IEC 60968:2012

(Main)Self-ballasted lamps for general lighting services - Safety requirements

Self-ballasted lamps for general lighting services - Safety requirements

IEC 60968:2012 specifies the safety and interchangeability requirements, together with the test methods and conditions, required to show compliance of tubular fluorescent and other gas-discharge lamps with integrated means for controlling starting and stable operation (self-ballasted lamps), intended for domestic and similar general lighting purposes, having:

- a rated wattage up to 60 W;

- a rated voltage of 100 V to 250 V;

- Edison screw or bayonet caps.

The requirements of this standard relate only to type testing. This second edition cancels and replaces the first edition published in 1988, Amendment 1:1991 and Amendment 2:1999. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition.

a) For reasons of photobiological safety, the scope has been extended.

b) A new definition and clause on UV radiation have been introduced.

c) Clauses on normative references and an annex on literature were added.

d) The latest IEC template has been adapted.

Lampes à ballast intégré pour l'éclairage général - Exigences de sécurité

La CEI 60968:2012 spécifie les exigences de sécurité et d'inter-changeabilité ainsi que les méthodes et les conditions d'essais exigés pour démontrer la conformité des lampes tubulaires à fluorescence et autres lampes à décharge à dispositif intégré d'amorçage et de stabilisation du fonctionnement (lampes autoballastées) destinées à l'éclairage domestique et similaire et ayant:

- une puissance nominale inférieure ou égale à 60 W;

- une tension nominale de 100 V à 250 V;

- un culot à vis Edison ou un culot à baïonnette.

Les exigences de la présente norme ne concernent que les essais de type. Cette deuxième édition annule et remplace la première édition parue en 1988, l'Amendement 1:1991 et l'Amendement 2:1999. Elle constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente.

a) Pour des raisons de sécurité photobiologique, le domaine d'application a été étendu.

b) Une nouvelle définition et un nouvel article traitant du rayonnement UV ont été introduits.

c) Un article concernant les références normatives et une annexe traitant de la littérature ont été introduits.

d) Le document a été adapté au format CEI le plus récent.

General Information

- Status

- Published

- Publication Date

- 25-Sep-2012

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 6 - TC 34/SC 34A/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 05-Feb-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60968:2012 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies safety and interchangeability requirements for self-ballasted lamps used in general lighting services. These lamps include tubular fluorescent and other gas-discharge lamps with integrated control means for starting and stable operation. The standard applies to lamps intended mainly for domestic and similar environments, with rated wattages up to 60 W and rated voltages between 100 V and 250 V. It covers lamps with Edison screw or bayonet caps.

This second edition of the standard, published in 2012, replaces the previous editions and amendments, incorporating significant technical revisions including photobiological safety aspects and UV radiation considerations.

Key Keywords: IEC 60968, self-ballasted lamps, general lighting services, safety requirements, tubular fluorescent lamps, gas-discharge lamps, Edison screw caps, bayonet caps, photobiological safety, UV radiation.

Key Topics

Scope and Application:

IEC 60968:2012 applies to type testing of self-ballasted lamps with integrated control gear, focusing on lamps rated up to 60 W and operational in voltages from 100 V to 250 V. It excludes lamps outside these parameters and addresses only type testing, not full product batch testing.Safety Requirements:

The standard ensures that the lamps are designed and manufactured to function reliably and safely under normal operating conditions. This includes requirements for protection against electric shock, insulation resistance, mechanical strength, temperature rise of caps, heat resistance, and fire hazard testing.Photobiological Safety:

A vital update in this edition is the inclusion of photobiological safety measures aligned with IEC 62471 and IEC/TR 62471-2 guidelines. This includes limits on UV radiation emissions from lamps to protect users from potential hazards, with specific clauses dedicated to UV radiation measurements and safety.Interchangeability:

IEC 60968 details requirements for lamp cap interchangeability to ensure that lamps can be properly and safely fitted into common holders-either Edison screw or bayonet types-following established gauge specifications.Test Methods and Conditions:

The document specifies rigorous test protocols to verify compliance, including electric strength after humidity exposure, mechanical durability, cap temperature rise measurements, and resistance to ignition and flame spread. These tests ensure lamp safety and longevity.Marking and Labeling:

While photobiological hazards for blue light and infrared radiation are within safe limits not requiring special marking, the standard emphasizes correct lamp labeling for rated wattage, voltage, frequency, and compliance information.

