IEC 62848-2:2019

(Main)Railway applications - DC surge arresters and voltage limiting devices - Part 2: Voltage limiting devices

Railway applications - DC surge arresters and voltage limiting devices - Part 2: Voltage limiting devices

IEC 62848-2:2019 applies to Voltage Limiting Devices (VLDs) to be applied in DC traction systems in order to comply with protective provisions against electric shock from DC, and combined AC – DC voltages, in accordance with the IEC 62128 series, taking into account stray current provisions.

VLDs operate in such a way as to connect the track return circuit of DC railway systems to the earthing system or to conductive parts within the overhead contact line zone or current collector zone.

Applications ferroviaires - Parafoudres et appareils limiteurs de tension pour réseaux à courant continu - Partie 2: Appareils limiteurs de tension

IEC 62848-9:2019 Le présent document concerne les appareils limiteurs de tension (VLD, Voltage Limiting Device) destinés à être appliqués aux réseaux de traction en courant continu afin de satisfaire aux dispositions de protection contre les chocs électriques dus aux tensions continues et aux tensions alternatives-continues combinées, conformément à la série IEC 62128, en tenant compte des mesures contre les courants vagabonds.

Les VLD fonctionnent de manière à raccorder le circuit de retour de voie des reseaux ferroviaires en courant continu à un réseau de mise à la terre ou aux parties conductrices de la zone de la ligne aérienne de contact ou de la zone de captage de courant.

General Information

- Status

- Published

- Publication Date

- 17-Jun-2019

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- PT 62848-2 - TC 9/PT 62848-2

- Current Stage

- PPUB - Publication issued

- Start Date

- 18-Jun-2019

- Completion Date

- 31-May-2019

Overview - IEC 62848-2:2019 (Voltage Limiting Devices)

IEC 62848-2:2019 is the International Electrotechnical Commission standard that defines Voltage Limiting Devices (VLDs) for DC traction systems. The standard specifies how VLDs must operate to meet protective provisions against electric shock from DC and combined AC–DC voltages in accordance with the IEC 62128 series, while taking stray current considerations into account. VLDs covered by this standard are intended to connect the track return circuit to the earthing system or to conductive parts within the overhead contact line or current collector zones to limit dangerous voltages.

Key topics and technical requirements

The standard addresses practical design, testing and performance requirements for VLDs used in railway DC systems, including:

- Classes of VLDs (classification and intended use: e.g., welding-shut spark gap, thyristor, mechanical switching, combined types)

- Characteristics and requirements

- Marking and identification

- Service conditions: normal outdoor/indoor and abnormal environments

- Electrical characteristics and thermal rating

- Response time and minimum performance criteria

- Protection against lightning and stray current effects

- Command and control features (for certain classes): local control, remote signalling, operation and alarm recordings

- Type and routine tests required for certification and quality assurance:

- Nominal triggering and non-triggering voltages

- Leakage current, DC current withstand, short-time withstand

- Response time tests for DC and combined AC–DC voltages

- Lightning and high-current impulse withstand

- Recovery voltage and reverse voltage tests

- Dielectric, degree-of-protection (IP), and environmental tests for outdoor equipment

- Determination of minimum current for safe short-circuiting (Class 1)

- Annex with preferred ranges of key parameters (nominal triggering voltage, rated current, impulse withstand, etc.)

Practical applications

IEC 62848-2:2019 is applied where limiting dangerous potentials on DC traction systems is required:

- Protection of track personnel and passengers by ensuring safe touch / step voltages

- Safety interfaces between the rail return and earthing systems in substations, depots and on-track equipment

- Design and selection of VLD components in overhead contact line zones and current collector zones

- Specification for procurement, factory testing and on-site acceptance of VLDs

Who should use this standard

- Railway electrical engineers and designers specifying protection systems for DC traction

- Manufacturers of voltage limiting devices and DC surge protection equipment

- Test laboratories and conformity assessment bodies performing type/routine tests

- Infrastructure owners, system integrators, and maintenance teams responsible for earthing and stray current mitigation

- Safety assessors and regulatory authorities referencing IEC 62128 and related railway safety standards

Related standards

- IEC 62848-1:2016 - Railway applications: DC surge arresters (metal-oxide surge arresters without gaps)

- IEC 62128 series - Electrical safety, earthing and the return circuit (protective provisions)

- IEC 60060‑1, IEC 62497‑1, IEC 62498‑2 and other normative references cited for test methods and environmental requirements

Keywords: IEC 62848-2:2019, voltage limiting devices, VLDs, DC traction systems, railway safety, surge arresters, IEC 62128, earthing, stray current, response time, type tests.

Buy Documents

IEC 62848-2:2019 - Railway applications - DC surge arresters and voltage limiting devices - Part 2: Voltage limiting devices Released:6/18/2019 Isbn:9782832268841

IEC 62848-2:2019 - Applications ferroviaires - Parafoudres et appareils limiteurs de tension pour réseaux à courant continu - Partie 2: Appareils limiteurs de tension Released:6/18/2019 Isbn:9782832708088

IEC 62848-2:2019 - Railway applications - DC surge arresters and voltage limiting devices - Part 2: Voltage limiting devices Released:6/18/2019 Isbn:9782832708088

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 62848-2:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - DC surge arresters and voltage limiting devices - Part 2: Voltage limiting devices". This standard covers: IEC 62848-2:2019 applies to Voltage Limiting Devices (VLDs) to be applied in DC traction systems in order to comply with protective provisions against electric shock from DC, and combined AC – DC voltages, in accordance with the IEC 62128 series, taking into account stray current provisions. VLDs operate in such a way as to connect the track return circuit of DC railway systems to the earthing system or to conductive parts within the overhead contact line zone or current collector zone.

IEC 62848-2:2019 applies to Voltage Limiting Devices (VLDs) to be applied in DC traction systems in order to comply with protective provisions against electric shock from DC, and combined AC – DC voltages, in accordance with the IEC 62128 series, taking into account stray current provisions. VLDs operate in such a way as to connect the track return circuit of DC railway systems to the earthing system or to conductive parts within the overhead contact line zone or current collector zone.

