ISO 21927-1:2008

(Main)Smoke and heat control systems — Part 1: Specification for smoke barriers

Smoke and heat control systems — Part 1: Specification for smoke barriers

ISO 21927-1:2008 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. ISO 21927-1:2008 provides the test methods for, and conformity assessment of, the smoke barrier systems. It covers only barriers installed in buildings; it does not cover barriers made of part of the building's structure. Smoke barriers are only covered by ISO 21927-1:2008 when calculation methods exist for the determination of the leakage rate of smoke. This requires the smoke barriers to be sufficiently fixed and guided on any free joints between two adjacent smoke barriers. An example is given of a design to which ISO 21927-1:2008 does not apply.

Systèmes pour le contrôle des fumées et de la chaleur — Partie 1: Spécifications des écrans de fumée

General Information

- Status

- Published

- Publication Date

- 06-Jan-2008

- Technical Committee

- ISO/TC 21/SC 11 - Smoke and heat control systems and components

- Drafting Committee

- ISO/TC 21/SC 11 - Smoke and heat control systems and components

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 22-Mar-2024

- Completion Date

- 12-Feb-2026

Overview: ISO 21927-1 (2008) - Smoke and heat control systems - Specification for smoke barriers

ISO 21927-1:2008 defines product performance, classification and test methods for smoke barriers used in building smoke and heat control systems (SHEVS). It covers both static smoke barriers (SSB) and active smoke barriers (ASB) - the barrier element itself, with or without associated activation and drive devices - and sets out how to assess conformity. The standard applies only to barriers installed in buildings (not to structural elements) and only where calculation methods exist to determine smoke leakage rate. ISO 21927-1 complements related parts of ISO 21927 for ventilators and is focused on ensuring reliable smoke containment and channelling during a fire.

Key topics and technical requirements

- Product requirements and classifications: Defines barrier types, temperature/time performance classes and containment efficiency.

- Leakage rate / containment efficiency: Specifies conditions for calculating and testing smoke leakage; requires barriers to be sufficiently fixed and guided at free joints.

- Reliability and durability: Tests and classifications for operational life, fail-safe behavior and prolonged performance under fire conditions.

- Response time: Requirements and test methods for the time an active smoke barrier takes to reach its fire-operational position.

- Auxiliary power and consumables: Rules for power supplies, fail-safe design and impact of consumable power sources on operation.

- Conformity assessment: Initial type testing, factory production control (FPC) and ongoing verification procedures.

- Installation, maintenance, marking: Guidance on correct installation, upkeep and labelling to ensure continued fitness for purpose.

- Normative annexes: Includes detailed test methods (reliability, permeability to smoke, temperature/time resistance, deflection and special 300 °C classifications).

Applications and practical value

ISO 21927-1 is intended to ensure smoke barriers perform predictably in real fires and integrate reliably into SHEVS to:

- Create smoke reservoirs and channel smoke

- Provide corridor, stairwell, escalator, elevator well and shop-unit containment

- Seal voids and control spill edges under balconies or canopies

- Reduce smoke logging and aid occupant evacuation and firefighting

The standard clarifies that smoke barriers may contain gases above 600 °C but are not substitutes for fire doors/shutters tested per fire-resistance standards.

Who uses this standard

- Fire safety engineers and consultants specifying SHEVS

- Manufacturers of smoke curtains, screens and powered barriers

- Building designers, specifiers and architects

- Installers and maintenance providers

- Certification bodies, testing laboratories and regulatory authorities

Related standards

- ISO 21927-2 (natural smoke and heat exhaust ventilators)

- ISO 21927-3 (powered smoke and heat exhaust ventilators)

- ISO 5925-1 (smoke-control doors and shutters - leakage tests)

- ISO 834-1, ISO 13943 and ISO/IEC 17000 / 17050 series (conformity assessment and fire vocabulary)

Keywords: ISO 21927-1, smoke barriers, SHEVS, smoke containment, leakage rate, active smoke barriers, smoke curtains, smoke and heat control systems.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO 21927-1:2008 is a standard published by the International Organization for Standardization (ISO). Its full title is "Smoke and heat control systems — Part 1: Specification for smoke barriers". This standard covers: ISO 21927-1:2008 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. ISO 21927-1:2008 provides the test methods for, and conformity assessment of, the smoke barrier systems. It covers only barriers installed in buildings; it does not cover barriers made of part of the building's structure. Smoke barriers are only covered by ISO 21927-1:2008 when calculation methods exist for the determination of the leakage rate of smoke. This requires the smoke barriers to be sufficiently fixed and guided on any free joints between two adjacent smoke barriers. An example is given of a design to which ISO 21927-1:2008 does not apply.

