ISO/TR 9464:1998

(Main)Guidelines for the use of ISO 5167-1:1991

Guidelines for the use of ISO 5167-1:1991

Lignes directrices pour l'utilisation de l'ISO 5167-1:1991

General Information

- Status

- Withdrawn

- Publication Date

- 29-Apr-1998

- Withdrawal Date

- 29-Apr-1998

- Technical Committee

- ISO/TC 30/SC 2 - Pressure differential devices

- Drafting Committee

- ISO/TC 30/SC 2 - Pressure differential devices

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 20-May-2008

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO/TR 9464:1998 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Guidelines for the use of ISO 5167-1:1991". This standard covers: Guidelines for the use of ISO 5167-1:1991

Guidelines for the use of ISO 5167-1:1991

ISO/TR 9464:1998 is classified under the following ICS (International Classification for Standards) categories: 17.120.10 - Flow in closed conduits. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 9464:1998 has the following relationships with other standards: It is inter standard links to ISO/TR 9464:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TR 9464:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

ISOITR

TECHNICAL

REPORT

First edition

1998-05-01

Guidelines for the use of IS0 5167-l :I991

Guide pour I’emploi de IWO 5 I67- I: I99 I

Reference number

ISO/rR 9464: 1998(E)

Page

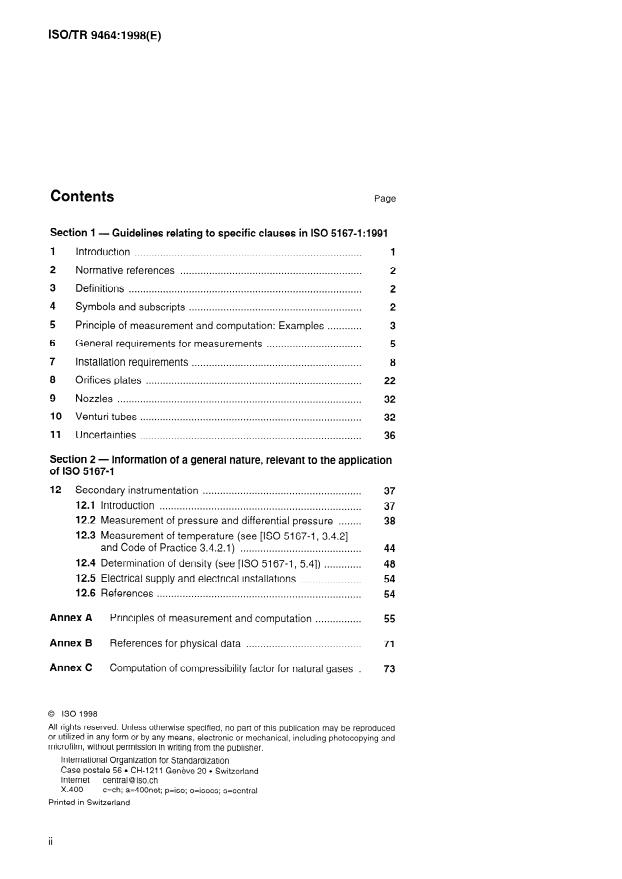

Contents

Section 1 - Guidelines relating to specific clauses in IS0 5167-l :1991

1 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Normative references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*.*.

4 . . . . . . . .~.~. 2

Symbols and subscripts

5 Principle of measurement and computation: Examples . . . . . . . . . . . .

6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General requirements for measurements

7 Installation requirements .,.*.*.

8 Orifices plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9 Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Venturi tubes . . . . . . . . . . . . . . . . . . . . . . . .*. 32

11 Uncertainties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2 - Information of a general nature, relevant to the application

of IS0 5167-1

12 Secondary instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

12.1 Introduction

12.2 Measurement of pressure and differential pressure . . . . . . . . 38

12.3 Measurement of temperature (see [ISO 5167-1, 3.4.21

and Code of Practice 3.4.2.1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Determination of density (see [ISO 5167-l , 5.41) . . . . . . . . . . . . . 48

12.4

12.5 Electrical supply and electrical installations . . . . . . . . . . . . . . . . . . . . . 54

12.6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Annex A Principles of measurement and computation . . . . . . . . . . . . . . . . 55

Annex B References for physical data . . . . . . . . . . . . . . . . . . . . . .e. 71

Annex C Computation of compressibility factor for natural gases .

0 IS0 1998

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Internet central @ iso.ch

x.400 c=ch; a=400net; p=iso; o=isocs; s=central

Printed in Switzerland

ii

ISO/rR 9464:1998(E)

@ IS0

FO reword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work of

preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for which

a technical committee has been established has the right to be represented

on that committee. International organizations, governmental and non-

governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

The main task of technical committees is to prepare International

Standards, but in exceptional circumstances a technical committee may

propose the publication of a Technical Report of one of the following types:

when the required support cannot be obtained for the

- type 13

publication of an International Standard, despite repeated efforts;

- type 2, when the subject is still under technical development or where

for any other reason there is the future but not immediate possibility of

an agreement on an International Standard;

- type 3, when a technical committee has collected data of a different

kind from that which is normally published as an International Standard

(“state of the art”, for example).