IEC 62848-2:2019 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62848-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62848-2 ®

Edition 1.0 2019-06

INTERNATIONAL

STANDARD

Railway applications – DC surge arresters and voltage limiting devices –

Part 2: Voltage limiting devices

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62848-2 ®

Edition 1.0 2019-06

INTERNATIONAL

STANDARD

Railway applications – DC surge arresters and voltage limiting devices –

Part 2: Voltage limiting devices

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 45.060.01 ISBN 978-2-8322-6884-1

– 2 – IEC 62848-2:2019 © IEC 2019

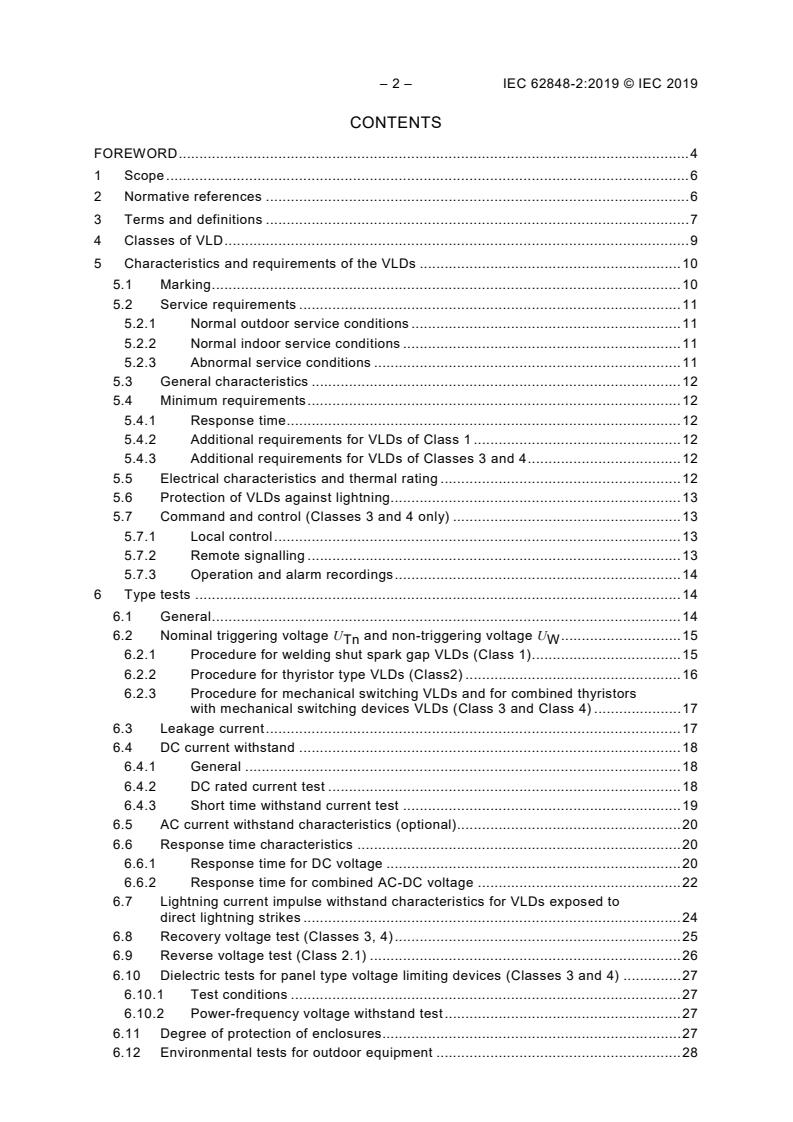

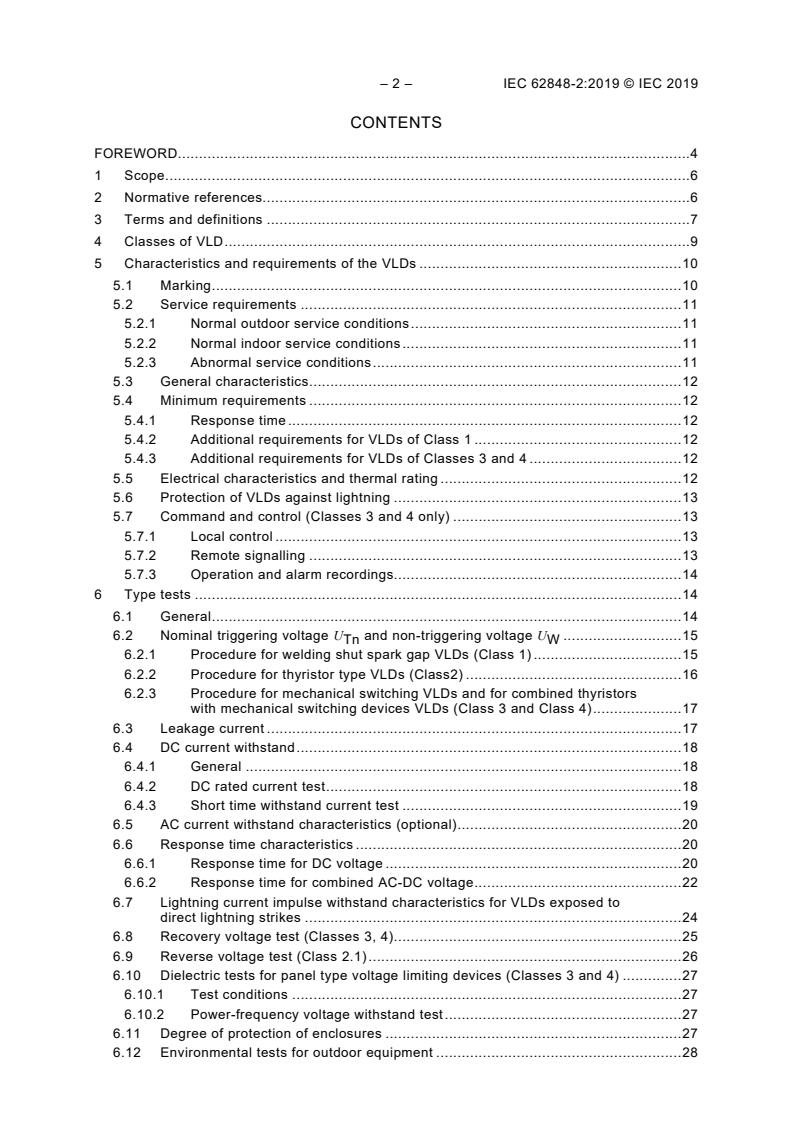

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Classes of VLD . 9

5 Characteristics and requirements of the VLDs . 10

5.1 Marking . 10

5.2 Service requirements . 11

5.2.1 Normal outdoor service conditions . 11

5.2.2 Normal indoor service conditions . 11

5.2.3 Abnormal service conditions . 11

5.3 General characteristics . 12

5.4 Minimum requirements . 12

5.4.1 Response time . 12

5.4.2 Additional requirements for VLDs of Class 1 . 12

5.4.3 Additional requirements for VLDs of Classes 3 and 4 . 12

5.5 Electrical characteristics and thermal rating . 12

5.6 Protection of VLDs against lightning. 13

5.7 Command and control (Classes 3 and 4 only) . 13

5.7.1 Local control . 13

5.7.2 Remote signalling . 13

5.7.3 Operation and alarm recordings . 14

6 Type tests . 14

6.1 General . 14

6.2 Nominal triggering voltage U and non-triggering voltage U . 15

Tn W

6.2.1 Procedure for welding shut spark gap VLDs (Class 1) . 15

6.2.2 Procedure for thyristor type VLDs (Class2) . 16

6.2.3 Procedure for mechanical switching VLDs and for combined thyristors

with mechanical switching devices VLDs (Class 3 and Class 4) . 17

6.3 Leakage current . 17

6.4 DC current withstand . 18

6.4.1 General . 18

6.4.2 DC rated current test . 18

6.4.3 Short time withstand current test . 19

6.5 AC current withstand characteristics (optional). 20

6.6 Response time characteristics . 20

6.6.1 Response time for DC voltage . 20

6.6.2 Response time for combined AC-DC voltage . 22

6.7 Lightning current impulse withstand characteristics for VLDs exposed to

direct lightning strikes . 24

6.8 Recovery voltage test (Classes 3, 4) . 25

6.9 Reverse voltage test (Class 2.1) . 26

6.10 Dielectric tests for panel type voltage limiting devices (Classes 3 and 4) . 27

6.10.1 Test conditions . 27

6.10.2 Power-frequency voltage withstand test . 27

6.11 Degree of protection of enclosures. 27

6.12 Environmental tests for outdoor equipment . 28

6.13 Determination of minimum current for safe short circuiting of Class 1 VLDs . 28

7 Routine tests . 29

7.1 General . 29

7.2 VLDs of Classes 3 and 4 . 29

7.3 Dielectric tests for panel type voltage limiting devices . 29

Annex A (informative) Preferred ranges of the principal properties of the VLDs. 30

Bibliography . 34

Figure 1 – Test circuit for testing of response time . 21

Figure 2 – T evaluation . 22

R

Figure 3 – Response time characteristic . 22

Figure 4 – Test circuit for testing of response time T for combined AC-DC voltage . 24

R

Figure 5 – Evaluation of response time T for combined AC-DC voltage . 24

R

Figure 6 – Circuit for the recovery voltage test . 26

Table 1 – Classes of voltage-limiting device. 10

Table 2 – Type tests . 15

Table 3 – Maximum response time as a function of DC voltages . 20

Table 4 – Response time for combined AC-DC voltages . 23

Table A.1 – Nominal triggering voltage U . 30

Tn

Table A.2 – Instantaneous triggering voltage U . 30

TI

Table A.3 – Rated current I . 30

r

Table A.4 – Short time withstand current I . 31

W

Table A.5 – Leakage current I . 31

L

Table A.6 – Making and breaking capacity . 31

Table A.7 – Lightning current impulse (8/20 µs) I . 31

imp-n

Table A.8 – High current impulse 8/20 μs and 4/10 μs I . 32

imp-high

Table A.9 – High charge impulse I . 32

imp-hc

Table A.10 – Current-time characteristic for safe short circuiting of Class 1 VLDs . 32

Table A.11 – Preferred parameters for high charge impulse I . 32

imp-hc

Table A.12 – Applicable tolerances according to IEC 61643-11:2011 . 33

– 4 – IEC 62848-2:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS –

DC SURGE ARRESTERS AND VOLTAGE LIMITING DEVICES –

Part 2: Voltage limiting devices