ISO 21927-1:2008 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. ISO 21927-1:2008 provides the test methods for, and conformity assessment of, the smoke barrier systems. It covers only barriers installed in buildings; it does not cover barriers made of part of the building's structure. Smoke barriers are only covered by ISO 21927-1:2008 when calculation methods exist for the determination of the leakage rate of smoke. This requires the smoke barriers to be sufficiently fixed and guided on any free joints between two adjacent smoke barriers. An example is given of a design to which ISO 21927-1:2008 does not apply.

ISO 21927-1:2008 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21927-1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21927-1

First edition

2008-01-15

Smoke and heat control systems —

Part 1:

Specification for smoke barriers

Systèmes pour le contrôle des fumées et de la chaleur —

Partie 1: Spécifications des écrans de fumée

Reference number

©

ISO 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2008 – All rights reserved

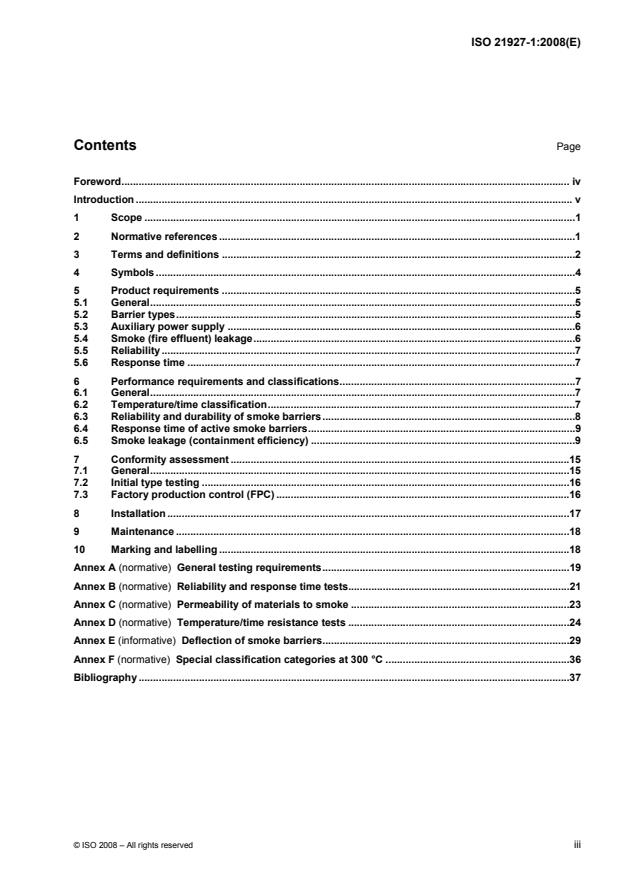

Contents Page

Foreword. iv

Introduction . v

1 Scope .1

2 Normative references .1

3 Terms and definitions .2

4 Symbols .4

5 Product requirements .5

5.1 General.5

5.2 Barrier types.5

5.3 Auxiliary power supply .6

5.4 Smoke (fire effluent) leakage.6

5.5 Reliability.7

5.6 Response time .7

6 Performance requirements and classifications.7

6.1 General.7

6.2 Temperature/time classification.7

6.3 Reliability and durability of smoke barriers.8

6.4 Response time of active smoke barriers.9

6.5 Smoke leakage (containment efficiency) .9

7 Conformity assessment .15

7.1 General.15

7.2 Initial type testing .16

7.3 Factory production control (FPC) .16

8 Installation .17

9 Maintenance .18

10 Marking and labelling .18

Annex A (normative) General testing requirements.19

Annex B (normative) Reliability and response time tests.21

Annex C (normative) Permeability of materials to smoke .23

Annex D (normative) Temperature/time resistance tests .24

Annex E (informative) Deflection of smoke barriers.29

Annex F (normative) Special classification categories at 300 °C .36

Bibliography .37

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 21927-1 was prepared by Technical Committee ISO/TC 21, Equipment for fire protection and fire fighting,

Subcommittee SC 11, Smoke and heat control systems and components.

ISO 21927 consists of the following parts, under the general title Smoke and heat control systems:

⎯ Part 1: Specification for smoke barriers

⎯ Part 2: Specification for natural smoke and heat exhaust ventilators

⎯ Part 3: Specification for powered smoke and heat exhaust ventilators

A Part 4, dealing with specifications for smoke ducts, a Part 5, dealing with specifications for smoke dampers,

a Part 6, dealing with specifications for control panels and a part 7, dealing with specifications or guidelines for

power supplies are planned.

iv © ISO 2008 – All rights reserved

Introduction

General

Smoke and heat exhaust ventilation systems (SHEVS) create a smoke-free layer above the floor by removing

smoke and heat and thus improve the conditions for the safe escape and/or rescue of people and animals and

the protection of property and permit the fire to be fought while still in its early stages.

