IEC 63270-1:2025

(Main)Predictive maintenance of industrial automation equipment and systems - Part 1: General requirements

Predictive maintenance of industrial automation equipment and systems - Part 1: General requirements

IEC 63270-1:2025 provides guidance on the functional structure model, procedure, method, interface of function blocks. It also offers guidance on data requirements for predictive maintenance of equipment, devices and systems for industrial automation applications.

Condition monitoring is not only within the scope of this document but can also be an important input for predictive maintenance.

Maintenance predictive des équipements et systèmes d'automatisation industrielle - Partie 1: Exigences générales

IEC 63270-1:2025 fournit des recommandations sur le modèle de structure fonctionnelle, la procédure, la méthode et l’interface des blocs fonctionnels. Elle fournit également des recommandations à propos des exigences en matière de données pour la maintenance prédictive des équipements, appareils et systèmes pour les applications d’automatisation industrielle.

La surveillance d’état relève non seulement du domaine d’application du présent document, mais peut également constituer une entrée importante de la maintenance prédictive.

General Information

- Status

- Published

- Publication Date

- 16-Apr-2025

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Drafting Committee

- WG 12 - TC 65/SC 65E/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 17-Apr-2025

- Completion Date

- 28-Mar-2025

Overview

IEC 63270-1:2025 is an international standard issued by the International Electrotechnical Commission (IEC) that sets the general requirements for predictive maintenance of industrial automation equipment and systems. This standard provides essential guidance on the functional structure model, procedures, methods, and interface requirements of function blocks used in predictive maintenance. It also highlights the importance of structured data management and compatibility for efficient maintenance strategies.

By applying IEC 63270-1:2025, industries can enhance equipment reliability, reduce downtime, and optimize maintenance costs through proactive interventions based on predictive insights rather than reactive repairs.

Key Topics

Functional Structure Model

The standard outlines a comprehensive functional structure model for predictive maintenance encompassing:

- Condition monitoring

- Fault diagnosis

- Remaining Useful Life (RUL) prediction

- Maintenance management

This model ensures systematic organization of predictive maintenance functions in industrial automation systems.

Procedure and Method

IEC 63270-1:2025 defines the procedural flow for predictive maintenance encompassing:

- Data collection and monitoring

- Fault identification and diagnosis

- Prediction of future failures using advanced algorithms

- Execution of maintenance activities based on predictive data

It prescribes methodologies for data analysis, fault algorithms, and verification to ensure accuracy and reliability.

Function Block Interfaces

The standard specifies interface requirements for predictive maintenance function blocks, facilitating seamless integration with automation systems and infrastructure. This standardization supports interoperability, simplified implementation, and scalability across diverse industrial environments.

Data Requirements

A key aspect of IEC 63270-1 is detailed guidance on data quality, compatibility, and modeling for condition monitoring and predictive analytics. The standard promotes effective data acquisition and management, which are critical for accurate fault detection and RUL predictions.

Condition Monitoring

While predictive maintenance encompasses multiple facets, condition monitoring is recognized as a vital input. The standard describes objectives, data needs, and compatibility considerations for successful condition monitoring implementation.

Applications

IEC 63270-1:2025 applies broadly across industries utilizing industrial automation technologies, including:

- Manufacturing Plants: For automated equipment like motion control systems, flow meters, compressors, and valves, enabling predictive insights that minimize unplanned shutdowns.

- Process Industries: Optimizing maintenance schedules for critical measurement devices (e.g., temperature transmitters, radar level sensors) to ensure continuous process control.

- Energy Sector: Improving reliability of electrical and mechanical components in power generation and distribution systems.

- Automotive and Robotics: Facilitating early detection of faults in robotic automation to maintain production efficiency and safety.

By following these guidelines, industries can substantially improve operational efficiency, resource utilization, and asset longevity.

Related Standards

- IEC 61508 (Functional Safety): Addresses electrical and electronic safety-related systems and complements predictive maintenance in managing system integrity.

- ISO 13374 (Condition Monitoring Data Processing): Provides frameworks for condition monitoring data handling that align with IEC 63270-1’s data requirements.

- IEC 62714 (AutomationML): Supports data modeling and system integration relevant to device templates in predictive maintenance.

