ISO 5910:2018

(Main)Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices

Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices

1.1 This document applies to all heart valve repair systems that have an intended use to repair and/or improve the function of native human heart valves by acting either on the valve apparatus or on the adjacent anatomy (e.g. ventricle, coronary sinus). 1.2 This document outlines an approach for verifying/validating the design and manufacture of a heart valve repair system through risk management. The selection of appropriate verification/validation tests and methods are derived from the risk assessment. The tests include assessments of the physical, chemical, biological, and mechanical properties of components and materials of heart valve repair systems. The tests also include preclinical in vivo evaluation and clinical investigation of the finished heart valve repair system to assess the safety and effectiveness of the heart valve repair system. NOTE For the purposes of this document, effectiveness endpoint includes clinical performance and benefits. 1.3 This document defines operational conditions and performance requirements for heart valve repair systems where adequate scientific and/or clinical evidence exists for their justification. 1.4 This document excludes Cardiac Resynchronization Therapy (CRT) devices, paravalvular leakage closure devices, systems that do not leave an implant in place (e.g. ablation, radio frequency annuloplasty), apical conduits and devices with components containing viable cells. This Standard also excludes materials not intended for repairing and/or improving the function of human heart valves according to its intended use (e.g. patch material and sutures used in general surgical practice). NOTE A rationale for the provisions of this document is given in Annex A.

Implants cardiovasculaires et circuits extra-corporels — Dispositifs de réparation de valves cardiaques

General Information

- Status

- Withdrawn

- Publication Date

- 30-May-2018

- Technical Committee

- ISO/TC 150/SC 2 - Cardiovascular implants and extracorporeal systems

- Drafting Committee

- ISO/TC 150/SC 2/WG 1 - Cardiac valves

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 05-Jul-2024

- Completion Date

- 14-Feb-2026

Relations

- Revised

ISO 5910:2024 - Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices - Effective Date

- 23-Apr-2020

Buy Documents

ISO 5910:2018 - Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices Released:5/31/2018

ISO 5910:2018 - Cardiovascular implants and extracorporeal systems -- Cardiac valve repair devices

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO 5910:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices". This standard covers: 1.1 This document applies to all heart valve repair systems that have an intended use to repair and/or improve the function of native human heart valves by acting either on the valve apparatus or on the adjacent anatomy (e.g. ventricle, coronary sinus). 1.2 This document outlines an approach for verifying/validating the design and manufacture of a heart valve repair system through risk management. The selection of appropriate verification/validation tests and methods are derived from the risk assessment. The tests include assessments of the physical, chemical, biological, and mechanical properties of components and materials of heart valve repair systems. The tests also include preclinical in vivo evaluation and clinical investigation of the finished heart valve repair system to assess the safety and effectiveness of the heart valve repair system. NOTE For the purposes of this document, effectiveness endpoint includes clinical performance and benefits. 1.3 This document defines operational conditions and performance requirements for heart valve repair systems where adequate scientific and/or clinical evidence exists for their justification. 1.4 This document excludes Cardiac Resynchronization Therapy (CRT) devices, paravalvular leakage closure devices, systems that do not leave an implant in place (e.g. ablation, radio frequency annuloplasty), apical conduits and devices with components containing viable cells. This Standard also excludes materials not intended for repairing and/or improving the function of human heart valves according to its intended use (e.g. patch material and sutures used in general surgical practice). NOTE A rationale for the provisions of this document is given in Annex A.

1.1 This document applies to all heart valve repair systems that have an intended use to repair and/or improve the function of native human heart valves by acting either on the valve apparatus or on the adjacent anatomy (e.g. ventricle, coronary sinus). 1.2 This document outlines an approach for verifying/validating the design and manufacture of a heart valve repair system through risk management. The selection of appropriate verification/validation tests and methods are derived from the risk assessment. The tests include assessments of the physical, chemical, biological, and mechanical properties of components and materials of heart valve repair systems. The tests also include preclinical in vivo evaluation and clinical investigation of the finished heart valve repair system to assess the safety and effectiveness of the heart valve repair system. NOTE For the purposes of this document, effectiveness endpoint includes clinical performance and benefits. 1.3 This document defines operational conditions and performance requirements for heart valve repair systems where adequate scientific and/or clinical evidence exists for their justification. 1.4 This document excludes Cardiac Resynchronization Therapy (CRT) devices, paravalvular leakage closure devices, systems that do not leave an implant in place (e.g. ablation, radio frequency annuloplasty), apical conduits and devices with components containing viable cells. This Standard also excludes materials not intended for repairing and/or improving the function of human heart valves according to its intended use (e.g. patch material and sutures used in general surgical practice). NOTE A rationale for the provisions of this document is given in Annex A.

ISO 5910:2018 is classified under the following ICS (International Classification for Standards) categories: 11.040.40 - Implants for surgery, prosthetics and orthotics. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 5910:2018 has the following relationships with other standards: It is inter standard links to ISO 5910:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 5910:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5910