The use of smoke and heat exhaust ventilation systems to create smoke-free areas beneath a buoyant smoke

layer has become widespread. Their value in assisting in the evacuation of people from construction works,

reducing fire damage and financial loss by preventing smoke logging, facilitating fire fighting, reducing roof

temperatures and retarding the lateral spread of fire is firmly established. To obtain these benefits, it is

essential that SHEVS operate fully and reliably whenever called upon to do so during their installed life. A

SHEVS is a scheme of safety equipment intended to perform a positive role in a fire emergency.

It is important that the components for smoke and heat exhaust systems be installed as part of a properly

designed smoke and heat exhaust system.

SHEVS help to

⎯ keep the escape and access routes free from smoke,

⎯ facilitate fire fighting operations by creating a smoke-free layer,

⎯ delay and/or prevent flashover and thus full development of the fire,

⎯ protect equipment and furnishings and contents,

⎯ reduce thermal effects on structural components during a fire,

⎯ reduce damage caused by thermal decomposition products and hot gases.

For the purpose of this part of ISO 21927, a smoke barrier is deemed to be any form of barrier to the

movement of fire effluent.

Smoke barriers control the movement of fire effluent within a construction works in the event of fire. Smoke

barriers, when used within a smoke and heat control system, become a critical element of that system. If

smoke barriers are not in their fire-operational position, the system does not perform as designed. However,

even in the event that other elements of the SHEVS do not function, smoke barriers in the fire operational

position provide essential smoke containment and channelling.

This part of ISO 21927 applies to smoke barriers used within smoke and heat control systems, which include

other equipment, e. g. natural smoke and heat exhaust ventilators (ISO 21927-2) and powered smoke and

heat exhaust ventilators (ISO 21927-3). Smoke barriers perform within specific time/temperature ranges.

Function of smoke barriers

The function of smoke barriers is to control the movement of fire effluent within construction works by forming

a barrier. The functions of active or manually deployed smoke barriers are identical to those of static smoke

barriers, but they also can be retracted and concealed when not in use.

Typical functions of smoke barriers are to

⎯ create a smoke reservoir by containing and limiting the travel of the smoke;

⎯ channel smoke in a pre-determined direction;

⎯ prevent or retard smoke entry to another area or void.

Applications of smoke barriers

The primary applications of smoke barriers are listed below. However, as their application becomes more

widespread, it is inevitable they will be put to a wider variety of uses. It is important to note that, within the

scope of this part of ISO 21927, smoke barriers can contain smoke and gases in excess of 600 °C but are not

intended to perform the same function as fire doors and shutters tested in accordance with ISO 3008 or

smoke-control doors tested in accordance with ISO 5925-1.

Typical applications for smoke barriers are as

⎯ smoke reservoir boundaries,

⎯ channelling screens,

⎯ void edge screens,

⎯ void sealing screens,

⎯ corridor containment,

⎯ shop unit containment,

⎯ escalator containment,

⎯ stairwell containment,

⎯ elevator well containment.

Types of smoke barrier

Construction-works elements can be used to create static smoke barriers and they can be augmented by

smoke barriers covered by this part of ISO 21927.

This part of ISO 21927 applies to the following types of smoke barriers:

⎯ static smoke barriers (SSB),

⎯ active smoke barriers (ASB).

A wide range of different materials can be used to create smoke barriers. Typical materials used for static

smoke barriers include fabric, glass, metal, fire-resisting board, fibreglass and mineral wool or any

impermeable material capable of resisting smoke at temperatures required by the design.

Typical examples of active smoke barriers include roller, pleated, folding, hinged or sliding, using the types of

material as described for static smoke barriers.

Static and active smoke barriers are categorized by type and performance in Clause 5.

In addition, an ASB product is deemed to include all controlling equipment, etc. This does not include external

controls, for example a fire alarm or a sprinkler flow switch.

vi © ISO 2008 – All rights reserved

INTERNATIONAL STANDARD ISO 21927-1:2008(E)

Smoke and heat control systems —

Part 1:

Specification for smoke barriers

1 Scope

This part of ISO 21927 specifies the product performance requirements, classifications and test methods for

smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices,

designed for use in smoke and heat control systems. It covers only barriers installed in buildings, i.e. it does

not cover barriers made of part of the building’s structure. This part of ISO 21927 provides the test methods

for, and conformity assessment of, the smoke barrier systems.

Smoke barriers are only covered by this part of ISO 21927 when calculation methods exist for the

determination of the leakage rate of smoke. This requires the smoke barriers to be sufficiently fixed and

guided on any free joints between two adjacent smoke barriers. Figure E.4 illustrates a design to which this

part of ISO 21927 does not apply.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 834-1, Fire-resistance tests — Elements of building construction — Part 1: General requirements

ISO 5925-1:2007 Fire tests — Smoke-control door and shutter assemblies — Part 1: Ambient- and medium-

temperature leakage tests

ISO 13943, Fire safety — Vocabulary

ISO/IEC 17000, Conformity assessment — Vocabulary and general principles

ISO/IEC 17050-1, Conformity assessment — Supplier's declaration of conformity — Part 1: General

requirements

ISO/IEC 17050-2, Conformity assessment — Supplier's declaration of conformity — Part 2: Supporting

documentation

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and the following apply.

