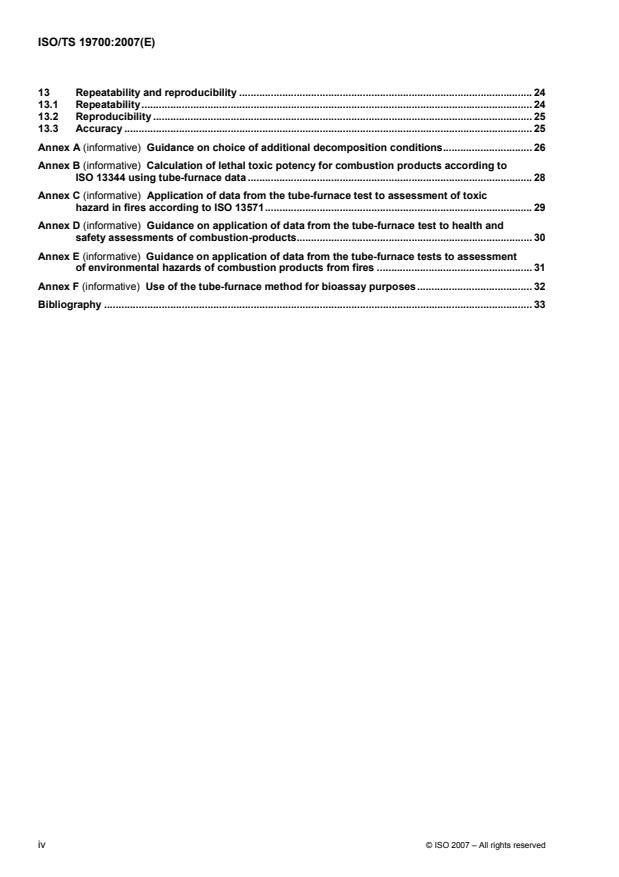

13 Repeatability and reproducibility . 24

13.1 Repeatability. 24

13.2 Reproducibility . 25

13.3 Accuracy . 25

Annex A (informative) Guidance on choice of additional decomposition conditions. 26

Annex B (informative) Calculation of lethal toxic potency for combustion products according to

ISO 13344 using tube-furnace data . 28

Annex C (informative) Application of data from the tube-furnace test to assessment of toxic

hazard in fires according to ISO 13571. 29

Annex D (informative) Guidance on application of data from the tube-furnace test to health and

safety assessments of combustion-products. 30

Annex E (informative) Guidance on application of data from the tube-furnace tests to assessment

of environmental hazards of combustion products from fires . 31

Annex F (informative) Use of the tube-furnace method for bioassay purposes. 32

Bibliography . 33

iv © ISO 2007 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of normative document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 19700 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 3, Fire threat

to people and environment.

Introduction

The framework for the long-term standardization of fire safety in support of performance-based design

(ISO/TC 92 SC 4) requires general engineering methods for specific performance aspects of fire safety, but is

applicable to all types of structural systems, products and processes. These are referred to in the document

as Level 2, Group B standards. One such aspect of fire safety is the yields of toxic products evolved in fires.

This Technical Specification has been developed to measure toxic product yields from materials and products

over a range of decomposition conditions in fires. The decomposition conditions are defined in terms of fuel/air

equivalence ratio, temperature and flaming behaviour.

The toxic potency of a fire effluent represents the combination of a number of factors, including the

concentrations of toxic products, gases, and smoke particles. The concentrations of toxic products in turn

depend upon a number of factors, one of which is the yield of each toxic product from the burning fuel. In

order to make a performance-based assessment of the toxic hazard in a fire, one required input is the yield of

toxic products under specified fire conditions.

For any specific material or product, the effluent yields in fires depend upon the thermal decomposition

conditions. The most important variables are whether the decomposition is non-flaming or flaming, and for

flaming decomposition the fuel/oxygen ratio. Based upon these variables, it is possible to classify fires into a

number of types, as detailed in ISO/TS 19706:2004, Table 1.

The use of this Technical Specification provides data on the range of toxic product yields likely to occur in

different types and stages of full-scale fires. More comprehensive data on the relationships between

decomposition conditions and product yields can be obtained by using a wider range of apparatus settings.

