ISO 21029-1:2018

(Main)Cryogenic vessels — Transportable vacuum insulated vessels of not more than 1 000 litres volume — Part 1: Design, fabrication, inspection and tests

Cryogenic vessels — Transportable vacuum insulated vessels of not more than 1 000 litres volume — Part 1: Design, fabrication, inspection and tests

ISO 21029-1:2018 specifies requirements for the design, fabrication, type test and initial inspection and test of transportable vacuum-insulated cryogenic pressure vessels of not more than 1 000 l volume. This document applies to transportable vacuum-insulated cryogenic vessels for fluids as specified in 3.1 and Table 1 and does not apply to such vessels designed for toxic fluids. NOTE 1 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land and marine vehicles, see ISO 13985. NOTE 2 Specific requirements for open top dewards are not covered by this document.

Récipients cryogéniques — Récipients transportables, isolés sous vide, d'un volume n'excédant pas 1 000 litres — Partie 1: Conception, fabrication, inspection et essais

General Information

- Status

- Published

- Publication Date

- 15-Feb-2018

- Technical Committee

- ISO/TC 220 - Cryogenic vessels

- Drafting Committee

- ISO/TC 220/WG 1 - Design and construction

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 28-Sep-2023

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 01-Jan-2022

- Effective Date

- 30-Nov-2013

Overview

ISO 21029-1:2018 specifies requirements for the design, fabrication, type testing, initial inspection and testing of transportable, vacuum‑insulated cryogenic pressure vessels with a capacity of not more than 1 000 litres. It covers transportable vacuum‑insulated cryogenic vessels for non‑toxic cryogenic fluids and sets out mandatory technical, inspection and documentation requirements needed to achieve safe, reliable performance in service. The standard excludes vessels designed for toxic fluids, open‑top dewars and refillable liquid hydrogen or LNG tanks primarily dedicated as vehicle fuel tanks (see ISO 13985).

Key topics and technical requirements

ISO 21029-1:2018 organizes technical requirements across the vessel lifecycle and includes:

- Design options and validation: design by calculation, or by calculation supplemented with experimental methods, and procedures for design validation and type approval.

- Mechanical, chemical and thermal loading: design loads, pressure test loads and other mechanical influences relevant to cryogenic operation.

- Materials and fabrication: base material selection, material properties and certificates, forming, welding qualification, manufacturing tolerances and assembly practices.

- Inspection and testing: non‑destructive testing (surface and volumetric examinations), production control test plates, pressure testing and rectification rules.

- Pressure safety and components: relief devices, piping, valves, inspection openings and protective guards.

- Marking, labelling and documentation: mandatory marking, labelling information and required documentation for initial inspection and handover.

- Normative and informative annexes: guidance on base materials, outer jacket relief devices, elastic stress analysis, external pressure calculations and type approval test procedures. (The standard references ISO 6520‑1 for weld classification.)

Practical applications and users

ISO 21029-1 is intended for organizations involved in the lifecycle of small transportable cryogenic vessels:

- Design engineers and manufacturers creating vacuum‑insulated cryogenic containers up to 1 000 L.

- Inspection bodies, testing laboratories and certification authorities performing type tests, initial inspections and conformity assessments.

- Operators and procurement teams in industries that transport or distribute non‑toxic cryogenic fluids (industrial gases, medical supplies, research facilities) who need compliant equipment.

- Quality and safety managers responsible for manufacturing controls, welding procedures and pressure testing regimes.

Related standards

- ISO 13985 - specific requirements for vehicle fuel tanks (liquid hydrogen, LNG) - referenced as excluded from ISO 21029‑1.

- ISO 6520‑1 - weld classification referenced for acceptance criteria.

Use ISO 21029-1:2018 to ensure safe design, consistent fabrication, rigorous inspection and reliable testing of transportable vacuum‑insulated cryogenic vessels under 1 000 L.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

ISO 21029-1:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Cryogenic vessels — Transportable vacuum insulated vessels of not more than 1 000 litres volume — Part 1: Design, fabrication, inspection and tests". This standard covers: ISO 21029-1:2018 specifies requirements for the design, fabrication, type test and initial inspection and test of transportable vacuum-insulated cryogenic pressure vessels of not more than 1 000 l volume. This document applies to transportable vacuum-insulated cryogenic vessels for fluids as specified in 3.1 and Table 1 and does not apply to such vessels designed for toxic fluids. NOTE 1 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land and marine vehicles, see ISO 13985. NOTE 2 Specific requirements for open top dewards are not covered by this document.