Technical Reports of types 1 and 2 are subject to review within three years

of publication, to decide whether they can be transformed into International

Standards. Technical Reports of type 3 do not necessarily have to be

reviewed until the data they provide are considered to be no longer valid or

useful.

ISO/TR 9464, which is a Technical Report of type 3, was prepared by

Technical Committee lSO/TC 30, Measurement of fluid flow in closed

conduits, Subcommittee SC 2, Differential pressure methods.

This page intentionally left blank

ISO/rR 9464:1998(E)

TECHNICAL REPORT o Is0

Guidelines for the use of IS0 5167-1:1991

Section 1 - Guidance relating to specific clauses in IS0 5167~I:1991

1 Introduction

The objective of this Technical Report is to assist users of IS0 5167-1:1991. For

convenience of use, it is divided into two Sections, as

Section 1 - Makes reference to specific clauses and subclauses in IS0 5167-1:1991,

and provides guidance on details and interpretation of the requirements specified in

IS0 5167-1:1991. The clause numbers in this Section have been arranged to be the

same as the corresponding clause numbers in IS0 5167-1:1991.

Section 2 - Gives further information of a general nature, relevant to the application of

IS0 5167-1:1991, but does not refer to specific clauses in IS0 5167-1:1991.

In Section 1, cross-reference is simplified by using the same clause and subclause

numbering as in IS0 5167-1. To avoid confusing figures and tables of this Technical

Report with those of the reference standard IS0 5167-1, references to the latter are

made within square brackets, i.e. [.I.

Some clauses of IS0 5167-1 are not commented upon and the corresponding clause

numbers are therefore omitted from this Technical Report, except when it has been

thought to be useful to keep a continuous numbering of paragraphs.

All quantities and constants quoted in this Technical Report are expressed in SI units.

1.1 IS0 5167-l

IS0 5167-I is an International Standard for flow measurement based on the

differential pressure generated by a constriction introduced into a circular conduit

[ISO 5167-1, 5.11. It presents a set of rules and requirements based on theory and

experimental work undertaken in the field of flow measurement. Neither IS0 5167-1

nor this Technical Report give the detailed theoretical background and reference

should be made to any general textbook on fluid flow.

With the application of the rules and requirements set out in IS0 5167-1, it is

practicable to achieve flow measurement within an uncertainty of approximately 1 per

cent on the calculated rate of flow.

For more detailed description of the scope, reference should be made to [ISO 5167-1,

clause I].

ISO/TR 9464: 1998(E)

1.2 Selection of the primary device

The constraints applicable to each of the primary devices need to be given proper

consideration before determining the most suitable type for a particular application.

Clause 4 of this Technical Report gives guidance. A final decision should not be made

unless it is clear that, for a particular application, the appropriate requirements of the

clauses and subclauses of IS0 5167-I listed in column 4 of table I of this Technical

Report can be fulfilled.

These paragraphs will also form the basis for preliminary design. [lSO 5167-1,

Clauses 3 and 41 give definitions and symbols.

1.3 Detail design

The information necessary for detailed design, manufacture and final check is specified in

the clauses and paragraphs of IS0 5167-I listed in column 2 of table 1.

1.4 Computation

Operation of a measuring system, once installed, requires several computations to

establish the resultant flow-rate, Some results of these calculations will be fixed with

installation dimensions and will only need to be computed once. Other calculations will

need to be repeated for every flow measurement point. The equations to be used are given

in the clauses and sub-clauses of IS0 5167-l listed in column 3 of table I.

15 . Secondary instrumentation

Secondary instrumentation is not covered by IS0 5167-1 but Section 2 of this

Technical Report makes reference to IS0 2186, which will be required.

2 Normative references

No comments on this clause.

3 Definitions

3.1 Pressure measurement

No comments on this clause

3.2 Primary devices

No comments on this clause

3.3 Flow

No comments on this clause

4 Symbols and subscripts

For explanation of the symbols and definitions, reference is made to [ISO 5167-1,

clause 4.11 which is based on IS0 4006.

ISCM-R 9464:1998(E)

Principle of measurement and computation : Examples

5.1 Principle of the method of measurement

No specific comments on this clause, but note that throughout this guide, p2 and c2 may be

used as alternatives to p1 and q .

5.2 Determination of the diameter ratio

Refer to annex A.

5.3 Determination of the rate of flow

Refer to annex A.

5.4 Determination of the density

For more details on density measurement, see Part 2.

For more details on density computation, see 6*2.

5.4.1 No specific comments on this clause.

Table 1 : Reference clauses in IS0 5167-l

1. Selection 3. Computation

2. Desian

3.3, 5.1, 5.3, 11

General 1, 2, 5.1 3.3.6

Fluid and flow conditions 6.2, 6.3 54 . 5.4.3

. 3.2, 6.1.3

Primary device 61

Pipe work 71 . 7.1 and 7.5 or 7.6 7.5.1.2

72 .