- IEC 61131 (Programmable Controllers): Relevant for implementing function blocks defined in this standard within industrial control systems.

Adherence to IEC 63270-1:2025 alongside related standards ensures a holistic and interoperable approach to predictive maintenance in industrial automation environments.

Keywords: IEC 63270-1, predictive maintenance, industrial automation, condition monitoring, fault diagnosis, remaining useful life (RUL), maintenance management, function blocks, industrial equipment, IEC standards, data requirements, automation system integration

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 63270-1:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Predictive maintenance of industrial automation equipment and systems - Part 1: General requirements". This standard covers: IEC 63270-1:2025 provides guidance on the functional structure model, procedure, method, interface of function blocks. It also offers guidance on data requirements for predictive maintenance of equipment, devices and systems for industrial automation applications. Condition monitoring is not only within the scope of this document but can also be an important input for predictive maintenance.

IEC 63270-1:2025 provides guidance on the functional structure model, procedure, method, interface of function blocks. It also offers guidance on data requirements for predictive maintenance of equipment, devices and systems for industrial automation applications. Condition monitoring is not only within the scope of this document but can also be an important input for predictive maintenance.

IEC 63270-1:2025 is classified under the following ICS (International Classification for Standards) categories: 25.040.01 - Industrial automation systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63270-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63270-1 ®

Edition 1.0 2025-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Predictive maintenance of industrial automation equipment and systems –

Part 1: General requirements

Maintenance predictive des équipements et systèmes d'automatisation

industrielle –

Partie 1 : Exigences générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform

IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63270-1 ®

Edition 1.0 2025-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Predictive maintenance of industrial automation equipment and systems –

Part 1: General requirements

Maintenance predictive des équipements et systèmes d'automatisation

industrielle –

Partie 1 : Exigences générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.01 ISBN 978-2-8327-0331-1