First edition

2018-06

Cardiovascular implants and

extracorporeal systems — Cardiac

valve repair devices

Implants cardiovasculaires et circuits extra-corporels — Dispositifs de

réparation de valves cardiaques

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Abbreviations.11

5 Fundamental requirements .12

5.1 General .12

5.2 Risk management .12

6 Device description .13

6.1 Intended use/Indication for use .13

6.2 Design inputs .13

6.2.1 General.13

6.2.2 Operational specifications .13

6.2.3 Functional, performance and safety requirements .14

6.2.4 Usability .15

6.2.5 Packaging, labelling, and sterilization .16

6.3 Design outputs .16

6.4 Design transfer (manufacturing verification/validation) .16

7 Design verification testing and analysis / Design validation .16

7.1 General requirements .16

7.2 In vitro assessment .16

7.2.1 General.16

7.2.2 Test articles, sample selection, test conditions and reporting requirements .17

7.2.3 Device material property assessment .18

7.2.4 Functional performance assessment .19

7.2.5 Device structural performance assessment .19

7.2.6 Device corrosion assessment .20

7.2.7 Delivery system design evaluation requirements .20

7.2.8 Visibility.20

7.2.9 Simulated use assessment .20

7.2.10 Human factors / Usability assessment .21

7.2.11 Device MRI safety .21

7.2.12 Design specific testing .21

7.3 Preclinical in vivo evaluation .21

7.3.1 General.21

7.3.2 Overall requirements .21

7.3.3 Methods .23

7.3.4 Test report .24

7.4 Clinical Investigations .24

7.4.1 General.24

7.4.2 Study considerations .25

7.4.3 Study endpoints .28

7.4.4 Ethical considerations .28

7.4.5 Distribution of subjects and investigators .28

7.4.6 Statistical considerations including sample size and duration .29

7.4.7 Patient selection criteria .31

7.4.8 Clinical data requirements .31

7.4.9 Clinical investigation analysis and reporting .34

7.4.10 Post-market clinical follow-up .34

Annex A (informative) Rationale for the provisions of this document .36

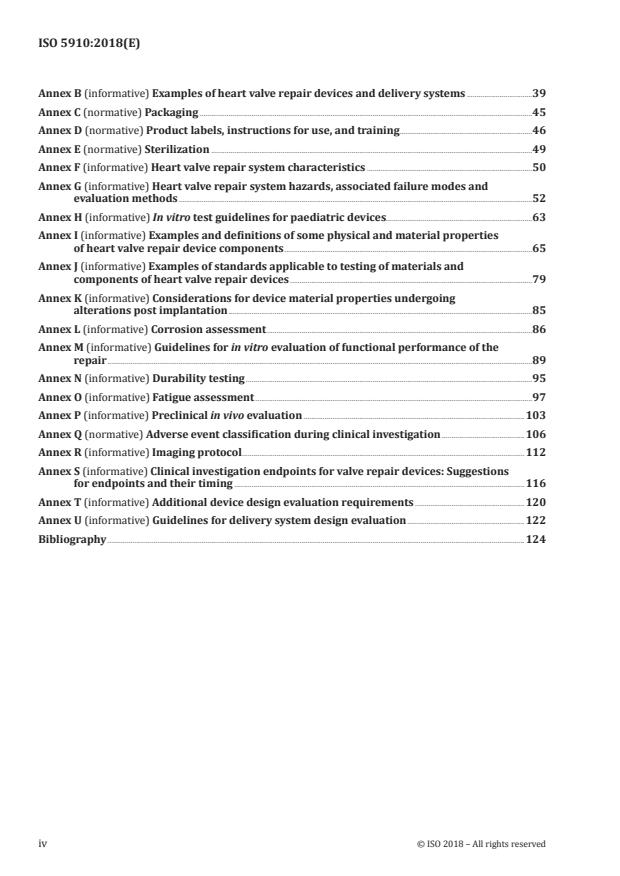

Annex B (informative) Examples of heart valve repair devices and delivery systems .39

Annex C (normative) Packaging .45

Annex D (normative) Product labels, instructions for use, and training .46

Annex E (normative) Sterilization .49

Annex F (informative) Heart valve repair system characteristics .50

Annex G (informative) Heart valve repair system hazards, associated failure modes and

evaluation methods .52

Annex H (informative) In vitro test guidelines for paediatric devices .63

Annex I (informative) Examples and definitions of some physical and material properties

of heart valve repair device components .65

Annex J (informative) Examples of standards applicable to testing of materials and

components of heart valve repair devices .79

Annex K (informative) Considerations for device material properties undergoing

alterations post implantation .85

Annex L (informative) Corrosion assessment .86

Annex M (informative) Guidelines for in vitro evaluation of functional performance of the

repair .89

Annex N (informative) Durability testing .95

Annex O (informative) Fatigue assessment .97

Annex P (informative) Preclinical in vivo evaluation .103

Annex Q (normative) Adverse event classification during clinical investigation .106

Annex R (informative) Imaging protocol .112

Annex S (informative) Clinical investigation endpoints for valve repair devices: Suggestions

for endpoints and their timing .116

Annex T (informative) Additional device design evaluation requirements .120

Annex U (informative) Guidelines for delivery system design evaluation .122

Bibliography .124

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by ISO/TC 150, Implants for surgery, Subcommittee SC 2, Cardiovascular

implants and extracorporeal systems.

Introduction

No heart valve repair device is ideal. Therefore, a group of engineers, scientists, and clinicians, experts

well aware of the problems associated with heart valve repair devices and their development, has

prepared this document. This document specifies types of tests, test methods, and requirements for

test apparatus. It requires documentation of test methods and results. This document deals with those

areas that will ensure adequate mitigation of device-associated risks for patients and other users of

the device, facilitate quality assurance, aid the heart team in choosing a heart valve repair device, and

ensure that the device will be provided in a convenient and usable form. This document emphasizes

the need to specify and report types of in vitro testing, preclinical in vivo and clinical evaluations. It

describes the labels and packaging of the device. Such a process involving in vitro, preclinical in vivo

and clinical evaluations is intended to clarify the requirements prior to market release and to enable

prompt identification and management of any subsequent problems.

With regard to in vitro testing and reporting, apart from basic material testing for mechanical, physical,

chemical and biocompatibility characteristics, this document also covers important functional and

durability characteristics of heart valve repair devices and their accessories. This document does not

specify exact test methods for functional and durability testing but it offers guidelines for the test

apparatus.

This document should be revised, updated, and amended as knowledge and techniques in heart valve

repair device technology improve.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 5910:2018(E)

Cardiovascular implants and extracorporeal systems —

Cardiac valve repair devices

1 Scope

1.1 This document applies to all heart valve repair systems that have an intended use to repair and/

or improve the function of native human heart valves by acting either on the valve apparatus or on the

adjacent anatomy (e.g. ventricle, coronary sinus).

1.2 This document outlines an approach for verifying/validating the design and manufacture of a

heart valve repair system through risk management. The selection of appropriate verification/validation

tests and methods are derived from the risk assessment. The tests include assessments of the physical,

chemical, biological, and mechanical properties of components and materials of heart valve repair

systems. The tests also include preclinical in vivo evaluation and clinical investigation of the finished

heart valve repair system to assess the safety and effectiveness of the heart valve repair system.

NOTE For the purposes of this document, effectiveness endpoint includes clinical performance and benefits.

1.3 This document defines operational conditions and performance requirements for heart valve

repair systems where adequate scientific and/or clinical evidence exists for their justification.

1.4 This document excludes Cardiac Resynchronization Therapy (CRT) devices, paravalvular

leakage closure devices, systems that do not leave an implant in place (e.g. ablation, radio frequency

annuloplasty), apical conduits and devices with components containing viable cells. This Standard also

excludes materials not intended for repairing and/or improving the function of human heart valves

according to its intended use (e.g. patch material and sutures used in general surgical practice).

NOTE A rationale for the provisions of this document is given in Annex A.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10993-1, Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk

management process

ISO 10993-2, Biological evaluation of medical devices — Part 2: Animal welfare requirements

ISO 11135, Sterilization of health-care products — Ethylene oxide — Requirements for the development,

validation and routine control of a sterilization process for medical devices

ISO 11137-1, Sterilization of health care products — Radiation — Part 1: Requirements for development,

validation and routine control of a sterilization process for medical devices

ISO 11137-2, Sterilization of health care products — Radiation — Part 2: Establishing the sterilization dose

ISO 11137-3, Sterilization of health care products — Radiation — Part 3: Guidance on dosimetric aspects of

development, validation and routine control

ISO 11607-1, Packaging for terminally sterilized medical devices — Part 1: Requirements for materials,

sterile barrier systems and packaging systems

ISO 11607-2, Packaging for terminally sterilized medical devices — Part 2: Validation requirements for

forming, sealing and assembly processes

ISO 13485, Medical devices — Quality management systems — Requirements for regulatory purposes

ISO 14155, Clinical investigation of medical devices for human subjects — Good clinical practice