3.1

active smoke barrier

smoke barrier that moves from its retracted position into its fire-operational position automatically when called

upon to do so

3.2

barrier movement

travel distance (e.g. height, drop) of an active barrier from its retracted position to its fire operational position

3.3

channelling screen

smoke barrier installed beneath a balcony or projecting canopy to direct the flow of smoke and hot gases from

a room opening to the spill edge

3.4

consumable power supplies

any form of power that, when not available, prevents an active smoke barrier from moving to the required fire

operational position

3.5

deflection

movement of a smoke barrier when subjected to the buoyant force of the hot smoke, the movement of air, air

pressure or any combination thereof

3.6

fail-safe

designed to return to a safe condition in the event of a failure or malfunction, etc.

3.7

fire operational position

final configuration of a device, e.g. a smoke barrier, specified by its designer to achieve and be sustained in

the ultimate fire condition of the design

3.8

fitness for purpose

ability of a product, process or service to serve a defined purpose under specific conditions

3.9

free area

total area of all designed openings and clearance gaps in and/or around the perimeter of a smoke barrier

3.10

integrity

ability of a barrier to maintain its soundness for the purpose for which it is intended without the transmission of

significant quantities of flames or hot gases to the non-exposed side

3.11

life safety application

application of the smoke and heat control system in its fire operational condition for the period of time required

for the occupants of the premises to be alerted, and to be able to exit the premises, with the smoke and heat

control system assisting in the protection of the means of escape

3.12

response time

time taken for an active smoke barrier to move to its fire operational position after initiation

2 © ISO 2008 – All rights reserved

3.13

smoke and heat exhaust ventilation system

SHEVS

set of components jointly selected to exhaust smoke and heat in order to establish a buoyant layer of warm

smoke above cooler, cleaner air

3.14

smoke and heat control system

arrangement of components installed in a construction works to limit the effects of smoke and heat from a fire

3.15

smoke barrier

device to channel, contain and/or prevent the migration of smoke (fire effluent)

NOTE Smoke barriers can also be referred to as smoke curtains, smoke blinds or smoke screens.

3.16

smoke reservoir

region within a construction works limited or bordered by smoke barriers or structural elements so as to retain

a thermally buoyant smoke layer in the event of a fire

3.17

spill edge

edge of a soffit beneath which a smoke layer is flowing and adjacent to a void, e.g. the edge of a balcony or

canopy or the top edge of a window through which the smoke is flowing out of a room

3.18

static smoke barrier

smoke barrier permanently fixed in its fire operational position

3.19

void edge screen

smoke barrier deployed beneath the edge of a balcony or projecting canopy

NOTE Void edge screens can be used either to create a smoke reservoir beneath the balcony or canopy or to restrict

the length of spill edge in order to create a more compact spill plume

3.20

void-sealing screen

smoke barrier deployed across a void to create a smoke reservoir beneath the smoke barrier

4 Symbols

A to A Area of the gaps between smoke barriers, or between barrier and structure, expressed in

g,a g,f

square metres

A Total free area of the smoke barrier system, calculated as the sum of the areas of the individual

g,tot

gaps between smoke barriers, or between barrier and structure, expressed in square metres

A Total area of the gaps in the head, obtained by summing the areas of the individual gaps, g

h,tot h,a

to g .

h,f

d Horizontal deflection of a smoke barrier, measured at its bottom bar, expressed in metres

C

D

Distance of movement (drop) of smoke barrier, expressed in millimetres

D Design depth of a smoke layer in a reservoir, expressed in metres

l

g Acceleration due to gravity, expressed in metres per square second

g Edge gap between the barrier and the surrounding construction, expressed in millimetres

e

g g Gaps the in header box, expressed in millimetres (see Figure 1)

h,a,… h,f

g Joint gap between adjacent barriers, expressed in millimetres

j

g Maximum joint gap when barriers are in the fire operational condition, expressed in millimetres;

j,max

g = g /2

j j,max

h Height of rise of a thermal line plume from an opening or balcony edge to the smoke layer,

B

expressed in metres

h Height of an opening

O

h Height of rise of leakage gases from the base of the hot gas layer in the smoke reservoir to the

p

ceiling in the adjacent protected area, expressed in metres

L Length of the smoke barrier from top to bottom bar, measured along the fabric, expressed in

