ISO 11999-5:2024

(Main)PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 5: Helmets

PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 5: Helmets

This document specifies the minimum design and performance requirements for helmets as part of personal protective equipment (PPE) to be used by firefighters, primarily but not solely to protect against impact and exposure to flame and high thermal loads.

Équipement de protection individuelle pour pompiers — Méthodes d'essai et exigences pour les équipements de protection individuelle utilisés par les pompiers qui risquent d'être exposés à des niveaux élevés de chaleur et/ou de flamme lorsqu'ils combattent des incendies dans des structures — Partie 5: Casques

General Information

- Status

- Published

- Publication Date

- 01-Aug-2024

- Technical Committee

- ISO/TC 94/SC 14 - Firefighters' personal equipment

- Drafting Committee

- ISO/TC 94/SC 14 - Firefighters' personal equipment

- Current Stage

- 6060 - International Standard published

- Start Date

- 02-Aug-2024

- Due Date

- 15-Aug-2025

- Completion Date

- 02-Aug-2024

Relations

- Effective Date

- 06-Jun-2022

Overview

ISO 11999-5:2024 defines minimum design and performance requirements for helmets used by firefighters who may be exposed to high levels of heat and/or flame while fighting structural fires. It is Part 5 of the ISO 11999 series on PPE for firefighters and focuses on helmet construction, materials, pre‑conditioning, performance testing and marking. The standard is intended to ensure helmets provide protection against impact, flame and high thermal loads while maintaining fit, visibility and user safety.

Key topics and technical requirements

The standard covers a comprehensive set of technical topics and test methods, including:

- Helmet design and fit

- Requirements for head coverage, protected area, fit adjustment and avoidance of protrusions or sharp edges.

- Materials and durability

- Material innocuousness, resistance to cleaning/disinfecting agents, reinforcement and component replacement guidance.

- Pre‑conditioning procedures

- Conditioning such as thermal shock, water soak, “thermal plus” and “thermal minus” treatments for realistic aging and exposure simulation.

- Mechanical performance tests

- Force impact resistance, optional impact energy attenuation, penetration resistance, lateral crushing and retention system strength/effectiveness.

- Thermal and flame performance

- Flame resistance, optional flame engulfment, radiant heat resistance, convective heat resistance and thermal protective performance for neck protectors/ear covers (Shikoro).

- Special hazards and ancillary tests

- Protection against molten metal splash, electrical insulation tests, chemical resistance, hardware corrosion resistance.

- Ocular integration

- Optical properties, scratch resistance, fogging resistance and high‑speed particle impact testing for integrated visors/oculars.

- Marking and documentation

- Requirements for marking helmets to convey conformity, sizing and care instructions.

Applications and users

ISO 11999-5:2024 is used by:

- Helmet manufacturers designing and validating structural firefighting helmets.

- Test laboratories and certification bodies conducting compliance testing and conformity assessments.

- Procurement and safety managers specifying helmet performance for fire brigades and emergency services.

- Regulatory authorities and standards developers aligning national requirements with international best practice.

- Equipment designers and R&D teams developing new materials and helmet systems for improved thermal and impact protection.

By following ISO 11999-5, stakeholders can ensure firefighter helmets meet harmonized test methods and performance expectations for structural firefighting scenarios.

Related standards

This part references and aligns with other standards such as ISO 11999-3 (clothing), ISO 11999-9 (firehoods), ISO 11612, EN 960 (headforms), EN 13087 test series and NFPA 1971, among others. These related documents address complementary PPE and testing contexts.

Buy Documents

ISO 11999-5:2024 - PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 5: Helmets Released:2. 08. 2024

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO 11999-5:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 5: Helmets". This standard covers: This document specifies the minimum design and performance requirements for helmets as part of personal protective equipment (PPE) to be used by firefighters, primarily but not solely to protect against impact and exposure to flame and high thermal loads.

This document specifies the minimum design and performance requirements for helmets as part of personal protective equipment (PPE) to be used by firefighters, primarily but not solely to protect against impact and exposure to flame and high thermal loads.

