IEC 61241-1-1:1999

(Main)Electrical apparatus for use in the presence of combustible dust - Part 1-1: Electrical apparatus protected by enclosures and surface temperature limitation - Specification for apparatus

Electrical apparatus for use in the presence of combustible dust - Part 1-1: Electrical apparatus protected by enclosures and surface temperature limitation - Specification for apparatus

Is applicable to electrical apparatus protected by enclosures and surface temperature limitation for use in areas where combustible dust may be present in quantities which could lead to a fire or explosion hazard. It specifies requirements for design, construction and testing of electrical apparatus. Note - IEC 61241-2 gives guidance on the selection, installation and maintenance of the apparatus. Apparatus within the scope of this standard may also be subject to additional requirements in other standards - for example, IEC 60079-0.

Matériels électriques destinés ŕ ętre utilisés en présence de poussičres combustibles - Partie 1-1: Matériels électriques protégés par enveloppes et limitation de la température de surface - Spécification pour les matériels

Electrical apparatus for use in the presence of combustible dust - Part 1: Electrical apparatus protected by enclousures - Section 1: Specification for apparatus

General Information

- Status

- Replaced

- Publication Date

- 16-Jun-1999

- Technical Committee

- TC 31 - Equipment for explosive atmospheres

- Drafting Committee

- MT 7 - TC 2/MT 7

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 07-Jul-2004

- Completion Date

- 26-Oct-2025

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 61241-1-1:1999 - Electrical apparatus for use in the presence of combustible dust - Part 1-1: Electrical apparatus protected by enclosures and surface temperature limitation - Specification for apparatus Released:6/17/1999 Isbn:2831848334

Frequently Asked Questions

IEC 61241-1-1:1999 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical apparatus for use in the presence of combustible dust - Part 1-1: Electrical apparatus protected by enclosures and surface temperature limitation - Specification for apparatus". This standard covers: Is applicable to electrical apparatus protected by enclosures and surface temperature limitation for use in areas where combustible dust may be present in quantities which could lead to a fire or explosion hazard. It specifies requirements for design, construction and testing of electrical apparatus. Note - IEC 61241-2 gives guidance on the selection, installation and maintenance of the apparatus. Apparatus within the scope of this standard may also be subject to additional requirements in other standards - for example, IEC 60079-0.

Is applicable to electrical apparatus protected by enclosures and surface temperature limitation for use in areas where combustible dust may be present in quantities which could lead to a fire or explosion hazard. It specifies requirements for design, construction and testing of electrical apparatus. Note - IEC 61241-2 gives guidance on the selection, installation and maintenance of the apparatus. Apparatus within the scope of this standard may also be subject to additional requirements in other standards - for example, IEC 60079-0.

IEC 61241-1-1:1999 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61241-1-1:1999 has the following relationships with other standards: It is inter standard links to IEC 61241-1:2004, IEC 61241-0:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC 61241-1-1:1999 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Electrical apparatus for use in the presence of combustible dust - Part 1: Electrical apparatus protected by enclousures - Section 1: Specification for apparatusElectrical apparatus for use in the presence of combustible dust - Part 1-1: Electrical apparatus protected by enclosures and surface temperature limitation - Specification for apparatus29.260.20Electrical apparatus for explosive atmospheresICS:Ta slovenski standard je istoveten z:IEC 61241-1-1 Ed. 2.0SIST IEC 61241-1-1:1998en01-april-1998SIST IEC 61241-1-1:1998SLOVENSKI

STANDA

...

INTERNATIONAL IEC

STANDARD

61241-1-1

Second edition

1999-06

Electrical apparatus for use in the presence

of combustible dust –

Part 1-1:

Electrical apparatus protected by

enclosures and surface temperature limitation –

Specification for apparatus

Matériels électriques destinés à être utilisés en présence

de poussières combustibles –

Partie 1-1:

Matériels électriques protégés par enveloppes et limitation

de la température de surface –

Spécification pour les matériels

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is to be found at the following IEC sources:

• IEC web site*

•

Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL IEC

STANDARD

61241-1-1

Second edition

1999-06

Electrical apparatus for use in the presence

of combustible dust –

Part 1-1:

Electrical apparatus protected by

enclosures and surface temperature limitation –

Specification for apparatus

Matériels électriques destinés à être utilisés en présence

de poussières combustibles –

Partie 1-1:

Matériels électriques protégés par enveloppes et limitation

de la température de surface –

Spécification pour les matériels

IEC 1999 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

V

International Electrotechnical Commission

For price, see current catalogue

– 2 – 61241-1-1 © IEC:1999(E)

