ISO 23551-11:2024

(Main)Safety and control devices for gas burners and gas-burning appliances — Particular requirements — Part 11: Automatic and semi-automatic shut-off valves for operating pressure of above 500 kPa up to and including 6 300 kPa

Safety and control devices for gas burners and gas-burning appliances — Particular requirements — Part 11: Automatic and semi-automatic shut-off valves for operating pressure of above 500 kPa up to and including 6 300 kPa

This document specifies safety, constructional and performance requirements and testing of automatic, semi-automatic shut-off valves, and general purpose valves for gas burners, gas appliances and appliances of similar use excluding use in fuel gas infrastructures (transportation and distribution systems). This document applies to controls for use at maximum operating pressures above 500 kPa up to and including 6 300 kPa with sizes up to DN 250 for use on burners or in appliances using fuel gases, such as natural gas, manufactured gas or liquefied petroleum gas (LPG). This document applies to: — valves being mounted in gas installations; — valves directly or indirectly actuated, electrically or by mechanical means; — valves actuated by hydraulic or pneumatic means, including the pilot valves for these fluids if actuated electrically and including release valves, but not to any external electrical devices for switching the actuating energy; — valves where the flow rate is controlled by external electrical signals, either in discrete steps or proportional to the applied signal and valves fitted with closed position indicator switches; — valves to be used in appliances, but not in gas transfer systems outside appliances. This document covers type testing only. This document does not apply to valves covered under the scope of ISO 23551-1 or the ISO 23555 series.

Dispositifs de commande et de sécurité pour brûleurs à gaz et appareils à gaz — Exigences particulières — Partie 11: Robinets automatiques et semi-automatiques de sectionnement pour une pression de fonctionnement supérieure à 500 kPa et jusqu'à 6 300 kPa inclus

General Information

- Status

- Published

- Publication Date

- 21-Nov-2024

- Technical Committee

- ISO/TC 161 - Controls and protective devices for gas and/or oil

- Drafting Committee

- ISO/TC 161 - Controls and protective devices for gas and/or oil

- Current Stage

- 6060 - International Standard published

- Start Date

- 22-Nov-2024

- Due Date

- 20-Jan-2025

- Completion Date

- 22-Nov-2024

Overview

ISO 23551-11:2024 specifies safety, constructional and performance requirements and type testing for automatic and semi-automatic shut-off valves and general-purpose valves used on gas burners and gas-burning appliances. It applies to valves for operating pressures above 500 kPa up to and including 6 300 kPa, with sizes up to DN 250, for fuels such as natural gas, manufactured gas and LPG. The standard is focused on controls installed on appliances (not on fuel gas transportation or distribution infrastructures) and covers electrically, mechanically, pneumatically or hydraulically actuated devices, including pilot valves when electrically actuated.

Key topics and technical requirements

ISO 23551-11 includes comprehensive requirements and test regimes. Major topics covered are:

- Classification of controls by sealing force, pressure surge characteristics, control function and device groups.

- Test conditions and tolerances for type testing (environmental and operational test parameters).

- Constructional requirements including housing, moving parts, breather/vent provisions, pre-setting devices and closed position indication.

- Materials guidance for housings, springs, seals, corrosion protection and bellows, plus hydrostatic strength considerations.

- Connections and permitted connection types (flanges, threads, compression fittings, etc.) up to DN 250.

- Performance tests such as leak-tightness, pressure surge resistance, rated flow rate verification, torsion and bending, and vibration.

- Functional and durability tests: closing function, closing/sealing forces, delay/opening/closing times, endurance testing.

- Endurance and durability criteria to confirm long-term performance under expected service conditions.

- Electrical requirements for valves and components where electrical actuation or signal control is employed.

Note: ISO 23551-11 addresses type testing only; it does not cover every aspect of production quality control or installation practices.

Practical applications and users

This standard is intended for organizations and professionals involved in the design, manufacture, testing and specification of gas appliance controls:

- Valve and actuator manufacturers designing shut-off devices for high-pressure gas appliances.