ISO 14160, Sterilization of health care products — Liquid chemical sterilizing agents for single-use medical

devices utilizing animal tissues and their derivatives — Requirements for characterization, development,

validation and routine control of a sterilization process for medical devices

ISO 14630, Non-active surgical implants — General requirements

ISO 14937, Sterilization of health care products — General requirements for characterization of a sterilizing

agent and the development, validation and routine control of a sterilization process for medical devices

ISO 14971, Medical devices — Application of risk management to medical devices

ISO 15223-1, Medical devices — Symbols to be used with medical device labels, labelling and information to

be supplied — Part 1: General requirements

ISO 15223-2, Medical devices — Symbols to be used with medical device labels, labelling, and information

to be supplied — Part 2: Symbol development, selection and validation

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 17664, Processing of health care products — Information to be provided by the medical device

manufacturer for the processing of medical devices

ISO 17665-1, Sterilization of health care products — Moist heat — Part 1: Requirements for the development,

validation and routine control of a sterilization process for medical devices

ISO/TS 17665-2, Sterilization of health care products — Moist heat — Part 2: Guidance on the application

of ISO 17665-1

ISO/TS 17665-3, Sterilization of health care products — Moist heat — Part 3: Guidance on the designation

of a medical device to a product family and processing category for steam sterilization

ISO 22442-1, Medical devices utilizing animal tissues and their derivatives — Part 1: Application of risk

management

ISO 22442-2, Medical devices utilizing animal tissues and their derivatives — Part 2: Controls on sourcing,

collection and handling

ISO 22442-3, Medical devices utilizing animal tissues and their derivatives — Part 3: Validation of the

elimination and/or inactivation of viruses and transmissible spongiform encephalopathy (TSE) agents

ISO/TR 22442-4, Medical devices utilizing animal tissues and their derivatives — Part 4: Principles for

elimination and/or inactivation of transmissible spongiform encephalopathy (TSE) agents and validation

assays for those processes

IEC 62366-1, Medical devices — Part 1: Application of usability engineering to medical devices

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

2 © ISO 2018 – All rights reserved

NOTE Additional definitions can be found in the informative annexes.

3.1

abnormal use

act or omission of an act by the operator or user of a medical device as a result of conduct which is

beyond any means of risk control by the manufacturer

3.2

accessory

device-specific tool that is required to assist in the implantation and/or adjustment of the heart valve

repair device, excluding the delivery system

3.3

active comparator

active control

intervention generally accepted or demonstrated to be safe and effective for the condition of interest

that can be used as a basis of comparison of the safety and effectiveness of the heart valve repair device

Note 1 to entry: The active comparator is generally the standard of care for the condition.

3.4

actuarial analysis

statistical technique for calculating event rates over time

Note 1 to entry: Standard actuarial methods calculate the probability of freedom from events within pre-specified

intervals of time. When the intervals approach zero width, the methods are called Kaplan-Meier methods.

3.5

adverse event

AE

untoward medical occurrence, unintended disease or injury, or untoward clinical signs (including

abnormal laboratory findings) in subjects, users or other persons, whether or not related to the heart

valve repair device implantation, adjustment or procedure

3.6

auxiliary device

device used during the procedure, not including accessories (e.g. sheath, guidewire) and delivery system

3.7

back pressure

differential pressure applied across the valve during the closed phase

3.8

body surface area

BSA

total surface area (m ) of the human body

Note 1 to entry: This can be calculated as the square root of product of the weight in kg times the height in cm

divided by 3 600. See Reference [30].

3.9

cardiac index

2 2

cardiac output (3.10) (CO, l/min) divided by the body surface area (3.8) (BSA, m ), with units l/min/m

3.10

cardiac output

CO

stroke volume multiplied by heart rate

3.11

closing volume

portion of the regurgitant volume that is associated with the dynamics of the valve closure during a

single cycle

Note 1 to entry: See Figure 1.

Key

X time

Y flowrate

1 forward flow volume

2 closing volume

3 leakage volume

Figure 1 — Schematic representation of flow waveform and regurgitant volumes for one cycle

3.12

coating

thin-film material that is applied to an element of a heart valve repair device to modify its properties

3.13

compliance

4 © ISO 2018 – All rights reserved

relationship between change in radius and change in pressure of a deformable tubular structure (e.g.

valve annulus, aorta, conduit), defined in this document as:

()rr−×100

C=×100%

rp×−()p

12 1

where

C is the compliance in units of % radial change/100 mmHg;

p is the diastolic pressure, in mmHg;

p is the systolic pressure, in mmHg;

r is the inner radius at p , in millimetres;

1 1

r is the inner radius at p , in millimetres.

2 2

Note 1 to entry: See Reference [7].

3.14

component-joining material

material, such as a suture, adhesive or welding compound, used to assemble the components of a heart

valve repair device, thereby becoming part of the implanted device

3.15

cycle

one complete sequence in the action of a heart valve under pulsatile flow conditions

3.16

cycle rate

number of complete cycles per unit of time, usually expressed as cycles per minute (cycles/min)

3.17

delivery system

system used to deliver, deploy, attach or adjust the device in the implant site

3.18

design validation

establishment by objective evidence that device specifications conform with user needs and intended

use(s) (3.34)

3.19

design verification

establishment by objective evidence that the design output meets the design input requirements

3.20

device embolisation

dislodgement from the intended and documented original position to an unintended and nontherapeutic

location

3.21

device failure

inability of a device to perform its intended function sufficient to cause a hazard

3.22

device migration

unintended movement or displacement of the device from its original position within the implant site,

without embolisation

3.23

effective orifice area

EOA

orifice area that has been derived from flow and pressure or velocity data

Note 1 to entry: For in vitro testing, EOA is defined as:

q

v

RMS

EOA=

Dp

51,6×

ρ

where

EOA is the effective orifice area (cm );

is the root mean square forward flow (ml/s) during the positive differential pressure period;

q

v

RMS

Δp is the mean pressure difference (measured during the positive differential pressure peri-

od) (mmHg);

ρ is the density of the test fluid (g/cm ).

3.24

failure mode

mechanism of device failure (3.21)

3.25

follow-up

continued assessment of subjects who have received the heart valve repair device

3.26

forward flow volume

volume of flow ejected through the heart valve in the forward direction during one cycle, not including

any regurgitant flow through the valve

Note 1 to entry: See Figure 1.

3.27

fracture

complete separation of any part of the heart valve repair device (3.28) that was previously intact

3.28

heart valve repair device

implant (3.31) intended to improve the function of native human heart valves by acting either on the

valve apparatus or on the adjacent anatomy (e.g. ventricle, coronary sinus)

Note 1 to entry: See examples in Annex B.