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62848-2 has been prepared by IEC technical committee 9:

Electrical equipment and systems for railways.

This document is based on EN 50526-2:2014.

The text of this International Standard is based on the following documents:

FDIS Report on voting

9/2492/FDIS 9/2503/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

A list of all parts in the IEC 62848 series, published under the general title Railway

applications – DC surge arresters and voltage limiting devices, can be found on the IEC

website.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 62848-2:2019 © IEC 2019

RAILWAY APPLICATIONS –

DC SURGE ARRESTERS AND VOLTAGE LIMITING DEVICES –

Part 2: Voltage limiting devices

1 Scope

This document applies to Voltage Limiting Devices (VLDs) to be applied in DC traction

systems in order to comply with protective provisions against electric shock from DC, and

combined AC – DC voltages, in accordance with the IEC 62128 series, taking into account

stray current provisions.

VLDs operate in such a way as to connect the track return circuit of DC railway systems to the

earthing system or to conductive parts within the overhead contact line zone or current

collector zone.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60085, Electrical insulation – Thermal evaluation and designation

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60850:2014, Railway applications – Supply voltages of traction systems

IEC 61643-311, Components for low-voltage surge protective devices – Part 311:

Performance requirements and test circuits for gas discharge tubes (GDT)

IEC 61992-1:2006, Railway applications – Fixed installations – DC switchgear – Part 1:

General

IEC 61992-1:2006/AMD1:2014

IEC 61992-7:2006 (all parts), Railway applications – Fixed installations – DC switchgear –

Part 7-x: Measurement, control and protection devices for specific use in d.c. traction systems

IEC 62128-1:2013, Railway applications – Fixed installations – Electrical safety, earthing and

the return circuit – Part 1: Protective provisions against electric shock

IEC 62128-3:2013, Railway applications – Fixed installations – Electrical safety, earthing and

the return circuit – Part 3: Mutual Interaction of a.c. and d.c. traction systems

IEC 62497-1, Railway applications – Insulation coordination – Part 1: Basic requirements –

Clearances and creepage distances for all electrical and electronic equipment

IEC 62498-2, Railway applications – Environmental conditions for equipment – Part 2: Fixed

electrical installations

IEC 62848-1:2016, Railway applications – DC surge arresters and voltage limiting devices –

Part 1: Metal-oxide surge arresters without gaps

ISO 4287:1997, Geometrical Product Specifications (GPS) -Surface texture: Profile method –

Terms, definitions and surface texture parameters

ISO 4892-1, Plastics – Methods of exposure to laboratory light sources – Part 1: General

guidance

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

voltage-limiting device

VLD

protective device whose function is to prevent existence of an impermissible high touch

voltage

[SOURCE: IEC 60050-811:2017, 811-29-41]

3.2

recoverable VLD

VLD that recovers after triggering

3.3

non-recoverable VLD

VLD remaining in its low resistance state permanently after triggering

3.4

welding shut spark gap

VLD which is triggered by electrical discharge across a gap causing a permanent short-circuit

by welding shut of metallic parts

Note 1 to entry: Sometimes the term voltage fuse is used for this type of VLD.

3.5

rated current

I

r

maximum value of the direct current that may flow for the

specified long term through the VLD in specified environmental conditions without exceeding

the temperature rise limits

– 8 – IEC 62848-2:2019 © IEC 2019

3.6

short time withstand current

I

W

current that a VLD can carry in closed status, during a specified short time under prescribed

conditions of use and behaviour

3.7

making capacity

I

NSS

value of prospective making current that a switching device

is capable of making at a stated voltage under prescribed conditions of use and behaviour

Note 1 to entry: The conditions to be prescribed are dealt with in the relevant specifications.

[SOURCE: IEC 60050-441:1984, 441-17-09, modified – The beginning of the Note has been

changed.]

