IEC 60968:1988/AMD2:1999

(Amendment)Amendment 2 - Self-ballasted lamps for general lighting services - Safety requirements

Amendment 2 - Self-ballasted lamps for general lighting services - Safety requirements

Amendement 2 - Lampes à ballast intégré pour l'éclairage général - Prescriptions de sécurité

General Information

- Status

- Published

- Publication Date

- 22-Jul-1999

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 6 - TC 34/SC 34A/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 26-Sep-2012

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

The IEC 60968:1988/AMD2:1999 amendment addresses updated safety requirements for self-ballasted lamps used in general lighting services. Developed by the International Electrotechnical Commission (IEC), this amendment builds upon the existing IEC 60968 standard to reinforce safety protocols, marking, and mechanical and electrical performance criteria for self-ballasted lamps.

This standard is essential for manufacturers, testing laboratories, and regulatory bodies involved in the design, production, and certification of energy-efficient lighting solutions. It helps ensure that self-ballasted lamps meet critical safety standards, protecting users and electrical systems from hazards such as electrical shock, overheating, and mechanical failure.

Key Topics

Marking and Labels

The amendment specifies updated marking requirements to include special conditions or restrictions necessary for lamp operation, such as compatibility with dimming circuits. Lamps that are not suitable for dimming may carry a specific IEC symbol indicating this limitation.Interchangeability and Dimensions

Detailed requirements for testing lamp cap interchangeability and dimensions are referenced via IEC 60061-3 gauge sheets. This includes caps such as B22d, B15d, E27, E26, and E14, with precise measurements for insertion, retention, and thread dimensions to ensure compatibility with lamp holders.Protection Against Electric Shock

Modified stipulations clarify compliance testing using gauges in accordance with IEC 60061-3. Special attention is given to various cap types, with some specifications, such as for E26 caps and bayonet insulation resistance, under consideration.Mechanical Strength and Torsion Resistance

Mechanical robustness is emphasized with defined torque resistance levels for lamp caps:- B22d and E26/E27 caps: 3 Nm

- B15d and E14 caps: 1.15 Nm

The standard mandates that caps must remain firmly attached during torque application, allowing minimal relative movement in uncemented caps. Post-test compliance with accessibility and safety is required.

Electrical Insulation and Strength

Electrical strength parameters focus on insulation resistance and the spacing between conductive and foil parts. Certain criteria, including insulation resistance for bayonet caps, are still under evaluation to ensure continued safety improvements.Temperature Rise Limits

The amendment defines maximum temperature rise (Δt) limits for lamp caps during operation, measured per IEC 60360. Limits vary by cap type, for instance, 125 K for B22d and 120 K for B15d, E27, and E14 caps. These limits are critical to prevent overheating, extend lamp life, and ensure user safety.Test Equipment and Procedures

Figures and tables provide detailed specifications for test holders and gauges necessary for mechanical and electrical testing, including dimensions with tolerances for accuracy in compliance verification.

Applications

Manufacturing Compliance

Lamp manufacturers must adhere to these safety amendments to certify their self-ballasted lamps for global markets. Compliance ensures lamps are safe for consumer use and compatible with existing fixtures.Product Testing and Certification

Testing laboratories utilize the detailed mechanical torque, marking, temperature rise, and electrical insulation criteria to evaluate lamp safety systematically and objectively.Lighting Design and Installation

Electrical engineers and installers benefit from understanding restrictions on dimming compatibility and torque requirements to optimize lighting system safety and performance.Regulatory Adoption

National and international regulatory bodies may reference this amendment when updating safety codes and certification mandates for energy-efficient lighting products.

Related Standards

IEC 60968

The base standard for self-ballasted lamps, detailing fundamental safety and performance requirements.IEC 60061-3

Defines gauges and dimensions of lamp caps, essential for interchangeability compliance checks.IEC 60360

Specifies measurement procedures for temperature rise of lamps and caps during operation.IEC 928/99

Provides symbols and indicators related to special operating restrictions such as dimmer incompatibility.