- Gas appliance and burner manufacturers specifying compliant safety controls for appliances operating above 500 kPa.

- Testing laboratories and certification bodies carrying out type testing and conformity assessment.

- Regulatory authorities and standards writers referencing performance and safety benchmarks for appliance-level gas controls.

- Specifiers and procurement teams selecting valves (DN 250 and below) for gas burner systems that require documented type-tested safety controls.

Related standards

- ISO 23551 series (other parts) - related appliance control requirements; ISO 23551-1 and the ISO 23555 series are explicitly outside the scope of this part.

- General ISO guidance on safety and control devices for gas-burning appliances.

Keywords: ISO 23551-11, shut-off valves, gas burners, gas-burning appliances, high-pressure valves, automatic shut-off, semi-automatic shut-off, DN 250, type testing, gas appliance safety.

ISO 23551-11:2024 - Safety and control devices for gas burners and gas-burning appliances — Particular requirements — Part 11: Automatic and semi-automatic shut-off valves for operating pressure of above 500 kPa up to and including 6 300 kPa Released:11/22/2024

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

ISO 23551-11:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Safety and control devices for gas burners and gas-burning appliances — Particular requirements — Part 11: Automatic and semi-automatic shut-off valves for operating pressure of above 500 kPa up to and including 6 300 kPa". This standard covers: This document specifies safety, constructional and performance requirements and testing of automatic, semi-automatic shut-off valves, and general purpose valves for gas burners, gas appliances and appliances of similar use excluding use in fuel gas infrastructures (transportation and distribution systems). This document applies to controls for use at maximum operating pressures above 500 kPa up to and including 6 300 kPa with sizes up to DN 250 for use on burners or in appliances using fuel gases, such as natural gas, manufactured gas or liquefied petroleum gas (LPG). This document applies to: — valves being mounted in gas installations; — valves directly or indirectly actuated, electrically or by mechanical means; — valves actuated by hydraulic or pneumatic means, including the pilot valves for these fluids if actuated electrically and including release valves, but not to any external electrical devices for switching the actuating energy; — valves where the flow rate is controlled by external electrical signals, either in discrete steps or proportional to the applied signal and valves fitted with closed position indicator switches; — valves to be used in appliances, but not in gas transfer systems outside appliances. This document covers type testing only. This document does not apply to valves covered under the scope of ISO 23551-1 or the ISO 23555 series.

This document specifies safety, constructional and performance requirements and testing of automatic, semi-automatic shut-off valves, and general purpose valves for gas burners, gas appliances and appliances of similar use excluding use in fuel gas infrastructures (transportation and distribution systems). This document applies to controls for use at maximum operating pressures above 500 kPa up to and including 6 300 kPa with sizes up to DN 250 for use on burners or in appliances using fuel gases, such as natural gas, manufactured gas or liquefied petroleum gas (LPG). This document applies to: — valves being mounted in gas installations; — valves directly or indirectly actuated, electrically or by mechanical means; — valves actuated by hydraulic or pneumatic means, including the pilot valves for these fluids if actuated electrically and including release valves, but not to any external electrical devices for switching the actuating energy; — valves where the flow rate is controlled by external electrical signals, either in discrete steps or proportional to the applied signal and valves fitted with closed position indicator switches; — valves to be used in appliances, but not in gas transfer systems outside appliances. This document covers type testing only. This document does not apply to valves covered under the scope of ISO 23551-1 or the ISO 23555 series.

ISO 23551-11:2024 is classified under the following ICS (International Classification for Standards) categories: 27.060.20 - Gas fuel burners. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 23551-11:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 23551-11

First edition

Safety and control devices for

2024-11

gas burners and gas-burning

appliances — Particular

requirements —

Part 11:

Automatic and semi-automatic

shut-off valves for operating

pressure of above 500 kPa up to and

including 6 300 kPa

Dispositifs de commande et de sécurité pour brûleurs à gaz et

appareils à gaz — Exigences particulières —

Partie 11: Robinets automatiques et semi-automatiques de

sectionnement pour une pression de fonctionnement supérieure à

500 kPa et jusqu'à 6 300 kPa inclus

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

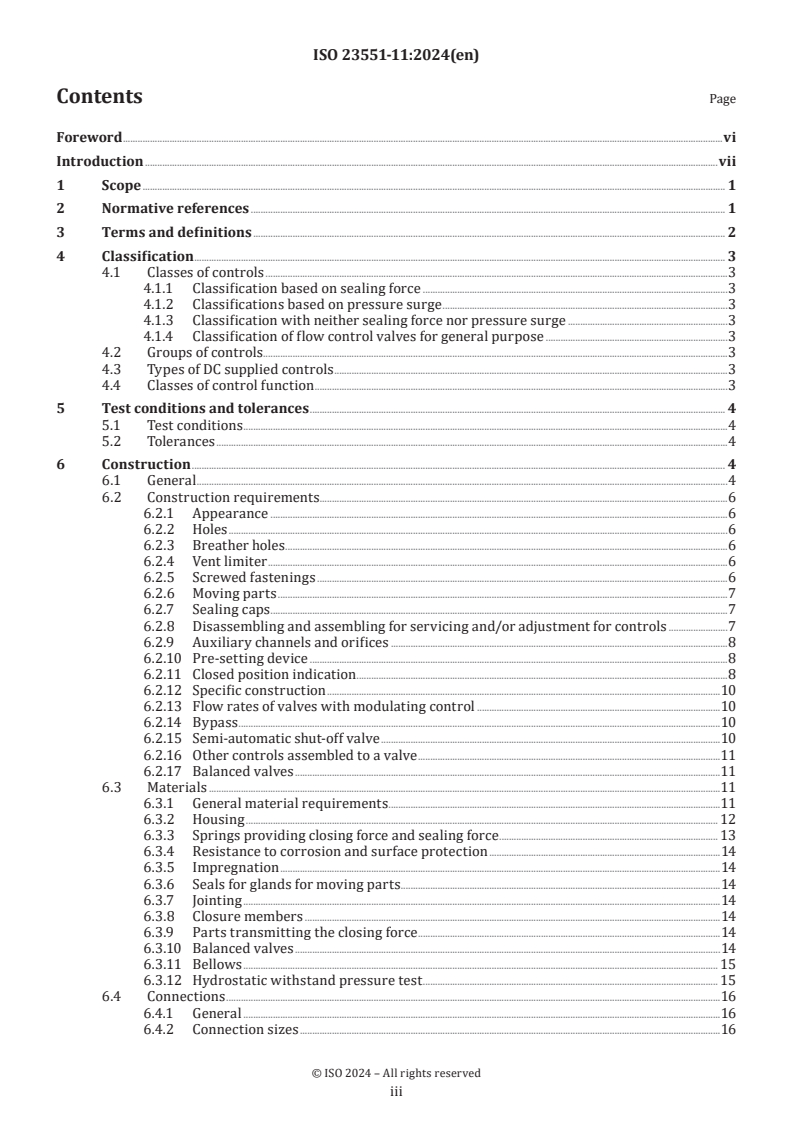

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Classification . 3

4.1 Classes of controls .3

4.1.1 Classification based on sealing force .3

4.1.2 Classifications based on pressure surge .3

4.1.3 Classification with neither sealing force nor pressure surge .3

4.1.4 Classification of flow control valves for general purpose .3

4.2 Groups of controls .3

4.3 Types of DC supplied controls .3

4.4 Classes of control function .3

5 Test conditions and tolerances . 4

5.1 Test conditions .4

5.2 Tolerances .4

6 Construction . 4

6.1 General .4

6.2 Construction requirements.6

6.2.1 Appearance .6

6.2.2 Holes .6

6.2.3 Breather holes .6

6.2.4 Vent limiter .6

6.2.5 Screwed fastenings .6

6.2.6 Moving parts .7

6.2.7 Sealing caps .7

6.2.8 Disassembling and assembling for servicing and/or adjustment for controls .7

6.2.9 Auxiliary channels and orifices .8

6.2.10 Pre-setting device .8

6.2.11 Closed position indication .8

6.2.12 Specific construction .10

6.2.13 Flow rates of valves with modulating control .10

6.2.14 Bypass .10

6.2.15 Semi-automatic shut-off valve .10

6.2.16 Other controls assembled to a valve .11

6.2.17 Balanced valves .11

6.3 Materials .11

6.3.1 General material requirements .11

6.3.2 Housing . 12

6.3.3 Springs providing closing force and sealing force . 13

6.3.4 Resistance to corrosion and surface protection .14

6.3.5 Impregnation .14

6.3.6 Seals for glands for moving parts.14

6.3.7 Jointing .14

6.3.8 Closure members .14

6.3.9 Parts transmitting the closing force .14

6.3.10 Balanced valves .14

6.3.11 Bellows . 15

6.3.12 Hydrostatic withstand pressure test . 15

6.4 Connections .16

6.4.1 General .16

6.4.2 Connection sizes .16

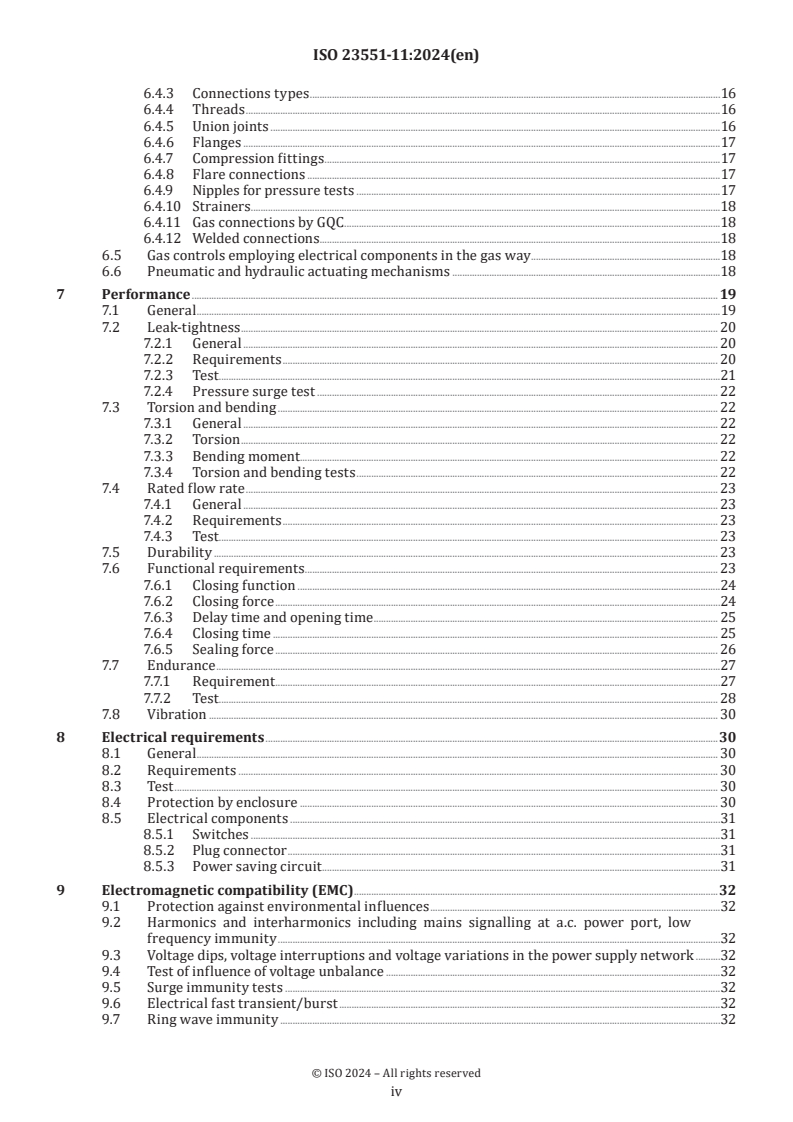

iii