3.29

heart valve repair system

heart valve repair device, delivery system, other accessories as applicable, packaging, labelling, and

instructions

3.30

imaging modality

method used to visualize and assess native anatomy and/or device position, geometry and/or function

3.31

implant

device placed surgically or non-surgically into the human body and intended to remain in place after

the procedure

6 © ISO 2018 – All rights reserved

3.32

implant site

location of heart valve repair device implantation or deployment

3.33

indication for use

clinical condition of the patient population that the heart valve repair device is intended to treat or

improve

3.34

intended use

purpose of a heart valve repair device, in accordance with the specifications, instructions, and

information provided by the manufacturer

3.35

Kaplan-Meier methods

statistical approaches to calculating event rates over time when the actual dates of events for each

person in the population are taken into account

3.36

leakage volume

component of the regurgitant volume that is associated with leakage during closed phase of a valve in a

single cycle

Note 1 to entry: See Figure 1. The point of separation between the closing and leakage volumes is obtained

according to a defined and stated criterion (the linear extrapolation shown in Figure 1 is just an example).

3.37

linearized rate

total number of events divided by the total time under evaluation

Note 1 to entry: Generally, the rate is expressed in terms of percent per patient year.

3.38

mean arterial pressure

time-averaged arithmetic mean value of the arterial pressure during one cycle

3.39

mean pressure difference

time-averaged arithmetic mean value of the pressure difference across a heart valve during the positive

differential pressure period of the cycle

Note 1 to entry: See Figure 2 for representative aortic and mitral flow and pressure waveforms. See Figure 3 for

representative pulmonary and tricuspid flow and pressure waveforms.

3.40

non-structural dysfunction

abnormality extrinsic to the heart valve repair device that results in abnormal function of the device or

causes clinical symptoms

3.41

pannus

ingrowth of tissue onto the heart valve repair device which may interfere with normal functioning

3.42

pull-out

situation in which the suture or anchoring device remains structurally intact but tears through the

tissue in which it is implanted

3.43

reference device

heart valve substitute or heart valve repair device with known clinical history used for comparative

preclinical and clinical evaluations

3.44

regurgitant fraction

regurgitant volume expressed as a percentage of the total ventricular stroke volume

3.45

regurgitant volume

volume of fluid that flows through a heart valve in the reverse direction during one cycle and is the sum

of the closing volume and leakage volume (3.36)

Note 1 to entry: See Figure 1.

3.46

repositioning

intentional change of implant position of a partially or fully deployed heart valve repair device

3.47

retrieval

removal of a partially or fully deployed heart valve repair device

3.48

risk

combination of the probability of occurrence of harm and the severity (3.53) of that harm

Note 1 to entry: See ISO 14971.

3.49

risk analysis

systematic use of available information to identify hazards and to estimate the associated risks (3.48)

Note 1 to entry: See ISO 14971.

3.50

risk assessment

overall process comprising a risk analysis (3.49) and a risk evaluation

Note 1 to entry: See ISO 14971.

3.51

root mean square forward flow

RMS forward flow

square root of the integral of the volume flow rate waveform squared during the positive differential

pressure interval of the forward flow phase used to calculate EOA

Note 1 to entry: Defining the time interval for flow and pressure measurement as the positive pressure period of

the forward flow interval for EOA computation provides repeatable and consistent results for comparison to the

minimum device performance requirements.

Note 2 to entry: This is calculated using the following equation:

t

qt dt

()

v

∫

t

q =

v

RMS

tt−

8 © ISO 2018 – All rights reserved

where

is the root mean square forward flow (ml/s) during the positive differential pressure period;

q

v

RMS

q (t) is the instantaneous flow at time t;

v

t is time at start of positive differential pressure period;

t is time at end of positive differential pressure period.

Note 3 to entry: The rationale for use of q is that the instantaneous pressure difference is proportional to

v

RMS

the square of instantaneous flow rate, and it is the mean pressure difference that is required.

Note 4 to entry: See Figure 2 for representative aortic and mitral flow and pressure waveforms from in vitro

testing. See Figure 3 for representative pulmonary and tricuspid flow and pressure waveforms from in vitro

testing.

Key

1 aortic pressure

2 left ventricular pressure

3 left atrial pressure

4 aortic flow rate

5 mitral flow rate

a

Positive pressure range.

b

q range.

v

RMS

Figure 2 — Schematic representation of aortic and mitral flow and pressure waveforms versus

time from in vitro testing

Key

1 pulmonary pressure

2 right ventricular pressure

3 right atrial pressure

4 pulmonary flow rate

5 tricuspid flow rate

a

Positive pressure range.

b

q range.

v

RMS

Figure 3 — Schematic representation of pulmonary and tricuspid flow and pressure waveforms

versus time from in vitro testing

3.52

safety

freedom from unacceptable risk

Note 1 to entry: See ISO 14971.

3.53

severity

measure of the possible consequences of a hazard

Note 1 to entry: See ISO 14971.

3.54

simulated cardiac output

forward flow volume multiplied by heart rate

Note 1 to entry: Simulated cardiac output applies to in vitro bench testing only in this document.

3.55

special process

process for which the product cannot be fully verified by inspection or test

3.56

sterility assurance level

SAL

probability of a single viable microorganism occurring on an item after sterilization

Note 1 to entry: The term SAL takes a quantitative value, generally 10−6 or 10−3. When applying this quantitative

value to assurance of sterility, an SAL of 10−6 has a lower value but provides a greater assurance of sterility than

an SAL of 10−3.

10 © ISO 2018 – All rights reserved

Note 2 to entry: See Reference [6].

3.57

sterilization

validated process used to render product free from viable microorganisms

Note 1 to entry: In a sterilization process, the nature of microbial inactivation is exponential and thus the survival

of a microorganism on an individual item can be expressed in terms of probability. While this probability can be

reduced to a very low number, it can never be reduced to zero.

Note 2 to entry: See Reference [6].

3.58

stroke volume

SV

volume of blood pumped by a ventricle in one contraction, which is equal to the difference between the

end diastolic ventricular volume and end systolic ventricular volume

3.59

structural device or component failure

degradation of structural integrity of the repair device (e.g. fractures) that results in the functional

performance of the implant no longer being acceptable and/or that results in adverse events (3.5)

3.60

structural native valve deterioration

structural native valve dysfunction

dysfunction or deterioration intrinsic to the native valve, including calcification, leaflet fibrosis, leaflet

tear or flail, resulting in stenosis or intra-prosthetic regurgitation

3.61

systolic duration

portion of cardiac cycle time corresponding to ventricular contraction

Note 1 to entry: For in vitro testing, systolic duration corresponds to the duration of forward flow in a cardiac cycle.

3.62

total product life cycle

period of time over which a product is developed, brought to market and eventually removed from

the market

3.63

usability

characteristic of the user interface that facilitates use and thereby establishes effectiveness, efficiency,

ease of user learning and user satisfaction in the intended use environment

3.64

use error

act or omission of an act that results in a different medical device response than intended by the

manufacturer or expected by the user

Note 1 to entry: Examples of use error include incorrect sizing, suboptimal positioning, structural distortion of

the device.

Note 2 to entry: An unexpected physiological response of the patient is not by itself considered use error.

4 Abbreviations

For the purposes of this document, the following abbreviations apply.