– 2 – IEC 63270-1:2025 © IEC 2025

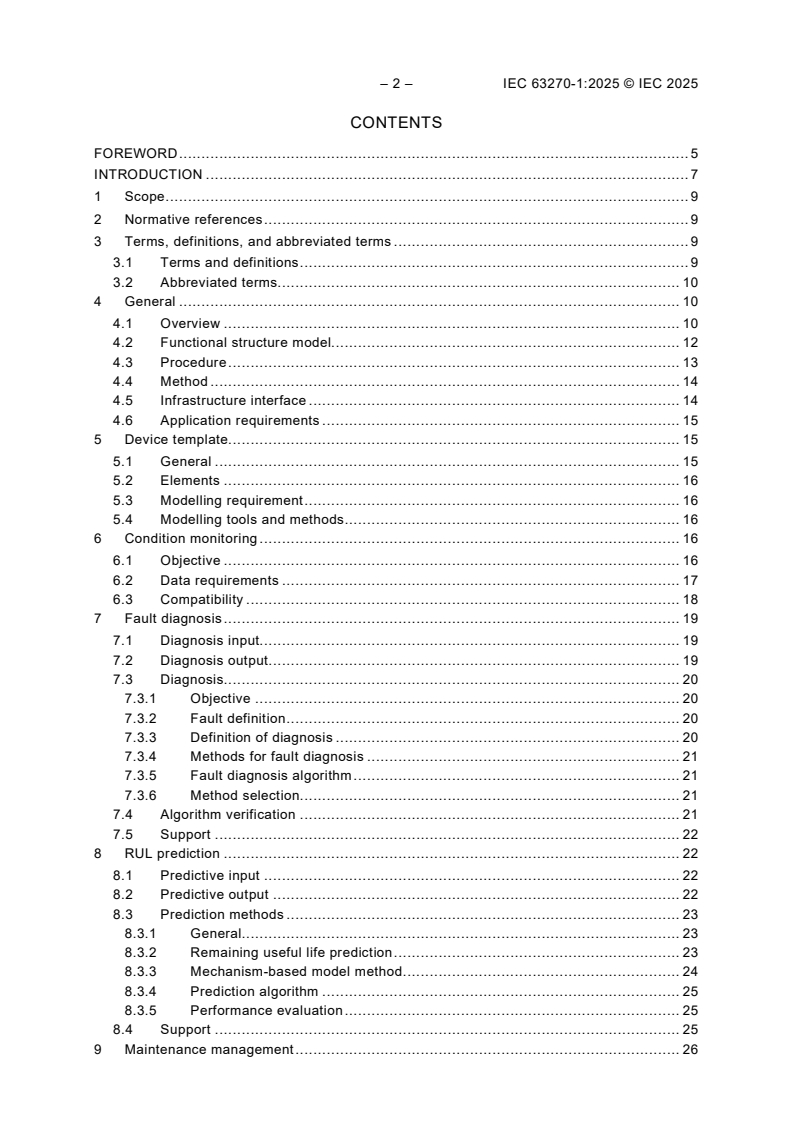

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 9

2 Normative references . 9

3 Terms, definitions, and abbreviated terms . 9

3.1 Terms and definitions . 9

3.2 Abbreviated terms. 10

4 General . 10

4.1 Overview . 10

4.2 Functional structure model. 12

4.3 Procedure . 13

4.4 Method . 14

4.5 Infrastructure interface . 14

4.6 Application requirements . 15

5 Device template. 15

5.1 General . 15

5.2 Elements . 16

5.3 Modelling requirement . 16

5.4 Modelling tools and methods . 16

6 Condition monitoring . 16

6.1 Objective . 16

6.2 Data requirements . 17

6.3 Compatibility . 18

7 Fault diagnosis . 19

7.1 Diagnosis input. 19

7.2 Diagnosis output . 19

7.3 Diagnosis. 20

7.3.1 Objective . 20

7.3.2 Fault definition . 20

7.3.3 Definition of diagnosis . 20

7.3.4 Methods for fault diagnosis . 21

7.3.5 Fault diagnosis algorithm . 21

7.3.6 Method selection. 21

7.4 Algorithm verification . 21

7.5 Support . 22

8 RUL prediction . 22

8.1 Predictive input . 22

8.2 Predictive output . 22

8.3 Prediction methods . 23

8.3.1 General. 23

8.3.2 Remaining useful life prediction . 23

8.3.3 Mechanism-based model method . 24

8.3.4 Prediction algorithm . 25

8.3.5 Performance evaluation . 25

8.4 Support . 25

9 Maintenance management . 26

9.1 Overview . 26

9.2 Type and relationship of maintenance processes . 26

9.3 Status and conversion . 26

9.4 System interface . 27

9.4.1 System interface overview . 27

9.4.2 System external interface . 28

Annex A (informative) Predictive maintenance in automation systems . 30

A.1 Overview . 30

A.2 Condition monitoring . 30

A.3 Fault diagnosis . 31

A.4 RUL prediction . 31

A.5 Maintenance management . 31

Annex B (informative) Device template of predictive maintenance. 33

B.1 Coriolis mass flowmeter . 33

B.2 Radar (level measurement) . 34

B.3 Temperature transmitter . 35

B.4 Motion control system . 36

Annex C (informative) Application scenarios for predictive maintenance . 38

C.1 Flow meter and compressor . 38

C.1.1 Overview . 38

C.1.2 Predictive maintenance of air compressors . 39

C.1.3 Flow meter . 40

C.2 Servo valve . 41

C.2.1 Condition monitoring based on characteristic values . 41

C.2.2 Frequency selectivity-based fault diagnosis . 42

C.2.3 Prediction based on an expert system . 42

Bibliography . 44

Figure 1 – Predictive maintenance work process . 7

Figure 2 – Automatic equipment and system predictive maintenance level. 11

Figure 3 – Functional structure model of predictive maintenance . 12

Figure 4 – Predictive maintenance flow chart. 13

Figure 5 – PM function block interface . 14

Figure 6 – An example of pump system condition monitoring . 17

Figure 7 – Mechanical damage of the motor . 17

Figure 8 – Device feature analysis and compatibility level . 18

Figure 9 – General process of fault diagnosis . 20

Figure 10 – Remaining life prediction process . 23

Figure 11 – Remaining life prediction methods . 25

Figure 12 – Maintenance status diagram . 27

Figure 13 – Interaction between the maintenance management of industrial automatic

equipment and other functions . 28

Figure A.1 – Positioning of condition monitoring, prediction, and maintenance

scheduling in manufacturing system . 30

Figure A.2 – Determining the health state of a component by processing actual input

values . 31

Figure A.3 – The relationships between time to failure, reliability, and cost . 32

