ISO 11041:1996

(Main)Workplace air - Determination of particulate arsenic and arsenic compounds and arsenic trioxide vapour - Method by hydride generation and atomic absorption spectrometry

Workplace air - Determination of particulate arsenic and arsenic compounds and arsenic trioxide vapour - Method by hydride generation and atomic absorption spectrometry

Gives a method by hydrid generation for the atomic absorption spectrometric determination of the mass concentration of particulate arsenic, arsenic compounds and arsenic trioxide vapour in workplace air. Applicable to the determination of mass concentrations of approximately 100 ng to 125 g of arsenic per sample. Not suitable for the determination of arsenic in the form of metal arsenides.

Air des lieux de travail — Dosage de l'arsenic particulaire, des composés particulaires de l'arsenic et des vapeurs de trioxyde d'arsenic — Méthode par production d'hydrures et spectrométrie d'absorption atomique

Zrak na delovnem mestu - Ugotavljanje arzenovega prahu, arzenovih spojin in plinastega arzenovega trioksida z metodo generiranja hidrida in atomsko absorpcijsko spektrometrijo

General Information

- Status

- Published

- Publication Date

- 24-Apr-1996

- Technical Committee

- ISO/TC 146/SC 2 - Workplace atmospheres

- Drafting Committee

- ISO/TC 146/SC 2/WG 2 - Inorganic particulate matter

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 04-Mar-2024

- Completion Date

- 13-Dec-2025

Overview

ISO 11041:1996 specifies an analytical procedure for measuring particulate arsenic, arsenic compounds and arsenic trioxide vapour in workplace air. The method uses hydride generation coupled with atomic absorption spectrometry (AAS) to determine arsenic mass in air samples. It is applicable to sample masses of approximately 100 ng to 125 g of arsenic per sample (as stated in the standard) and is intended for both personal and fixed-location monitoring. The method is not suitable for arsenic present as metal arsenides. The standard includes safety warnings because arsenic and its compounds are toxic and carcinogenic.

Key Topics

- Sampling strategy

- Collection of the inhalable fraction using cellulose ester membrane filters plus a sodium-carbonate–impregnated backup paper pad to trap arsenic trioxide vapour.

- Designed for personal and fixed-location samplers; applicable concentration range in air depends on sampling volume and procedure.

- Sample preparation

- Wet-ashing (nitric acid, sulfuric acid, hydrogen peroxide) to convert particulate arsenic compounds to soluble arsenate.

- Chemical reduction of As(V) to As(III) using potassium iodide prior to hydride generation.

- Hydride generation and detection

- Reaction of trivalent arsenic with sodium tetrahydroborate to produce arsine gas (AsH3).

- Gas/liquid separation and transfer of arsine into a silica or quartz absorption cell mounted in an atomic absorption spectrometer.

- Absorbance measurement at 197.2 nm or 193.7 nm using an arsenic hollow-cathode lamp or equivalent.

- Use of continuous-flow or flow-injection hydride generation systems; absorption cell heated electrically or by an air/acetylene flame.

- Interferences and quality

- Potential interferences from transition metals and matrix effects; analytical-curve or analyte-addition techniques recommended.

- Reagent purity, blank controls, and recommended reagent preparations (e.g., NaBH4, KI, acids) are specified.

Applications

- Occupational exposure monitoring in industries such as metal refining, smelting, welding, mining, and chemical manufacturing.

- Use by industrial hygienists, occupational-health laboratories, environmental testing labs, and regulatory agencies for compliance testing and risk assessment.

- Monitoring of airborne arsenic species where vapour-phase arsenic trioxide and particulate arsenic are expected.

Related standards

- ISO 7708 - particle-size fractions for health-related sampling (inhalable fraction)

- EN 482 - general performance requirements for workplace atmosphere chemical agent measurement

- ISO 6955 - atomic spectroscopic vocabulary and measurement techniques

- ISO 3696 - water for analytical laboratory use

Keywords: ISO 11041, workplace air, particulate arsenic, arsenic trioxide vapour, hydride generation, atomic absorption spectrometry, arsenic monitoring, inhalable fraction, occupational exposure.

ISO 11041:1996 - Workplace air — Determination of particulate arsenic and arsenic compounds and arsenic trioxide vapour — Method by hydride generation and atomic absorption spectrometry Released:4/25/1996

ISO 11041:1996 - Air des lieux de travail — Dosage de l'arsenic particulaire, des composés particulaires de l'arsenic et des vapeurs de trioxyde d'arsenic — Méthode par production d'hydrures et spectrométrie d'absorption atomique

Frequently Asked Questions

ISO 11041:1996 is a standard published by the International Organization for Standardization (ISO). Its full title is "Workplace air - Determination of particulate arsenic and arsenic compounds and arsenic trioxide vapour - Method by hydride generation and atomic absorption spectrometry". This standard covers: Gives a method by hydrid generation for the atomic absorption spectrometric determination of the mass concentration of particulate arsenic, arsenic compounds and arsenic trioxide vapour in workplace air. Applicable to the determination of mass concentrations of approximately 100 ng to 125 g of arsenic per sample. Not suitable for the determination of arsenic in the form of metal arsenides.

Gives a method by hydrid generation for the atomic absorption spectrometric determination of the mass concentration of particulate arsenic, arsenic compounds and arsenic trioxide vapour in workplace air. Applicable to the determination of mass concentrations of approximately 100 ng to 125 g of arsenic per sample. Not suitable for the determination of arsenic in the form of metal arsenides.

ISO 11041:1996 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11041:1996 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-1997

Zrak na delovnem mestu - Ugotavljanje arzenovega prahu, arzenovih spojin in

plinastega arzenovega trioksida z metodo generiranja hidrida in atomsko

absorpcijsko spektrometrijo

Workplace air -- Determination of particulate arsenic and arsenic compounds and arsenic

trioxide vapour -- Method by hydride generation and atomic absorption spectrometry

Air des lieux de travail -- Dosage de l'arsenic particulaire, des composés particulaires de

l'arsenic et des vapeurs de trioxyde d'arsenic -- Méthode par production d'hydrures et

spectrométrie d'absorption atomique

Ta slovenski standard je istoveten z: ISO 11041:1996

ICS:

13.040.30 Kakovost zraka na delovnem Workplace atmospheres

mestu

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

IS0 11041:1996(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work of

preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 11041 was prepared by Technical Committee

lSO/TC 146, Air quality, Subcommittee SC 2, Workplace atmospheres.

Annex A of this International Standard is for information only.

0 IS0 1996

All rights reserved. Unless otherwise specified, no part of this publication may be

reproduced or utilized in any form or by any means, electronic or mechanical, including

photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

ii

IS0 11041:1996(E)

INTERNATIONAL STANDARD @ IS0

Workplace air - Determination of particulate arsenic and arsenic

compounds and arsenic trioxide vapour - Method by hydride

generation and atomic absorption spectrometry

WARNING - Arsenic and arsenic compounds are toxic and are recognized as human carcinogens (see reference

[I] in annex A). Avoid any exposure by inhalation. Personal protection (e.g. an effective respirator) must be used

in all cases where exposure to arsenic or arsenic compounds is possible.

this International Standard. At the time of publication,

1 Scope

the editions indicated were valid. All standards are

subject to revision, and parties to agreements based

This International Standard specifies a method for the

on this International Standard are encouraged to in-

determination of the mass concentration of particulate

vestigate the possibility of applying the most recent

arsenic and arsenic compounds and arsenic trioxide

editions of the standards indicated below. Members

vapour in workplace air, using either continuous-flow

of IEC and IS0 maintain registers of currently valid

hydride generation or flow-injection-analysis hydride

International Standards.

generation and atomic absorption spectrometry. The

method is not suitable for determination of arsenic in

the form of metal arsenides which decompose in the IS0 648:1977, Laboratory glassware - One-mark

presence of water or acid (see 10.1). pipettes.

The method is applicable to the determination of

IS0 1042: 1983, Laboratory glassware - One-mark

masses of approximately 100 ng to 125 pg of arsenic

volumetric flasks.

per sample, for analysis of test solutions prepared

using sample solution aliquots in the recommended

IS0 3585: 1991, Borosilicate glass 3.3 - Properties.

range (see 9.3.2). The concentration range for arsenic

in air, for which this procedure is applicable, is deter-

IS0 3696: 1987, Water for analytical labora tory use -

mined in part by the sampling procedure selected by

Specification and test methods.

the user.

IS0 6955: 1982, Analytical spectroscopic methods -

The method is applicable to personal and fixed-

Flame emission, atomic absorption and atomic

location sampling.

fluorescence - Vocabulary.

A number of transition metals may interfere with the

IS0 7708:1995, Air quality - Particle size fraction

determination of arsenic by hydride generation and

definitions for health-related sampling.

atomic absorption spectrometry (see 10.3)

IS0 8655-l :-I), Piston and/or plunger opera ted

volumetric apparatus (POVA) - Part 1: Definitions.

2 Normative references

I SO 8655-2:--l 1, Piston and/or plunger opera ted

volumetric apparatus (POVA) - Part 2: Operating

The following standards contain provisions which,

considerations.

through reference in this text, constitute provisions of

1) To be published.