Guidance on the choice of additional decomposition conditions, the application of test data to ISO 13344 and

ISO 13571, to health and safety and environmental situations and the use of the tube-furnace method for

bioassay purposes is provided in the annexes.

This Technical Specification makes use of the same apparatus and a similar basic methodology as specified

in IEC 60695-7-50. The test method has been developed to fulfil the requirements of ISO 16312-1 and

ISO/TS 19706, for data on the yields of toxic products in fire effluents evolved under different fire conditions as

part of the data required for input to the toxic-hazard-assessment calculation methods described in ISO 13571.

The data may also be used as input for the toxic-potency calculation methods described in ISO 13344 and

ISO 13571.

vi © ISO 2007 – All rights reserved

TECHNICAL SPECIFICATION ISO/TS 19700:2007(E)

Controlled equivalence ratio method for the determination of

hazardous components of fire effluents

1 Scope

This Technical Specification describes a tube-furnace method for the generation of fire effluent for the

identification and measurement of its constituent combustion products, in particular, the yields of toxic

products under a range of fire decomposition conditions.

It uses a moving test specimen and a tube furnace at different temperatures and air flow rates as the fire

model. The use of this apparatus is generally applicable to individual materials, to products that are layered

such that the layering will not result in a significant change in product yields with time in real fires, i.e. to

products where the upper surface does not provide major protection to the sub-layers.

This method has been designed as a TC 92 Level Group B performance-based engineering method to

provide data for input to hazard assessments and fire-safety engineering design calculations. The method can

be used to model a wide range of fire conditions by using different combinations of temperature, non-flaming

and flaming decomposition conditions and different fuel/oxygen ratios in the tube furnace. These include the

following types of fires, as detailed in ISO/TS 19706:2004, Table 1:

⎯ Stage 1: Non-flaming:

⎯ Stage 1b) Oxidative pyrolysis from externally applied radiation;

⎯ Stage 2: Well-ventilated flaming (representing a flaming developing fire) (see Note 1);

⎯ Stage 3: Less well-ventilated flaming (see Note 2):

⎯ Stage 3a) Small vitiated fires in closed or poorly ventilated compartments;

⎯ Stage 3b) Post-flashover fires in large or open compartments.

NOTE 1 Where the fire size is small in relation to the size of the compartment, the flames are below the base of the hot

layer and the fire size is fuel-controlled.

NOTE 2 Where the fire size may be large in relation to the size of the compartment, the flames are partly above the

base of the hot layer and the fire size is ventilation-controlled.

For each flaming fire type, the minimum conditions of test are specified in terms of the equivalence ratio φ as

follows:

Stage 2: φ < 0,75;

Stages 3a) and 3b) φ = 2 ± 0,2.

Guidance on the choice of additional decomposition conditions is given in Annex A.

The data on toxic product concentrations and yields obtained using this Technical Specification may be used

as part of the assessment of toxic potencies, in conjunction with toxic potency calculation methods in

ISO 13344, and as an input to the toxic hazard assessment from fires in conjunction with fire growth and

effluent dispersal modelling, and fractional effective dose (FED) calculation methods in ISO 13571.

Application of data from the tube-furnace test to the calculation of lethal toxic potency according to ISO 13344,

and to the assessment of toxic hazards in fires according to ISO 13571 is considered in Annex B and Annex C,

respectively.

Guidance on application of data from the tube-furnace test to health and safety assessments of combustion

products, and to the assessment of environmental hazards of combustion products from fires is given in

Annex D and Annex E, respectively. Guidance on the use of the tube-furnace method for bioassay purposes

is given in Annex F.