AE adverse event

AWT accelerated wear testing

CO cardiac output

CT computed tomography

CIP clinical investigation plan

CFD computational fluid dynamics

ECG electrocardiogram

EOA effective orifice area

FEA finite element analysis

IFU instructions for use

INR international normalized ratio

LV left ventricle, left ventricular

MAP mean arterial pressure

MRI magnetic resonance imaging

PET positron emission tomography

PMCF post-market clinical follow-up

SV stroke volume

TEE transoesophageal echocardiography

TTE transthoracic echocardiography

5 Fundamental requirements

5.1 General

The manufacturer shall determine, at all stages of the total product life cycle, the acceptability of the

product for clinical use.

5.2 Risk management

Risk management is the essential element for design and verification of medical devices. A risk-based

methodology challenges the manufacturer to continually evaluate known and theoretical risks of the

device, to develop the most appropriate methods for mitigating the risks of the device, and to implement

the appropriate test and analysis methods to demonstrate that the risks have been mitigated. The

manufacturer shall define, implement and document risk management activities in accordance

with ISO 14971. The risk analysis shall be an iterative process over the total product life cycle of the

device based on evolving knowledge of device performance. Annex G outlines a risk management

approach relevant to heart valve repair devices, and provides examples of potential approaches to risk

management. In addition, a list of potential hazards specific to the various types of heart valve repair

devices that can serve as the basis for a risk analysis is also provided.

12 © ISO 2018 – All rights reserved

6 Device description

6.1 Intended use/Indication for use

The manufacturer shall identify the pathophysiological condition(s) to be treated, the intended patient

population, and intended claims.

6.2 Design inputs

6.2.1 General

The design attribute requirements of ISO 14630 shall apply.

6.2.2 Operational specifications

The manufacturer shall define the operational specifications for the system, including the principles of

operation, intended device delivery approach if applicable, expected device lifetime, shelf life, shipping/

storage limits, and the physiological environment in which it is intended to function. The manufacturer

shall define all relevant dimensional parameters that will be required to accurately select the size of

device to be implanted, if applicable. Table 1 and Table 2 define the expected physiological parameters

of the intended adult patient population for heart valve repair devices for both normal and pathological

patient conditions. See Annex H for guidelines regarding suggested test conditions for the paediatric

population.

Table 1 — Heart valve repair device operational environment for left side of heart — Adult

population

Parameter General Condition

Surrounding medium Human heart/Human blood

Temperature 34 °C to 42 °C

Heart rate 30 bpm to 200 bpm

Cardiac output 3 l/min to 15 l/min

Forward flow volume 25 ml to 100 ml

Peak differential pressure across

Aortic peak Aortic end

a

Pressures and result- closed valve

systolic diastolic

ant pressure loads by

pressure pressure

Aortic ΔP Mitral ΔP

A M

patient condition

mmHg mmHg

mmHg mmHg

Normotensive 90 to 140 60 to 90 80 to 115 90 to 140

Hypotensive <90 <60 <80 <90

Mild hypertensive 140 to 159 90 to 99 115 to 129 140 to 159

Moderate hypertensive 160 to 179 100 to 109 130 to 144 160 to 179

Severe hypertensive 180 to 209 110 to 119 145 to 164 180 to 209

Very severe hypertensive ≥210 ≥120 ≥165 ≥210

a

Peak differential pressure across closed aortic valve estimated using the following relationship:

— ΔP ≈ pressure associated with dicrotic notch assuming LV pressure is zero ≈ Aortic end diastolic

A

pressure + ½(Aortic peak systolic pressure – Aortic end diastolic pressure).

Peak differential pressure across closed mitral valve estimated to be equivalent to Aortic peak

systolic pressure.

Pressure values obtained from references (See references [28], [33]).

Table 2 — Heart valve repair devices operational environment for right side of heart – Adult

population

Parameter General Condition

Surrounding medium Human heart/Human blood

Temperature 34 °C to 42 °C

Heart rate 30 bpm to 200 bpm

Cardiac output 3 l/min to 15 l/min

Forward flow volume 25 ml to 100 ml

Pulmonary Peak differential pressure across

Pulmonary ar-

a

artery end closed valve

Pressures and resultant

tery peak sys-

diastolic

pressure loads by patient

tolic pressure

Pulmonary ΔP Tricuspid ΔP

P T

pressure

condition

mmHg

mmHg mmHg

mmHg

Normotensive 18 to 35 8 to 15 13 to 28 18 to 35

Hypotensive <18 <8 <13 <18

Mild hypertensive 35 to 49 15 to 19 28 to 34 35 to 49

Moderate hypertensive 50 to 59 20 to 24 35 to 42 50 to 59

Severe hypertensive 60 to 84 25 to 34 43 to 59 60 to 84

Very severe hypertensive ≥85 ≥35 ≥60 ≥85

a

Peak differe

...

INTERNATIONAL ISO

STANDARD 5910

First edition

2018-06

Cardiovascular implants and

extracorporeal systems — Cardiac

valve repair devices

Implants cardiovasculaires et circuits extra-corporels — Dispositifs de

réparation de valves cardiaques

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Abbreviations.11

5 Fundamental requirements .12

5.1 General .12

5.2 Risk management .12

6 Device description .13

6.1 Intended use/Indication for use .13

6.2 Design inputs .13

6.2.1 General.13

6.2.2 Operational specifications .13

6.2.3 Functional, performance and safety requirements .14

6.2.4 Usability .15

6.2.5 Packaging, labelling, and sterilization .16

6.3 Design outputs .16

6.4 Design transfer (manufacturing verification/validation) .16

7 Design verification testing and analysis / Design validation .16

7.1 General requirements .16

7.2 In vitro assessment .16

7.2.1 General.16

7.2.2 Test articles, sample selection, test conditions and reporting requirements .17

7.2.3 Device material property assessment .18

7.2.4 Functional performance assessment .19

7.2.5 Device structural performance assessment .19

7.2.6 Device corrosion assessment .20

7.2.7 Delivery system design evaluation requirements .20

7.2.8 Visibility.20

7.2.9 Simulated use assessment .20

7.2.10 Human factors / Usability assessment .21

7.2.11 Device MRI safety .21

7.2.12 Design specific testing .21

7.3 Preclinical in vivo evaluation .21

7.3.1 General.21

7.3.2 Overall requirements .21

7.3.3 Methods .23

7.3.4 Test report .24

7.4 Clinical Investigations .24

7.4.1 General.24

7.4.2 Study considerations .25

7.4.3 Study endpoints .28

7.4.4 Ethical considerations .28

7.4.5 Distribution of subjects and investigators .28

7.4.6 Statistical considerations including sample size and duration .29

7.4.7 Patient selection criteria .31

7.4.8 Clinical data requirements .31

7.4.9 Clinical investigation analysis and reporting .34

7.4.10 Post-market clinical follow-up .34

Annex A (informative) Rationale for the provisions of this document .36

Annex B (informative) Examples of heart valve repair devices and delivery systems .39

