ISO 10303-227:2005

(Main)Industrial automation systems and integration — Product data representation and exchange — Part 227: Application protocol: Plant spatial configuration

Industrial automation systems and integration — Product data representation and exchange — Part 227: Application protocol: Plant spatial configuration

ISO 10303-227:2005 specifies the data structures for representing and exchanging spatial configuration information for plants sytems and ship systems, with an emphasis on piping systems. ISO 10303-227:2005 specifies the data structures for representing and exchanging the information to design, fabricate and construct a piping system, including the shape, material, connectionsand arrangements of the components of the system. It also specifies the data structures for representing and exchangingrequirements for the physical aspects of other plant and ship distribution systems including HVAC, cableways and mechanical systems.

Systèmes d'automatisation industrielle et intégration — Représentation et échange de données de produits — Partie 227: Protocole d'application: Configuration spatiale d'usine

General Information

- Status

- Published

- Publication Date

- 10-Oct-2005

- Technical Committee

- ISO/TC 184/SC 4 - Industrial data

- Drafting Committee

- ISO/TC 184/SC 4/WG 12 - STEP product modelling and resources

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 28-Jun-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Overview

ISO 10303-227:2005 - part of the ISO 10303 (STEP) family - is the Application Protocol for Plant spatial configuration. It specifies the data structures and information models needed to represent and exchange spatial configuration information for plant and ship systems, with a primary focus on piping systems. The standard covers the geometric shape, materials, connections and arrangements of piping components and extends to physical aspects of other distribution systems such as HVAC, cableways, and mechanical systems.

Key topics and requirements

- Data structures for spatial configuration: Defines application objects and information requirements to describe component geometry, topology and spatial relationships for plant equipment and pipework.

- Piping system coverage: Emphasis on piping design, fabrication, construction and inspection information - including component shapes, connections and materials.

- Multi-domain support: Data models for HVAC, cableways and mechanical distribution systems alongside piping.

- Units of functionality (UoF): Modular functional building blocks (for example, piping_component_characterization, hvac_component_characterization, connection, shape) used to structure information requirements.

- Application interpreted model (AIM) and mappings: Includes AIM EXPRESS listings and mapping specifications to enable consistent implementation and software integration.

- Conformance classes and PICS: Defines multiple conformance classes (e.g., piping design, component spatial information, fabrication, inspection, HVAC spatial info) and provides a Protocol Information Conformance Statement (PICS) proforma.

- Annexes and guidance: Normative and informative annexes provide implementation guidance, AIM listings, usage guides and registration details.

Applications and practical value

ISO 10303-227 is used to:

- Enable interoperable exchange of plant layout and piping data between CAD, piping design, PLM/PDM and fabrication systems.

- Support engineering workflows across lifecycle stages: conceptual design, detailed piping design, fabrication, construction and inspection.

- Facilitate data handover between EPC contractors, fabricators and shipyards, reducing rework and data translation errors.

- Integrate analysis and simulation tools that require accurate spatial and material data from plant models.

Practical benefits include improved data consistency, reduced manual re-entry, better collaboration across disciplines (piping, HVAC, mechanical), and clearer traceability for fabrication and inspection.

Who should use it

- Plant and ship designers, piping and HVAC engineers

- CAD/CAE/PDM/PLM software vendors and integrators

- EPC contractors, fabricators and inspection teams

- Data managers and systems architects implementing STEP-based exchange

Related standards

- ISO 10303 (STEP) general parts (e.g., ISO 10303-1, ISO 10303-31) and other ISO 10303 application protocols for product data exchange.

Keywords: ISO 10303-227, plant spatial configuration, piping systems, STEP, product data representation and exchange, HVAC, cableways, application protocol, piping fabrication, conformance classes.

ISO 10303-227:2005 - Industrial automation systems and integration -- Product data representation and exchange

ISO 10303-227:2005 - Industrial automation systems and integration -- Product data representation and exchange

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 10303-227:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems and integration — Product data representation and exchange — Part 227: Application protocol: Plant spatial configuration". This standard covers: ISO 10303-227:2005 specifies the data structures for representing and exchanging spatial configuration information for plants sytems and ship systems, with an emphasis on piping systems. ISO 10303-227:2005 specifies the data structures for representing and exchanging the information to design, fabricate and construct a piping system, including the shape, material, connectionsand arrangements of the components of the system. It also specifies the data structures for representing and exchangingrequirements for the physical aspects of other plant and ship distribution systems including HVAC, cableways and mechanical systems.