Minimum straight lengths 7.2 or 7.4

8.3.2, 8.3.3

Orifice plates 8.3.1, 8.4 8.1, 8.2

9.1.6.1, 9.1.8 9.1.2 to 9.1.5 9.1.6.2, 9.1.6.3, 9.1.7

ISA 1932 nozzles

9.251, 9.2.7 9.2.1 to 9.2.4 9.2.5.2, 9.2.5.3, 9.2.6

Long radius nozzles

10.1.1, 10.1.5, 10.1.9.2

Classical Venturi tubes 10.1.2 to 10.1.4 10.1.5 to 10.1.8

10.2.4.1, 10.2.6 10.2.1 to 10.2.3 10.2.4.2, 10.2.4.3, 10.2.5.1, 10.2.5.2

Venturi nozzles

ISO/rR 94643 998(E)

@ IS0

5.4.2 Temperature measurement

Within the limits of application of the international standard [ISO 5167-1, 5.4.21 it may be

assumed that the downstream and the upstream temperatures of the fluid are the same.

For very accurate measurements it is advisable that the actual temperature at the upstream

plane is measured under flowing conditions using a temporarily installed temperature

probe.

If the fluid being measured is a gas and high accuracy is required and there is a large

pressure loss between the upstream pressure tapping and the location of the temperature

measuring device downstream of the primary device, then it is necessary to calculate the

upstream temperature from the temperature measured downstream. Experimental work has

shown that an isenthalpic expansion is a reasonable approximation for orifice plates.

Further work is required to check its correctness for other primary devices. To perform the

calculation, the pressure loss AO should be calculated from IS0 5167-1, 8.4, 9.1.8, 9.2.8,

10.1.9.2, or 10.2.6, The corresponding temperature drop from the upstream tapping to the

downstream temperature measurement location, AT, can be evaluated given the rate of

change of T with respect to p at constant enthalpy:

I

CT

AT=- A0

I

$I,,

RJ-

cz

Z------------

- -lo

q,

vcp

where T is the absolute temperature, R, is the universal gas constant, cp is the heat

capacity at constant pressure and Z is the compressibility factor.

In the 1980 edition of IS0 5167-I it was stated that if the measured fluid is a gas an

isentropic expansion should be assumed through the primary device. This is now known to

be incorrect. The complete process includes both isentropic and isenthalpic expansions

between upstream of the primary device and the location at which the static pressure

recovery is completed.

REFERENCE : “Performance Equations for Compressible Flow Through Orifices and Other

LIP Devices : A Thermodynamic Approach”, AlChe Journal, March 1986, Vol. 32, No 3.

5.4.3 No specific comments on this clause.

5.4.4 Temperature of primary device

- -

This assumption is made when correcting the primary device dimensions for temperature

changes when very accurate flow measurement is required.

6 General requirements for measurements

6.1 Material and manufacture

Table 2 whilst not exhaustive, lists materials most commonly used for orifice plate

manufacture.

@ IS0

ISOFI-R 94643 998(E)

Table 2 : Commonly used steels for orifice plate manufacture

Stainless steels

stainless steel

I I I I

I I

Table 3 gives the mean linear expansion coefficient, elasticity modulii and yield stresses for

the materials of table 2 according to their AISI designation.

Table 3 : Characteristics of commonly used steels

IO-” Mean Linear

Expansion Coefficient

between 0 and 100°C

NOTE : the figures given in table 3 vary with both temperature and the treatment

process of the steel. For precise calculations it is recommended that the data are

obtained from the manufacturer.

6.1.1 No specific comments on this clause.

6.1.2 No specific comments on this clause.

6.1.3 When the primary device under operating conditions is at a different temperature

from the one at which the diameter “d” was determined (this temperature is referred to as

the reference or calibration temperature) the expansion or contraction of the primary

device shall be taken into account in the computation of diameter ratio and flowrate using

the following equation, assuming there is no restraint due to the mounting :

d = do [I + kd(T - To)]

(1)

where d : primary device diameter in flowing conditions ;

do : primary device diameter at reference temperature ;

hd : mean linear expansion coefficient of the primary device material ;

T : primary device temperature in flowing conditions ;

TO : reference or calibration temperature.

Where automatic temperature correction is not required in the flow computer, the

uncertainty for “d” included in the overall uncertainty calculations should be increased to

allow for the change in “d” due to temperature variation (see IS0 51674, 11.2.2.3). An

initial calculation may show that this additional uncertainty is small enough to be considered

negligible.

6.2

Nature of the fluid

6.2.1 No specific comments on this clause.

6.2.2 Universal gas constant

The value indicated for the universal gas constant

6.2.3 Ascertaining density and viscosity of the flowing fluid

Annex B lists references for physical properties whilst annex C gives specific information for

natural gases. They provide data relating to the dependence of density and viscosity on

. -

temperature and pressure.

For gases, several methods can be used to calculate density from pressure and

temperature :

(a) by using tables, or equations of density versus pressure and temperature.

(b) when the molar mass M of the fluid is known, by first computing the compressibility

factor Zl, in flowing conditions, and then the density using the equation :

ISO/rR 9464: 1998(E)

PM

(2)

P1 =

AZ

1 1

where R is the universal gas constant (= 8,314 50 J.mol-l.K-l)

(c) when the density at standard conditions, PR is known (from calculation or

measurement) for given conditions of pressure and temperature, pR and TRY by first

computing the compressibility factors Z1 and ZR and then using the equation :

PAA

P (3)

1=

PRV,

For complex mixtures such as natural gas, the two latter methods are generally the only

practicable ones. Annex C gives a list of the main existing methods of computation of the

compressibility factor Z for a number of gas mixtures.

