ISO 17409:2015

(Main)Electrically propelled road vehicles — Connection to an external electric power supply — Safety requirements

Electrically propelled road vehicles — Connection to an external electric power supply — Safety requirements

ISO 17409:2015 specifies electric safety requirements for conductive connections of electrically propelled road vehicles to an external electric power supply using a plug or vehicle inlet. It applies to electrically propelled road vehicles with voltage class B electric circuits. In general, it may apply to motorcycles and mopeds if no dedicated standards for these vehicles exist. It applies only to vehicle power supply circuits. It applies also to dedicated power supply control functions used for the connection of the vehicle to an external electric power supply. It does not provide requirements regarding the connection to a non-isolated d.c. charging station. It does not provide comprehensive safety information for manufacturing, maintenance, and repair personnel. The requirements when the vehicle is not connected to the external electric power supply are specified in ISO 6469‑3. NOTE 1 This International Standard does not contain requirements for vehicle power supply circuits using protection by class II or double/reinforced insulation but it is not the intention to exclude such vehicle applications. NOTE 2 Requirements for EV supply equipment are specified in IEC 61851.

Véhicules routiers à propulsion électrique — Connexion à une alimentation électrique externe — Exigences de sécurité

L'ISO 17409:2015 spécifie les exigences de sécurité électrique relatives aux connexions conductives des véhicules routiers à propulsion électrique à une alimentation électrique externe au moyen d'une fiche ou d'un socle de connecteur. Elle s'applique aux véhicules routiers à propulsion électrique ayant des circuits électriques de classe de tension B. En général, elle peut s'appliquer aux motocycles et aux cyclomoteurs s'il n'existe aucune norme dédiée à ces véhicules. Elle s'applique uniquement aux circuits d'alimentation électrique du véhicule. Elle s'applique également aux fonctions dédiées de contrôle de l'alimentation électrique utilisées pour la connexion du véhicule à une alimentation électrique externe. Elle ne fournit pas d'exigence concernant la connexion à une borne de charge conductive en courant continu non isolée. Elle ne fournit pas d'informations complètes concernant la sécurité pour le personnel de fabrication, de maintenance et de réparation. Lorsque le véhicule n'est pas connecté à la borne d'alimentation électrique externe, les exigences sont spécifiées dans l'ISO 6469‑3. NOTE 1 L'ISO 17409:2015 ne contient pas d'exigences pour les circuits d'alimentation électrique de véhicules utilisant une isolation double ou renforcée d'un équipement de classe II, mais n'a pas pour intention d'exclure de telles applications pour véhicules. NOTE 2 Les exigences pour les systèmes d'alimentation pour VE sont spécifiées dans l'IEC 61851.

General Information

- Status

- Withdrawn

- Publication Date

- 22-Oct-2015

- Withdrawal Date

- 22-Oct-2015

- Technical Committee

- ISO/TC 22/SC 37 - Electrically propelled vehicles

- Drafting Committee

- ISO/TC 22/SC 37 - Electrically propelled vehicles

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 26-Feb-2020

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 17-Dec-2016

ISO 17409:2015 - Electrically propelled road vehicles -- Connection to an external electric power supply -- Safety requirements

ISO 17409:2015 - Véhicules routiers a propulsion électrique -- Connexion a une alimentation électrique externe -- Exigences de sécurité

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 17409:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Electrically propelled road vehicles — Connection to an external electric power supply — Safety requirements". This standard covers: ISO 17409:2015 specifies electric safety requirements for conductive connections of electrically propelled road vehicles to an external electric power supply using a plug or vehicle inlet. It applies to electrically propelled road vehicles with voltage class B electric circuits. In general, it may apply to motorcycles and mopeds if no dedicated standards for these vehicles exist. It applies only to vehicle power supply circuits. It applies also to dedicated power supply control functions used for the connection of the vehicle to an external electric power supply. It does not provide requirements regarding the connection to a non-isolated d.c. charging station. It does not provide comprehensive safety information for manufacturing, maintenance, and repair personnel. The requirements when the vehicle is not connected to the external electric power supply are specified in ISO 6469‑3. NOTE 1 This International Standard does not contain requirements for vehicle power supply circuits using protection by class II or double/reinforced insulation but it is not the intention to exclude such vehicle applications. NOTE 2 Requirements for EV supply equipment are specified in IEC 61851.

ISO 17409:2015 specifies electric safety requirements for conductive connections of electrically propelled road vehicles to an external electric power supply using a plug or vehicle inlet. It applies to electrically propelled road vehicles with voltage class B electric circuits. In general, it may apply to motorcycles and mopeds if no dedicated standards for these vehicles exist. It applies only to vehicle power supply circuits. It applies also to dedicated power supply control functions used for the connection of the vehicle to an external electric power supply. It does not provide requirements regarding the connection to a non-isolated d.c. charging station. It does not provide comprehensive safety information for manufacturing, maintenance, and repair personnel. The requirements when the vehicle is not connected to the external electric power supply are specified in ISO 6469‑3. NOTE 1 This International Standard does not contain requirements for vehicle power supply circuits using protection by class II or double/reinforced insulation but it is not the intention to exclude such vehicle applications. NOTE 2 Requirements for EV supply equipment are specified in IEC 61851.

ISO 17409:2015 is classified under the following ICS (International Classification for Standards) categories: 43.120 - Electric road vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 17409:2015 has the following relationships with other standards: It is inter standard links to ISO 17409:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 17409:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17409

First edition

2015-11-01

Corrected version

2015-12-15

Electrically propelled road vehicles —

Connection to an external electric

power supply — Safety requirements

Véhicules routiers à propulsion électrique — Connexion à une borne

d’alimentation électrique externe — Exigences de sécurité

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

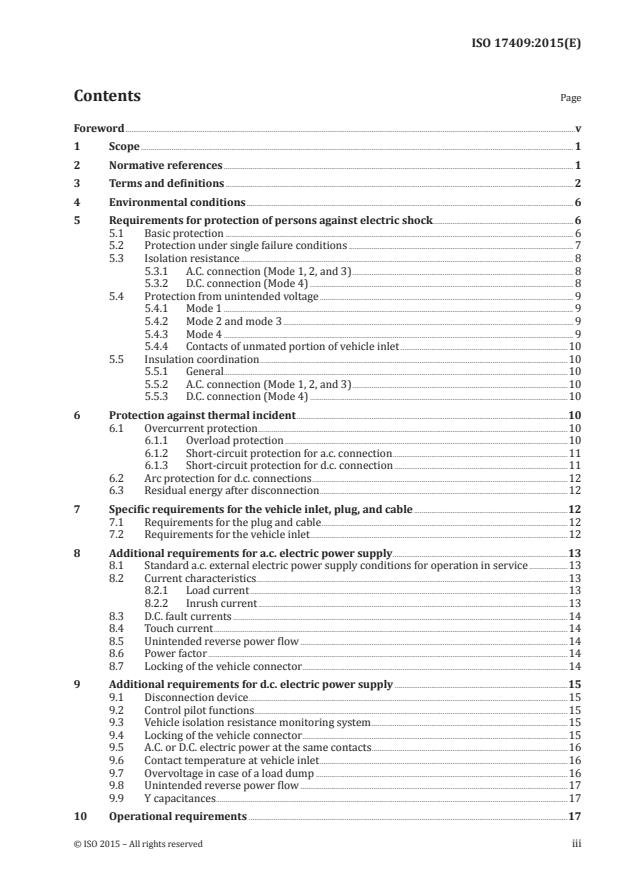

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Environmental conditions . 6