Applications

IEC 60968:2012 is essential for manufacturers, testing laboratories, and regulatory bodies involved with the design, production, safety verification, and market approval of self-ballasted lamps for general lighting purposes. Its applications include:

Domestic Lighting:

Ensuring self-ballasted lamps used in homes meet electrical safety and photobiological safety requirements.Commercial and Public Lighting:

Providing guidelines for safe use of self-ballasted lamps in offices, public spaces, and other environments similar to domestic settings.Product Certification and Quality Control:

Serving as a reference standard for type testing before market release to certify lamp compliance with international safety standards.Compliance with Photobiological Safety:

Helping manufacturers incorporate UV radiation limits and blue light hazard considerations into lamp design.

Related Standards

Compliance with IEC 60968:2012 is supported by referencing and aligning with several related IEC standards that cover specific safety aspects of lamp components and testing methods:

IEC 62471 and IEC/TR 62471-2:

Photobiological safety standards that define risk groups for optical radiation and specify measurement techniques.IEC 60061 (Lamp Caps and Holders):

Defines dimensions and interchangeability requirements for lamp caps and holders, critical for ensuring lamp compatibility and safety.IEC 60238 (Edison Screw Lampholders):

Provides design and testing requirements specific to Edison screw holders.IEC 60360 (Cap Temperature Rise Measurement):

Specifies how to measure temperature rise at lamp caps, ensuring thermal safety.IEC 60695 Series (Fire Hazard Testing):

Includes glow-wire testing methods to assess fire hazards and flammability of lamp components.IEC 60901 (Single-capped Fluorescent Lamps):

Covers performance specifications of fluorescent lamps, related to the light source integrated in self-ballasted lamps.

Conclusion

IEC 60968:2012 is a comprehensive and critical international standard focusing on the safety and interchangeability of self-ballasted lamps used in general lighting services. It addresses electrical safety, mechanical robustness, thermal properties, fire resistance, and photobiological safety, particularly concerning UV radiation. Adherence to this standard helps minimize user hazards, ensures product reliability, and facilitates global market acceptance of these lighting products.

For manufacturers and testers, IEC 60968 acts as a benchmark standard to design safe, reliable self-ballasted lamps that meet both electrical and photobiological safety requirements in residential and similar applications.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60968:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Self-ballasted lamps for general lighting services - Safety requirements". This standard covers: IEC 60968:2012 specifies the safety and interchangeability requirements, together with the test methods and conditions, required to show compliance of tubular fluorescent and other gas-discharge lamps with integrated means for controlling starting and stable operation (self-ballasted lamps), intended for domestic and similar general lighting purposes, having: - a rated wattage up to 60 W; - a rated voltage of 100 V to 250 V; - Edison screw or bayonet caps. The requirements of this standard relate only to type testing. This second edition cancels and replaces the first edition published in 1988, Amendment 1:1991 and Amendment 2:1999. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition. a) For reasons of photobiological safety, the scope has been extended. b) A new definition and clause on UV radiation have been introduced. c) Clauses on normative references and an annex on literature were added. d) The latest IEC template has been adapted.

IEC 60968:2012 specifies the safety and interchangeability requirements, together with the test methods and conditions, required to show compliance of tubular fluorescent and other gas-discharge lamps with integrated means for controlling starting and stable operation (self-ballasted lamps), intended for domestic and similar general lighting purposes, having: - a rated wattage up to 60 W; - a rated voltage of 100 V to 250 V; - Edison screw or bayonet caps. The requirements of this standard relate only to type testing. This second edition cancels and replaces the first edition published in 1988, Amendment 1:1991 and Amendment 2:1999. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition. a) For reasons of photobiological safety, the scope has been extended. b) A new definition and clause on UV radiation have been introduced. c) Clauses on normative references and an annex on literature were added. d) The latest IEC template has been adapted.

