ISO 13577-3:2016

(Main)Industrial furnaces and associated processing equipment — Safety — Part 3: Generation and use of protective and reactive atmosphere gases

Industrial furnaces and associated processing equipment — Safety — Part 3: Generation and use of protective and reactive atmosphere gases

ISO 13577-3:2016 specifies safety requirements for generation and use of protective and reactive atmosphere gases that are part of industrial thermo-processing equipment (TPE). NOTE The general safety requirements common to TPE are provided in ISO 13577‑1 (see Introduction). ISO 13577-3:2016 deals with significant hazards, hazardous situations and events relevant to the generation and use of protective and reactive atmosphere gases created by thermochemical reactions and their use in TPE that are part of TPE as listed in Clause 4 and Clause 5, when used as intended and under the conditions foreseen by the manufacturer. It covers - pipework downstream of and including the manual isolating valve, - equipment for the generation of atmosphere gases, - additional equipment for the use of atmosphere gases in TPE, - safety devices, and - functional requirements for safety related control system for the generation and use of protective and reactive atmosphere gases. It applies to the supply of atmosphere gas, source gas, inert gas and process liquids to TPE and their removal from TPE, confined to equipment integrated in the TPE. ISO 13577-3:2016 also details the anticipated significant hazards associated with atmosphere gas systems and their use in TPE and specifies the appropriate preventative measures for the reduction or elimination of these hazards. The pressure hazard of the piping and components covered by this standard is within the maximum pressure/size relationship of group I as described in Annex C. It - specifies the requirements to be met to ensure the safety of persons and property during installation, commissioning, start up, operation, shutdown and maintenance, - does not cover the relevant risks involved in the flue gas ducting system when it is not considered a part of TPE, - is not applicable to utility supply upstream of the TPE main disconnects, - does not apply to TPE for semi-conductor devices, - does not apply to TPE with atmosphere, such as air and flue gas from an over stoichiometric combustion, - does not cover the decommissioning of the TPE, - does not cover vacuum furnaces, - does not deal with the hazard of noise which is covered in ISO 13577‑1, - is not applicable to generation and use of atmosphere gas in TPE and associated plant which is manufactured before the date of its publication, and - gives the necessary requirements for the information for use. A TPE designed according to ISO 13577-3:2016 does not create any potentially explosive atmosphere in the area around the TPE and is not designed to be located in an area with a potentially explosive or hazardous atmosphere. A table of typical protective and reactive gases is given in Annex B.

Fours industriels et équipements associés — Sécurité — Partie 3: Génération et utilisation des gaz d'atmosphère protectrice et réactive

General Information

- Status

- Published

- Publication Date

- 18-Sep-2016

- Technical Committee

- ISO/TC 244 - Industrial furnaces and associated processing equipment

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 17-Jan-2022

- Completion Date

- 12-Feb-2026

Overview

ISO 13577-3:2016 - "Industrial furnaces and associated processing equipment - Safety - Part 3: Generation and use of protective and reactive atmosphere gases" specifies safety requirements for the generation, distribution and use of protective and reactive atmosphere gases that are integrated into industrial thermo‑processing equipment (TPE). The standard addresses hazards, preventive measures and functional safety requirements for equipment and pipework that are part of the TPE (including pipework from and including the manual isolating valve). Annexes list typical atmosphere gases (Annex B) and allowed maximum pressures (Annex C).

Key topics and technical requirements

- Scope of coverage: Atmosphere gas generation equipment, downstream pipework, additional atmosphere-use equipment, safety devices and safety‑related control functions integrated with TPE.

- Pipework and fittings: Requirements for connections, marking, condensate drains, purge points, vents, pressure relief and soundness/tightness.

- Safety devices and controls: Atmosphere gas control equipment, emergency purge, flame arrestors, burners for exothermic/endothermic generation, and monitoring (including flame detection).

- Change-of‑atmosphere procedures: Purging methods (purge gas, self‑ignition, burning, evacuation) and interfaces to exhaust systems for combustible or toxic gases.

- Functional safety: Requirements for safety‑related control systems and guidance on determining SIL/PL (see Annex E for examples).

- Verification and information for use: Commissioning, start‑up, operation, shutdown, maintenance procedures, marking and the instruction handbook requirements.

- Limitations and exclusions: Not applicable to utility supplies upstream of TPE disconnects, vacuum furnaces, TPE for semiconductor manufacture, decommissioning, or TPE manufactured before the publication date. Noise hazards are covered in ISO 13577‑1.

Practical applications and who uses it

ISO 13577-3:2016 is used by:

- Manufacturers and designers of industrial furnaces and TPE integrating atmosphere gas systems

- Plant safety and process engineers responsible for heat‑treatment atmospheres (e.g., carburizing, nitriding, annealing)

- System integrators, control engineers and automation teams implementing safety-related control functions (SIL/PL)

- Commissioning teams, maintenance personnel and certification bodies assessing compliance and risk reduction measures

The standard helps ensure safe generation, handling and switching of protective/reactive atmospheres, preventing ignitable or toxic releases and defining safe purge and exhaust practices.