C

metres

M Mass per metre length of the barrier’s bottom bar, expressed in kilograms per metre

b

M Mass flow rate under a balcony, expressed in kilograms per second

B

M Mass per square metre of the barrier fabric, expressed in kilograms per square metre

C

M Mass of gas flowing through a gap, expressed in kilograms per second

g

M Mass of gas flowing into the gas layer in a protected area after having leaked through gaps in

p

smoke barriers, expressed in kilograms per second

t Time, expressed in minutes

T

Absolute temperature of gases, expressed in kelvin

T Absolute temperature of gas layer in a reservoir, expressed in kelvin

I

T Absolute ambient temperature, expressed in kelvin

Temperature rise above ambient of smoky gases in a reservoir, expressed in degrees Celsius

θ

l

ρ Density of ambient air, expressed in kilograms per cubic metre

W Width of smoke barrier, expressed in millimetres

4 © ISO 2008 – All rights reserved

5 Product requirements

5.1 General

The smoke barrier requirements are intended to provide the SHEVS designers with smoke barriers that fulfil

the system design requirements. Compliance with this part of ISO 21927 does not necessarily, by itself,

ensure fitness for purpose for an application, as defined in ISO/IEC Guide 2.

The system design parameters dictate the minimum classification and performance of smoke barriers that can

be used in any particular application. The criteria for the correct choice of smoke barrier shall take into

account the total system, function and location requirements without hindering the means of escape or

endangering the occupants.

5.2 Barrier types

5.2.1 General

Smoke barriers shall be defined as one of the following types:

⎯ static smoke barrier: flexible material;

⎯ static smoke barrier: rigid material;

⎯ active smoke barrier: flexible material;

⎯ active smoke barrier: rigid material.

5.2.2 Static smoke barriers (SSB)

Static smoke barriers shall be fixed in their fire operational position at all times and according to their design

classification.

NOTE Static smoke barriers are used as alternatives and/or additions to the elements of the construction works that

can act as permanent static smoke barriers.

5.2.3 Active smoke barriers (ASB)

Active smoke barriers shall move to the fire operational position upon external initiation and according to their

design classification. Active smoke barriers shall be defined according to their application, e.g. life safety

protection or property protection, method of operation and external initiations.

NOTE Active smoke barriers are used as alternatives and/or additions to elements of the construction works that can

act as permanent static smoke barriers.

Active smoke barriers shall be categorized as follows:

⎯ ASB1: smoke barriers that fail safe in/to the fire operational position (not lower than 2,5 m above the

finished floor level or in any location hazardous to occupants or objects), in a controlled manner (see 6.4)

when all consumable primary and auxiliary power sources are removed, in the event of wiring or system

corruption, or any combination thereof;

⎯ ASB2: smoke barriers that move to/stay in the fire operational position (not lower than 2,5 m above the

finished floor level or in any location hazardous to occupants or objects), in a controlled manner (see 6.4)

upon external initiation but requiring a consumable power source in order to move to or be maintained in

the fire operational position;

⎯ ASB3: smoke barriers, conforming to type ASB1, that can be deployed to any height (see 6.4);

⎯ ASB4: smoke barriers conforming to ASB2, that can be deployed to any height (see 6.4).

In the majority of applications, active smoke barriers shall fail safe. But if it is necessary for the smoke barrier

to remain retracted, even in the event of fail-safe, the system shall be so designed and tested.

ASB1 and ASB3 do not require fire-rated cables or cable systems.

Active smoke barriers without the fail-safe facility i.e. those requiring a power source to drive them down

(ASB2 and ASB4), require fire-rated cables or cable systems.

In certain applications, smoke barriers are used for life-safety applications where types ASB1 and ASB3 may

be more fit for purpose.

5.3 Auxiliary power supply

If batteries are used as the primary or auxiliary power source (types ASB2 and ASB4), batteries shall be

submitted to an active battery test at intervals not exceeding 60 min. During this test, the connected load shall

be at least 110 % of the normal motor current and shall be powered solely from the battery set. A fault-

indicating signal shall be given as a volt-free contact and as an optical indication on the control panel upon

⎯ battery set insufficiently charged,

⎯ faulty battery set (e.g. short circuit),

⎯ battery set not connected to load (e.g. open circuit).

Upon detection of a fault signal, the active smoke barrier shall move to the fire operational position.

Other stored energy systems shall have an equivalent level of monitoring and shall be capable of moving the

barrier to its fire operational position upon detection of a fault signal.

Power supplies shall comply with regulatory requirements valid in the place of use.

5.4 Smoke (fire effluent) leakage

5.4.1 Openings, gaps and/or perimeter spaces

The free area through and around the complete system, materials and joints inherent in the product design

shall be stated by the manufacturer.

All gaps in and around all types of smoke barrier shall be minimized to maintain the smoke-barrier

containment efficiency as defined in 6.5.