3.8

breaking capacity

maximum current that a recoverable VLD can interrupt at a

stated voltage

3.9

leakage current

I

L

current which flows through the terminals when the VLD is in

open status

3.10

lightning current impulse

I

imp-n

8/20 µs current impulse with limits on the adjustment of equipment such that the measured

values are from 7 µs to 9 µs for the virtual front time and from 18 µs to 22 µs for the time to

half value on the tail

Note 1 to entry: The time to half-value on the tail is not critical and may have any tolerance during the residual

voltage type tests.

[SOURCE: IEC 60099-4:2014, 3.31]

3.11

high current impulse

I

imp-high

peak value of discharge current having a 4/10 µs or 8/20 µs impulse shape which is used to

test the ability of the VLD to withstand direct lightning strikes from the dielectric point of view

3.12

high charge impulse

I

imp-hc

crest value of a high charge impulse through the VLD with specified charge transfer Q and

specified energy W/R in the specified time

Note 1 to entry: A crest value of a high charge impulse having a 10/350 µs waveshape is also a commonly known

expression.

3.13

triggering voltage

U

T

voltage at which a VLD becomes conductive

3.14

nominal triggering voltage

U

Tn

voltage at which the VLD becomes conductive when a DC voltage is applied for long term

Note 1 to entry: This voltage is used to identify the VLD.

3.15

instantaneous triggering voltage

U

Ti

minimum triggering voltage at which the VLD becomes conductive shortly after its application

Note 1 to entry: A maximum delay of 5 ms is taken in this document.

3.16

non-triggering voltage

U

W

maximum voltage below which the VLD will not trigger for any duration of the applied voltage

3.17

residual voltage of a VLD

U

res

value of voltage that appears between the terminals of the VLD

during the passage of a specified current

3.18

combined voltage

voltage having significant AC and DC components

3.19

response time

T

R

time between the application of a voltage until VLD becomes

conductive

3.20

degree of protection

extent of protection provided by an enclosure against access to hazardous parts, against

ingress of solid foreign objects and/or against ingress of water and verified by standardized

test methods

[SOURCE: IEC 60529:1989, 3.3]

3.21

IP Code

coding system to indicate the degree of protection provided by an enclosure against access to

hazardous parts, ingress of solid foreign objects, ingress of water and to give an additional

information in connection with such protection

[SOURCE: IEC 60529:1989, 3.4]

4 Classes of VLD

This document identifies the properties and the technology of a VLD using the classes of VLD

which are defined in Table 1.

– 10 – IEC 62848-2:2019 © IEC 2019

Table 1 – Classes of voltage-limiting device

Able to

Auxiliary

Method for interrupt

power supply

switching between Maximum response time Recoverable the

Class necessary Polarity

the high and low T or not current

R

for normal

resistance status in the

operation

VLD

Can be

Welding shut of recoverable in

1 No Bidirectional 5 ms No

metallic parts some

a

conditions

Passive

5 ms

at natural

Triggering of

2.1 No Unidirectional Yes zero

(for voltages equal to or

thyristors

crossing

higher than U )

TI

of current

Passive

5 ms

at natural

Triggering of

2.2 No Bidirectional Yes zero

(for voltages equal to or

thyristors

crossing

higher than U )

TI

of current

Voltage dependent and

not exceeding the limits

given in IEC 62128-

3.1 Contactor only Yes Bidirectional Yes Yes

1:2013, 9.3.2.2 or

IEC 62128-3:2013, 7.2

through 7.5

Voltage dependent and

not exceeding the limits

3.2 Contactor only Yes Bidirectional given in IEC 62128- Yes Yes

1:2013, 9.3.2.3,

IEC 62128-3:2013, 7.6

Specified by the

3.3 Contactor only Yes Bidirectional manufacturer or the Yes Yes

purchaser

For voltages up to U ,

TI

voltage dependent and

not exceeding the limits

given in IEC 62128-

Combination of

1:2013, 9.3.2.2 or

4.1 thyristors and Yes Bidirectional Yes Yes

IEC 62128-3:2013, 7.2

contactor

through 7.5.

For voltages equal to or

higher than U 5 ms.

Ti

For voltages up to U ,

TI

voltage dependent and

not exceeding the limits

Combination of given in IEC 62128-

4.2 thyristors and Yes Bidirectional Yes Yes

1:2013, 9.3.2.3,

contactor

IEC 62128-3:2013, 7.6.

For voltages equal to or

higher than U 5 ms

Ti

Combination of Specified by the

4.3 thyristors and Yes Bidirectional manufacturer or the Yes Yes

contactor purchaser

NOTE IEC 62128-1 defines two functionalities for VLDs, VLD-O and VLD-F. In this document a discrimination

is not necessary.

a

For transient low currents associated with low energy dissipation no welding shut may occur.

5 Characteristics and requirements of the VLDs

5.1 Marking

VLDs shall be identified by the following minimum information which shall appear on the rating

plate (nameplate):

– manufacturer's name or trademark and manufacture type designation;

– class of VLD according to IEC 62848-2 (optional);

– rated current I in A;

r

– short time withstand current I in kA;

w

– nominal triggering voltage U ;

Tn

– year of manufacture;

– serial number.

The terminals of unidirectional devices shall be marked with the symbols + and -.

In case of small VLDs not having space for a rating plate with all information, the devices

shall be marked with the manufacturer’s name or trademark, the type designation and the

nominal triggering voltage. The remaining information shall be given in a data-sheet.

5.2 Service requirements

5.2.1 Normal outdoor service conditions

VLDs which conform to this document shall be suitable for operation under the following

normal service conditions:

– ambient temperature within the range of -40 °C to +40 °C;

– solar radiation lower than 1 120 W/m as given in IEC 62498-2;

– altitude not exceeding 1 400 m (from Annex B in IEC 61992-1:2006);

– any pollution not exceeding PD 4 as given in IEC 62497-1.

The equipment shall be suitable for installation in the vicinity of a rail track on foundations

designed so as to damp the main effects of the passage of the trains. Nevertheless, a limited

vibration or limited shocks may affect the equipment, which shall be capable of operating

satisfactorily when subjected to the following conventional accelerations separately applied:

– g : vertical acceleration:5 m/s ;

v

– g : horizontal acceleration:5 m/s .

h

5.2.2 Normal indoor service conditions

VLDs which conform to this document shall be suitable for operation under the following

normal service conditions:

– ambient temperature within the range of -5 °C to +40 °C (from Annex B in IEC 61992-

1:2006);

– altitude not exceeding 1 400 m (from Annex B in IEC 61992-1:2006);

– any pollution not exceeding PD3 as given in IEC 62497-1.

