ISO/TR 8865:1990

(Main)Mining — Guidance on methods of verifying dimensions of sprocket assemblies for chain conveyors

Mining — Guidance on methods of verifying dimensions of sprocket assemblies for chain conveyors

Gives guidance on methods of verifying sprocket dimensions specified in ISO 5613. Specifies those dimensions which should be measured to ensure compatibility between chain and sprocket.

Exploitation minière — Lignes directrices sur les méthodes de contrôle dimensionnel des tourteaux d’entraînement pour convoyeurs à chaînes

Rudarstvo - Navodila za kontroliranje mer ozoblenj pogonskih verižnih koles verižnih transporterjev

General Information

- Status

- Published

- Publication Date

- 21-Nov-1990

- Technical Committee

- ISO/TC 82 - Mining

- Drafting Committee

- ISO/TC 82 - Mining

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 30-Sep-2019

- Completion Date

- 12-Feb-2026

Overview

ISO/TR 8865:1990 is a Technical Report (type 3) from ISO that gives guidance on verifying dimensions of sprocket assemblies for chain conveyors used in mining. It complements ISO 5613 by identifying which sprocket dimensions should be measured to ensure compatibility with chain assemblies and by recommending practical measurement methods - especially for dimensions that cannot be measured directly with conventional instruments.

Key Topics

- Purpose and scope

- Guidance for checking sprocket dimensions specified in ISO 5613 to ensure compatibility between sprocket and chain components.

- Published as a Technical Report (type 3) to provide state‑of‑the‑art guidance rather than prescriptive requirements.

- Verification methods

- Simple "go / no‑go" system: wrap specially calibrated chain assemblies (made to upper and lower tolerance limits) around a sprocket to check fit and compatibility.