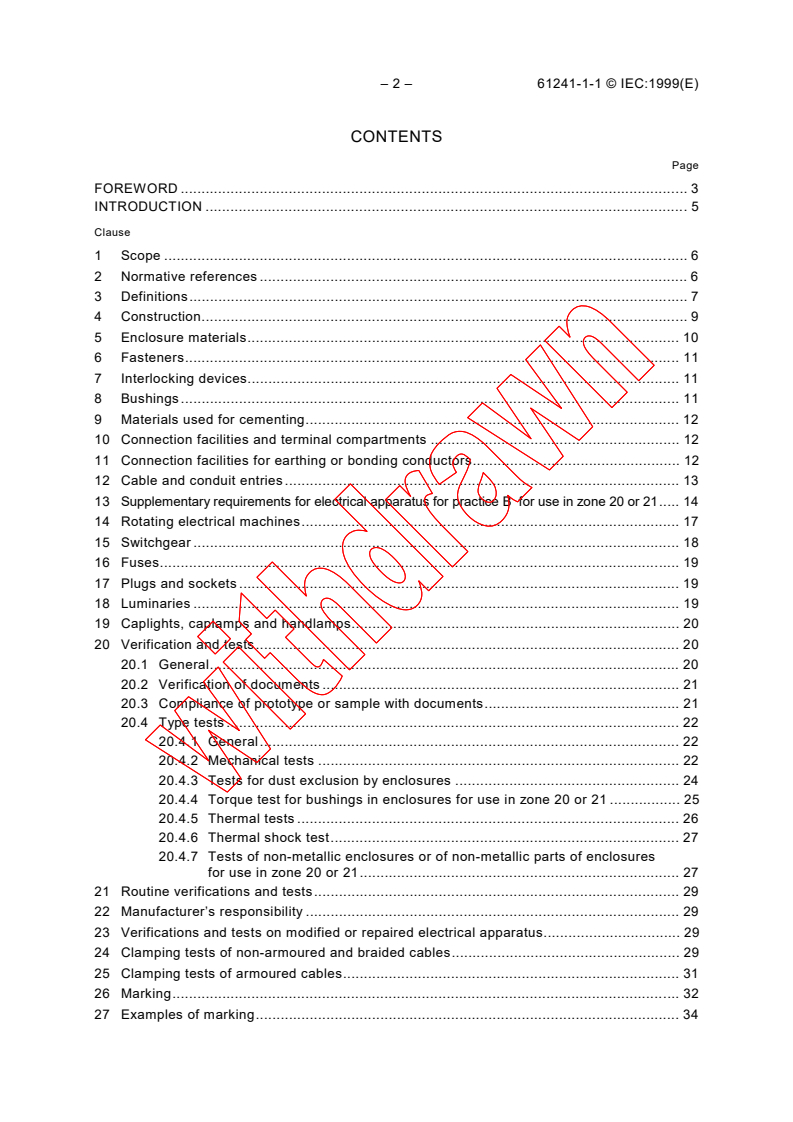

CONTENTS

Page

FOREWORD . 3

INTRODUCTION .5

Clause

1 Scope . 6

2 Normative references . 6

3 Definitions. 7

4 Construction. 9

5 Enclosure materials. 10

6 Fasteners. 11

7 Interlocking devices. 11

8 Bushings. 11

9 Materials used for cementing. 12

10 Connection facilities and terminal compartments . 12

11 Connection facilities for earthing or bonding conductors. 12

12 Cable and conduit entries . 13

13 Supplementary requirements for electrical apparatus for practice B for use in zone 20 or 21. 14

14 Rotating electrical machines. 17

15 Switchgear . 18

16 Fuses. 19

17 Plugs and sockets . 19

18 Luminaries . 19

19 Caplights, caplamps and handlamps. 20

20 Verification and tests. 20

20.1 General. 20

20.2 Verification of documents . 21

20.3 Compliance of prototype or sample with documents. 21

20.4 Type tests . 22

20.4.1 General. 22

20.4.2 Mechanical tests . 22

20.4.3 Tests for dust exclusion by enclosures . 24

20.4.4 Torque test for bushings in enclosures for use in zone 20 or 21 . 25

20.4.5 Thermal tests . 26

20.4.6 Thermal shock test. 27

20.4.7 Tests of non-metallic enclosures or of non-metallic parts of enclosures

for use in zone 20 or 21. 27

21 Routine verifications and tests. 29

22 Manufacturer’s responsibility . 29

23 Verifications and tests on modified or repaired electrical apparatus. 29

24 Clamping tests of non-armoured and braided cables. 29

25 Clamping tests of armoured cables. 31

26 Marking. 32

27 Examples of marking. 34

61241-1-1 © IEC:1999(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL APPARATUS FOR USE IN THE

PRESENCE OF COMBUSTIBLE DUST –

Part 1-1: Electrical apparatus protected by enclosures and

surface temperature limitation – Specification for apparatus

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61241-1-1 has been prepared by subcommittee 31H: Apparatus for

use in the presence of combustible dust, of IEC technical committee 31: Electrical apparatus

for explosive atmospheres.