ISO 10303-227:2005 specifies the data structures for representing and exchanging spatial configuration information for plants sytems and ship systems, with an emphasis on piping systems. ISO 10303-227:2005 specifies the data structures for representing and exchanging the information to design, fabricate and construct a piping system, including the shape, material, connectionsand arrangements of the components of the system. It also specifies the data structures for representing and exchangingrequirements for the physical aspects of other plant and ship distribution systems including HVAC, cableways and mechanical systems.

ISO 10303-227:2005 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10303-227:2005 has the following relationships with other standards: It is inter standard links to ISO 10303-227:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 10303-227:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10303-227

Second edition

2005-10-01

Industrial automation systems and

integration — Product data

representation and exchange —

Part 227:

Application protocol: Plant spatial

configuration

Systèmes d'automatisation industrielle et intégration — Représentation

et échange de données de produits —

Partie 227: Protocole d'application: Configuration spatiale d'usine

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

This CD-ROM/DVD contains:

1) the publication ISO 10303-227:2005 in portable document format (PDF), which can be viewed using

Adobe® Acrobat® Reader;

2) Two electronic attachments.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

This second editio

...

INTERNATIONAL ISO

STANDARD 10303-227

Second edition

2005-10-01

Industrial automation systems and

integration — Product data

representation and exchange —

Part 227:

Application protocol: Plant spatial

configuration

Systèmes d'automatisation industrielle et intégration — Représentation

et échange de données de produits —

Partie 227: Protocole d'application: Configuration spatiale d'usine

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

CONTENTS PAGE

Overview of this document.xii

Changes from the previous edition . xiv

1 Scope. 1

2 Normative references . 4

3 Terms, definitions, and abbreviations. 5

3.1 Terms defined in ISO 10303-1. 5

3.2 Terms defined in ISO 10303-31. 5

3.3 Other definitions . 6

3.4 Abbreviations. 14

4 Information requirements. 15

4.1 Units of functionality . 16

4.1.1 associative_schematics UoF . 16

4.1.2 cableway_component_characterization UoF . 17

4.1.3 change_information UoF . 18

4.1.4 connection UoF. 20

4.1.5 connector UoF. 20

4.1.6 hvac_component_characterization UoF. 21

4.1.7 hvac_system_functional_characterization UoF . 23

4.1.8 hybrid_shape_representation UoF . 24

4.1.9 mechanical_component_characterization UoF . 24

4.1.10 mechanical_system_functional_characterization UoF. 25

4.1.11 piping_component_characterization UoF . 26

4.1.12 piping_inspection UoF. 29

4.1.13 piping_system_functional_characterization UoF. 29

4.1.14 plant_characterization UoF . 30

4.1.15 plant_csg_shape_representation UoF. 31

4.1.16 plant_item_characterization UoF. 32

4.1.17 shape UoF . 35

4.1.18 site_characterization UoF . 36

4.2 Application objects . 37

4.3 Application assertions. 234

5 Application interpreted model . 270

5.1 Mapping specification. 270

5.2 AIM EXPRESS short listing. 1029

6 Conformance requirements. 1184

6.1 Conformance class 1, piping system functional information. 1185

6.2 Conformance class 2, equipment and component spatial information. 1185

6.3 Conformance class 3, plant layout and piping design information along with HVAC, cableway, and

mechanical system information . 1185

6.4 Conformance class 4, piping fabrication and installation information . 1188

6.5 Conformance class 5, piping inspection information. 1188

6.6 Conformance class 6, HVAC system functional information. 1189

6.7 Conformance class 7, HVAC spatial information. 1190

6.8 Conformance class 8, cableway spatial information. 1191

6.9 Conformance class 9, piping and HVAC analysis information . 1192

6.10 Conformance class 10, mechanical system functional information. 1192

6.11 Conformance class 11, mechanical system spatial information. 1192

6.12 Options within a conformance class . 1193

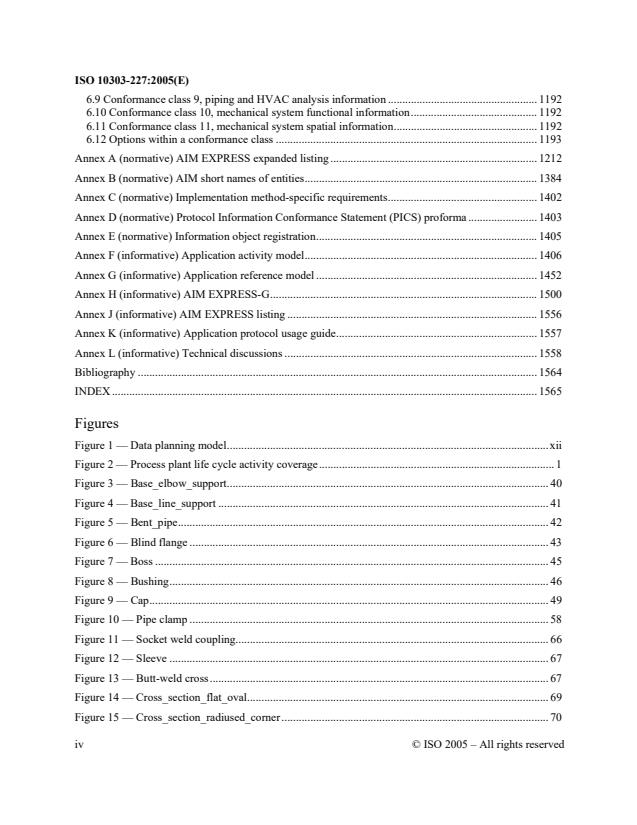

Annex A (normative) AIM EXPRESS expanded listing . 1212

Annex B (normative) AIM short names of entities. 1384

Annex C (normative) Implementation method-specific requirements. 1402

Annex D (normative) Protocol Information Conformance Statement (PICS) proforma . 1403