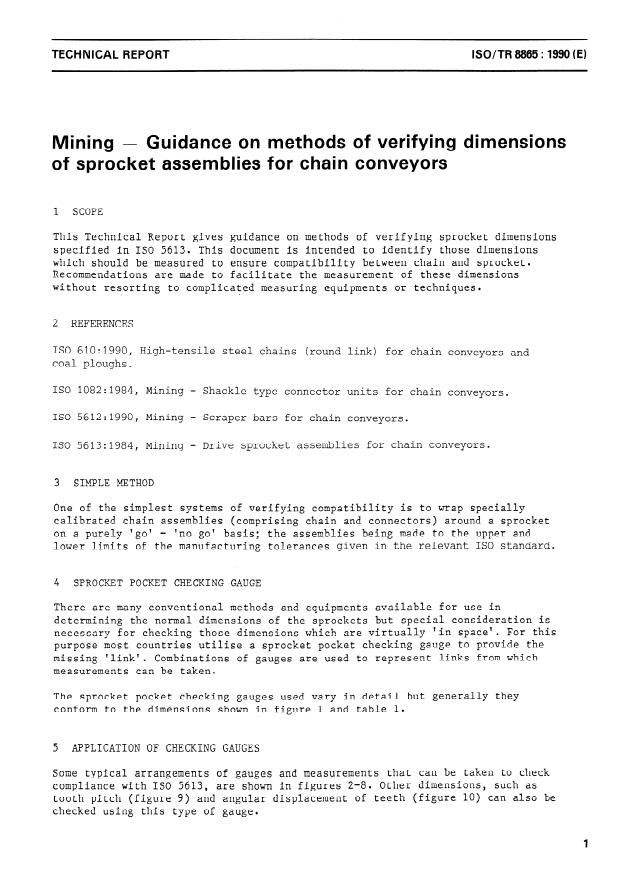

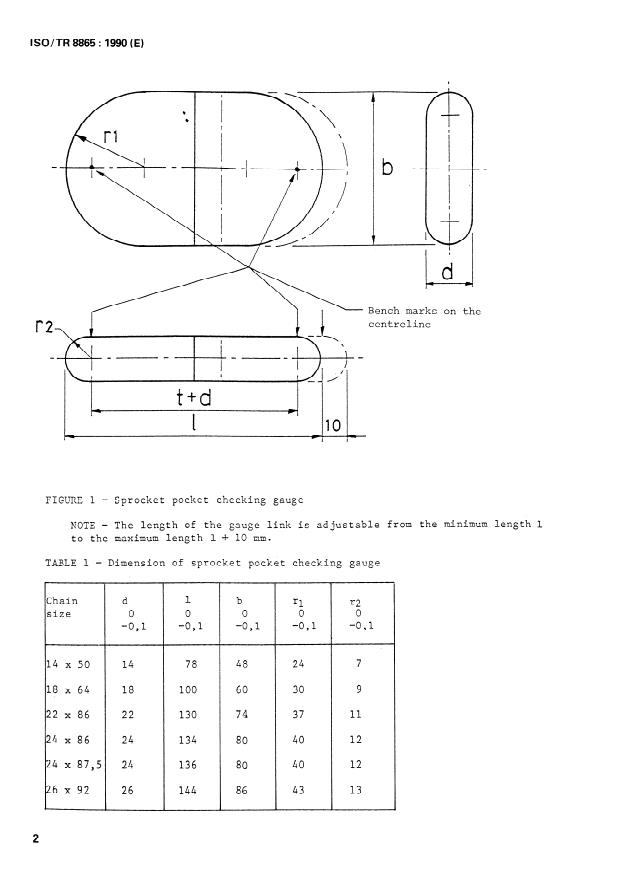

- Use of a sprocket pocket checking gauge to represent the missing chain link(s) and enable measurement of internal features that are “virtually in space.”

- Gauge arrangements and measurements illustrated (figures in the report) to check features such as tooth profile, root radius, pocket depth, tooth pitch and angular displacement of teeth.

- Note: many conventional measuring tools are suitable for normal dimensions; special gauges are recommended where direct measurement is impractical.

- Measurement coordination

- Methods for verification should be agreed between purchaser and manufacturer (per ISO 5613), and the report highlights essential features of checking gauges rather than mandating a single instrument.

Applications

Who benefits and when to use it:

- Manufacturers of sprocket rings and drive sprocket assemblies - to validate production parts against ISO 5613 requirements.

- Purchasers and inspectors - to establish mutually agreed verification procedures and acceptance criteria.

- Maintenance and quality engineers in mining operations - to check sprocket/chain compatibility during installation, service and replacement.

- Use cases: incoming inspection of sprocket assemblies, verification during manufacture, troubleshooting chain engagement problems and periodic maintenance checks.

Related Standards

- ISO 5613: Drive sprocket assemblies for chain conveyors (primary dimensional requirements)

- ISO 610: High‑tensile steel chains (round link)

- ISO 1082: Shackle type connector units for chain conveyors

- ISO 5612: Scraper bars for chain conveyors

ISO/TR 8865 is practical, non‑prescriptive guidance aimed at ensuring reliable sprocket‑to‑chain compatibility in mining chain conveyor systems, with emphasis on simple, repeatable verification techniques and the use of sprocket pocket checking gauges.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

ISO/TR 8865:1990 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Mining — Guidance on methods of verifying dimensions of sprocket assemblies for chain conveyors". This standard covers: Gives guidance on methods of verifying sprocket dimensions specified in ISO 5613. Specifies those dimensions which should be measured to ensure compatibility between chain and sprocket.

Gives guidance on methods of verifying sprocket dimensions specified in ISO 5613. Specifies those dimensions which should be measured to ensure compatibility between chain and sprocket.

ISO/TR 8865:1990 is classified under the following ICS (International Classification for Standards) categories: 53.040.20 - Components for conveyors; 73.100.40 - Haulage and hoisting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 8865:1990 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-1995

Rudarstvo - Navodila za kontroliranje mer ozoblenj pogonskih verižnih koles

verižnih transporterjev

Mining -- Guidance on methods of verifying dimensions of sprocket assemblies for chain

conveyors

Titre manque

Ta slovenski standard je istoveten z: ISO/TR 8865:1990

ICS:

53.040.20 Deli za transporterje Components for conveyors

73.100.40 Oprema za vleko in dviganje Haulage and hoisting

equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

ISO/TR

TECHNICAL

REPORT

First edition

1990-12-01

Mining - Guidance on methods of verifying

dimensions of sprocket assemblies for chain

conveyors

Reference number

IS0 8865 : 1990 (El

ISO/TR 8865 : 1990 (E)

Foreword

IS0 (the international Organization for Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The main task of IS0 technical committees is to prepare International Standards. In ex-

ceptional circumstances a technical committee may propose the publication of a

Technical Report of one of the following types:

-

type 1, when the required support cannot be obtained for the publication of an

International Standard, despite repeated efforts;

-

type 2, when the subject is still under technical development or where for any

other reason there is the future but not immediate possibility of an agreement on an

International Standard;

-

type 3, when a technical committee has collected data of a different kind from

that which is normally published as an International Standard (“state of the art”, for

example).