The test method described in this Technical Specification can be used solely to measure and describe the

properties of materials, products or systems in response to heat or flame under controlled laboratory

conditions. It is not suitable to be used by itself for describing or appraising the fire hazard of materials,

products or systems under actual fire conditions, or as the sole source on which regulations pertaining to

toxicity can be based.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 291:2005, Plastics — Standard atmospheres for conditioning and testing

ISO 554:1976, Standard atmospheres for conditioning and/or testing — Specifications

ISO 5660-2:2002, Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 2:

Smoke production rate (dynamic measurement)

ISO 13344:2004, Estimation of the lethal toxic potency of fire effluents

ISO 13571, Life-threatening components of fire — Guidelines for the estimation of time available for escape

using fire data

ISO/IEC 13943, Fire safety — Vocabulary

ISO 19701:2005, Methods for sampling and analysis of fire effluents

ISO 19702:2006, Toxicity testing of fire effluents — Guidance for analysis of gases and vapours in fire

effluents using FTIR gas analysis

ISO/TS 19706:2004, Guidelines for assessing the fire threat to people

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13344, ISO 13571, ISO 13943, and

the following apply.

3.1

combustible load

mass of the components of a test specimen capable of combustion in the furnace

NOTE This usually includes all components of a specimen excluding inert fillers and other non-combustible

components, such as metal frames.

2 © ISO 2007 – All rights reserved

3.2

equivalence ratio

φ

fuel mass to oxygen mass ratio in the test divided by the stoichiometric fuel mass to oxygen mass ratio

NOTE For the tube-furnace method, this is the mass loss rate of combustible effluent from the test specimen, in

−1

milligrams per minute (mg⋅min ), divided by the mass flow rate of oxygen in the primary air introduced into the furnace, in

−1

milligrams per minute (mg⋅min ), divided by the stoichiometric fuel mass to oxygen mass ratio for the material under test.

3.3

exposure dose

Ct

product of a gaseous toxicant or of a fire effluent which is available for inhalation, i.e. the integrated area

under the concentration(C)-time(t) curve

3.4

extinction coefficient

natural logarithm of the ratio of incident light intensity to transmitted light intensity, per unit light path length

3.5

fractional effective concentration

FEC

ratio of the concentration of an irritant to that expected to produce a given effect on an exposed subject of

average susceptibility

NOTE 1 As a concept, FEC may refer to any effect, including incapacitation, lethality or even other endpoints. Within

the context of this Technical Specification, FEC refers only to incapacitation.

NOTE 2 When not used with reference to a specific irritant, the term FEC represents the summation of FECs for all

irritants in a combustion atmosphere.

NOTE 3 When FEC = 1, the defined effect (incapacitation or death) is predicted to occur.

3.6

fractional effective dose

FED

ratio of the Ct product for an asphyxiant toxicant to that Ct product of the asphyxiant expected to produce a

given effect on an exposed subject of average susceptibility

NOTE 1 As a concept, FED may refer to any effect, including incapacitation, lethality or even other endpoints. Within

the context of this Technical Specification, FED refers only to incapacitation.

NOTE 2 When FED = 1, the defined effect (incapacitation or death) is predicted to occur.

3.7

LC

concentration of a toxic gas or fire effluent statistically calculated from concentration-response data to produce

lethality in 50 % of test animals within a specified exposure and post-exposure time

−3

NOTE The typical units are µL/L for a gaseous toxicant and gm for fire effluent.

3.8

LCt

product of LC and the exposure duration over which it was determined

−1 −3

NOTE The typical units are µLL min for a gaseous toxicant and gm min for fire effluent. This constitutes a measure

of lethal toxic potency.

3.9

mass-charge concentration

concentration of fire effluents from a material defined in terms of the mass of material exposed to burning

−3

conditions (mass charge) and the volume into which the effluent is dispersed, expressed in g⋅m

3.10

mass loss concentration

concentration of fire effluents from a material defined in terms of the mass of material decomposed (mass

−3

loss) and the volume into which the effluent is dispersed, expressed in g⋅m

3.11

mass loss exposure dose

−3

mass loss concentration multiplied by the exposure time, expressed in g⋅m min

[BS 7899-2:1999, definition 2.22]

3.12

smoke extinction area

SEA

−1

ratio of the smoke extinction coefficient, in reciprocal metres (m ) to the mass loss concentration of the test

−3 2 −1

specimen, expressed as grams per cubic metre (g⋅m ) having units of metres squared per gram (m⋅g )

3.13

smoke obscuration

reduction, usually expressed as a percentage, in the intensity of light due to its passage through smoke