Related standards

- ISO 13577‑1 - General requirements for TPE

- ISO 13577‑2 - Combustion and fuel handling systems

- ISO 13577‑4 - Protective systems

- ISO 13574 - Vocabulary (terms referenced in Annex J)

Note: compliance with product standards such as ISO 22967/22968 alone is not sufficient; ISO 13577‑3 takes precedence for TPE covered by this Part.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 13577-3:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial furnaces and associated processing equipment — Safety — Part 3: Generation and use of protective and reactive atmosphere gases". This standard covers: ISO 13577-3:2016 specifies safety requirements for generation and use of protective and reactive atmosphere gases that are part of industrial thermo-processing equipment (TPE). NOTE The general safety requirements common to TPE are provided in ISO 13577‑1 (see Introduction). ISO 13577-3:2016 deals with significant hazards, hazardous situations and events relevant to the generation and use of protective and reactive atmosphere gases created by thermochemical reactions and their use in TPE that are part of TPE as listed in Clause 4 and Clause 5, when used as intended and under the conditions foreseen by the manufacturer. It covers - pipework downstream of and including the manual isolating valve, - equipment for the generation of atmosphere gases, - additional equipment for the use of atmosphere gases in TPE, - safety devices, and - functional requirements for safety related control system for the generation and use of protective and reactive atmosphere gases. It applies to the supply of atmosphere gas, source gas, inert gas and process liquids to TPE and their removal from TPE, confined to equipment integrated in the TPE. ISO 13577-3:2016 also details the anticipated significant hazards associated with atmosphere gas systems and their use in TPE and specifies the appropriate preventative measures for the reduction or elimination of these hazards. The pressure hazard of the piping and components covered by this standard is within the maximum pressure/size relationship of group I as described in Annex C. It - specifies the requirements to be met to ensure the safety of persons and property during installation, commissioning, start up, operation, shutdown and maintenance, - does not cover the relevant risks involved in the flue gas ducting system when it is not considered a part of TPE, - is not applicable to utility supply upstream of the TPE main disconnects, - does not apply to TPE for semi-conductor devices, - does not apply to TPE with atmosphere, such as air and flue gas from an over stoichiometric combustion, - does not cover the decommissioning of the TPE, - does not cover vacuum furnaces, - does not deal with the hazard of noise which is covered in ISO 13577‑1, - is not applicable to generation and use of atmosphere gas in TPE and associated plant which is manufactured before the date of its publication, and - gives the necessary requirements for the information for use. A TPE designed according to ISO 13577-3:2016 does not create any potentially explosive atmosphere in the area around the TPE and is not designed to be located in an area with a potentially explosive or hazardous atmosphere. A table of typical protective and reactive gases is given in Annex B.

ISO 13577-3:2016 specifies safety requirements for generation and use of protective and reactive atmosphere gases that are part of industrial thermo-processing equipment (TPE). NOTE The general safety requirements common to TPE are provided in ISO 13577‑1 (see Introduction). ISO 13577-3:2016 deals with significant hazards, hazardous situations and events relevant to the generation and use of protective and reactive atmosphere gases created by thermochemical reactions and their use in TPE that are part of TPE as listed in Clause 4 and Clause 5, when used as intended and under the conditions foreseen by the manufacturer. It covers - pipework downstream of and including the manual isolating valve, - equipment for the generation of atmosphere gases, - additional equipment for the use of atmosphere gases in TPE, - safety devices, and - functional requirements for safety related control system for the generation and use of protective and reactive atmosphere gases. It applies to the supply of atmosphere gas, source gas, inert gas and process liquids to TPE and their removal from TPE, confined to equipment integrated in the TPE. ISO 13577-3:2016 also details the anticipated significant hazards associated with atmosphere gas systems and their use in TPE and specifies the appropriate preventative measures for the reduction or elimination of these hazards. The pressure hazard of the piping and components covered by this standard is within the maximum pressure/size relationship of group I as described in Annex C. It - specifies the requirements to be met to ensure the safety of persons and property during installation, commissioning, start up, operation, shutdown and maintenance, - does not cover the relevant risks involved in the flue gas ducting system when it is not considered a part of TPE, - is not applicable to utility supply upstream of the TPE main disconnects, - does not apply to TPE for semi-conductor devices, - does not apply to TPE with atmosphere, such as air and flue gas from an over stoichiometric combustion, - does not cover the decommissioning of the TPE, - does not cover vacuum furnaces, - does not deal with the hazard of noise which is covered in ISO 13577‑1, - is not applicable to generation and use of atmosphere gas in TPE and associated plant which is manufactured before the date of its publication, and - gives the necessary requirements for the information for use. A TPE designed according to ISO 13577-3:2016 does not create any potentially explosive atmosphere in the area around the TPE and is not designed to be located in an area with a potentially explosive or hazardous atmosphere. A table of typical protective and reactive gases is given in Annex B.