– 4 – IEC 63270-1:2025 © IEC 2025

Figure B.1 – Graphical device template for a motion control system . 37

Figure C.1 – Schematic diagram of the air compressor system PM scenario . 39

Figure C.2 – Verification of the Coriolis mass flow meter . 41

Figure C.3 – Condition Monitoring of the Servo valve . 42

Figure C.4 – PM scenario of a servo valve (based on frequency selectivity). 42

Figure C.5 – PM scenario of a servo valve (based on an expert system) . 43

Table B.1 – Device template for a Coriolis mass flowmeter . 33

Table B.2 – Device template for a radar (level measurement). 34

Table B.3 – Device template for a temperature transmitter . 35

Table B.4 – Device template for a motion control system . 36

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PREDICTIVE MAINTENANCE OF INDUSTRIAL

AUTOMATION EQUIPMENT AND SYSTEMS –

Part 1: General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 63270-1 has been prepared by subcommittee SC 65E: Devices and integration in enterprise

systems, of IEC technical committee 65: Industrial process measurement, control and

automation. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

65E/1148/FDIS 65E/1159/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

– 6 – IEC 63270-1:2025 © IEC 2025

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 63270 series, published under the general title Predictive

maintenance of industrial automation equipment and systems, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

INTRODUCTION

Efficient production significantly depends on the availability of production equipment. The status

of the equipment and its components, further referred to as “assets” can be monitored and

assessed in order to guarantee the intended usage of equipment and to avoid unplanned

downtimes. The results of the predictive maintenance assessment are, for example, the

remaining useful lifetime prediction, necessary maintenance activities, etc. The results can also

lead to the optimization of production workflow by targeting the reorganization of equipment

usage. The work process of PM (predictive maintenance) is depicted in Figure 1.

Figure 1 – Predictive maintenance work process

The availability of status information is the main prerequisite for such a prediction. Modern

automation equipment is often equipped with sensors and self-monitoring capabilities. These

functions can gather data that can be used to determine the status of the equipment. However,

the equipment is delivered from different suppliers and is based on different technologies.

Therefore, there is currently no uniform solution for accessing the data and calculating status

information. Access to data is a prerequisite for predictive maintenance solutions. Therefore,

an integration project is often an integral part of the solution. This significantly hinders efforts

to implement solutions for predictive maintenance.

In addition, standards can define the definition, scope, procedure, and functional structure of

PM, as well as the relationship between PM and CBM. In predictive maintenance, industrial

automation equipment and systems play two different roles: "measuring tool" and " object of

prediction". Condition monitoring, fault diagnosis and remaining useful life prediction methods

can be based on a data-driven model, a mechanism-based model, or both. Without

standardization, it is difficult to maintain accuracy and be able to compare the PM results.

– 8 – IEC 63270-1:2025 © IEC 2025

From the description above, a need for standardization can be deduced. Providing an

appropriate method and infrastructure, comprised of a uniform ontology, predictive methods,

and system interfaces. Such an approach will facilitate the easy composition of complex

condition monitoring and predictive maintenance solutions. It will also provide critical

information for equipment and factories based on original data and analytical methods.

PREDICTIVE MAINTENANCE OF INDUSTRIAL

AUTOMATION EQUIPMENT AND SYSTEMS –

Part 1: General requirements

1 Scope

This part of IEC 63270 provides guidance on the functional structure model, procedure, method,

interface of function blocks. It also offers guidance on data requirements for predictive

maintenance of equipment, devices and systems for industrial automation applications.

Condition monitoring is not only within the scope of this document but can also be an important

input for predictive maintenance.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TR 62390, Common automation device – Profile guideline

ISO/IEC/IEEE 42010:2022, Software, systems and enterprise – Architecture description

3 Terms, definitions, and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

predictive maintenance

form of preventive maintenance performed continuously or at intervals governed by observed

conditions to monitor, diagnose or trend a structure, system or component’s condition indicators

Note 1 to entry: Results indicate present and future functional ability or the nature of, and schedule for, planned

maintenance.

[SOURCE: IEC 62342:2007, 3.14, modified – The note has been deleted.]

