ISO 18797-1:2016

(Main)Petroleum, petrochemical and natural gas industries — External corrosion protection of risers by coatings and linings — Part 1: Elastomeric coating systems-polychloroprene or EPDM

Petroleum, petrochemical and natural gas industries — External corrosion protection of risers by coatings and linings — Part 1: Elastomeric coating systems-polychloroprene or EPDM

ISO 18797-1:2016 specifies the minimum requirements for materials selection, surface preparation, application, inspection, testing, qualification and acceptance criteria of external coating for steel risers pipes used in the splash zone, their field joints and clamps/guides, using an elastomeric protective coating based on polychloroprene, EPDM or equivalent. This is applicable for new construction and repair of applied pipes before installation. Maintenance requirements and field repairs are covered in ISO 18797-2. ISO 18797-1:2016 also specifies the requirements for transportation, handling and storage of riser pipes before and after surface preparation and coating application.

Industries du pétrole, de la pétrochimie et du gaz naturel — Protection de la corrosion externe des tubes de production par revêtements et doublures — Partie 1: Systèmes de revêtement élastomère-polychloroprène ou EPDM

L'ISO 18797-1:2016 spécifie les exigences minimales applicables à la sélection des matériaux, à la préparation de surface, à l'application, à l'inspection, aux essais, à la qualification et aux critères d'acceptation de revêtement externe pour tuyaux de risers en acier utilisés dans la zone d'action des vagues, leurs joints soudés sur site et colliers/guides, au moyen d'un revêtement de protection en élastomère à base de polychloroprène, EPDM ou équivalent. Cela concerne les nouvelles constructions et les réparations de tuyaux appliqués avant installation. Les exigences de maintenance et les réparations sur site sont traitées dans l'ISO 18797‑2. L'ISO 18797-1:2016 spécifie également les exigences de transport, de manutention et de stockage des tuyaux de risers avant et après la préparation de surface et l'application du revêtement.

General Information

- Status

- Published

- Publication Date

- 18-Aug-2016

- Technical Committee

- ISO/TC 67 - Materials, equipment and offshore structures for petroleum, petrochemical and natural gas industries

- Drafting Committee

- ISO/TC 67/WG 11 - Coating and lining of structures and equipment

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 01-Nov-2023

- Completion Date

- 12-Feb-2026

Overview

ISO 18797-1:2016 provides minimum technical requirements for the external corrosion protection of risers in the petroleum, petrochemical and natural gas industries using elastomeric coating systems based on polychloroprene, EPDM or equivalent. The standard covers materials selection, surface preparation, application, inspection, testing, qualification and acceptance criteria for coated steel riser pipes used in the splash zone, including field joints and clamps/guides. It applies to new construction and pre-installation repairs; in-service maintenance and field repairs are addressed in ISO 18797-2.

Key topics and technical requirements

- Materials and handling

- Minimum requirements for elastomeric coating materials (polychloroprene, EPDM or equivalents)

- Packaging, transportation, storage and handling of pipes and coating materials before/after surface preparation

- Surface preparation

- Removal of contaminants and pipe imperfections

- Abrasive blast cleaning as a core preparatory method

- Coating application

- Priming and application methods for blast-cleaned surfaces

- Vulcanization and manual application for clamps, guides, bolt holes and flanges

- Procedures for coating of field joints and pre-installation repairs

- Inspection and testing

- Visual inspection, holiday detection, thickness measurement, adhesion (bond) testing, hardness testing

- Elastomer-specific tests: tensile, tear, elongation, compression set, abrasion, ozone resistance, specific gravity, cathodic disbondment, thermal conductivity and vulcanization characteristics

- Ultrasonic and sound testing for defect detection

- Qualification, documentation and quality

- Qualification of application and inspection personnel

- Test reports, batch certificates and acceptance/rejection criteria

- Requirements for handling and stacking coated pipes

Practical applications and users

ISO 18797-1 is intended for organizations and professionals involved in offshore and nearshore riser installation and fabrication:

- Corrosion and materials engineers specifying riser protection systems

- Coating manufacturers and suppliers of polychloroprene/EPDM systems

- Offshore fabricators and pipe coating contractors performing pre-installation application

- QA/QC and inspection teams performing coating verification and acceptance

- Asset owners and operators defining procurement and inspection criteria for risers in the splash zone

This standard supports reliability and asset protection by reducing external corrosion risks to risers exposed to cyclic wet/dry splash-zone conditions.

Related standards

- ISO 18797-2 (maintenance and field repairs)

- Referenced test standards such as ISO 34, ISO 37, ISO 48, ISO 813/ISO 814, ISO 815 and ISO 1431-1 for elastomer property testing

- Developed under ISO/TC 67 (materials, equipment and offshore structures)

Keywords: external corrosion protection, risers, elastomeric coating, polychloroprene, EPDM, splash zone, riser pipes, coating application, surface preparation, inspection and testing.

ISO 18797-1:2016 - Petroleum, petrochemical and natural gas industries -- External corrosion protection of risers by coatings and linings

ISO 18797-1:2016 - Industries du pétrole, de la pétrochimie et du gaz naturel -- Protection de la corrosion externe des tubes de production par revetements et doublures

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 18797-1:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum, petrochemical and natural gas industries — External corrosion protection of risers by coatings and linings — Part 1: Elastomeric coating systems-polychloroprene or EPDM". This standard covers: ISO 18797-1:2016 specifies the minimum requirements for materials selection, surface preparation, application, inspection, testing, qualification and acceptance criteria of external coating for steel risers pipes used in the splash zone, their field joints and clamps/guides, using an elastomeric protective coating based on polychloroprene, EPDM or equivalent. This is applicable for new construction and repair of applied pipes before installation. Maintenance requirements and field repairs are covered in ISO 18797-2. ISO 18797-1:2016 also specifies the requirements for transportation, handling and storage of riser pipes before and after surface preparation and coating application.

ISO 18797-1:2016 specifies the minimum requirements for materials selection, surface preparation, application, inspection, testing, qualification and acceptance criteria of external coating for steel risers pipes used in the splash zone, their field joints and clamps/guides, using an elastomeric protective coating based on polychloroprene, EPDM or equivalent. This is applicable for new construction and repair of applied pipes before installation. Maintenance requirements and field repairs are covered in ISO 18797-2. ISO 18797-1:2016 also specifies the requirements for transportation, handling and storage of riser pipes before and after surface preparation and coating application.

ISO 18797-1:2016 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 18797-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18797-1

First edition

2016-09-01

Petroleum, petrochemical and natural

gas industries — External corrosion

protection of risers by coatings and

linings —

Part 1:

Elastomeric coating systems-

polychloroprene or EPDM

Industries du pétrole, de la pétrochimie et du gaz naturel —

Protection de la corrosion externe des risers par revêtements et

doublures —

Partie 1: Systèmes de revêtement élastomère-polychloroprène ou EPDM

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Abbreviated terms . 5

5 Pre-work requirements . 6

5.1 General . 6

5.2 Health, safety and environmental (HSE) . 6

5.3 Qualification of coating/lining application and inspection personnel . 6

6 Materials . 7

6.1 General requirements . 7

6.2 Material requirements. 8

6.3 Materials packing, handling and storage . 9

6.4 Coating materials . 9

7 Bare pipes transportation, handling and storage .10

7.1 Transportation and handling of pipes .10

7.2 Storage of pipes .10

8 Surface preparation .10

8.1 General .10

8.2 Pipe imperfections/damages removal .11

8.3 Contaminants removal .11

8.4 Abrasive blast cleaning .11

9 Coating application for risers .13

9.1 General .13

9.2 Priming and coating on abrasive blast-cleaned surface .13

9.3 Polychloroprene or EPDM application and vulcanization .14

9.4 Manual coating application on clamps, guides, bolt holes, inner sections of flanges

and pipe section used for modifications at worksites .15

9.5 Coating application of field joints .16

9.6 Coating repair .16

10 Inspection and testing .17

10.1 General .17

10.2 Testing of elastomer properties .17

10.2.1 General.17

10.2.2 Cure and hardness .17

10.2.3 Specific gravity.17

10.2.4 Rheological properties . .17

10.2.5 Tensile strength, tear strength and elongation at break .17

10.2.6 Compression set .18

10.2.7 Abrasion resistance .18

10.2.8 Ozone resistance .18

10.2.9 Adhesion .18

10.2.10 Resistance to seawater .18

10.2.11 Thermal conductivity . .18

10.2.12 Vulcanization characteristics (rotorless curemeters) .18

10.2.13 Cathodic disbondment .19

10.2.14 Volume resistivity .19

10.3 Inspection/testing of coated pipes .19

10.3.1 Visual inspection .19

10.3.2 Holiday detection .19

10.3.3 Thickness test .20

10.3.4 Adhesion (bond) test . .20

10.3.5 Hardness testing .20

10.3.6 Ultrasonic inspection .20

10.3.7 Sound testing .20

10.3.8 Rejection .20

10.4 Inspection and testing of field joint coating .21

10.5 Test reports and certificate of compliance .21

11 Coating damage/defect repair .21

11.1 Defect acceptance criteria .21

11.2 Repair procedures .21

12 Handling and stacking of coated pipes .22

13 Quality requirements .22

14 Documentation .23

Annex A (informative) Contents in a batch certificate .24

Annex B (normative) Physical properties of polychloroprene or EPDM elastomer .25

Annex C (normative) Riser pipe external coating progress chart .26

Bibliography .28

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries.

A list of all parts in the ISO 18797 series can be found on the ISO website.

Introduction

This document is based on GSO 2273. This document defines the minimum technical requirements

for the external corrosion protection of risers by coatings and linings based on elastomeric coating

systems-polychloroprene, EPDM or equivalent elastomeric coatings that are employed in the oil and

gas industry and provides technical guidance for developing local standards and specifications in

order to ensure compliance in coating and lining material selection and performance with contract

requirements.

Users of this document need to be aware that further or differing requirements can be needed for

individual applications. This document is not limiting the contractor and/or manufacturer from

proposing or company from accepting alternative engineering solutions for the individual application.

This can be particularly applicable where there is innovative or developing technology. Where an

alternative is proposed, the specification issuer needs to identify any deviations from this document

and provide details.

This document does not incorporate any form of passive fireproofing requirements or any related

compatibility issues. Any requirements with regards to passive fireproofing are to be addressed

separately.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 18797-1:2016(E)

Petroleum, petrochemical and natural gas industries —

External corrosion protection of risers by coatings and

linings —

Part 1:

Elastomeric coating systems-polychloroprene or EPDM

1 Scope

This document specifies the minimum requirements for materials selection, surface preparation,

application, inspection, testing, qualification and acceptance criteria of external coating for steel risers

pipes used in the splash zone, their field joints and clamps/guides, using an elastomeric protective

coating based on polychloroprene, EPDM or equivalent. This is applicable for new construction and

repair of applied pipes before installation. Maintenance requirements and field repairs are covered in

ISO 18797-2.

This document also specifies the requirements for transportation, handling and storage of riser pipes

before and after surface preparation and coating application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 34 (all parts), Rubber, vulcanized or thermoplastic — Determination of tear strength

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and

100 IRHD)

ISO 813, Rubber, vulcanized or thermoplastic — Determination of adhesion to rigid substrate — 90 degree

peel method [alternative to ISO 814]

ISO 814, Rubber, vulcanized or thermoplastic — Determination of adhesion to metal — Two-plate method

[alternative to ISO 813]

ISO 815-1, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At ambient

or elevated temperatures

ISO 815-2, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 2: At low

temperatures

ISO 1431-1, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and

dynamic strain testing

ISO 1817, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 2781, Rubber, vulcanized or thermoplastic — Determination of density

ISO 2812-2, Paints and varnishes — Determination of resistance to liquids — Part 2: Water immersion method

ISO 4649, Rubber, vulcanized or thermoplastic — Determination of abrasion resistance using a rotating

cylindrical drum device

ISO 6502, Rubber — Guide to the use of curemeters

ISO 7619-1, Rubber, vulcanized or thermoplastic — Determination of indentation hardness — Part 1:

Durometer method (Shore hardness)

1)

ISO 8501-1:2007, Preparation of steel substrates before application of paints and related products —

Visual assessment of surface cleanliness — Part 1: Rust grades and preparation grades of uncoated steel

substrates and of steel substrates after overall removal of previous coatings

ISO 8502-2, Preparation of steel substrates before application of paints and related products — Tests for

the assessment of surface cleanliness — Part 2: Laboratory determination of chloride on cleaned surfaces

ISO 8502-3, Preparation of steel substrates before application of paints and related products — Tests for

the assessment of surface cleanliness — Part 3: Assessment of dust on steel surfaces prepared for painting

(pressure-sensitive tape method)

ISO 8502-4, Preparation of steel substrates before application of paints and related products — Tests for the

assessment of surface cleanliness — Part 4: Guidance on the estimation of the probability of condensation

prior to paint application

ISO 8502-5, Preparation of steel substrates before application of paints and related products — Tests for

the assessment of surface cleanliness — Part 5: Measurement of chloride on steel surfaces prepared for

painting (ion detection tube method)

ISO 8502-6, Preparation of steel substrates before application of paints and related products — Tests for

the assessment of surface cleanliness — Part 6: Extraction of soluble contaminants for analysis — The

Bresle method

ISO 8502-9, Preparation of steel substrate before application of paints and related products ― Tests for the

assessment of surface cleanliness — Part 9: Field method for the conductometric determination of water-

soluble salts

ISO 8503-2, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 2: Method for the grading of surface

profile of abrasive blast-cleaned steel — Comparator procedure

ISO 8503-4, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 4: Method for the calibration of ISO

surface profile comparators and for the determination of surface profile — Stylus instrument procedure

[alternative to ISO 8503-5]

ISO 8503-5, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 5: Replica tape method for the

determination of the surface profile [alternative to ISO 8503-4]

ISO 10474:2013, Steel and steel products — Inspection documents

ISO 11126 (all parts), Preparation of steel substrates before application of paints and related products —

Specifications for non-metallic blast-cleaning abrasives

ISO 21457, Petroleum, petrochemical and natural gas industries — Materials selection and corrosion

control for oil and gas production systems

ISO 21809-3, Petroleum and natural gas industries — External coatings for buried or submerged pipelines

used in pipeline transportation systems — Part 3: Field joint coatings

1) SSPC SP10 is equivalent to ISO 8501-1.