IEC 60968:2012 is classified under the following ICS (International Classification for Standards) categories: 29.140.30 - Fluorescent lamps. Discharge lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60968:2012 has the following relationships with other standards: It is inter standard links to IEC 60968:2015, IEC 60968:1988/AMD2:1999, IEC 60968:1988. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60968:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60968 ®

Edition 2.0 2012-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Self-ballasted lamps for general lighting services – Safety requirements

Lampes à ballast intégré pour l'éclairage général – Exigences de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60968 ®

Edition 2.0 2012-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Self-ballasted lamps for general lighting services – Safety requirements

Lampes à ballast intégré pour l'éclairage général – Exigences de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX R

ICS 29.140.30 ISBN 978-2-83220-378-1

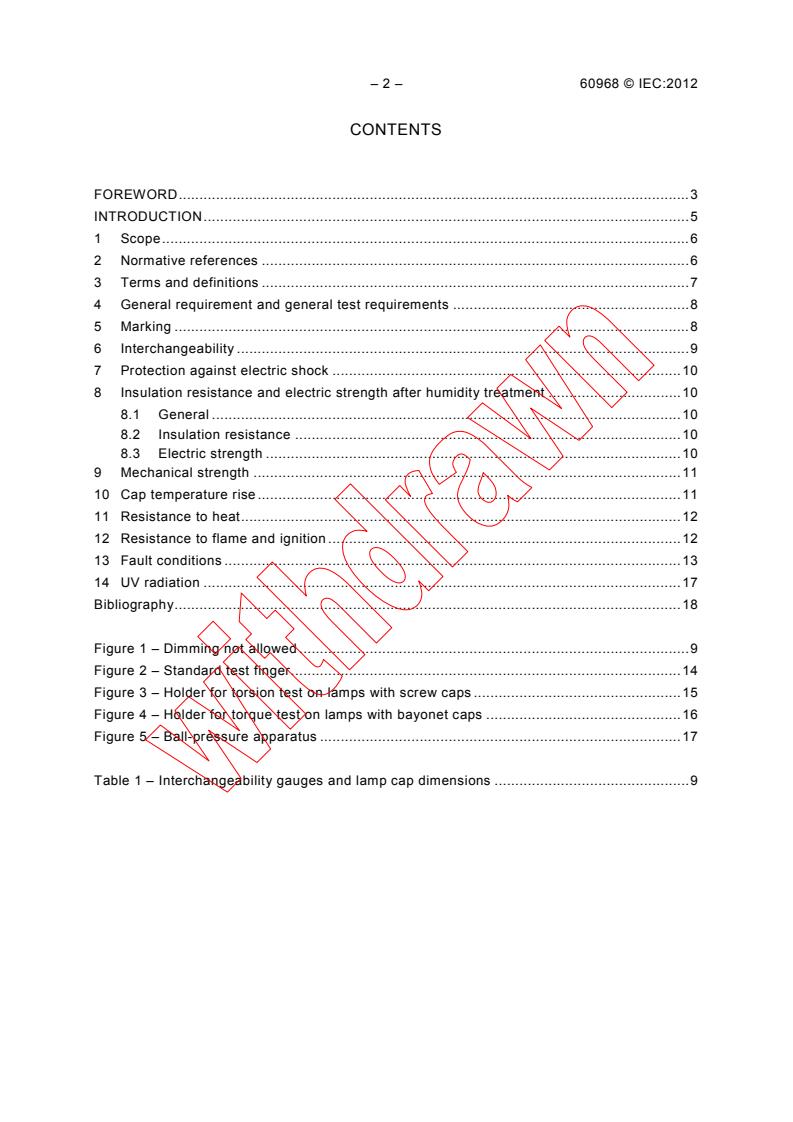

– 2 – 60968 © IEC:2012

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General requirement and general test requirements . 8

5 Marking . 8

6 Interchangeability . 9

7 Protection against electric shock . 10

8 Insulation resistance and electric strength after humidity treatment . 10

8.1 General . 10

8.2 Insulation resistance . 10

8.3 Electric strength . 10

9 Mechanical strength . 11

10 Cap temperature rise . 11

11 Resistance to heat . 12

12 Resistance to flame and ignition . 12

13 Fault conditions . 13

14 UV radiation . 17

Bibliography . 18

Figure 1 – Dimming not allowed . 9

Figure 2 – Standard test finger . 14

Figure 3 – Holder for torsion test on lamps with screw caps . 15

Figure 4 – Holder for torque test on lamps with bayonet caps . 16

Figure 5 – Ball-pressure apparatus . 17

Table 1 – Interchangeability gauges and lamp cap dimensions . 9

60968 © IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SELF-BALLASTED LAMPS FOR

GENERAL LIGHTING SERVICES –

Safety requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60968 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This second edition cancels and replaces the first edition published in 1988,

Amendment 1:1991 and Amendment 2:1999. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition.

a) For reasons of photobiological safety, the scope has been extended.

b) A new definition and clause on UV radiation have been introduced.

c) Clauses on normative references and an annex on literature were added.

d) The latest IEC template has been adapted.