5 Requirements for protection of persons against electric shock . 6

5.1 Basic protection . 6

5.2 Protection under single failure conditions . 7

5.3 Isolation resistance . 8

5.3.1 A.C. connection (Mode 1, 2, and 3) . 8

5.3.2 D.C. connection (Mode 4) . 8

5.4 Protection from unintended voltage . 9

5.4.1 Mode 1 . 9

5.4.2 Mode 2 and mode 3 . 9

5.4.3 Mode 4 . 9

5.4.4 Contacts of unmated portion of vehicle inlet .10

5.5 Insulation coordination .10

5.5.1 General.10

5.5.2 A.C. connection (Mode 1, 2, and 3) .10

5.5.3 D.C. connection (Mode 4) .10

6 Protection against thermal incident .10

6.1 Overcurrent protection .10

6.1.1 Overload protection .10

6.1.2 Short-circuit protection for a.c. connection .11

6.1.3 Short-circuit protection for d.c. connection .11

6.2 Arc protection for d.c. connections .12

6.3 Residual energy after disconnection .12

7 Specific requirements for the vehicle inlet, plug, and cable .12

7.1 Requirements for the plug and cable .12

7.2 Requirements for the vehicle inlet .12

8 Additional requirements for a.c. electric power supply .13

8.1 Standard a.c. external electric power supply conditions for operation in service .13

8.2 Current characteristics.13

8.2.1 Load current .13

8.2.2 Inrush current .13

8.3 D.C. fault currents .14

8.4 Touch current .14

8.5 Unintended reverse power flow .14

8.6 Power factor .14

8.7 Locking of the vehicle connector .14

9 Additional requirements for d.c. electric power supply .15

9.1 Disconnection device .15

9.2 Control pilot functions.15

9.3 Vehicle isolation resistance monitoring system .15

9.4 Locking of the vehicle connector .15

9.5 A.C. or D.C. electric power at the same contacts.16

9.6 Contact temperature at vehicle inlet .16

9.7 Overvoltage in case of a load dump .16

9.8 Unintended reverse power flow .17

9.9 Y capacitances .17

10 Operational requirements .17

11 Owner’s manual and marking .17

11.1 Owner’s manual .17

11.2 Marking .17

12 Test procedure .17

12.1 General note on tests .17

12.2 Resistance of protective conductor .17

12.3 Isolation resistance test .17

12.3.1 Preconditioning and conditioning .17

12.3.2 Isolation resistance measurements at the vehicle inlet or plug .18

12.4 Withstand voltage test .18

12.4.1 General.18

12.4.2 Preconditioning and conditioning .19

12.4.3 Test procedure .19

12.4.4 Test voltage .19

12.5 Inrush current tests .20

12.5.1 General.20

12.5.2 Measurement .20

12.6 Touch current .21

Bibliography .23

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information.

The committee responsible for this document is ISO/TC 22, Road vehicles, Subcommittee SC 37,

Electrically propelled vehicles.

This corrected version of ISO 17409:2015 incorporates the following corrections.

6.1.2 and 6.1.3: The phrase ‘overload protection’ has been replaced with ‘short-circuit protection’ in

four places.

INTERNATIONAL STANDARD ISO 17409:2015(E)

Electrically propelled road vehicles — Connection to an

external electric power supply — Safety requirements

1 Scope

This International Standard specifies electric safety requirements for conductive connections of

electrically propelled road vehicles to an external electric power supply using a plug or vehicle inlet.

It applies to electrically propelled road vehicles with voltage class B electric circuits. In general, it may

apply to motorcycles and mopeds if no dedicated standards for these vehicles exist.

It applies only to vehicle power supply circuits. It applies also to dedicated power supply control

functions used for the connection of the vehicle to an external electric power supply.

It does not provide requirements regarding the connection to a non-isolated d.c. charging station.

It does not provide comprehensive safety information for manufacturing, maintenance, and repair

personnel.

The requirements when the vehicle is not connected to the external electric power supply are specified

in ISO 6469-3.

NOTE 1 This International Standard does not contain requirements for vehicle power supply circuits

using protection by class II or double/reinforced insulation but it is not the intention to exclude such vehicle

applications.

NOTE 2 Requirements for EV supply equipment are specified in IEC 61851.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 6469-1, Electrically propelled road vehicles — Safety specifications — Part 1: On-board rechargeable

energy storage system (RESS)

ISO 6469-3, Electrically propelled road vehicles — Safety specifications — Part 3: Protection of persons

against electric shock

ISO 13849 (all parts), Safety of machinery — Safety-related parts of control systems

ISO 20653, Road vehicles — Degrees of protection (IP code) — Protection of electrical equipment against

foreign objects, water and access

ISO 26262 (all parts), Road vehicles — Functional safety

IEC 60309-1, Plugs, socket-outlets and couplers for industrial purposes — Part 1: General requirements

IEC 60309-2, Plugs, socket-outlets and couplers for industrial purposes — Part 2: Dimensional

interchangeability requirements for pin and contact-tube accessories

IEC 60364-4-43, Electrical installations of buildings — Part 4-43: Protection for safety — Protection

against overcurrent

IEC 60364-5-54, Low-voltage electrical installations — Part 5-54: Selection and erection of electrical

equipment — Earthing arrangements and protective conductors

IEC 60364-6, Low-voltage electrical installations — Part 6: Verification

IEC 60664 (all parts), Insulation coordination for equipment within low-voltage systems

IEC 60884-1, Plugs, socket-outlets and couplers for household and similar purposes — Part 1: General

requirements

IEC 61851-1, Electric vehicle conductive charging system — Part 1: General requirements

IEC 61851-23, Electric vehicle conductive charging system — Part 23: D.C. electric vehicle charging station

IEC 62196-1, Plugs, socket-outlets, vehicle connectors and vehicle inlets — Conductive charging of electric

vehicles — Part 1: General requirements

IEC 62196-2, Plugs, socket-outlets, vehicle connectors and vehicle inlets — Conductive charging of electric

vehicles — Part 2: Dimensional compatibility and interchangeability requirements for a.c. pin and contact-

tube accessories

IEC 62196-3, Plugs, socket-outlets, vehicle connectors and vehicle inlets — conductive charging of electric

vehicles — Part 3: Dimensional compatibility and interchangeability requirements for dedicated d.c. and

combined a.c./d.c. pin and contact-tube vehicle couplers

ISO/IEC 15118 (all parts), Road vehicles — Vehicle to grid communication interface

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

balance of electric power system

remaining portion of a voltage class B electric circuit when all RESS and fuel cell stacks are disconnected

3.2

barrier

part providing protection against direct contact from any usual direction of access

3.3

basic insulation

insulation of hazardous-live-parts which provides basic protection

3.4

case A

connection of an EV to the a.c. supply network (mains) utilizing a supply cable and plug permanently

attached to the EV

3.5

case B

connection of an EV to the a.c. supply network (mains) utilizing a detachable cable assembly with a

vehicle connector and a.c. EV supply equipment

3.6

case C

connection of an EV to the a.c. supply network (mains) utilizing a supply cable and vehicle connector

permanently attached to the EV supply equipment.

Note 1 to entry: Only case C is applicable for mode 4 (see IEC 61851–1).

3.7

charger

power converter at the vehicle power supply circuit which supplies electric power, e.g. for charging a RESS

2 © ISO 2015 – All rights reserved

3.8

conductive part

part capable of conducting electric current

3.9

control pilot circuit

circuit designed for the transmission of signals and/or communication between an EV and an EV

supply equipment

3.10

control pilot conductor

insulated conductor incorporated in an EV cable assembly that creates, together with the protective

conductor, the control pilot circuit

3.11

control pilot function

functionality used to monitor and control the interaction between the electric vehicle and the

supply equipment

3.12

d.c. EV charging station

EV supply equipment intended to supply d.c. current to an EV

3.13

direct contact

contact of persons with live parts

3.14

distortion power factor

product of the displacement power factor and the total harmonic distortion up to the 40th harmonics of

the load current

3.15

displacement power factor

power factor due to the phase shift between voltage and current at the fundamental line frequency

3.16

double insulation

insulation comprising both basic insulation and supplementary insulation

3.17

electric chassis

conductive parts of a vehicle that are electrically connected and whose potential is taken as reference

3.18

electric shock

physiological effect resulting from an electric current passing through a human body

3.19

electric vehicle

electric road vehicle

EV

any vehicle propelled by an electric motor drawing current from a RESS intended primarily for use

on public roads

3.20

enclosure

part providing protection of equipment against direct contact from any direction

3.21

EV supply equipment

equipment or combined equipment providing dedicated functions for an electric power supply from

a fixed installation to an EV for the purpose of charging for all dedicated charging modes and cases

of connection

3.22

exposed conductive part

conductive part of the electric equipment, which can be touched by a test finger according to IPXXB (see

ISO 20653) after removing barriers/enclosures which can be removed without using tools and which is

not normally live, but which can become live under fault conditions

3.23

external electric power supply

electric power source that is not part of the vehicle for supplying electric energy to an EV using an EV

supply equipment

3.24

hazard

potential source of harm

3.25

isolation resistance

resistance between live parts of voltage class B electric circuit and the electric chassis, as well as the

voltage class A system

3.26

live conductor (line and neutral)

conductor which is energized in normal operation and capable of contributing to the transmission or

distribution of electric energy

3.27

live part

conductor or conductive part intended to be electrically energized in normal operation

3.28

maximum working voltage

highest value of a.c. voltage (rms) or of d.c. voltage which can occur in an electric system under any

normal operating conditions according to manufacturer’s specifications, disregarding transients

3.29

mode 1

connection of the EV to the a.c. supply network (mains) utilizing a cable and plug, that is not fitted with

any supplementary pilot or auxiliary contacts, and connects to a standard socket-outlet

3.30

mode 2

connection of the EV to the a.c. supply network (mains) utilizing a cable and plug connected to a

standard socket-outlet, with a control pilot function and system for personal protection against electric

shock placed between the EV and the socket outlet

3.31

mode 3

connection of the EV utilizing EV supply equipment permanently connected to the a.c. supply network

(mains) and where the control pilot function extends to control equipment in the EV supply equipment

Note 1 to entry: Mode 3 includes the use of cable assembly not permanently connected to the a.c supply network

(case A and case B).