3.14

smoke production

integral of the smoke production rate over the steady-state burn period being considered

3.15

volume yield

volume of an effluent component at 20 °C and 101,325 kPa divided by the mass loss of the test specimen

associated with the production of that volume of the effluent component

3.16

yield

mass of an effluent component divided by the mass loss of the test specimen associated with the production

of that mass of the effluent component

4 Principle

Since the yields of products in fires depend upon the decomposition conditions (references [1] to [5]), it is

possible to examine the relationships between product yield and a range of variables affecting the

decomposition conditions using this apparatus and the methodology described. The specified test conditions

represent a minimum set designed to obtain data for oxidative pyrolysis under non-flaming conditions, for well-

ventilated flaming conditions at an equivalence ratio of less than 0,75, and for vitiated flaming conditions at an

equivalence ratio of more than 2. The test is designed to replicate real fire conditions, and it is essential that

proper observations are made to ensure that those conditions are being met.

Samples of a material or product are combusted under steady-state conditions in one or more of four

environments whose temperature and equivalence ratio are representative of a particular stage of a fire. The

four types of fire to be represented are: oxidative pyrolysis, well-ventilated flaming developing fires, small

flaming vitiated fires, and post-flashover vitiated fires, as defined in ISO/TS 19706.

A test specimen in granular or rod form, or a product, is placed in a quartz boat, and introduced at a constant

rate into a furnace tube through the hot zone of a fixed tubular furnace. A stream of primary air is passed

through the furnace tube and over the test specimen at constant flow rate, to support combustion. The fire

4 © ISO 2007 – All rights reserved

effluent is expelled from the quartz furnace tube into a mixing and measuring chamber, where it is diluted with

−

secondary air to a nominal total air flow rate of (50 ± 1) l⋅min through the chamber and then exhausted to

waste.

In the oxidative pyrolysis mode, the furnace temperature is set below the auto-ignition temperature. The three

flaming modes are accomplished by using vapour temperatures above typical auto-ignition temperatures. For

flaming decomposition conditions, different fuel-to-oxygen ratios, and hence different equivalence ratios, are

obtained when different, constant primary air flows are used in relation to the constant rate of introduction of

the fuel. To achieve the required gasification rates, materials may be combusted under different conditions

from each other.

The secondary, dilution air is added to generate a greater sample flow and cooler effluent which permits a

large number of gas and smoke sampling procedures to be used without the need for a large number of

replicate tests.

The requirement in each test run is to obtain stable, steady-state decomposition conditions for at least 5 min

during which the concentrations of effluent gases and particles can be measured. The time taken for steady-

state conditions to be established varies, depending upon the nature of the test specimen and the test

conditions.

The concentrations of carbon dioxide and oxygen are recorded to establish the steady-state period and

samples of the effluent mixture are taken from the chamber during the steady-state period for analysis. Smoke

obscuration and smoke yield are calculated from measurement of the attenuation of a light beam by the

combustion effluent stream in the mixing chamber. A sample of smoke is drawn through a filter, and the mass

of particles is determined.

5 Apparatus

5.1 General apparatus

The apparatus consists of a tube furnace and a quartz tube which passes through the furnace and into a

mixing and measurement chamber. A drive mechanism pushes the specimen boat into the furnace tube at a

preset, controlled rate. A constant, predetermined stream of primary air is provided at the furnace-tube entry

and a preset, secondary supply into the mixing and measurement chamber. Gas samples are taken from the

mixing and measurement chamber. A light/photo cell system is used to determine smoke density across the

mixing and measurement chamber.

The arrangement of the apparatus is shown in Figure 1. Unless otherwise stated, all tolerances are ± 5 mm.

5.2 Tube furnace

The tube furnace shall have a heating zone length of 500 mm to 800 mm and an inside diameter of 50 mm to

65 mm. The furnace shall be equipped with an adjustable electric heating system capable of maintaining the

furnace temperature to within ± 2 % of the set temperature. The heating element should preferably be rated at

1 300 °C (see Note 1).

With the peak furnace temperature set at (650 ± 10) °C, the temperature shall not decrease by more than

100 °C over a length of at least ± 125 mm from the point of peak temperature measurement. The method

used to determine this temperature profile is given in 7.2 (see Note 2).