– 4 – 60968 © IEC:2012

The text of this standard is based on the following documents:

CDV Report on voting

34A/1540/CDV 34A/1579/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this standard, the following print types are used:

– requirements proper: in roman type,

– test specifications: in italic type,

– explanatory matter: in smaller roman type.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60968 © IEC:2012 – 5 –

INTRODUCTION

With IEC 62471 and IEC/TR 62471-2, there are horizontal requirements available that need to

be introduced into product standards, e.g. to IEC 60968. The horizontal requirement is

transformed into a requirement for self-ballasted lamps.

The lamps within the scope of this standard are general lighting service (GLS) lamps

according to the definition 3.11 in IEC 62471:2006. ".lamps intended for lighting spaces that

are typically occupied or viewed by people.".

According to Clause 6 of IEC 62471:2006, radiation of GLS lamps is measured at a distance

equivalent to 500 lx.

Measured at the 500 lx distance, GLS lamps will not exceed risk group 1 for blue light hazard

and risk group 0 for IR radiation. This combination of risk group and hazard does not require

marking (Table 1 of IEC/TR 62471-2:2009).

Hazards from UV radiation of GLS lamps will be covered by Clause 14 of IEC 60968.

Hence, IEC 62471 does not require any additional marking for GLS lamps.

– 6 – 60968 © IEC:2012

SELF-BALLASTED LAMPS FOR

GENERAL LIGHTING SERVICES –

Safety requirements

1 Scope

This International Standard specifies the safety and interchangeability requirements, together

with the test methods and conditions, required to show compliance of tubular fluorescent and

other gas-discharge lamps with integrated means for controlling starting and stable operation

(self-ballasted lamps), intended for domestic and similar general lighting purposes, having:

– a rated wattage up to 60 W;

– a rated voltage of 100 V to 250 V;

– Edison screw or bayonet caps.

The requirements of this standard relate only to type testing.

Recommendations for whole product testing or batch testing are under consideration.

This part of the standard covers photobiological safety according to IEC 62471 and

IEC/TR 62471-2.

Blue light and infrared hazards are below the level which requires marking.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60061, Lamp caps and holders together with gauges for the control of interchangeability

and safety

IEC 60061-1, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 1: Lamp caps

IEC 60061-3, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 3: Gauges

IEC 60238, Edison screw lampholders

IEC 60360, Standard method of measurement of lamp cap temperature rise

IEC 60695-2-10:2000, Fire hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end products

60968 © IEC:2012 – 7 –

IEC 60695-2-12:2010, Fire hazard testing – Part 2-12: Glowing/hot-wire based test methods

– Glow-wire flammability test method for materials

IEC 60695-2-13:2010, Fire hazard testing – Part 2-13: Glowing/hot-wire based test methods

– Glow-wire ignitability test method for materials

IEC 60901, Single-capped fluorescent lamps – Performance specifications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1

self-ballasted lamp

unit which cannot be dismantled without being permanently damaged, provided with a lamp

cap and incorporating a light source and any additional elements necessary for starting and

stable operation of the light source

3.2

type

lamps that, independent of the type of cap, are identical in photometric and electrical rating

3.3

rated voltage

voltage or voltage range marked on the lamp

3.4

rated wattage

wattage marked on the lamp

3.5

rated frequency

frequency marked on the lamp

3.6

cap temperature rise

∆t

s

surface temperature rise (above ambient) of a standard test lampholder fitted to the lamp,

when measured in accordance with the standard method described in IEC 60360

3.7

live part

conductive part which may cause an electric shock in normal use

3.8

type test

test or series of tests made on a type test sample for the purpose of checking compliance of

the design of a given product with the requirements of the relevant standard

3.9

type test sample

sample consisting of one or more similar units submitted by the manufacturer or responsible

vendor for the purpose of the type test

3.10

specific effective radiant UV power

effective power of the UV radiation of a lamp related to its luminous flux

– 8 – 60968 © IEC:2012

Note 1 to entry: The specific effective radiant UV power is expressed in mW/klm.

Note 2 to entry: The effective power of the UV radiation is obtained by weighting the spectral power distribution of

the lamp with the UV hazard function S (λ). Information about the relevant UV hazard function is given in

UV

IEC 62471. It only relates to possible hazards regarding UV exposure of human beings. It does not deal with the

possible influence of optical radiation on materials, like mechanical damage or discoloration.