0 IS0

IS0 11041:1996(E)

Piston and/or plunger opera ted charge lamp, and it is heated either electrically or by

IS0 8655-3:-l),

an oxidizing air/acetylene flame.

volumetric apparatus (POVA) - Part 3: Methods of

test.

NOTE 2 This International Standard describes the use of

two types of hydride generation system. Continuous flow

IS0 8655-4:-l), Piston and/or plunger opera ted

systems function by pumping a continuous stream of test

volumetric apparatus (POVA) - Part 4: Specifications.

solution to the mixing piece, and such systems generate a

constant atomic absorption signal. Flow injection analysis

IS0 8756: 1994, Air quality - Handling of tempera-

systems inject a discrete volume of test solution, and

ture, pressure and humidity data.

produce a transient atomic absorption signal.

EN 482: 1994, Workplace atmospheres - General

3.5 Absorbance measurements are made at

requirements for the performance of procedures for

197,2 nm or 193,7 nm, and results are obtained by the

the measurement of chemical agents. EN 482, CEN,

analytical-curve technique (see IS0 6955: 1982, sub-

Brussels, Belgium (1994).

clause 6.1 .I ), or the analyte addition technique (see

IS0 6955:1982, subclause 6.1.3).

EN 1232: --I), Workplace atmospheres - Pumps for

personal sampling of chemical agents - Require-

ments and test methods.

4 Reactions

3 Principle

4.1 In most workplace situations where exposure to

arsenic can occur (e.g. in the refining of base metals,

3.1 Particulate arsenic and arsenic compounds and

welding and other hot metal processes) a significant

arsenic trioxide vapour are collected by drawing a

proportion of the arsenic is present in the form of

measured volume of air through a cellulose ester

arsenic trioxide vapour (see reference [3] in annex A).

membrane filter and a back-up paper pad impregnated

This vapour is collected by reaction with sodium

with sodium carbonate and mounted in a sampler de-

carbonate on an impregnated back-up paper pad.

signed to collect the inhalable fraction of airborne par-

ticles.

As,O, + Na,CO, -+ ZNaAsO, + CO,

3.2 The cellulose ester membrane filter, back-up

4.2 The majority of arsenic compounds which are

paper pad and collected sample are wet-ashed using

commonly found in samples of workplace air are con-

nitric acid, sulfuric acid and hydrogen peroxide. The

verted to soluble arsenate ions (As0,3-) by the wet-

nitric acid and hydrogen peroxide are removed by

ashing procedure specified in 8.2.2. However, if there

boiling on a hotplate until dense, white fumes of sulfur

is any doubt about the effectiveness of this procedure

trioxide are evolved, and the sample solution is then

for dissolution of particulate arsenic compounds which

allowed to cool and diluted to a given volume with

could be present in the test atmosphere, investigate

water.

before proceeding with the method (see 10.2).

NOTE 1 The wet-ashing procedure specified in 8.2.2 is

based upon a NIOSH procedure (see reference [2] in annex

A) which has been modified to avoid taking the sample

4.3 Prior to hydride generation (see 4.4) arsenate

solution to dryness.

ions (AsO,s-) are reduced to arsenite ions (AsO,-) by

reaction with potassium iodide (see 8.2.4).

3.3 A test solution is prepared by transferring an

aliquot of the sample solution to a volumetric flask,

AsOds- + Zl- + 4H+ + AsO,- + I2 + 2H,O

together with appropriate volumes of dilute sulfuric

This reduction is necessary since pentavalent arsenic

acid, concentrated hydrochloric acid and potassium

gives a lower analytical response than trivalent arsenic

iodide solution, and diluting to volume with water.

because it is less rapidly converted to arsine.

3.4 The test solution is reacted with sodium tetra-

hydroborate solution in a continuous-flow hydride

generation system or flow-injection-analysis hydride

4.4 Hydride generation occurs as a result of the

generation system to liberate arsine and hydrogen.

reaction between trivalent arsenic and nascent hydro-

These gaseous products are separated from the

gen produced by the action of hydrochloric acid on

reaction liquid in a gas/liquid separator and carried by

sodium tetrahydroborate solution.

an inert purge gas into a silica or quartz absorption

cell. This absorption cell is mounted in the optical path

BH,- + H+ + 3H,O -+ H,BO, + 8H . . .

(1 >

of an atomic absorption spectrometer equipped with

an arsenic hollow cathode lamp or electrodeless dis- AsO,- + H+ + 6H + ASH, + 2H,O . . .

(2)

1) To be published.

IS0 11041:1996(E)

@ IS0

5.6 Nitric acid (HNO$, concentrated,

4.5 Arsenic atoms are produced from arsine by the

- I,42 g/ml, 69 % (m/m) to 71 % (d.).

action of heat in a silica or quartz absorption cell,

P

heated either by a lean air/acetylene flame or elec-

The concentration of arsenic shall be less than

trically.

0,Ol pg/ml.

WARNING - Concentrated nitric acid is corrosive

5 Reagents

and oxidizing, and nitric acid fumes are irritant.

During the analysis, use only reagents of analytical Avoid exposure by contact with the skin or eyes,

or by inhalation of fumes. Personal protective

grade, and only water as specified in 5.1.

equipment (e.g. gloves, face shield or safety spec-

5.1 Water, complying with the requirements for

tacles, etc.) must be used when working with the

IS0 3696 grade 2 water (electrical conductivity less concentrated or diluted nitric acid, and concen-

than 0,l mS/m and resistivity greater than 0,Ol ML&m

trated nitric acid must be used in a fume hood.

at 25 “C).

5.7 Sulfuric acid (HzSOa), concentrated,

5.2 Sodium carbonate, 1 mol/l solution in 5 %

w I,84 g/ml, about 98 % (m/m).

P

glycerol solution.

The concentration of arsenic shall be less than

to a

Weigh IO,6 g of sodium carbonate (Na2C03) it 0,05 pg/ml.

and

250 ml beaker (6.2.1 .I). Add 5 ml of glycerol

WARNING - Concentrated sulfuric acid is corros-

50 ml of water (5.1) and swirl to dissolve. Quantita-

ive and causes burns. Avoid exposure by contact

tively transfer the solution to a 100 ml one-mark

with the skin or eyes. Personal protective equip-

volumetric flask (6.2.1.5) dilute to the mark with

ment (e.g. gloves, face shield or safety spectacles,

water, stopper and mix thoroughly.

etc.) must be used when working with the con-

centrated or diluted sulfuric acid. Fumes produced

5.3 Hydrochloric acid (HCI), concentrated

by heating concentrated sulfuric acid are irritant,

- 1 ,I8 g/ml, 35 % (m/m) to 36 % (m/m).

P

and this operation must therefore be carried out in

a fume hood. Caution must be exercised if adding

The concentration of arsenic shall be less than

water to sulfuric acid, since this reacts violently

0,Ol pg/ml.

with water (acid/water mixtures must be prepared

WARNING - Concentrated hydrochloric acid is

by adding acid to water).

corrosive, and hydrochloric acid vapour is irritant.

Avoid exposure by contact with the skin or eyes,

5.8 Hydrogen peroxide (HzO$, approximately

or by inhalation of fumes. Personal protective

30 % (m/m) solution.

equipment (e.g. gloves, face shield or safety spec-

tacles, etc.) must be used when working with the The concentration of arsenic shall be less than

concentrated or diluted hydrochloric acid, and 0,Ol pg/rnl.

concentrated hydrochloric acid must be used in a

WARNING - Hydrogen peroxide is corrosive and

fume hood. The vapour pressure of hydrochloric is

oxidizing. Avoid exposure be contact with the skin

high, therefore beware of pressure build-up in

or eyes. Personal protective equipment (e.g.

stoppered flasks when preparing acid/water

gloves, face shield or safety spectacles, etc.) must

mixtures.

be used when working with protective equipment

5.4 Hydrochloric acid, diluted 1 + 1. hydrogen peroxide.

Pour approximately 900 ml of water (5.1) into a 5.9 Potassium iodide, 100 g/l solution.

2 000 ml one-mark volumetric flask (6.2.1.5). Carefully

Weigh IO,0 g of potassium iodide (KI) into a 250 ml

add 1 000 ml of concentrated hydrochloric acid (5.3) to

beaker (6.2.1 .I ). Add 50 ml of water (5.1) and swirl to

the flask and swirl to mix. Allow to cool, dilute to the

dissolve. Quantitatively transfer the solution to a

mark with water, stopper and mix thoroughly.

100 ml one-mark volumetric flask (6.2.1.5) dilute to

NOTE 3 This is used as the solvent blank, as defined in the mark with water, stopper and mix thoroughly.

IS0 6955:1982, subclause 5.4.2, but in this International

Standard the solvent blank is referred to as the acid blank.

Prepare a fresh solution each month.