6.4.3 Connections types .16

6.4.4 Threads .16

6.4.5 Union joints .16

6.4.6 Flanges .17

6.4.7 Compression fittings .17

6.4.8 Flare connections .17

6.4.9 Nipples for pressure tests .17

6.4.10 Strainers . . .18

6.4.11 Gas connections by GQC .18

6.4.12 Welded connections . .18

6.5 Gas controls employing electrical components in the gas way .18

6.6 Pneumatic and hydraulic actuating mechanisms .18

7 Performance . 19

7.1 General .19

7.2 Leak-tightness . 20

7.2.1 General . 20

7.2.2 Requirements . 20

7.2.3 Test . . .21

7.2.4 Pressure surge test . 22

7.3 Torsion and bending . 22

7.3.1 General . 22

7.3.2 Torsion . 22

7.3.3 Bending moment . . 22

7.3.4 Torsion and bending tests . 22

7.4 Rated flow rate . 23

7.4.1 General . 23

7.4.2 Requirements . 23

7.4.3 Test . . . 23

7.5 Durability . 23

7.6 Functional requirements . . 23

7.6.1 Closing function .24

7.6.2 Closing force .24

7.6.3 Delay time and opening time . 25

7.6.4 Closing time . 25

7.6.5 Sealing force . 26

7.7 Endurance .27

7.7.1 Requirement .27

7.7.2 Test . . . 28

7.8 Vibration . 30

8 Electrical requirements .30

8.1 General . 30

8.2 Requirements . 30

8.3 Test . 30

8.4 Protection by enclosure . 30

8.5 Electrical components .31

8.5.1 Switches .31

8.5.2 Plug connector .31

8.5.3 Power saving circuit .31

9 Electromagnetic compatibility (EMC) . .32

9.1 Protection against environmental influences .32

9.2 Harmonics and interharmonics including mains signalling at a.c. power port, low

frequency immunity .32

9.3 Voltage dips, voltage interruptions and voltage variations in the power supply network .32

9.4 Test of influence of voltage unbalance .32

9.5 Surge immunity tests .32

9.6 Electrical fast transient/burst .32

9.7 Ring wave immunity .32

iv

9.8 Electrostatic discharge . 33

9.9 Radio-frequency electromagnetic field immunity . 33

9.10 Influence of supply frequency variations . 33

9.11 Power frequency magnetic field immunity . 33

9.12 Evaluation of compliance . 33

10 Marking, installation and operating instructions .33

10.1 Marking . 33

10.2 Installation and operating instructions . 33

10.3 Warning notice . 34

10.4 Annexes . 34

Annex A (normative) Specific regional requirements in European countries .35

