ISO 16065-1:2014

(Main)Pulps — Determination of fibre length by automated optical analysis — Part 1: Polarized light method

Pulps — Determination of fibre length by automated optical analysis — Part 1: Polarized light method

ISO 16065-1:2014 specifies a method for determining fibre length using polarized light. ISO 16065-1:2014 is applicable to all kinds of pulp. However, fibrous particles shorter than 0,2 mm are not regarded as fibres for the purposes of ISO 16065-1:2014 and, therefore, are not to be included in the results.

Pâtes — Détermination de la longueur de fibre par analyse optique automatisée — Partie 1: Méthode de la lumière polarisée

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16065-1

Second edition

2014-04-01

Pulps — Determination of fibre length

by automated optical analysis —

Part 1:

Polarized light method

Pâtes — Détermination de la longueur de fibre par analyse optique

automatisée —

Partie 1: Méthode de la lumière polarisée

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

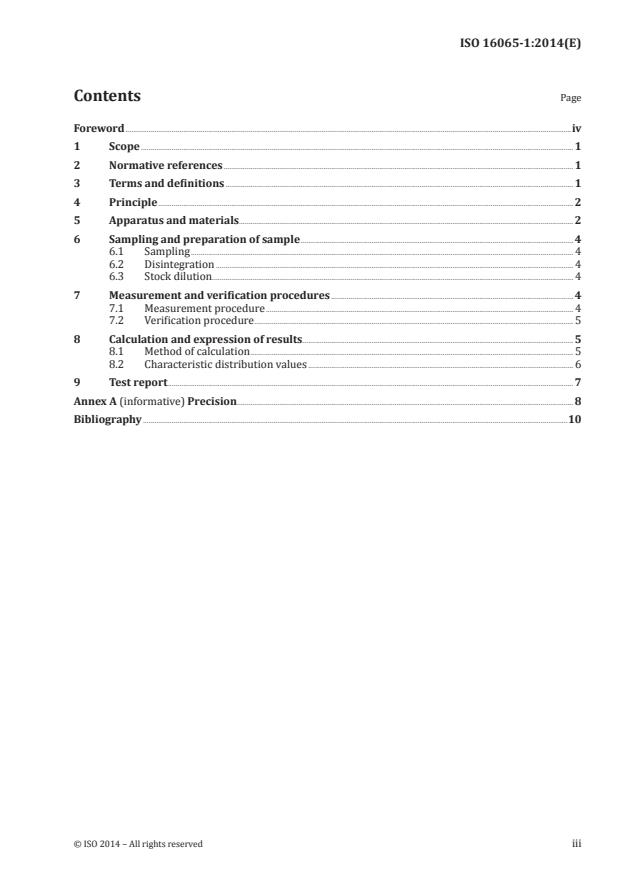

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Apparatus and materials. 2

6 Sampling and preparation of sample . 4

6.1 Sampling . 4

6.2 Disintegration . 4

6.3 Stock dilution. 4

7 Measurement and verification procedures . 4

7.1 Measurement procedure . 4

7.2 Verification procedure . 5

8 Calculation and expression of results . 5

8.1 Method of calculation . 5

8.2 Characteristic distribution values . 6

9 Test report . 7

Annex A (informative) Precision . 8

Bibliography .10

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 6, Paper, board and pulps.

This second edition cancels and replaces the first edition (ISO 16065-1:2001), of which it constitutes a

minor revision with the following changes:

— a new precision statement that complies with the requirements of ISO/TR 24498 has been added.

ISO 16065 consists of the following parts, under the general title Pulps — Determination of fibre length

by automated optical analysis:

— Part 1: Polarized light method

— Part 2: Unpolarized light method

iv © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 16065-1:2014(E)

Pulps — Determination of fibre length by automated

optical analysis —

Part 1:

Polarized light method

1 Scope

This part of ISO 16065 specifies a method for determining fibre length using polarized light.