2 © ISO 2016 – All rights reserved

ISO 29601, Paints and varnishes — Corrosion protection by protective paint systems — Assessment of

porosity in a dry film [alternative to ASTM D5162]

EN 10204:2004, Metallic products — Types of inspection documents

EN 12664, Thermal performance of building materials and products — Determination of thermal resistance

by means of guarded hot plate and heat flow meter methods — Dry and moist products of medium and low

thermal resistance [alternative to ISO 29601]

EN 14879-4:2007, Organic coating systems and linings of protection of industrial apparatus and plants

against corrosion caused by aggressive media — Part 4: Linings on metallic components

API RP 5LW, Recommended Practice for Transportation of Line Pipe on Barges and Marine Vessels

[alternative to API RP 5L1]

API RP 5L1, Recommended Practice for Railroad Transportation of Line Pipe [alternative to API RP 5LW]

ASTM D2084, Standard Test Method for Rubber Property ― Vulcanization Using Oscillating Disc Cure Meter

ASTM D4285, Standard Test Method for Indicating Oil or Water in Compressed Air

ASTM D5162, Standard Practice for Discontinuity (Holiday) Testing of Nonconductive Protective Coating

on Metallic Substrates [alternative to ISO 29601]

ASTM D5894, Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures

in a Fog/Dry Cabinet and a UV/Condensation Cabinet)

SSPC-AB 2, Cleanliness of Recycled Ferrous Metallic Abrasive

SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements

SSPC-SP 1, Solvent Cleaning

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

atmospheric zone

areas of offshore structures and riser pipes that extend upward from the splash zone (3.18) up to top

decks of the platform (3.12) which are exposed to sun, wind, sprays and rains

3.2

applicator

organization appointed by contractor (3.3)/client (3.4) to perform application of coatings/linings on

riser pipes as per project procedures prepared in accordance with this document

3.3

contractor

organization appointed by the client (3.4) to perform the works (3.21) in accordance with this document

3.4

client

organization for which professional services are rendered or person that receives a product

3.5

dew point

temperature at which moisture in air will condense out on to a solid surface, like blast-cleaned metal

surface or newly coated surfaces

3.6

dust

loose fine particulate matter present on a steel surface prepared for rubber lining, arising from blast

cleaning or other grinding activities or from worksite environments

3.7

elastomeric coatings

flexible skins, permanently bonded to risers (3.15) and structures

Note 1 to entry: Elastomeric coatings are designed and developed to withstand aggressive environment or

conditions affecting platform structures and risers in marine splash zones. These provide add on durability to

designed life to structures and risers in offshore environment, while providing resistance to seawater ingression,

ozone oxidation, erosion and abrasion.

3.8

ethylene propylene diene monomer

EPDM

elastomeric compound or synthetic rubber applied as a protective coating on riser pipes in splash

zones (3.18) to withstand erosion of riser pipe material caused by continuous exposure to seawater

and wave actions

Note 1 to entry: EPDM provides resistance to outdoor and high temperature services in the range of -35 °C to 120 °C.

3.9

flash rusting

slight rust formation on a freshly blast-cleaned carbon steel surfaces due to humidity in air and if not

painted within 4 h from start of blasting

3.10

holiday

discontinuity in a protective coating (cracks, pinholes, voids, etc.) that exhibits electrical conductivity

when exposed to specific voltage

Note 1 to entry: Holiday also means a small defect in the lining that would permit corrosion of substrate

under service conditions for which lining is designed. The term can be considered synonymous with cracks or

mechanical damages occurring in rubber lining, while in services.

3.11

manufacturer

organization responsible for the manufacture of coating material(s)

3.12

platform

offshore structure used to accommodate oil and gas wells related production equipment, pipelines and

living quarters

3.13

production batch

one loading capacity of the internal mixer used for preparing the mixed rubber prior to forming strip

of sheet

3.14

polychloroprene

light yellow synthetic rubber compound obtained by polymerization of chloroprene

Note 1 to entry: Polychloroprene is commonly known as polychloroprene compound.

4 © ISO 2016 – All rights reserved

Note 2 to entry: Polychloroprene is applied as a protective coating on riser pipes in splash zones (3.18) and below

to withstand erosion of riser pipe material caused by continuous exposure to seawater and wave actions. It

provides resistance to outdoor and services temperature in the range of −35 °C to 90 °C.

3.15

riser

section of pipeline carrying crude/gas between ocean floor and upper decks of platform (3.12) on

offshore structures

3.16

shore hardness

methods for determining the hardness of materials by means of durometer

3.17

site

lands and waters and other places on, under, in or through which the works (3.21) are to be carried

out and any other lands, waters or places provided by the client (3.4) for the purposes of the contract

together with any other places designated in the contract

3.18

splash zone

external surfaces of an offshore structure or pipeline that are, periodically wet and dry by the influence

of the astronomical tides, winds and waves, the limits are as defined by the contract specifications

3.19

surface profile

micro-roughness of surface generally expressed as an average of height of highest peaks relative to

lowest valleys sometime referred to as amplitude

3.20

vulcanization

curing of elastomeric materials by chemical reaction under heat and pressure to improve strength and

elasticity of applied rubber lining

3.21

works

activities to be executed in accordance with the contract, as defined in the specified conditions and

including both permanent and temporary activities

4 Abbreviated terms

µm micrometer (microns)

ASTM American Society for Testing and Materials

BS British Standard

DFT dry film thickness

HSE health, safety and environment

GSO Gulf Standardization Organization ITP

MS method statement

MSDS material safety data sheet

NACE National Association of Corrosion Engineers

NPS nominal pipe size

pphm parts per hundred million

PPT pre-production trial

PQT procedure qualification trial

QA/QC quality assurance/quality control

SSPC Society for Protective Coatings

5 Pre-work requirements

5.1 General

5.1.1 All requirements in this document and the referenced documents shall be followed, except if they

are modified or supplemented by project specification or datasheet.

5.1.2 The equipment, materials, consumables, spaces and stockpile areas that are necessary to carry

out surface preparation, coating application, qualification testing, inspection and QA/QC shall be in

accordance with this document and in a manner satisfactory to the client.

5.1.3 Surface preparation, priming, coating application, qualification testing/inspection and QA/QC

works shall be carried out in a continuous sequence as per this document and as recommended by the

manufacturers, unless otherwise specified by the client.

5.2 Health, safety and environmental (HSE)

5.2.1 All necessary health, safety and environmental (HSE) procedures shall be employed to protect

the personnel and the surrounding environment during on-site/field works. The contractors shall

submit their HSE manual for client’s approval. The approved HSE procedures for the safe coating/lining

processes shall be strictly followed.

5.2.2 All relevant international safety requirements, client’s safety regulations for contractors and

lifting equipment regulations shall be adhered, while performing coating and lining works.

5.2.3 Materials safety data sheets (MSDS) for all chemicals to be used within the client’s operation

areas shall be submitted to the client for review and approval. Health and safety precautions shall be

clearly described on each materials container/package.

5.2.4 All wastes resulting from supply, preparation and application shall be contained, collected

and properly disposed of in accordance with international/local environmental protection

standards/regulations.

5.3 Qualification of coating/lining application and inspection personnel

5.3.1 The coating/lining operatives shall be competent to undertake the coating application,

inspection/testing procedures and repair work. The qualification shall be obtained as agreed with the

client or by demonstration at a procedure qualification trial (PQT) during pre-production trial (PPT).

5.3.2 Inspectors and applicator personnel carrying out the coating inspection shall be competent

to carry out the requirements of this document. The applicator shall request the manufacturer of the

coating/lining material(s) and equipment to provide technical assistance to the coating/lining operatives

if necessary.

6 © ISO 2016 – All rights reserved

6 Materials

6.1 General requirements

6.1.1 The general requirements for the selection of materials for coating system and surface

preparation shall be in accordance with ISO 21457. Materials proposed for coating of the riser pipe

shall be tested by the product manufacturer and approved by the client before use. Non-conforming

materials shall be rejected and replaced with approved materials. Test certificates shall be provided for

all materials.

6.1.2 Identification of corrosion mechanism and parameter for evaluation when performing selection

of materials for pipelines, piping related to transport and processing of hydrocarbon production including

utility, injection system and wellheads shall be in accordance with ISO 21457.

NOTE ISO 21457 refers to materials that are generally available with properties that are known and

documented. It also allows other materials to be evaluated and qualified for use.

6.1.3 Materials shall be of high quality, uniform in composition and free from all inclusions and foreign

contaminants.