NOTE 1 The furnace is similar to that used in IEC 60754-2.

NOTE 2 This will also reduce the likelihood of a hot spot in the furnace, to which the pyrolysis rate will be sensitive.

Key

1 tube furnace 8 ports for sampling lines

2 quartz furnace tube 9 smoke-particle filter

3 test-specimen boat 10 tube containing light source

4 test-specimen boat drive mechanism 11 tube containing photodetector

5 mixing and measurement chamber 12 gas bubblers

6 primary air inlet 13 pump with flow meter

7 secondary air inlet

a) General arrangement of apparatus

Dimensions in millimetres

Key

1 secondary air inlet 45° to vertical

2 tube furnace

3 furnace tube

4 sample boat 800

b) Critical dimensions of assembly

Figure 1 — Tube-furnace decomposition and sampling apparatus

6 © ISO 2007 – All rights reserved

5.3 Calibrated thermocouples

Calibrated stainless-steel sheathed thermocouples, 1,5 ± 0,1 mm in diameter, shall be used for measuring the

temperature in the furnace tube, the temperature in the mixing and measurement chamber and for calibrating

the furnace. Three thermocouples are required.

5.4 Quartz furnace tube

The quartz furnace tube, as shown in Figure 2, is made of clear heat-resistant quartz, resistant to the effects

of fire effluent. The tube is 1 600 mm long, and has an external, approximately concentric diameter of

(47,5 ± 1) mm and a wall thickness of (2 ± 0,5) mm. The outside diameter shall permit a smooth fit within the

tube furnace (5.2) and allow expansion at operating temperatures.

The input end of the furnace tube shall have a closure with openings in it to allow the primary air inlet and the

specimen boat drive to pass through (see Note 1).

The downstream end of the furnace tube shall pass through a heat-resisting sealed gland and shall protrude

55 ± 5 mm into the mixing and measurement chamber (5.7). (see Note 2).

The distance between the mixing and measurement chamber and the exit of the furnace shall be 30 ± 5 mm.

NOTE 1 A PTFE gland seal has been found to be suitable.

NOTE 2 A gland made from glass wool inside a brass collar has been found to be suitable.

5.5 Test-specimen boat

The test-specimen boat, as shown in Figure 2, is made from quartz glass (see Note 1), of diameter

(41 ± 2) mm, with a length of 800 mm and a wall thickness of (2 ± 0,5) mm (see Notes 2 and 3). The boat

should be cleaned after each test (see Note 4).

NOTE 1 A convenient method for making a suitable test-specimen boat for a 47,5 mm diameter furnace tube is to use

quartz tubing with a nominal diameter less than that of the furnace tube (nominal 41 mm). This can then be sliced in half to

provide a semi-circular cross-section, nominally of 41 mm width, 18 mm depth and 800 mm length.

NOTE 2 A test-specimen-boat diameter (41 mm) of just less than the furnace-tube internal diameter (47 mm) provides

the maximum sample capacity.

NOTE 3 A boat length of 800 mm has been found suitable for testing most materials. Where materials take a long time

to reach steady-state burning, or where a steady-state period of longer that 5 min is required, longer boats may be used.

NOTE 4 A convenient method of cleaning both the boat and tube is to remove obvious residues mechanically, then fire

at 1 000 °C, followed by washing in water to remove any inorganic residues.

5.6 Test-specimen-boat drive mechanism

The test-specimen boat is connected to a hooked drive bar, which passes through a gland seal (see 5.4) at

the upstream end of the furnace tube, and connects to a drive mechanism. The drive mechanism advances

−1

the sample boat at a typical rate of (40 ± 1) mm⋅min . The drive mechanism shall allow different speeds to be

used, because the actual rate is dependent upon the flame spread characteristics of the sample (see Note).

The mechanism shall enable the specimen boat to be rapidly retracted into the upstream, external part of the

furnace tube at the end of the test burn. This may be achieved manually after detaching the push rod from the

drive mechanism.