Technical Reports of types 1 and 2 are subject to review within three years of publica-

tion, to decide whether they can be transformed into International Standards.

Technical Reports of type 3 do not necessarily have to be reviewed until the data they

provide are considered to be no longer valid or useful.

ISO/TR 8865, which is a Technical Report of type 3, was prepared by Technical Com-

mittee ISO/TC 82, M/‘nlng, Sub-Committee SC 2, Components of coalface machinery

using high-tensile round link chains.

International Standard IS0 5613 : 1984 covering drive sprocket assemblies for mining

chain conveyors specifies requirements for a range of sprocket assemblies for use with

twin outboard assemblies. These assemblies incorporate sprocket rings designed to

accept chains complying with IS0 610, shackle type connectors complying with

IS0 1082 and scraper bars complying with IS0 5612.

The dimensions of the component parts of the sprocket assembly are laid down in

IS0 5613 and these dimensions have to be verified in order to check compliance with

the standard. It is stated that the methods to be used for the verification of the dimen-

sions shall be agreed between the purchaser and the manufacturer (IS0 5613 : 1984,

4.3). A number of the dimensions specified, in particular those relating to the tooth

profile of the sprocket, cannot be measured by the direct application of conventional

measuring instruments and it was decided to give some guidance on the special techni-

ques involved.

The member bodies participating in the work of lSO/TC 82/SC 2 studied the problem

and it was found that a number of varying methods and instruments were used, all

equally satisfactory if the appropriate dimensions were controlled to ensure com-

patibili

...

ISO/TR

TECHNICAL

REPORT

First edition

1990-12-01

Mining - Guidance on methods of verifying

dimensions of sprocket assemblies for chain

conveyors

Reference number

IS0 8865 : 1990 (El

ISO/TR 8865 : 1990 (E)

Foreword

IS0 (the international Organization for Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The main task of IS0 technical committees is to prepare International Standards. In ex-

ceptional circumstances a technical committee may propose the publication of a

Technical Report of one of the following types:

-

type 1, when the required support cannot be obtained for the publication of an

International Standard, despite repeated efforts;

-

type 2, when the subject is still under technical development or where for any

other reason there is the future but not immediate possibility of an agreement on an

International Standard;

-

type 3, when a technical committee has collected data of a different kind from

that which is normally published as an International Standard (“state of the art”, for

example).

Technical Reports of types 1 and 2 are subject to review within three years of publica-

tion, to decide whether they can be transformed into International Standards.

Technical Reports of type 3 do not necessarily have to be reviewed until the data they

provide are considered to be no longer valid or useful.

ISO/TR 8865, which is a Technical Report of type 3, was prepared by Technical Com-

mittee ISO/TC 82, M/‘nlng, Sub-Committee SC 2, Components of coalface machinery

using high-tensile round link chains.

International Standard IS0 5613 : 1984 covering drive sprocket assemblies for mining

chain conveyors specifies requirements for a range of sprocket assemblies for use with

twin outboard assemblies. These assemblies incorporate sprocket rings designed to

accept chains complying with IS0 610, shackle type connectors complying with

IS0 1082 and scraper bars complying with IS0 5612.

The dimensions of the component parts of the sprocket assembly are laid down in

IS0 5613 and these dimensions have to be verified in order to check compliance with

the standard. It is stated that the methods to be used for the verification of the dimen-

sions shall be agreed between the purchaser and the manufacturer (IS0 5613 : 1984,

4.3). A number of the dimensions specified, in particular those relating to the tooth

profile of the sprocket, cannot be measured by the direct application of conventional

measuring instruments and it was decided to give some guidance on the special techni-

ques involved.

The member bodies participating in the work of lSO/TC 82/SC 2 studied the problem

and it was found that a number of varying methods and instruments were used, all

equally satisfactory if the appropriate dimensions were controlled to ensure com-

patibility with the other components of the chain assembly.

The committee therefore came to the conclusion that no one method or instrument

need be adopted as the “standard” method but guidance would be helpful on certain

general principles and essential features of the checking gauges. This document is

therefore published in the form of a Technical Report rather than an International

Standard.

0 IS0 1990

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...