Deflection of a smoke barrier can occur due to pressure differences or air movement. This can increase edge

gaps or reduce the effective smoke-reservoir depth. The system design shall take this into consideration (see

6.5.2).

Care should be taken to ensure that any adjacent surfaces that form part of the barrier to smoke, e.g. false

ceilings or fittings, have properties, e.g. resistance to temperature and permeability, at least equivalent to

those of the smoke barrier.

NOTE The above criteria require consideration to ensure the efficiency of the smoke barrier to control the movement

of fire effluent and aid the effectiveness of the SHEVS.

6 © ISO 2008 – All rights reserved

5.4.2 Permeability of materials

The smoke barrier shall be manufactured from materials that restrict the passage of smoke (see Annex C and

6.5.5).

Where a specific system leakage rate is required, a complete product shall be tested to ISO 5925-1

(see 6.5.5).

5.5 Reliability

The reliability of smoke barriers shall be determined in accordance with 6.3.

5.6 Response time

The response time of active smoke barriers shall conform to 6.4.

6 Performance requirements and classifications

6.1 General

Smoke barriers shall be tested in the orientation and use intended by the manufacturer for their application

and installation.

6.2 Temperature/time classification

The temperature/time classifications of all smoke barriers shall be determined in accordance with the test

methods in Annex D.

Smoke barriers shall be classified in accordance with the classification categories in Table 1.

Table 1 — Standard classification categories

a

Temperature Time

Classification

°C min

D 30 600 30

D 60 600 60

D 90 600 90

D 120 600 120

DA 600 Actual time reached above 120

a

See Annex F for the application of additional classification categories at 300 °C (DL).

The heat exposure at 600°C, designated “D”, represents the constant temperature of the smoke barrier test.

The designations “30”, “60”, “90”, “120” represent the period of the smoke barrier test. A smoke barrier that

meets the requirements of D 60 also meets the requirements of D 30; equally, a D 90, or D 120, smoke barrier

also meets the requirements of all categories with shorter times. A DA smoke barrier meets all “D”

requirements.

If smoke barriers are intended for operation at higher time/temperature ranges, they shall be classified in

accordance with the classification categories in Table 2. The testing shall meet the time/temperature

requirements of ISO 834-1.

Table 2 — Classification categories for smoke barriers operating at higher temperatures

Classification Temperature Time

°C min

DH 30 Standard heating curve 30

(ISO 834-1)

DH 60 As above 60

DH 90 As above 90

DH 120 As above 120

DHA As above Actual time reached above 120

The performance requirements of smoke barrier test specimens, when tested in accordance with Annex D,

are as follows.

a) Test specimens shall conform to Clause A.1.

b) Test specimens shall maintain integrity, without either

1) permitting the penetration of a gap gauge (except for those free areas defined in 5.4.1 and 6.5);

2) resulting in sustained flaming;

3) collapsing.

c) Test specimens shall not release flaming droplets or particles within the first 600 s when tested in

accordance with this part of ISO 21927.

Observation of any components or droplets falling during the test is recorded in the test report. When selecting

a barrier for a particular application where falling components can be considered a significant threat to

occupants, for example where people are expected to escape beneath smoke barriers, the full test report

should be obtained and checked.

6.3 Reliability and durability of smoke barriers

6.3.1 Reliability and durability of smoke barriers — Static smoke barriers

The manufacturer/supplier shall provide verification that the materials used for static smoke barriers are fit for

the purpose intended. For integrity and perforations, see Clause B.3; and for gaps, see 6.5.3.

This should be done taking into account, for example, breaking loads, tear strength, flexural strength and

resistance-to-flexing requirements valid in the place of use.

6.3.2 Reliability of smoke barriers — Active smoke barriers

Active smoke barrier specimens conforming to Clause A.1 shall be tested in accordance with the reliability test

in Annex B and shall complete the required number of cycles and shall then not allow the passage of either of

the defined gap gauges (except for those free areas defined in 5.4.1 and 6.5).

8 © ISO 2008 – All rights reserved

6.4 Response time of active smoke barriers

Active smoke barrier specimens conforming to Clause A.1 shall be tested in accordance with the response

time test in Annex B and shall operate within the velocity ranges specified in this subclause.

Active smoke barrier specimens types ASB1 and ASB2 shall commence movement immediately upon

initiation or any initiation failure and move to their operational position, in all operating modes, at a velocity

range of between 0,06 m/s and 0,30 m/s.

Active smoke barriers types ASB3 and ASB4 that are located in critical areas of a construction works, e.g.

escape routes, entrances/exits to escalators or stairways, shall have a velocity range of 0,06 m/s to 0,15 m/s.

Active smoke barriers with long barrier movements that cannot be fully deployed within 60 s in order to

conform to the requirements of this subclause, can, nevertheless, provide progressive protection. Such

operation should not compromise SHEVS design, e.g. for a single barrier that is designed to protect multiple

floors around an atrium, the protection to higher floors can be delayed when the fire occurs on a lower floor.