5.5 Hydrochloric acid, diluted 1 + 4.

5.18 Sulfuric acid, diluted 1 + 9.

Pour approximately 700 ml of water (5.1) into a Carefully add 25 ml of concentrated sulfuric acid (5.7)

1 000 ml one-mark volumetric flask (6.2.1.5). Carefully to 200 ml of water (5.1) in a 1 litre beaker. Swirl to

add 200 ml of concentrated hydrochloric acid (5.3) to

mix, allow to cool and quantitatively transfer to a

the flask and swirl to mix. Allow to cool, dilute to the

250 ml one-mark volumetric flask (6.2.1.5). Dilute to

mark with water, stopper and mix thoroughly.

the mark with water, stopper and mix thoroughly.

IS0 11041:1996(E) @ IS0

5.11 Arsenic stock standard solution, correspond- ide (NaOH) pellets into a 1 litre beaker (6.2.1 .I). Add

ing to 1 000 mg of As per litre. 200 ml of water (5.1) and swirl to mix. Quantitatively

transfer the solution to a 1 000 ml one-mark volu-

511.1 Use a commercially available arsenic standard

metric flask (6.2.1.5) filtering through a membrane

solution at a concentration of 1 000 mg/l. Observe the

filter using a suction filtration apparatus (6.2.6). Dilute

manufacturer’s expiry date or recommended shelf-life.

to the mark with water (5.1) stopper and mix

thoroughly.

Alternatively, prepare an arsenic standard solution

according to the procedure specified in 5.11.2.

Prepare a fresh solution daily.

511.2 Accurately weigh 1,320 g + 0,001 g of arsenic NOTES

trioxide (As203) into a 50 ml beaker (6.2.1.1), add

4 Filtration of the solution is necessary to remove

10 ml of concentrated hydrochloric acid - (5.3), cover

undissolved particulate material which might otherwise

with a watch glass (6.2.1.2) and heat to approximately

cause clogging of the tubing or mixing piece of the hydride

150 “C on the hotplate (6.2.5) in a fume hood until dis-

generation system (6.2.8). The addition of alkali minimizes

solution is complete. Remove the beaker from the

hydrolysis of the sodium tetrahydroborate solution.

hotplate, allow to cool, quantitatively transfer the sol-

ution to a 1 000 ml one-mark volumetric flask (6.2.1.5)

5 A few drops of anti-foaming agent may be added to the

dilute to the mark with hydrochloric acid diluted 1 + 1

solution to reduce foaming in the gas/liquid separator of the

(5.4), stopper and mix thoroughly.

hydride generation system (6.2.8) which may result in a

noisy baseline signal.

This solution may be stored in a polypropylene bottle

6 The solution should be stored in a polypropylene bottle

(6.2.2) for up to one year.

(6.2.2) if it is not transferred to the reductant reservoir of

the continuous hydride generation system (6.2.8) immedi-

WARNING - Arsenic trioxide is toxic and is

ately after preparation (see 8.4.2.2). The top of the bottle

recognized as a human carcinogen (see reference

should not be fully tightened or pressure will build up due

[I] in annex A). See the general warning about

to the slow release of hydrogen.

arsenic or arsenic compounds, just after the title

of this International Standard.

5.15 Sodium hydroxide, 5 g/l solution.

5.12 Arsenic working standard solution A, corre-

Weigh 5,0 g of sodium hydroxide (NaOH) pellets into a

sponding to 10 mg of As per litre.

1 litre beaker (6.2.1 .I). Add 250 ml of water (5.1) and

swirl to dissolve. Quantitatively transfer the solution to

Using a pipette (6.2.1.3), accurately add I,00 ml of

a 1 000 ml volumetric flask (6.2.1.5) dilute to the mark

stock arsenic solution (5.11) to a 100 ml one-mark

with water, stopper and mix thoroughly.

volumetric flask (6.2.1.5) dilute to the mark with

hydrochloric acid diluted 1 + 1 (5.4) stopper and mix

5.16 Laboratory

detergent solution, suitable for

thoroughly.

cleaning samplers

and laboratory apparatus, diluted

with water (5.1)

according to the manufacturer’s

This solution may be stored in a polypropylene bottle

instructions.

(6.2.2) for up to one month.

5.17 Inert purge gas, for example argon or nitro-

5.13 Arsenic working standard solution B,

gen, supplied in a cylinder or as a cryogenic fluid.

corresponding to 1 mg of As per litre.

Using a pipette (6.2.1.3), accurately add 10 ml of 5.18 Air, compressed and filtered.

working arsenic solution A (5.12) to a 100 ml one-mark

NOTE 7 This gas is not required if the silica or quartz

volumetric flask (6.2.1.5), dilute to the mark with

absorption cell (6.2.9) used is electrically heated.

hydrochloric acid diluted 1 + 1 (5.4) stopper and mix

thoroughly.

5.19 Acetylene, in a cylinder.

This solution may be stored in a polypropylene bottle

NOTE 8 This gas is not required if the silica or quartz

(6.2.2) for up to one month.

absorption cell (6.2.9) used is electrically heated.

5.14 Sodium tetrahydroborate, solution corre-

sponding to between 2 g and 20 g of sodium tetra-

hydroborate per litre in 0,l mol/l sodium hydroxide

6 Apparatus

solution.

Prepare a sodium tetrahydroborate solution at the 6.1 Sampling equipment

concentration recommended by the manufacturer of

6.1.1 Samplers, for collection of the inhalable frac-

the hydride generation system (6.2.8). Weigh be-

tion of airborne particles (see 7.1 .I) as defined in

tween 2 g and 20 g of sodium tetrahydroborate

IS0 7708, suitable for use with the cellulose ester

(NaBHd) pellets or powder and 4 g of sodium hydrox-

@ IS0 IS0 11041:1996(E)

membrane filters and back-up paper pads (6.1.2) and for several hours at room temperature. Store the

with the sampling pumps (6.1.3) used. paper pads impregnated with sodium carbonate in an

compatible

airtight container and use within one week of prep-

NOTES aration.

9 A number of different terms are used to describe sam-

NOTES

plers designed for collection of the inhalable fraction of air-

borne particles, for example, sampling heads, filter holders,

13 The volume of sodium carbonate solution required to

filter cassettes and air monitoring cassettes.

impregnate the back-up paper pads is typically 175 ~1 for a

25 mm diameter paper pad or 400 ~1 for a 37 mm diameter

10 In general, the collection characteristics of inhalable

paper pad.

samplers are such that particulate material collected on the

filter is the inhalable fraction of airborne particles, and any

14 The drying time for paper pads impregnated with

deposited on the internal surfaces of the sampler is not of

sodium carbonate may be reduced by placing them in an

interest. However, some samplers are designed such that

oven at 40 “C for 45 min.

airborne particles which pass through the entry orifice(s)

constitute the inhalable fraction; in which case any particu-

15 Glass-fibre or quartz-fibre filters impregnated with so-

late material deposited on the internal surfaces of the sam-

dium carbonate have also been shown to be efficient for

pler is part of the sample. Certain samplers of this type

collecting arsenic trioxide vapour (see reference [4] in annex

incorporate an internal filter cassette or cartridge which

A) and may be used as an alternative to cellulose ester

may be removed from the sampler to enable this material

membrane filters and back-up paper pads impregnated with

to be easily recovered.

sodium carbonate. Neither glass-fibre nor quartz-fibre filters

are dissolved by the wet-ashing procedure specified in

11 Samplers which are assembled by means of screw-

8.2.2, but this may be modified to permit their use (see

threaded fittings may be unsuitable for use with a cellulose

note 33).

ester membrane filter and a back-up paper pad. The high

restriction of a cellulose ester membrane filter, compared

6.1.3 Sampling pumps, complying with the require-

with that of a paper pad, means that there is a tendency for

ments of EN 1232, with an adjustable flow rate, incor-

air to take the path of least resistance and to be drawn

porating a flowmeter or a flow-fault indicator, and

along screw threads and in through the edges of the paper

pad, rather than through the cellulose ester membrane capable of maintaining the appropriate flow rate (see

filter. Leakage can sometimes be eliminated by tightening

7.1 .I) to within + 5 % of the nominal value throughout

screw-threaded fittings as much as possible to compress

the sampling period (see 7.1.2). For personal sam-

and seal the edges of the paper pads, but this is not fully

pling, the pumps shall be capable of being worn by a

effective for certain types of sampler. Samplers with push-

person without impeding normal work activity. The

fit components can, in general, be used more reliably.

pumps shall give a pulsation-free flow (if necessary, a

pulsation damper shall be incorporated between the

12 Samplers manufactured in non-conducting material

sampler and the pump, as near to the pump as

have electrostatic properties which may influence represen-

possible).

tative sampling. Electrostatic influences should be reduced,

where possible, by using samplers manufactured from

NOTE 16 Flow-stabilized sampling pumps may be required

conducting material.

to maintain the flow rate within the limits specified in 6.1.3.

6.1.2 Cellulose ester membrane filters and back-

6.1.4 Portable flowmeter, capable of measuring the

up paper pads, of a diameter suitable for use in the

appropriate flow rate (see 7.1 .I) to within & 5 %, and

selected sampler (6.1.1).

calibrated against a primary standard, i.e. a flowmeter

of which the accuracy is traceable to national

The mass of arsenic of a cellulose ester membrane

standards.

filter and back-up paper pad shall be less than 0,Ol pg.