3.1.2

preventive maintenance

maintenance carried out at predetermined intervals or according to prescribed criteria and

intended to reduce the probability of failure or the degradation of the functioning of an item

[SOURCE: IEC 61918:2018, 3.1.62]

– 10 – IEC 63270-1:2025 © IEC 2025

3.1.3

condition monitoring

recording and evaluation of technical entity status for maintenance purposes

3.1.4

maintenance

activity including supervisory actions, intended to retain an item in, or restore it to, a state in

which it can perform a required function

3.1.5

condition-based maintenance

maintenance activity performed on the basis of the documentation of the performance

degradation of an item (as results of, for example, auto diagnostic or wear measurement)

Note 1 to entry: It is based on a proper visibility of performance degradation or intermittent failures.

[SOURCE: IEC 61918:2018, 3.1.23, modified – "preventive activity" has been replaced by

"maintenance activity".]

3.1.6

infrastructure interface

shared boundary between two function units defined by functional characteristics, signal

characteristics, or other characteristics as appropriate

[SOURCE: IEC TR 62390:2005, 3.1.16]

3.2 Abbreviated terms

CBM Condition-Based Maintenance

DTM Device Type Manager

FDT Field Device Tool

FDI Field Device Integration

FMEA Fault Modes and Effect Analysis

FTA Fault Tree Analysis

MES Manufacturing Execution System

OPC UA Open Platform Communications Unified Architecture

PM Predictive Maintenance

RUL Remaining Use Life

TBM Time-Based Maintenance

XML Extensible Markup Language

4 General

4.1 Overview

Based on the differences in requirements and purposes, the implementation of predictive

maintenance of automation equipment and systems can be divided into the following three

categories, as shown in Figure 2:

Category I: The realization of CBM, that is, through the acquisition of critical data of the

equipment’s operating state, complete functions of status identification and basic fault diagnosis

and to provide basic repair and maintenance strategies, such as alarms, shutdowns, etc. This

type of predictive maintenance can be based on MES or other information systems.

Category II: The realization of predictive-based maintenance, which means that through the

acquisition of data related to the operating status of the equipment, the functions of status

recognition, fault diagnosis, life prediction, etc., are completed in order to provide repair and

maintenance programs in advance to help with the management of equipment repair and

maintenance. This type of predictive maintenance should be based on a system that can be

interconnected with MES or other information systems.

Category III: The realization of maintenance based on whole life cycle management, that is,

through the comprehensive acquisition of equipment operating state data, complete the

functions of condition monitoring, fault diagnosis, life prediction, etc. Moreover, it can judge the

confidence of the remaining useful life to provide a complete and credible repair and

maintenance program in advance and guide the management of equipment’s repair and

maintenance. The system that performs this task can continuously optimize the prediction

results and enhance the confidence and feasibility of the prediction with the help of technologies

such as virtual simulation, artificial intelligence, and system integration. This type of

maintenance not only reduces the cost of use and maintenance of equipment but also creates

new value by optimizing operating decisions.

Breakdown maintenance and preventive maintenance are also important maintenance practices.

However, they are outside the scope of this document. It mainly focuses on the predictive

maintenance of categories I and II, and some of the contents can apply to the predictive

maintenance of categories I and III.

Figure 2 – Automatic equipment and system predictive maintenance level

– 12 – IEC 63270-1:2025 © IEC 2025

4.2 Functional structure model

The overall functional structure for PM will, however, stay rather fixed (see Figure 3). The

determination of the current state of an asset needs to be carried out using sensing functions.

According to this, a calculation of the state of health and a condition status assessment can be

carried out. This is a prerequisite for fault diagnosis and defining repair measures on the one

hand, and for remaining useful life prediction and defining maintenance actions on the other.

The fault diagnosis process includes fault identification, fault location, etc. It is not necessary

to enter the prediction process if the fault has occurred but directly enter the maintenance

management phase. If the fault does not occur or is about to occur, fault diagnosis data and

condition monitoring data are required to be transmitted together to the prediction phase to

conduct the Remaining Useful Life (RUL) prediction and transmit the RUL information to the

maintenance management phase.

RUL prediction is the major phase of predictive maintenance. The required inputs include

history information about equipment (working conditions, environment, fault information, etc.),

equipment status information, fault diagnosis information, etc. The relevant prediction methods

are described in Clause 7 of this document.