ISO 11999-5:2024 is classified under the following ICS (International Classification for Standards) categories: 13.340.20 - Head protective equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11999-5:2024 has the following relationships with other standards: It is inter standard links to ISO 11999-5:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 11999-5:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 11999-5

Second edition

PPE for firefighters — Test methods

2024-08

and requirements for PPE used

by firefighters who are at risk of

exposure to high levels of heat

and/or flame while fighting fires

occurring in structures —

Part 5:

Helmets

Équipement de protection individuelle pour pompiers —

Méthodes d'essai et exigences pour les équipements de protection

individuelle utilisés par les pompiers qui risquent d'être exposés

à des niveaux élevés de chaleur et/ou de flamme lorsqu'ils

combattent des incendies dans des structures —

Partie 5: Casques

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

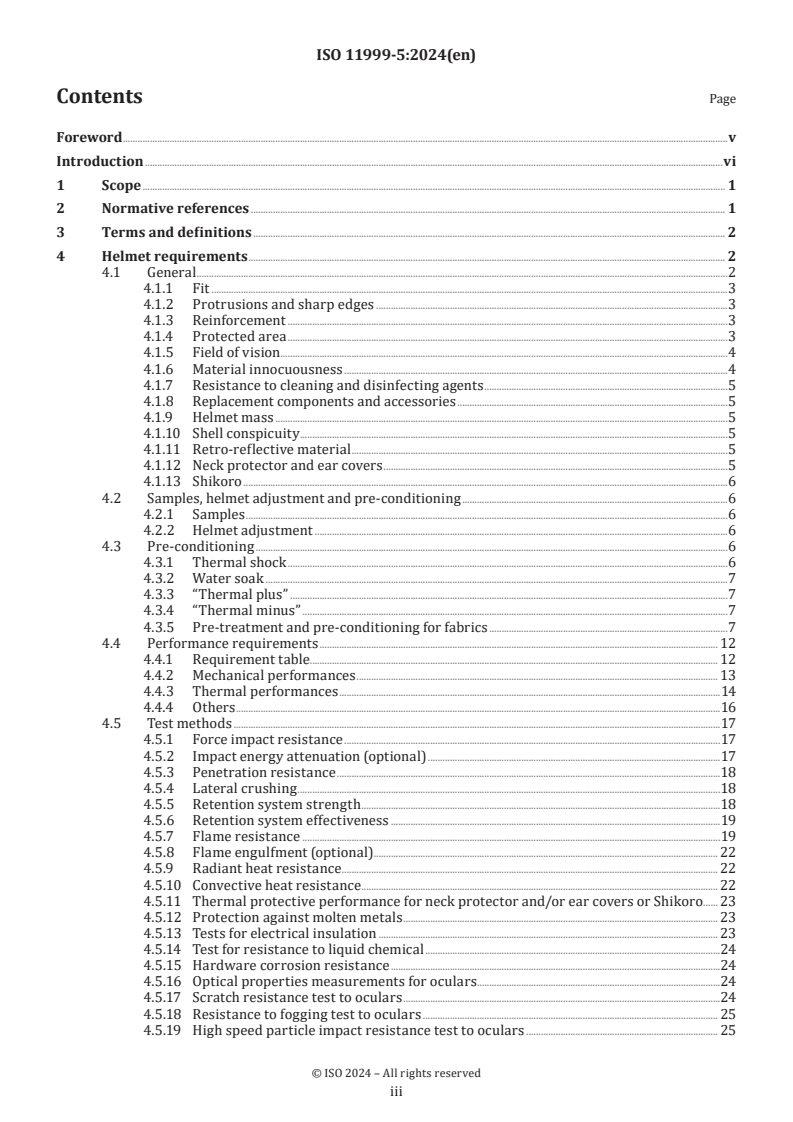

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Helmet requirements . 2

4.1 General .2

4.1.1 Fit .3

4.1.2 Protrusions and sharp edges .3

4.1.3 Reinforcement .3

4.1.4 Protected area .3

4.1.5 Field of vision.4

4.1.6 Material innocuousness .4

4.1.7 Resistance to cleaning and disinfecting agents .5

4.1.8 Replacement components and accessories .5

4.1.9 Helmet mass .5

4.1.10 Shell conspicuity .5

4.1.11 Retro-reflective material .5

4.1.12 Neck protector and ear covers .5

4.1.13 Shikoro .6

4.2 Samples, helmet adjustment and pre-conditioning .6

4.2.1 Samples .6

4.2.2 Helmet adjustment .6

4.3 Pre-conditioning .6

4.3.1 Thermal shock .6

4.3.2 Water soak .7

4.3.3 “Thermal plus” .7

4.3.4 “Thermal minus” .7

4.3.5 Pre-treatment and pre-conditioning for fabrics .7

4.4 Performance requirements . 12

4.4.1 Requirement table . 12

4.4.2 Mechanical performances . 13

4.4.3 Thermal performances .14

4.4.4 Others .16

4.5 Test methods .17

4.5.1 Force impact resistance .17

4.5.2 Impact energy attenuation (optional) .17

4.5.3 Penetration resistance .18

4.5.4 Lateral crushing .18

4.5.5 Retention system strength .18

4.5.6 Retention system effectiveness .19

4.5.7 Flame resistance .19

4.5.8 Flame engulfment (optional) . 22

4.5.9 Radiant heat resistance . 22

4.5.10 Convective heat resistance . 22

4.5.11 Thermal protective performance for neck protector and/or ear covers or Shikoro . 23

4.5.12 Protection against molten metals . 23

4.5.13 Tests for electrical insulation . 23

4.5.14 Test for resistance to liquid chemical .24

4.5.15 Hardware corrosion resistance .24

4.5.16 Optical properties measurements for oculars . .24

4.5.17 Scratch resistance test to oculars .24

4.5.18 Resistance to fogging test to oculars . 25

4.5.19 High speed particle impact resistance test to oculars . 25

iii

5 Marking . .25

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 94, Personal safety — Protective clothing and

equipment, Subcommittee SC 14, Fire-fighters’ personal equipment.

This second edition cancels and replaces the first edition (ISO 11999-5:2015), which has been technically

revised.

The main changes are as follows:

— the content has been revised with a focus on single performance requirements.

A list of all parts in the ISO 11999 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

Figures are reproduced from AS/NZS 4067:2012 and AS/NZS 2512.1:2009, with permission from Standards