Annex B (normative) Specific regional requirements in Canada and USA .36

Annex C (normative) Specific regional requirements in Japan .37

Annex D (normative) Specific regional requirements in China .38

Bibliography .39

v

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 161, Controls and protective devices for gaseous

and liquid fuels.

A list of all parts in the ISO 23551 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

vi

Introduction

This document is designed to be used in combination with ISO 23550. Together, they establish the full

requirements as they apply to the product covered by this document.

Where needed, this document adapts ISO 23550 by stating in the corresponding clause:

— “with the following modification”;

— “with the following addition”;

— “is replaced by the following”; or

— “is not applicable”.

In order to identify specific requirements that are particular to this document, that are not already covered

by ISO 23550, this document can contain clauses or subclauses that are additional to the structure of

ISO 23550. These subclauses are indicated by the introductory sentence: “Subclause (or Annex) specific to

this document.”

To ensure global relevance of this document, the differing requirements resulting from practical experience

and installation practices in various regions of the world have been taken into account. The variations in

basic infrastructure associated with gas controls and appliances have also been recognized, some of which

are addressed in Annexes A, B, C and D. This document intends to provide a basic framework of requirements

that recognize these differences.

vii

International Standard ISO 23551-11:2024(en)

Safety and control devices for gas burners and gas-burning

appliances — Particular requirements —

Part 11:

Automatic and semi-automatic shut-off valves for operating

pressure of above 500 kPa up to and including 6 300 kPa

1 Scope

This document specifies safety, constructional and performance requirements and testing of automatic,

semi-automatic shut-off valves, and general purpose valves for gas burners, gas appliances and appliances of

similar use excluding use in fuel gas infrastructures (transportation and distribution systems).