Finally, all the maintenance measures shall be seamlessly integrated into a maintenance

management solution at the Manufacturing Operation Management (MOM) level. Independent

of the specific functionalities, a systematic approach should be introduced in order to establish

a predictive maintenance system. However, cause-and-remedy actions and advice can be

derived from the predictive results.

This functional structure covers both approaches: on-site and remote maintenance. The

technological developments, particularly the communication and data processing solutions, will

enhance the use of remote monitoring and maintenance. The mapping of this functional

structure model in an automation system is depicted in Annex A.

Figure 3 – Functional structure model of predictive maintenance

The dotted lines in Figure 3 indicate that the function is not within the scope of PM. The

maintenance actions and repair measures are not within the scope of PM but shall be within

the scope of maintenance activities.

4.3 Procedure

The general process and the key steps that should be followed in the implementation of

predictive maintenance of equipment are depicted in Figure 4. The work of predictive

maintenance of equipment shall focus on identifying and avoiding root cause failure modes.

Figure 4 – Predictive maintenance flow chart

– 14 – IEC 63270-1:2025 © IEC 2025

4.4 Method

Prediction is the core of predictive maintenance. Depending on the input data, there are usually

three categories of predictive maintenance methods.

– The first category is based on the prediction using the mechanism-based model.

– The second category is prediction based on a data-driven model.

– The third category is prediction based on a hybrid model, a mixture of a mechanism-based

model method and a data-driven method, or a mixture of different data-driven methods.

The type and requirements of data acquisition vary based on the prediction method.

4.5 Infrastructure interface

The predictive maintenance function shall be modularized and contain the necessary

maintenance activities in order to realize the functions as shown in Figure 5. It shall be defined

based on the functional viewpoint as defined in ISO/IEC/IEEE 42010:2022. Therefore, a

function block shall specify the necessary parts, the overall structure, the internal interfaces

between the functional parts, and the external interfaces to relevant systems. It shall not define

a specific, technology-dependent implementation.

The parts of predictive maintenance function include functionalities for:

– data acquisition and pre-processing (sensing),

– condition state assessment,

– fault diagnosis,

– remaining useful life prediction,

– feedback from repair and maintenance measures.

Figure 5 – PM function block interface

In addition, all parts of this function block shall contain functions for common identification,

self-description, and management of parts. These functions can be realized using an asset

administration shell.

The definition of functional interfaces shall include a description of interfaces (see Figure 5).

– Between the functional parts, see item 1 of Figure 5 above.

– Between data sources and the functional parts, see item 2 of Figure 5 above.

– Between functional parts and maintenance management, see item 3 of Figure 5 above, e.g.,

to manufacturing operations management (MOM), as defined in IEC 62264-3 activities.

– Between the functional parts and engineering and commissioning tools,see item 4 of

Figure 5 above.

A mapping to specific implementation technologies can be realized based on these interface

specifications.

4.6 Application requirements

The implementation of predictive maintenance shall meet the following requirements:

1) The necessity to implement predictive maintenance shall be confirmed. Predictive

maintenance requires hardware, software, and data and requires a costly investment. In

addition, due to the accuracy of the prediction method, the implementation of predictive

maintenance can bring additional risks. Therefore, the subject of the implementation of

predictive maintenance shall have the necessity of cost and security.

2) The implementation of predictive maintenance shall be directed to faults with "deterioration"

characteristics rather than random faults. Objects that implement predictive maintenance

shall have a working process that meets the requirements for condition monitoring before a

failure occurs. Predictive maintenance will not work for failures that cannot be determined

by the failure mechanism and cannot be monitored in advance.

3) The parameters related to the fault shall be monitored. Condition monitoring is the basis for

predictive maintenance. The premise of predictive maintenance is the ability to find

monitorable parameters that have fault information. For instance, the corrosion of a fixture

casing is presently difficult to monitor with sensors. However, once cracks due to corrosion

or other fatigue factors occurs, predictive maintenance can be performed by monitoring its

vibration signals.

4) Historical data and the associated necessary tests can provide data support. Historical data

can provide information regarding fault diagnosis and location. The necessary tests can

enhance the accuracy of the prediction algorithm and are essential for the implementation

of predictive maintenance.