4 © ISO 2015 – All rights reserved

3.32

mode 4

connection of the EV to the a.c. or d.c. supply network (mains) utilizing a d.c. EV supply equipment or

d.c. EV charging station using a control pilot function

3.33

non-isolated d.c. EV charging station

d.c. EV charging station with d.c. circuit on output side which is not electrically separated by at least

basic insulation from the supply system

3.34

plug

accessory having contacts designed to engage with the contacts of a socket-outlet, also incorporating

means for the electrical connection and mechanical retention of flexible cables or cords

3.35

protective conductor (PE)

conductor provided for purposes of safety, for example protection against electric shock

3.36

rechargeable energy storage system

RESS

system that stores energy for delivery of electric energy and which is rechargeable

EXAMPLE Batteries and capacitors.

3.37

reinforced insulation

insulation of hazardous-live-parts which provides a degree of protection against electric shock

equivalent to double insulation

Note 1 to entry: Reinforced insulation may comprise several layers which cannot be tested singly as basic

insulation or supplementary insulation.

3.38

residual current device

RCD

mechanical switching device or association of devices designed to make, carry and break currents

under normal service conditions and to cause the opening of the contacts when the residual current

attains a given value under specified conditions

Note 1 to entry: A residual current device can be a combination of various separate elements designed to detect

and evaluate the residual current and to make and break current.

3.39

socket-outlet

accessory having socket-contacts designed to engage with the contacts of a plug and having terminals

for the connection of cables or cords

3.40

standard plug and socket-outlet

plug and socket-outlet which meets the requirements of any IEC and/or national standard that

provides interchangeability by standard sheets, excluding the specific EV accessories as defined in the

IEC 62196 series

Note 1 to entry: The standards IEC 60309–1, IEC 60309–2, and IEC 60884–1 define standard plugs and

socket-outlets.

3.41

supplementary insulation

independent insulation applied in addition to basic insulation for fault protection

3.42

touch current

electric current passing through a human body or through an animal body when it touches one or more

accessible parts of an electrical installation or electrical equipment

3.43

vehicle connector

part of a vehicle coupler integral with or intended to be attached to the cable assembly

3.44

vehicle coupler

means of enabling the manual connection of a flexible cable to an EV for the purpose of supplying

electric energy to an EV

Note 1 to entry: It consists of two parts: a vehicle connector and a vehicle inlet.

3.45

vehicle inlet

part of a vehicle coupler incorporated in, or fixed to, an electric vehicle

3.46

vehicle isolation resistance monitoring system

system which periodically or continuously monitors the isolation resistance between live parts of

voltage class B electric circuits and the electric chassis

3.47

vehicle power supply circuit

voltage class B electric circuit which includes all parts that are galvanically connected to the vehicle

inlet (case B, case C) or the plug (case A) and that is operational when connected to an external

electric power supply

3.48

voltage class A

classification of an electric component or circuit as belonging to voltage class A, if its maximum working

voltage is ≤30 V a.c. (rms) or ≤60 V d.c., respectively

3.49

voltage class B

classification of an electric component or circuit as belonging to voltage class B, if its maximum working

voltage is (>30 V and ≤1 000) V a.c. (rms) or (>60 V and ≤1 500) V d.c., respectively

4 Environmental conditions

The requirements given in this International Standard shall be met across the range of environmental

conditions for which the electric vehicle is designed to operate when connected to an external electric

power supply, as specified by the vehicle manufacturer.

NOTE See ISO 16750-4 for guidance.

5 Requirements for protection of persons against electric shock

5.1 Basic protection

In this Clause, requirements for protection against direct contact at the vehicle inlet (case B and C) and

at the plug (case A) are specified.

Standard plug mated with standard socket-outlet (case A) shall comply with the requirements of relevant

standards and the national requirements of the country where the product is placed on the market.

6 © ISO 2015 – All rights reserved

Plug according to IEC 62196 mated with socket-outlet according to IEC 62196 (case A) shall comply with

the degree of protection IPXXD at minimum in accordance with ISO 20653.

Mated portion of the vehicle inlet mated with vehicle connector (case B and case C) shall comply with

IPXXD at minimum in accordance with ISO 20653. The requirements for unmated contacts of such a

vehicle inlet are specified in 5.4.

5.2 Protection under single failure conditions

For mode 1, 2, 3, and 4, the plug (case A) or the vehicle inlet (case B and case C) shall have a contact for

connecting the vehicle electric chassis to the protective conductor of an external electric power supply.

To provide protection under single failure conditions, at least one of the following requirements shall

be fulfilled.

— The protective conductor terminal of the plug (case A) or the vehicle inlet (case B and case C) shall

be connected to the vehicle electric chassis fulfilling the requirements for protective conductor

connection. All exposed conductive parts of the vehicle power supply circuit shall be connected to

the vehicle electric chassis fulfilling the requirements for the protective conductor connection. An

example for this option is given in Figure 1.

7 6

Key

1 vehicle power supply circuit 5 electric chassis

2 charger with galvanic separation 6 protective conductor

3 RESS 7 protective conductor

4 potential equalization according to ISO 6469 8 vehicle inlet

Figure 1 — Connection between protective conductor and electric chassis (example for Option 1)

— The protective conductor terminal of the plug (case A) or the vehicle inlet (case B and case C)

shall be connected to exposed conductive parts of the vehicle power supply circuit fulfilling the

requirements for protective conductor connection. All exposed conductive parts of the vehicle

power supply circuit shall be connected to the vehicle electric chassis fulfilling the requirements

for protective conductor connection. An example for this option is given in Figure 2.

Key

1 vehicle power supply circuit 5 electric chassis

2 charger with galvanic separation 6 protective conductor

3 RESS 7 protective conductor

4 potential equalization according to ISO 6469 8 vehicle inlet

Figure 2 — Connection between protective conductor and electric chassis (example for Option 2)

The cross-sectional area of the protective conductor shall be designed in accordance with IEC 60364-5-54.

For the specification of the protective conductor of a vehicle power supply circuit used for a d.c.

connection, a fault current and the disconnecting time in case of a fault current in accordance with

IEC 61851-23 shall be considered.

The resistance of the protective conductor connection between the protective conductor contact of

the plug (case A) or the vehicle inlet (case B, case C) and the vehicle electrical chassis, as well as all

exposed conductive parts of the vehicle power supply circuit shall be less than 0,1 Ω. All paths used for

protective conductor connection shall be considered.

The resistance of protective conductor shall be tested in accordance with 12.2.

NOTE Protective conductor requirement for double/reinforced insulation is under consideration.

5.3 Isolation resistance

5.3.1 A.C. connection (Mode 1, 2, and 3)

The total isolation resistance of the vehicle power supply circuit shall be at least 500 Ω/V when the

vehicle is not connected to an external electric power supply. The reference shall be the maximum

working voltage of the relevant electric circuit.

Compliance shall be tested in accordance with 12.3.

5.3.2 D.C. connection (Mode 4)

The isolation resistance of the vehicle power supply circuit shall comply with the requirements in

ISO 6469-3 when the vehicle connector is not mated with the vehicle inlet.

Compliance shall be tested in accordance with 12.3.

8 © ISO 2015 – All rights reserved

5.4 Protection from unintended voltage

5.4.1 Mode 1

The plug (case A) or vehicle inlet (case B and case C) shall comply with at least one of the following

requirements:

— the charge between any contacts shall be below 50 µC within 1 s after cut off of the external

electric power supply;

— the voltage between any contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) within 1 s

after cut off of the external electric power supply.