ISO 13577-3:2016 is classified under the following ICS (International Classification for Standards) categories: 13.100 - Occupational safety. Industrial hygiene; 25.180.01 - Industrial furnaces in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13577-3:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13577-3

First edition

2016-09-15

Industrial furnaces and associated

processing equipment — Safety —

Part 3:

Generation and use of protective and

reactive atmosphere gases

Fours industriels et équipements associés — Sécurité —

Partie 3: Génération et utilisation des gaz d’atmosphère protectrice et

réactive

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

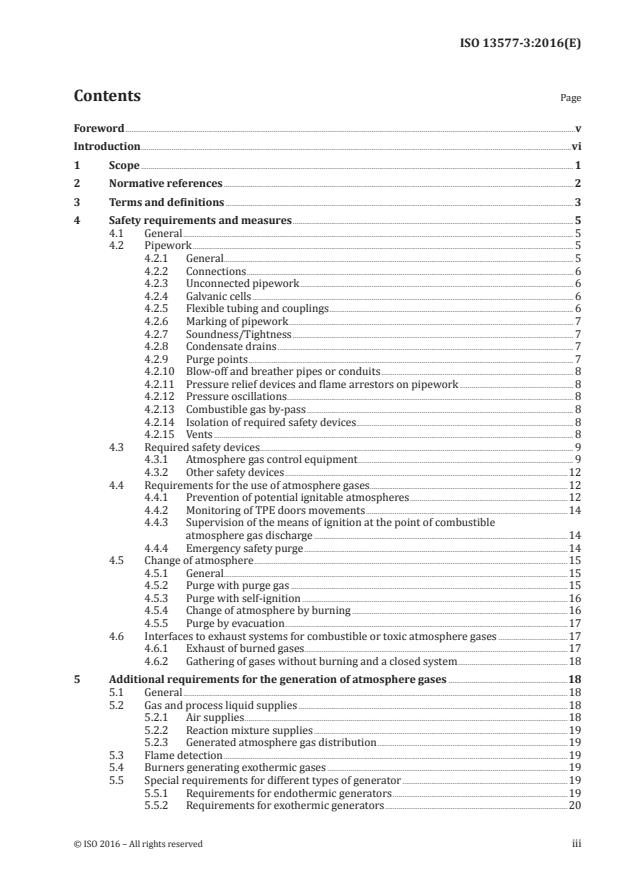

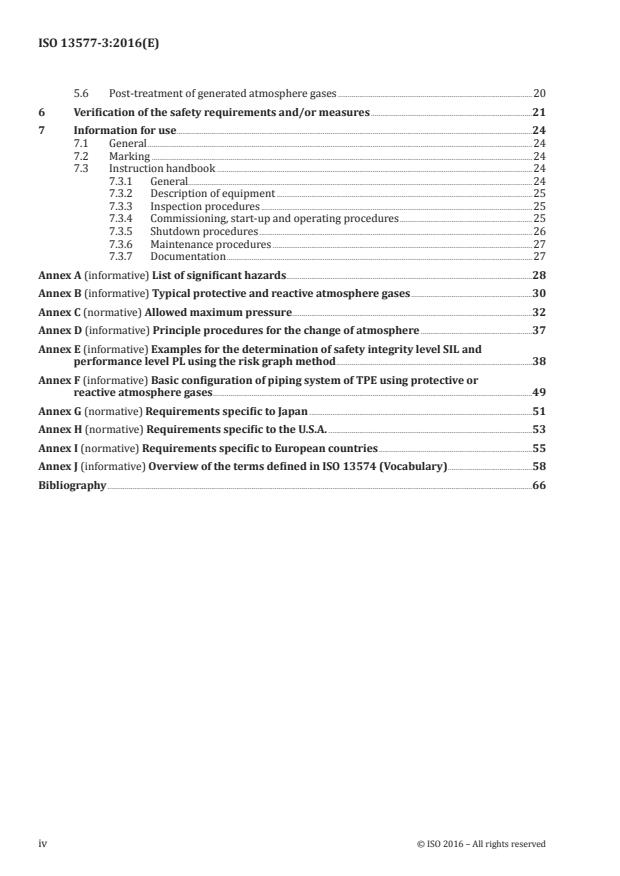

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Safety requirements and measures . 5