This document applies to controls for use at maximum operating pressures above 500 kPa up to and

including 6 300 kPa with sizes up to DN 250 for use on burners or in appliances using fuel gases, such as

natural gas, manufactured gas or liquefied petroleum gas (LPG).

This document applies to:

— valves being mounted in gas installations;

— valves directly or indirectly actuated, electrically or by mechanical means;

— valves actuated by hydraulic or pneumatic means, including the pilot valves for these fluids if actuated

electrically and including release valves, but not to any external electrical devices for switching the

actuating energy;

— valves where the flow rate is controlled by external electrical signals, either in discrete steps or

proportional to the applied signal and valves fitted with closed position indicator switches;

— valves to be used in appliances, but not in gas transfer systems outside appliances.

This document covers type testing only.

This document does not apply to valves covered under the scope of ISO 23551-1 or the ISO 23555 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 7005-1, Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems

ISO 7005-2, Metallic flanges — Part 2: Cast iron flanges

ISO 7005-3, Pipe flanges — Part 3: Copper alloy and composite flanges

ISO 9692-1, Welding and allied processes — Types of joint preparation — Part 1: Manual metal arc welding, gas-

shielded metal arc welding, gas welding, TIG welding and beam welding of steels

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 23550:2018, Safety and control devices for gas and/or oil burners and appliances — General requirements

ISO 23551-1:2024, Safety and control devices for gas burners and gas-burning appliances — Particular

requirements — Part 1: Automatic and semi-automatic shut-off valves

IEC 60730-1:2022, Automatic electrical controls— Part 1: General requirements

IEC 61058-1, Switch for appliances — Part 1: General requirements

IEC 60529, Degrees of Protection Provided by Enclosures (IP Code)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 23550, ISO 23551-1 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

pilot valve

valve which controls the fluid (e.g. compressed air) supplied to the actuating mechanism

Note 1 to entry: A typical pilot and release valve (3.2) application is shown in Figure 1.

3.2

release valve

valve in the line from the pilot valve (3.1) to the actuating mechanism which closes the vent automatically

when the actuating fluid is released by the pilot valve and opens it automatically when the pilot valve is closed

Note 1 to entry: A typical pilot and release valve application is shown in Figure 1.

Key

1 control under test

2 pilot valve (normally closed)

3 release valve (normally open)

Figure 1 — Typical pilot and release valve application

3.3

design pressure

DP

pressure on which design calculations are based

Note 1 to entry: In particular, DP is the maximum pressure for which the body, its inner metallic partition walls and

some other pressure-containing parts are designed.

Note 2 to entry: According to local regulations, DP can be defined as maximum allowable pressure.

[SOURCE: ISO 23555-1:2022, 3.1.4.3 modified — Note 2 to entry has been added.]

4 Classification

4.1 Classes of controls

Shall be according to ISO 23550:2018, 4.1, with the following addition:

4.1.1 Classification based on sealing force

Subclause specific to this document.

Automatic shut-off valves where the sealing force is not decreased by the gas inlet pressure are classified

according to sealing force requirements and shall be designated according to Class A (see Tables 1, 4, 6, 7 and 8).

These valves may also have:

— modulating control function, or

— step control function/multi-stage.

4.1.2 Classifications based on pressure surge

Subclause specific to this document.

Automatic and semi-automatic valves with pressure surge requirements shall be designated according to

class C/I (see ISO 23551-1:2024 3.1.4 and Tables 1, 4, 6, 7 and 8).

4.1.3 Classification with neither sealing force nor pressure surge

Subclause specific to this document.

Automatic and semi-automatic shut-off valves without sealing force and without pressure surge

requirements shall be designated according to Class E (see Tables 1, 4, 6, 7 and 8).

4.1.4 Classification of flow control valves for general purpose

Subclause specific to this document.

General purpose valves with modulating control that do not provide a shut-off function shall be designated

according to Class D (see Tables 1, 4, 6, 7 and 8).