5.2.3 Abnormal service conditions

The following are examples of abnormal service conditions which require special

consideration in the manufacture or application of VLD and should be brought to the attention

of the supplier:

– temperature in excess of +40 °C or below -5 °C for indoor installations or below -40 °C for

outdoor installations;

– application at altitudes higher than 1 400 m; in this case the temperature-rise tests and

dielectric tests (for VLDs inside a cabinet), carried out at laboratories at lower levels, shall

take into account a correction in the temperature-rises and dielectric test values to be

agreed between the involved parties;

– 12 – IEC 62848-2:2019 © IEC 2019

– all excessive environmental conditions that may degrade insulating surface or mounting

hardware: fumes, vapours dirt, salt spray or other conducting materials; moisture,

humidity, dropping water or steam;

– explosive mixtures of dust, gases or fumes;

– special mechanical requirements (earthquakes, vibrations, high ice loads, high cantilever

stresses);

– unusual transportation or storage;

– heat sources near the VLD.

5.3 General characteristics

The following characteristics shall be defined to identify each VLD:

– the class of VLD;

– if relevant, the auxiliary power supply voltage, with its tolerances.

The manufacturer shall specify whether the device is recoverable or non-recoverable at

defined currents and durations.

5.4 Minimum requirements

5.4.1 Response time

A VLD shall become conductive in a time not greater than the specified response time

depending on the applied voltage. The response time of the VLD shall be stated as function of

the applied voltage.

For VLDs of Classes 2, 3 and 4 the triggering may be delayed intentionally in order that

unwanted triggering will not take place due to switching transients and similar phenomena.

5.4.2 Additional requirements for VLDs of Class 1

If gas discharge tubes are used in VLDs, they shall comply with IEC 61643-311.

5.4.3 Additional requirements for VLDs of Classes 3 and 4

The VLD shall not open if the current through it exceeds its breaking capacity.

The VLD shall open at an adjustable time after it has closed unless the breaking capacity is

exceeded. The range of variation of this time setting shall be specified.

If the VLD re-opens automatically and then re-triggers, after a set number of operations in a

given time interval either:

– it shall be prevented from re-opening and a warning or an alarm shall be signalled; or

– only a warning or an alarm shall be signalled.

The VLD shall provide the possibility to be manually operated at site.

If the VLD requires a power supply for operation, the VLD shall be provided with a failsafe

function such that it turns into the conductive state in case of failure of the power supply.

5.5 Electrical characteristics and thermal rating

In addition to the general characteristics indicated in 5.3, the manufacturer shall state the

following electrical characteristics of each type of VLD if applicable. In case of adjustable

parameters, the setting ranges shall be stated:

– for VLDs of Classes 3 and 4, the nominal voltages of the electric traction systems in which

the VLDs are to be installed;

– the nominal triggering voltage U ;

Tn

– the non-triggering voltage U ;

W

– the maximum response time as function of the voltage;

– the instantaneous triggering voltage U ;

Ti

– the maximum leakage current I at U , when the VLD is in its non-conducting state;

L W

– the short-time withstand current I and the duration of the current flow;

W

– the rated current I ;

r

– the maximum residual voltage at the short-time withstand current;

– the maximum residual voltage at the rated current;

– the conditions in which the VLD is recoverable;

– the lightning current impulse, or sequence of lightning impulses, which the VLD can

withstand in the specified test conditions;

– for VLDs of Classes 3 and 4, the breaking capacity, determined in accordance with 6.8;

– for VLDs of Classes 3 and 4, the making capacity, in accordance with 6.4.3.

5.6 Protection of VLDs against lightning

If requested by the purchaser the VLD shall withstand the effects of the specified lightning

surges. The requirements can be different according to the class of VLD. If necessary a surge

arrester, according to IEC 62848-1, may be integrated into the VLD.

5.7 Command and control (Classes 3 and 4 only)

5.7.1 Local control

On the cabinet, the following characteristics and measuring indications should be foreseen to

provide a monitoring and control locally:

a) the instantaneous DC voltage across the terminals of the VLD;

b) the instantaneous DC current flowing through the device;

c) the operating state of the VLD (open or closed);

d) a push or touch button to manually command the closing and the opening of the device;

e) a push or touch button to start a manual self-test (if possible);

f) access to recorded data as given in 5.7.3, the activations, warnings, alarms, etc., in the

past and stored in a register file (if applicable).

NOTE 1 Conventionally the voltage in item a) is the voltage on the rails relative to earth. This means that if the

rail potential is positive the figure displayed is positive.

NOTE 2 The manual self-test procedure in item e) will trigger the thyristor and will also close the contactor for a

limited time (typically 1 s).

5.7.2 Remote signalling

If remote signalling is requested at least the following signals shall be offered:

a) contactor open;

b) contactor closed;

c) warnings, alarms.

Further information may be agreed between purchaser and manufacturer such as current or

voltage.

– 14 – IEC 62848-2:2019 © IEC 2019

5.7.3 Operation and alarm recordings

Recordings are optional. A list of the recordings that can be stored is indicated as an example

in the following:

a) operation recordings:

1) the status of the VLD;

2) the total number of operations (1 operation = 1 x close + 1 x open);

b) alarm recordings with time stamp:

1) interruption of the auxiliary power supply of the device;

2) device in closed position state during a long period of time, eventually parameterised

in 2 or more levels;

3) internal operation faults: an internal self-diagnostic function controls the correct

functioning of closing and opening the device; in case of an internal fault, an alarm is

created;

4) the exceeding of a given frequency of operations, eventually parameterised in 2 or

more levels.

6 Type tests

6.1 General

The characteristics of the VLD shall be verified by type tests.

Type tests shall be carried out as indicated in Table 2. All tests are mandatory unless stated

otherwise.

Once made, these type tests need not be repeated unless the design is changed so as to

modify the VLD performance. In such a case only the relevant tests need be repeated.

For all the tests the ambient temperature shall be recorded.

An alternating current test is foreseen, if requested, because even if the VLD is not specified

to conduct AC, the wave-form of the current in the VLD can flow in both directions due to

ripple currents from the substations, tripping of the feeders during short-circuits or earth faults

in the DC power system, transient effects due to switching of the current by the trains,

regenerative braking currents of the trains or AC currents injected by AC power systems.

Table 2 – Type tests

Tests Classes of Subclause

VLD

Nominal triggering voltage and non-triggering voltage: 6.2

Procedure for welding shut spark gap VLDs 1 6.2.1

Procedure for thyristor type VLDs 2 6.2.2

Procedure for mechanical switching VLDs and for combined thyristor with 3, 4 6.2.3

mechanical switching devices

Leakage current 1, 2, 4 6.3

DC current withstand All 6.4

Procedure to determine long-term current All 6.4.2

Procedure to determine short time withstand All 6.4.3

AC current withstand characteristics All 6.5

(Optional)

Response time characteristics All 6.6

Lightning current withstand characteristics for VLDs exposed to direct lightning All 6.7

strikes

Recovery test 3, 4 6.8

Reverse voltage test 2.1 6.9

Dielectric test 3, 4 6.10

Degree of protection All 6.11

Environmental tests for outdoor equipment All 6.12

Determination of minimum current for safe short circuiting of Class 1 VLDs 1 6.13

The required number of samples and their conditions are specified in the individual

subclauses.