Annex E (normative) Information object registration. 1405

Annex F (informative) Application activity model. 1406

Annex G (informative) Application reference model . 1452

Annex H (informative) AIM EXPRESS-G. 1500

Annex J (informative) AIM EXPRESS listing . 1556

Annex K (informative) Application protocol usage guide. 1557

Annex L (informative) Technical discussions . 1558

Bibliography . 1564

INDEX . 1565

Figures

Figure 1 — Data planning model.xii

Figure 2 — Process plant life cycle activity coverage. 1

Figure 3 — Base_elbow_support. 40

Figure 4 — Base_line_support . 41

Figure 5 — Bent_pipe. 42

Figure 6 — Blind flange . 43

Figure 7 — Boss . 45

Figure 8 — Bushing. 46

Figure 9 — Cap. 49

Figure 10 — Pipe clamp . 58

Figure 11 — Socket weld coupling. 66

Figure 12 — Sleeve . 67

Figure 13 — Butt-weld cross. 67

Figure 14 — Cross_section_flat_oval. 69

Figure 15 — Cross_section_radiused_corner . 70

iv © ISO 2005 – All rights reserved

Figure 16 — Dummy_leg . 74

Figure 17 — Eccentric_base_elbow_support . 74

Figure 18 — Eccentric_reducer . 75

Figure 19 — Elbow. 76

Figure 20 — Expander_flange. 80

Figure 21 — Female_end. 83

Figure 22 — Ferrule. 84

Figure 23 — Hole_straddle_centreline_orientation. 86

Figure 24 — Flanged_end . 87

Figure 25 — Raised face flange .88

Figure 26 — Flat face flange . 88

Figure 27 — Ring type joint flange .88

Figure 28 — Male and female flange . 88

Figure 29 — Tongue and groove flange . 89

Figure 30 — Grooved_end . 94

Figure 31 — Gusset . 95

Figure 32 — Hangers both without_spring and with_spring. 96

Figure 33 — Hvac_elbow_90deg_reducing . 107

Figure 34 — Hvac_elbow_centred . 108

Figure 35 — Hvac_elbow_mitre. 109

Figure 36 — Hvac_offset_ogee_centred . 116

Figure 37 — Transition - rectangular to round . 124

Figure 38 — Transition - rectangle to round slanted . 125

Figure 39 — Insert_fitting . 127

Figure 40 — Lap_joint_flange. 131

Figure 41 — Lap_joint_stub_end . 131

Figure 42 — Lateral. 133

Figure 43 — Lug. 137

Figure 44 — Mitre_bend_pipe. 147

Figure 45 — Nipple . 148

Figure 46 — Olet . 149

Figure 47 — Orifice_flange. 151

Figure 48 — Orifice_plate . 152

Figure 49 — Pad . 154

Figure 50 — Paddle_blank . 155

Figure 51 — Paddle_spacer . 155

Figure 52 — Perforated_cap. 156

Figure 53 — Butt-weld Pipe Cap. 158

Figure 54 — Plate . 186

Figure 55 — Plug. 187

Figure 56 — Reducer. 190

Figure 57 — Reducing_flange. 191

Figure 58 — Reinforcing_plate . 192

Figure 59 — Reinforcing_ring. 193

Figure 60 — Ring_spacer . 194

Figure 61 — Forward and aft pointing ship's axes . 203

Figure 62 — Shoe . 205

Figure 63 — Slip_on_flange. 208

Figure 64 — Slip_on_jacket_flange . 209

Figure 65 — Socket . 209

Figure 66 — Socket_weld_flange. 210

Figure 67 — Spectacle_blind. 212

Figure 68 — Stay. 214

Figure 69 — Stopper. 215

Figure 70 — Stub_in. 219

Figure 71 — Tee . 224

Figure 72 — Threaded . 225

Figure 73 — Threaded_flange . 226

Figure 74 — Trunnion . 228

Figure 75 — Union . 229

Figure 76 — Weld_neck_flange. 231

Figure 77 — Weld_neck_jacket_flange . 232

Figure 78 — Y_type_lateral . 233

Figure F.1 — IDEF0 basic notation. 1425

Figure F.2 — A-0: Process plants. 1426

Figure F.3 — A0: Perform process plant life-cycle activities . 1427

vi © ISO 2005 – All rights reserved

Figure F.4 — A1: Manage and plan project . 1428

Figure F.5 — A2: Design and engineer plant . 1429

Figure F.6 — A21: Produce conceptual process design . 1430

Figure F.7 — A22: Produce conceptual plant design . 1431

Figure F.8 — A23: Produce final process design . 1432

Figure F.9 — A24: Produce final plant design . 1433

Figure F.10 — A242: Finalize layout and spatial design. 1434

Figure F.11 — A2426: Finalize piping. 1435

Figure F.12 — A24262: Finalize 3D piping details. 1436

Figure F.13 — A3: Procure goods and services . 1437

Figure F.14 — A4: Construct and commission plant . 1438

Figure F.15 — A42: Obtain construction services. 1439

Figure F.16 — A423: Obtain piping systems . 1440

Figure F.17 — A4233: Shop fabricate piping. 1441

Figure F.18 — A42331: Prepare shop fabrication piping. 1442

Figure F.19 — A42332: Shop fabricate piping. 1443

Figure F.20 — A42333: Inspect shop fabricated piping. 1444

Figure F.21 — A42334: Complete and ship shop fabricated piping . 1445

Figure F.22 — A5: Manage, operate, and maintain plant. 1446