Australia. ISO has no responsibility and context in which are extracts are reproduced, nor is ISO in anyway

responsible for the other content or accuracy therein.

vi

International Standard ISO 11999-5:2024(en)

PPE for firefighters — Test methods and requirements for

PPE used by firefighters who are at risk of exposure to high

levels of heat and/or flame while fighting fires occurring in

structures —

Part 5:

Helmets

1 Scope

This document specifies the minimum design and performance requirements for helmets as part of personal

protective equipment (PPE) to be used by firefighters, primarily but not solely to protect against impact and

exposure to flame and high thermal loads.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 3146, Plastics — Determination of melting behaviour (melting temperature or melting range) of semi-

crystalline polymers by capillary tube and polarizing-microscope methods

ISO 6330:2021, Textiles — Domestic washing and drying procedures for textile testing

ISO 6942:2022, Protective clothing — Protection against heat and fire — Method of test: Evaluation of materials

and material assemblies when exposed to a source of radiant heat

ISO 9151, Protective clothing against heat and flame — Determination of heat transmission on exposure to flame

ISO 9185:2007, Protective clothing — Assessment of resistance of materials to molten metal splash

ISO 11612:2015, Protective clothing — Clothing to protect against heat and flame — Minimum performance

requirements

ISO 11999-3, PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk

of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 3: Clothing

ISO 11999-9, PPE for firefighters — Test methods and requirements for PPE used by firefighters who are at risk

of exposure to high levels of heat and/or flame while fighting fires occurring in structures — Part 9: Firehoods

ISO 13688:2013 + ISO 13688:2013/Amd.1:2021, Protective clothing — General requirements

ISO 15025, Protective clothing — Protection against flame — Method of test for limited flame spread

ISO 17492, Clothing for protection against heat and flame — Determination of heat transmission on exposure to

both flame and radiant heat

ISO 17493, Clothing and equipment for protection against heat — Test method for convective heat resistance

using a hot air circulating oven

ISO/TR 19591, Personal protective equipment for firefighters — Standard terms and definitions

EN 136:1998, Respiratory protective devices - Full face masks

EN 137:2006, Respiratory protective devices. Self-contained open-circuit compressed air breathing apparatus

with full facemask. Requirements, testing, marking

EN 167:2001, Personal eye protection — Optical test methods

EN 168:2001, Personal eye protection — Non-optical test methods

EN 172:1994 + A1: 2000, Personal eye protection — Sunglare filters for industrial use

EN 960, Headforms for use in the testing of protective helmets

EN 13087-1:2012, Protective helmets — Test methods — Part 1: Conditions and conditioning

EN 13087-2:2012, Protective helmets — Test methods — Part 2: Shock absorption

EN 13087-4, Protective helmets — Test methods — Part 4: Retention system effectiveness

EN 13087-5:2012, Protective helmets — Test methods — Part 5: Retention system strength

EN 13087-6, Protective helmets — Test methods — Part 6: Field of vision

EN 13087-8:2000, Protective helmets — Test methods — Part 8: Electrical properties

EN 13087-10, Protective helmet — Test methods — Part 10: Resistance to radiant heat