VLDs are considered to be of the same design if the following conditions are fulfilled:

– they are based on the same components resulting in the same performance

characteristics;

– they are characterised by similar construction resulting in equivalent heat dissipation

conditions whereas mounting or arrangement on the supporting structure may differ.

If not specified otherwise in the individual clauses, tests shall be carried out on the complete

VLD as used in service, i.e. with surge arrester in parallel, if applicable.

6.2 Nominal triggering voltage U and non-triggering voltage U

Tn W

6.2.1 Procedure for welding shut spark gap VLDs (Class 1)

6.2.1.1 General

This test shall be carried out on 3 samples of VLD in dry condition at 20 °C ± 15 °C.

6.2.1.2 Non-triggering voltage test

The non-triggering voltage U of the VLD shall be applied for a duration greater than 300 s.

W

This test shall be carried out at both polarities. The non-triggering voltage U should typically

W

be 80 % of U as given in Table A.1 (see Annex A).

Tn

– 16 – IEC 62848-2:2019 © IEC 2019

a) Pass criteria

No trigger shall occur.

6.2.1.3 Triggering voltage test

The test samples are connected to a DC voltage generator with a current ≥ 1 mA after

triggering but such that the device recovers after the trigger.

NOTE For VLD class 1 the nominal triggering voltage and the instantaneous triggering voltage are equal.

The test samples shall be further tested by applying a DC voltage increasing from 0 V with a

rise du/dt within 100 V/s up to 2 000 V/s according to IEC 61643-311 until the test sample

VLD triggers.

The procedure shall be repeated 5 times per sample for positive and negative polarity within a

period of 15 min.

The value of the trigger voltage shall be recorded.

a) Pass criteria

All measured triggering voltages are below or equal to the nominal triggering voltage U , no

Tn

mechanical destructions occurred and the VLD will not trigger for any duration when

non-triggering voltage U is applied. The nominal triggering voltage U should be in

W Tn

accordance with Table A.1.

6.2.2 Procedure for thyristor type VLDs (Class2)

6.2.2.1 General

This test shall be carried out on 3 samples of VLD in dry condition at 20 °C ± 15 °C. The test

shall be carried out at both polarities for bidirectional VLDs.

6.2.2.2 Non-triggering voltage test

The non-triggering voltage of the VLD shall be applied for a duration greater than 300 s. The

non-triggering voltage U should be 80 % of U as given in Table A.1.

W Tn

a) Pass criteria

No trigger shall occur.

6.2.2.3 Triggering and instantaneous triggering voltage test

The test samples shall be further tested by applying a DC voltage increasing from 0 V with a

rise to the:

– instantaneous triggering voltage within 5 ms;

– triggering voltage(s) according to a duration which is specified for the triggering voltage,

until the test sample VLD triggers.

The test of the triggering voltage(s) may be omitted, if the nominal triggering voltage

coincides with the instantaneous triggering voltage.

The procedure shall be repeated 5 times per sample for positive and negative polarity within a

period of 15 min. The value of the instantaneous triggering voltage and the triggering

voltage(s) shall be recorded.

a) Pass criteria

All measured triggering voltages are below or equal to the specified nominal triggering voltage

U . The nominal triggering voltage U should be in accordance with Table A.1.

Tn Tn

6.2.3 Procedure for mechanical switching VLDs and for combined thyristors with

mechanical switching devices VLDs (Class 3 and Class 4)

6.2.3.1 General

This test shall be carried out on 1 sample of VLD in dry condition at 20 °C ± 15 °C. The test

shall be carried out at both polarities for bidirectional VLDs.

6.2.3.2 Non-triggering voltage test

The non-triggering voltage of the VLD shall be applied for a duration greater than 300 s. The

non-triggering voltage U should be 80 % of U as given in Table A.1.

W Tn

a) Pass criteria

No trigger shall occur.

6.2.3.3 Triggering and instantaneous triggering voltage test

The test samples shall be further tested by applying a DC voltage increasing from 0 V with a

rise to the:

– instantaneous triggering voltage within 5 ms;

– triggering voltage(s) according to a duration which is specified for the triggering voltage

until the test sample VLD triggers.

The procedure shall be repeated 5 times per sample for positive and negative polarity within a

period of 15 min. The value of the instantaneous triggering voltage and the triggering

voltage(s) shall be recorded.

a) Pass criteria

All measured triggering voltages are below or equal to the specified instantaneous triggering

voltage U and the nominal triggering voltage(s) U . The instantaneous triggering voltage

TI Tn

U should be in accordance with Table A.2. The nominal triggering voltage U shall be in

TI Tn

accordance with Table A.1.

6.3 Leakage current

This test shall be carried out on one sample of VLD in dry condition at a temperature of

20 °C ± 15 °C for minimum duration of 1 min.

A DC voltage equal to the non-triggering voltage U of the VLD shall be applied and the

W

leakage current through the VLD shall be recorded. This test shall be carried out at both

polarities.

a) Pass criteria

The leakage current for each polarity should be within the specified limits of Table A.5.

– 18 – IEC 62848-2:2019 © IEC 2019

6.4 DC current withstand

6.4.1 General

The test is intended to check that the device withstands the rated current.

6.4.2 DC rated current test

This test shall be carried out on one VLD in dry condition at an ambient temperature of

20 °C ± 15 °C.

The DC rated current shall be applied to the VLD for a time duration of 60 min. Values of DC

rated current should be in the range of Table A.3.

The test sample shall be mounted and connected with connecting cables of equivalent cross-

section such that the current density of 1,5 A/mm² of copper or equivalent is not exceeded

based on the rated current.

The temperature of the device and its terminal temperatures shall be measured by at least 3

thermo elements or equivalent temperature sensors, one at each terminal and at least one on

the surface of the device. Good thermal conductivity shall be ensured between the sensor and

the surface of the VLD. The position of the temperature sensors shall be noted in the test

report.

The current, residual voltage and temperatures shall be monitored during the test and plotted

versus time in a diagram.

For VLDs of Classes 1, 3 and 4 the test current may also be an AC current with an RMS equal

to the specified DC test current.

The test comprises:

– select polarity;

...