6.3 Flow conditions

6.3.1 No specific comments on this clause.

6.3.2 If there is a likelihood of such a change of phase, a way of overcoming the problem is

to increase the diameter ratio, so that the differential pressure is reduced.

7 Installation requirements

7.0 Inspection equipment

The following list of inspection equipment is not exhaustive, but provides a basis for

inspection control.

- calipers (thickness, diameters) ;

- internal micrometer (diameters) ;

- micrometer (thickness) ;

- gauge block, feeler gauge (relative position, absolute standard for checking

micrometers) ;

- protractor (angles) ;

- profile measuring apparatus (edge) ;

- straight edge rule (flatness) ;

- three point bore gauge (internal diameter).

Only instruments which may be calibrated to primary standards should be used if optimum

accuracy is required.

7.1 Pipe sections adjacent to the primary device

For additional requirements for orifice plates, nozzles and Venturi nozzles, refer to [ISO

5167-1, 7.51. For classical Venturi tubes, refer to [ISO 5167-1, 7.61.

ISO/rR 9464:1998(E)

For pipe roughness criteria, refer to the following paragraphs of [ISO 5167-I : 8.3.1,

9.1.6.1, 10.2.4.1].

7.1.1 No specific comments on this clause.

7X? No specific comments on this clause.

7.1.3 No specific comments on this clause.

7.1.4 No specific comments on this clause.

7.1.5 Internal diameter of the measuring pipe

The value of ‘ID”, corrected for thermal expansion (see below), is that used for the

computation of the diameter ratio p. This value of “D” is also used as the basis for

establishing the circularity of the pipe over a length of at least 2 D upstream and

downstream of the primary device (see 7.51).

The distance to the measurement station is expressed in terms of “D”, which is not known

before taking measurements at prescribed stations. For the purpose of establishing the

position of these stations, it is permissible to take “D” as equal to the nominal bore of the

.

pipe

Figure 1 gives an example for orifice meters where diameters are measured in only three

different cross-sections :

- A 1 ,B 1 , C, for orifice plates with corner tappings.

- A 2, B 2, C 2 for orifice plates with flange tappings.

- A 3, B 3, C 3 for orifice plates with D and D/2 tappings.

In any case, individual diameters should be measured with an accuracy of at least 0,l per

cent, as the overall tolerance is 0,3 per cent (see 7.51).

When the measuring pipe under flowing conditions is at a significantly different temperature

from the one at which diameter DO was determined (this temperature, referred to as the

reference or calibration temperature) the expansion or contraction of the pipe shall be taken

into account in the computation of diameter ratio and flow-rate, using the following equation:

(4)

D=Do[l+hD(~-To)]

where :

D : diameter of the pipe in flowing conditions ;

D : diameter of the pipe at reference temperature ;

.

. mean linear expansion coefficient of the pipe material ;

hg

T : pipe temperature in flowing conditions ;

T : reference or calibration temperature.

The value for hr, should be obtained from the manufacturer of the measuring pipe.

@ IS0

Dimensions in millimetres

B3 c3 81

A3

B2

0 250 0,250

- m

9d---

D3x

1. Plate upstream face

2. Cross section X

Internal diameter D to be used in flowrate computation :

=-

+iD

D

kDiA +iDiB iC,

n n

i=l i=l i=l

n = 1 for corner tappings

n = 2 for flange tappings

n = 3 for D and D/2 tappings

Figure 1 : Measurement of internal diameter D

ISOKR 9464: 1998(E)

@ IS0

Where automatic temperature correction is not required in the flow computer the

uncertainty for I’D” included in the overall uncertainty should be increased to allow for the

change in “D” due to temperature variation (see 11.2.2.3). An initial calculation may show

that this additional uncertainty is small enough to be considered negligible.

7.1.6 No specific comments on this clause.

7.1.7 No specific comments on this clause.

7.1.8 The requirements in [7.1.8] where drain or vent holes are located near to the primary

device are illustrated in Figure2. It should be realised that the flowing fluid may cause

deposition, corrosion or erosion of the inner wall of the pipe. The installation may therefore

not comply with the requirements of IS0 5167-I. Users should consider internal inspection

of the pipe at intervals appropriate to the conditions of application.

7.1.9 This clause is intended to ensure a reliable measurement of temperature. Although

the flowing temperature is not a quantity directly involved in the equation for calculating

flow-rate, it is an important parameter since it may be used to calculate “d” and “D” plus

critical process parameters under flowing conditions.

7.2 Straight lengths

7.2.1 When designing a metering pipe installation it is recommended that the required

minimum straight lengths are determined by the maximum diameter ratio that is expected in

the life of the installation.

For diameter ratios not covered by [ISO 5167-l) table 1 or 21 but inside the limits of the

standard, it is reasonable practice to interpolate linearly between the nearest table values

of the closest diameter ratio and to round up to the next integer number for [table I] and to

the next half number for [table 21.