Precautions should be taken to ensure that descending barriers in such areas do not cause injury, panic,

confusion, etc., e.g. by the use of visual or audible warnings, and partial and progressive descent of barriers

should be considered.

The above criteria require consideration to ensure the efficiency of the smoke barrier to control the movement

of fire effluent and aid the effectiveness of the SHEVS.

6.5 Smoke leakage (containment efficiency)

6.5.1 General

Smoke barriers have a functional requirement to channel, contain and/or prevent the migration of smoke (fire

effluent). The provisions of 6.5.2 to 6.5.5 shall therefore be followed.

6.5.2 Gaps and leakage areas

Operational gaps and/or areas of leakage of a barrier shall be stated for the product by the manufacturer (see

Figures 1 to 10, which illustrate possible operational gaps required by the design of roller type smoke barrier

applications). These gaps can increase under fire conditions; see Annex E.

NOTE Barriers can require operational tolerances, e.g. static barriers installed in buildings with expansion

characteristics or active barriers at corners.

The system designer, when calculating for a specific installation, should take containment efficiency into

consideration.

Key

1 barrier

g to g gaps in the header box

h,a h,f

a

Smoke flow through the head box is controlled by the smallest gap when the barrier is in the fire operational position.

Gaps g to g are representative of the potential smallest gaps. It is recommended to use the gap, g to g , with the

h,a h,f h,a h,f

smallest value.

Figure 1 — Potential gaps within a header box when barrier deployed

Key

1 barrier

2 wall

g edge gap between a barrier and the surrounding construction

e

Figure 2 — Potential edge gaps between the barrier and surrounding construction

10 © ISO 2008 – All rights reserved

Key

g joint gap between barriers

j

a

The gap is measured with the barriers in their fire operational position.

Figure 3 — Gaps between adjacent barriers when overlapped but not conjoined

Key

g maximum gap when barriers are in the fire operational condition, expressed in millimetres

j,max

D distance of movement (drop) of smoke barrier, expressed in millimetres

a

gg= 2 .

jj,max

Figure 4 — Gaps between adjacent barriers when overlapped and conjoined

Figure 5 — Barriers overlapped with no gaps at the overlap

Key

g joint gap

j

a

The gap shown is in the passive condition.

Figure 6 — Adjacent barriers with no overlap

12 © ISO 2008 – All rights reserved

Key

1 barrier

g joint gap

j

a

To prevent independent barrier movement, the barrier bottoms are generally conjoined at the corner.

Figure 7 — Adjacent barriers at a corner

6.5.3 Openings, gaps and/or perimeter spaces

Smoke barriers that do not require functional tolerances shall have all gaps sealed to prevent smoke leakage.

Active smoke barriers shall be overlapped and conjoined where they are fixed in a straight line to prevent

leakage. Where this cannot be achieved or if products are manufactured otherwise, the designer shall make

allowances for increased leakage within his calculations (see Annex E).

For the typical roller barriers shown in Figures 1 to 9, the area, e.g. A , of an individual gap, expressed in

g,a

millimetres, is calculated as given in Equation (1):

A = W × g (1)

g,a a h,a

where W is the width of the smoke barrier, expressed in millimetres, associated with g .

a h,a

The total area, A , of the gaps in the head is obtained by summing the areas of the individual gaps, g to

h,tot h,a

g , as given in Equation (2):

h,f

A=+AA+ .A (2)

g,tot ∑ g,a g,b g,f

The area of each edge gap and joint gap, A and A , respectively, expressed in square millimetres, is

e,a j,a

calculated as given in Equations (3) and (4), respectively:

A = D × g (3)

e e

A = D × g (4)

j j

where D is the distance of movement (drop) of the smoke barrier, expressed in millimetres.

The total areas of the edge gaps and the joint gaps, A and A , respectively, expressed in square

e,tot j,tot

millimetres, are calculated by summing the areas of all the individual gaps.

The total free area, A , of the smoke barrier system is calculated by summing the areas of the head gaps, the

tot

joint gaps and the edge gaps, as given in Equation (5):

A = A + A + A (5)

tot g,tot e,tot j,tot

For functional reasons, gaps can be required between the barrier and the construction works, and for angled

and adjacent barriers. In these cases, any gap, based on the maximum travel distance specified by the

manufacturer, should not exceed

a) 20 mm for barriers that travel up to and including 2 m;

b) 40 mm for barriers that travel from 2 m up to and including 6 m;

c) 60 mm for barriers that travel more than 6 m.