−1

NOTE A drive advance rate of 40 mm⋅min has been found suitable for most materials under most decomposition

conditions. For some fast-burning or low-density materials, it has been found necessary to use advance rates of up to

−1

60 mm⋅min .

Dimensions in millimetres

a) Quartz furnace tube

b) Test-specimen boat

Figure 2 — Dimensions of a suitable quartz furnace tube and test-specimen boat

5.7 Mixing and measurement chamber

This shall consist of an approximately cubic box with a side length of 30 to 32 cm (see Figure 3) although the

exact dimensions are not critical. The box should accommodate the necessary sampling and measurement

points (gas sampling probes to bubblers, etc., particulate filters and smoke meter) (see Note 1). The front of

the chamber has a door providing a seal when shut. The walls of the box are made of PMMA, polycarbonate,

polyethylene or other suitable material, except for the back wall of the chamber and the rear portion of the roof

which are made of stainless steel, so as to be resistant to heat and any flames emanating from the end of the

furnace tube (see Notes 2 and 3).

The roof of the chamber is fitted with a safety blow-out panel 75 mm in diameter, made of aluminium foil

approximately 0,04 mm thick (see Note 3).

Sampling ports and probes are provided in the mixing chamber for taking samples of the test atmosphere. The

open end of the sampling probe shall be (30 ± 5) mm from the wall of the mixing and measurement chamber

(see Note 4).

A port approximately 35 mm in diameter is provided at the base of the rear face of the chamber for the test

atmosphere to be exhausted to waste.

Ports are provided in the mixing and measurement chamber for the insertion of a light source and detector for

the measurement of smoke density (see Note 5). Measurement points are located away from the rising plume

and the chamber walls; these may be sited in any convenient location. Suitable methods for the prevention of

the deposition of particles on the surfaces of both the light source and detector shall be used (see Note 6).

8 © ISO 2007 – All rights reserved

A thermocouple (5.3), extending approximately 50 mm into the mixing and measurement chamber, is located

as shown in Figure 3, for monitoring of the temperature in the chamber during the tests.

NOTE 1 The volume of the mixing and measurement chamber needs to be large enough to accommodate the

sampling points but smaller than the total volume of air flowing through the box in 1 min.

NOTE 2 A suitable chamber can be made from a commercially available desiccator cabinet with nominal dimensions of

310 mm × 310 mm × 340 mm (see Figure 3). This would have an internal volume of 33 l compared to the air flow volume

of 50 l in 1 min. The furnace-tube entry wall of the chamber cabinet should be covered by a stainless-steel plate fitted to

the inner surface; the top of the plate extending 140 mm across the chamber roof to provide heat protection for the plastic

surfaces.

NOTE 3 This is important for safety reasons.

NOTE 4 The sampling points are positioned away from the furnace-tube exit plume and chamber walls but can be sited

in any convenient location. Suitable locations are shown in Figure 3.

NOTE 5 A suitable smoke-measurement path length has been found to be approximately 300 mm.

NOTE 6 A suitable method has been to mount the photodectector and lamp vertically as in Figure 3 and pass part of

−1

the chamber diluent air into tubes containing the light source and detector at a rate of 500 ml⋅min . A further modification

to reduce particle deposition is to mount the photodetector and lamp horizontally.

5.8 Analysis of gases

This Technical Specification requires the determination of certain combustion gases. The means of gas

sampling and analysis shall be those given in ISO 19701 and ISO 19702.

Carbon dioxide and oxygen concentrations shall be sampled and determined continuously throughout the test.

These data are used to identify and monitor the steady-state burn period and also to quantify the gas yields.

The concentration of carbon monoxide shall also be determined continuously to quantify the gas yield.

The oxygen meter shall be capable of an accuracy of 0,01 %. Details of a suitable oxygen meter and sampling

system are given in ISO 5660-1.

The following other gases shall be determined during the steady-state burn period (see Note):

⎯ organic irritants including formaldehyde and acrolein;

⎯ total organic fraction;

⎯ acid gases, including hydrogen cyanide, hydrogen chloride, hydrogen bromide, hydrogen fluoride,

nitrogen oxides and sulfur dioxide if the presence of the relevant elements is suspected.