ISO 21029-1:2018 specifies requirements for the design, fabrication, type test and initial inspection and test of transportable vacuum-insulated cryogenic pressure vessels of not more than 1 000 l volume. This document applies to transportable vacuum-insulated cryogenic vessels for fluids as specified in 3.1 and Table 1 and does not apply to such vessels designed for toxic fluids. NOTE 1 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land and marine vehicles, see ISO 13985. NOTE 2 Specific requirements for open top dewards are not covered by this document.

ISO 21029-1:2018 is classified under the following ICS (International Classification for Standards) categories: 23.020.40 - Cryogenic vessels. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21029-1:2018 has the following relationships with other standards: It is inter standard links to ISO 21029-1:2018/Amd 1:2019, ISO 21029-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 21029-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21029-1

Second edition

2018-02

Cryogenic vessels — Transportable

vacuum insulated vessels of not more

than 1 000 litres volume —

Part 1:

Design, fabrication, inspection and

tests

Récipients cryogéniques — Récipients transportables, isolés sous vide,

d'un volume n'excédant pas 1 000 litres —

Partie 1: Conception, fabrication, inspection et essais

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

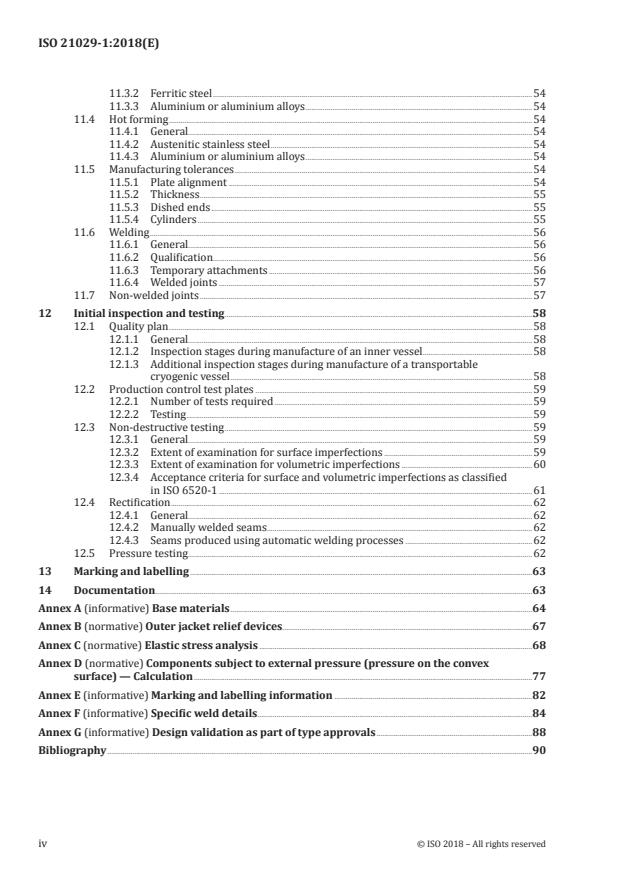

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols . 5

5 General requirements . 6

6 Mechanical loads . 7

6.1 General . 7

6.2 Load during the pressure test . 7

6.3 Other mechanical loads . 7

7 Chemical effects . 8

8 Thermal conditions . 8

9 Material . 8

9.1 General . 8

9.2 Material properties . 8

9.3 Inspection certificate . 9

9.4 Materials for outer jackets and equipment . 9

10 Design . 9

10.1 Design options . 9

10.1.1 General. 9

10.1.2 Design by calculation . 9

10.1.3 Design by calculation and supplemented with experimental methods .10

10.2 Common design requirements .11

10.2.1 General.11

10.2.2 Design specification .11

10.2.3 Design loads .12

10.2.4 Inspection openings .14

10.2.5 Pressure relief .14

10.2.6 Piping, valves and equipment .15

10.2.7 Degree of filling .16

10.3 Design by calculation .16

10.3.1 General.16

10.3.2 Inner vessel .16

10.3.3 Outer jacket .18

10.3.4 Supports, lifting points and frame .19

10.3.5 Protective guards .19

10.3.6 Piping .19

10.3.7 Calculation formulae .19

10.3.8 Calculations for operating loads .49

10.4 Design validation by experimental method .50

10.4.1 General.50

10.4.2 Procedure for experimental test programme .50

10.4.3 Tests for pressure integrity . .50

10.4.4 Tests for structural integrity .50

10.4.5 Test conditions.52

11 Fabrication .53

11.1 General .53

11.2 Cutting .53

11.3 Cold forming .53

11.3.1 Austenitic stainless steel .53

11.3.2 Ferritic steel .54

11.3.3 Aluminium or aluminium alloys .54

11.4 Hot forming .54

11.4.1 General.54

11.4.2 Austenitic stainless steel .54

11.4.3 Aluminium or aluminium alloys .54

11.5 Manufacturing tolerances .54

11.5.1 Plate alignment .54

11.5.2 Thickness .55

11.5.3 Dished ends .55

11.5.4 Cylinders .55

11.6 Welding .56

11.6.1 General.56

11.6.2 Qualification .56

11.6.3 Temporary attachments .56

11.6.4 Welded joints .57

11.7 Non-welded joints .57

12 Initial inspection and testing .58

12.1 Quality plan .58

12.1.1 General.58

12.1.2 Inspection stages during manufacture of an inner vessel .58

12.1.3 Additional inspection stages during manufacture of a transportable

cryogenic vessel .58