If an orifice meter is designed to measure the flowrate in either direction, the minimum

straight lengths of pipe on both sides of the orifice plate shall comply with the minimum

requirements for upstreamstraight lengths as specified in [ISO 5167-1, 7.2 and Tables 1

and 21.

7.2.2 No specific comments on this clause.

7.2.3 No specific comments on this clause.

- -

7.2.4 No specific comments on this clause.

7.2.5 No specific comments on this clause.

7.2.6 No specific comments on this clause.

7.2.7 No specific comments on this clause.

ISOER 9464:1998(E)

-

-7

Q

-

t3

--

~ 1 -

6 c 0,080

u

A

B-B

A-A

!

B

I

1. Pressure tapping

2. Row direction

3. Pressure tapping

4. Orifice plate

5. Origin holes and /or vent holes

6. Cross section A-A

7. Cross section B-B

Figure 2 : Location of drain holes and/or vent holes

ISO/rR 9464:1998(E)

7.2.8 Several upstream fittings

7.2.8 (a)No specific comments on this clause.

7.2.8 (b)The requirements of this clause define the minimum straight length between the

first and second fittings in series, upstream of the primary device, except for two or more

90” bends, where the third and fourth columns of [ISO 5167-1, table 1 or 21 shall apply.

[Clause 7.41 allows the requirements of [ISO 5167-1, table 1 or 21 to be ignored if it can be

demonstrated “that the flow conditions immediately upstream (of the primary device)

sufficiently approach those of a fully developed profile and are free from swirl” [ISO 5167-l)

7.1.31.

Consideration should be given to disturbances in the flow conditions caused possibly by

additional upstream devices before the second fitting eg. a globe valve as the third fitting

would need to be sufficiently remote from the second fitting so as to present immediately

upstream of this second fitting a flow condition sufficiently close to a fully developed and

swirl free flow. No specific guidance is given in IS0 5167-l but it is recommended that the

separation of such fittings comply with the requirements of [ISO 5167-1, 7.2.8 (b)].

[ISO 5167-1, 7.2.8 (b) Note IO] also states that in the case of several 90” bends, the data

in tables 1 and 2 can be applied, whatever the lengths between two consecutive bends.

7.3 Flow conditioners

Introduction

The use of straightening devices is only recommended where it is not practicable to install

the minimum upstream straight lengths defined in [ISO 5167-1,7.2]. Nevertheless, it should

be noted that although swirl is generally not detectable in visual inspection of the pipe, it

has a greater effect on measurement than any other fluid dynamic mechanism, and may

persist over considerable distances. The use of straight lengths of pipe to eliminate swirl is

of question, especially in large pipe sizes as the degradation of induced swirl from common

pipe components may not be sufficient to ensure fully developed profiles within the

minimum lengths required in the tables.

The measurement of fluid flow by means of the primary devices described in IS0 5167-I

requires “that the flow conditions immediately upstream sufficiently approach those of a

fully developed profile and are free from swirl” (see [ISO 5167-1, 7.1.31). IS0 5167-I does

permit the use of flow straighteners in two situations :

(a) where the fittings are not defined in [table 1 and 21 ;

(b) where a large diameter ratio primary device is to be used, the installation of a flow

conditioner may allow shorter upstream lengths to be specified.

ISO/rR 9464:1998(E)

Scope and field of application

For a given fitting, a flow straightener may reduce the upstream length necessary to

achieve a good velocity profile, or may improve the velocity profile for a given straight

length.

The distance between the flow straightener and the primary device, for no additional

uncertainty, is given in [ISO 5167-1, 7.3.11. The standard does not define any relaxation

permitted for any additional uncertainty, as is defined in [7.2.4] relating to the required

straight lengths, although it should be noted that the DOWNSTREAM requirements may

affect uncertainty.

7.3.1 No specific comments on this clause.

7.3.2 Type of straightening devices

New types of flow conditioners have been developed during recent years. These are not

dealt with in IS0 5167-I : 1991, which specifies five types of flow straigthener :

Other types of flow straighteners are not specified in IS0 5167-I but their use would be

permitted provided the requirements of [ISO 5167-1, 7.41 are met. Refer to IS0 7194 for

other types of flow straightener and velocity profile measurement techniques.

7.3.2.1 Type A : Zanker

Flow straighteners which give better performances often combine the characteristics of two

simple designs. Of these types, the Zanker straightener combines the “Honeycomb” and

“Perforated Plate” (see also type B). Its pressure loss is approximately 5 times the dynamic

pressure (ie. the loss of energy is about 5 times the kinetic energy due to flow velocity). It

removes both swirl and velocity profile asymmetry.

7.3.2.2 Type B : Sprenkle

This is “Perforated plate” type and specified by :

.

(a) the thickness of the plate ;

(b) the ratio of the restricted flow area to the cross-sectional area of the pipe ;

(c) the

pitch of the holes ;

(d) the bevel angle of the holes.

The spacing and diameters of the perforations are not designed to distibute the velocity

profile in line with a fully developed velocity profile.

NOTE : (c) is not defined in IS0 5167-I. Nevertheless it is recommended the holes to

be evenly distributed over the whole cross-sectional area of the pipe.

The Sprenkle straightener specified by IS0 5167-l incorporates a pressure loss of about

15 times the dynamic pressure. It is very efficient in removing profile asymmetry.