Annex C (normative) Packaging .45

Annex D (normative) Product labels, instructions for use, and training .46

Annex E (normative) Sterilization .49

Annex F (informative) Heart valve repair system characteristics .50

Annex G (informative) Heart valve repair system hazards, associated failure modes and

evaluation methods .52

Annex H (informative) In vitro test guidelines for paediatric devices .63

Annex I (informative) Examples and definitions of some physical and material properties

of heart valve repair device components .65

Annex J (informative) Examples of standards applicable to testing of materials and

components of heart valve repair devices .79

Annex K (informative) Considerations for device material properties undergoing

alterations post implantation .85

Annex L (informative) Corrosion assessment .86

Annex M (informative) Guidelines for in vitro evaluation of functional performance of the

repair .89

Annex N (informative) Durability testing .95

Annex O (informative) Fatigue assessment .97

Annex P (informative) Preclinical in vivo evaluation .103

Annex Q (normative) Adverse event classification during clinical investigation .106

Annex R (informative) Imaging protocol .112

Annex S (informative) Clinical investigation endpoints for valve repair devices: Suggestions

for endpoints and their timing .116

Annex T (informative) Additional device design evaluation requirements .120

Annex U (informative) Guidelines for delivery system design evaluation .122

Bibliography .124

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by ISO/TC 150, Implants for surgery, Subcommittee SC 2, Cardiovascular

implants and extracorporeal systems.

Introduction

No heart valve repair device is ideal. Therefore, a group of engineers, scientists, and clinicians, experts

well aware of the problems associated with heart valve repair devices and their development, has

prepared this document. This document specifies types of tests, test methods, and requirements for

test apparatus. It requires documentation of test methods and results. This document deals with those

areas that will ensure adequate mitigation of device-associated risks for patients and other users of

the device, facilitate quality assurance, aid the heart team in choosing a heart valve repair device, and

ensure that the device will be provided in a convenient and usable form. This document emphasizes

the need to specify and report types of in vitro testing, preclinical in vivo and clinical evaluations. It

describes the labels and packaging of the device. Such a process involving in vitro, preclinical in vivo

and clinical evaluations is intended to clarify the requirements prior to market release and to enable

prompt identification and management of any subsequent problems.

With regard to in vitro testing and reporting, apart from basic material testing for mechanical, physical,

chemical and biocompatibility characteristics, this document also covers important functional and

durability characteristics of heart valve repair devices and their accessories. This document does not

specify exact test methods for functional and durability testing but it offers guidelines for the test

apparatus.

This document should be revised, updated, and amended as knowledge and techniques in heart valve

repair device technology improve.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 5910:2018(E)

Cardiovascular implants and extracorporeal systems —

Cardiac valve repair devices

1 Scope

1.1 This document applies to all heart valve repair systems that have an intended use to repair and/

or improve the function of native human heart valves by acting either on the valve apparatus or on the

adjacent anatomy (e.g. ventricle, coronary sinus).

1.2 This document outlines an approach for verifying/validating the design and manufacture of a

heart valve repair system through risk management. The selection of appropriate verification/validation

tests and methods are derived from the risk assessment. The tests include assessments of the physical,

chemical, biological, and mechanical properties of components and materials of heart valve repair

systems. The tests also include preclinical in vivo evaluation and clinical investigation of the finished

heart valve repair system to assess the safety and effectiveness of the heart valve repair system.

NOTE For the purposes of this document, effectiveness endpoint includes clinical performance and benefits.

1.3 This document defines operational conditions and performance requirements for heart valve

repair systems where adequate scientific and/or clinical evidence exists for their justification.

1.4 This document excludes Cardiac Resynchronization Therapy (CRT) devices, paravalvular

leakage closure devices, systems that do not leave an implant in place (e.g. ablation, radio frequency

annuloplasty), apical conduits and devices with components containing viable cells. This Standard also

excludes materials not intended for repairing and/or improving the function of human heart valves

according to its intended use (e.g. patch material and sutures used in general surgical practice).

NOTE A rationale for the provisions of this document is given in Annex A.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10993-1, Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk

management process

ISO 10993-2, Biological evaluation of medical devices — Part 2: Animal welfare requirements

ISO 11135, Sterilization of health-care products — Ethylene oxide — Requirements for the development,

validation and routine control of a sterilization process for medical devices

ISO 11137-1, Sterilization of health care products — Radiation — Part 1: Requirements for development,

validation and routine control of a sterilization process for medical devices

ISO 11137-2, Sterilization of health care products — Radiation — Part 2: Establishing the sterilization dose

ISO 11137-3, Sterilization of health care products — Radiation — Part 3: Guidance on dosimetric aspects of

development, validation and routine control

ISO 11607-1, Packaging for terminally sterilized medical devices — Part 1: Requirements for materials,

sterile barrier systems and packaging systems

ISO 11607-2, Packaging for terminally sterilized medical devices — Part 2: Validation requirements for

forming, sealing and assembly processes

ISO 13485, Medical devices — Quality management systems — Requirements for regulatory purposes

ISO 14155, Clinical investigation of medical devices for human subjects — Good clinical practice

ISO 14160, Sterilization of health care products — Liquid chemical sterilizing agents for single-use medical

devices utilizing animal tissues and their derivatives — Requirements for characterization, development,

validation and routine control of a sterilization process for medical devices

ISO 14630, Non-active surgical implants — General requirements

ISO 14937, Sterilization of health care products — General requirements for characterization of a sterilizing

agent and the development, validation and routine control of a sterilization process for medical devices

ISO 14971, Medical devices — Application of risk management to medical devices

ISO 15223-1, Medical devices — Symbols to be used with medical device labels, labelling and information to

be supplied — Part 1: General requirements

ISO 15223-2, Medical devices — Symbols to be used with medical device labels, labelling, and information

to be supplied — Part 2: Symbol development, selection and validation

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 17664, Processing of health care products — Information to be provided by the medical device

manufacturer for the processing of medical devices

ISO 17665-1, Sterilization of health care products — Moist heat — Part 1: Requirements for the development,

validation and routine control of a sterilization process for medical devices

ISO/TS 17665-2, Sterilization of health care products — Moist heat — Part 2: Guidance on the application

of ISO 17665-1

ISO/TS 17665-3, Sterilization of health care products — Moist heat — Part 3: Guidance on the designation

of a medical device to a product family and processing category for steam sterilization

ISO 22442-1, Medical devices utilizing animal tissues and their derivatives — Part 1: Application of risk

management

ISO 22442-2, Medical devices utilizing animal tissues and their derivatives — Part 2: Controls on sourcing,

collection and handling

ISO 22442-3, Medical devices utilizing animal tissues and their derivatives — Part 3: Validation of the

elimination and/or inactivation of viruses and transmissible spongiform encephalopathy (TSE) agents

ISO/TR 22442-4, Medical devices utilizing animal tissues and their derivatives — Part 4: Principles for

elimination and/or inactivation of transmissible spongiform encephalopathy (TSE) agents and validation

assays for those processes

IEC 62366-1, Medical devices — Part 1: Application of usability engineering to medical devices

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

2 © ISO 2018 – All rights reserved

NOTE Additional definitions can be found in the informative annexes.