6.1.4 Materials shall not contain any asbestos/fibrous constituents, i.e. fibrous fillers or asbestos felt.

6.1.5 The contractor shall provide details of manufacturer, materials composition, technical

specification, physical properties, data sheets and test certificates for all materials, prior to use, for the

client’s review and approval. The client has the right to request a complete performance test for any

material used during the surface preparation and coating processes. The contractor and/or lining

applicator shall select polychloroprene or EPDM compound, which is suitable for company specified

characteristics and services and also select adhesive system, which will provide an adequate bond

between rubber and riser pipe surface to ascertain designed life of services in seawater splash zone.

Adhesive system shall depend upon the type of rubber compound and method of vulcanization.

6.1.6 The client shall at least provide the following characteristics of riser lines or pipe sections to be

coated with polychloroprene or EPDM rubber:

a) nominal diameter;

b) wall thickness;

c) type of pipe joint;

d) design temperature (max-min);

e) operating temperature (max-min);

f) design pressure, service – seawater splash zone;

g) chemical analysis of seawater and designed service life of coating while indicating special site

requirements.

6.1.7 Rubber compound and adhesive system shall be selected on the basis of previous project

references and industry experience to ascertain that it is suitable for specified services. If this requirement

could not be satisfied, appropriate testing shall be carried out as per manufacturer’s recommendations.

Where it is not possible to test sample elastomer lining in actual conditions, specified service conditions

shall be simulated accurately.

6.1.8 Polychloroprene and EPDM coating as described in this document comprise the following coats

or layers of coating materials:

a) 1st coat — primer coat that shall be compatible with the bonding agent and is bonded adequately to

the steel substrate;

b) 2nd coat — bonding agent that shall be compatible with both the primer and the elastomer coating;

c) 3rd coat — tack cement rubber solution (rubber compound solution), if deemed necessary;

d) 4th coat — elastomeric coating material (polychloroprene or EPDM).

6.1.9 Elastomer compound and adhesive manufacturing facility and in-house testing laboratory shall

be in compliance with the quality management system requirements.

6.1.10 The materials shall be compatible with each other to provide adequate bonding when vulcanized

to enhance inbuilt chemical and physical properties as desired for corrosion protection of riser pipes in

the splash zone.

6.1.11 Nylon tape to be wrapped temporarily over the elastomer coated pipe shall be of sufficient

strength to withstand tension and secure coating tightly adherent to substrate. It shall also withstand

autoclave temperatures during the vulcanization process.

6.1.12 The contractor/applicator shall provide the following to the client for review and approvals, well

before entering into actual application of elastomer coating on specified surfaces:

a) name and number of elastomer compound;

b) test panels coated with proposed elastomer compound and vulcanized as a reference sample;

c) test certificate by in-house laboratory as well as client’s designated external laboratory certifying

qualification of polychloroprene and/or EPDM, meeting desired chemical and physical properties

along with satisfaction of special considerations, if any.

6.1.13 Clearance for usage shall be obtained for coating materials to be used on riser pipes in seawater

splash zone from local and international environment authorities governing or controlling marine

pollution to specified norms.

6.1.14 On client’s approval of selected elastomeric coating/lining, the applicator shall assess site

requirements, prepare method statement (MS), inspection test plan (ITP) and quality assurance/quality

control documentations and submit to the client for approval.

6.1.15 After approval of documents (as in 6.1.14), the applicator shall arrange for procedure qualification

trial (PQT), demonstrating coating work to be carried out on automatic pipe coating machine and also by

hand lay methods, while producing a test sample (as required in 6.1.12). The PQT shall be witnessed by

the contractor, client and coating material manufacturer for approvals.

6.2 Material requirements

6.2.1 Polychloroprene elastomer coatings for risers shall be suitable for use in seawater, ambient air

temperatures down to −35 °C and service temperatures of maximum +90 °C for the specified design life.

6.2.2 Ethylene propylene diene monomer (EPDM) elastomer coatings for risers shall be suitable

for use in seawater, ambient air temperatures down to −35 °C and service temperatures of maximum

+120 °C for the specified design life.

8 © ISO 2016 – All rights reserved

6.2.3 Other equivalent products shall comply with the material requirements specified within this

document.

6.3 Materials packing, handling and storage

6.3.1 All materials shall be supplied in the manufacturer’s original packaging in an undamaged

condition to the plant/coating yard, clearly marked with the batch code, storage conditions, date

of manufacture, shelf life and accompanied with the relevant batch certificate. The content of a batch

certificate for different coating materials are shown in Annex A for reference.

6.3.2 All materials taken to worksite shall be stored in covered, cool, dry, well-ventilated areas and

shall be kept clean, dry and free from any contaminants prior to and during application in addition to the

manufacturer’s recommendations. Any material that has been affected by the climate or contaminated in

any way shall be rejected and replaced with approved materials.

6.4 Coating materials

6.4.1 All coating materials, in any one system, should originate from one client’s approved manufacturer

with his assurance that they are fully compatible with one another.

6.4.2 Bulk of coating materials shall be stored in air conditioned store rooms at temperature and under

conditions as specified by material manufacturer as it should not be affected by climate or other factors.

Coating materials found in unusable conditions shall be replaced by new stocks. Materials shall be used

on first-in-first-out basis stock rotations. Expired material shall be quarantined and then disposed of as

per HSE norms.

6.4.3 Elastomer coating materials shall be uniform in composition and free from contaminations.

6.4.4 The metal bonding agent and the elastomer bonding agent shall be those recommended by

the polychloroprene rubber/EPDM manufacturers, or equivalent, as selected or developed for the

environmental conditions and application process considered in this document.

6.4.5 The applied coating shall be resistant to oxidation, solar radiation, ozone, oil contamination and

marine organisms. It shall be suitable and stable under applicable service temperature range. It shall

be resistant to damage caused by twisting and flexing, exhibit outstanding physical toughness, resist

degradation from UV, ozone and marine weather conditions and exhibit better fire retardant properties.

6.4.6 The applied coating shall be suitable for long-term use in offshore environments when immersed

continuously in seawater (under the influence of cathodic protection), in the splash zone or in the

atmospheric zone with moist conditions and salt laden air.

6.4.7 The applied coating shall be capable of preventing corrosion under the specified conditions. It

shall have good resistance to mechanical damage and exhibit strong adhesion to steel.

6.4.8 The applied coating material shall have physical properties in accordance with those listed in

Annex B. It shall be tested in accordance with 10.2. The applied coating shall have proven resistance to

cathodic disbondment in accordance with the parameters set in Annex B.

6.4.9 If the client requests antifouling treatments to the surface of the coated riser pipe work, the

contractor shall propose a compatible material required for antifouling, stating the application method

and thickness of any treatment for client’s approval. In most cases, the thickness of any treatment will be

in addition to the minimum thickness specified for the elastomer coating.

6.4.10 Elastomeric coating manufacturer shall confirm compatibility of antifouling paints.

7 Bare pipes transportation, handling and storage

7.1 Transportation and handling of pipes

7.1.1 The contractor shall specify the proposed method for transportation, handling and storage of

pipes for the client’s approval. These requirements shall be in accordance with the relative clauses under

API RP 5LW or API RP 5L1, unless otherwise specified.

7.1.2 All pipes shall be inspected at the time of loading and unloading. All damage to pipe existing

at that time shall be reported. Damaged pipe shall be marked and kept separately until repaired, after

which it can be coated.

7.1.3 The pipe shall be fitted with end caps to protect the pipe end bevels. These caps shall be

maintained by the applicator until the pipe is withdrawn from its custody. Damaged or lost end caps shall

be replaced. The applicator shall ensure that the pipes are returned to the contractor/client in the same

condition as they were received.