NOTE : dimension “d” is shown in some versions of [ISO 5167-1, figure 1 and figure

21 as the diameter of the bevel; it should be the diameter of the perforated hole.

ISO/TR 94643 998(E)

7.3.2.3 Type C : Tube Bundle

These are specified by :

a) the length of the bundle ;

b) the diameter of the tubes ;

c) the thickness of the tubes ;

d) a minimum number of tubes.

(c) is not specified in IS0 5167-I. It should provide sufficient strength whilst not unduly

restricting the flow.

The pressure loss of the tube bundle flow straighteners as specified in IS0 5167-I is

usually low. This device eliminates practically all swirl but has little effect on the velocity

profile.

7.3.2.4 Type D : AMCA

These are specified by :

a) the length of the blades ;

b) the distance between blades ;

c) the thickness of the blades.

(c) is not specified in IS0 5167-I. It should provide sufficient strength whilst not unduly

restricting the flow.

The pressure loss of the AMCA flow straighteners as specified in IS0 5167-I varies with

the thickness of the blades, but is usually less than the dynamic pressure. This device

eliminates practically all swirl but has little effect on the velocity profile.

7.3.2.5 Type E : Etoile

These are specified by :

a) the length of the blades ;

b) the distance between blades ;

c) the thickness of the blades.

(c) is not specified in SO 5167-I. It should provide sufficient strength whilst not unduly

restricting the flow.

he Etoile flow straighteners as specified in IS0 5167-l varies with the

The pressure loss of

thickness of the blades, but is usually less than the dynamic pressure. This device

eliminates practically all swirl but has little effect on the velocity profile.

7.4 No specific comments on this clause.

ISOmR 9464:1998(E)

7.5 Additional specific installation conditions

7.5.1 Circularity of the pipe

To meet the given specifications, the pipe lengths adjacent to the primary device may have

to be specially machined. As no significant diameter difference must exist between the

various lengths of the measuring pipe (IS0 5167-1, 7.5.1.2 and 7.6.1.21) the ones adjacent

to the primary device may have to be made of a thicker pipe so that the proper internal

diameter can be obtained after machining a length of 2 pipe diameters upstream of the

primary device. This method will result in a measuring pipe having homogeneous

dimensions.

7.5. I. 1 Inspection of the upstream length of the measuring pipe

A check shall be made so that, over a length of 2 D upstream of the primary device, any

diameter measured in any plane does not vary by more than 0,3 per cent from the mean

diameter previously obtained (see 7.5.1.2).

In addition to the diameters measured in three cross sections to establish “D”, additional

diameters shall be measured in at least each of two different cross sections at locations

dependent on the device to be installed :

- 0.5D and 2 D for orifice plates with D and D/2 pressure tappings and long radius

nozzles ;

- D and 2 D for orifice plates with corner and flange tappings, ISA 1932 nozzles and

Venturi nozzles.

In those cases where few cross sections are used, one should check that no systematic

variation of the measured diameters can be found.

7.5.7.2 No specific comments on this clause

7.5.1.3 Steps between pipe lengths

It must be noted that measuring ‘the internal diameter at the ends of each pipe length (see

figure 3) is not sufficient to ensure conformity with [ISO 5167-1, 7.5.1.31. In addition, a

check should be made to determine that the different pipe lengths are properly mounted

and do not have a step in excess of IS0 5167-l limits when connected together.

The use of self centering pipe joints is recommended. Consideration should be given to the

. -

use of tongue and groove flanges, dowel pins or spigot and recess.

ISO/rR 9464:1998(E)

Check that the maximum internal step “e” between any two adjacent sections of pipe

- A and B - more than two pipe diameters-upstream of the primary device, does not exceed

0,3% D, where D is the mean pipe diameter computed over 0.5 D - see Fig 1

Figure 3 : Inspection of measuring pipe sections

ISOnR 9464:1998(E)

It is possible to determine the step between coupled pipe lengths with sufficient accuracy

by fixing external reference points whilst the pipe is uncoupled. Reference points can be on

the extension of a matching piece or plane and shall be constructed in pairs, just over the

joint, one on each side of it. Four or six pairs of reference points equally spaced around the

circumference of the pipe joint will usually be adequate.

The distance from the pipe wall to the reference point shall be measured while uncoupled.

To determine the position of a reference point in space on the extension of a plane (figure

4(a) left hand side), the plane shall be extended by a sliding reference piece.

Once coupled the distance between two reference points of a pair shall be measured with a

micrometer. To bridge the gap, the micrometer is best fixed in a smooth plane fitting piece

sliding over an equally smooth plane. Two or more measurements are then needed to

determine the distance between reference points.

If the pipe joints are self centering, then the external reference points are not needed.

Careful measurement of the pipe bore and centering device will produce equally accurate

results.

Examples are given in figure 4.

7.5.2 Location of the primary device and rings

7.5.2.7 No specific comments on this clause.

7.5.2.2 No specific comments on this clause.

7.5.2.3Table 4 and figure 5 shows the maximum distance e, between the centre-line of the

orifice and the centre-line of the pipe on the upstream and downstream sides, as a function

of a diameter ratio /3 and of the pipe diameter D, for no additional error.