Conclusion

IEC 60968:1988/AMD2:1999 amendment enhances safety benchmarks for self-ballasted lamps by updating marking protocols, dimensional compatibility, mechanical strength, electrical insulation, and temperature rise requirements. Compliance with this amendment ensures high reliability and safety in general lighting applications, supporting sustainable and secure lighting system deployment worldwide. Manufacturers, testers, and regulators are encouraged to integrate these updated safety requirements for continued product excellence and regulatory adherence.

Keywords: IEC 60968 amendment, self-ballasted lamps safety, lamp cap dimensions, electric shock protection, lamp torque resistance, lamp temperature rise, general lighting safety standards, IEC lamp standards, electrical insulation in lamps

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60968:1988/AMD2:1999 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Amendment 2 - Self-ballasted lamps for general lighting services - Safety requirements". This standard covers: Amendment 2 - Self-ballasted lamps for general lighting services - Safety requirements

Amendment 2 - Self-ballasted lamps for general lighting services - Safety requirements

IEC 60968:1988/AMD2:1999 is classified under the following ICS (International Classification for Standards) categories: 29.140.30 - Fluorescent lamps. Discharge lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60968:1988/AMD2:1999 has the following relationships with other standards: It is inter standard links to IEC 60968:1988, IEC 60968:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60968:1988/AMD2:1999 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

STANDARD

AMENDEMENT 2

AMENDMENT 2

1999-07

Amendement 2

Lampes à ballast intégré pour

l'éclairage général – Prescriptions de sécurité

Amendment 2

Self-ballasted lamps for

general lighting services – Safety requirements

IEC 1999 Droits de reproduction réservés Copyright - all rights reserved

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

F

PRICE CODE

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 60968 amend. 2 © CEI:1999

AVANT-PROPOS

Le présent amendement a été établi par le sous-comité 34A: Lampes, du comité d’études 34

de la CEI: Lampes et équipements associés.

Le texte de cet amendement est issu des documents suivants:

FDIS Rapport de vote

34A/874/FDIS 34A/888/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l’approbation de cet amendement.