This second edition cancels and replaces the first edition, published in 1993, and constitutes a

technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

31H/90/FDIS 31H/96/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A bilingual version of this standard may be issued at a later date.

– 4 – 61241-1-1 © IEC:1999(E)

IEC 61241 consists of the following parts under the general title: Electrical apparatus for use in

the presence of combustible dust:

– Part 1: Electrical apparatus protected by enclosures and surface temperature limitation

– Part 2: Test methods

– Part 3: Classification of areas where combustible dusts are or may be present

1)

– Part 4: Type of protection pressurization "p"

1)

– Part 5: Intrinsically safe apparatus

________

1)

Under consideration.

61241-1-1 © IEC:1999(E) – 5 –

INTRODUCTION

Combustible dust can be ignited by electrical apparatus in several main ways:

• by surfaces of the apparatus that are above the minimum ignition temperature of the dust

concerned. The temperature at which a type of dust ignites is a function of the properties of

the dust, whether the dust is in a cloud or layer, the thickness of the layer and the geometry

of the heat source;

• by arcing or sparking of electrical parts such as switches, contacts, commutators, brushes,

or the like;

• by discharge of an accumulated electrostatic charge;

• by radiated energy (for example electromagnetic radiation);

• by mechanical sparking or frictional sparking or heating associated with the apparatus.

In order to avoid ignition hazards it is necessary that

• the temperature of surfaces, on which dust can be deposited, or which would be in contact

with a dust cloud, is kept below the temperature limitation specified in IEC 61241-1-2;

• any electrical sparking parts, or parts having a temperature above the minimum ignition

temperature of the dust

– are contained in an enclosure which adequately prevents the ingress of dust, or

– the energy of electrical circuits is limited so as to avoid arcs, sparks or temperatures

capable of igniting combustible dust;

• any other ignition sources are avoided.

The protection specified in this standard will not provide the required level of safety unless the

electrical apparatus is operated within its rating and is installed and maintained according to

the relevant codes of practice or requirements, for example in respect of protection against

over-currents, internal short circuits, and other electrical faults. In particular, it is essential that

the severity and duration of an internal or external fault be limited to values that can be

sustained by the electrical apparatus without damage.

Two different types of practice, A and B, are specified in this standard. Both are intended to

provide an equivalent level of protection.

– 6 – 61241-1-1 © IEC:1999(E)

ELECTRICAL APPARATUS FOR USE IN THE

PRESENCE OF COMBUSTIBLE DUST –

Part 1-1: Electrical apparatus protected by enclosures and

surface temperature limitation – Specification for apparatus

1 Scope

This part of IEC 61241 is applicable to electrical apparatus protected by enclosures and

surface temperature limitation for use in areas where combustible dust may be present in

quantities which could lead to a fire or explosion hazard. It specifies requirements for design,

construction and testing of electrical apparatus.

NOTE – IEC 61241-1-2 gives guidance on the selection, installation and maintenance of the apparatus. Apparatus

within the scope of this standard may also be subject to additional requirements in other standards – for example,

IEC 60079-0.

The ignition protection is based on the limitation of the maximum surface temperature of the

enclosure and other surfaces which could be in contact with dust and on the restriction of dust

ingress into the enclosure by the use of "dust-tight" or "dust-protected" enclosures.

The application of electrical apparatus in atmospheres which may contain explosive gas as well

as combustible dust, whether simultaneously or separately, requires additional protective

measures.

Where the apparatus has to meet other environmental conditions, for example, protection

against ingress of water and resistance to corrosion, additional methods of protection may be

necessary. The method used is not to adversely affect the integrity of the enclosure.

The principles of this standard may also be followed when combustible fibres or flyings cause a

hazard.

This standard does not apply to dusts of explosives which do not require atmospheric oxygen

for combustion, or to pyrophoric substances.

This standard is not applicable to electrical apparatus intended for use in underground parts of

mines as well as those parts of surface installations of such mines endangered by fire damp

and/or combustible dust. This standard does not take account of any risk due to an emission of

flammable or toxic gas from the dust.

This standard does not include other types of protection and is only applicable to protection by

enclosures and surface temperature limitation.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 61241. For dated references, subsequent amendments

to, or revisions of, any of these publications do not apply. However, parties to agreements

based on this part of IEC 61241 are encouraged to investigate the possibility of applying the

most recent editions of the normative documents indicated below. For undated references, the

latest edition of the normative document referred to applies. Members of IEC and ISO maintain

registers of currently valid International Standards.