Figure F.23 — A6: Decommission and dispose of plant. 1447

Figure G.1 — Off-page connectors. 1452

Figure G.2 — ARM diagram 1 of 47. 1453

Figure G.3 — ARM diagram 2 of 47. 1454

Figure G.4 — ARM diagram 3 of 47. 1455

Figure G.5 — ARM diagram 4 of 47. 1456

Figure G.6 — ARM diagram 5 of 47. 1457

Figure G.7 — ARM diagram 6 of 47. 1458

Figure G.8 — ARM diagram 7 of 47. 1459

Figure G.9 — ARM diagram 8 of 47. 1460

Figure G.10 — ARM diagram 9 of 47. 1461

Figure G.11 — ARM diagram 10 of 47. 1462

Figure G.12 — ARM diagram 11 of 47. 1463

Figure G.13 — ARM diagram 12 of 47. 1464

Figure G.14 — ARM diagram 13 of 47. 1465

Figure G.15 — ARM diagram 14 of 47. 1466

Figure G.16 — ARM diagram 15 of 47. 1467

Figure G.17 — ARM diagram 16 of 47. 1468

Figure G.18 — ARM diagram 17 of 47. 1469

Figure G.19 — ARM diagram 18 of 47. 1470

Figure G.20 — ARM diagram 19 of 47. 1471

Figure G.21 — ARM diagram 20 of 47. 1472

Figure G.22 — ARM diagram 21 of 47. 1473

Figure G.23 — ARM diagram 22 of 47. 1474

Figure G.24 — ARM diagram 23 of 47. 1475

Figure G.25 — ARM diagram 24 of 47. 1476

Figure G.26 — ARM diagram 25 of 47. 1477

Figure G.27 — ARM diagram 26 of 47. 1478

Figure G.28 — ARM diagram 27 of 47. 1479

Figure G.29 — ARM diagram 28 of 47. 1480

Figure G.30 — ARM diagram 29 of 47. 1481

Figure G.31 — ARM diagram 30 of 47. 1482

Figure G.32 — ARM diagram 31 of 47. 1483

Figure G.33 — ARM diagram 32 of 47. 1484

Figure G.34 — ARM diagram 33 of 47. 1485

Figure G.35 — ARM diagram 34 of 47. 1486

Figure G.36 — ARM diagram 35 of 47. 1487

Figure G.37 — ARM diagram 36 of 47. 1488

Figure G.38 — ARM diagram 37 of 47. 1489

Figure G.39 — ARM diagram 38 of 47. 1490

Figure G.40 — ARM diagram 39 of 47. 1491

Figure G.41 — ARM diagram 40 of 47. 1492

Figure G.42 — ARM diagram 41 of 47. 1493

Figure G.43 — ARM diagram 42 of 47. 1494

Figure G.44 — ARM diagram 43 of 47. 1495

Figure G.45 — ARM diagram 44 of 47. 1496

Figure G.46 — ARM diagram 45 of 47. 1497

viii © ISO 2005 – All rights reserved

Figure G.47 — ARM diagram 46 of 47. 1498

Figure G.48 — ARM diagram 47 of 47. 1499

Figure H.1 — AIM EXPRESS-G diagram 1 of 55. 1501

Figure H.2 — AIM EXPRESS-G diagram 2 of 55. 1502

Figure H.3 — AIM EXPRESS-G diagram 3 of 55. 1503

Figure H.4 — AIM EXPRESS-G diagram 4 of 55. 1504

Figure H.5 — AIM EXPRESS-G diagram 5 of 55. 1505

Figure H.6 — AIM EXPRESS-G diagram 6 of 55. 1506

Figure H.7 — AIM EXPRESS-G diagram 7 of 55. 1507

Figure H.8 — AIM EXPRESS-G diagram 8 of 55. 1508

Figure H.9 — AIM EXPRESS-G diagram 9 of 55. 1509

Figure H.10 — AIM EXPRESS-G diagram 10 of 55. 1510

Figure H.11 — AIM EXPRESS-G diagram 11 of 55. 1511

Figure H.12 — AIM EXPRESS-G diagram 12 of 55. 1512

Figure H.13 — AIM EXPRESS-G diagram 13 of 55. 1513

Figure H.14 — AIM EXPRESS-G diagram 14 of 55. 1514

Figure H.15 — AIM EXPRESS-G diagram 15 of 55. 1515

Figure H.16 — AIM EXPRESS-G diagram 16 of 55. 1516

Figure H.17 — AIM EXPRESS-G diagram 17 of 55. 1517

Figure H.18 — AIM EXPRESS-G diagram 18 of 55. 1518

Figure H.19 — AIM EXPRESS-G diagram 19 of 55. 1519

Figure H.20 — AIM EXPRESS-G diagram 20 of 55. 1520

Figure H.21 — AIM EXPRESS-G diagram 21 of 55. 1521

Figure H.22 — AIM EXPRESS-G diagram 22 of 55. 1522

Figure H.23 — AIM EXPRESS-G diagram 23 of 55. 1523

Figure H.24 — AIM EXPRESS-G diagram 24 of 55. 1524

Figure H.25 — AIM EXPRESS-G diagram 25 of 55. 1525

Figure H.26 — AIM EXPRESS-G diagram 26 of 55. 1526

Figure H.27 — AIM EXPRESS-G diagram 27 of 55. 1527

Figure H.28 — AIM EXPRESS-G diagram 28 of 55. 1528

Figure H.29 — AIM EXPRESS-G diagram 29 of 55. 1529

Figure H.30 — AIM EXPRESS-G diagram 30 of 55. 1530

Figure H.31 — AIM EXPRESS-G diagram 31 of 55. 1531

Figure H.32 — AIM EXPRESS-G diagram 32 of 55. 1532

Figure H.33 — AIM EXPRESS-G diagram 33 of 55. 1533

Figure H.34 — AIM EXPRESS-G diagram 34 of 55. 1534

Figure H.35 — AIM EXPRESS-G diagram 35 of 55. 1535

Figure H.36 — AIM EXPRESS-G diagram 36 of 55. 1536

Figure H.37 — AIM EXPRESS-G diagram 37 of 55. 1537

Figure H.38 — AIM EXPRESS-G diagram 38 of 55. 1538

Figure H.39 — AIM EXPRESS-G diagram 39 of 55. 1539

Figure H.40 — AIM EXPRESS-G diagram 40 of 55. 1540

Figure H.41 — AIM EXPRESS-G diagram 41 of 55. 1541

Figure H.42 — AIM EXPRESS-G diagram 42 of 55. 1542

Figure H.43 — AIM EXPRESS-G diagram 43 of 55. 1543

Figure H.44 — AIM EXPRESS-G diagram 44 of 55. 1544