5) The confidence of predictive maintenance shall be within the acceptable range for the user.

Predictive maintenance with low confidence can result in an unnecessary maintenance,

which increases costs and wastes resources. Therefore, predictive maintenance is used to

help in decision-making and continuously enhance the confidence level.

5 Device template

5.1 General

Device templates are tools to build equipment models in accordance with expected failure

modes. It provides common failure modes and corresponding data requirements that can be

predicted.

Device templates are references for predictive maintenance data collection. Moreover, they do

not directly support diagnosis and prediction. However, the establishment of device templates

is a necessary process for predictive maintenance. For details about the Device template, see

Annex B.

– 16 – IEC 63270-1:2025 © IEC 2025

5.2 Elements

The basic elements of the device templates include:

– equipment: information about systems, equipment, and devices;

– failure mode: a failure mode related to each level of equipment and system, particularly a

diagnosable and predictable systemic failure;

– data requirements: necessary data for diagnosis and prediction related to the failure mode.

Device templates can also include descriptions of each element, specifying detailed

requirements for the data, such as minimum sampling frequency, sampling duration, and other

specific content as needed.

5.3 Modelling requirement

Device templates are made up of elements based on different relationships. An element is the

minimum unit of device template modelling, including necessary information.

Elements can be divided into variables, parts, and objects. Variables contain analog quantities,

discrete quantities, and static information. Analog quantities include values, such as

temperature and current. Discrete quantities include values such as operating state. Static

information is attribute information that does not change over time, such as equipment

parameters or failure modes. Parts represent the physical entity. Objects refers to a specific

type of device.

In modelling, the information entity needs to be divided into different elements to build a

component model. The object-oriented information model and modelling technology can be

used to achieve unified data organization and management, based on relevant industry

standards, coding systems, and application requirements, so that the data of each system can

be associated through a unified device object.

5.4 Modelling tools and methods

The device template modelling method consists of three steps:

– step 1: Sort out the model structure and organizational relationships based on objects;

– step 2: Create an equipment model based on the sorting results from Step 1;

– step 3: Create a device template.

There are many tools available for device templates. XML is a commonly used option for

machine-readable systems.

6 Condition monitoring

6.1 Objective

Condition monitoring is the basis for predictive maintenance. In addition, data acquisition and

condition discrimination are the core of condition monitoring. By analysing the data, such as

the running logs of the device, the running status of the device can be effectively evaluated,

and the potential abnormal conditions of the device running can be discovered dynamically and

timely to generate a targeted maintenance solution.

As the example shown in Figure 6, mechanical damage and electrical faults can be predicted

by monitoring the condition of the pump and motor.

Figure 6 – An example of pump system condition monitoring

6.2 Data requirements

The data acquisition from equipment shall be determined based on the requirements and

methods of predictive maintenance. The working conditions, alarm status, and statistical

information of the equipment are collected if the analysis method based on data statistics is

adopted. The data on the equipment’s operating state is collected if the analysis method based

on the mechanism-based model is used. In addition, the data is required to continuously and

truly reflect the operating state of the device over time.

Take the mechanical damage to the motor as an example, as shown in Figure 7. The status of

that motor can be monitored and evaluated through the acquisition of torque and speed data.

Furthermore, the real-time analysis and diagnosis of the data are conducted to perform early

maintenance when abnormal waveforms occur to reduce the loss caused by equipment failure.

Figure 7 – Mechanical damage of the motor

– 18 – IEC 63270-1:2025 © IEC 2025

The methods for data acquisition from equipment mainly include:

– basic data acquisition for the equipment;

– acquisition of working status data for equipment;

– acquisition of operating status data for equipment;

– acquisition of alarm status data for equipment;

– acquisition of statistical data on equipment;

– acquisition of management data on equipment processing status;

– other relevant data (environment, personnel).

6.3 Compatibility

Predictive maintenance requires standardized communication schemes that allow different

communication protocols to coexist in order to support data requirements. In order to ensure

the compatibility of communication schemes, indicators such as interconnection,

intercommunication, interoperability, and interchange can be considered, as can integration into

a single platform to enable the predictive maintenance solution’s easy access to data.

According to IEC TR 62390, the following aspect shall be considered in the field of eq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...