For compliance, cut off of external electric power supply can be simulated by unmating the plug (case A)

or the vehicle connector (case B and case C).

NOTE Cut off of external electric power supply means loss of supply voltage, including disconnection and

voltage outage on the supply.

5.4.2 Mode 2 and mode 3

The plug (case A) or vehicle inlet (case B and case C) shall comply with at least one of the following

requirements if their voltage class B live parts are not protected at least by IPXXB in accordance

with ISO 20653:

— the charge between any contacts shall be below 50 µC within 1 s after disconnection of the vehicle

from external electric power supply;

— the voltage between any contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) within 1 s

after disconnection of the vehicle from external electric power supply.

The plug (case A) or vehicle inlet (case B and case C) shall comply with at least one of the following

requirements if their voltage class B live parts are protected at least by IPXXB in accordance with

ISO 20653:

— the energy between any contacts shall be below 0,2 J within 10 s after disconnection of the vehicle

from external electric power supply;

— the voltage between any contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) within 10 s

after disconnection of the vehicle from external electric power supply.

For case B and case C, the voltage or energy shall be measured at the unmated vehicle inlet.

5.4.3 Mode 4

The vehicle inlet shall comply with at least one of the following requirements if its voltage class B live

parts are not protected at least by IPXXB in accordance with ISO 20653:

— the charge between any contacts shall be below 50 µC within 1 s after disconnection of the vehicle

from external electric power supply;

— the voltage between any contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) within 1 s

after disconnection of the vehicle connector from external electric power supply.

The vehicle inlet shall comply with at least one of the following requirements if its voltage class B live

parts are protected at least by IPXXB in accordance with ISO 20653:

— the energy between any contacts shall be below 0,2 J within 10 s after disconnection of the vehicle

from external electric power supply;

— the voltage between any contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) within 10 s

after disconnection of the vehicle from external electric power supply.

The voltage or energy shall be measured at the unmated vehicle inlet

5.4.4 Contacts of unmated portion of vehicle inlet

The contacts of an unmated portion of the vehicle inlet shall fulfil at least one of the following

requirements, when the other contacts of this vehicle inlet are mated with a vehicle connector (e.g. d.c.

contacts of a combined vehicle inlet unmated and other contacts mated with a type 1 or type 2 vehicle

connector according to IEC 62196 series):

— the energy between any unmated contacts shall be below 0,2 J if live parts are protected at least by

IPXXB in accordance with ISO 20653;

— the voltage between any unmated contacts shall be below or equal to 60 V d.c. and 30 V a.c. (rms) if

live parts are protected at least by IPXXB in accordance with ISO 20653;

— the charge between any contacts shall be below 50 µC if live parts are not protected at least by

IPXXB in accordance with ISO 20653.

5.5 Insulation coordination

5.5.1 General

The vehicle power supply circuit shall fulfil the applicable sections of IEC 60664 series on insulation

coordination and meet the withstand voltage capability according to the details in 5.5.2 or 5.5.3.

Neither dielectric breakdown nor flashover shall occur during the withstand voltage test.

Compliance shall be tested in accordance with 12.4.

5.5.2 A.C. connection (Mode 1, 2, and 3)

The vehicle power supply circuit shall be designed according to the overvoltage category II unless

appropriate overvoltage reduction in accordance with IEC 60664-1 is provided in the vehicle power

supply circuit.

5.5.3 D.C. connection (Mode 4)

The vehicle power supply circuit shall be designed according to a rated impulse voltage of at least 2 500 V.

NOTE IEC 61851–23 has adopted this fixed value of the rated impulse voltage independent of input voltage of

d.c. charging station

6 Protection against thermal incident

6.1 Overcurrent protection

6.1.1 Overload protection

The cross-sectional area of the live conductors of the vehicle power supply circuit, as well as the rated

current of the plug (case A) or vehicle inlet (case B and case C), shall be according to the maximum load

current of the vehicle unless parts of this circuit are separately protected by an overcurrent protection

device in the vehicle. (e.g. fuse, circuit breaker, etc.).

10 © ISO 2015 – All rights reserved

6.1.2 Short-circuit protection for a.c. connection

For short-circuit current supplied by external power supply, the requirements in a), b), or c) shall

be fulfilled.

a) The cross-sectional area of the live conductors of the vehicle power supply circuit shall have a

short-circuit current withstand rating (I t) according to the characteristics of the overcurrent

protection device of the external electric power supply. For the connection to an external electric

power supply with a rated current up to 80 A, the vehicle power supply circuit shall have a short-

2 2 2

circuit current withstand rating (I t) of at least 80 000 A s. I t value shall be calculated according

to IEC 60364-4-43.

NOTE Breaking time for overcurrent protection device is less than 0,1 s (see IEC 60364–4-43).

b) An overcurrent protection device (e.g. fuse, circuit breaker) shall be provided in each live conductor

of the vehicle power supply circuit. The cross-sectional area of the live conductor downstream

this overcurrent protection device shall be designed according to the rating of this overcurrent

protection device.

c) For case B and case C, all of the following requirements shall be fulfilled:

— cross-sectional area of the vehicle power supply circuits shall be designed according to the

maximum load current of the vehicle;

— protection against mechanical damage for vehicle power supply circuit wiring between the

vehicle inlet and the charger shall be provided so that single failure does not cause insulation

fault between live conductors and between live conductors and electrical chassis;

— an overcurrent protection device (e.g. fuse, circuit breaker) shall be provided inside the charger.

The overcurrent protection device rating and short-circuit current interrupt rating shall be

sufficient to protect the wiring of the vehicle power supply circuit between the vehicle inlet and

the on-board charger.

For short-circuit current supplied by power sources of the vehicle, short-circuit protection shall be

provided for the vehicle power supply circuit.

6.1.3 Short-circuit protection for d.c. connection

For short-circuit current supplied by external electric power supply, the requirements in a) or b) shall

be fulfilled for short-circuit protection.

a) The cross-sectional area of the live conductors of the vehicle power supply circuit shall have a

short-circuit current withstand rating (I t) of at least the following values:

— 1 000 000 A s for System A according to IEC 61851-23;

— 5 000 000 A s for System C according to IEC 61851-23;

— a value in A s to be coordinated for any other d.c.-EV charging station.

I t value of the live conductors shall be calculated according to IEC 60364-4-43.

NOTE 1 This short-circuit current withstand rating (I t) corresponds to the characteristics of the

overcurrent protection device of the external electric power supply.

b) An overcurrent protection device (e.g. fuse, circuit breaker) shall be provided in the vehicle power

supply circuit. The cross-sectional area of the live conductors to be protected by this overcurrent

protection device shall be designed according to the short-circuit interrupt rating of this

overcurrent protection device. The cross-sectional area of the live conductors upstream from this

overcurrent protection device (to vehicle inlet) shall comply with the requirement of a).

The breaking time for interruption of a short-circuit current shall be gathered from the technical data

of the selected overcurrent protection device.

For short-circuit current supplied by vehicle sources, the vehicle power supply circuit shall have an

overcurrent protection device with a rating not higher than following values:

— 2 500 000 A s for System A according to IEC 61851-23;

— 12 000 000 A s for System C according to IEC 61851-23;

— a value in A s to be coordinated for any other d.c. EV charging station.

The cross-sectional area of the live conductors of the vehicle power supply circuit upstream from

this overcurrent protection device (to vehicle inlet) shall be designed according to the rating of the

overcurrent protection device of the vehicle power supply circuit.

I t value of the live conductors shall be calculated according to IEC 60346-4-43.

NOTE 2 This characteristics of the overcurrent protection device (I t) corresponds to the short-circuit

current withstand rating of the live conductors of an external electric power supply, if no additional overcurrent

protection device is provided, see e.g. IEC 61851–23.

6.2 Arc protection for d.c. connections

Arc protection is covered by the requirements in 9.4.

6.3 Residual energy after disconnection

One second after having disconnected the vehicle from the external electric power supply, the stored

energy at the voltage class B live parts at the plug (case A) or vehicle inlet

...