NOTES

6.1.2.1 The cellulose ester membrane filters shall

have a retentivity not less than 99 % for particles

17 The flowmeter incorporated in the sampling pump may

of median aerodynamic diameter 0,3 pm (see

be used provided that it has adequate sensitivity, that it has

IS0 7708:1995, subclause 2.2).

been calibrated against a primary standard with a loaded

sampler in line, and that it is read whilst in a vertical orien-

6.1.2.2 The back-up paper pads shall be impregnated

tation if it is of the supported float type. However, it is

with sodium carbonate in an area where arsenic important to ensure that there are no leaks in the sampling

train between the sampler and the flowmeter, since in this

contamination is known to be low, using the following

event a flowmeter in the sampling pump or elsewhere in

procedure:

line will give an erroneous flow rate.

Place the paper pads on a clean polytetrafluoro-

18 A soap bubble flowmeter may be used as a primary

ethylene (PTFE) sheet or similar, inert, flat surface

standard, provided its accuracy is traceable to national

(6.2.4). Establish the volume of sodium carbonate sol-

standards.

ution (5.2) required to just wet the entire paper pad

after the solution has been allowed to spread for a

19 If appropriate (see 7.1.3.21, the atmospheric tempera-

few minutes. Dispense this volume of sodium car-

ture and pressure at which the flowmeter was calibrated

bonate solution onto each paper pad and allow to dry should be recorded.

IS0 11041:1996(E) @ IS0

6.15 Ancillary equipment, including flexible plastics 62.3 Piston-operated volumetric apparatus, com-

plying with the requirements of IS0 8655-l to

tubing of a diameter suitable for making a leakproof

IS0 8655-4. Automatic pipettes, as an alternative to

connection from the samplers (6.1 .I ) to the sampling

one-mark pipettes (621.3) for preparation of the

pumps (6.1.3); belts or harnesses to which the sam-

pling pumps can conveniently be fixed, unless they working standard solutions (5.12 and 5.13), calibration

are small enough to fit in workers’ pockets; flat-tipped solutions (see 8.3) and sample solutions (see 8.2.4),

forceps for loading and unloading cellulose ester and dispensers for dispensing acids and potassium

membrane filters and paper pads into samplers; and iodide solution (see 8.2 and 8.3).

filter-transport cassettes or similar, if required (see

7.4.11, to transport samples to the laboratory.

6.2.4 PTFE sheet, or other similar inert flat surface

suitable for treatment of filters and paper pads with

sodium carbonate solution.

6.1.6 Thermometer, 0 “C to 50 OC, graduated in

divisions of 1 “C or better, for measurement of at-

mospheric temperature (see 7.1.3). 6.2.5 Hotplate, thermostatically controlled, capable

of maintaining surface temperatures of approximately

150 “C (see 8.1.2), 175 “C and 200 “C (see 8.22).

6.1.7 Barometer, for measurement of atmospheric

pressure (see 7.1.3).

NOTE 22 The efficiency of thermostatting of hotplates is

sometimes deficient, and the surface temperature can also

vary considerably with position on a hotplate with a large

surface area. It may therefore be useful to characterize the

6.2 Analytical or laboratory apparatus

performance of the hotplate before use.

Ordinary laboratory apparatus, and

6.2.6 Suction filtration apparatus

6.2.1 Glassware, made of borosilicate glass 3.3

complying with the requirements of IS0 3585.

6.2.6.1 Filter funnel with support assembly, for

filtration through a 47 mm diameter filter, made of

NOTE 20 It is preferable to reserve a set of glassware for

borosilicate glass 3.3 complying with the require-

analysis of arsenic by this method. Heavily contaminated

glassware in general usage may not be satisfactorily ments of IS0 3585.

cleaned by the cleaning procedure specified in 8.1.4.

6.2.6.2 Conical flask, of capacity 1 litre, either

6.2.1.1 Beakers, of capacity 50 ml for wet-ashing of

standard or Buchner type according to the design of

cellulose ester membrane filters and back-up paper

the filter funnel with support assembly (6.2.6.1),

pads of the diameter used in the sampler (see 8.2.2),

which may incorporate the vacuum connection, and

and for preparation of the arsenic stock standard

made of borosilicate glass 3.3 complying with the re-

solution (5.11.2); of capacity 250 ml for preparation of

quirements of IS0 3585.

the sodium carbonate solution (5.2) and the potassium

iodide solution (5.9); and of capacity 1 litre for prep-

aration of sodium tetrahydroborate solution (5.14) and

6.2.6.3 Filter pump, water-operated or vacuum

sodium hydroxide solution (5. I 5).

pump, connected to the filter funnel with support

assembly (6.2.6.1) or the conical flask (6.2.6.2) with

6.2.1.2 Watch glasses, to fit the 50 ml beakers plastics tubing (6.1.5).

(6.2.1 .I).

6.2.6.4 Membrane filters, of diameter 47 mm and

6.2.1.3 One-mark pipettes, complying with the re-

pore size 0,8 pm, made of cellulose ester, PVC or

quirements of IS0 648, as an alternative to piston-

other material not degraded by sodium tetrahydro-

operated volumetric apparatus (6.2.3).

borate solution (5.14).

6.2.1.4 Measuring cylinders, of capacities between

6.2.7 Atomic absorption spectrometer, equipped

IO ml and 1 litre.

with an arsenic hollow cathode lamp or electrodeless

discharge lamp. If the absorption cell (6.2.9) is heated

6.2.1.5 One-mark volumetric flasks, of capacities

by an air/acetylene flame, the atomic absorption

between IO ml and 2 000 ml, complying with the re-

spectrometer shall be fitted with an air/acetylene

quirements of IS0 1042.

burner assembly, suitable for mounting the absorption

cell, and supplied with compressed air (5.18) and

6.2.2 Polypropylene bottles, of capacity 1 litre.

acetylene (5.19).

NOTE 21 Bottles made of alternative plastics may be

used, provided that they are suitable for the intended use 6.2.8 Hydride generation system, of one of the

(see 5.11.2, 5.12, 5.13 and 5.14).

types described in 6.2.8.1 and 6.2.8.2.

IS0 11041:1996(E)

@ IS0

WARNING - Arsine (AsH3) is generated when

6.2.8.1 Continuous-flow hydride generation sys-

solutions containing arsenic are reacted with so-

tem, set up and operated according to the manu-

dium tetrahydroborate. This gas is very toxic, but

facturers’ instructions; incorporating

it will normally be produced only in very small

a) reservoirs for sodium tetrahydroborate solution

quantities. However, in order to eliminate the

and acid blank; possibility of exposure to arsine, it is essential that

the liquid waste container used be equipped with

b) an autosampler for presentation of the sample

efficient local exhaust ventilation to prevent any

solution (optional);

gases emanating from the liquid waste from

c) an inert switching valve(s), either solenoid or entering the general laboratory environment.

pneumatically actuated, to facilitate switching

6.2.9 Absorption cell, made of silica or quartz,

between sample and acid blank streams (optional);

heated either electrically or by an air/acetylene flame,

d) peristaltic pumps or a multi-channel peristaltic

and mounted in the optical path of the atomic absorp-

pump, fitted with appropriate acid-resistant pump

tion spectrometer (6.2.7).

tubing;

NOTE 24 Spray from the gas/liquid separator may be

e) a chemically inert mixing piece(s) to facilitate

carried into the absorption cell by the argon stream in some

mixing of acid blank or test solution, sodium

hydride generation systems. This is detrimental to the

stability of response of the system and damaging to quartz

tetrahydroborate solution and inert gas streams;

cells. It is recommended that a membrane filter made of

f ) a reaction coil (optional);

PTFE be inserted into the tubing connecting the gas/liquid

separator to the absorption cell.

g) a gas/liquid separator, with appropriate inlets for

the reaction liquid stream and inert purge gas, and

WARNING - Arsine (AsH3) is passed into the ab-

outlets for waste liquid and the purge gas plus

sorption cell. This gas is very toxic, but it will

gaseous products.

normally be decomposed in the cell. However, in

order to eliminate the possibility of exposure to

A schematic diagram of a typical system is given in

arsine, it is essential that efficient local exhaust

figure I.

ventilation be installed to prevent waste gases

from entering the general laboratory environment.

NOTE 23 Continuous-flow hydride generation systems all

work on the same principle, but the plumbing of the various

6.2.10 Analytical balance, capable of weighing to

systems is different. In particular, the configuration of some

the nearest 0,l mg.

continuous flow hydride generation systems is such that

there is (are) no switching valve(s), and both acid and test

6.2.11 Disposable gloves, impermeable, to avoid

solutions are continuously pumped to an additional mixing

the possibility of contamination from the hands and to

piece situated upstream of the mixing piece where the

protect them from contact with toxic and corrosive

sodium tetrahydroborate solution is introduced.

substances. Poly(vinyl chloride) (PVC) gloves are

suitable.