IEC 62848-2 ®

Edition 1.0 2019-06

NORME

INTERNATIONALE

Applications ferroviaires - Parafoudres et appareils limiteurs de tension pour

réseaux à courant continu -

Partie 2: Appareils limiteurs de tension

ICS 45.060.01 ISBN 978-2-8327-0808-8

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications gratuitement tous les aperçus des publications, symboles

IEC en utilisant différents critères (numéro de référence, graphiques et le glossaire. Avec un abonnement, vous aurez

texte, comité d’études, …). Elle donne aussi des toujours accès à un contenu à jour adapté à vos besoins.

informations sur les projets et les publications remplacées

ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au

IEC Just Published - webstore.iec.ch/justpublished monde, avec plus de 22 500 articles terminologiques en

Restez informé sur les nouvelles publications IEC. Just anglais et en français, ainsi que les termes équivalents

Published détaille les nouvelles publications parues. dans 25 langues additionnelles. Egalement appelé

Disponible en ligne et une fois par mois par email. Vocabulaire Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-

nous: sales@iec.ch.

– 36 – IEC 62848-2:2019 © IEC 2019

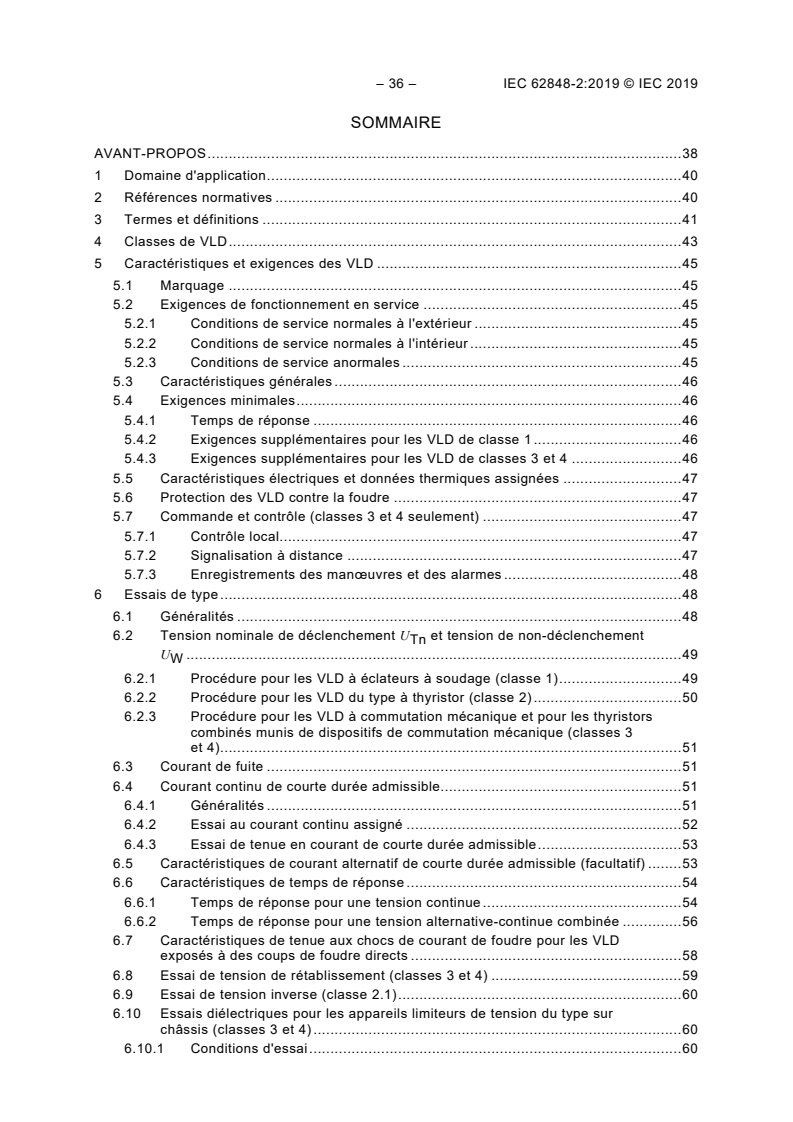

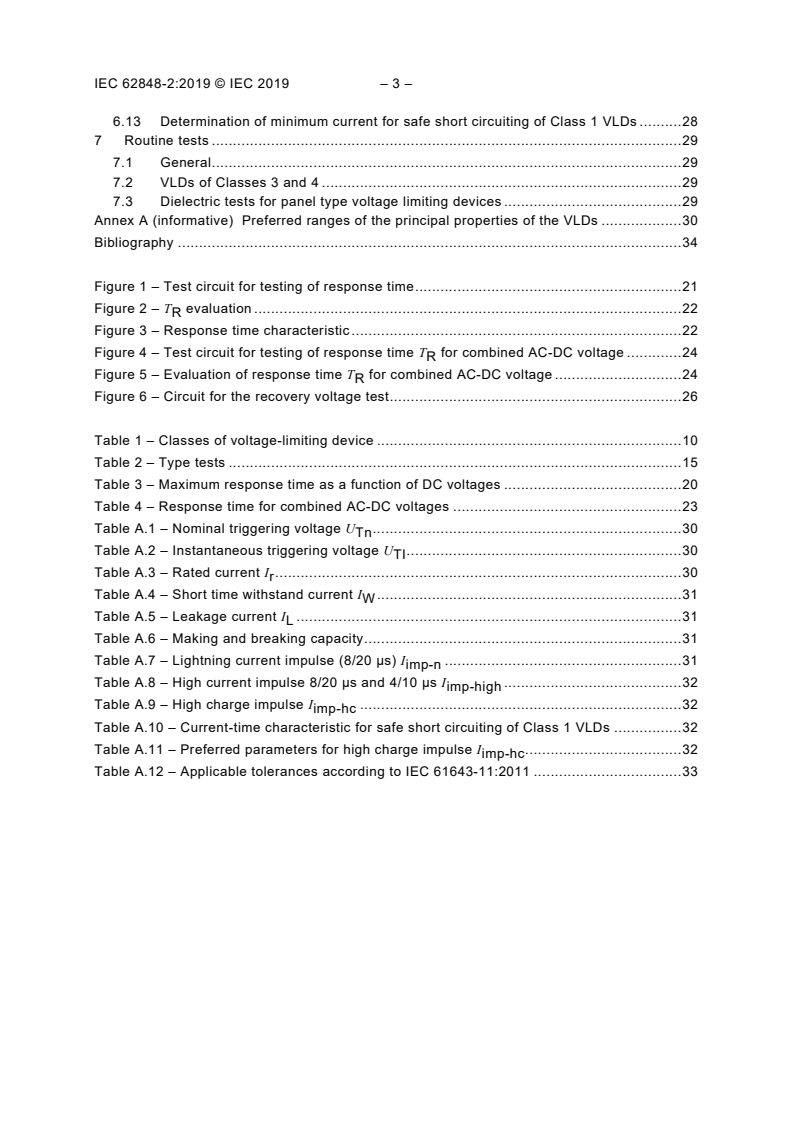

SOMMAIRE

AVANT-PROPOS . 38

1 Domaine d'application . 40

2 Références normatives . 40

3 Termes et définitions . 41

4 Classes de VLD . 43

5 Caractéristiques et exigences des VLD . 45

5.1 Marquage . 45

5.2 Exigences de fonctionnement en service . 45

5.2.1 Conditions de service normales à l'extérieur . 45

5.2.2 Conditions de service normales à l'intérieur . 45

5.2.3 Conditions de service anormales . 45

5.3 Caractéristiques générales . 46

5.4 Exigences minimales . 46

5.4.1 Temps de réponse . 46

5.4.2 Exigences supplémentaires pour les VLD de classe 1 . 46

5.4.3 Exigences supplémentaires pour les VLD de classes 3 et 4 . 46

5.5 Caractéristiques électriques et données thermiques assignées . 47

5.6 Protection des VLD contre la foudre . 47

5.7 Commande et contrôle (classes 3 et 4 seulement) . 47

5.7.1 Contrôle local. 47

5.7.2 Signalisation à distance . 47

5.7.3 Enregistrements des manœuvres et des alarmes . 48

6 Essais de type . 48

6.1 Généralités . 48

6.2 Tension nominale de déclenchement U et tension de non-déclenchement

Tn

U . 49

W