NORME ISO

INTERNATIONALE 17409

Première édition

2015-11-01

Véhicules routiers à propulsion

électrique — Connexion à une

alimentation électrique externe —

Exigences de sécurité

Electrically propelled road vehicles — Connection to an external

electric power supply — Safety requirements

Numéro de référence

©

ISO 2015

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2015, Publié en Suisse

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni utilisée

sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur

l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à

l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – Tous droits réservés

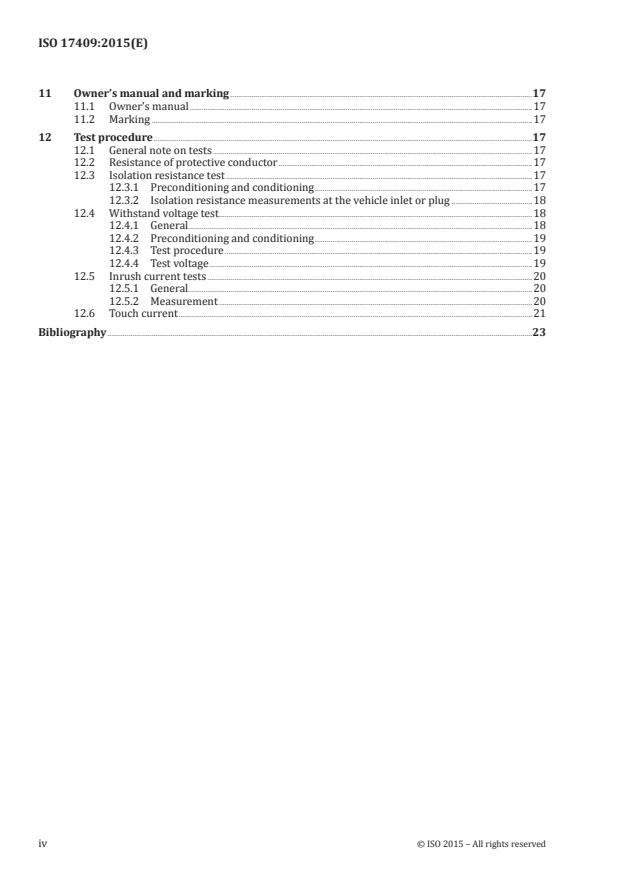

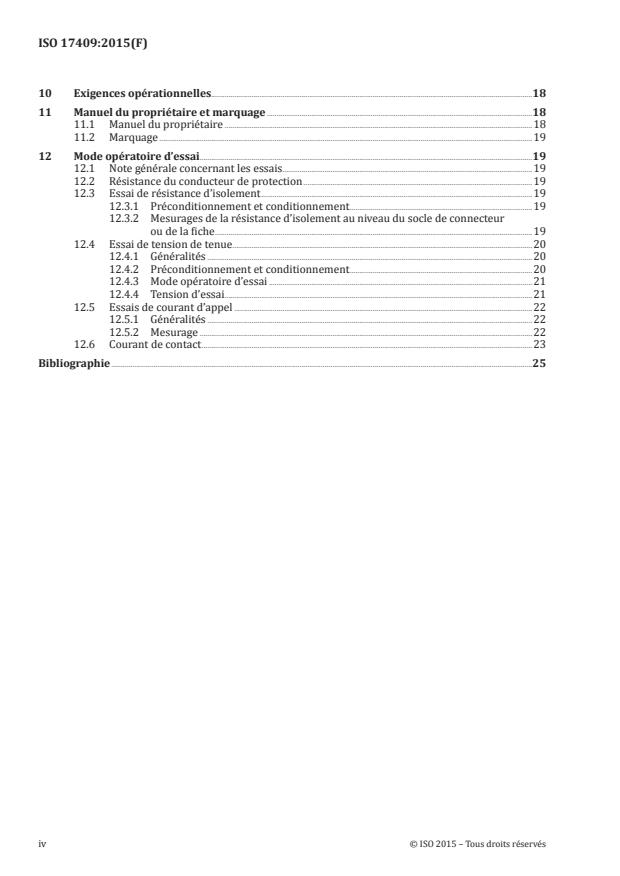

Sommaire Page

Avant-propos .v

1 Domaine d’application . 1

2 Références normatives . 1

3 Termes et définitions . 2

4 Conditions environnementales . 7

5 Exigences relatives à la protection des personnes contre les chocs électriques .7

5.1 Protection principale . 7

5.2 Protection dans des conditions de défaillance unique . 7

5.3 Résistance d’isolement . 9

5.3.1 Connexion c.a. (modes 1, 2 et 3) . 9

5.3.2 Connexion c.c. (mode 4) . 9

5.4 Protection contre une tension inattendue . 9

5.4.1 Mode 1 . 9

5.4.2 Mode 2 et mode 3 . 9

5.4.3 Mode 4 .10

5.4.4 Contacts de la partie non accouplée du socle de connecteur de véhicule .10

5.5 Coordination de l’isolement .11

5.5.1 Généralités .11

5.5.2 Connexion c.a. (modes 1, 2 et 3) .11

5.5.3 Connexion c.c. (mode 4) .11

6 Protection contre les incidents thermiques .11

6.1 Protection contre les surintensités.11

6.1.1 Protection de surcharge .11

6.1.2 Protection contre les courts-circuits pour une connexion c.a. .11

6.1.3 Protection contre les courts-circuits pour une connexion c.c. .12

6.2 Protection contre les arcs électriques pour les connexions c.c .13

6.3 Énergie résiduelle après déconnexion .13

7 Exigences spécifiques relatives au socle de connecteur, à la fiche et au câble .13

7.1 Exigences relatives à la fiche et au câble .13

7.2 Exigences relatives au socle de connecteur de véhicule .13

8 Exigences supplémentaires pour une borne d’alimentation électrique c.a. .14

8.1 Conditions normalisées de la borne d’alimentation électrique externe c.a. pour un

fonctionnement en service .14

8.2 Caractéristiques du courant .14

8.2.1 Courant de charge .14

8.2.2 Courant d’appel .14

8.3 Courants de défaut c.c. .15

8.4 Courant de contact .15

8.5 Inversion inattendue du courant .15

8.6 Facteur de puissance.15

8.7 Verrouillage de la prise mobile .15

9 Exigences supplémentaires pour une borne d’alimentation électrique c.c. .16

9.1 Appareil de sectionnement .16

9.2 Fonctions pilote de contrôle .16

9.3 Système de surveillance de la résistance d’isolement du véhicule .16

9.4 Verrouillage de la prise mobile .16

9.5 Puissance électrique c.a. ou c.c. au niveau des mêmes contacts .17

9.6 Température de contact au niveau du socle de connecteur .18

9.7 Surtension en cas de perte de charge .18

9.8 Inversion inattendue du courant .18

9.9 Capacités Y .18

10 Exigences opérationnelles.18

11 Manuel du propriétaire et marquage .18

11.1 Manuel du propriétaire .18

11.2 Marquage .19

12 Mode opératoire d’essai.19

12.1 Note générale concernant les essais.19

12.2 Résistance du conducteur de protection .19

12.3 Essai de résistance d’isolement .19

12.3.1 Préconditionnement et conditionnement .19

12.3.2 Mesurages de la résistance d’isolement au niveau du socle de connecteur

ou de la fiche .19

12.4 Essai de tension de tenue .20

12.4.1 Généralités .20

12.4.2 Préconditionnement et conditionnement .20

12.4.3 Mode opératoire d’essai .21

12.4.4 Tension d’essai .21

12.5 Essais de courant d’appel .22

12.5.1 Généralités .22

12.5.2 Mesurage .22

12.6 Courant de contact .23

Bibliographie .25

iv © ISO 2015 – Tous droits réservés

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d’approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www.

iso.org/directives).

L’attention est appelée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets reçues par l’ISO (voir www.iso.org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la signification des termes et expressions spécifiques de l’ISO liés à l’évaluation

de la conformité, ou pour toute information au sujet de l’adhésion de l’ISO aux principes de l’Organisation

mondiale du commerce (OMC) concernant les obstacles techniques au commerce (OTC) voir le lien

suivant: Avant-propos — Informations supplémentaires.

Le comité responsable du présent document est l’ISO/TC 22, Véhicules routiers, sous-comité SC 37,

Véhicules à propulsion électrique.

La présente version française de l’ISO 17409:2015 correspond à la version anglaise corrigée du

2015-12-15.

NORME INTERNATIONALE ISO 17409:2015(F)

Véhicules routiers à propulsion électrique — Connexion

à une alimentation électrique externe — Exigences de

sécurité

1 Domaine d’application

La présente Norme internationale spécifie les exigences de sécurité électrique relatives aux connexions

conductives des véhicules routiers à propulsion électrique à une alimentation électrique externe au

moyen d’une fiche ou d’un socle de connecteur.