––––––––––––

Page 8

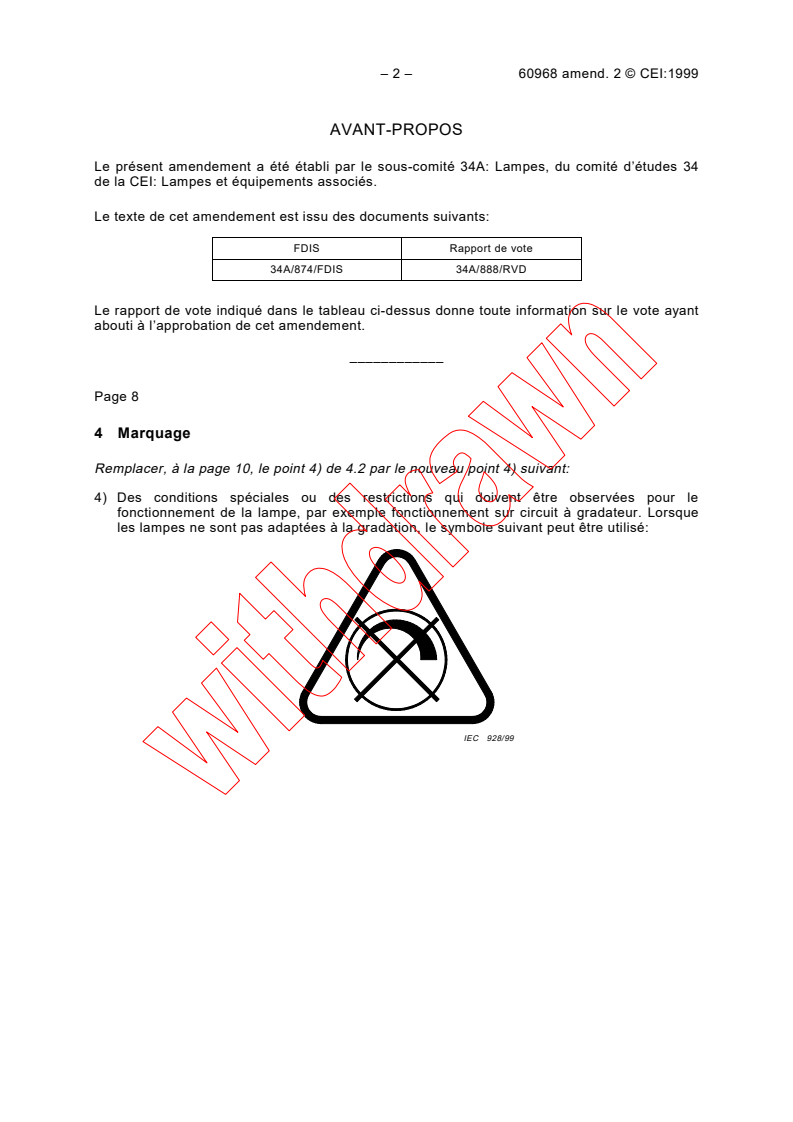

4 Marquage

Remplacer, à la page 10, le point 4) de 4.2 par le nouveau point 4) suivant:

4) Des conditions spéciales ou des restrictions qui doivent être observées pour le

fonctionnement de la lampe, par exemple fonctionnement sur circuit à gradateur. Lorsque

les lampes ne sont pas adaptées à la gradation, le symbole suivant peut être utilisé:

IEC 928/99

60968 Amend. 2 © IEC:1999 – 3 –

FOREWORD

This amendment has been prepard by subcommittee 34A: Lamps, of IEC technical committee 34:

Lamps and related equipment.

The text of this amendment is based on the following documents:

FDIS Report on voting

34A/874/FDIS 34A/888/RVD

Full information on the voting for the approval of this amendment can be found in the report on

voting indicated in the above table.