12.2 Production control test plates .59

12.2.1 Number of tests required .59

12.2.2 Testing .59

12.3 Non-destructive testing .59

12.3.1 General.59

12.3.2 Extent of examination for surface imperfections .59

12.3.3 Extent of examination for volumetric imperfections .60

12.3.4 Acceptance criteria for surface and volumetric imperfections as classified

in ISO 6520-1 .61

12.4 Rectification .62

12.4.1 General.62

12.4.2 Manually welded seams .62

12.4.3 Seams produced using automatic welding processes .62

12.5 Pressure testing .62

13 Marking and labelling .63

14 Documentation .63

Annex A (informative) Base materials .64

Annex B (normative) Outer jacket relief devices .67

Annex C (normative) Elastic stress analysis .68

Annex D (normative) Components subject to external pressure (pressure on the convex

surface) — Calculation .77

Annex E (informative) Marking and labelling information .82

Annex F (informative) Specific weld details .84

Annex G (informative) Design validation as part of type approvals .88

Bibliography .90

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.

This document was prepared by ISO/TC 220, Cryogenic vessels.

This second edition cancels and replaces the first edition (ISO 21029-1:2004), which has been technically

revised. The main changes compared to the previous edition are as follows:

— amendments were made in order to increase consistency with the UN model regulations;

— the partial exchange of calculation methods by experimental methods is explained in detail in order

to improve clarity;

— subclauses 10.2 and 12.3 were technically revised, Annex A has been integrated in the main text.

A list of all parts in the ISO 21029 series can be found on the ISO website.

INTERNATIONAL STANDARD ISO 21029-1:2018(E)

Cryogenic vessels — Transportable vacuum insulated

vessels of not more than 1 000 litres volume —

Part 1:

Design, fabrication, inspection and tests

1 Scope

This document specifies requirements for the design, fabrication, type test and initial inspection and

test of transportable vacuum-insulated cryogenic pressure vessels of not more than 1 000 l volume.

This document applies to transportable vacuum-insulated cryogenic vessels for fluids as specified in

3.1 and Table 1 and does not apply to such vessels designed for toxic fluids.

NOTE 1 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that

are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land and marine vehicles, see ISO 13985.

NOTE 2 Specific requirements for open top dewards are not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 2244, Packaging — Complete, filled transport packages and unit loads — Horizontal impact tests

ISO 3834-2, Quality requirements for fusion welding of metallic materials — Part 2: Comprehensive quality

requirements

ISO 4126-1, Safety devices for protection against excessive pressure — Part 1: Safety valves

ISO 4126-2, Safety devices for protection against excessive pressure — Part 2: Bursting disc safety devices

ISO 4136, Destructive tests on welds in metallic materials — Transverse tensile test

ISO 5173, Destructive tests on welds in metallic materials — Bend tests

ISO 5817, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections

ISO 9606-1, Qualification testing of welders — Fusion welding — Part 1: Steels

ISO 9606-2, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium alloys

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

ISO 10474:2013, Steel and steel products — Inspection documents

ISO 10042, Welding — Arc-welded joints in aluminium and its alloys — Quality levels for imperfections