6.2.8.2 Flow-injection-analysis hydride generation

system, set up and operated according to the

7 Sampling

manufacturer’s instructions; incorporating

reservoirs for sodium tetrahydroborate solution

a)

7.1 Sampling procedure

and acid blank;

multi-channel peristaltic pumps, fitted with appro- 7.1 .I Collection characteristics and flow rate

b)

priate acid-resistant pump tubing;

Select a sampler (6.1 .I) suitable for collection of the

an autosampler for presentation of the sample

d

inhalable fraction of airborne particles, as defined in

solution;

IS0 7708, and use at the flow rate at which the sam-

an inert injection valve, either solenoid or pneu-

d) pler exhibits the required collection characteristics.

matically actuated, to inject a reproducible volume

NOTE 25 lnhalable samplers are typically used at a flow

of sample solution into the acid blank stream;

rate of around 2I/min (it is advisable to refer to the manu-

a chemically inert mixing piece(s) to facilitate

e)

facturer’s recommendations).

mixing of acid blank or test solution, sodium tetra-

hydroborate solution and inert purge gas streams;

.

f 1 a reaction coil (optional);

7.1.2 Sampling period

a gas/liquid separator, with an inlet for the reaction

9)

Select a sampling period of appropriate duration, using

liquid stream and outlets for waste liquid and the

any available information about the work process and

purge gas plus gaseous products.

test atmosphere, so that the amount of arsenic

A schematic diagram of a typical system is given in collected is within the recommended working range

figure 2. of the method.

IS0 11041:1996(E)

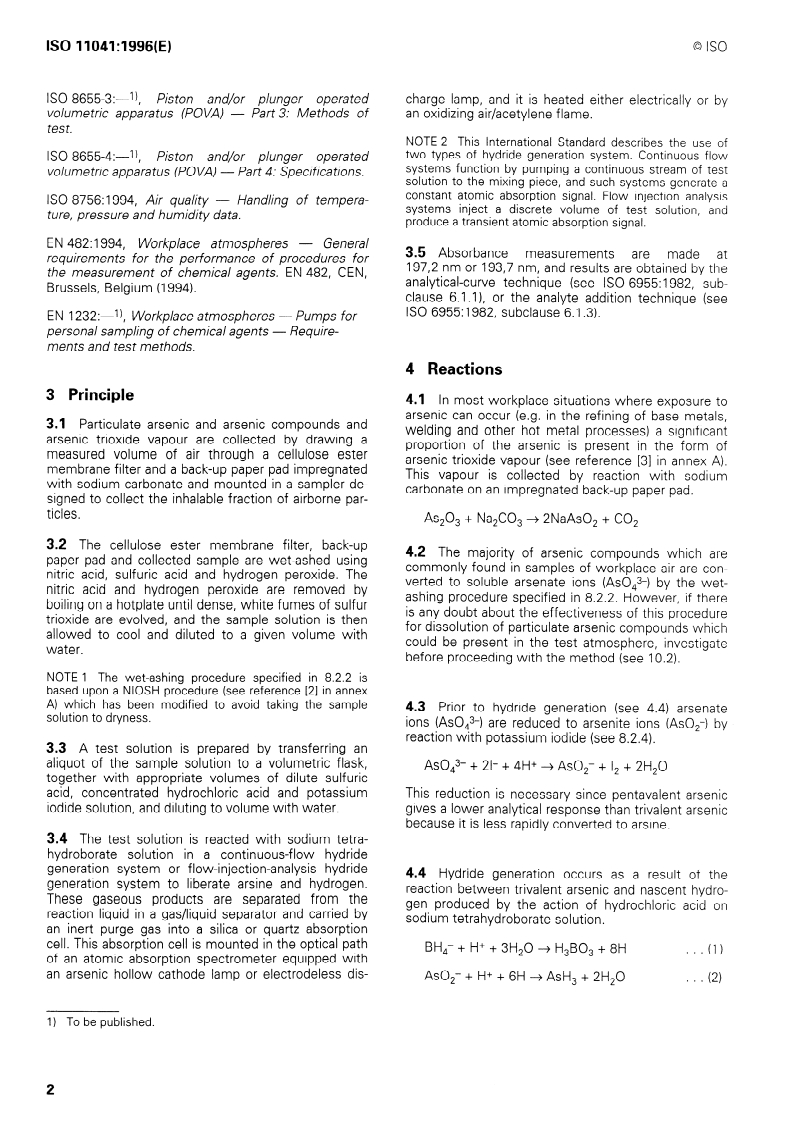

Sodium

borohydride

To heated silica

solution

l-

or quartz cell mounted

in atomic absorption

spectrometer

Two-channel

i Gas/liquid separator

Gaseous/liquid

reactants

Mixing piece

..:-.::..:;.:I:..:-..:~...~ ..*.* I.,:

. . . . . . .*.-. . . . . . . . . . . . . .

I I

. . . . . . . . . . . . . .‘.: . . . . :I.‘.:. .: . . . . . . ;.,-:;.$J

. . . . . ;.:

I If I: . . . . . . . . . . . . . .-. :.:::::.:. \I

ste

Solenoid valve

--I

Acid blank

Zero flow detector

Acidified sample

Inert gas (argon or nitrogen)

Time (s)

45,00

Atomic absorption output when valve is operated, changing the flow to the mixing piece from acid blank

to acidified sample solution

Schematic example of a configuration of a continuous-flow hydride generation system

Figure 1 -

IS0 11041:1996(E)

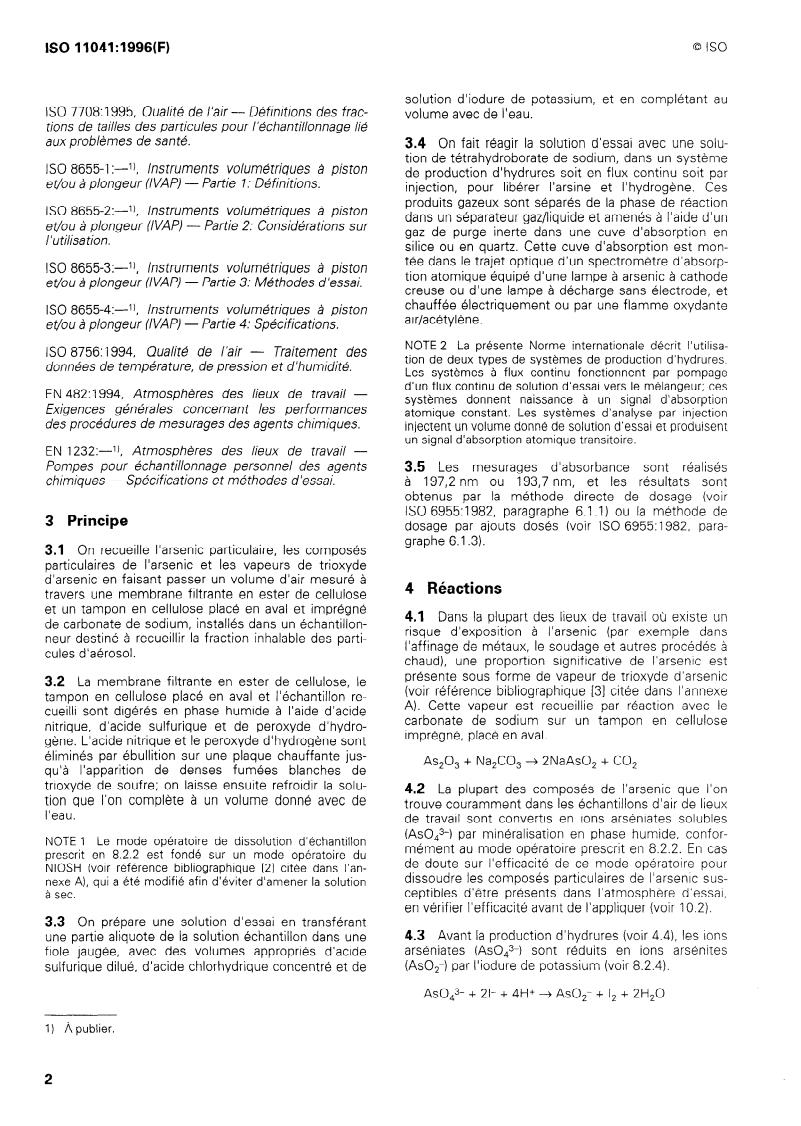

Autosampler

‘7TzTEY

Gas/liquid

HCI

separator

NaBHa

.................

...... .............................

..................

.................

..................

.................

...................................