4 General requirement and general test requirements

4.1 Self-ballasted lamps shall be so designed and constructed that in normal use they

function reliably and cause no danger to the user or surroundings.

In general, compliance is checked by carrying out all the tests specified.

4.2 All measurements unless otherwise specified, are carried out at rated voltage and

frequency and in a draught-proof room at (25 ± 1) °C.

If lamps are marked with a voltage range, rated voltage is taken as the mean of the voltage

range marked.

4.3 Self-ballasted lamps are non-repairable, factory sealed units. They shall not be opened

for any tests. In the case of doubt based on the inspection of the lamp and the examination of

the circuit diagram, and in agreement with the manufacturer or responsible vendor, lamps

specially prepared so that a fault condition can be simulated shall be submitted for testing

(see Clause 13).

5 Marking

5.1 Lamps shall be clearly and durably marked with the following mandatory markings:

a) mark of origin (this may take the form of a trade mark, the manufacturer's name or the

name of the responsible vendor);

b) rated voltage or voltage range (marked "V" or "volts");

c) rated wattage (marked "W" or "watts");

d) rated frequency (marked in "Hz").

5.2 In addition the following information shall be given by the lamp manufacturer either on

the lamp or packing or in the installation instructions:

a) lamp current;

b) burning position if restricted;

c) for lamps with a weight significantly higher than that of the lamps for which they are a

replacement, attention should be drawn to the fact that the increased weight may reduce

the mechanical stability of certain luminaires;

d) special conditions or restrictions which shall be observed for lamp operation, for example,

operation in dimming circuits. Where lamps are not suitable for dimming, the symbol in

Figure 1 may be used:

60968 © IEC:2012 – 9 –

Figure 1 – Dimming not allowed

5.3 Compliance is checked by the following:

a) presence and legibility of the marking required in 5.1 – by visual inspection;

b) the durability of the marking is checked by trying to remove it by rubbing lightly for 15 s

with a piece of cloth soaked with water and, after drying, for a further 15 s with a piece of

cloth soaked with hexane. The marking shall be legible after the test;

c) availability of information required in 5.2 – by visual inspection.

6 Interchangeability

6.1 Interchangeability shall be ensured by the use of caps in accordance with IEC 60061-1.

6.2 Compliance of the combination of cap and bulb is checked by the use of gauges for

checking the dimensions controlling interchangeability in accordance with Table 1.

The gauges are those shown in the standard sheet included in IEC 60061-3.

6.3 Self-ballasted lamps, when capped either B22d or E27 shall have a mass not exceeding

1 kg and shall not impart a bending moment, at the lampholder, of more than 2 Nm.

Compliance shall be checked by measurement.

Table 1 – Interchangeability gauges and lamp cap dimensions

Lamp cap Cap dimensions to be checked Gauge sheet no. from

by the gauge IEC 60061-3

B22d A max. and A min. 7006-10

or D1 max. and

B15d N min. 7006-11

Diametrical position of the pins

Insertion in lampholder 7006-4A

Retention in lampholder 7006-4B

E27 Max. dimensions of the screw thread 7006-27B

Min. major diameter of the screw thread 7006-28A

Contact making 7006-50

E26 Max. dimensions of the screw thread 7006-27D

E14 Max. dimensions of the screw thread 7006-27F

Min. major diameter of the screw thread 7006-28B

Contact making 7006-54

– 10 – 60968 © IEC:2012

7 Protection against electric shock

Self-ballasted lamps shall be so constructed that, without any additional enclosure in the form

of a luminaire, no internal metal parts or live metal parts of the lamp cap are accessible when

the lamp is installed in a lampholder according to IEC 60238.

Compliance is checked by means of the test finger specified in Figure 2, if necessary, with a

force of 10 N.

Lamps with Edison screw caps shall be so designed that they comply with the requirements

for inaccessibility for general lighting service (GLS) lamps.

Compliance is checked with the aid of a gauge in accordance with the current edition of

IEC 60061-3, sheet 7006-51A for E27 caps and sheet 7006-55 for E14 caps.

NOTE Requirements for E26 caps are under consideration.

Lamps with B22 or B15 caps are subject to the same requirements as normal incandescent

lamps with this cap.