IEC 60034-5:1991, Rotating electrical machines – Part 5: Classification of degrees of

protection provided by enclosures of rotating electrical machines (IP code)

IEC 60050(426):1990, International Electrotechnical Vocabulary (IEV) – Chapter 426: Electrical

apparatus for explosive atmospheres

61241-1-1 © IEC:1999(E) – 7 –

IEC 60079-0:1998, Electrical apparatus for explosive gas atmospheres – Part 0: General

requirements

IEC 60079-7:1990, Electrical apparatus for explosive gas atmospheres – Part 7: Increased

safety "e"

IEC 60079-11:1991, Electrical apparatus for explosive gas atmospheres – Part 11: Intrinsic

safety "i"

IEC 60093:1980, Methods of test for volume resistivity and surface resistivity of solid electrical

insulating materials

IEC 60192:1973, Low-pressure sodium vapour lamps

IEC 60243-1:1998, Electrical strength of insulating materials – Test methods – Part 1: Tests at

power frequencies

IEC 60216-1:1990, Guide for the determination of thermal endurance properties of electrical

insulating materials – Part 1: General guidelines for ageing procedures and evaluation of test

results

IEC 60216-2:1990, Guide for the determination of thermal endurance properties of electrical

insulating materials – Part 2: Choice of test criteria

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60662:1980, High-pressure sodium vapour lamps

IEC 60947-3:1990, Low-voltage switchgear and controlgear – Part 3: Switches, disconnectors,

switch-disconnectors and fuse-combination units

IEC 61241-1-2:199X, Electrical apparatus for use in the presence of combustible dust –

Part 1-2: Electrical apparatus protected by enclosures – Selection, installation and maintenance

IEC 61241-2-1:1994, Electrical apparatus for use in the presence of combustible dust – Part 2:

Test methods – Section 1: Methods for determining the minimum ignition temperatures of dust

IEC 61241-3:1997, Electrical apparatus for use in the presence of combustible dust – Part 3:

Classification of areas where combustible dusts are or may be present

ISO 178:1993, Plastics – Determination of flexural properties

ISO 527 (all parts), Plastics – Determination of tensile properties

ISO 4225:1994, Air quality – General aspects – Vocabulary

3 Definitions

For the purpose of this part of IEC 61241, the following definitions apply:

3.1

dust

small solid particles in the atmosphere which settle out under their own weight, but which may

remain suspended in air for some time (includes dust and grit as defined in ISO 4225)

– 8 – 61241-1-1 © IEC:1999(E)

3.2

combustible dust

dust, fibres or flyings that can burn or glow in air and could form explosive mixtures with air at

atmospheric pressure and normal temperatures

3.3

conductive dust

dust fibres or flyings with electrical resistivity equal to or less than 10 Ωm

3.4

explosive dust atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of dust or

fibres in which, after ignition, combustion spreads throughout the unconsumed mixture

[IEV 426-02-04]

3.5

minimum ignition temperature of a dust layer

lowest temperature of a hot surface at which ignition occurs in a dust layer of specified

thickness on this hot surface

[see 3.3 of IEC 61241-2-1, modified]

3.6

minimum ignition temperature of a dust cloud

lowest temperature of the hot inner wall of a furnace at which ignition occurs in a dust cloud in

air contained therein

[see 3.5 of IEC 61241-2-1, modified]

3.7

dust ignition protection (DIP)

all relevant measures specified in this standard (for example, dust ingress protection and

surface temperature limitation) applied to electrical apparatus to avoid ignition of a dust layer

or cloud

3.8

dust-tight enclosure

enclosure capable of preventing the ingress of all observable dust particles

3.9

dust-protected enclosure

enclosure in which the ingress of dust is not totally prevented but does not enter in sufficient

quantity to interfere with the safe operation of the equipment. Dust should not accumulate in a

position within the enclosure where it is liable to cause an ignition hazard

3.10

maximum surface temperature

highest temperature which is attained by any part of the surface of electrical apparatus when

tested under the defined dust-free or blanket conditions

NOTE – This temperature is attained under the test condition. Increasing the layer thickness can increase this

temperature due to the thermal insulation properties of dust.

61241-1-1 © IEC:1999(E) – 9 –

3.11

maximum permissible surface temperature

highest temperature a surface of electrical apparatus is allowed to reach in practical service to

avoid ignition. The maximum permissible surface temperature will depend upon the type of

dust, whether as a cloud or layer, if a layer, its thickness, and the application of a safety factor

[see IEC 61241-1-2, clause 6]

3.12

zones

see 2.10 of IEC 61241-3

3.13

zone 20

see 2.11 of IEC 61241-3

3.14

zone 21

see 2.12 of IEC 61241-3

3.15

zone 22

see 2.13 of IEC 61241-3

4 Construction

4.1 Electrical apparatus for use in potentially explosive dust atmospheres shall comply with

the requirements of this standard.