These valves include:

— valves with modulating control function,

— valves with step control function/multi-stage.

4.2 Groups of controls

Shall be according to ISO 23550:2018, 4.2.

4.3 Types of DC supplied controls

Shall be according to ISO 23550:2018, 4.3.

4.4 Classes of control function

Shall be according to ISO 23550:2018, 4.4.

5 Test conditions and tolerances

5.1 Test conditions

Shall be according to ISO 23550:2018, 5.1.

5.2 Tolerances

Shall be according to ISO 23550:2018, 5.2 with the following addition:

The full range of the measuring apparatus is chosen to be suitable for maximum anticipated value.

The measurement uncertainties concern individual measurements. For measurements requiring a

combination of individual measurements (e.g. efficiency measurements), lower uncertainties for the

individual measurements can be necessary to limit the total uncertainty.

Testing labs performing equipment calibration and testing measurement uncertainty are in conformity with

ISO/IEC 17025.

Therefore, where specified, the tolerances in this document apply. Otherwise, ISO/IEC 17025 applies.

6 Construction

6.1 General

Shall be according to ISO 23550:2018, 6.1, with the following addition:

If an automatic shut-off valve requires a release and/or a pilot valve to fulfil the requirements of this

document, these are considered to be part of the automatic shut-off valve and shall be specified in the

installation and operating instructions.

The combination of automatic shut-off valve and release and/or pilot valve shall conform to all requirements

of this document.

The interaction of all valves participating in the closing mechanism shall be evaluated. An appropriate risk

assessment shall be carried out.

For each pressurized compartment, the local maximum pressure shall be considered for the strength

design and for the selection of the material. It shall be ensured by mechanical means that parts for different

pressures are separated. A diaphragm shall not be used for this purpose.

Table 1 describes applicable constructions requirements and tests for the classified valves. Combination of

valve types are not excluded (e.g. automatic Class A and C/I valve). If the respective construction requirement

is used, the design shall be according to the assigned clause in Table 1, if applicable.

The marking "x” identifies the minimum requirements to be verified by the given subclauses in this

document.

Requirements without existing construction or performance properties cannot be verified and those

associated clauses are therefore not applicable.

EXAMPLE Strainers are an optional element in the design of the valve. Therefore, 6.4.10 is not always applicable

even though the assignment is given in Table 1.

Table 1 — Assignment of valve construction requirements and tests

Clause Title Shut-off valve (Classes) General

purpose

automatic automatic semi- automatic semi-

valve

automatic automatic

(Class)

A C/I C/I E E D

6.2 Construction requirements

6.2.1 Appearance x x x x x x

6.2.2 Holes x x x x x x

6.2.3 Breather holes x x x x x x

6.2.4 Vent limiter x x x x x x

6.2.5 Screwed fastenings x x x x x x

6.2.6 Moving parts x x x x x x

6.2.7 Sealing caps x x x x x x

6.2.8 Disassembling and assem- x x x x x x

bling for servicing and/or

adjustment for controls

6.2.9 Auxiliary channels and x x x x x x

orifices

6.2.10 Pre-setting device x x x x x x

6.2.11 Closed position indication x x x x x —

6.2.12 Specific construction x x x — — —

6.2.13 Flow rates of valves with x x x x x x

modulating control

6.2.14 Bypass x x x x x —

6.2.15 Semi-automatic shut-off — — x — x —

valve

6.2.16 Other controls assembled to x x x x x x

a valve

6.2.17 Balanced valves x x x x x x

6.3 Materials x x x x x X

6.4 Connections

6.4.1 General x x x x x x

6.4.2 Connection sizes x x x x x x

6.4.3 Connection types x x x x x x

6.4.4 Threads x x x x x x

6.4.5 Union joints x x x x x x

6.4.6 Flanges x x x x x x

6.4.7 Compression fittings x x x x x x

6.4.8 Flare connections x x x x x x

6.4.9 Nipples for pressure tests x x x x x x

6.4.10 Strainers x x x x x x

6.4.11 Gas connections by GQC x x x x x x

Key

x required only if the construction is present in the design of the valve

— no requirement even if the function is present

GQC gas quick connector

TTabablele 1 1 ((ccoonnttiinnueuedd))