4.1 General . 5

4.2 Pipework . 5

4.2.1 General. 5

4.2.2 Connections . 6

4.2.3 Unconnected pipework . 6

4.2.4 Galvanic cells . 6

4.2.5 Flexible tubing and couplings . 6

4.2.6 Marking of pipework . 7

4.2.7 Soundness/Tightness . 7

4.2.8 Condensate drains . 7

4.2.9 Purge points . 7

4.2.10 Blow-off and breather pipes or conduits . 8

4.2.11 Pressure relief devices and flame arrestors on pipework . 8

4.2.12 Pressure oscillations . . 8

4.2.13 Combustible gas by-pass . 8

4.2.14 Isolation of required safety devices. 8

4.2.15 Vents . 8

4.3 Required safety devices . 9

4.3.1 Atmosphere gas control equipment . 9

4.3.2 Other safety devices .12

4.4 Requirements for the use of atmosphere gases.12

4.4.1 Prevention of potential ignitable atmospheres .12

4.4.2 Monitoring of TPE doors movements .14

4.4.3 Supervision of the means of ignition at the point of combustible

atmosphere gas discharge .14

4.4.4 Emergency safety purge .14

4.5 Change of atmosphere .15

4.5.1 General.15

4.5.2 Purge with purge gas .15

4.5.3 Purge with self-ignition .16

4.5.4 Change of atmosphere by burning .16

4.5.5 Purge by evacuation .17

4.6 Interfaces to exhaust systems for combustible or toxic atmosphere gases .17

4.6.1 Exhaust of burned gases.17

4.6.2 Gathering of gases without burning and a closed system .18

5 Additional requirements for the generation of atmosphere gases .18

5.1 General .18

5.2 Gas and process liquid supplies .18

5.2.1 Air supplies .18

5.2.2 Reaction mixture supplies .19

5.2.3 Generated atmosphere gas distribution .19

5.3 Flame detection .19

5.4 Burners generating exothermic gases .19

5.5 Special requirements for different types of generator .19

5.5.1 Requirements for endothermic generators .19

5.5.2 Requirements for exothermic generators .20

5.6 Post-treatment of generated atmosphere gases .20

6 Verification of the safety requirements and/or measures .21

7 Information for use .24

7.1 General .24

7.2 Marking .24

7.3 Instruction handbook .24

7.3.1 General.24

7.3.2 Description of equipment .25

7.3.3 Inspection procedures .25

7.3.4 Commissioning, start-up and operating procedures .25

7.3.5 Shutdown procedures .26

7.3.6 Maintenance procedures .27

7.3.7 Documentation .27

Annex A (informative) List of significant hazards.28

Annex B (informative) Typical protective and reactive atmosphere gases .30

Annex C (normative) Allowed maximum pressure.32

Annex D (informative) Principle procedures for the change of atmosphere .37

Annex E (informative) Examples for the determination of safety integrity level SIL and

performance level PL using the risk graph method .38

Annex F (informative) Basic configuration of piping system of TPE using protective or

reactive atmosphere gases .49

Annex G (normative) Requirements specific to Japan .51

Annex H (normative) Requirements specific to the U.S.A. .53

Annex I (normative) Requirements specific to European countries .55

Annex J (informative) Overview of the terms defined in ISO 13574 (Vocabulary) .58

Bibliography .66

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 244, Industrial furnaces and associated

processing equipment.

ISO 13577 consists of the following parts, under the general title Industrial furnaces and associated

processing equipment — Safety:

— Part 1: General requirements

— Part 2: Combustion and fuel handling systems

— Part 3: Generation and use of protective and reactive atmosphere gases

— Part 4: Protective systems

Introduction

This part of ISO 13577 is a Type C-Standard as defined in ISO 12100.

The machinery concerned and the extent, to which hazards, hazardous situations and events are

covered, is indicated in the scope of this part of ISO 13577.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type C

standard.

Compliance with product standards, e.g. ISO 22967 or ISO 22968 is not sufficient to ensure the minimum

safety requirement for TPE. This part of ISO 13577 shall always have priority for TPE.

Industrial furnaces and associated thermo-processing equipment (TPE) generally consists of the

following components:

— processing chamber (e.g. steel construction with lining and/or refractory);

— heating systems;

— protective system;

— control and instrumentation system/operator-control level.

ISO 13577-1 provides the general safety requirements common to TPE. This part of ISO 13577 details

in addition specific safety requirements for generation and use of protective and reactive atmosphere

gases that are part of TPE as listed in the scope. These requirements establish the minimum acceptable

requirements for safety functions required for various processes. Where a process is not part of the

TPE, the requirements do not apply.

For example, the minimum requirements for the opening and closing of doors on a TPE does not apply

to TPE that do not have doors in their design.

NOTE As stated in its scope, ISO 13577-1 does not cover blast furnaces, converters (in steel plants), boilers

and equipment not covered under ISO 12100.

The requirements of protective system are specified in ISO 13577-4.

If a general provision of ISO 13577-1 counters provisions in this part of ISO 13577, the provisions of this

part of ISO 13577 take precedence.

It is assumed that TPE will only be operated and maintained by trained personnel.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 13577-3:2016(E)

Industrial furnaces and associated processing

equipment — Safety —

Part 3:

Generation and use of protective and reactive

atmosphere gases

1 Scope

This part of ISO 13577 specifies safety requirements for generation and use of protective and reactive

atmosphere gases that are part of industrial thermo-processing equipment (TPE).

NOTE The general safety requirements common to TPE are provided in ISO 13577-1 (see Introduction).

This part of ISO 13577 deals with significant hazards, hazardous situations and events relevant to the

generation and use of protective and reactive atmosphere gases created by thermochemical reactions

and their use in TPE that are part of TPE as listed in Clause 4 and Clause 5, when used as intended and

under the conditions foreseen by the manufacturer.