NOTE – If the electrical apparatus has to withstand particularly adverse service conditions (for example rough

handling, humidity effects, ambient temperature variations, effects of chemical agents, corrosion), these should be

specified to the manufacturer by the user and are not the responsibility of the testing station.

4.2 Enclosures for use in zone 20 or 21 which can be opened more quickly than the time

necessary

• to allow incorporated capacitors, charged by a voltage of 200 V or more, to discharge to a

value of residual energy of 0,2 mJ; or

• to allow the cooling of enclosed hot components to a surface temperature below the

temperature class of the electrical apparatus

shall be marked with the following or equivalent warning:

“AFTER DE-ENERGIZING, DELAY X MINUTES BEFORE OPENING”

“X” being the value in minutes of the delay required.

Alternatively the apparatus may be marked with the warning:

“DO NOT OPEN WHEN AN EXPLOSIVE DUST ATMOSPHERE IS PRESENT”.

4.3 Where the apparatus has to meet other environmental conditions, for example, protection

against ingress of water and resistance to corrosion, the method of protection used shall not

adversely affect the integrity of the enclosure.

– 10 – 61241-1-1 © IEC:1999(E)

5 Enclosure materials

5.1 Non-metallic enclosures and non-metallic parts of enclosures

The following requirements apply to non-metallic enclosures and non-metallic parts of

enclosures on which the type of protection depends. In addition, the requirements of 20.4.7

apply to enclosures for use in zone 20 or 21.

5.1.1 Documents submitted to the manufacturer shall specify both the material and the

manufacturing process of the enclosure or part of the enclosure.

5.1.2 The specification for plastic materials shall include

a) the name of the manufacturer;

b) the exact and complete reference of the material including its colour, percentage of fillers

and any other additives if used;

c) the possible surface treatments, such as varnishes, etc.;

d) the temperature index “TI” corresponding to the 20 000 h point on the thermal endurance

graph without loss of flexural strength exceeding 50 %, determined in accordance

with IEC 60216-1 and IEC 60216-2 and based on the flexing property in accordance with

ISO 178. If the material does not break in this test before exposure to the heat, the index

shall be based on the tensile strength in accordance with ISO 527 with test bars of type 1.

The data by which these characteristics are defined shall be supplied by the manufacturer.

5.1.3 The testing station is not required to verify compliance of the material with its

specification.

5.1.4 Thermal endurance

5.1.4.1 Plastic materials shall have a temperature index “TI” corresponding to the 20 000 h

point of at least 20 K greater than the temperature of the hottest point of the enclosure or the

part of the enclosure (see 20.4.7.1), having regard to the maximum ambient temperature in

service.

5.1.4.2 The endurance to heat and to cold of the enclosures, or parts of enclosures, of plastic

materials shall be satisfactory (see 20.4.7.3 and 20.4.7.4).

5.1.5 Electrostatic charges on enclosures or parts of enclosures of plastic material for use in

zone 20 or 21.

5.1.5.1 The following requirements apply only to plastic enclosures, to plastic parts of

enclosures and to other exposed plastic parts of electrical apparatus for

• non-fixed electrical apparatus;

• fixed apparatus with plastic parts that are likely to be rubbed or cleaned on site.

5.1.5.2 Enclosures of plastic material with surface area projected in any direction of more

than 100 cm shall be so designed that under normal conditions of use, maintenance and

cleaning, danger of ignition due to electrostatic charges is avoided.

61241-1-1 © IEC:1999(E) – 11 –

5.1.5.3 This can be achieved by the use of plastic material having one or more of the

following characteristics:

• Insulation resistance ≤10

Ω (resistance against electrostatic discharge to earth through or

across the surface of insulation, measured according to the method described in IEC 60093

with an effective area of the circular electrode of 20 cm ).

• Breakdown voltage ≤4 kV (measured across the thickness of the insulating material

according to the method described in IEC 60243-1).

• Thickness ≥8 mm of the external insulation on metal parts. (External plastic layers of 8 mm

and greater on metal parts such as measurement probes or similar components make

propagating brush discharges unlikely to occur. When evaluating the minimum thickness of

the insulation to be used or specified, it is necessary to allow for any expected wear under

normal usage.)

5.1.5.4 If, however, the danger of ignition cannot be avoided in the design, a warning label

shall indicate the safety measures to be applied in service.

NOTE – When selecting electrical insulating materials, attention should be paid to maintaining a minimum insulation

resistance to avoid problems arising from touching exposed plastic parts that are in contact with live parts.

5.2 Enclosures containing light metals

5.2.1 Materials used in the construction of enclosures of electrical apparatus to be used in

explosive dust atmospheres shall not contain, by weight, more than 6 % in total of magnesium

and titanium.