@ IS0

C

1. Smooth plane

A. Some possible constructions

2. Reference points

of reference points

3. Fixed reference piece

B. Direct measurement of distance between

4. Inside pipe wall

reference points

5. Sliding reference piece

C. Indirect measurement of distance

6. Smooth plane

between reference points

Figure 4 : Measurement of steps between pipe lengths

ISO/TR 9464: 1998(E)

Table 4 : Maximum distance e, between the orifice centre-line

and the centre-lines of upstream and downstream pipe sections in mm

D in mm

c c

c

300 300

P P 100 100 150 150 200 200 400 400 500 500 600 600 700 700

3,20 3,20 2,41 2,41 3,62 3,62 4,82 4,82 7,23 7,23 9,65 9,65 12,06 12,06 14,47 14,47 16,88 16,88

0,25 0,25 2,29 2,29 3,44 3,44 4,59 4,59 6,88 6,88 9,18 9,18 II,47 II,47 13,76 13,76 16,06 16,06

0,30 0,30 2,ll 2,11 3,16 3,16 4,21 4,21 6,32 6,32 8,43 8,43 IO,54 IO,54 12,64 12,64 14,75 14,75

0,35 0,35 I,86 I,86 1 2,79 2,79 3,72 3,72 5,58 5,58 7,43 7,43 9,29 9,29 II,15 II,15 13,Ol 13,Ol

’ I

0,40 0,40 2,36 2,36 3,15 3,15 4,72 4,72 6,29 6,29 7,87 7,87 9,44 9,44 II,01 II,01

157 I,57

0,45 0,45 I,29 I,29 1 I,93 I,93 2,57 2,57 3,86 3,86 5,15 5,15 6,43 6,43 7,72 7,72 9,Ol 9,Ol

0,50 0,50 I,03 I,03 I,54 I,54 2,05 2,05 3,08 3,08 4,lO 4,lO 513 513 6,15 6,15 7,18 7,18

4,03 4,03 5,64 5,64

0,55 0,55 0,81 0,81 I,21 I,21 I,61 I,61 2:42 2:42 3,22 3,22 4783 4783

0,60 0,60 0,63 0,63 0,94 0,94 I,26 I,26 I,88 I,88 2,51 2,51 3,14 3,14 3,77 3,77 4,40 4,40

0,65 0,65 0,49 0,49 0,73 0,73 0,98 0,98 I,47 I,47 I,96 I,96 2,45 2,45 2,94 2,94 3:43 3:43

2,68 2,68

0,70 0,70 0,38 0,38 0,57 0,57 0,77 0,77 I,15 I,15 I,53 I,53 I,92 I,92 2,30 2,30

0,75 0,75 0,30 0,60 0,60 0,91 0,91 I,21 I,21 I,51 I,51 I,81 I,81 ~ 2,ll 2,ll

7.53 Fixing and gaskets

In order to avoid flow measurement errors due to incorrect centering, great care should be

given to the design of the system holding the primary element in the pipe.

To meet the requirements of centering and fixing the primary device, it may be necessary,

in many practical situations, to design a special fitting to suit the line size, type of fluid,

pressure and temperature fluctuations of the fluid, ease of maintenance and operation,

required accuracy and the system already in existence.

If the primary device can be made an integral part of the measuring pipe, the resulting

installation can be defined precisely, allowing flow measurements to be highly reproducible.

Other arrangements use pairs of flanges (slip-on or weld-on) or special proprietary fittings.

Figure 6 illustrates recommended arrangements for orifice plates, which are equally valid

for nozzles. When using flanges, it is good practice to provide a pair of Jack screws in

diametrically opposite positions.

ISOTTR 9464:1998(E)

/3 = 02

/3 = 0,3

p = 0,4

/3 = 0,s

/3 = 0,6

/1 = 0,7

/3 = 0,8

900 D/mm

?OO 800

300 400 500 600

100 200

Figure 5 : Maximum distance e, between orifice (or nozzle) centre-line and the

centre-lines of upstream and downstream pipe sections as a function of the pipe

diameter D and the diameter ratio p

ISO/rR 94643 998(E)

Gaskets are cheap and easy to produce but they must not be allowed to protrude into the

pipe at any point. It is recommended that gaskets are not thicker than 0,03 D. It is inevitable

therefore that a recess is formed at this point. The depth of the recess does not affect flow

measurement, but it is necessary to maintain adequate gasket material to ensure a leak

proof joint.

O-ring seals are easy to use and give a tight smooth joint if manufactured correctly.

Ring-joints (self-centering and sealing) always produce a gap and a recess between

sections. Provided the gap does not exceed that which is specified in the flange standard,

flow measurement will not be affected. Tests have shown that this is true when the gap

does not exceed 13 mm.

Care should always be taken to avoid unacceptable flexibility of the primary device

mounting with respect to the eccentricity and tapping point location tolerance [ISO 5167-1,

8.2.1.31.

It should be stressed that good metering requires maintenance of the primary device within

the tolerances of the standard, thus necessitating inspection of the device from time to

time. With some types of mounting for orifice plates, it is impracticable to inspect the device

and the installation without dismantling the pipework. Devices allowing easy withdrawal and

re-insertion of orifice plates to known tolerances may be the only practicable solution.