External metal parts other than current-carrying metal parts of the cap shall not be or become

live. For testing, any movable conductive material shall be placed in the most onerous

position without using a tool.

Compliance is checked by means of the insulation resistance and electric strength test (see

Clause 8).

8 Insulation resistance and electric strength after humidity treatment

8.1 General

Insulation resistance and electric strength shall be adequate between current-carrying metal

parts of the lamp and accessible parts of the lamp.

8.2 Insulation resistance

The lamp shall be conditioned for 48 h in a cabinet containing air with a relative humidity

between 91 % and 95 %. The temperature of the air is maintained within 1 °C of any

convenient value between 20 °C and 30 °C.

Insulation resistance shall be measured in the humidity cabinet with a d.c. voltage of

approximately 500 V, 1 min after application of the voltage. The insulation resistance between

current-carrying metal parts of the cap and accessible parts of the lamp (accessible parts of

insulating material are covered with metal foil) shall be not less than 4 MΩ.

NOTE The insulation resistance of bayonet caps between shell and contacts is under consideration.

8.3 Electric strength

Immediately after the insulation resistance test, the same parts as specified above shall

withstand a voltage test for 1 min with an a.c. voltage as follows:

– ES caps: between accessible parts and parts of screw caps (accessible parts of insulating

material are covered with metal foil):

• type HV (220 V to 250 V): 4 000 V r.m.s.

60968 © IEC:2012 – 11 –

• type BV (100 V to 120 V): 2U + 1 000 V

Value U = rated voltage.

During the test, the eyelet and the shell of the cap are short-circuited.

Initially, no more than half the prescribed voltage is applied. It is then gradually raised to

the full value.

No flash-over or breakdown shall occur during the test. Measurements shall be carried out

in the humidity cabinet.

NOTE The distance between the foil and the current-carrying parts is under consideration.

– Bayonet caps: between shell and contacts (under consideration).

9 Mechanical strength

Torsion resistance: The cap shall remain firmly attached to the bulb or that part of the lamp

which is used for screwing the lamp in or out when subjected to the torque levels listed below.

B22d . 3 Nm

B15d . 1,15 Nm

E26 and E27 . 3 Nm

E14 . 1,15 Nm

The test is made by means of the test holders shown in Figures 3 and 4.

The torque shall not be applied suddenly, but shall be increased continuously from zero to the

specified value.

In the case of uncemented caps, relative movement between cap and bulb is permitted

provided it does not exceed 10°.

After the mechanical strength test, the sample shall comply with the requirements of

accessibility (see Clause 7).

10 Cap temperature rise

The cap temperature rise ∆t of the complete lamp during run-up, stabilization period and after

s

stabilization shall not exceed the values mentioned below when measured under the

conditions specified in IEC 60360:

B22d . 125 K

B15d . 120 K

E27 . 120 K

E14 . 120 K

E26 . under consideration

Measurement shall be carried out at rated voltage. If the lamp is marked with a voltage range,

it shall be measured at the mean voltage of that range, provided the limits of the voltage

range do not differ by more than 2,5 % from the mean voltage. For lamps with a wider range,

the measurement shall be made at the highest value of the range.

– 12 – 60968 © IEC:2012

11 Resistance to heat

Self-ballasted lamps shall be sufficiently resistant to heat. External parts of insulating material

providing protection against electric shock, and parts of insulating material retaining live parts

in position shall be sufficiently resistant to heat.

Compliance is checked by subjecting the parts to a ball-pressure test by means of the

apparatus shown in Figure 5.

The test is made in a heating cabinet at a temperature of (25 ± 5) °C in excess of the

operating temperature of the relevant part according to Clause 10, with a minimum of 125 °C

*

for parts retaining live parts in position and 80 °C for other parts. The surface of the part to

be tested is placed in the horizontal position and a steel ball of 5 mm diameter pressed

against this surface with a force of 20 N.

The test load and the supporting means are placed within the heating cabinet for a sufficient

time to ensure that they have attained the stabilized testing temperature before the test

commences.

The part to be tested is placed in the heating cabinet, for a period of 10 min, before the test

load is applied.

If the surface under test bends, the part where the ball presses is supported. For this

purpose, if the test cannot be made on the complete specimen, a suitable part may be cut

from it.

The specimen shall be at least 2,5 mm thick, but if such a thickness is not available on the

specimen, then two or more pieces are placed together.