––––––––––––

Page 9

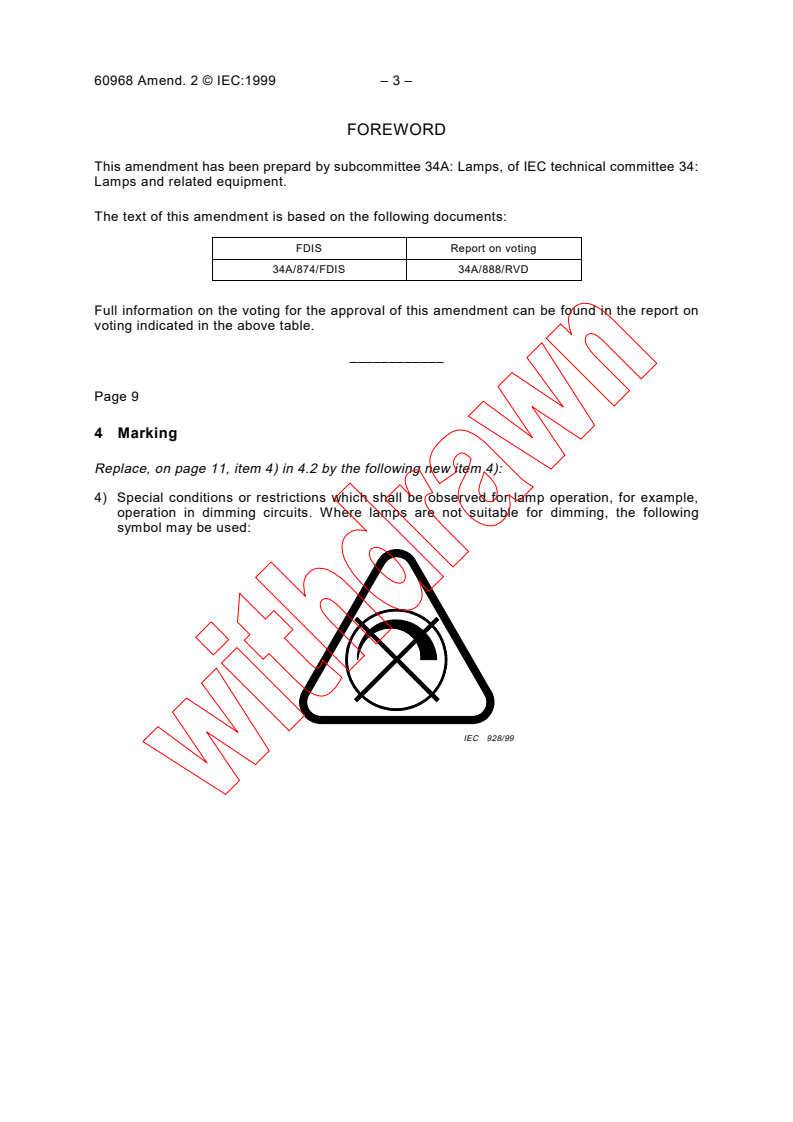

4 Marking

Replace, on page 11, item 4) in 4.2 by the following new item 4):

4) Special conditions or restrictions which shall be observed for lamp operation, for example,

operation in dimming circuits. Where lamps are not suitable for dimming, the following

symbol may be used:

IEC 928/99

– 4 – 60968 amend. 2 © CEI:1999

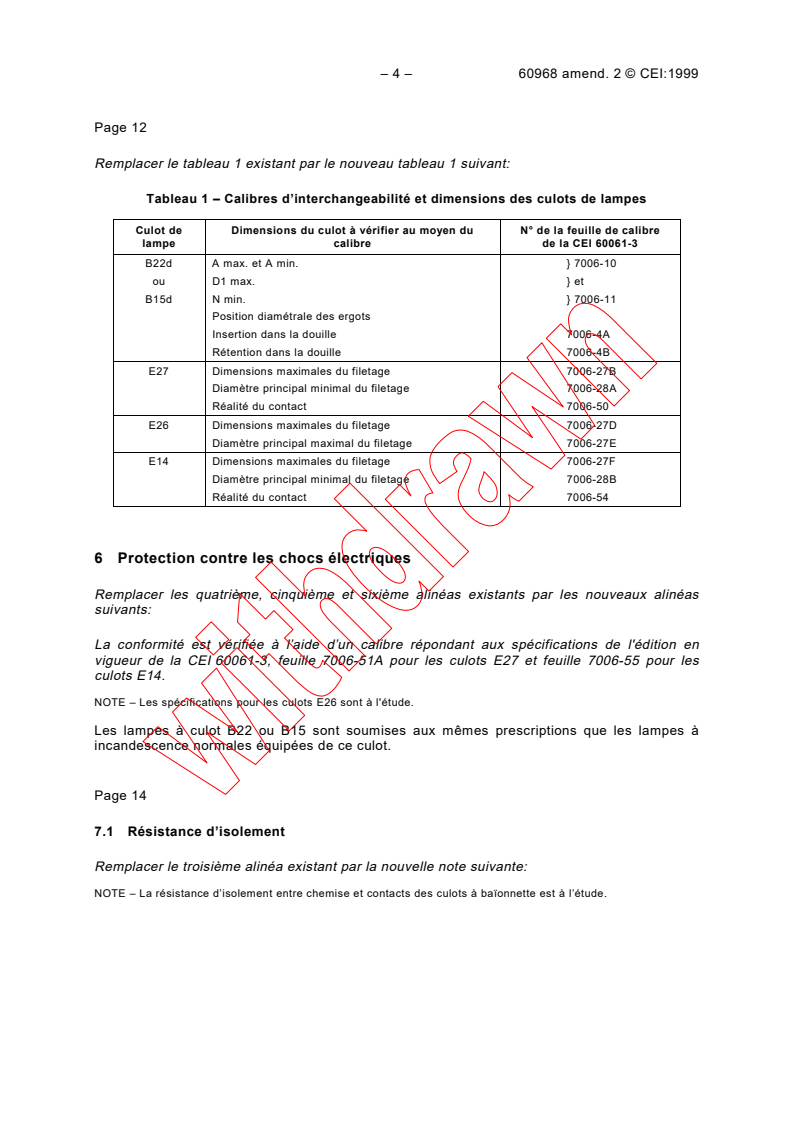

Page 12

Remplacer le tableau 1 existant par le nouveau tableau 1 suivant:

Tableau 1 – Calibres d’interchangeabilité et dimensions des culots de lampes

Culot de Dimensions du culot à vérifier au moyen du N° de la feuille de calibre

lampe calibre de la CEI 60061-3

B22d A max. et A min. } 7006-10

ou D1 max. } et

B15d N min. } 7006-11

Position diamétrale des ergots

Insertion dans la douille 7006-4A

Rétention dans la douille 7006-4B

E27 Dimensions maximales du filetage 7006-27B

Diamètre principal minimal du filetage 7006-28A

Réalité du contact 7006-50

E26 Dimensions maximales du filetage 7006-27D

Diamètre principal maximal du filetage 7006-27E

E14 Dimensions maximales du filetage 7006-27F

Diamètre principal minimal du filetage 7006-28B

Réalité du contact 7006-54

6 Protection contre les chocs électriques

Remplacer les quatrième, cinquième et sixième alinéas existants par les nouveaux alinéas

suivants:

La conformité est vérifiée à l’aide d’un calibre répondant aux spécifications de l'édition en

vigueur de la CEI 60061-3, feuille 7006-51A pour les culots E27 et feuille 7006-55 pour les

culots E14.

NOTE – Les spécifications pour les culots E26 sont à l'étude.

Les lampes à culot B22 ou B15 sont soumises aux mêmes prescriptions que les lampes à

incandescence normales équipées de ce culot.

Page 14

7.1 Résistance d’isolement

Remplacer le troisième alinéa existant par la nouvelle note suivante:

NOTE – La résistance d’isolement entre chemise et contacts des culots à baïonnette est à l’étude.

60968 Amend. 2 © IEC:1999 – 5 –

Page 13

Replace the existing table 1 by the following new table 1:

Table 1 – Interchangeability gauges and lamp cap dimensions

Lamp cap Cap dimensions to be checked Gauge sheet No. from

by the gauge IEC 60061-3

B22d A max. and A min. } 7006-10

or D1 max. } and

B15d N min. } 7006-11

Diametrical position of the pins

Insertion in lampholder 7006-4A

Retention in lampholder 7006-4B

E27 Max. dimensions of the screw thread 7006-27B

Min. major diameter of the screw thread 7006-28A

Contact making 7006-50

E26 Max. dimensions of the screw thread 7006-27D

Max. major diameter of the screw thread 7006-27E

E14 Max. dimensions of the screw thread 7006-27F

Min. major diameter of the screw thread 7006-28B

Contact making 7006-54

6 Protection against electric shock

Replace the existing fourth, fifth and sixth paragraphs by the following new paragraphs:

Compliance is checked with the aid of a gauge in accordance with the current edition of

IEC 60061-3, sheet 7006-51A for E27 caps and sheet 7006-55 for E14 caps.

NOTE – Requirements for E26 caps are under consideration.

Lamps with B22 or B15 caps are subject to the same requirements as normal incandescent

lamps with this cap.

Page 15

7.1 Insulation resistance

Replace the existing third paragraph by the following new note:

NOTE – The insulation resistance of bayonet caps between shell and contacts is under consideration.

– 6 – 60968 amend. 2 © CEI:1999

7.2 Rigidité électrique

Remplacer le cinquième alinéa existant du premier tiret par la nouvelle note suivante:

NOTE – La distance entre la feuille et les parties transportant le courant est à l’étude.

Remplacer le deuxième tiret existant par le nouveau tiret suivant:

– Culots à baïonnette: entre chemise et contacts (à l’étude)

Page 16

Remplacer l’article 8 existant par le nouvel article 8 suivant:

8 Résistance mécanique

Résistance à la torsion

Le culot doit demeurer fermement lié à l’ampoule ou à la partie de la lampe utilisée pour visser

ou dévisser celle-ci lorsqu’elle est soumise à un couple de torsion de la valeur indiquée dans la

liste ci-dessous:

B22d .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...