For static barriers, the expansion and contraction characteristics of the construction works should be taken

into account when calculating the gaps. The attachment of the barrier to the structure, the load and the

temperature should be verified. The load includes the barrier’s own mass, side pressure from the fire-side

(20 Pa) and a safety coefficient. The minimum dilatation gap should be left. When panels are used to form the

barrier, the connections should be tight and resistant to loading and temperature changes (see Figure 8).

Static and active smoke barriers can require functional tolerances, within the construction of the smoke barrier

assembly itself, between the smoke barrier, another barrier and/or the construction works.

Any gaps within a smoke-barrier system should not prejudice the fitness for purpose of the system in

accordance with the system design. Any gaps above or around the smoke-barrier assembly in the smoke

reservoir should be sealed or minimized.

Key

1 barrier

Figure 8 — Example of a static smoke barrier, flexible or rigid material

14 © ISO 2008 – All rights reserved

6.5.4 Deflection

Static and active smoke barriers shall perform in accordance with the functional requirements of the system

design, other SHEVS design requirements and construction works requirements for the intended application.

In all tests, the smoke barrier shall be mounted as in practice, including the specified barrier mass and

tensioning force where required to reduce deflection. Deflection shall be assessed using a suitable method of

calculating deflection to ensure that it is valid for the application. A method of calculating deflection is given in

Annex E.

Smoke barriers in continuous, overlapped and conjoined runs provide additional resistance to deflection and

smoke leakage. The gaps between adjacent smoke barriers conforming to 6.5.3 are maintained when

conjoined (for example, by using conjoined bottom bars). Where this cannot be achieved or if products are

manufactured otherwise, the designer shall make allowances for increased leakage within his calculations

(see Annex E).

Care should be taken to ensure that the smoke barriers are positioned in the construction works in such a way

as to minimize problems caused by deflection, e.g. barriers placed between curved columns can conform in

the passive condition but, when subjected to deflecting conditions, move away from the columns creating

large gaps and unacceptable smoke leakage.

Figure 9 shows a lightweight smoke barrier mounted adjacent to columns. Even with a heavy bottom bar or

retained in guides, large side and lateral lift gaps can occur.

Figure 10 shows a lightweight barrier mounted adjacent to columns. When not retained, large side and lateral

lift gaps occur.

6.5.5 Permeability of materials

Smoke barriers shall be manufactured from materials conforming to Annex C with a maximum leakage rate of

3 2 1)

25 m /h/m at 25 Pa and ambient and/or medium temperature . If the leakage test is carried out only at one

temperature (either ambient or medium temperature), then it is necessary that the product be declared for the

temperature at which the test was carried out.

NOTE The permeability of materials is tested by samples with a size of (1 × 1) m (see Annex C).

7 Conformity assessment

7.1 General

The compliance of a smoke barrier with the requirements of this part of ISO 21927 shall be demonstrated by

⎯ initial type testing,

⎯ factory production control by the manufacturer.

Conformity assessment for products in accordance with this part of ISO 21927 shall be according to

ISO/IEC 17000, ISO/IEC 17050-1 and ISO/IEC 17050-2.

1) ISO 5925-1:2007 allows a test at ambient as well as at medium temperature. ISO 5925-1:1981 (which has been

withdrawn) allowed only for a test at ambient temperature.

7.2 Initial type testing

All characteristics given in Clauses 5 and 6 shall be subject to initial type testing, except as described in

paragraph 2 of this subclause. Tests shall be carried out in accordance with Annexes A, B, C, D and, if

required, F.

Tests previously performed in accordance with the provisions of this part of ISO 21927 [same product, same

characteristic(s), test method, sampling procedure, etc.)] may be taken into account.

In addition, initial type testing shall be performed at the beginning of the production of a new product type or at

the beginning of a new method of production (where these can affect the stated properties).

7.3 Factory production control (FPC)

A FPC system conforming with the requirements of ISO 9001, and made specific to the requirements of this

part of ISO 21927, is considered to satisfy the requirements of this part of ISO 21927.

Key

1 excessive gaps

Figure 9 — Example of excess gap caused by deflection

16 © ISO 2008 – All rights reserved

Key

1 excessive gaps

Figure 10 — Example of excess gap caused by deflection

8 Installation

The supplier shall provide appropriate installation information, which shall include the following:

a) fixing component information;

b) power requirements and connections (active smoke barriers only);

c) installation instructions, including perimeter requirements where applicable;

d) commissioning procedure;

e) operating instruction (active smoke barriers only);

f) warnings to avoid obstructions to operation (active smoke barriers only);

g) penetrations (static only);

h) operating instructions, with maximum operating and loading tolerance for the product, e. g. maximum

barrier mass, bottom bar masses, minimum/maximum motor speeds, overlapping and conjoining, and

fixing methods.

Care should be taken to ensure that the operation of an active smoke barrier is not obstructed, e.g. by

cosmetic finishes, lighting, shelving, sales displays or racking.

9 Maintenance

In order to ensure continued c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...