Pressure regulator

~~~~

Argon

Pump 2

--

Flow injection valve functions

~ I:il-;ii;,:/*

Fill

Injection

... . .............

..................

...................................

.................

...................................

..................

...............

..................

................. Waste

......... ............... , ... , ......

..................

.................

..................

::::: ~_~_~.~,~.~.~.~,~.~.‘.~,

.................

...................................

....................

..............

..................

.................

..................

:::.: :.:.y.:.: :.:.:.:.:.:.:.:.

.: .

................

.... . . .

............................................

.................................

.~.~.‘.~.~.~.~.~.~.~.~.~.~ .::;

..................

~

Time (s)

15,oo

Atomic absorption output when sample valve is operated, injecting a fixed volume of acidified sample solution

into the acid blank flow

Figure 2 - Schematic example of a configuration of a flow-injection-analysis hydride

generation system

@ IS0

IS0 11041:1996(E)

sampling pump (6.1.3) using plastics tubing (6.1.5),

NOTE 26 In order to estimate a sampling period of

appropriate duration it is necessary to consider the flow

ensuring that no leaks can occur. Switch on the sam-

rate used (see 7.1 .I) and the anticipated concentration of

pling pump, attach the calibrated flowmeter (6.1.4) to

arsenic in the test atmosphere. When low arsenic-in-air

the sampler so that it measures the flow through the

concentrations are anticipated, the lower limit of the

sampler inlet orifice(s), and set the appropriate flow

working range of the method (see 9.3.2) should be taken

rate (see 7.1 .I) with an accuracy of k 5 %. Switch off

into consideration. For example, to determine arsenic in air

the sampling pump and seal the sampler with its pro-

at a concentration of 0,l pg/ms, the minimum sampling

tective cover or plug to prevent contamination with

time at a flow rate of 2 I/min is approximately 2 h. When

arsenic during transport to the sampling position.

high arsenic-in-air concentrations are anticipated, the

sampling time should not be long enough to risk over-

NOTE 29 It might be necessary to warm up certain types

loading the filter with particulate matter.

of sampling pump (it is recommended to refer to the manu-

facturer’s instructions).

7.1.3 Temperature and pressure effects

7.1.3.1 Consider whether it is necessary to

7.3 Collection of samples

recalculate the mass concentration of arsenic in the

air to reference conditions of temperature and

pressure in order to comply with national standards

7.3.1 For personal sampling, fix the sampler to the

and regulations (see IS0 8756). If appropriate,

lapel of the worker, in the breathing zone and as close

measure and record the atmospheric temperature and

to the mouth and nose as is reasonably practicable.

pressure throughout the sampling period (see 7.32,

Then, either place the sampling pump in a convenient

7.3.3 and 7.3.5) and use the equation given in-9.1.3 to

pocket or attach it to the worker in a manner that

apply the necessary correction. causes minimum inconvenience, for example, to a

belt (6.1.5) around the waist. For fixed-location sam-

NOTE 27 Arsenic-in-air concentrations are generally stated

pling, position the sampler at the sampling site.

for the actual environmental conditions (temperature,

pressure) at the workplace.

NOTE 30 The breathing zone has been defined in EN 1540

(reference [6] in annex A) as the space around the worker’s

7.1.3.2 The indicated flow rate of certain types of

face from where he takes his breath. For technical pur-

flowmeter is dependent upon temperature and press-

poses, a more precise definition can be provided, as fol-

ure. Therefore, refer to the manufacturer’s directions

lows: hemisphere (generally accepted to be 0,3 m in radius)

for the particular flowmeter used, and consider

extending in front of the human face, centred on the mid-

whether it is necessary to make a correction to take

point of a line joining the ears; the base of the hemisphere

into account any difference between the atmospheric

is a plane through this line, the top of the head and the

larynx.

temperature and pressure at the time of calibration of

the flowmeter and at the time of sampling. Make such

a correction if it is considered possible that an error of

7.32 When ready to begin sampling, remove the

greater than + 5 % will be introduced by not doing so.

protective cover or plug from the sampler and switch

If a correction is to be made, measure and record the

on the sampling pump. Record the time at the start of

atmospheric temperature and pressure at which the

the sampling period and, if the sampling pump has an

flowmeter (6.1.4) was calibrated.

elapsed time indicator, set this to zero. If appropriate

(see 7.1.3.1) measure the atmospheric temperature

NOTE 28 An example of temperature and pressure cor-

and pressure at the start of the sampling period using

rection for the indicated flow rate is given in 9.1.2, for a

the thermometer (6.1.6) and barometer (6J.7) and

flowmeter of variable area with constant pressure drop.

record the measured values.

7.2 Preparation of sampling equipment

7.3.3 Since it is possible for a filter to become

clogged, monitor the performance of the sampler fre-

where arsenic con-

Perform th e following in an area

quently, a minimum of once per hour. Measure the

tamination IS known to be low.

flow rate with an accuracy of -t 5 % using the cali-

brated flowmeter (6.1.4) and, if appropriate (see

7.2.1 Clean the samplers (6.1 .I) before use. Dis-

7.1.3.1) measure the atmospheric temperature using

assemble the samplers, soak in laboratory detergent

the thermometer (6.1.6) and the atmospheric pressure

solution (5.166, rinse thoroughly with water (5.1) wipe

using the barometer (6l.7). Record the measured

with absorptive tissue and allow to dry before re-

values.

assembly.

NOTE 31 Regular observation of the flow-fault indicator is

an acceptable means of ensuring that the flow rate of a

7.2.2 Load the back-up paper pads impregnated with

flow-stabilized sampling pump is maintained satisfactorily,

sodium carbonate (6.1.2.2) followed by the cellulose

provided that the flow-fault indicator indicates malfunction

ester membrane filters (6.1.2.1) into clean, dry sam-

when the flow rate is outside t 5 % of the nominal value.

plers (7.2.1) so that the filter is upstream in relation to

the back-up paper pad when air is drawn through the

7.3.4 Terminate sampling and consider the sample to

sampler. Handle the filters only with clean, flat-tipped

be invalid if the flow rate is not maintained to within

forceps (6.1.5). Connect each loaded sampler to a

0 IS0 IS0 11041:1996(E)

the laborato

If: 5 % of the nominal value throughout the sampling ry in the samplers in which they were

collected.

period.

7.4.4 Transport the filter-transport cassettes (see

7.3.5 At the end of the sampling period (see 7.12)

7.4.1), sampler filter cassettes (see 7.4.2) or samplers

measure the flow rate with an accuracy of + 5 %

(see 7.4.3) in a container which has been designed to

using the calibrated flowmeter (6.1.4), switch off the

prevent damage to the samples in transit and which

sampling pump and record the flow rate and the time.

has been labelled to assure proper handling.

Also observe the reading on the elapsed time indi-

cator, if fitted, and consider the sample to be invalid if

the reading on the elapsed time indicator and the

timed interval between switching the sampling pump

on and off do not agree to within ?I 5 %, since this

8 Procedure for analysis

may suggest that the sampling pump has not been

operating throughout the sampling period. Reseal the

8.1 Cleaning of glassware and

sampler with its protective cover or plug and discon-

polypropylene bottles

nect it from the sampling pump. If appropriate (see

7.1.3.1), measure the atmospheric temperature and

8.1.1 Before use, clean all glassware to remove any

pressure at the end of the sampling period using the

residual grease or chemicals, by soaking in laboratory

thermometer (6.1.6) and barometer (6.1.7) and record

detergent solution (5.16) and then rinsing thoroughly

the measured values.

with water (5.1).

7.3.6 Carefully record the sample identity and all

8.1.2 After initial cleaning (see 8.1 .I), clean all

relevant sampling data (see clause 11). C

...

IS0 11041:1996(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work of

preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 11041 was prepared by Technical Committee

lSO/TC 146, Air quality, Subcommittee SC 2, Workplace atmospheres.

Annex A of this International Standard is for information only.

0 IS0 1996

All rights reserved. Unless otherwise specified, no part of this publication may be

reproduced or utilized in any form or by any means, electronic or mechanical, including

photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

ii

IS0 11041:1996(E)

INTERNATIONAL STANDARD @ IS0

Workplace air - Determination of particulate arsenic and arsenic

compounds and arsenic trioxide vapour - Method by hydride

generation and atomic absorption spectrometry

WARNING - Arsenic and arsenic compounds are toxic and are recognized as human carcinogens (see reference

[I] in annex A). Avoid any exposure by inhalation. Personal protection (e.g. an effective respirator) must be used

in all cases where exposure to arsenic or arsenic compounds is possible.

this International Standard. At the time of publication,

1 Scope

the editions indicated were valid. All standards are

subject to revision, and parties to agreements based

This International Standard specifies a method for the

on this International Standard are encouraged to in-