NFPA 1971:2018, Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting

CIE 54.2, Retroreflection – Definition and measurement

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/TR 19591 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Helmet requirements

4.1 General

Helmets shall consist of at least the following assembled components:

a) Shell (at the minimum area above the A-A’ line as per Figure 1).

b) Energy absorbing system.

c) Retention system. The retention system shall include a chinstrap having a minimum width of 19 mm,

quick release buckle, and size adjustment mechanism.

d) Neck protector and/or ear covers, or Shikoro.

e) Face shield or goggles or both —

— where a face shield is selected, the face shield shall be attached to and tested with the helmet;

— where goggles are selected, the goggles shall be permitted to be removed from the helmet before it is

tested. This only applies to those which are removable. Where they are attached to the helmet, they

shall be tested with the helmet.

f) Retro-reflective material.

4.1.1 Fit

The fit of the helmet shall be adjustable laterally and/or vertically to improve the wearing comfort and the

helmet efficiency. This adjustment shall be easily done by the wearer without the use of tools. It should

be possible for the wearer to remove the helmet by loosening the chinstraps, using one hand wearing a

structural firefighting glove.

When this adjustment covers several sizes of head circumference, the relevant instructions shall be given in

the information supplied by the manufacturer.

4.1.2 Protrusions and sharp edges

There shall be no sharp edges, roughness, or projection on any part of the helmet. Projections intruding

more than 5 mm from the shell interior surface and above the test line, shall not be acceptable unless

covered by protective padding or impact liner. Projections above the test line shall be impacted directly over

the position of the said projection in accordance with 4.4.2.1, and the testing laboratory shall assess that the

projection did not make contact with the head form.

Rigid internal projections below the test line and above the reference plane shall not be able to touch the

head of the wearer when the helmet is normally affixed to the head.

The profile at the front of the helmet shall not prevent the wearing of spectacles or goggles as specified by

the helmet manufacturer.

4.1.3 Reinforcement

The shell construction shall be uniformly reinforced. This does not exclude a gradual increase of the shell’s

thickness or of the grooves or fixation devices of the harness or of the accessories, but it does exclude every

other localized reinforcement.

4.1.4 Protected area

When adjusted on the head form as in 4.2.2, the helmet shall at the minimum cover the entire area 12,7 mm

above the reference plane (see line A -A’ in Figure 1).

Dimensions in millimetres

Key

1 reference plane

2 basic plane

3 central vertical axis

Figure 1 — Protected area (Image taken from AS/NZS 2512.1:2009)

4.1.5 Field of vision

When the helmet is tested in accordance with EN 13087-6, with any attached face shield or goggle in both

the stowed and deployed positions, the wearer’s field of vision shall correspond to the following angles:

a) A dihedral angle of at least 105° measured horizontally between L and K on each side of the sagittal plane

which passes through the point L (see Figure 2). Remove the neck protector or Shikoro, if necessary.

b) An upper dihedral angle greater than 7° above the reference plane and which is defined by the straight

line passing through L1, L2 (see Figure 2).

c) A lower dihedral angle greater than 45° under the basic plane and which is defined by the straight line

passing through K1 K2 situated on the surface of the head form as 31 mm on each side of the point K (see

Figure 2).

d) With face shield or goggles in the stowed position, the helmet shall provide peripheral vision clearance

of at least 94° to each side.

NOTE “Stowed position” means to be placed in “out of use” position when it is not providing the designed

protection.

4.1.6 Material innocuousness

Materials used in helmets that may come into contact with the wearer’s skin shall not be known to be likely

to cause irritation or any other adverse effect to health. They shall meet the requirements as detailed in

ISO 13688:2013, 4.2.

4.1.7 Resistance to cleaning and disinfecting agents

All helmet materials shall be unimpaired after cleaning and disinfection by the agents and procedures

specified in the information provided by the manufacturer. Such agents shall not be known to be likely to

cause irritation or any other adverse effect to the health of the wearer.

4.1.8 Replacement components and accessories

The fitting and/or replacement of any interchangeable parts or accessories shall not impair the function

and/or safety of the helmet. All accessories and their respective replacement procedures shall be given in

the information supplied by the manufacturer. No openings shall penetrate the helmet shell other than those

provided by the manufacturer for mounting energy absorbing systems, retention systems or accessories.

Face shields shall not be considered as accessories and along with neck protectors shall be considered as

fixed components of the helmet assembly.

4.1.9 Helmet mass

If helmet mass, excluding non-permanently fitted accessory parts, exceed 1 500 g it shall be marked on the

helmet visible to users.