This part of ISO 16065 is applicable to all kinds of pulp. However, fibrous particles shorter than 0,2 mm

are not regarded as fibres for the purposes of this part of ISO 16065 and, therefore, are not to be included

in the results.

NOTE ISO 16065-2 deals with the determination of fibre length using unpolarized light.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 638, Paper, board and pulps — Determination of dry matter content — Oven-drying method

ISO 4119, Pulps — Determination of stock concentration

ISO 5263-1, Pulps — Laboratory wet disintegration — Part 1: Disintegration of chemical pulps

ISO 5263-2, Pulps — Laboratory wet disintegration — Part 2: Disintegration of mechanical pulps at 20

degrees C

ISO 5263-3, Pulps — Laboratory wet disintegration — Part 3: Disintegration of mechanical pulps at > 85

degrees C

ISO 7213, Pulps — Sampling for testing

ISO/TR 24498, Paper, board and pulps — Estimation of uncertainty for test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

unpolarized light

light composed of light waves whose planes of vibration are randomly oriented

3.2

polarizer

material which only transmits a component of a light wave which is vibrating in a particular direction,

which is the direction of polarization of the material

3.3

plane polarized light

light composed of light waves which all vibrate in the same plane

3.4

crossed polarizers

pair of polarizers placed in a light path, such that the direction of polarization of one is at right angles to

the direction of polarization of the other, thus resulting, ideally, in none of the light, which has passed

directly from one polarizer to the other, being transmitted

3.5

birefringence

property of certain materials, such as cellulose fibres, which have a crystalline

structure that results in the refractive index varying with the direction of polarization of the light

Note 1 to entry: This has the effect of rotating the direction of polarization of a plain polarized beam of light

resulting in light which has passed through this material being transmitted through the second polarizer of a

crossed pair.

3.6

mean length

L

total length of all fibres counted divided by the number of fibres

Note 1 to entry: See Formula (3).

3.7

length-weighted mean length

L

l

average of the length-weighted fibre-length distribution

Note 1 to entry: See Formula (4).

3.8

mass-weighted mean length

L

w

average of the mass-weighted fibre-length distribution

Note 1 to entry: See Formula (5).

Note 2 to entry: Mass-weighted mean length was formerly called weight-weighted mean length.

3.9

light extinction

difference, expressed as a percentage, in the maximum and minimum light level transmitted through

two axially aligned polarizers when one polarizer is rotated 90° about the axis

4 Principle

Fibres suspended in water are routed through a fibre orienting cell (FOC). The projected lengths of

individual fibres are measured automatically. A crossed-polarizers setup is used to discriminate

between fibres and other materials like air bubbles, which do not rotate the plane of polarization. The

numerical and weighted average fibre lengths and fibre-length distributions of pulp are calculated.

5 Apparatus and materials

Ordinary laboratory equipment and the following are required.

5.1 Fibre-length analyser, consisting of a measurement section and a sample transport system (see

Figure 1).

The measurement section consists of a fibre orienting cell (FOC), through which fibres in a liquid are

drawn. There is a uniform light source on one side of the FOC and a photo sensor matrix on the opposite

2 © ISO 2014 – All rights reserved

side. There are crossed polarizing filters, on either side of the FOC, between the light source and the

photo sensor matrix. The photo sensor matrix senses the length of the image of the fibre from the light

that due to the birefringence is transmitted through the second polarizer. The length of this image is

converted to fibre length. The flow orientates the fibres into a plane or tube normal to the light path and

no thicker than 0,5 mm in the direction of the light path. The resolution of the analyser shall be equal to

or better than 100 µm over the range 0 mm to 7 mm.

NOTE Fibres constrained to flow through a capillary no wider than 0,5 mm have been found to straighten

enough to be measured accurately with projected light.

At least 90 % of the transmitted light spectrum shall be within the spectral sensitivity of the detector.

The light extinction of the crossed polarizers shall exceed 99 %. The detection efficiency shall be 100 %

for all

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...