Figure H.45 — AIM EXPRESS-G diagram 45 of 55. 1545

Figure H.46 — AIM EXPRESS-G diagram 46 of 55. 1546

Figure H.47 — AIM EXPRESS-G diagram 47 of 55. 1547

Figure H.48 — AIM EXPRESS-G diagram 48 of 55. 1548

Figure H.49 — AIM EXPRESS-G diagram 49 of 55. 1549

Figure H.50 — AIM EXPRESS-G diagram 50 of 55. 1550

Figure H.51 — AIM EXPRESS-G diagram 51 of 55. 1551

Figure H.52 — AIM EXPRESS-G diagram 52 of 55. 1552

Figure H.53 — AIM EXPRESS-G diagram 53 of 55. 1553

Figure H.54 — AIM EXPRESS-G diagram 54 of 55. 1554

Figure H.55 — AIM EXPRESS-G diagram 55 of 55. 1555

Figure L.1 — Relationship between logical connectivity and physical connectivity. 1563

Tables

Table 1 — Plant_item_shape interference clash detection . 183

Table 2 — Conformance classes. 1195

Table 3 — Conformance class (1 –11) elements . 1197

Table B. 1 — Short names of entities . 1384

Table F.1 — AAM ICOM to ARM UoF/entity mapping . 1449

x © ISO 2005 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

Draft International Standards adopted by technical committees are circulated to the member bodies for

voting. Publication as an International Standard requires approval by at least 75% of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this part of ISO may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 10303-227 was prepared by Technical Committee ISO/TC 184, Industrial

automation systems and integration, Subcommittee SC4, Industrial data.

This second edition of ISO 10303-227 cancels and replaces the first edition (ISO 10303-227:2001), of

which it constitutes a technical revision.

This International Standard is organized as a series of parts, each published separately. The structure of

this international standard is described in ISO 10303-1.

Each part of this International Standard is a member of one of the following series: description methods,

implementation methods, conformance testing methodology and framework, integrated generic resources,

integrated application resources, application protocols, abstract test suites, application interpreted

constructs, and application modules. This part is a member of the application protocols series.

A complete list of parts of ISO 10303 is available from the Internet:

http://www.tc184-sc4.org/titles/STEP_titles.htm

Should further parts of ISO 10303 be published, they will follow the same numbering pattern.

Introduction

ISO 10303 is an International Standard for the computer-interpretable representation of product

information and for the exchange of product data. The objective is to provide a neutral mechanism

capable of describing products throughout their life cycle. This mechanism is suitable not only for neutral

file exchange, but also as a basis for implementing and sharing product databases, and as a basis for

archiving.

Overview of this document

This part of ISO 10303 is a member of the application protocol series. This part of ISO 10303 specifies

an application protocol (AP) for the exchange of the spatial configuration information of industrial

facilities, for example, process plants, ships and their supporting systems. This information includes the

shape, spatial arrangement and connection characteristics of piping, HVAC (heating, ventilation and air-

conditioning), mechanical, and cableway system components as well as the shape and spatial arrangement

characteristics of other related plant systems (for example, instrumentation and controls, and structural

systems). Users of this standard should understand the basic principles and concepts of plant design, and

piping, HVAC, cableway, and mechanical system design.

PLANT

CHANGE

SCHEMATIC

REPRESENTATION

PLANT SYSTEM

PIPING SYSTEM

HVAC SYSTEM

FUNCTIONAL

FUNCTIONAL

CHARACTERIZATION MECHANICAL SYSTEM

CHARACTERIZATION

FUNCTIONAL

CHARACTERIZATION

PLANT ITEM

CABLEWAY COMPONENT

HVAC COMPONENT

CONNECTOR

MECHANICAL COMPONENT

CONNECTION

PIPING COMPONENT

PIPING FABRICATION

AND INSPECTION

ITEM SHAPE

Figure 1 — Data planning model

This AP specifies requirements for the exchange of information required for the design, analysis,

fabrication and installation of piping components and piping systems and information on the inspection of

xii © ISO 2005 – All rights reserved

fabricated piping. This AP specifies requirements fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...