Elle s’applique aux véhicules routiers à propulsion électrique ayant des circuits électriques de classe de

tension B. En général, elle peut s’appliquer aux motocycles et aux cyclomoteurs s’il n’existe aucune

norme dédiée à ces véhicules.

Elle s’applique uniquement aux circuits d’alimentation électrique du véhicule. Elle s’applique également

aux fonctions dédiées de contrôle de l’alimentation électrique utilisées pour la connexion du véhicule à

une alimentation électrique externe.

Elle ne fournit pas d’exigence concernant la connexion à une borne de charge conductive en courant

continu non isolée.

Elle ne fournit pas d’informations complètes concernant la sécurité pour le personnel de fabrication, de

maintenance et de réparation.

Lorsque le véhicule n’est pas connecté à la borne d’alimentation électrique externe, les exigences sont

spécifiées dans l’ISO 6469-3.

NOTE 1 La présente Norme internationale ne contient pas d’exigences pour les circuits d’alimentation

électrique de véhicules utilisant une isolation double ou renforcée d’un équipement de classe II, mais n’a pas pour

intention d’exclure de telles applications pour véhicules.

NOTE 2 Les exigences pour les systèmes d’alimentation pour VE sont spécifiées dans l’IEC 61851.

2 Références normatives

Les documents suivants, en tout ou partie, sont référencés de manière normative dans le présent

document et sont indispensables à son application. Pour les références datées, seule l’édition citée

s’applique. Pour les références non datées, la dernière édition du document de référence s’applique (y

compris les éventuels amendements).

ISO 6469-1, Véhicules routiers électriques — Spécifications de sécurité — Partie 1: Système de stockage

d’énergie rechargeable à bord du véhicule (RESS)

ISO 6469-3, Véhicules routiers électriquesSpécifications de sécuritéPartie 3: Protection des personnes

contre les chocs électriques

ISO 13849 (toutes les parties), Sécurité des machinesParties des systèmes de commande relatives à la

sécurité

ISO 20653, Véhicules routiers — Degrés de protection (codes IP) — Protection des équipements électriques

contre les corps étrangers, l’eau et les contacts

ISO 26262 (toutes les parties), Véhicules routiersSécurité fonctionnelle

IEC 60309-1, Prises de courant pour usages industrielsPartie 1: Règles générales

IEC 60309-2, Prises de courant pour usages industrielsPartie 2: Règles d’interchangeabilité dimensionnelle

pour les appareils à broches et alvéoles

IEC 60364-4-43, Installations électriques des bâtimentsPartie 4-43: Protection pour assurer la

sécuritéProtection contre les surintensités

IEC 60364-5-54, Installations électriques basse-tensionPartie 5-54: Choix et mise en œuvre des matériels

électriquesInstallations de mise à la terre et conducteurs de protection

IEC 60364-6, Installations électriques à basse tensionPartie 6: Vérification

IEC 60664 (toutes les parties), Coordination de l’isolement des matériels dans les systèmes (réseaux) à

basse tension

IEC 60884-1, Prises de courant pour usages domestiques et analoguesPartie 1: Règles générales

IEC 61851-1, Système de charge conductive pour véhicules électriquesPartie 1: Règles générales

IEC 61851-23, Système de charge conductive pour véhicules électriquesPartie 23: Borne de charge en

courant continu pour véhicules électriques

IEC 62196-1, Fiches, socles de prise de courant, prises mobiles et socles de connecteur pour véhiculeCharge

conductive des véhicules électriquesPartie 1: Règles générales

IEC 62196-2, Fiches, socles de prise de courant, prises mobiles et socles de connecteurs de véhiculeCharge

conductive des véhicules électriquesPartie 2: Exigences dimensionnelles de compatibilité et

d’interchangeabilité pour les appareils à broches et alvéoles pour courant alternatif

IEC 62196-3, Fiches, socles de prise de courant, prises mobiles de véhicule et socles de connecteur de

véhiculeCharge conductive des véhicules électriquesPartie 3: Exigences dimensionnelles de compatibilité et

d’interchangeabilité pour les connecteurs de véhicule à broches et alvéoles pour courant continu et pour

courant alternatif et continu

ISO/IEC 15118 (toutes les parties), Véhicules routiersInterface de communication entre véhicule et réseau

électrique

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

3.1

équipement restant du système de puissance électrique

partie restante d’un circuit électrique de classe de tension B lorsque tous les RESS et les ensembles de

piles à combustible sont déconnectés

3.2

barrière

partie assurant la protection contre les contacts directs dans toute direction habituelle d’accès

3.3

isolation principale

isolation des parties actives dangereuses qui assure la protection principale

3.4

cas A

raccordement d’un VE au réseau d’alimentation en courant alternatif (secteur) en utilisant un câble

d’alimentation et d’une fiche attachée en permanence au VE

2 © ISO 2015 – Tous droits réservés

3.5

cas B

raccordement d’un VE au réseau d’alimentation en courant alternatif (secteur) en utilisant un câble de

charge détachable avec une prise mobile et un système d’alimentation en courant alternatif pour VE

3.6

cas C

raccordement d’un VE au réseau d’alimentation en courant alternatif (secteur) en utilisant un câble

d’alimentation et une prise mobile fixés à demeure sur le système d’alimentation du VE

Note 1 à l’article: Seul le cas «C» est applicable pour le mode 4 (voir l’IEC 61851–1).

3.7

chargeur

convertisseur d’énergie au niveau du circuit d’alimentation électrique du véhicule, qui fournit

l’alimentation électrique, par exemple pour charger un RESS

3.8

partie conductrice

partie capable de conduire le courant électrique

3.9

circuit pilote de contrôle

circuit destiné à la transmission de signaux et/ou à la communication entre un VE et un système

d’alimentation pour VE

3.10

conducteur pilote de contrôle

conducteur isolé incorporé dans un câble de charge pour VE qui crée, avec le conducteur de protection,

le circuit pilote de contrôle

3.11

fonction pilote de contrôle

fonctionnalité utilisée pour surveiller et contrôler l’interaction entre le véhicule électrique et le système

d’alimentation

3.12

borne de charge en courant continu pour VE

système d’alimentation pour VE destiné à fournir du courant continu à un VE

3.13

contact direct

contact de personnes avec des parties actives

3.14

facteur de puissance de distorsion

ème

produit du facteur de puissance de déplacement et de la distorsion harmonique jusqu’à la 40

harmonique du courant de charge

3.15

facteur de puissance de déplacement

facteur de puissance dû au déplacement de phase entre la tension et le courant à la fréquence

fondamentale de ligne

3.16

double isolation

isolation comprenant à la fois une isolation principale et une isolation supplémentaire

3.17

châssis électrique

parties conductrices d’un véhicule qui sont électriquement connectées et dont le potentiel sert de

référence

3.18

choc électrique

effet physiologique résultant du passage d’un courant électrique à travers le corps humain

3.19

véhicule électrique

véhicule routier électrique

VE

tout véhicule propulsé par un moteur électrique dont le courant électrique provient d’un RESS, destiné

principalement à l’utilisation sur la voie publique

3.20

enveloppe

élément assurant la protection des matériels contre le contact direct dans toutes les directions

3.21

système d’alimentation pour VE

équipement ou équipement combiné assurant des fonctions dédiées pour l’alimentation en énergie

électrique d’un VE à partir d’une installation fixe dans le but de le charger, pour tous les modes de

charge et cas de connexion

3.22

partie conductrice accessible

partie conductrice d’un équipement électrique, qui peut être touchée par un doigt d’essai conformément à

IPXXB, (voir l’ISO 20653), après retrait des barrières/enveloppes de protection qui peuvent être retirées

sans l’aide d’un outil et qui n’est pas normalement sous tension mais peut le devenir en cas de défaut

3.23

borne d’alimentation électrique externe

source d’énergie électrique qui ne fait pas partie du véhicule et qui est destinée à fournir de l’énergie