3.1

abnormal use

act or omission of an act by the operator or user of a medical device as a result of conduct which is

beyond any means of risk control by the manufacturer

3.2

accessory

device-specific tool that is required to assist in the implantation and/or adjustment of the heart valve

repair device, excluding the delivery system

3.3

active comparator

active control

intervention generally accepted or demonstrated to be safe and effective for the condition of interest

that can be used as a basis of comparison of the safety and effectiveness of the heart valve repair device

Note 1 to entry: The active comparator is generally the standard of care for the condition.

3.4

actuarial analysis

statistical technique for calculating event rates over time

Note 1 to entry: Standard actuarial methods calculate the probability of freedom from events within pre-specified

intervals of time. When the intervals approach zero width, the methods are called Kaplan-Meier methods.

3.5

adverse event

AE

untoward medical occurrence, unintended disease or injury, or untoward clinical signs (including

abnormal laboratory findings) in subjects, users or other persons, whether or not related to the heart

valve repair device implantation, adjustment or procedure

3.6

auxiliary device

device used during the procedure, not including accessories (e.g. sheath, guidewire) and delivery system

3.7

back pressure

differential pressure applied across the valve during the closed phase

3.8

body surface area

BSA

total surface area (m ) of the human body

Note 1 to entry: This can be calculated as the square root of product of the weight in kg times the height in cm

divided by 3 600. See Reference [30].

3.9

cardiac index

2 2

cardiac output (3.10) (CO, l/min) divided by the body surface area (3.8) (BSA, m ), with units l/min/m

3.10

cardiac output

CO

stroke volume multiplied by heart rate

3.11

closing volume

portion of the regurgitant volume that is associated with the dynamics of the valve closure during a

single cycle

Note 1 to entry: See Figure 1.

Key

X time

Y flowrate

1 forward flow volume

2 closing volume

3 leakage volume

Figure 1 — Schematic representation of flow waveform and regurgitant volumes for one cycle

3.12

coating

thin-film material that is applied to an element of a heart valve repair device to modify its properties

3.13

compliance

4 © ISO 2018 – All rights reserved

relationship between change in radius and change in pressure of a deformable tubular structure (e.g.

valve annulus, aorta, conduit), defined in this document as:

()rr−×100

C=×100%

rp×−()p

12 1

where

C is the compliance in units of % radial change/100 mmHg;

p is the diastolic pressure, in mmHg;

p is the systolic pressure, in mmHg;

r is the inner radius at p , in millimetres;

1 1

r is the inner radius at p , in millimetres.

2 2

Note 1 to entry: See Reference [7].

3.14

component-joining material

material, such as a suture, adhesive or welding compound, used to assemble the components of a heart

valve repair device, thereby becoming part of the implanted device

3.15

cycle

one complete sequence in the action of a heart valve under pulsatile flow conditions

3.16

cycle rate

number of complete cycles per unit of time, usually expressed as cycles per minute (cycles/min)

3.17

delivery system

system used to deliver, deploy, attach or adjust the device in the implant site

3.18

design validation

establishment by objective evidence that device specifications conform with user needs and intended

use(s) (3.34)

3.19

design verification

establishment by objective evidence that the design output meets the design input requirements

3.20

device embolisation

dislodgement from the intended and documented original position to an unintended and nontherapeutic

location

3.21

device failure

inability of a device to perform its intended function sufficient to cause a hazard

3.22

device migration

unintended movement or displacement of the device from its original position within the implant site,

without embolisation

3.23

effective orifice area

EOA

orifice area that has been derived from flow and pressure or velocity data

Note 1 to entry: For in vitro testing, EOA is defined as:

q

v

RMS

EOA=

Dp

51,6×

ρ

where

EOA is the effective orifice area (cm );

is the root mean square forward flow (ml/s) during the positive differential pressure period;

q

v

RMS

Δp is the mean pressure difference (measured during the positive differential pressure peri-

od) (mmHg);

ρ is the density of the test fluid (g/cm ).

3.24

failure mode

mechanism of device failure (3.21)

3.25

follow-up

continued assessment of subjects who have received the heart valve repair device

3.26

forward flow volume

volume of flow ejected through the heart valve in the forward direction during one cycle, not including

any regurgitant flow through the valve

Note 1 to entry: See Figure 1.

3.27

fracture

complete separation of any part of the heart valve repair device (3.28) that was previously intact

3.28

heart valve repair device

implant (3.31) intended to improve the function of native human heart valves by acting either on the

valve apparatus or on the adjacent anatomy (e.g. ventricle, coronary sinus)

Note 1 to entry: See examples in Annex B.

3.29

heart valve repair system

heart valve repair device, delivery system, other accessories as applicable, packaging, labelling, and

instructions

3.30

imaging modality

method used to visualize and assess native anatomy and/or device position, geometry and/or function

3.31

implant

device placed surgically or non-surgically into the human body and intended to remain in place after

the procedure

6 © ISO 2018 – All rights reserved

3.32

implant site

location of heart valve repair device implantation or deployment

3.33

indication for use

clinical condition of the patient population that the heart valve repair device is intended to treat or

improve

3.34

intended use

purpose of a heart valve repair device, in accordance with the specifications, instructions, and

information provided by the manufacturer

3.35

Kaplan-Meier methods

statistical approaches to calculating event rates over time when the actual dates of events for each

person in the population are taken into account

3.36

leakage volume

component of the regurgitant volume that is associated with leakage during closed phase of a valve in a

single cycle

Note 1 to entry: See Figure 1. The point of separation between the closing and leakage volumes is obtained

according to a defined and stated criterion (the linear extrapolation shown in Figure 1 is just an example).

3.37

linearized rate

total number of events divided by the total time under evaluation

Note 1 to entry: Generally, the rate is expressed in terms of percent per patient year.

3.38

mean arterial pressure

time-averaged arithmetic mean value of the arterial pressure during one cycle

3.39

mean pressure difference

time-averaged arithmetic mean value of the pressure difference across a heart valve during the positive

differential pressure period of the cycle

Note 1 to entry: See Figure 2 for representative aortic and mitral flow and pressure waveforms. See Figure 3 for

representative pulmonary and tricuspid flow and pressure waveforms.

3.40

non-structural dysfunction

abnormality extrinsic to the heart valve repair device that results in abnormal function of the device or

causes clinical symptoms

3.41

pannus

ingrowth of tissue onto the heart valve repair device which may interfere with normal functioning

3.42

pull-out

situation in which the suture or anchoring device remains structurally intact but tears through the

tissue in which it is implanted

3.43

reference device

heart valve substitute or heart valve repair device with known clinical history used for comparative

preclinical and clinical evaluations

3.44

regurgitant fraction

regurgitant volume expressed as a percentage of the total ventricular stroke volume

3.45

regurgitant volume

volume of fluid that flows through a heart valve in the reverse direction during one cycle and is the sum

of the closing volume and leakage volume (3.36)

Note 1 to entry: See Figure 1.