7.1.4 At all times, for the purpose of loading, unloading and handling of pipe, the contractor shall use

approved certified slings, spreader bars and protected pipe end hooks to the satisfaction of the client’s

lifting equipment regulations/standards. All slings, hooks, supports and skids shall be padded and

suitable to prevent damage or deterioration of pipe and coating.

7.1.5 The contractor shall pr

...

NORME ISO

INTERNATIONALE 18797-1

Première édition

2016-09-01

Industries du pétrole, de la

pétrochimie et du gaz naturel —

Protection de la corrosion externe des

risers par revêtements et doublures —

Partie 1:

Systèmes de revêtement élastomère-

polychloroprène ou EPDM

Petroleum, petrochemical and natural gas industries — External

corrosion protection of risers by coatings and linings —

Part 1: Elastomeric coating systems-polychloroprene or EPDM

Numéro de référence

©

ISO 2016

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2016, Publié en Suisse

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni utilisée

sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur

l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à

l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – Tous droits réservés

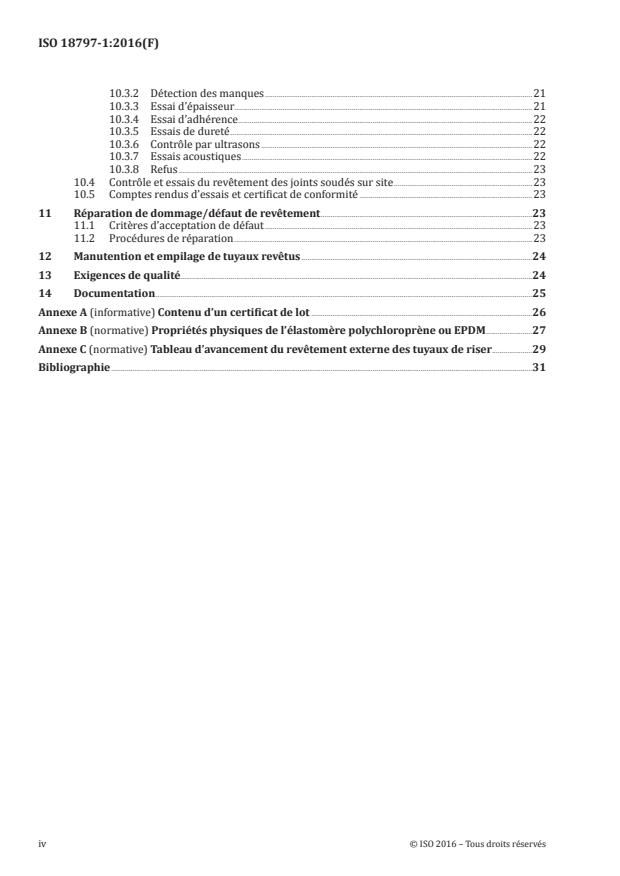

Sommaire Page

Avant-propos .v

Introduction .vi

1 Domaine d’application . 1

2 Références normatives . 1

3 Termes et définitions . 3

4 Abréviations . 6

5 Exigences préalables aux travaux . 6

5.1 Généralités . 6

5.2 Santé, sécurité et environnement (HSE) . 6

5.3 Qualification du personnel chargé de l’application du revêtement/lining et des contrôles 7

6 Matériaux . 7

6.1 Exigences générales . 7

6.2 Exigences relatives aux matériaux . 9

6.3 Conditionnement, manutention et stockage des matériaux . 9

6.4 Matériaux de revêtement . 9

7 Transport, manutention et stockage des tuyaux nus .10

7.1 Transport et manutention des tuyaux .10

7.2 Stockage des tuyaux .11

8 Préparation de surface .11

8.1 Généralités .11

8.2 Élimination des imperfections/dommages des tuyaux .11

8.3 Élimination de contaminants .12

8.4 Décapage par projection d’abrasif .12

9 Application du revêtement pour risers .14

9.1 Généralités .14

9.2 Application de primaire et revêtement sur la surface décapée par projection d’abrasif .15

9.3 Application et vulcanisation de polychloroprène ou EPDM .15

9.4 Application manuelle du revêtement sur colliers, guides, trous de fixation, sections

internes des brides et de la section de tuyau pour modifications sur les sites de travail .16

9.5 Application de revêtement de joints soudés sur site .17

9.6 Réparation de revêtement .18

10 Contrôles et essais .18

10.1 Généralités .18

10.2 Essais portant sur les propriétés des élastomères .19

10.2.1 Généralités .19

10.2.2 Polymérisation et dureté .19

10.2.3 Gravité spécifique . .19

10.2.4 Propriétés rhéologiques .19

10.2.5 Résistance à la traction, résistance au déchirement et allongement à la rupture 19

10.2.6 Déformation rémanente après compression .19

10.2.7 Résistance à l’abrasion.20

10.2.8 Résistance à l’ozone .20

10.2.9 Adhérence .20

10.2.10 Résistance à l’eau de mer .20

10.2.11 Conductivité thermique .20

10.2.12 Caractéristiques de vulcanisation (rhéomètres sans rotor) .20

10.2.13 Décollement cathodique .21

10.2.14 Résistivité transversale .21

10.3 Contrôle/Essai des tuyaux revêtus .21

10.3.1 Examen visuel.21

10.3.2 Détection des manques .21

10.3.3 Essai d’épaisseur . .21

10.3.4 Essai d’adhérence . .22

10.3.5 Essais de dureté .22

10.3.6 Contrôle par ultrasons .22

10.3.7 Essais acoustiques .22

10.3.8 Refus .23

10.4 Contrôle et essais du revêtement des joints soudés sur site .23

10.5 Comptes rendus d’essais et certificat de conformité .23

11 Réparation de dommage/défaut de revêtement .23

11.1 Critères d’acceptation de défaut .23

11.2 Procédures de réparation .23

12 Manutention et empilage de tuyaux revêtus .24

13 Exigences de qualité .24

14 Documentation .25

Annexe A (informative) Contenu d’un certificat de lot .26

Annexe B (normative) Propriétés physiques de l’élastomère polychloroprène ou EPDM .27

Annexe C (normative) Tableau d’avancement du revêtement externe des tuyaux de riser .29

Bibliographie .31

iv © ISO 2016 – Tous droits réservés

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d’approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www.

iso.org/directives).

L’attention est appelée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets reçues par l’ISO (voir www.iso.org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la signification des termes et expressions spécifiques de l’ISO liés à l’évaluation

de la conformité, ou pour toute information au sujet de l’adhésion de l’ISO aux principes de l’OMC

concernant les obstacles techniques au commerce (OTC), voir le lien suivant: www.iso.org/iso/

foreword.html.

Le comité chargé de l’élaboration du présent document est l’ISO/TC 67, Matériels, équipements et

constructions en mer pour les industries du pétrole, de la pétrochimie et du gaz naturel.

Une liste de toutes les parties de la série ISO 18797 peut être consultée sur le site Web de l’ISO.

Introduction

Le présent document est basé sur le GSO 2273. Le présent document définit les exigences techniques

minimales applicables à la protection contre la corrosion externe des risers par revêtements et

linings basée sur les systèmes de revêtement en élastomère-polychloroprène, EPDM ou revêtements

en élastomère équivalents employés dans l’industrie du pétrole et du gaz naturel, et fournit des

préconisations techniques pour l’élaboration de normes et spécifications locales afin de garantir la

conformité de la sélection et des performances des matériaux de revêtement et de lining aux exigences

contractuelles.

Les utilisateurs du présent document doivent avoir conscience que des exigences supplémentaires ou

différentes peuvent être nécessaires à des applications particulières. Le présent document n’interdit

pas à l’entrepreneur et/ou au fabricant de proposer des solutions techniques alternatives pour

l’application considérée, ni à l’entreprise de les accepter. Cela peut notamment s’appliquer en présence

de technologies innovantes ou en développement. Si une alternative est proposée, l’émetteur de la

spécification doit identifier tout écart par rapport au présent document et fournir des détails.