électrique à un VE au moyen d’un système d’alimentation pour VE

3.24

phénomène dangereux

source potentielle de dommage

3.25

résistance d’isolement

résistance entre les parties actives d’un circuit électrique de classe B et le châssis électrique ainsi que le

système de tension de classe A

3.26

conducteur sous tension (ligne et neutre)

conducteur qui est sous tension en service normal et capable de contribuer à la transmission ou à la

distribution de l’énergie électrique

3.27

partie active

conducteur ou partie conductrice destiné(e) à être sous tension en usage normal

3.28

tension maximale de service

valeur la plus haute de la tension efficace en courant alternatif ou de la tension en courant continu

qui peut être observée dans un circuit électrique dans toutes les conditions normales de service,

conformément aux spécifications du fabricant, sans tenir compte des transitoires

4 © ISO 2015 – Tous droits réservés

3.29

mode 1

connexion du VE au réseau d’alimentation en courant alternatif (secteur) en utilisant un câble et une

fiche, qui n’est munie d’aucune fonction pilote ni d’aucun contact auxiliaire supplémentaire, et qui se

raccorde à un socle de prise normalisé

3.30

mode 2

connexion du VE au réseau d’alimentation en courant alternatif (secteur) en utilisant un câble et une

fiche raccordée à un socle de prise normalisé, avec une fonction pilote de contrôle et un système de

protection individuelle contre les chocs électriques entre le VE et le socle de prise

3.31

mode 3

connexion du VE en utilisant le système d’alimentation pour VE connecté en permanence au réseau

d’alimentation en courant alternatif (secteur) et où la fonction pilote de contrôle s’étend jusqu’à

l’équipement de contrôle dans le système d’alimentation pour VE

Note 1 à l’article: Le mode 3 comprend l’utilisation d’un câble de charge qui n’est pas connecté en permanence au

réseau d’alimentation en courant alternatif (cas A et cas B).

3.32

mode 4

connexion du VE au réseau d’alimentation en courant alternatif ou en courant continu (secteur) en

utilisant un système d’alimentation pour VE destiné à fournir du courant continu à un VE ou une borne

de charge en courant continu utilisant une fonction pilote de contrôle

3.33

borne de charge en courant continu non isolée pour VE

borne de charge en courant continu pour VE avec un circuit de courant continu du côté sortie qui n’est

pas séparé électriquement du réseau d’alimentation par au moins une isolation principale

3.34

fiche

appareil pourvu de contacts conçus pour s’engager dans les alvéoles d’un socle et comprenant également

des pièces pour la connexion électrique et la retenue mécanique d’un câble ou d’un cordon souple

3.35

conducteur de protection (PE)

conducteur utilisé comme mesure de protection, par exemple contre les chocs électriques

3.36

système de stockage de l’énergie rechargeable

RESS

système qui stocke de l’énergie pour la fourniture d’énergie électrique et qui est rechargeable

EXEMPLE Batteries et condensateurs.

3.37

isolation renforcée

isolation des parties actives dangereuses qui assure un degré de protection contre les chocs électriques

équivalent à une double isolation

Note 1 à l’article: L’isolation renforcée peut comprendre plusieurs couches qui ne peuvent pas être essayées

individuellement en tant qu’isolation principale ou isolation supplémentaire.

3.38

dispositif à courant différentiel résiduel

DDR

appareil mécanique de connexion ou association d’appareils destiné à établir, supporter et couper des

courants dans les conditions de service normales et à provoquer l’ouverture des contacts quand le

courant différentiel atteint, dans des conditions spécifiées, une valeur donnée

Note 1 à l’article: Un dispositif à courant différentiel résiduel peut être une combinaison de plusieurs éléments

séparés conçus pour détecter et évaluer le courant résiduel et à établir et couper un courant.

3.39

socle de prise de courant

accessoire pourvu d’alvéoles de contact dans un socle, conçu pour recevoir les contacts d’une fiche et

pourvu de bornes pour la connexion de câbles ou cordons

3.40

fiche et prise de courant normalisées

fiche et prise de courant conformes aux exigences d’une norme IEC et/ou d’une norme nationale qui

assure l’interchangeabilité par des feuilles normalisées, à l’exclusion des accessoires spécifiques pour

VE tels que définis dans la série IEC 62196

Note 1 à l’article: Les normes IEC 60309–1, IEC 60309–2, et IEC 60884–1 définissent des fiches et prises de

courant normalisées.

3.41

isolation supplémentaire

isolation indépendante prévue, en plus de l’isolation principale, en tant que protection en cas de défaut

3.42

courant de contact

courant électrique passant dans le corps humain ou dans le corps d’un animal lorsque ce corps est en

contact avec une ou plusieurs parties accessibles d’une installation ou de matériels

3.43

prise mobile

partie de connecteur intégrée ou destinée à être fixée au câble de charge

3.44

connecteur

moyen de réaliser la connexion manuelle entre un câble souple et un VE dans le but de fournir de

l’énergie électrique à un VE

Note 1 à l’article: Il comprend deux parties: une prise mobile et un socle de connecteur.

3.45

socle de connecteur

partie de connecteur intégrée ou fixée dans un véhicule électrique

3.46

système de surveillance de la résistance d’isolement du véhicule

système qui permet de surveiller périodiquement ou constamment la résistance d’isolement entre les

parties actives de circuits électriques de classe B et le châssis électrique du véhicule

3.47

circuit d’alimentation du véhicule

circuit électrique de classe de tension B contenant toutes les parties connectées galvaniquement au

socle de connecteur (cas B, cas C) ou à la fiche (cas A) et qui est opérationnel lorsqu’elles sont connectées

à une alimentation électrique externe

6 © ISO 2015 – Tous droits réservés

3.48

tension classe A

classement d’un composant ou d’un circuit électrique appartement à la classe de tension A, si sa tension

maximale de travail est ≤ 30 V c.a. (efficace) ou ≤ 60 V c.c. respectivement

3.49

tension classe B

classement d’un composant ou d’un circuit électrique appartement à la classe de tension B, si sa tension

maximale de travail est (> 30 et ≤ 1 000) V c.a. (efficace) ou (> 60 et ≤ 1 500) V c.c. respectivement

4 Conditions environnementales

Les exigences indiquées dans la présente Norme internationale doivent être satisfaites dans l’ensemble

des conditions environnementales pour lesquelles le véhicule électrique a été conçu pour fonctionner

lorsqu’il est connecté à une borne d’alimentation électrique externe, telles qu’elles sont spécifiées par le

constructeur du véhicule.

NOTE Voir l’ISO 16750-4 pour des recommandations.

5 Exigences relatives à la protection des personnes contre les chocs électriques

5.1 Protection principale

Le présent paragraphe spécifie les exigences relatives à la protection contre le contact direct au niveau

du socle de connecteur (cas B et C) et au niveau de la fiche (cas A).

Une fiche normalisée accouplée à un socle de prise normalisé (cas A) doit satisfaire aux exigences des

normes pertinentes ainsi qu’aux exigences nationales du pays dans lequel le produit est mis sur le marché.

Une fiche conforme à l’IEC 62196, accouplée à un socle de prise de courant conforme à l’IEC 62196

(cas A), doit au moins être conforme au degré de protection IPXXD conformément à l’ISO 20653.

La partie du socle de connecteur accouplée à une prise mobile (cas B et cas C) doit au moins être

conforme au degré de protection IPXXD conformément à l’ISO 20653. Les exigences pour les contacts

non accouplés de ce socle de connecteur sont spécifiées au 5.4.

5.2 Protection dans des conditions de défaillance unique

Pour les modes 1, 2, 3 et 4, la fiche (cas A) ou le socle de connecteur (cas B et cas C) doit comporter

un contact pour raccorder le châssis électrique du véhicule au conducteur de protection d’une borne

d’alimentation électrique externe.

Pour assurer la protection dans des conditions de défaillance unique, au moins l’une des exigences

suivantes doit être satisfaite:

— la borne du conducteur de protection de la fiche (cas A) ou du socle de connecteur (cas B et cas C) doit

être connectée au châssis électrique du véhicule en respectant les exigences relatives à la connexion

du conducteur de protection. Toutes les parties conductrices accessibles du circuit d’alimentation

électrique du véhicule doivent être connectées au châssis électrique du véhicule en respectant les

exigences relatives à la connexion du conducteur de protection. Un exemple pour cette option est

donné à la Figure 1.

7 6

Légende

1 circuit d’alimentation du véhicule 5 châssis électrique

2 chargeur avec séparation galvanique 6 conducteur de protection

3 RESS 7 conducteur de protection

4 égalisation des potentiels conformément à l’ISO 64698 socle de connecteur de véhicule

Figure 1 — Connexion entre conducteur de protection et châssis électrique

(exemple pour l’option 1)

— la borne du conducteur de protection de la fiche (cas A) ou du socle de connecteur (cas B et cas C) doit

être connectée aux parties conductrices accessibles du circuit d’alimentation électrique du véhicule

en respectant les exigences relatives à la connexion du conducteur de protection. Toutes les parties

conductrices accessibles du circuit d’alimentation électrique du véhicule doivent être connectées au

châssis électrique du véhicule en respectant les exigences relatives à la connexion du conducteur de

protection. Un exemple pour cette option est donné à la Figure 2.