4.1.10 Shell conspicuity

The helmet shell shall have retro-reflective markings in accordance with 4.1.11 adhered to the shell exterior.

A minimum of 26 cm of the markings shall be visible when the helmet is viewed from any angle at the

reference plane (see Key 2 on Figure 1). A material which combines both fluorescent and retro-reflective

properties may be used. Care should be exercised when selecting marking materials to ensure they will not

degrade the helmet shell.

4.1.11 Retro-reflective material

The material shall have a coefficient of luminous intensity per square meter (CIL/m ) of not less than

−1 −2

100 cd·lux ·m when measured in accordance with CIE 54.2 with an observation angle of 0,2° and entrance

angle of −4°.

4.1.12 Neck protector and ear covers

Neck protector and/or ear covers shall cover the wearer’s neck and ears and shall provide at least the

following area of coverage as described below.

The helmet with neck protector and ear cover shall be donned in the proper wearing position as specified

by the manufacturer on an EN 960 head form 575 according to its helmet positioning index. The helmet

positioning index shall be the vertical distance, as specified by the manufacturer, from the lowest point of

the brow at the lateral midpoint of the helmet to the basic plane of the EN 960 head form 575 with the helmet

firmly positioned on the head form. See Figure 4.

In this position, the neck coverage shall be measured downward from the reference plane to the lower edge

of the neck coverage:

a) 95 mm measured 50 mm forward of the coronal plane;

b) 120 mm measured 25 mm forward of the coronal plane;

c) 130 mm measured at the coronal plane;

d) 130 mm measured at the midsagittal plane at the rear of the head form.

4.1.13 Shikoro

Where Shikoro is fitted, it shall be made of fire resistant fabric that surrounds the entire wearer’s head,

neck part below the helmet brim level except eye portion covered by the face shield. Its purpose is to prevent

direct flame contact to wearer’s head, face, or neck and also to reduce heat stress. The helmet fitted with

Shikoro shall continue to meet the relevant requirements of 4.4.3.1 to 4.4.3.5.

4.2 Samples, helmet adjustment and pre-conditioning

Helmet samples shall be submitted for testing in the condition in which they are offered for sale, including

any means of attachment for energy absorbing systems, retention systems, neck protector and ear covers or

Shikoro, as well as face shield or goggles as specified in the test methods.

4.2.1 Samples

Unless otherwise specified in the test methods, the number of specimens needed for pre-conditioning and

testing shall be in accordance with Table 2.

4.2.2 Helmet adjustment

The helmet shall be adjusted in accordance with the Head Positioning Index (HPI) provided by the

manufacturer before testing is performed. Following alignment with the selected head form, the helmet is

firmly seated on the head form with the aid of a (5,0 ± 0,5) kg ballast mass. If the wearing adjustment covers

several sizes of head form, then the size of head form representing the most unfavourable case shall be used.

Helmets shall be tested on head forms that conform to EN 960 and to sizes as appropriate to the test

performed.

4.3 Pre-conditioning

Unless otherwise specified in the specific test methods, all specimens (complete with any attached

accessories, which shall be in the stowed position, where appropriate) shall be pre-conditioned for a

minimum of 24 h by exposure to a temperature of (20 ± 2) °C and a relative humidity of (65 ± 15) % prior to

testing.

Testing shall be carried out within 5 min of removing the samples from pre-conditioning.

Where specified in the test methods, helmets shall be conditioned in accordance with the conditioning

sequence defined in Table 2 and testing shall be carried out within 5 min of removing from the conditioning

chamber.

4.3.1 Thermal shock

Expose the helmet successively to the following conditions:

a) 1 h at the temperature of: (choose a condition mark accordingly) –10 °C ± 2 °C; −20 °C ± 2 °C; −30 °C ± 2 °C

or −40 °C ± 2 °C,

b) 1 h at a temperature of 60 °C ± 2 °C;

c) 15 min totally immersed in fresh tap water at a temperature of 10 °C ± 2 °C;

d) 1 h at a temperature of 60 °C ± 2 °C;

e) 20 h to 24 h at standard temperature 20 °C ± 2 °C and standard relative humidity 65 % ± 5 %.

The time interval between sequences a) to b), b) to c) and c) to d) shall be within 5 s. During sequences d)

and e), the helmet shall be in a position that allows it to drain.

4.3.2 Water soak

The helmet shall be conditioned according to EN 13087-1:2012, 4.6, with tap water temperature not greater

than 27 °C, for between 4 h and 24 h.