determination of the mass concentration of particulate

vestigate the possibility of applying the most recent

arsenic and arsenic compounds and arsenic trioxide

editions of the standards indicated below. Members

vapour in workplace air, using either continuous-flow

of IEC and IS0 maintain registers of currently valid

hydride generation or flow-injection-analysis hydride

International Standards.

generation and atomic absorption spectrometry. The

method is not suitable for determination of arsenic in

the form of metal arsenides which decompose in the IS0 648:1977, Laboratory glassware - One-mark

presence of water or acid (see 10.1). pipettes.

The method is applicable to the determination of

IS0 1042: 1983, Laboratory glassware - One-mark

masses of approximately 100 ng to 125 pg of arsenic

volumetric flasks.

per sample, for analysis of test solutions prepared

using sample solution aliquots in the recommended

IS0 3585: 1991, Borosilicate glass 3.3 - Properties.

range (see 9.3.2). The concentration range for arsenic

in air, for which this procedure is applicable, is deter-

IS0 3696: 1987, Water for analytical labora tory use -

mined in part by the sampling procedure selected by

Specification and test methods.

the user.

IS0 6955: 1982, Analytical spectroscopic methods -

The method is applicable to personal and fixed-

Flame emission, atomic absorption and atomic

location sampling.

fluorescence - Vocabulary.

A number of transition metals may interfere with the

IS0 7708:1995, Air quality - Particle size fraction

determination of arsenic by hydride generation and

definitions for health-related sampling.

atomic absorption spectrometry (see 10.3)

IS0 8655-l :-I), Piston and/or plunger opera ted

volumetric apparatus (POVA) - Part 1: Definitions.

2 Normative references

I SO 8655-2:--l 1, Piston and/or plunger opera ted

volumetric apparatus (POVA) - Part 2: Operating

The following standards contain provisions which,

considerations.

through reference in this text, constitute provisions of

1) To be published.

0 IS0

IS0 11041:1996(E)

Piston and/or plunger opera ted charge lamp, and it is heated either electrically or by

IS0 8655-3:-l),

an oxidizing air/acetylene flame.

volumetric apparatus (POVA) - Part 3: Methods of

test.

NOTE 2 This International Standard describes the use of

two types of hydride generation system. Continuous flow

IS0 8655-4:-l), Piston and/or plunger opera ted

systems function by pumping a continuous stream of test

volumetric apparatus (POVA) - Part 4: Specifications.

solution to the mixing piece, and such systems generate a

constant atomic absorption signal. Flow injection analysis

IS0 8756: 1994, Air quality - Handling of tempera-

systems inject a discrete volume of test solution, and

ture, pressure and humidity data.

produce a transient atomic absorption signal.

EN 482: 1994, Workplace atmospheres - General

3.5 Absorbance measurements are made at

requirements for the performance of procedures for

197,2 nm or 193,7 nm, and results are obtained by the

the measurement of chemical agents. EN 482, CEN,

analytical-curve technique (see IS0 6955: 1982, sub-

Brussels, Belgium (1994).

clause 6.1 .I ), or the analyte addition technique (see

IS0 6955:1982, subclause 6.1.3).

EN 1232: --I), Workplace atmospheres - Pumps for

personal sampling of chemical agents - Require-

ments and test methods.

4 Reactions

3 Principle

4.1 In most workplace situations where exposure to

arsenic can occur (e.g. in the refining of base metals,

3.1 Particulate arsenic and arsenic compounds and

welding and other hot metal processes) a significant

arsenic trioxide vapour are collected by drawing a

proportion of the arsenic is present in the form of

measured volume of air through a cellulose ester

arsenic trioxide vapour (see reference [3] in annex A).

membrane filter and a back-up paper pad impregnated

This vapour is collected by reaction with sodium

with sodium carbonate and mounted in a sampler de-

carbonate on an impregnated back-up paper pad.

signed to collect the inhalable fraction of airborne par-

ticles.

As,O, + Na,CO, -+ ZNaAsO, + CO,

3.2 The cellulose ester membrane filter, back-up

4.2 The majority of arsenic compounds which are

paper pad and collected sample are wet-ashed using

commonly found in samples of workplace air are con-

nitric acid, sulfuric acid and hydrogen peroxide. The

verted to soluble arsenate ions (As0,3-) by the wet-

nitric acid and hydrogen peroxide are removed by

ashing procedure specified in 8.2.2. However, if there

boiling on a hotplate until dense, white fumes of sulfur

is any doubt about the effectiveness of this procedure

trioxide are evolved, and the sample solution is then

for dissolution of particulate arsenic compounds which

allowed to cool and diluted to a given volume with

could be present in the test atmosphere, investigate

water.

before proceeding with the method (see 10.2).

NOTE 1 The wet-ashing procedure specified in 8.2.2 is

based upon a NIOSH procedure (see reference [2] in annex

A) which has been modified to avoid taking the sample

4.3 Prior to hydride generation (see 4.4) arsenate

solution to dryness.

ions (AsO,s-) are reduced to arsenite ions (AsO,-) by

reaction with potassium iodide (see 8.2.4).

3.3 A test solution is prepared by transferring an

aliquot of the sample solution to a volumetric flask,

AsOds- + Zl- + 4H+ + AsO,- + I2 + 2H,O

together with appropriate volumes of dilute sulfuric

This reduction is necessary since pentavalent arsenic

acid, concentrated hydrochloric acid and potassium

gives a lower analytical response than trivalent arsenic

iodide solution, and diluting to volume with water.

because it is less rapidly converted to arsine.

3.4 The test solution is reacted with sodium tetra-

hydroborate solution in a continuous-flow hydride

generation system or flow-injection-analysis hydride

4.4 Hydride generation occurs as a result of the

generation system to liberate arsine and hydrogen.

reaction between trivalent arsenic and nascent hydro-

These gaseous products are separated from the

gen produced by the action of hydrochloric acid on

reaction liquid in a gas/liquid separator and carried by

sodium tetrahydroborate solution.

an inert purge gas into a silica or quartz absorption

cell. This absorption cell is mounted in the optical path

BH,- + H+ + 3H,O -+ H,BO, + 8H . . .

(1 >

of an atomic absorption spectrometer equipped with

an arsenic hollow cathode lamp or electrodeless dis- AsO,- + H+ + 6H + ASH, + 2H,O . . .

(2)

1) To be published.

IS0 11041:1996(E)

@ IS0

5.6 Nitric acid (HNO$, concentrated,

4.5 Arsenic atoms are produced from arsine by the

- I,42 g/ml, 69 % (m/m) to 71 % (d.).

action of heat in a silica or quartz absorption cell,

P

heated either by a lean air/acetylene flame or elec-

The concentration of arsenic shall be less than

trically.

0,Ol pg/ml.

WARNING - Concentrated nitric acid is corrosive

5 Reagents

and oxidizing, and nitric acid fumes are irritant.

During the analysis, use only reagents of analytical Avoid exposure by contact with the skin or eyes,

or by inhalation of fumes. Personal protective

grade, and only water as specified in 5.1.

equipment (e.g. gloves, face shield or safety spec-

5.1 Water, complying with the requirements for

tacles, etc.) must be used when working with the

IS0 3696 grade 2 water (electrical conductivity less concentrated or diluted nitric acid, and concen-

than 0,l mS/m and resistivity greater than 0,Ol ML&m

trated nitric acid must be used in a fume hood.

at 25 “C).

5.7 Sulfuric acid (HzSOa), concentrated,

5.2 Sodium carbonate, 1 mol/l solution in 5 %

w I,84 g/ml, about 98 % (m/m).

P

glycerol solution.

The concentration of arsenic shall be less than

to a

Weigh IO,6 g of sodium carbonate (Na2C03) it 0,05 pg/ml.

and

250 ml beaker (6.2.1 .I). Add 5 ml of glycerol

WARNING - Concentrated sulfuric acid is corros-

50 ml of water (5.1) and swirl to dissolve. Quantita-

ive and causes burns. Avoid exposure by contact

tively transfer the solution to a 100 ml one-mark

with the skin or eyes. Personal protective equip-

volumetric flask (6.2.1.5) dilute to the mark with

ment (e.g. gloves, face shield or safety spectacles,

water, stopper and mix thoroughly.

etc.) must be used when working with the con-

centrated or diluted sulfuric acid. Fumes produced

5.3 Hydrochloric acid (HCI), concentrated

by heating concentrated sulfuric acid are irritant,

- 1 ,I8 g/ml, 35 % (m/m) to 36 % (m/m).

P

and this operation must therefore be carried out in

a fume hood. Caution must be exercised if adding

The concentration of arsenic shall be less than

water to sulfuric acid, since this reacts violently

0,Ol pg/ml.

with water (acid/water mixtures must be prepared

WARNING - Concentrated hydrochloric acid is

by adding acid to water).

corrosive, and hydrochloric acid vapour is irritant.

Avoid exposure by contact with the skin or eyes,

5.8 Hydrogen peroxide (HzO$, approximately

or by inhalation of fumes. Personal protective

30 % (m/m) solution.

equipment (e.g. gloves, face shield or safety spec-

tacles, etc.) must be used when working with the The concentration of arsenic shall be less than

concentrated or diluted hydrochloric acid, and 0,Ol pg/rnl.

concentrated hydrochloric acid must be used in a

WARNING - Hydrogen peroxide is corrosive and

fume hood. The vapour pressure of hydrochloric is

oxidizing. Avoid exposure be contact with the skin

high, therefore beware of pressure build-up in

or eyes. Personal protective equipment (e.g.

stoppered flasks when preparing acid/water

gloves, face shield or safety spectacles, etc.) must

mixtures.

be used when working with protective equipment

5.4 Hydrochloric acid, diluted 1 + 1. hydrogen peroxide.

Pour approximately 900 ml of water (5.1) into a 5.9 Potassium iodide, 100 g/l solution.