Légende

1 circuit d’alimentation du véhicule 5 châssis électrique

2 chargeur avec séparation galvanique 6 conducteur de protection

3 RESS 7 conducteur de protection

4 égalisation des potentiels conformément à l’ISO 64698 socle de connecteur de véhicule

Figure 2 — Connexion entre conducteur de protection et châssis électrique

(exemple pour l’option 2)

La section du conducteur de protection doit être calculée conformément à l’IEC 60364-5-54.

8 © ISO 2015 – Tous droits réservés

Pour la spécification du conducteur de protection du circuit d’alimentation électrique du véhicule

utilisé pour une connexion c.c., il est nécessaire de tenir compte d’un courant de défaut et du temps de

déconnexion en cas de courant de défaut conformément à l’IEC 61851-23.

La résistance de la connexion du conducteur de protection entre le contact du conducteur de protection

de la fiche (cas A) ou du socle de connecteur (cas B, cas C) et le châssis électrique du véhicule, ainsi que

toutes les parties conductrices accessibles du circuit d’alimentation électrique du véhicule, doit être

inférieure à 0,1 Ω. Tous les parcours utilisés pour la connexion du conducteur de protection doivent être

pris en considération.

La résistance du conducteur de protection doit être soumise à essai conformément à 12.2.

NOTE L’exigence d’isolation double/renforcée du conducteur de protection est à l’étude.

5.3 Résistance d’isolement

5.3.1 Connexion c.a. (modes 1, 2 et 3)

La résistance d’isolement totale du circuit d’alimentation électrique du véhicule doit être d’au moins

500 Ω/V lorsque le véhicule n’est pas connecté à une borne d’alimentation électrique externe. La

référence doit être la tension maximale de service du circuit électrique concerné.

La conformité doit être évaluée par essai conformément à 12.3.

5.3.2 Connexion c.c. (mode 4)

La résistance d’isolement du circuit d’alimentation électrique du véhicule doit satisfaire aux exigences

de l’ISO 6469-3 lorsque la prise mobile n’est pas accouplée au socle de connecteur.

La conformité doit être évaluée par essai conformément à 12.3.

5.4 Protection contre une tension inattendue

5.4.1 Mode 1

La fiche (cas A) ou le socle de connecteur (cas B et cas C) doit satisfaire à au moins l’une des exigences

suivantes:

— la charge entre contacts doit être inférieure à 50 µC dans la seconde qui suit la coupure de

l’alimentation électrique externe;

— la tension entre contacts doit être inférieure ou égale à 60 V c.c. et à 30 V c.a. (efficace) dans la

seconde qui suit la coupure de l’alimentation électrique externe.

Pour vérifier la conformité, la coupure de l’alimentation électrique externe peut être simulée en

désaccouplant la fiche (cas A) ou le socle de connecteur (cas B et cas C).

NOTE La coupure de l’alimentation électrique externe signifie une perte de tension d’alimentation, y compris

la déconnexion et la coupure de l’alimentation.

5.4.2 Mode 2 et mode 3

La fiche (cas A) ou le socle de connecteur (cas B et cas C) doit satisfaire à au moins l’une des exigences

suivantes si leurs parties actives de classe de tension B ne sont pas protégées selon un degré de

protection IPXXB conformément à l’ISO 20653:

— la charge entre contacts doit être inférieure à 50 µC dans la seconde qui suit la déconnexion du

véhicule de la borne d’alimentation électrique externe;

— la tension entre contacts doit être inférieure ou égale à 60 V c.c. et à 30 V c.a. (efficace) dans la

seconde qui suit la déconnexion du véhicule de la borne d’alimentation électrique externe.

La fiche (cas A) ou le socle de connecteur (cas B et cas C) doit satisfaire à au moins l’une des exigences

suivantes si leurs parties actives de classe de tension B sont protégées au moins selon un degré de

protection IPXXB conformément à l’ISO 20653:

— l’énergie entre contacts doit être inférieure à 0,2 J dans les dix secondes qui suivent la déconnexion

du véhicule de la borne d’alimentation électrique externe;

— la tension entre contacts doit être inférieure ou égale à 60 V c.c. et à 30 V c.a. (efficace) dans les dix

secondes qui suivent la déconnexion du véhicule de la borne d’alimentation électrique externe.

Pour le cas B et le cas C, la tension ou l’énergie doit être mesurée au niveau du socle de connecteur non

accouplé.

5.4.3 Mode 4

Le socle de connecteur doit satisfaire à au moins l’une des exigences suivantes si leurs parties actives de

classe de tension B ne sont pas protégées au moins selon un degré de protection IPXXB conformément

à l’ISO 20653:

— la charge entre contacts doit être inférieure à 50 µC dans la seconde qui suit la déconnexion du

véhicule de la borne d’alimentation électrique externe;

— la tension entre contacts doit être inférieure ou égale à 60 V c.c. et à 30 V c.a. (efficace) dans la

seconde qui suit la déconnexion du véhicule de la borne d’alimentation électrique externe.

Le socle de connecteur doit satisfaire à au moins l’une des exigences suivantes si leurs parties actives

de classe de tension B sont protégées au moins selon un degré de protection IPXXB conformément à

l’ISO 20653:

— l’énergie entre contacts doit être inférieure à 0,2 J dans les dix secondes qui suivent la déconnexion

du véhicule de la borne d’alimentation électrique externe;

— la tension entre contacts doit être inférieure ou égale à 60 V c.c. et à 30 V c.a. (efficace) dans les dix

secondes qui suivent la déconnexion du véhicule de la borne d’alimentation électrique externe.

La tension ou l’énergie doit être mesurée au niveau du socle de connecteur non accouplé.

5.4.4 Contacts de la partie non accouplée du socle de connecteur de véhicule

Les contacts d’une partie non accouplée du socle de connecteur de véhicule doivent satisfaire à au moins

l’une des exigences suivantes, lorsque les autres contacts de ce socle de connecteur sont accouplés avec

une prise mobile (par exemple contacts c.c. non accouplés d’un socle de connecteur combiné et d’autres

contacts accouplés avec une prise mobile de type 1 ou de type 2 conformément à la série de normes

IEC 62196):

— l’énergie entre des contacts non accouplés doit être inférieure à 0,2 J si les parties actives sont

protégées selon au moins un degré de protection IPXXB conformément à l’ISO 20653;

— la tension entre des contacts non accouplés doit être inférieure ou égale à 60 V c.c. et à 30 V c.a.

(efficace) si les parties actives sont protégées selon au moins un degré de protection IPXXB

conformément à l’ISO 20653;

— la charge entre des contacts doit être inférieure à 50 µC si les parties actives ne sont pas protégées

selon au moins un degré de protection IPXXB conformément à l’ISO 20653.

10 © ISO 2015 – Tous droits réservés

5.5 Coordination de l’isolement

5.5.1 Généralités

Le circuit d’alimentation électrique du véhicule doit satisfaire aux parties applicables de la série de

normes IEC 60664 relative à la coordination de l’isolement et atteindre la capacité de tension de tenue

selon les détails indiqués en 5.5.2 ou 5.5.3.

Aucun claquage diélectrique et aucun contournement ne doivent survenir au cours de l’essai de tension

de tenue.

La conformité doit être évaluée par essai conformément à 12.4.

5.5.2 Connexion c.a. (modes 1, 2 et 3)

Le circuit d’alimentation électrique du véhicule doit être conçu selon la catégorie II de surtension, sauf

si une réduction appropriée des surtensions conformément à l’IEC 60664-1 est prévue dans le circuit

d’alimentation électrique du véhicule.

5.5.3 Connexion c.c. (mode 4)

Le circuit d’alimentation électrique du véhicule doit être calculé selon une tension de choc assignée d’au

moins 2 500 V.

NOTE L’IEC 61851–23 a adopté cette valeur fixe de tension de choc assignée indépendamment de la tension

d’entrée de la borne de charge en courant continu.

6 Protection contre les incidents thermiques

6.1 Protection contre les surintensités