4.3.3 “Thermal plus”

The helmet shall be conditioned according to EN 13087-1:2012, 4.4 at the temperature of 50 °C ± 2 °C for

between 4 h and 24 h.

4.3.4 “Thermal minus”

The helmet shall be conditioned according to EN 13087-1:2012, 4.5 at the temperature chosen in 4.3.1 a) for

between 4 h and 24 h.

4.3.5 Pre-treatment and pre-conditioning for fabrics

The neck protector and/or ear cover or Shikoro shall be laundered in line with the manufacturer’s

instructions on the basic standardized processes for five cleaning cycles. If the cleaning method is not

specified, the specimens shall be subjected to five cleaning cycles in accordance with the procedure defined

in Table 1.

Table 1 — Laundering procedure

Wash procedure Dry procedure

ISO 6330, 6N (front load, normal, 60 °C, 1 g/L ECE deter- ISO 6330:2021, Annex F, (machine Type A1)

gent in soft water) exhaust temperature normal

Following pre-treatment, specimens shall be pre-conditioned in accordance with 4.3.

Key

CTV central transverse vertical plane

LVM longitudinal vertical median plane

F front

B back

a

Reference plane.

b

Basic plane.

Figure 2 — Section of head form, longitudinal, vertical, medial, reference and basic planes (Image

taken from of AS/NZS 4067)

Key

A mid-sagittal plane

B reference plane

C basic plane

D coronal plane

E central vertical axis

1 crown

2 front

3 rear

4 left or right

Figure 3 — Impact points for force impact

Dimensions in millimetres

Key

A central and vertical axis

B front vertical transverse plane

C front test area

D front test line (85 mm above basic plane)

E top test area

F rear vertical transverse plane

G two side test area (left and right)

H rear test area

I rear test line (60 mm above test line)

J reference plane

K basic plane

Figure 4 — Impact sites for impact energy attenuation (Image taken from AS/NZ 4067)

Table 2 — Pre-conditioning and testing sequence

Sequence 0 1 2 3 4 5

Helmet Pre-con- Ther- Ther- Ther- Water Specific test

specimen dition- mal mal mal soak

number ing shock plus minus

4.3.2

4.3.3 4.3.4

4.3.1

1 X 4.1.4 Protected area

1 X 4.1.5 Field of vision

1 X X

2 X X 4.5.1 Force impact resistance

3 X X

4 X X

5 X X 4.5.2 Impact energy attenuation (optional)

6 X X

7 X X

4.5.3 Penetration

8 X X

2 X 4.5.4 Lateral crushing

3 X 4.5.5 Retention system strength

7 X 4.5.6 Retention system effectiveness

4.5.7.2 Flame resistance tests on helmets, Method 1

9 X X

4.5.7.2 Flame resistance tests on helmets, Method 2

X 4.5.7.3 Flame resistance on face shield/goggles

4.5.7.4 Flame resistance on neck protector and/or ear

X

cover of Shikoro and chin strap material

13 X 4.5.8 Flame engulfment (optional)

(optional)

10 X 4.5.9.1 (method A) Radiant heat resistance: Helmet

X 4.5.9.2 (method B) Radiant heat resistance: Face

shield/goggle

Fabric X 4.5.9.3 Radiant heat transfer: Neck protector and ear

assembly cover/Shikoro

11 X 4.5.10 Convective heat: Helmet

X 4.5.10 Convective heat: Neck protector and ear cover/

Shikoro, thread

X 4.5.10 Convective heat: Face shield/goggles

Fabric X 4.5.11 TPP: neck protector and ear cover or Shikoro

assembly HTI: Shikoro only

14 X 4.5.12 Protection against molten metal

3 X 4.5.13.1 Electrical: Conductive head form

(On helmet and face shield)

6 X 4.5.13.2 Electrical: Wet helmet insulation

3 X 4.5.13.3 Electrical: Surface insulation

4.5.14 Contact with liquid chemicals

12 X

(On helmet and face shield/goggles)

X 4.5.15 Hardware corrosion resistance

X 4.5.16 Optical properties: Face shield/goggles

X 4.5.17 Resistance to scratch: Face shield/goggle

X 4.5.18 Resistance to fogging: Face shield/goggles

X 4.5.19 High speed particle impact: Face shield

4.4 Performance requirements

4.4.1 Requirement table

No helmet sample that has been subjected to testing shall be offered for sale.