ISO 10675-1, Non-destructive testing of welds — Acceptance levels for radiographic testing — Part 1: Steel,

nickel, titanium and their alloys

ISO 10675-2, Non-destructive testing of welds — Acceptance levels for radiographic testing — Part 2:

Aluminium and its alloys

ISO 14732, Welding personnel — Qualification testing of welding operators and weld setters for mechanized

and automatic welding of metallic materials

ISO 15607, Specification and qualification of welding procedures for metallic materials — General rules

ISO 15613, Specification and qualification of welding procedures for metallic materials — Qualification

based on pre-production welding test

ISO 15614-1, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 15614-2, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 2: Arc welding of aluminium and its alloys

ISO 17635:2016, Non-destructive testing of welds — General rules for metallic materials

ISO 17636-1, Non-destructive testing of welds — Radiographic testing — Part 1: X- and gamma-ray

techniques with film

ISO 17636-2, Non-destructive testing of welds — Radiographic testing — Part 2: X- and gamma-ray

techniques with digital detectors

ISO 17637, Non-destructive testing of welds — Visual testing of fusion-welded joints

ISO 21011, Cryogenic vessels — Valves for cryogenic service

ISO 21013-1, Cryogenic vessels — Pressure-relief accessories for cryogenic service — Part 1: Reclosable

pressure-relief valves

ISO 21013-2, Cryogenic vessels — Pressure-relief accessories for cryogenic service — Part 2: Non-reclosable

pressure-relief devices

ISO 21013-3, Cryogenic vessels — Pressure-relief accessories for cryogenic service — Part 3: Sizing and

capacity determination

ISO 21014, Cryogenic vessels — Cryogenic insulation performance

ISO 21028-1, Cryogenic vessels — Toughness requirements for materials at cryogenic temperature —

Part 1: Temperatures below -80 °C

ISO 21028-2, Cryogenic vessels —Toughness requirements for materials at cryogenic temperature —

Part 2: Temperatures between −80 °C and −20 °C

ISO 21029-2, Cryogenic vessels — Transportable vacuum insulated vessels of not more than 1 000 litres

volume — Part 2: Operational requirements

ISO 23208, Cryogenic vessels — Cleanliness for cryogenic service

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at https:// www .iso .org/ obp

2 © ISO 2018 – All rights reserved

3.1

cryogenic fluid

refrigerated liquefied gas

gas which is partially liquid because of its low temperature

Note 1 to entry: In the context of this document the (refrigerated but) non-toxic gases given in Table 1 and

mixtures of them are referred to as cryogenic fluids.

Note 2 to entry: This includes totally evaporated liquids and supercritical fluids.

Table 1 — Refrigerated but non-toxic gases

a a

UN No. Proper shipping name and description

Asphyxiant gases

1913 neon, refrigerated liquid

1951 argon, refrigerated liquid

1963 helium, refrigerated liquid

1970 krypton, refrigerated liquid

1977 nitrogen, refrigerated liquid

2187 carbon dioxide, refrigerated liquid

2591 xenon, refrigerated liquid

3136 trifluoromethane, refrigerated liquid

b

3158 gas, refrigerated liquid, N.O.S

Oxidizing gases

1003 air, refrigerated liquid

1073 oxygen, refrigerated liquid

2201 nitrous oxide, refrigerated liquid

b

3311 gas, refrigerated liquid, oxidizing, N.O.S

Flammable gases

1038 ethylene, refrigerated liquid

1961 ethane, refrigerated liquid

1966 hydrogen, refrigerated liquid

1972 methane, refrigerated liquid or natural gas, refrigerated liquid, with

high methane content

3138 ethylene, acetylene and propylene mixture, refrigerated liquid,

containing at least 71,5 % ethylene with not more than 22,5 %

acetylene and not more than 6 % propylene

b

3312 gas, refrigerated liquid, flammable, N.O.S

a

U.N. No. and proper shipping name according to UN Recommendations.

b

N.O.S. = not otherwise specified.

3.2

transportable cryogenic vessel

thermally insulated vessel comprising a complete assembly ready for service, consisting of an inner

vessel, an outer jacket, all of the valves and equipment together with any additional framework,

intended for the transport of one or more cryogenic fluids

3.3

thermal insulation

vacuum interspace between the inner vessel and the outer jacket

Note 1 to entry: The space may or may not be filled with material to reduce the heat transfer between the inner

vessel and the outer jacket.