5.2.2 Threaded holes in enclosures for fasteners which secure covers intended to be opened

in service for adjustment, inspection and other operational reasons may only be tapped in the

material of the enclosure when the thread form is compatible with the material used for the

enclosure.

6 Fasteners

6.1 Parts necessary to achieve a standard type of protection or used to prevent access to

uninsulated live parts shall be capable of being released or removed only with the aid of a tool.

6.2 Threaded holes for fasteners which secure covers intended to be opened in service for

adjustment, inspection and other operational reasons may only be tapped into the plastic or

light metal material when the thread form is compatible with the plastic or light metal material

of the enclosure.

7 Interlocking devices

Interlocking devices used to maintain a type of protection shall be so constructed that their

effectiveness cannot readily be defeated by the use, for example, of a screwdriver or pliers.

8 Bushings

8.1 Bushings in enclosures used as connection facilities, and which may be subjected to a

torque while the connection or disconnection is being made, shall be mounted in such a way

that all parts are secured against turning.

8.2 Bushings in enclosures for use in zone 20 or 21 shall comply with the relevant torque test

as specified in 20.4.4.

– 12 – 61241-1-1 © IEC:1999(E)

9 Materials used for cementing

9.1 The manufacturer’s documents submitted according to 20.2 of this standard shall testify

that for the intended operating conditions, the materials used for cementing, and on which

safety depends, have a thermal stability adequate for the minimum and maximum temperatures

to which they will be subjected, within the rating of the electrical apparatus.

9.2 The thermal stability is considered adequate if the limiting values for the material are

below or equal to the lowest working temperature and at least 20 K above the maximum

temperature in service.

NOTE – If the cementing has to withstand adverse service conditions, appropriate measures should be agreed

between user and manufacturer.

9.3 The testing station is not required to verify the characteristics listed in the documents

mentioned in 9.1.

10 Connection facilities and terminal compartments

10.1 Electrical apparatus which is intended for connection to external circuits shall include

connection facilities, except if the electrical apparatus is manufactured with a cable

permanently connected to it. All apparatus constructed with permanently connected

unterminated cables shall be marked with the symbol “X” to indicate the need for appropriate

connection of the free end of the cable.

10.2 Terminal compartments and their access openings shall be dimensioned so that the

conductors can be readily connected.

10.3 Terminal compartments shall be so designed that after proper connection of the

conductors, the creepage distances and the clearances comply with the requirements, if any, of

the specific standard for the type of apparatus concerned.

11 Connection facilities for earthing or bonding conductors

11.1 A connection facility for the connection of an earthing or equipotential bonding conductor

shall be provided inside the terminal compartment of electrical apparatus and near the other

connection facilities.

11.2 Electrical apparatus with a metallic enclosure shall have an additional external

connection facility for an earthing or equipotential bonding conductor. This external connection

facility shall be electrically in contact with the facility required in 11.1. The external connection

facility is not required for electrical apparatus which is designed to be moved when energized

and is supplied by a cable incorporating an earthing or equipotential bonding conductor.

NOTE – The expression “electrically in contact” does not necessarily involve the use of a conductor.

11.3 Neither an internal nor external earthing or bonding connection facility is required for

electrical apparatus for which earthing (or bonding) is not required, such as electrical

apparatus having double or reinforced insulation, or for which supplementary earthing is not

necessary.

11.4 Earthing or equipotential bonding connection facilities shall allow for the effective

connection of at least one conductor with a cross-sectional area as shown in table 1.

61241-1-1 © IEC:1999(E) – 13 –

Table 1 – Minimum cross-sectional areas of protective conductors

Cross-sectional area of phase conductors of Minimum cross-sectional area of the

the installation corresponding protective conductor

S Sp

2 2

mm mm

S

S ≤ 16

16 < S ≤ 35

S > 35 0,5 S

11.5 In addition to meeting this requirement, earthing or bonding connection facilities on the out-

side of electrical apparatus shall provide for effective connection of a conductor of at least 4 mm .

11.6 Connection facilities shall effectively be protected against corrosion. They shall also be

designed so that the conductors are secured against loosening and twisting and so that the

contact pressure is maintained.

11.7 Contact pressure of electrical connections shall not be affected by dimensional changes

of insulating materials in service, due to temperature or humidity, etc.

11.8 Special precautions shall be taken if one of the parts in contact consists of a material

containing light metal. One example of a means of connecting to a material containing light

metal is to use an intermediate part made from steel.

12 Cable and conduit entries

12.1 The manufacturer shall specify in the documents submitted according to 20.2, the

entries intended for use with cable or conduit, their position on the apparatus and the maximum

number permitted.

12.2 Cable and conduit entries shall be constructed and fixed so that they do not alter the

specific characteristics of the type of protection of the electrical apparatus on which they are

mounted. This shall apply to the whole range of cable dimensions specified by the

manufacturer of the cable entries as suitable for use with those entries.