Helmets shall be tested according to the performance requirements in accordance with Table 3, as

appropriate with manufacturer’s accessories in place as appropriate. The required state of deployment of

these accessories during testing are described in 4.4.2 to 4.4.4.

Table 3 — Overview of helmet performance requirements

Performance property Applies to Clause

Mechanical

Resistance to force impact Helmet 4.4.2.1

Impact energy attenuation (optional) Helmet 4.4.2.2

Resistance to penetration Helmet 4.4.2.3

Lateral crushing Helmet 4.4.2.4

Retention system strength Retention system 4.4.2.5

Retention system effectiveness Retention system 4.4.2.6

Thermal

Flame resistance Helmet

Neck protector and/or ear cover or Shikoro

4.4.3.1

Chin strap

Face shield/goggles

Flame engulfment (optional) Helmet and accessories 4.4.3.2

Radiant heat resistance Helmet

Face shield/goggles 4.4.3.3

Neck protector and/or ear cover or Shikoro

Convective heat resistance Helmet

Face shield/goggles

Neck protector and/or ear cover or Shikoro 4.4.3.4

Thread

Label (for traditional style helmet)

Thermal protective performance Neck protector and/or ear cover or Shikoro 4.4.3.5

Molten metal Helmet

4.4.3.6

Neck protector and/or ear cover or Shikoro

Others

Electrical, conductive headform Helmet

4.4.4.1.1

Face shield

Electrical, wet helmet insulation Helmet 4.4.4.1.2

Electrical, surface insulation Helmet 4.4.4.1.3

Contact with liquid chemical Helmet

4.4.4.2

Face shield

Corrosion resistance Hardware 4.4.4.3

Optical properties Face shield/goggles 4.4.4.4

Resistance to scratch Face shield/goggles 4.4.4.5

Resistance to fogging Face shield/goggles 4.4.4.6

High speed particle impact Face shield/goggles 4.4.4.7

4.4.2 Mechanical performances

4.4.2.1 Force impact resistance

The helmet shall be tested according to 4.5.1, with face shield/goggles attached (excluding neck protector

and/or ear cover or Shikoro), and the force transmitted to the head form shall not exceed 15 kN with an

impact energy of (123 ± 1) J on the crown and (25 ± 1) J on the off-crowns.

4.4.2.2 Impact energy attenuation (optional)

The helmet, with face shield/goggles in the deployed position (excluding neck protector and ear cover/

Shikoro), shall be tested according to 4.5.2, and shall not exceed the maximum acceleration as specified

follows:

— top: 1 471,5 m/s (150g);

— front: 2 943,0 m/s (300g);

— sides: 2 943,0 m/s (300g);

— back: 2 943,0 m/s (300g).

Any acceleration above 1 962 m/s (200g) shall not exceed a duration of 3 ms, and an acceleration above

1 471,5 m/s (150g) shall not exceed a duration of 6 ms.

4.4.2.3 Penetration resistance

The helmet shall be tested according to 4.5.3 with the face shield/goggles in deployed position (excluding

neck protector and ear cover/Shikoro), and shall have no contact between the striker and the test block.

4.4.2.4 Lateral crushing

The helmet shall be tested according to 4.5.4 with the maximum transverse and longitudinal deformations

not exceeding 40 mm, and the residual deformations not exceeding 15 mm.

4.4.2.5 Retention system strength

The helmet shall be tested according to 4.5.5:

a) the maximum elongation of the whole system shall not exceed 20 mm for a load of 250 N;

b) the minimum width of the chin strap shall not be less than 15 mm for a load of 250 N;

c) the release point of the retention system shall be between 500 N and 1 000 N.

NOTE Users are reminded of the following possible consequences when making a decision with regards to c):

— Option to not adopt – there is a risk of strangulation due to the wearer being hung by the chinstrap if the chinstrap

does not release below 1 000 N.

— Option to adopt – there is a risk of losing head protection by having the helmet retention system break prematurely

(i.e. below 500 N) due to deterioration of retention system over time.

4.4.2.6 Retention system effectiveness

Tested according to 4.5.6, the helmets shall not come off the head form.

4.4.3 Thermal performances

4.4.3.1 Flame resistance

The helmet, together with face shield/goggles, neck protector and/or ear cover or Shikoro and chin strap

material shall be tested according to the respective subclauses of 4.5.7 and shall meet the following

requirements.

a) Helmet material, including edging shall not show any visible after flame or glow 5 s after removal from

the test f lame.

b) Face shield/goggles shall not show any visible flame or glow 5 s after removal from the test flame.

c) No part of the helmet and face shield/goggles around test point shall show separation, melting or

dripping.

d) Individual materials in the fabric assembly of neck protector and/or ear cover or Shikoro and chin strap

webbing shall demonstrate the following performances:

Table 4 — Limited flame spread performance following Surface ignition

Properties Requirements

Flame spread No specimen shall permit any part of the lowest boundary of any flame to reach the upper or

either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

Hole formation No specimen shall give hole formation of 5 mm or greater in any direction, except for an inner

layer that is used for specific protection other than flame or heat protection.