3.4

inner vessel

vessel intended to contain the cryogenic fluid

3.5

outer jacket

gas-tight enclosure that contains the inner vessel and enables the vacuum to be established

3.6

normal operation

intended operation of the vessel at maximum permissible pressure including the handling loads

defined in 3.7

3.7

handling loads

loads exerted on the transportable cryogenic vessel in all normal conditions of transport including

loading, unloading, moving by hand or by fork-lift truck

3.8

piping system

all pipes and piping components which can come in contact with cryogenic fluids including valves,

fittings, pressure relief devices and their supports

3.9

equipment

devices that have a safety-related function with respect to pressure containment and/or control (e.g.

protective or limiting devices, regulating and monitoring devices, valves, indicators)

3.10

manufacturer of the transportable cryogenic vessel

company that carries out the final assembly of the transportable cryogenic vessel

3.11

gross volume of the inner vessel

volume of the inner vessel, excluding nozzles, pipes etc. determined at minimum design temperature

and atmospheric pressure

3.12

tare mass

mass of the empty transportable cryogenic vessel

3.13

net mass

maximum permissible mass of the cryogenic fluid which may be filled

Note 1 to entry: The maximum permissible mass is equal to the mass of the cryogenic fluid occupying 98 % of the

net volume of the inner vessel under conditions of incipient opening of the relief device with the vessel in a level

attitude and the mass of the gas at the same conditions in the remaining volume of the inner vessel.

Note 2 to entry: Cryogenic liquid helium can occupy 100 % of the volume of the inner vessel at any pressure.

3.14

gross mass

sum of tare mass plus net mass

3.15

pressure

pressure relative to atmospheric pressure, i.e. gauge pressure

4 © ISO 2018 – All rights reserved

3.16

automatic welding

welding in which all operations are performed without welding operator intervention during the process

Note 1 to entry: Manual adjustment of welding variables by the welding operator during welding is not possible.

[SOURCE: ISO 14732:2013, 3.1]

3.17

maximum allowable working pressure

MAWP

p

s

maximum effective gauge pressure permissible at the top of the vessel in its normal operating position

including the highest effective pressure during filling and discharge

Note 1 to entry: Adapted from UN Model Regulations, Rev.19, Vol. II, 6.2.1.3.6.5.

3.18

net volume of the inner vessel

volume of the shell, below the inlet to the relief devices, excluding nozzles, pipes, etc. determined at

minimum design temperature and atmospheric pressure

3.19

type approval

vessel type, which was successfully subjected to the design calculation and/or the experimental type

test, as issued by the responsible authority or its delegate

Note 1 to entry: Vessel type is as defined by 10.2.2.

Note 2 to entry: If it can be proven that the calculation and the experimental tests also cover variants of the

prototype these variants may be included in the type approval. If the type includes variants it might also be

called “family”.

3.20

relief plate/plug

plate or plug retained by atmospheric pressure but which allows relief of excess internal pressure

3.21

bursting disc device

non-reclosing pressure relief device ruptured by differential pressure

Note 1 to entry: It is the complete assembly of installed components including, where appropriate, the bursting

disc holder.

4 Symbols

Symbol Designation Unit

A cross sectional area of reinforcing element mm

C, β design factors 1

c allowance for corrosion mm

D shell diameter mm

D external diameter e.g. of a cylindrical shell mm

a

D internal diameter e.g. of a cylindrical shell mm

i

d external diameter of tube or nozzle mm

a

d diameter of opening mm

i

E Young’s modulus N/mm

f narrow side of rectangular or elliptical plate mm

Symbol Designation Unit

I moment of inertia of reinforcing element mm

K material property used for design N/mm

K (e.g. K20 for material

T

material property at temperature T expressed in °C N/mm

property at 20 °C)

l l’ buckling length mm

b, b

n number of lobes 1

bar

p design pressure as defined in 10.2.3.1.1

(MPa)

bar

p permissible external pressure limited by elastic buckling

e

(MPa)

bar

p strengthening pressure

k

(MPa)

bar

p permissible external pressure limited by plastic deformation

p

(MPa)

bar

p maximum permissible pressure

s

(MPa)

bar

p test pressure (see 10.2.3.1.2)

t

(MPa)