This part of ISO 13577 covers

— pipework downstream of and including the manual isolating valve,

— equipment for the generation of atmosphere gases,

— additional equipment for the use of atmosphere gases in TPE,

— safety devices, and

— functional requirements for safety related control system

for the generation and use of protective and reactive atmosphere gases.

It applies to the supply of atmosphere gas, source gas, inert gas and process liquids to TPE and their

removal from TPE, confined to equipment integrated in the TPE.

This part of ISO 13577 also details the anticipated significant hazards associated with atmosphere gas

systems and their use in TPE and specifies the appropriate preventative measures for the reduction or

elimination of these hazards.

The pressure hazard of the piping and components covered by this standard is within the maximum

pressure/size relationship of group I as described in Annex C.

This part of ISO 13577

— specifies the requirements to be met to ensure the safety of persons and property during installation,

commissioning, start up, operation, shutdown and maintenance,

— does not cover the relevant risks involved in the flue gas ducting system when it is not considered a

part of TPE,

— is not applicable to utility supply upstream of the TPE main disconnects,

— does not apply to TPE for semi-conductor devices,

— does not apply to TPE with atmosphere, such as air and flue gas from an over stoichiometric

combustion,

— does not cover the decommissioning of the TPE,

— does not cover vacuum furnaces,

— does not deal with the hazard of noise which is covered in ISO 13577-1,

— is not applicable to generation and use of atmosphere gas in TPE and associated plant which is

manufactured before the date of its publication, and

— gives the necessary requirements for the information for use.

A TPE designed according to this part of ISO 13577 does not create any potentially explosive atmosphere

in the area around the TPE and is not designed to be located in an area with a potentially explosive or

hazardous atmosphere.

A table of typical protective and reactive gases is given in Annex B.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances

and designation

ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 5817, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections

ISO 7005-1, Metallic flanges — Part 1: Steel flanges

ISO 7005-2, Metallic flanges — Part 2: Cast iron flanges

ISO 8434-1, Metallic tube connections for fluid power and general use — Part 1: 24 degree cone connectors

ISO 8434-2, Metallic tube connections for fluid power and general use — Part 2: 37 degree flared connectors

ISO 8434-3, Metallic tube connections for fluid power and general use — Part 3: O-ring face seal connectors

ISO 12100, Safety of machinery — General principles for design — Risk assessment and risk reduction

ISO 13574:2015, Industrial furnaces and associated processing equipment — Vocabulary

ISO 13577-1:2012, Industrial furnaces and associated processing equipment — Safety — Part 1: General

requirements

ISO 13577-2:2014, Industrial furnaces and associated processing equipment — Safety — Part 2: Combustion

and fuel handling systems

ISO 13577-4, Industrial furnace and associated processing equipment — Safety — Part 4: Protective systems

ISO 13849-1, Safety of machinery — Safety-related parts of control systems — Part 1: General principles

for design

ISO 19879, Metallic tube connections for fluid power and general use — Test methods for hydraulic fluid

power connections

2 © ISO 2016 – All rights reserved

ISO 23551-1, Safety and control devices for gas burners and gas-burning appliances — Particular

requirements — Part 1: Automatic and semi-automatic valves

ISO 23551-2, Safety and control devices for gas burners and gas-burning appliances — Particular

requirements — Part 2: Pressure regulators

IEC 60730-2-5:2011, Automatic electrical controls for household and similar use—Part 2-5: Particular

requirements for automatic electrical burner control systems

IEC 60730-2-6:2007, Automatic electrical controls for household and similar use—Part 2-6: Particular

requirements for automatic electrical pressure sensing controls including mechanical requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13574 and the following apply.

NOTE See Annex J for the list of terms specified in ISO 13574.

3.1

safety shutdown

function that takes the TPE out of operation and brings it in a defined safe state

Note 1 to entry: The definition is different from safety shutdown according ISO 13574:2015, 2.166 which is

applicable to ISO 13577-2.

3.2

flame failure

loss of flame from the normally detected position by any cause other than the action of de-energising

the automatic shut-off valves system

Note 1 to entry: The term is used in ISO 13577-2.

3.3

gas generator

equipment that converts or modifies a fluid or a mixture of fluids (gaseous or liquid) into a gas which

can be utilized as the controlled atmosphere within the thermo-processing equipment

3.4

endothermic generator

gas generator that produces atmosphere gas by an endothermic reaction

3.5

exothermic generator

gas generator that produces atmosphere gas by an exothermic reaction

3.6

combustible atmosphere gas

any gas mixture that is capable of forming ignitable mixtures with air or oxygen under the conditions

of temperature and pressure used in the process, according to the lower explosion level (LEL) of the

actual gas mixture

3.7

inert gas

non-combustible gas which will not support combustion and does not react at all

Note 1 to entry: Nitrogen, helium and argon are typical inert gases.

3.8

purge gas

gas which can be used to purge a TPE

Note 1 to entry: A purge gas can safely be used for pre- and post-purging of cold and hot enclosures of TPE.

Note 2 to entry: Typically, purge gases are nitrogen, argon, helium and lean exothermic gas.