After 1 h the ball is removed from the specimen which is then immersed for 10 s in cold water

for cooling down to approximately room temperature. The diameter of the impression is

measured, and shall not exceed 2 mm.

In the event of curved surfaces the shorter axis is measured if the indent is elliptical.

In case of doubt, the depth of the impression is measured and the diameter calculated using the formula

φ

= 2 p (5 − p)

, in which p is the depth of impression.

The test is not made on parts of ceramic material.

12 Resistance to flame and ignition

Parts of insulating material retaining live parts in position and external parts of insulating

material providing protection against electric shock are subjected to the glow-wire test in

accordance with IEC 60695-2-10, IEC 60695-2-11, IEC 60695-2-12 and IEC 60695-2-13,

subject to the following details.

– The test specimen is a complete lamp. It may be necessary to take away parts of the lamp

to perform the test, but care is taken to ensure that the test conditions are not significantly

different from those occurring in normal use.

– The test specimen is mounted on the carriage and pressed against the glow-wire tip with a

force of 1 N, preferably 15 mm, or more, from the upper edge, into the centre of the

surface to be tested. The penetration of the glow-wire into the specimen is mechanically

limited to 7 mm.

________

*

Under consideration.

60968 © IEC:2012 – 13 –

If it is not possible to make the test on a specimen as described above because the

specimen is too small, the above test is made on a separate specimen of the same

material, 30 mm square and with a thickness equal to the smallest thickness of the

specimen.

– The temperature of the tip of the glow-wire is 650 °C. After 30 s the specimen is withdrawn

from contact with the glow-wire tip.

The glow-wire temperature and heating current are constant for 1 min prior to commencing

the test. Care is taken to ensure that heat radiation does not influence the specimen

during this period. The glow-wire tip temperature is measured by means of a sheathed

fine-wire thermocouple constructed and calibrated as described in IEC 60695-2-10.

– Any flame or glowing of the specimen shall extinguish within 30 s of withdrawing the glow-

wire, and any flaming drop shall not ignite a piece of the tissue paper, spread out

± 5 mm below the specimen.

horizontally 200 mm

The test is not made on parts of ceramic material.

13 Fault conditions

The lamps shall not impair safety when operated under fault conditions which may occur

during the intended use.

Each of the following fault conditions is applied in turn, as well as any other associated fault

conditions that may arise from it as logical consequences. Only one component at a time is

subjected to a fault condition.

a) In a switch-start circuit, the starter is short-circuited.

b) Short-circuit across capacitors.

c) The lamp does not start, because one of the cathodes is broken.

d) The lamp does not start, although the cathode circuits are intact (de-activated lamp).

e) The lamp operates, but one of the cathodes is de-activated or broken (rectifying effect).

f) Opening or bridging other points in the circuit where the diagram indicates that such a

fault condition may impair safety.

Examination of the lamp and its circuit diagram will generally show the fault conditions which

should be applied. These are applied in sequence in the order that is most convenient.

The manufacturer or responsible vendor shall submit a specially prepared lamp with the

relevant fault condition, where possible in such a way that by operating a switch outside the

lamp the fault condition is introduced.

Components or devices in which a short-circuit does not occur shall not be bridged. Similarly,

components or devices in which an open circuit cannot occur shall not be interrupted.

Manufacturers or responsible vendors shall produce evidence that the components behave in

a way that does not impair safety, for instance, by showing compliance with the relevant

specification.

In the case of fault conditions a), b) or f), compliance is checked by operating the sample free

burning at room temperature and at a voltage between 90 % and 110 % of the rated voltage

or, in case of a voltage range, at a voltage between 90 % and 110 % of the mean voltage of

that range until stable conditions have been reached, then introducing the fault condition.

In the case of fault conditions c), d) or e), the same operating conditions apply but the fault

condition is introduced at the start of the test.

– 14 – 60968 © IEC:2012

The sample is then tested a further 8 h. During this test it shall not catch fire, or produce

flammable gases and live parts shall not become accessible.

To check if gases liberated from component parts are flammable or not, a test with a high-

frequency spark generator is made.

To check if accessible parts have become live, a test in accordance with Clause 7 is made.

The insulation resistance (see 8.2) is checked with a d.c. voltage of approximately 1 000 V.

Linear dimensions in millimetres

Tolerances on dimensions without specific tolerance:

on angles:

′

−10

on linear dimensions:

up to 25 mm:

−0,05

over 25 mm: ± 0,2

Material of finger: e.g. heat-treated steel

+10 °

Both joints of this finger may be bent through an angle of 90 , but in one and the same direction only.