R radius of curvature e.g. inside crown radius of dished end mm

R (1 % proof stress for

e

minimum guaranteed yield stress or 0,2 % proof stress N/mm

austenitic steel)

R minimum guaranteed tensile strength (actual or guaranteed) N/mm

m

r radius, e.g. inside knuckle radius of dished end and cones mm

S safety factor at design pressure, with respect to R 1

e

S safety factor against elastic buckling at design pressure 1

k

S safety factor against plastic deformation 1

p

s minimum thickness mm

s actual wall thickness mm

e

u out of roundness (see 11.5.4.2) 1

factor indicative of the utilization of the permissible design stress in joints

v 1

or factor allowing for weakenings

χ (decay-length zone) distance over which governing stress is assumed to act mm

i

Z auxiliary value 1

ν Poisson’s ratio 1

5 General requirements

5.1 Applicable regulations may require conformity assessment.

5.2 The transportable cryogenic vessel shall safely withstand the mechanical and thermal loads and

the chemical effects encountered during pressure testing and normal operation. These requirements are

deemed to be satisfied if Clauses 6 to 11 are fulfilled. The vessel shall be marked in accordance with

Clause 13, tested in accordance with Clause 12 and operated in accordance with ISO 21029-2.

5.3 Transportable cryogenic vessels shall be equipped with valves and pressure relief devices

configured and installed in such a way that the vessel can be operated safely.

The inner vessel, the outer jacket and any section of pipework containing cryogenic fluid which can be

trapped, shall be protected against over pressurization.

6 © ISO 2018 – All rights reserved

5.4 The transportable cryogenic vessel shall be cleaned for the intended service in accordance with

ISO 23208 or an equivalent standard (e.g. EN 12300).

5.5 For transportable cryogenic vessel intended for service with flammable cryogenic fluids, all

metallic components of the vessel shall be electrically continuous. The vessel shall be provided with a

means of attachment to an earthing device(s) so that the resistance to earth is less than 10 Ω.

5.6 The manufacturer shall retain the documentation defined in Clause 14 for a period required

by regulations (e.g. product liability). In addition, the manufacturer shall retain all supporting and

background documentation issued by his subcontractors (if any) which establishes that the vessel

conforms to this document.

6 Mechanical loads

6.1 General

The transportable cryogenic vessel shall resist the mechanical loads without suffering deformation

which could affect safety and which could lead to leakage. This requirement can be validated by:

— calculation (10.2.1);

— experimental method (10.4);

— calculation and experimental method (10.1.3).

The mechanical loads to be considered are given in 6.2 and 6.3.

6.2 Load during the pressure test

The load exerted during the pressure test is given by:

p ≥1,3 p +1 in bar or pp≥+13,,+01 inMPa

() ()

ts ts

where

p is the test pressure, in bar;

t

p is the maximum permissible pressure (= relief device set pressure), bar (+0,1 MPa);

s

+1 is the allowance for external vacuum.

6.3 Other mechanical loads

6.3.1 The following loads shall be considered to act in combination where relevant:

a) a pressure equal to the maximum permissible pressure in the inner vessel and pipework;

b) the pressure exerted by the liquid when the vessel is filled to capacity;

c) loads produced by the thermal movement of the inner vessel, outer jacket and interspace piping;

d) loads imposed in lifting and handling fixtures (at the vessel);

e) full vacuum in the outer jacket;

f) a pressure in the outer jacket equal to the set pressure of the relief device protecting the outer jacket;

g) load due to dynamic effects, when the vessel is filled to capacity, giving consideration to:

1) the inner vessel support system including attachments to the inner vessel and outer jacket;

2) the interspace and external piping;

3) the outer jacket supports and, where applicable, the supporting frame.

6.3.2 Dynamic loads during normal operation, equal to twice the mass of the inner vessel when filled

to the capacity shown on the data plate exerted by the inner vessel both horizontally and vertically, shall

be considered.

6.3.3 If the vessel has a volume of more than 100 l or a gross mass of more than 150 kg or if the height

of the centre of gravity of the fully loaded vessel is less than twice the smallest horizontal dimension at

its base, the vertically upwards acting reference load may be reduced to equal the gross mass.

7 Chemical effects

Due to their temperatures and the materials of construction used, the possibility of chemical action on

the inner surfaces in contact with the cryogenic fluids can be neglected.