3.46

repositioning

intentional change of implant position of a partially or fully deployed heart valve repair device

3.47

retrieval

removal of a partially or fully deployed heart valve repair device

3.48

risk

combination of the probability of occurrence of harm and the severity (3.53) of that harm

Note 1 to entry: See ISO 14971.

3.49

risk analysis

systematic use of available information to identify hazards and to estimate the associated risks (3.48)

Note 1 to entry: See ISO 14971.

3.50

risk assessment

overall process comprising a risk analysis (3.49) and a risk evaluation

Note 1 to entry: See ISO 14971.

3.51

root mean square forward flow

RMS forward flow

square root of the integral of the volume flow rate waveform squared during the positive differential

pressure interval of the forward flow phase used to calculate EOA

Note 1 to entry: Defining the time interval for flow and pressure measurement as the positive pressure period of

the forward flow interval for EOA computation provides repeatable and consistent results for comparison to the

minimum device performance requirements.

Note 2 to entry: This is calculated using the following equation:

t

qt dt

()

v

∫

t

q =

v

RMS

tt−

8 © ISO 2018 – All rights reserved

where

is the root mean square forward flow (ml/s) during the positive differential pressure period;

q

v

RMS

q (t) is the instantaneous flow at time t;

v

t is time at start of positive differential pressure period;

t is time at end of positive differential pressure period.

Note 3 to entry: The rationale for use of q is that the instantaneous pressure difference is proportional to

v

RMS

the square of instantaneous flow rate, and it is the mean pressure difference that is required.

Note 4 to entry: See Figure 2 for representative aortic and mitral flow and pressure waveforms from in vitro

testing. See Figure 3 for representative pulmonary and tricuspid flow and pressure waveforms from in vitro

testing.

Key

1 aortic pressure

2 left ventricular pressure

3 left atrial pressure

4 aortic flow rate

5 mitral flow rate

a

Positive pressure range.

b

q range.

v

RMS

Figure 2 — Schematic representation of aortic and mitral flow and pressure waveforms versus

time from in vitro testing

Key

1 pulmonary pressure

2 right ventricular pressure

3 right atrial pressure

4 pulmonary flow rate

5 tricuspid flow rate

a

Positive pressure range.

b

q range.

v

RMS

Figure 3 — Schematic representation of pulmonary and tricuspid flow and pressure waveforms

versus time from in vitro testing

3.52

safety

freedom from unacceptable risk

Note 1 to entry: See ISO 14971.

3.53

severity

measure of the possible consequences of a hazard

Note 1 to entry: See ISO 14971.

3.54

simulated cardiac output

forward flow volume multiplied by heart rate

Note 1 to entry: Simulated cardiac output applies to in vitro bench testing only in this document.

3.55

special process

process for which the product cannot be fully verified by inspection or test

3.56

sterility assurance level

SAL

probability of a single viable microorganism occurring on an item after sterilization

Note 1 to entry: The term SAL takes a quantitative value, generally 10−6 or 10−3. When applying this quantitative

value to assurance of sterility, an SAL of 10−6 has a lower value but provides a greater assurance of sterility than

an SAL of 10−3.

10 © ISO 2018 – All rights reserved

Note 2 to entry: See Reference [6].

3.57

sterilization

validated process used to render product free from viable microorganisms

Note 1 to entry: In a sterilization process, the nature of microbial inactivation is exponential and thus the survival

of a microorganism on an individual item can be expressed in terms of probability. While this probability can be

reduced to a very low number, it can never be reduced to zero.

Note 2 to entry: See Reference [6].

3.58

stroke volume

SV

volume of blood pumped by a ventricle in one contraction, which is equal to the difference between the

end diastolic ventricular volume and end systolic ventricular volume

3.59

structural device or component failure

degradation of structural integrity of the repair device (e.g. fractures) that results in the functional

performance of the implant no longer being acceptable and/or that results in adverse events (3.5)

3.60

structural native valve deterioration

structural native valve dysfunction

dysfunction or deterioration intrinsic to the native valve, including calcification, leaflet fibrosis, leaflet

tear or flail, resulting in stenosis or intra-prosthetic regurgitation

3.61

systolic duration

portion of cardiac cycle time corresponding to ventricular contraction

Note 1 to entry: For in vitro testing, systolic duration corresponds to the duration of forward flow in a cardiac cycle.

3.62

total product life cycle

period of time over which a product is developed, brought to market and eventually removed from

the market

3.63

usability

characteristic of the user interface that facilitates use and thereby establishes effectiveness, efficiency,

ease of user learning and user satisfaction in the intended use environment

3.64

use error

act or omission of an act that results in a different medical device response than intended by the

manufacturer or expected by the user

Note 1 to entry: Examples of use error include incorrect sizing, suboptimal positioning, structural distortion of

the device.

Note 2 to entry: An unexpected physiological response of the patient is not by itself considered use error.

4 Abbreviations

For the purposes of this document, the following abbreviations apply.

AE adverse event

AWT accelerated wear testing

CO cardiac output

CT computed tomography

CIP clinical investigation plan

CFD computational fluid dynamics

ECG electrocardiogram

EOA effective orifice area

FEA finite element analysis

IFU instructions for use

INR international normalized ratio

LV left ventricle, left ventricular

MAP mean arterial pressure

MRI magnetic resonance imaging

PET positron emission tomography

PMCF post-market clinical follow-up

SV stroke volume

TEE transoesophageal echocardiography

TTE transthoracic echocardiography

5 Fundamental requirements

5.1 General

The manufacturer shall determine, at all stages of the total product life cycle, the acceptability of the

product for clinical use.

5.2 Risk management

Risk management is the essential element for design and verification of medical devices. A risk-based

methodology challenges the manufacturer to continually evaluate known and theoretical risks of the

device, to develop the most appropriate methods for mitigating the risks of the device, and to implement

the appropriate test and analysis methods to demonstrate that the risks have been mitigated. The

manufacturer shall define, implement and document risk management activities in accordance

with ISO 14971. The risk analysis shall be an iterative process over the total product life cycle of the

device based on evolving knowledge of device performance. Annex G outlines a risk management

approach relevant to heart valve repair devices, and provides examples of potential approaches to risk

management. In addition, a list of potential hazards specific to the various types of heart valve repair

devices that can serve as the basis for a risk analysis is also provided.

12 © ISO 2018 – All rights reserved

6 Device description

6.1 Intended use/Indication for use

The manufacturer shall identify the pathophysiological condition(s) to be treated, the intended patient

population, and intended claims.

6.2 Design inputs

6.2.1 General

The design attribute requirements of ISO 14630 shall apply.

6.2.2 Operational specifications

The manufacturer shall define the operational specifications for the system, including the principles of

operation, intended device delivery approach if applicable, expected device lifetime, shelf life, shipping/

storage limits, and the physiological environment in which it is intended to function. The manufacturer

shall define all relevant dimensional parameters that will be required to accurately select the size of