Le présent document ne comprend aucun type d’exigence d’ignifugeage passif or autres problèmes de

compatibilité associés. Toute exigence concernant l’ignifugeage passif est à traiter séparément.

vi © ISO 2016 – Tous droits réservés

NORME INTERNATIONALE ISO 18797-1:2016(F)

Industries du pétrole, de la pétrochimie et du gaz

naturel — Protection de la corrosion externe des risers par

revêtements et doublures —

Partie 1:

Systèmes de revêtement élastomère-polychloroprène ou

EPDM

1 Domaine d’application

Le présent document spécifie les exigences minimales applicables à la sélection des matériaux, à

la préparation de surface, à l’application, à l’inspection, aux essais, à la qualification et aux critères

d’acceptation de revêtement externe pour tuyaux de risers en acier utilisés dans la zone d’action des

vagues, leurs joints soudés sur site et colliers/guides, au moyen d’un revêtement de protection en

élastomère à base de polychloroprène, EPDM ou équivalent. Cela concerne les nouvelles constructions et

les réparations de tuyaux appliqués avant installation. Les exigences de maintenance et les réparations

sur site sont traitées dans l’ISO 18797-2.

Le présent document spécifie également les exigences de transport, de manutention et de stockage des

tuyaux de risers avant et après la préparation de surface et l’application du revêtement.

2 Références normatives

Les documents suivants cités dans le texte constituent, pour tout ou partie de leur contenu, des

exigences du présent document. Pour les références datées, seule l’édition citée s’applique. Pour les

références non datées, la dernière édition du document de référence s’applique (y compris les éventuels

amendements).

ISO 34 (toutes les parties), Caoutchouc vulcanisé ou thermoplastique — Détermination de la résistance au

déchirement

ISO 37, Caoutchouc vulcanisé ou thermoplastique — Détermination des caractéristiques de contrainte-

déformation en traction

ISO 48, Caoutchouc vulcanisé ou thermoplastique — Détermination de la dureté (dureté comprise entre

10 DIDC et 100 DIDC)

ISO 813, Caoutchouc vulcanisé ou thermoplastique — Détermination de l’adhérence à un substrat rigide —

Méthode par pelage à angle droit

ISO 814, Caoutchouc vulcanisé ou thermoplastique — Détermination de l’adhérence au métal — Méthode à

deux plaques [variante de la norme ISO 813]

ISO 815-1, Caoutchouc vulcanisé ou thermoplastique — Détermination de la déformation rémanente après

compression — Partie 1: À températures ambiantes ou élevées

ISO 815-2, Caoutchouc vulcanisé ou thermoplastique — Détermination de la déformation rémanente après

compression — Partie 2: À basses températures

ISO 1431-1, Caoutchouc vulcanisé ou thermoplastique — Résistance au craquelage par l’ozone — Partie 1:

Essais sous allongement statique et dynamique

ISO 1817, Caoutchouc vulcanisé ou thermoplastique — Détermination de l’action des liquides

ISO 2781, Caoutchouc vulcanisé ou thermoplastique — Détermination de la masse volumique

ISO 2812-2, Peintures et vernis — Détermination de la résistance aux liquides — Partie 2: Méthode par

immersion dans l’eau

ISO 4649, Caoutchouc vulcanisé ou thermoplastique — Détermination de la résistance à l’abrasion à l’aide

d’un dispositif à tambour tournant

ISO 6502, Caoutchouc — Guide pour l’emploi des rhéomètres

ISO 7619-1, Caoutchouc vulcanisé ou thermoplastique — Détermination de la dureté par pénétration —

Partie 1: Méthode au duromètre (dureté Shore)

1)

ISO 8501-1:2007 , Préparation des subjectiles d’acier avant application de peintures et de produits

assimilés — Évaluation visuelle de la propreté d’un subjectile — Partie 1: Degrés de rouille et degrés de

préparation des subjectiles d’acier non recouverts et des subjectiles d’acier après décapage sur toute la

surface des revêtements précédents

ISO 8502-2, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 2: Recherche en laboratoire des chlorures sur les

surfaces nettoyées

ISO 8502-3, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 3: Évaluation de la poussière sur les surfaces

d’acier préparées pour la mise en peinture (méthode du ruban adhésif sensible à la pression)

ISO 8502-4, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 4: Principes directeurs pour l’estimation de la

probabilité de condensation avant application de peinture

ISO 8502-5, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 5: Mesurage des chlorures sur les surfaces d’acier

préparées pour la mise en peinture (méthode du tube détecteur d’ions)

ISO 8502-6, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 6: Extraction des contaminants solubles en vue de

l’analyse — Méthode de Bresle

ISO 8502-9, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Essais pour apprécier la propreté d’une surface — Partie 9: Méthode in situ pour la détermination des sels

solubles dans l’eau par conductimétrie

ISO 8503-2, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Caractéristiques de rugosité des subjectiles d’acier décapés — Partie 2: Méthode de classification d’un profil

de surface en acier décapée par projection d’abrasif — Utilisation des comparateurs viso-tactiles

ISO 8503-4, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Caractéristiques de rugosité des subjectiles d’acier décapés — Partie 4: Méthode d’étalonnage des

comparateurs viso-tactiles ISO et de classification d’un profil de surface — Utilisation d’un appareil à palpeur

ISO 8503-5, Préparation des subjectiles d’acier avant application de peintures et de produits assimilés —

Caractéristiques de rugosité des subjectiles d’acier décapés — Partie 5: Méthode de l’empreinte sur ruban

adhésif pour la détermination du profil de surface

ISO 10474:2013, Aciers et produits sidérurgiques — Documents de contrôle

ISO 11126 (toutes les parties), Préparation des subjectiles d’acier avant application de peintures et de

produits assimilés — Spécifications pour abrasifs non métalliques destinés à la préparation par projection

1) La norme SSPC SP10 est l’équivalent de l’ISO 8501-1.

2 © ISO 2016 – Tous droits réservés

ISO 21457, Industries du pétrole, de la pétrochimie et du gaz naturel — Choix des matériaux et contrôle de

la corrosion pour les systèmes de production de pétrole et de gaz

ISO 21809-3, Industries du pétrole et du gaz naturel — Revêtements externes des conduites enterrées ou

immergées utilisées dans les systèmes de transport par conduites — Partie 3: Revêtements des joints soudés

sur site

ISO 29601, Peintures et vernis — Anticorrosion par systèmes de peinture — Évaluation de la porosité d’un

feuil sec

EN 10204:2004, Produits métalliques — Types de documents de contrôle

EN 12664, Performance thermique des matériaux et produits pour le bâtiment — Détermination de la

résistance thermique par la méthode de la plaque chaude gardée et la méthode fluxmétrique — Produits

secs et humides de moyenne et basse résistance thermique [variante de la norme ISO 29601]

EN 14879-4:2007, Systèmes des revêtements organiques de peinture et autres revêtements rapportés

pour la protection des appareils et installations industriels contre la corrosion par des milieux agressifs —

Partie 4: Revêtements rapportés sur composants métalliques

API RP 5LW, Recommended Practice for Transportation of Line Pipe on Barges and Marine Vessels [variante

de la norme API RP 5L1]

API RP 5L1, Recommended Practice for Railroad Transportation of Line Pipe [variante de la norme

API RP 5LW]

ASTM D2084, Standard Test Method for Rubber Property ― Vulcanization Using Oscillating Disc Cure Meter