3.9

safety purge volume

volume of purge gas needed to displace either air or a combustible gas from a furnace chamber/enclosure

to achieve a volume fraction of 1 % or less oxygen and/or a non-combustible atmosphere gas and/or

25 % of the lower flammability limit

Note 1 to entry: Typically, this will be a volume equal to five times the volume of the thermo-processing equipment

chamber to be purged, if the purging gas is an inert gas.

Note 2 to entry: Non-combustible atmosphere gas as defined in 3.6.

3.10

multi-turn valve

valve which, in order to operate from the fully closed to the fully open position, requires a number of

revolutions of the operating key or handwheel to be completed

3.11

safe ignition temperature

minimum temperature at which spontaneous, safe auto-ignition of combustible gases occurs

Note 1 to entry: The safe ignition temperature has been established at 750 °C.

3.12

toxic atmosphere gas

gas which, in addition to having asphyxiating properties, also acts as a poison

3.13

internal gas generator

gas generator integrated into or directly connected to a TPE

3.14

gas control equipment

centralized mounting of components such as: pipework, safety components, pressure and flow

accessories, assembled in a functional unit

3.15

atmosphere gas

gas that is supplied into or formed in TPE in accordance with a defined specification for thermo-

processes

Note 1 to entry: Atmosphere gas is used to react with the material processed or to avoid a reaction with the

material processed.

3.16

process liquids

liquids that are supplied to TPE to create an atmosphere gas

4 © ISO 2016 – All rights reserved

4 Safety requirements and measures

4.1 General

Protective and reactive atmosphere gases in TPE are used to react with the material processed or to

avoid a reaction with the material processed. Protective and reactive atmosphere gases are fed into the

TPE at determined points and are discharged out of the TPE at determined points too.

Protective and reactive atmosphere gases shall only be used in TPE that has been constructed to avoid

leakage of the protective and reactive atmosphere gases out of the TPE or ambient air into the TPE.

Electrical circuits shall be designed in accordance with IEC 60204-1.

A risk assessment according to ISO 12100 shall be carried out. Safety functions shall be designed in

accordance with ISO 13577-4, where the use of standards for functional safety IEC 62061, ISO 13849-1,

IEC 61511 and IEC 61508 is included. Annex E provides information for the determination of the SIL or

PL of safety-related functions covered in this part of ISO 13577.

Specific regional requirements are given in Annex G, Annex H and Annex I. The safety requirements of

Annex G, Annex H and Annex I shall ensure at least the equivalent level of safety to the requirements

given in this part of ISO 13577.

CAUTION — Toxic hazards for persons occur at lower concentrations than hazards by generation

of ignitable atmospheres.

NOTE Requirements for maximum allowable concentrations values are identified by national regulations.

Materials used shall comply with the requirements for gas and liquids (e.g. non-ferrous metals are not

suitable for NH and natural rubber is not suitable for natural gas).

For basic configuration of piping system of TPE using atmosphere gas, see Annex F.

4.2 Pipework

4.2.1 General

The pipework design shall take into account the composition and properties (e.g. pressure, temperature,

corrosiveness, specific gravity, velocity) of gas and liquids and the need for venting, purging and

cleaning.

The pipework material shall comply with the relevant standards.

Due to durability, steel is the preferred material for pipes and components but where appropriate

and the same safety levels can be achieved, then other materials may be utilized. Such materials and

conditions of service shall be specified in the instruction handbook.

Vibration which may cause damage to pipework, components or safety systems shall be prevented (by

firm anchoring and/or use of flexible couplings).

Pipework shall be arranged so that safe isolation of atmosphere gas and process liquids to all parts of

the TPE can be guaranteed

NOTE An example is shown in Figure F.1.

The isolation method shall be clearly identified (e.g. by removable spool piece painted in red, blanking

plate), and provision for blanking opened pipes shall be provided secured against loss (e.g. by an

attached chain).

Use of brass or other copper alloy components in contact with ammonia or dissociated ammonia is not

allowed.

4.2.2 Connections

Pipework connections shall be metallic and shall be of threaded, compression, press fittings, flanged

welded or brazed types. Threaded connections shall be used only for the following pressure/diameter

combinations:

— pressures up to 15 kPa and diameters up to DN 100;

— pressures up to 200 kPa and diameters up to DN 50;

— pressures up to 500 kPa and diameters up to DN 25;

— pressures up to 1 MPa and diameters up to DN 15

For other combinations of pressures and diameters, connections shall be made by means of welded

flanges or welded joints. The number of connections shall be kept to a minimum.

For fittings according to ISO 49, the following limitations shall be observed:

— fittings are class “A”;

— maximum allowed pressure is 50 kPa;

— for dimensions DN 25 or less, the maximum pressure is 500 kPa.

Where the equipment has a threaded connection, this thread shall comply with ISO 228-1 or ISO 7-1,

as appropriate. The use of threads complying with ISO 228-1 is limited to diameter up to DN 50. In

the case of threads according to ISO 228-1, the tightness shall be ensured by a ring gasket. In case of

threads according ISO 7-1 suitable sealants shall be used to ensure tightness. Hemp shall not be used in

threaded connections unless reinforced with a suitable sealant.