Using the pin and groove solution is only one of the possible approaches in order to limit the bending angle to 90°.

For this reason dimensions and tolerances of these details are not given in the drawing. The actual design shall

ensure a 90° bending angle with a 0° to +10° tolerance.

Figure 2 – Standard test finger

60968 © IEC:2012 – 15 –

Dimension E14 E26 E27 Tolerance

C 20,0 32,0 32,0 Min.

K 11,5 11,0 11,0 ± 0,3

O 12,0 23,0 23,0

± 0,1

S 7,0 12,0 12,0 Min.

The drawing is intended only to illustrate the essential dimensions of the holder.

Thread to be in accordance with holder threads of IEC 60061.

Figure 3 – Holder for torsion test on lamps with screw caps

– 16 – 60968 © IEC:2012

IEC 929/99

Dimensions B15 B22 Tolerance

mm mm mm

A 15,27 22,27 +0,03

B 19,0 19,0 Min.

C 21,0 28,0 Min.

D 9,5 9,5 Min.

E 3,0 3,0 +0,17

G 18,3 24,6

± 0,3

H 9,0 12,15 Min.

K 12,7 12,7

± 0,3

R 1,5 1,5 Approx.

The drawing illustrates the essential dimensions of the holder which need only be checked if doubt arises from the

application of the test.

a

These slots shall be symmetrical on centre line.

Figure 4 – Holder for torque test on lamps with bayonet caps

60968 © IEC:2012 – 17 –

Figure 5 – Ball-pressure apparatus

14 UV radiation

The specific effective radiant UV power emitted by the lamp shall not exceed the value of

2 mW/klm. For reflector lamps, it shall not exceed the value of 2 mW/(m²⋅klx).

NOTE In IEC 62471, exposure limits are given as effective irradiance values (unit W/m²) and for risk group

classification the values for general lighting lamps are to be reported at an illuminance level of 500 lx. The

borderline for risk group exempt is 0,001 W/m² at an illuminance level of 500 lx. This means the specific value,

related to the illuminance, is 0,001 divided by 500 in W/(m²⋅lx), which is 2 mW/(m²⋅klx). Since lx = lm/m², this

equals 2 mW/klm specific UV power.

Compliance is checked by spectroradiometric measurement, under analogue conditions as for

the lamp’s electrical and photometric characteristics as given in IEC 60901.

– 18 – 60968 © IEC:2012

Bibliography

IEC 62471:2006, Photobiological safety of lamps and lamp systems

IEC/TR 62471-2:2009, Photobiological safety of lamps and lamp systems – Part 2: Guidance

on manufacturing requirements relating to non-laser optical radiation safety

____________

– 20 – 60968 © CEI:2012

SOMMAIRE

AVANT-PROPOS . 21

INTRODUCTION . 23

1 Domaine d'application . 24

2 Références normatives . 24

3 Termes et définitions . 25

4 Exigence générale et généralités sur les essais . 26

5 Marquage . 26

6 Interchangeabilité . 27

7 Protection contre les chocs électriques . 28

8 Résistance d'isolement et rigidité électrique après traitement à l'humidité . 29

8.1 Généralités . 29

8.2 Résistance d'isolement . 29

8.3 Rigidité électrique . 29

9 Résistance mécanique . 29

10 Echauffement du culot . 30

11 Résistance à la chaleur . 30

12 Résistance à l'inflammation et à la combustion . 31

13 Conditions de défaut. 31

14 Rayonnement UV . 36

Bibliographie . 37

Figure 1 – Utilisation avec un gradateur interdite . 27

Figure 2 – Doigt d'épreuve . 33

Figure 3 – Douille pour les essais de torsion sur lampes avec culot à vis . 34

Figure 4 – Douille pour essai de torsion sur lampes à culot à baïonnette . 35

Figure 5 – Appareil pour l'essai à la bille . 36

Tableau 1 – Calibres d'interchangeabilité et dimensions des culots de lampes . 28

60968 © CEI:2012 – 21 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

LAMPES À BALLAST INTÉGRÉ POUR

L'ÉCLAIRAGE GÉNÉRAL –

Exigences de sécurité

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de la CEI. La CEI n'est responsable d'aucun des services effectués par les organismes de

certification indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...