Cable and conduit entries may form an integral part of the apparatus, i.e. one major

12.3

element or part forms an inseparable part of the enclosure of the apparatus. In such cases, the

entries shall be tested and certified with the apparatus.

NOTE – Cable and conduit entries, which are separate from, but installed with the apparatus, are usually tested and

certified separately from the apparatus but may be tested and certified together with the apparatus if the apparatus

manufacturer so requests.

12.4 Where the design of a cable entry is such that twisting of the cable can be transmitted to

the connections, then an anti-rotation device shall be fitted.

12.5 Entry by conduit or cable entries shall be either by screwing into threaded holes or by

locking in plain holes

• in the wall of the enclosure; or

• in an adaptor plate designed to be fitted in or on the walls of the enclosure; or

• in a suitable stopping box, integral with or attached to the wall of the enclosure.

– 14 – 61241-1-1 © IEC:1999(E)

12.6 Blanking elements intended to close openings in the walls of electrical apparatus when

they are not fitted with cable or conduit entries, shall, together with the enclosure wall of the

apparatus, satisfy the requirements of the specific type of protection concerned. The means

provided for this shall be such that the blanking element can be removed only with the aid of a

tool.

12.7 When the temperature under rated conditions, including any manufacturer’s installation

requirements, is higher than 70 °C at the cable or conduit entry point, or 80 °C at the branching

point of the conductors, the outside of the electrical apparatus shall be marked as a guide for

the selection by the user of the cable or of the wiring in the conduit, in order to ensure that the

rated temperature of the cable is not exceeded (see figure 1).

IEC 790/99

Key

1 Branching point of the conductors

2 Sealing ring

3 Cable entry body

4 Clamping ring with curved rim

5 Cable

Figure 1 – Illustration of entry points and branching points

13 Supplementary requirements for electrical apparatus for practice B

for use in zone 20 or 21

13.1 Joints

13.1.1 Plain joints (see figure 2) shall have a minimum contact width from inside to outside of

the enclosure and a maximum allowable clearance between the surfaces as shown in table 2.

61241-1-1 © IEC:1999(E) – 15 –

Table 2 – Plain joints

Minimum contact width of the plain joint (mm), W 522

Maximum allowable clearance between the surfaces of the joint (mm), G 0,05 0,22

NOTE – For widths of joints between 5 mm and 22 mm the maximum clearance may be increased by 0,01 mm for

each millimetre increase in joint width greater than 5 mm.

G

W

IEC 791/99

Figure 2 – Plain joints

Spigotted joints (see figure 3) which have axial, , and radial, , paths neither of

13.1.2 L W

which is less than 1,2 mm, may have diametrical clearances as shown for plain joints in

table 2. The radial section, , of the spigotted joint shall have a maximum allowable clearance,

W

G, as shown for plain joints in table 2.

L

W

G

IEC 792/99

Figure 3 – Spigotted joints

– 16 – 61241-1-1 © IEC:1999(E)

13.1.3 For gasketed joints (see figure 4) requirements are given in table 3.

O

W

IEC 793/99

Figure 4 – Gasketed joints

Table 3 – Gasketed joints

Maximum opening dimension (mm), O 305 915 >915

Minimum required effective width of gasketed joint (mm), W 3 4,8 9,5

NOTE – For maximum opening dimensions between 305 mm and 915 mm, the

effective width of the gasketed joint shall be increased by 0,003 mm for each

millimetre increase in the maximum opening dimension greater than 305 mm.

13.2 Operating rods, spindles or shafts

13.2.1 Equipment meeting the requirements of “Dust ignition protected apparatus type

DIP B20 or DIP B21” and the test requirements of 20.4.3 of this standard shall not depend on

running contact seals to ensure dust-tightness.

13.2.2 If running contact seals are used, the equipment shall meet the design details of

table 4 and table 5 and the dust tests of 20.4.3 without the running contact seals installed.

13.2.3 Power shafts for transmitting power at rotational speeds of 100 r/min or more (see

figure 5) shall meet the requirements for the length of path from the inside to the outside of the

enclosure as given in table 4.

Running contact seal

D

D

1 2

L

IEC 794/99

Figure 5 – Power shafts for speeds of 100 r/min. or more

61241-1-1 © IEC:1999(E) – 17 –

Table 4 – Power shafts for speeds of 100 r/min or more

Minimum length of path for power shafts (mm), L 12,5 38,5

Maximum allowable diametrical clearance (mm), D – D 0,26 0,57

2 1

NOTE 1 – For lengths of path for power shafts between 12,5 mm and 38,5 mm the maximum diametrical clearance

may be increased by 0,012 mm for each millimetre increase in the length of path greater than 12,5 mm.