ASTM D4285, Standard Test Method for Indicating Oil or Water in Compressed Air

ASTM D5162, Standard Practice for Discontinuity (Holiday) Testing of Nonconductive Protective Coating

on Metallic Substrates [alternative to ISO 29601]

ASTM D5894, Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures

in a Fog/Dry Cabinet and a UV/Condensation Cabinet)

SSPC-AB 2, Cleanliness of Recycled Ferrous Metallic Abrasive

SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements

SSPC-SP 1, Solvent Cleaning

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

L’ISO et l’IEC tiennent à jour des bases de données terminologiques destinées à être utilisées en

normalisation, consultables aux adresses suivantes:

— ISO Online browsing platform: disponible à l’adresse http://www.iso.org/obp

— IEC Electropedia: disponible à l’adresse http://www.electropedia.org/

3.1

zone atmosphérique

parties des structures en mer et des tuyaux de risers qui s’élèvent au-dessus de la zone d’action des

vagues (3.18) jusqu’aux ponts supérieurs de la plate-forme (3.12) et qui sont exposées au soleil, au vent,

aux embruns et à la pluie

3.2

applicateur

organisme désigné par l’entrepreneur (3.3)/client (3.4) pour effectuer l’application des

revêtements/linings sur les tuyaux de riser suivant les procédures de projet préparées conformément

au présent document

3.3

entrepreneur

organisme désigné par le client (3.4) pour réaliser les travaux (3.21) conformément au présent document

3.4

client

organisme pour lequel des services professionnels sont rendus ou personne qui reçoit un produit

3.5

point de rosée

température à laquelle l’humidité dans l’air se condense sur une surface solide, telle qu’une surface

métallique décapée par projection ou des surfaces récemment revêtues

3.6

poussière

fines particules sans cohésion présentes sur une surface d’acier préparée pour recevoir un lining

en caoutchouc, générées par le décapage par projection ou autres activités de broyage, ou par les

environnements de sites de travail

3.7

revêtements en élastomère

peaux flexibles, fixées de manière permanente aux risers (3.15) et aux structures

Note 1 à l’article: Les revêtements en élastomère sont conçus et développés pour résister à un environnement

agressif ou à des conditions préjudiciables aux structures de plate-forme et aux risers dans les zones d’action des

vagues. Ils offrent une durabilité supplémentaire de la durée de vie de conception des structures et risers dans

un environnement marin, tout en assurant une résistance à la pénétration par l’eau de mer, l’oxydation à l’ozone,

l’érosion et l’abrasion.

3.8

éthylène-propylène-diène monomère

EPDM

composé d’élastomère ou caoutchouc synthétique appliqué comme revêtement de protection sur les

tuyaux de riser dans les zones d’action des vagues (3.18) afin de résister à l’érosion du matériau des

tuyaux de riser causée par l’exposition continue à l’eau de mer et aux actions des vagues

Note 1 à l’article: L’EPDM assure la résistance en service à l’extérieur et à haute température dans une plage de

−35 °C à 120 °C.

3.9

oxydation rapide

légère formation de rouille sur surfaces d’acier au carbone récemment décapées par projection due à

l’humidité dans l’air, si elles n’ont pas été peintes dans les 4 heures suivant le début du décapage

3.10

manque

discontinuité dans un revêtement de protection (fissures, piqûres, interstices, etc.) qui présente une

conductivité électrique lorsqu’elle est exposée à une tension spécifique

Note 1 à l’article: Un manque signifie également un petit défaut dans le lining qui pourrait permettre la corrosion

du substrat dans les conditions de service pour lesquelles le lining est conçu. Ce terme peut être considéré comme

étant un synonyme de fissures ou détériorations mécaniques qui apparaissent dans le lining de caoutchouc en

service.

4 © ISO 2016 – Tous droits réservés

3.11

fabricant

organisme chargé de la fabrication du ou des matériau(x) du revêtement

3.12

plate-forme

structure en mer utilisée pour intégrer les équipements de production associés aux puits de gaz et de

pétrole, les conduites et les quartiers d’habitation

3.13

lot de production

une capacité de chargement du mélangeur interne servant à préparer le mélange de caoutchouc avant

de former une bande de feuille

3.14

polychloroprène

composé de caoutchouc synthétique jaune pâle obtenu par polymérisation du chloroprène

Note 1 à l’article: Le polychloroprène est couramment appelé composé de polychloroprène.

Note 2 à l’article: Le polychloroprène est appliqué comme revêtement de protection sur les tuyaux de riser dans

les zones d’action des vagues (3.18) et en dessous de celles-ci afin de résister à l’érosion du matériau des tuyaux

de riser causée par l’exposition continue à l’eau de mer et aux actions des vagues. Il assure la résistance à la

température extérieure et en service dans une plage de −35 °C à 90 °C.

3.15

riser

section de conduite transportant le pétrole/gaz brut entre le fond océanique et les ponts supérieurs de

la plate-forme (3.12) sur les structures en mer

3.16

dureté Shore

méthodes permettant de déterminer la dureté des matériaux au moyen d’un duromètre

3.17

site

terres émergées et eaux et autres endroits sur, sous, dans ou à travers lesquels les travaux (3.21) doivent

être réalisés, et autres terres émergées, eaux ou endroits mis à disposition par le client (3.4) pour les

besoins du contrat, ainsi que tout autre endroit désigné dans le contrat

3.18

zone d’action des vagues

surfaces extérieures d’une structure en mer ou d’une conduite qui sont périodiquement humides et

sèches en raison de l’influence des marées astronomiques, des vents et des vagues, dont les limites sont

définies par les spécifications contractuelles

3.19

profil de surface

microrugosité d’une surface, généralement exprimée par la hauteur moyenne des plus hautes crêtes par

rapport aux creux les plus profonds, parfois appelé amplitude

3.20

vulcanisation

polymérisation de matériaux élastomères par réaction chimique sous l’action de la chaleur et de la

pression, destinée à améliorer la résistance et l’élasticité du lining de caoutchouc appliqué

3.21

travaux

activités à réaliser conformément au contrat, telles que définies dans les conditions spécifiées, et

comprenant à la fois les activités permanentes et temporaires

4 Abréviations

µm micromètre (microns)

ASTM American Society for Testing et Materials

BS Norme britannique (British Standard)

DFT épaisseur de feuil sec (dry film thickness)

HSE santé, sécurité et environnement (health, safety et environment)

GSO Organization de normalization du Golfe (Gulf Standardization Organization ITP)

MS exposé de méthode (method statement)

MSDS fiche technique de sécurité des matériaux

NACE Association nationale des ingénieurs en corrosion (National Association of Corrosion

Engineers)

NPS taille nominale de tuyau (nominal pipe size)

pphm partie pour cent millions

PPT essai de préproduction (pre-production trial)

PQT épreuve de qualification du mode opératoire (procedure qualification trial)

AQ/CQ assurance qualité/contrôle qualité

SSPC Société des revêtements de protection (Society for Protective Coatings)

5 Exigences préalables aux travaux

5.1 Généralités

5.1.1 Toutes les exigences du présent document et des documents référencés doivent être suivies, à

moins d’être modifiées ou complétées par la spécification du projet ou la fiche de données.

5.1.2 Les équipements, matériaux, consommables, espaces et zones d’amoncellement nécessaires à la

réalisation de la préparation de surface, à l’application d’un revêtement, aux essais de qualification, au

contrôle et à l’AQ/CQ doivent être conformes au document et de nature à satisfaire le client.

5.1.3 La préparation de surface, l’application du primaire, l’application du revêtement, les essais

et contrôles de qualification et les travaux d’AQ/CQ doivent être effectués suivant un ordre continu

conformément au présent document et aux recommandations des fabricants, sauf spécification contraire

du client.