REFERENCES : HF ZEDAN and RG TEYSSANDIER, “The effect of recesses on the

discharge coefficient of a Flange Tapped Orifice Plate”, ASME Symposium on Mass Flow

Measurement, 1984.

7.6 Additional specific installation requirements for classical Venturi tubes

7.6J Circularity of the pipe

7.6.7.7 No specific comments on this clause.

7.6.7.2 No specific comments on this clause.

*

8 Orifice plates

8.1 Description

8.1 .l General shape

8.7.7.7 No specific comments on this clause.

8.7.7.2 No specific comments on this clause.

ISO/TR 9464: 1998(E)

Orifice plate between raised face flanges;

centering by flange bolts; sealing by gaskets;

inaccurate.

Orifice plate between raised face flanges;

centering by dowel pins; sealing by O-rings or

gaskets; used generally.

Orifice plate between flanges; centered on

raised face; very accurate centering possible

with great care in manufacture.

Orifice plate between flanges; centered in

chambered faces; very accurate centering

possible with great care in manufacture.

Sandwiched orifice plate section with integral

tappings; small and medium sized meter runs

with corner or flange tappings; very accurate

centering possible with great care in

manufacture.

Flanges or weld mounted orifice plate fitting;

plate with fixed seal inserted through slit; also

available with lockchamber for changing under

pressure; accurate centering possible with

great care in manufacture.

1. Clamping bar

2. Sealing bar

Figure 6 : Examples of orifice plate fittings

ISO/TR 9464: 1998(E)

8.7.7.3Three factors need to be taken into consideration in designing an orifice plate to

avoid excessive deformation.

First, the mounting arrangements should not impose any forces onto the orifice plate which

would cause the limit of 0,5% slope given in [ISO 5167-I j 8.1.2.11 to be exceeded under

the condition of no differential pressure.

Secondly, the thickness of the plate E should be such that, taking account of the modulus

of elasticity of the plate material, the differential pressure for the maximum design flowrate

should not cause a 1% slope to be exceeded. When the flowrate is reduced to zero the

plate will then return to the original 0,5% slope.

Thirdly, it is necessary to ensure that if it is possible for the differential pressures in excess

of those for maximum design flowrate to be applied, plastic buckling (i.e. permanent

deformation) will not occur.

For the first point, great care is needed in both the design and manufacture of the mounting

arrangements. The single or double chamber mounting devices are satisfactory. When

mounting orifice plates between standard flanges, the flanges must be at 90” & I” to the

pipe axis. The pipe sections on both sides of the orifice plate should be adequately

supported to ensure that no undue strain is placed on the orifice plate.

For the second point it should be understood that elastic deformation of an orifice plate

introduces an error in the flow measurement results. As long as the deformation does not

exceed the 1% slope required by [ISO 5167-1, 8.1 .I .3], no additional uncertainty will result.

Theoretical and experimental research (see reference at the end of 8.1.2.1) indicates that

the maximum change in discharge coefficient for a 1% slope is 0,2%. Therefore orifice

plates that comply with the 0,5% slope specified in [ISO 5167-1, 8.1.2.11 can be allowed to

deform an additional 0,5% slope (i.e. 0,l % change in discharge coefficient) whilst still

meeting the requirements of this clause. Table 5 tabulates the plate thickness to pipe

diameter ratios (E/D) for various values of p and differential pressures, valid for an orifice

plate manufactured from AISI stainless steel 304 or 316, and simply supported at its rim.

Table 5 : Minimum E/D’ ratios for orifice plate manufacture in

AISI 304 or AISI 316 stainless steel

Ap for maximum flowrate in kPa u

50 75 100 200 400

0,011 0,013 0,014 0,014 0,016

0,018

0,013

0,015 0,016 0,017 0,020 0,022

0,014 0,016 0,018 0!019 0,022

0,025

0,014

0,016 0,018 0,020 0,023 0,027

0,014 0,016 0,018 0,019 0,023

0,026

0,012

0,014 0,016 0,017 0,020 0,024

0,011 0,013 0,014 0,016 0,018

0,021

Table 5 is based on the use of the following expression when 100 Aqm/qm = 0,l

and E* = 193 x IO9 Pa.

where e = % change in discharge coefficient,

a = p (13,5 - 15,5 p),

b = 117 - 106 p1y3,

*-

E - modulus of elasticity of plate material,

D’ = plate support diameter (this may differ from pipe bore D).

E = Plate thickness

REFERENCES : R. NORMAN, MS RAWAT, P JEPSON : “Buckling and eccentricity effects

1983, International Gas Research Conference.

on orifice metering accuracy”,

For the third point the maximum differential pressure (which can be greater than Ap in table

5) that could be applied has to be determined by the designer. This could occur when the

metering section is isolated and then vented to reduce it to atmospheric pressure to enable

the orifice plate to be removed for inspection, or when pressurising the metering section

before putting into service.

@ IS0

ISO/rR 9464: 1998(E)

To avoid plastic deformation (buckling), the orifice plate thickness should be such that :

E

AP

-> (0.68 1 - 0.65 lp)

(6)

I

D

(T,

where Ap : maximum differential pressure de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...