Also, due to the fact that the inner vessel is inside an evacuated outer jacket, neither external corrosion

of the inner vessel, nor corrosion on the inner surfaces of the outer jacket will occur. Therefore

inspection openings are not required in the inner vessel or the outer jacket.

Corrosion allowance is also not required on surfaces in contact with the operating fluid or exposed to

the vacuum interspace between the inner vessel and the outer jacket.

8 Thermal conditions

The following thermal conditions shall be taken into account:

a) for the inner vessel and its associated equipment the full range of temperature expected;

b) for the outer jacket and equipment thereof [other than equipment covered by a)]:

1) a minimum working temperature of −20 °C;

2) a maximum working temperature of 50 °C.

9 Material

9.1 General

For the materials used to manufacture the transportable cryogenic vessels, the following requirements

shall be met.

9.2 Material properties

9.2.1 All materials that will, or might, be in contact with cryogenic fluids shall be in accordance with the

relevant standards for compatibility for the specific cryogenic fluid(s) that they might be in contact with.

Particular consideration shall be given to material compatibility with cryogenic fluids that are either

flammable or oxidants.

8 © ISO 2018 – All rights reserved

Material compatibility and cleanliness requirements for vessels intended for service in oxygen or

other oxidising liquids are described in ISO 21010 and ISO 23208 (or in equivalent standard such as

EN 12300).

For liquid hydrogen vessels, consideration shall be given to the possible presence of oxygen enriched air

due to condensation on uninsulated cold parts. See also ISO 21010.

9.2.2 Materials used at low temperatures shall follow the toughness requirements of the relevant

standard. For temperatures below −80 °C, see ISO 21028-1. For non-metallic materials low temperature

suitability shall be demonstrated by providing sufficient test data.

9.2.3 The base materials, listed in Annex A, subject to meeting the extra requirements given in the

main body of this document, are suitable for and may be used in the manufacture of the cryogenic vessels

conforming to this document.

9.3 Inspection certificate

9.3.1 The material shall be declared by an inspection certificate 3.1 in accordance with ISO 10474.

9.3.2 The material manufactured to a recognized International Standard shall meet the testing

requirements of ISO 21028-1 and ISO 21028-2 and shall be certified by inspection certificate 3.1 in

accordance with ISO 10474.

9.3.3 The delivery of material which is not manufactured to a recognized standard shall be certified

by inspection certificate 3.1 in accordance with ISO 10474 confirming that the material fulfils the

requirements listed in 9.2. The material manufacturer shall follow a recognized standard for processing

and establishing the guaranteed material properties.

9.4 Materials for outer jackets and equipment

The outer jacket and the equipment not subjected to cryogenic temperature shall be manufactured

from material suitable for the intended service.

10 Design

10.1 Design options

10.1.1 General

The design shall be carried out in accordance with one of the options given in 10.1.2 or 10.1.3.

NOTE For design validation as part of type approvals see Annex G.

10.1.2 Design by calculation

This option requires calculation of all pressure and load-bearing components. The pressure part

thicknesses of the inner vessel and outer jacket shall be not less than the requirements given in 10.3.

Additional calculations are required to ensure the design is satisfactory for the operating conditions

including an allowance for dynamic loads.

Fatigue life calculation shall be conducted according to EN 13445-3, ASME VIII-2 or equivalent

standards/codes, if the pressure loading is exceeding the limit of predominantly non-cyclic nature

defined by the applied standard/code.

The fatigue life calculation shall be conducted for unlimited lifetime.

Alternatively, the fatigue life of the vessel may be specified. The user of the vessel shall estimate the

operational fatigue load regime during the expected lifetime. Then the designer can take into account

the operational load regime in the fatigue life calculation.

To avoid fatigue damage in case of cyclic loading, more severe fabrication, inspection and testing

requirements are needed for critical areas of the pressure vessels, see also 12.3.4.

For cyclic loaded vessels, the absence of surface imperfections and the necessity of smooth transitions

are essential. Only smooth transitions are allowed.

Similarly, shape imperfections such as peaking are absolutely critical and the maximum permissible

peaking of the applied standard/code, or the value permitted in the fatigue analysis, shall not be

exceeded.

10.1.3 Design by calculation and supplemented with experimental methods

This option requires validation of the pressure-retaining capacity by calculation except that the

minimum wall thickness requirements of Tables 2 and 3 do not apply. Structural

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...