5.2 Santé, sécurité et environnement (HSE)

5.2.1 Toutes les procédures de santé, sécurité et environnement (HSE) nécessaires doivent être

employées en vue de protéger le personnel et l’environnement immédiat durant les travaux sur

le site/terrain. L’entrepreneur doit soumettre son manuel HSE au client pour approbation. Les

procédures HSE approuvées pour des processus de revêtement/lining sûrs doivent être strictement

respectées.

6 © ISO 2016 – Tous droits réservés

5.2.2 Toutes les exigences internationales pertinentes en matière de sécurité, toutes les règlementations

de sécurité du client destinées aux entrepreneurs et les règlementations relatives aux équipements de

levage doivent être respectées durant la réalisation de travaux de revêtement et de lining.

5.2.3 Les fiches techniques relatives à la sécurité des matériaux (MSDS) pour tous les produits

chimiques à utiliser dans les zones d’opération du client doivent être soumises au client pour examen

et approbation. Les précautions en matière de santé et de sécurité doivent être clairement indiquées sur

chaque conteneur/emballage de matériaux.

5.2.4 Tous les déchets résultant de la fourniture, de la préparation et de l’application doivent

être contenus, recueillis et éliminés correctement conformément aux normes/règlementations

internationales/locales de protection de l’environnement.

5.3 Qualification du personnel chargé de l’application du revêtement/lining et des

contrôles

5.3.1 Les applicateurs de revêtements/linings doivent posséder les compétences nécessaires pour

effectuer les travaux d’application du revêtement, mettre en œuvre les procédures de contrôle/d’essai

et effectuer les travaux de réparation. La qualification doit être obtenue comme convenu avec le client ou

par démonstration dans le cadre d’une épreuve de qualification du mode opératoire (PQT) lors de l’essai

de préproduction (PPT).

5.3.2 Les contrôleurs et le personnel de l’applicateur effectuant le contrôle du revêtement doivent

posséder les compétences requises pour mettre en œuvre les exigences du présent document.

L’applicateur doit demander au fabricant des équipements et du(des) produit(s) de revêtement/lining

de fournir une aide technique aux applicateurs de revêtements/linings, si nécessaire.

6 Matériaux

6.1 Exigences générales

6.1.1 Les exigences générales de sélection des matériaux pour le système de revêtement et la

préparation de surface doivent être conformes à l’ISO 21457. Les matériaux proposés pour le revêtement

du tuyau de riser doivent être soumis à essais par le fabricant du produit et approuvés par le client avant

utilisation. Les matériaux non conformes doivent être refusés et remplacés par des matériaux approuvés.

Des certificats d’essai doivent être fournis pour tous les matériaux.

6.1.2 L’identification du mécanisme de corrosion et le paramètre d’évaluation lors de la sélection

des matériaux pour les conduites, les tuyauteries liées au transport et au traitement de la production

d’hydrocarbures, y compris l’installation, le système d’injection et les têtes de puits, doivent être

conformes à l’ISO 21457.

NOTE L’ISO 21457 fait référence à des matériaux qui sont généralement disponibles et qui ont des propriétés

connues et documentées. Elle permet également à d’autres matériaux d’être évalués et qualifiés pour utilisation.

6.1.3 Les matériaux doivent être de bonne qualité, d’une composition uniforme, et exempts de toute

inclusion et de tout contaminant étranger.

6.1.4 Les matériaux ne doivent pas contenir d’amiante/de composants fibreux, c’est-à-dire de charges

fibreuses ou de feutre d’amiante.

6.1.5 L’entrepreneur doit fournir les coordonnées du fabricant, la composition des matériaux, la

Spécification technique, les propriétés physiques, les fiches de données et les certificats d’essai pour tous

les matériaux, avant utilisation, pour examen et approbation par le client. Le client a le droit de demander

un essai de performance complet pour tout matériau utilisé au cours des processus de préparation de

surface et de revêtement. L’entrepreneur et/ou l’applicateur du revêtement doivent choisir un composé

de polychloroprène ou d’EPDM adapté aux caractéristiques et services spécifiés par la société, ainsi qu’un

système d’adhésif, qui assurera une bonne adhérence entre le caoutchouc et la surface du tuyau de riser

afin de garantir la durée de vie de conception en service dans la zone d’action des vagues d’eau de mer. Le

système d’adhésif doit dépendre du type de composé de caoutchouc et de la méthode de vulcanisation.

6.1.6 Le client doit fournir au moins les caractéristiques suivantes de sections de canalisation ou de

tuyau de riser à revêtir avec le polychloroprène ou le caoutchouc EPDM:

a) diamètre nominal;

b) épaisseur de paroi;

c) type de joint de tuyau;

d) température de calcul (max.-min.);

d) température d’exploitation (max.-min.);

f) pression de calcul, service – zone d’action des vagues d’eau de mer;

g) analyse chimique de l’eau de mer et durée de vie de conception en service du revêtement en

indiquant les exigences spéciales du site.

6.1.7 Le composé de caoutchouc et le système d’adhésif doivent être choisis d’après les références de

projet précédentes et l’expérience du secteur afin de s’assurer qu’ils sont adaptés aux services spécifiés.

Si cette exigence n’a pas pu être satisfaite, des essais appropriés doivent être effectués suivant les

recommandations du fabricant. Lorsque l’essai d’un échantillon de lining en élastomère en conditions

réelles n’est pas possible, des conditions de service spécifiées doivent être simulées avec exactitude.

6.1.8 Le revêtement en polychloroprène et en EPDM décrit dans le présent document comprend les

couches ou pellicules suivantes de matériaux de revêtement:

re

a) 1 couche — couche primaire qui doit être compatible avec le liant et être suffisamment liée au

substrat en acier;

b) 2ème couche — liant qui doit être compatible avec le primaire et le revêtement en élastomère;

c) 3ème couche — solution caoutchouc-ciment d’accrochage (solution de composé de caoutchouc), si

cela est jugé nécessaire;

d) 4ème couche — matériau de revêtement élastomère (polychloroprène ou EPDM).

6.1.9 L’installation de fabrication du composé d’élastomère et de l’adhésif et le laboratoire d’essai

interne doivent être conformes aux exigences du système de management de la qualité.

6.1.10 Les matériaux doivent être compatibles entre eux pour assurer un collage adéquat à l’état

vulcanisé afin renforcer les propriétés chimiques et physiques inhérentes comme requis pour la

protection contre la corrosion des tuyaux de riser dans la zone d’action des vagues.

6.1.11 Le ruban de nylon à enrouler temporairement sur le tuyau revêtu d’élastomère doit avoir

une force suffisante pour supporter la tension et fixer le revêtement pour qu’il adhère étroitement au

substrat. Il doit également résister aux températures en autoclave durant le processus de vulcanisation.

6.1.12 L’entrepreneur/applicateur doit fournir les éléments suivants au client pour examen et

approbations, bien avant de lancer l’application du revêtement en élastomère sur les surfaces spécifiées:

a) nom et numéro du composé d’élastomère;

8 © ISO 2016 – Tous droits réservés

b) panneaux d’essai revêtus avec le composé d’élastomère proposé et vulcanisé comme échantillon de

référence;

c) certificat d’essai émis par le laboratoire interne, ainsi que par le laboratoire externe désigné par

le client, attestant que le polychloroprène et/ou l’EPDM sont qualifiés, conformes aux propriétés

chimiques et physiques désirées, et satisfont aux considérations spéciales éventuelles.

6.1.13 Une autorisation d’utilisation doit être obtenue pour les matériaux de revêtement à utiliser sur

les tuyaux de riser dans la zone d’action des vagues d’eau de mer auprès des autorités environnementales

locales et internationales qui gèrent ou contrôlent la pollution marine d’après des normes spécifiées.