NOTE 2 – The minimum length of path may include both the inner and outer lips of the bearing housing.

13.2.4 Operating rods, spindles or shafts having rotary motion of less than 100 r/min or axial

motion, shall have either a threaded joint with three full threads engaging, or have a minimum

length of path from the inside to the outside of the enclosure as given in table 5.

Table 5 – Power shafts for speeds of less than 100 r/min

Minimum length of path for operating rods, spindles or shafts (mm), L 12,5 25,5

Maximum allowable diametrical clearance (mm), D – D 0,13 0,21

2 1

NOTE – For lengths of path for operating rods, spindles or shafts between 12,5 mm and 25,5 mm, the maximum

diametrical clearance may be increased by 0,006 mm for each millimetre length of path greater than 12,5 mm.

13.3 Clearance of bolts

Bolts passing through the enclosure wall shall have a maximum diametrical clearance between

the unthreaded shank of the bolt, N, and the clearance hole in the enclosure, DS-DH, of not

more than 0,26 mm and a length of path, , of not less than 12,5 mm (see figure 6).

L

L

N

IEC 795/99

Figure 6 – Clearance of bolts

14 Rotating electrical machines

14.1 External, shaft-driven cooling fans of rotating electrical machines shall be enclosed by a

fanhood which is not considered to be part of the enclosure of the electrical apparatus. Such

fans and fanhoods shall meet the following requirements.

– 18 – 61241-1-1 © IEC:1999(E)

14.2 Ventilation openings for external fans

The degree of protection (IP) of ventilation openings for external fans of rotating electrical

machines shall be at least

• IP20 on the air inlet side,

• IP10 on the air outlet side,

according to IEC 60034-5.

14.3 For vertical rotating machines for use in zone 20 or 21, foreign objects shall be

prevented from falling into the ventilation openings.

14.4 Construction and mounting of the ventilating systems

Fans, fanhoods and ventilation screens shall be constructed so as to meet the requirements

of the resistance to impact test according to 20.4.2.1 and the required results according

to 20.4.2.3.

14.5 Clearances for the ventilating system for use in zone 20 or 21

In normal operation the clearances, taking into account design tolerances, between the

external fan and its hood, ventilation screens and their fasteners shall be at least 1/100 of the

maximum diameter of the fan, except that the clearances need not exceed 5 mm and may be

reduced to 1 mm if the opposing parts are manufactured so as to have dimensional accuracy

and stability. In no case shall the clearance be less than 1 mm.

14.6 Materials for external fans and fanhoods for use in zone 20 or 21

14.6.1 External fans, fanhoods, ventilation screens, etc., shall have an electrical insulation

resistance measured according to 5.1.5.3 not exceeding 10 Ω.

14.6.2 The thermal stability of plastic materials shall be considered adequate if the

manufacturer’s specified operating temperature of the material exceeds the maximum

temperature to which the material will be subjected in service (within the rating) by at least 20 K.

14.6.3 The external fans, fanhoods, ventilation screens, of rotating electrical machines,

manufactured from materials containing light metals shall not contain by weight more than 6 %

of magnesium.

15 Switchgear

15.1 Switchgear with contacts immersed in flammable dielectric is not permitted.

15.2 Disconnectors (which are not designed to be operated under the intended load) shall:

• be electrically or mechanically interlocked with a suitable load breaking device; or

• be marked at a place near the actuator of the disconnector, with the warning

“DO NOT OPERATE UNDER LOAD”.

15.3 Where switchgear includes a disconnector, the latter shall disconnect all poles and shall be

designed so that the position of the disconnector contacts is visible, or their open position is

indicated in accordance with the requirements for the isolation function specified in IEC 60947-3.

Any interlock between such disconnector and the cover or door of the switchgear shall allow this

cover or door to be opened only when the separation of the disconnector contacts is effective.

61241-1-1 © IEC:1999(E) – 19 –

16 Fuses

Enclosures containing fuses shall

• be interlocked so that insertion or removal of replaceable elements can be carried out only

with the supply disconnected and so that the fuses cannot be energized until the enclosure

is correctly closed; or

• alternatively, the apparatus shall be marked with the warning

“DO NOT OPEN WHEN ENERGIZED”.

17 Plugs and sockets

17.1 Plugs and sockets shall comply with either a) or b) below:

a) be interlocked mechanically, or electrically, or otherwise designed so that they cannot be

separated when the contacts are energized and the contacts cannot be energized when the

plug and socket are separated; or

b) be fixed together by means of special fasteners according to 9.2 of IEC 60079-0 and the

apparatus marked with the warning:

“DO NOT SEPARATE WHEN ENERGIZED”.

17.2 In the case where bolted types cannot be de-energized before separation because they

are connected to a battery, the marking shall then state:

“SEP

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...