Clause Title Shut-off valve (Classes) General

purpose

automatic automatic semi- automatic semi-

valve

automatic automatic

(Class)

A C/I C/I E E D

6.4.12 Welded connections x x x x x x

6.5 Gas controls employing x x x x x x

electrical components in the

gas way

6.6 Pneumatic and hydraulic x x x x x x

actuating mechanisms

Key

x required only if the construction is present in the design of the valve

— no requirement even if the function is present

GQC gas quick connector

6.2 Construction requirements

6.2.1 Appearance

Shall be according to ISO 23550:2018, 6.2.1.

6.2.2 Holes

6.2.2.1 General

Shall be according to ISO 23550:2018, 6.2.2.1.

6.2.2.2 Requirements

ISO 23550:2018, 6.2.2.2 is replaced by the following:

The wall thickness between the holes and gas ways shall take into account the design, material selected and

method of manufacturing. Holes necessary during manufacture, which connect gas ways passageways to

the atmosphere but which do not affect the operation of the control, shall be permanently sealed by metallic

means. Suitable jointing compounds may additionally be used.

6.2.2.3 Test

Shall be according to ISO 23550:2018, 6.2.2.3.

6.2.3 Breather holes

ISO 23550:2018, 6.2.3, is not applicable.

6.2.4 Vent limiter

ISO 23550:2018, 6.2.4, is not applicable.

6.2.5 Screwed fastenings

Shall be according to ISO 23550:2018, 6.2.5.

6.2.6 Moving parts

Shall be according to ISO 23550:2018, 6.2.6, with the following modification to 6.2.6.1:

6.2.6.1 General

Shall be according to ISO 23550:2018, 6.2.6.1 with the following addition:

Fastening parts (e.g. screws and nuts) shall be secured to prevent loosening under the conditions of actual use.

6.2.7 Sealing caps

Shall be according to ISO 23550:2018, 6.2.7.

6.2.8 Disassembling and assembling for servicing and/or adjustment for controls

Shall be according to ISO 23550:2018 6.2.8, with the following modification:

6.2.8.1 General

Shall be according to ISO 23550:2018, 6.2.8.1.

6.2.8.2 Requirements

Shall be according to ISO 23550:2018, 6.2.8.2.

6.2.8.3 Test

Shall be according to ISO 23550:2018, 6.2.8.3.

6.2.8.4 Factory adjustment

Subclause specific to this document.

6.2.8.4.1 General

Factory adjustment, not intended for field adjustment, shall be securely protected.

6.2.8.4.2 Requirements

Factory adjustment not intended for field adjustment shall be secured by suitable means that provides

protection against access or shall be declared as requiring such protection in the application.

Examples of "suitable means" include the following:

a) being sealed with a material suitable for the temperature range of the valve such that tampering is

apparent;

b) being accessible only with the use of special purpose tools; or

c) being accompanied by instructions requiring the equipment manufacturer to mount the valve such that

the adjustment means is inaccessible.

6.2.8.4.3 Test

Conformance is checked by inspection. Where sealing is used, inspection is carried out before and after the

endurance tests.

6.2.8.5 Maintaining of adjustments

Subclause specific to this document.

6.2.8.5.1 General

All factory adjustments shall be designed so that they are maintained in the field.

6.2.8.5.2 Requirements

Suitable means for maintaining all adjustments shall be provided.

Lock nuts or adjusting nuts held by springs or compression are acceptable unless their adjustment can be

accidentally disturbed.

6.2.8.5.3 Test

Conformance is checked by inspection.

6.2.8.6 Field adjustments

Subclause specific to this document.

6.2.8.6.1 General

Field adjustments shall be protected.

6.2.8.6.2 Requirements

Necessary field adjustments shall be capped according to 6.2.7 or otherwise protected in such a manner as

to resist tampering and prevent accidental change.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...