Other threaded connections shall only be used providing they ensure tight connections and are suitably

identified.

The design of pipework shall be such as to avoid tensile loading of the joints.

Compression fittings shall comply with ISO 8434-1, ISO 8434-2 and ISO 8434-3 or ISO 19879. They shall

only be used for pressures up to 500 kPa and diameters up to 42 mm.

Where press fitting according to EN 10352:2012-09 are used, they shall comply with the application

restrictions (e.g. temperature, vibration, gas, liquids).

Any pipe passing through an unventilated space shall not have a connection except welded joints.

Flanges shall comply with ISO 7005-1 and ISO 7005-2 as appropriate.

Arc welding shall comply with ISO 5817, quality Level C.

4.2.3 Unconnected pipework

Any unconnected pipework shall be plugged, capped or blank flanged by means of metallic parts.

4.2.4 Galvanic cells

The formation of galvanics cell shall be avoided by suitable choice of materials.

4.2.5 Flexible tubing and couplings

Flexible tubing shall comply with the general requirements of 4.2.1, together with the following:

— shall be as short as possible;

— shall be suitable for the maximum and minimum working temperatures;

6 © ISO 2016 – All rights reserved

— shall be suitable for a pressure 1,5 times the working operating pressure (with a minimum of

15 kPa), at the maximum and minimum working temperatures;

— shall have a directly accessible, upstream manual shut-off valve;

— shall be mounted in such a way as to avoid distortion, whiplash and damage;

— shall have end fittings as integral parts of the tubing;

— shall be constructed from suitable material both metallic and/or non-metallic selected for the

application duty and not be easily damaged.

Couplings for removable equipment shall ensure a gastight connection with the equipment connected

and disconnected.

4.2.6 Marking of pipework

Marking of pipework is required which enable medium and flow direction to be identified in accordance

with national regulations.

4.2.7 Soundness/Tightness

The pipework shall be tight and shall be designed to withstand the internal pressure. After assembly,

the pipework shall be submitted to its test pressure and tested for tightness. The test pressure shall be

not less than 1,1 times the maximum working pressure at any point with a minimum of 5 kPa.

The external leakage rate shall not give rise to a dangerous condition, combustible and/or toxic, in the

foreseen circumstances of the equipment or installation. The frequency of testing to determine the

external leakage shall be specified in the instruction handbook.

3 3

NOTE It is generally agreed that an external leak rate of ~1 dm (n)/h for gas or 1 cm (n)/h for methanol will

not create a dangerous condition in typical ventilated industrial installation.

The external leak rate test method shall take into account the volume, number of connections, test gas,

number of valves and component parts contained and temperature. Methods of testing shall include

spray bubble leak identification and/or pressure decay test.

4.2.8 Condensate drains

In cases where condensates can create a hazard, means shall be provided at the lowest points of the

equipment for draining any condensate. When moist gases are being used, condensate drains of a

suitable type shall be installed. Any condensate drains, siphons, etc. shall be in a position such that they

can be easily checked. Combustible condensates shall be collected by an appropriate means (e.g. piped

into a container).

Valves in condensate drains shall be suitably plugged, capped or blank flanged by metallic parts.

4.2.9 Purge points

Means shall be provided to facilitate purging of pipework during commissioning and maintenance to

prevent the forming of an ignitable atmosphere.

All distribution pipework and storage vessels for atmosphere gas shall be designed, so that purging

procedures in accordance with 4.6 or in such a manner which excludes the simultaneous presence of

combustible gas/air mixtures and an ignition source can be done. Each purging point shall be provided

with a valve which shall either

— be fitted with a device to prevent unauthorised operation, or

— be blanked off during normal operation of the plant.

4.2.10 Blow-off and breather pipes or conduits

Where blow-off or breather pipes or conduits are fitted on regulators or relief valves, adequate means

shall be provided to facilitate the venting of gas from the system to a safe discharge area.

In case breathers or blow-off pipes are gathered, the cross section of the collector shall be suitable to

evacuate simultaneously total flow rates of the exhaust sources.

4.2.11 Pressure relief devices and flame arrestors on pipework

For equipment designed for situations in which flash-backs can occur, flame arrestors and/or pressure

relief devices shall be fitted.

Pressure relief devices shall be designed to yield at a pressure below the design pressure of the

pipework and shall be positioned such that the discharge flow and the pressure relief device does not

constitute a risk to the equipment, personnel or third parties.

A flash-back shall trigger an alarm. The required measures after a flash-back shall be described in the

instruction handbook.

4.2.12 Pressure oscillations

The pipework shall be designed so as to avoid the possibility of gas velocities and pressure fluctuations

causing oscillations which could cause damage to pipework, components or safety systems (e.g. by

designing the correct sizing of pipes or using pressure regulators).

4.2.13 Combustible gas by-pass

By-passes shall not be fitted in parallel with any item of combustible gas safety equipment.