2 000 ml one-mark volumetric flask (6.2.1.5). Carefully

Weigh IO,0 g of potassium iodide (KI) into a 250 ml

add 1 000 ml of concentrated hydrochloric acid (5.3) to

beaker (6.2.1 .I ). Add 50 ml of water (5.1) and swirl to

the flask and swirl to mix. Allow to cool, dilute to the

dissolve. Quantitatively transfer the solution to a

mark with water, stopper and mix thoroughly.

100 ml one-mark volumetric flask (6.2.1.5) dilute to

NOTE 3 This is used as the solvent blank, as defined in the mark with water, stopper and mix thoroughly.

IS0 6955:1982, subclause 5.4.2, but in this International

Standard the solvent blank is referred to as the acid blank.

Prepare a fresh solution each month.

5.5 Hydrochloric acid, diluted 1 + 4.

5.18 Sulfuric acid, diluted 1 + 9.

Pour approximately 700 ml of water (5.1) into a Carefully add 25 ml of concentrated sulfuric acid (5.7)

1 000 ml one-mark volumetric flask (6.2.1.5). Carefully to 200 ml of water (5.1) in a 1 litre beaker. Swirl to

add 200 ml of concentrated hydrochloric acid (5.3) to

mix, allow to cool and quantitatively transfer to a

the flask and swirl to mix. Allow to cool, dilute to the

250 ml one-mark volumetric flask (6.2.1.5). Dilute to

mark with water, stopper and mix thoroughly.

the mark with water, stopper and mix thoroughly.

IS0 11041:1996(E) @ IS0

5.11 Arsenic stock standard solution, correspond- ide (NaOH) pellets into a 1 litre beaker (6.2.1 .I). Add

ing to 1 000 mg of As per litre. 200 ml of water (5.1) and swirl to mix. Quantitatively

transfer the solution to a 1 000 ml one-mark volu-

511.1 Use a commercially available arsenic standard

metric flask (6.2.1.5) filtering through a membrane

solution at a concentration of 1 000 mg/l. Observe the

filter using a suction filtration apparatus (6.2.6). Dilute

manufacturer’s expiry date or recommended shelf-life.

to the mark with water (5.1) stopper and mix

thoroughly.

Alternatively, prepare an arsenic standard solution

according to the procedure specified in 5.11.2.

Prepare a fresh solution daily.

511.2 Accurately weigh 1,320 g + 0,001 g of arsenic NOTES

trioxide (As203) into a 50 ml beaker (6.2.1.1), add

4 Filtration of the solution is necessary to remove

10 ml of concentrated hydrochloric acid - (5.3), cover

undissolved particulate material which might otherwise

with a watch glass (6.2.1.2) and heat to approximately

cause clogging of the tubing or mixing piece of the hydride

150 “C on the hotplate (6.2.5) in a fume hood until dis-

generation system (6.2.8). The addition of alkali minimizes

solution is complete. Remove the beaker from the

hydrolysis of the sodium tetrahydroborate solution.

hotplate, allow to cool, quantitatively transfer the sol-

ution to a 1 000 ml one-mark volumetric flask (6.2.1.5)

5 A few drops of anti-foaming agent may be added to the

dilute to the mark with hydrochloric acid diluted 1 + 1

solution to reduce foaming in the gas/liquid separator of the

(5.4), stopper and mix thoroughly.

hydride generation system (6.2.8) which may result in a

noisy baseline signal.

This solution may be stored in a polypropylene bottle

6 The solution should be stored in a polypropylene bottle

(6.2.2) for up to one year.

(6.2.2) if it is not transferred to the reductant reservoir of

the continuous hydride generation system (6.2.8) immedi-

WARNING - Arsenic trioxide is toxic and is

ately after preparation (see 8.4.2.2). The top of the bottle

recognized as a human carcinogen (see reference

should not be fully tightened or pressure will build up due

[I] in annex A). See the general warning about

to the slow release of hydrogen.

arsenic or arsenic compounds, just after the title

of this International Standard.

5.15 Sodium hydroxide, 5 g/l solution.

5.12 Arsenic working standard solution A, corre-

Weigh 5,0 g of sodium hydroxide (NaOH) pellets into a

sponding to 10 mg of As per litre.

1 litre beaker (6.2.1 .I). Add 250 ml of water (5.1) and

swirl to dissolve. Quantitatively transfer the solution to

Using a pipette (6.2.1.3), accurately add I,00 ml of

a 1 000 ml volumetric flask (6.2.1.5) dilute to the mark

stock arsenic solution (5.11) to a 100 ml one-mark

with water, stopper and mix thoroughly.

volumetric flask (6.2.1.5) dilute to the mark with

hydrochloric acid diluted 1 + 1 (5.4) stopper and mix

5.16 Laboratory

detergent solution, suitable for

thoroughly.

cleaning samplers

and laboratory apparatus, diluted

with water (5.1)

according to the manufacturer’s

This solution may be stored in a polypropylene bottle

instructions.

(6.2.2) for up to one month.

5.17 Inert purge gas, for example argon or nitro-

5.13 Arsenic working standard solution B,

gen, supplied in a cylinder or as a cryogenic fluid.

corresponding to 1 mg of As per litre.

Using a pipette (6.2.1.3), accurately add 10 ml of 5.18 Air, compressed and filtered.

working arsenic solution A (5.12) to a 100 ml one-mark

NOTE 7 This gas is not required if the silica or quartz

volumetric flask (6.2.1.5), dilute to the mark with

absorption cell (6.2.9) used is electrically heated.

hydrochloric acid diluted 1 + 1 (5.4) stopper and mix

thoroughly.

5.19 Acetylene, in a cylinder.

This solution may be stored in a polypropylene bottle

NOTE 8 This gas is not required if the silica or quartz

(6.2.2) for up to one month.

absorption cell (6.2.9) used is electrically heated.

5.14 Sodium tetrahydroborate, solution corre-

sponding to between 2 g and 20 g of sodium tetra-

hydroborate per litre in 0,l mol/l sodium hydroxide

6 Apparatus

solution.

Prepare a sodium tetrahydroborate solution at the 6.1 Sampling equipment

concentration recommended by the manufacturer of

6.1.1 Samplers, for collection of the inhalable frac-

the hydride generation system (6.2.8). Weigh be-

tion of airborne particles (see 7.1 .I) as defined in

tween 2 g and 20 g of sodium tetrahydroborate

IS0 7708, suitable for use with the cellulose ester

(NaBHd) pellets or powder and 4 g of sodium hydrox-

@ IS0 IS0 11041:1996(E)

membrane filters and back-up paper pads (6.1.2) and for several hours at room temperature. Store the

with the sampling pumps (6.1.3) used. paper pads impregnated with sodium carbonate in an

compatible

airtight container and use within one week of prep-

NOTES aration.

9 A number of different terms are used to describe sam-

NOTES

plers designed for collection of the inhalable fraction of air-

borne particles, for example, sampling heads, filter holders,

13 The volume of sodium carbonate solution required to

filter cassettes and air monitoring cassettes.

impregnate the back-up paper pads is typically 175 ~1 for a

25 mm diameter paper pad or 400 ~1 for a 37 mm diameter

10 In general, the collection characteristics of inhalable

paper pad.

samplers are such that particulate material collected on the

filter is the inhalable fraction of airborne particles, and any

14 The drying time for paper pads impregnated with

deposited on the internal surfaces of the sampler is not of

sodium carbonate may be reduced by placing them in an

interest. However, some samplers are designed such that

oven at 40 “C for 45 min.

airborne particles which pass through the entry orifice(s)

constitute the inhalable fraction; in which case any particu-

15 Glass-fibre or quartz-fibre filters impregnated with so-

late material deposited on the internal surfaces of the sam-

dium carbonate have also been shown to be efficient for

pler is part of the sample. Certain samplers of this type

collecting arsenic trioxide vapour (see reference [4] in annex

incorporate an internal filter cassette or cartridge which

A) and may be used as an alternative to cellulose ester

may be removed from the sampler to enable this material

membrane filters and back-up paper pads impregnated with

to be easily recovered.

sodium carbonate. Neither glass-fibre nor quartz-fibre filters

are dissolved by the wet-ashing procedure specified in

11 Samplers which are assembled by means of screw-

8.2.2, but this may be modified to permit their use (see

threaded fittings may be unsuitable for use with a cellulose

note 33).

ester membrane filter and a back-up paper pad. The high

restriction of a cellulose ester membrane filter, compared

6.1.3 Sampling pumps, complying with the require-

with that of a paper pad, means that there is a tendency for

ments of EN 1232, with an adjustable flow rate, incor-

air to take the path of least resistance and to be drawn

porating a flowmeter or a flow-fault indicator, and

along screw threads and in through the edges of the paper

pad, rather than through the cellulose ester membrane capable of maintaining the appropriate flow rate (see

filter. Leakage can sometimes be eliminated by tightening

7.1 .I) to within + 5 % of the nominal value throughout

screw-threaded fittings as much as possible to compress

the sampling period (see 7.1.2). For personal sam-

and seal the edges of the paper pads, but this is not fully

pling, the pumps shall be capable of being worn by a

effective for certain types of sampler. Samplers with push-

person without impeding normal work activity. The

fit components can, in general, be used more reliably.

pumps shall give a pulsation-free flow (if necessary, a

pulsation damper shall be incorporated between the

12 Samplers manufactured in non-conducting material

sampler and the pump, as near to the pump as

have electrostatic properties which may influence represen-

possible).

tative sampling. Electrostatic influences should be reduced,

where possible, by using samplers manufactured from

NOTE 16 Flow-stabilized sampling pumps may be required

conducting material.

to maintain the flow rate within the limits specified in 6.1.3.

6.1.2 Cellulose ester membrane filters and back-

6.1.4 Portable flowmeter, capable of measuring the

up paper pads, of a diameter suitable for use in the