Afterglow Afterglow time shall be ≤2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and

for the purpose of this clause is not regarded as afterglow.

After flame After flame time shall be ≤2 s.

Table 5 — Limited flame spread performance following Bottom-edge ignition

Properties Requirements

Flame spread No specimen shall permit any part of the lowest boundary of any flame to reach the upper or

either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

After flame After flame time shall be ≤2 s.

Afterglow Afterglow time shall be ≤2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and

for the purpose of this clause is not regarded as afterglow.

Char length Char length shall be <100 mm in accordance with ISO 15025:2016, Annex C.

4.4.3.2 Flame engulfment (optional)

When tested in accordance with 4.5.8, the helmet together with face shield/goggles, neck protector and/or

ear cover or Shikoro, shall not show any visible afterflame or glow 5 s after removal from the test flame.

4.4.3.3 Radiant heat resistance

The helmet, with face shield/goggle attached in the stowed position, shall be tested in accordance with

4.5.9.1 (method A) for helmet, 4.5.9.2 (method B) for face shield/goggles and 4.5.9.3 for neck protector and/

or ear cover or Shikoro, and shall meet the following requirements.

a) No part of the helmet, face shield/goggles shall ignite or melt to such a degree as to cause softening or

dripping of material such that there is contact of the material with the head form.

b) The temperature measured at the surface of the artificial head shall not rise more than 20 °C above the

standard laboratory temperature of 20 °C ± 3 °C.

c) Neck protector and/or ear cover or Shikoro shall achieve the radiant heat transfer performances in

Table 6 and results rounded to the nearest whole second (s).

Table 6 — Radiant heat transfer

Heat transfer index Performance (s)

RHTI ≥11

RHTI – RHTI ≥4

24 12

4.4.3.4 Convective heat resistance

When tested according to 4.5.10, helmets with neck protector and ear cover/Shikoro, and face shield/goggles

attached in the deployed position shall meet the following requirements.

a) no part of the helmet assembly that is not in contact with the head form before the test shall come into

contact with the head form as a result of the test. Evaluate by visual inspection.

b) there shall be no ignition, separation, melting or dripping of any part of the helmet assembly, including

threads.

c) any moveable elements of the helmet, (e.g. chin strap closure and release device(s) or face shield

mechanism) shall remain functional.

d) there shall be no ignition, melting or loss of legibility of any part of the product labels.

e) no part of the face shield/goggles component that was not below the brim line prior to the test shall be

below the brim line after the test.

f) there shall be no dripping of the face shield/goggle component.

g) no part of the neck protector and ear cover and Shikoro shall ignite, melt or shrink more than 5 % (10 %

for Shikoro) in two perpendicular directions.

4.4.3.5 Thermal protective performance (TPP)

When tested according to 4.5.11, neck protector and/or ear cover assembly or Shikoro shall have an average

TPP of at least 20.

Shikoro only shall be tested in accordance with ISO 9151, after 4.3.5 pre-treatment with the performance of

HTI ≥ 10 s and HTI – HTI ≥ 3 s.

24 24 12

4.4.3.6 Protection against molten metals

When tested according to 4.5.12, helmets, neck protector and/or ear covers or Shikoro:

a) shall not be penetrated by the molten metal;

b) shall not show any deformation greater than 10 mm when measured at right angles to the base plane of

the helmet;

c) shall not burn with the emission of a flame after a period of 5 s has elapsed after the pouring of the

molten metal has ceased;

d) neck protector and ear cover/Shikoro shall meet the requirements of ISO 11612:2015, 7.5 Performance

level E2.

4.4.4 Others

4.4.4.1 Electrical resistance

4.4.4.1.1 Conductive headform test

The helmet assembly shall be tested according to 4.5.13.1 and shall show no visible evidence of breakdown

and the leakage current shall not exceed 3,0 mA.

4.4.4.1.2 Wet helmet insulation test

When tested according to 4.5.13.2, the helmet assembly shall show no visible evidence of breakdown and the

leakage current shall not exceed 3,0 mA.

4.4.4.1.3 Surface in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...