This requirement shall not apply to valve proving systems (see ISO 23551-4) on automatic shut-off valves.

4.2.14 Isolation of required safety devices

Required safety devices (e.g. pressure switches, relief valves) shall not be isolated from the equipment

they protect during start-up or operation of the TPE. In case isolating valves cannot be avoided and are

mounted between these required devices and the main lines, these isolating valves shall be locked in

the open position during operation of the equipment by adequate means (e.g. manual lock).

4.2.15 Vents

Any vent from a gas supply pipe, reaction gas control system, gas/air mixture pipe or generated

atmosphere gas line shall be adequately sized for the duty intended.

Any vent which is likely to carry a combustible gas/air mixture and which is fitted with a pilot burner

shall be equipped with a flame trap.

Any vent from the mixture supply pipe shall be taken from a point downstream of the flame trap or be

fitted with a separate flame trap. Any vent which is not fitted with a pilot burner shall terminate above

roof level and be remote from potential sources of ignition, having due regard to the layout of adjacent

buildings. These vents shall not be manifold.

8 © ISO 2016 – All rights reserved

4.3 Required safety devices

4.3.1 Atmosphere gas control equipment

4.3.1.1 General

A TPE that generates or uses atmosphere gases shall be equipped with atmosphere gas control

equipment.

Atmosphere gas control equipment means a centralized mounting of components assembled in a

functional unit such as

— pipework,

— safety devices as referred in 4.3.1.2, and

— other pressure and flow accessories (e.g. manometer(s), flow adjusting valve(s), test connection(s)

and/or purging nipples).

Atmosphere gas control equipment shall be designed based on the TPE’s demand for atmosphere gas

supply. It shall be designed with components suitable for this purpose.

The atmosphere gas control equipment shall be placed in a sufficiently ventilated area.

If atmosphere gas control equipment is enclosed and combustible and/or toxic gas or liquids are

used, the enclosure shall be sufficiently ventilated and equipped with devices to detect toxic gases.

Combustible gas detection should also be considered.

The atmosphere gas control equipment shall be suitably marked to be identified as such using written

indications in the languages of the user land.

NOTE Identification of atmosphere gas control equipment can be dealt by national regulations.

The atmosphere gas control equipment shall be freely accessible.

4.3.1.2 Safety devices for introduction of atmosphere gases to TPE

4.3.1.2.1 Manual isolating valve

A manually operated and lockable isolation valve shall be fitted upstream of the first control device

in each circuit. Manual isolation valves shall be so designed and positioned as to prevent inadvertent

operation but shall be easily accessible and capable of rapid operation when required.

They shall be so designed that the “OPEN” and “CLOSED” positions are readily distinguishable (e.g. a

90° turn valve).

4.3.1.2.2 Filter/strainer

Filters shall be fitted to protect automatic shut-off valves, other controls and pipework.

Special care shall be taken to prevent the ingress of particles, either from the pipework or from the

gas and liquids, which would be detrimental to the operation of the equipment by the incorporation

of a suitable filter or strainer immediately downstream of the first manual isolating valve of the TPE.

Additional filters/strainers may be required (e.g. immediately upstream of the automatic shut-off

valve). The filter and/or the strainer shall be positioned in such a way that periodic servicing remains

easy. The filtering capacity of the filter/strainer has to be chosen according to the requirements of

downstream equipment.

In case of the installation of a by-pass to the filter and/or the strainer, an identical filtering device shall

be installed on the by-pass line.

The intervals for checking the filter and/or the strainer shall be specified in the instruction handbook.

The location of filters shall consider service requirements.

NOTE An equipment for purging filters/strainer is in some cases necessary.

4.3.1.2.3 Pressure regulator and over pressure protection

A pressure regulator shall be incorporated when necessary to control the pressure of atmosphere gases.

Gas pressure regulators when fitted shall comply with ISO 23551-2 as appropriate.

If the outlet side of the gas pressure regulator and/or the following line section with equipment up

to the TPE is/are not designed for the maximum supply pressure (inlet pressure upstream to the gas

pressure regulator under fault conditions) and an overpressure will create a hazard, the following

measures shall be applied shutting off the gas supply before an excessively high pressure occurs.

The over pressure cut off device shall be

— a mechanical valve which measures the gas pressure downstream of the gas pressure regulator by

means of an impulse line and closes by spring force in case the pressure exceeds the set response

pressure, or

— an automatic shut-off valve according to ISO 23551-1 actuated by an overpressure switch according

to IEC 60730-2-6 installed downstream of the gas pressure regulator. In this case, signal processing

shall fulfil the requirements of a protective system according to ISO 13577-4.

A small capacity relief valve (token relief valve) shall always be applied downstream of the gas pressure

regulator if an over pressure cut-off device is installed to vent small leakages of the high pressure cut-off.

Attention shall be paid to the unintended decrease of atmosphere supply to the TPE which can result in

unintended disability of maintaining positive pressure of TPE (see 4.4.2 and 4.4.4).

Pressure adjustment on the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...