Other gases may need to be determined, if suspected from knowledge of the compound (see Note).

NOTE The above list is not to be considered inclusive. A compound may be excluded from the effluent analysis if one

or more of the elements in that compound is determined not to be present in the test specimen, or if citable evidence

shows the compound is not likely to be present in a toxicologically significant quantity. For more sophisticated analyses,

other individual organic irritants (e.g. other organo-aldehydes, isocyanates, organo-nitriles, etc.) may be measured directly.

The selection of organics to be monitored should be justified in the report and based on citable scientific literature on

combustion-product analyses or elemental composition of the material tested.

Dimensions in millimetres

Key

1 door 8 smoke particle filter

2 tube containing photodetector 9 ports for sampling lines

3 tube containing light source 10 secondary air inlet

4 purge tubes for photodetector and light source 11 port for thermocouple

5 quartz furnace tube 12 port for tube to sample atmosphere in furnace tube for

measurement of oxygen concentration

6 stainless-steel plate

13 exhaust port

7 safety blow-out panel

A top

B front

C back

Figure 3 — Dimensions of mixing and measurement chamber

10 © ISO 2007 – All rights reserved

5.9 Determination of smoke

5.9.1 Aerosols and particulates

These are continuously sampled in the mixing and measurement chamber through a particle filter at an

appropriate flow.

NOTE A glass microfibre filter 0,26 mm thick with a 1,6 µm particle retention characteristic and a diameter of 37 mm

has been found to be suitable.

5.9.2 Optical density of smoke

The smoke optical density is calculated from measurement of the attenuation of a laser light beam by the

combustion-product stream in the mixing chamber. Smoke obscuration is recorded continuously for the

steady-state burn period of the test.

A suitable smoke-determining system is given in ISO 5660-2 (see Note).

Two glass neutral-density dispersion filters, accurately calibrated at the laser wavelength of 632,8 nm, are

required to calibrate the smoke-determining system. The filters used shall not be of the coated type, because

these filters can give rise to interference effects with laser light and can deteriorate with time. The filters shall

have nominal optical densities (D) of 0,3 and 0,8. Corresponding values of extinction coefficient, k, are

obtained from the formula:

−1

k = (2,303D)L

where L is the distance between the entrances of the light emitter/detector system.

NOTE Experimental work has been performed with ISO 5660-2 with systems using a white light source with

collimating optics. Such systems have been shown to yield generally similar results, but not under all conditions.

Theoretical predictions have been verified experimentally. White light systems may be used if they are shown to have an

equivalent accuracy.

6 Establishment of air supplies

6.1 The primary and secondary air supplies to the apparatus shall be clean and free from excessive

moisture that could interfere with burning characteristics or combustion-product analysis. The water content

and/or the relative humidity of the air shall be reported (see Note 1).

6.2 Both the primary and secondary air flows are delivered at a constant, predetermined rate, positive

pressure and monitored using in-line flow meters. Air flow rates must be calibrated at the point of entry to the

furnace tube and chamber (see Note 2).

6.3 The primary air shall be introduced through the closure at the input end of the furnace tube.

6.4 The secondary air shall be introduced into the mixing box using piping of internal diameter 3 mm to

4 mm, passing through the wall of the mixing and measurement chamber and ending (70 ± 5) mm above and

in line with the end of the furnace tube and pointing upwards at an angle of approximately 45°. The secondary

air supply intercepts the rising plume to facilitate the efficient mixing of the test atmosphere (see Note 3).

NOTE 1 Oil free compressed air passed through a carbon trap and silica gel, or bottled air, has been found to be

suitable.

NOTE 2 The flow meters shall be calibrated using a bubble meter. A correction for back pressure at the in-line flow

meters may be necessary.

NOTE 3 This system will give good mixing of the furnace effluent and the secondary air, and removes the need for a

mechanical stirring device.

7 Establishment of furnace temperature and setting of furnace temperature

7.1 General

There are two stages included in the temperature standardization. The first stage is to establish that the

temperature profile (change of temperature with distance through the furnace tube) of the particular furnace to

be used is suitable; the second stage is to determine the temperature setting needed for the particular

experimental-run condition to b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...