6.2.1 Procédure pour les VLD à éclateurs à soudage (classe 1) . 49

6.2.2 Procédure pour les VLD du type à thyristor (classe 2) . 50

6.2.3 Procédure pour les VLD à commutation mécanique et pour les thyristors

combinés munis de dispositifs de commutation mécanique (classes 3

et 4) . 51

6.3 Courant de fuite . 51

6.4 Courant continu de courte durée admissible. 51

6.4.1 Généralités . 51

6.4.2 Essai au courant continu assigné . 52

6.4.3 Essai de tenue en courant de courte durée admissible . 53

6.5 Caractéristiques de courant alternatif de courte durée admissible (facultatif) . 53

6.6 Caractéristiques de temps de réponse . 54

6.6.1 Temps de réponse pour une tension continue . 54

6.6.2 Temps de réponse pour une tension alternative-continue combinée . 56

6.7 Caractéristiques de tenue aux chocs de courant de foudre pour les VLD

exposés à des coups de foudre directs . 58

6.8 Essai de tension de rétablissement (classes 3 et 4) . 59

6.9 Essai de tension inverse (classe 2.1) . 60

6.10 Essais diélectriques pour les appareils limiteurs de tension du type sur

châssis (classes 3 et 4) . 60

6.10.1 Conditions d'essai . 60

6.10.2 Essai de tenue à la tension à fréquence industrielle . 60

6.11 Degré de protection des enveloppes . 61

6.12 Essais d'environnement pour le matériel destiné à un usage extérieur . 61

6.13 Détermination du courant minimal pour court-circuiter les VLD de classe 1

en toute sécurité . 62

7 Essais individuels de série . 62

7.1 Généralités . 62

7.2 VLD de classes 3 et 4 . 63

7.3 Essais diélectriques pour les appareils limiteurs de tension du type sur

châssis . 63

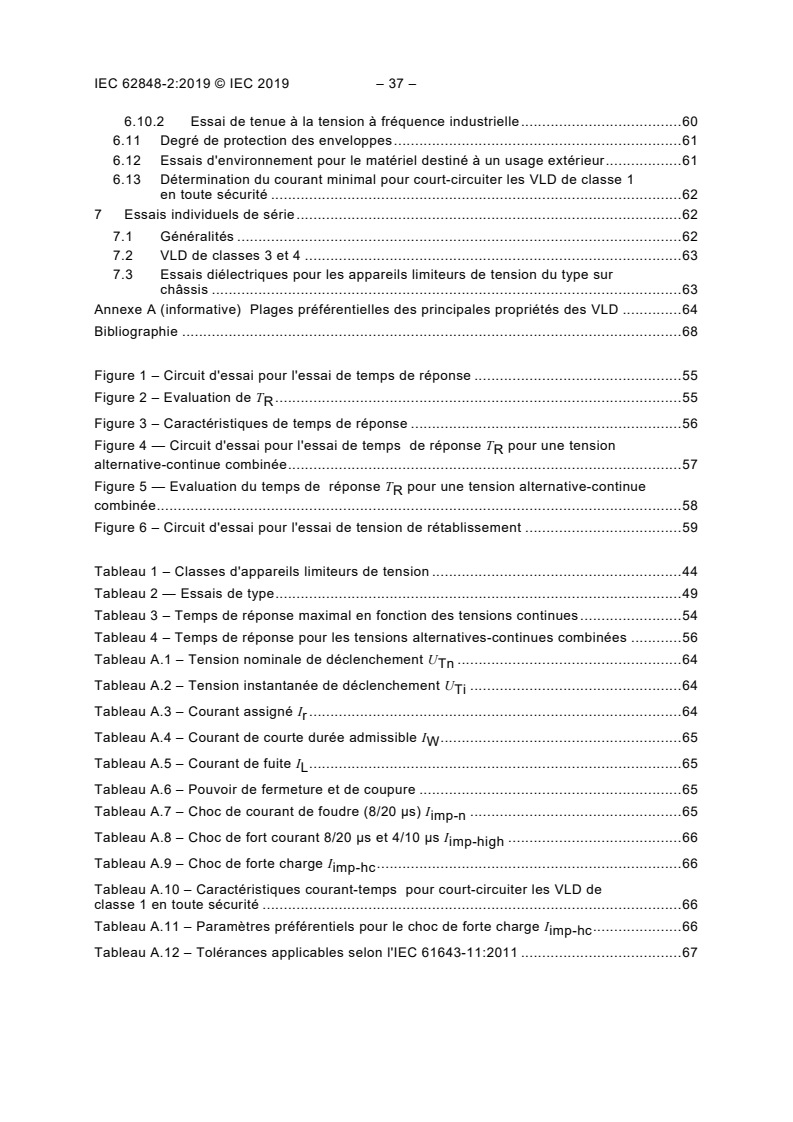

Annexe A (informative) Plages préférentielles des principales propriétés des VLD . 64

Bibliographie . 68

Figure 1 – Circuit d'essai pour l'essai de temps de réponse . 55

Figure 2 – Evaluation de T . 55

R

Figure 3 – Caractéristiques de temps de réponse . 56

Figure 4 — Circuit d'essai pour l'essai de temps de réponse T pour une tension

R

alternative-continue combinée . 57

Figure 5 — Evaluation du temps de réponse T pour une tension alternative-continue

R

combinée . 58

Figure 6 – Circuit d'essai pour l'essai de tension de rétablissement . 59

Tableau 1 – Classes d'appareils limiteurs de tension . 44

Tableau 2 — Essais de type . 49

Tableau 3 – Temps de réponse maximal en fonction des tensions continues . 54

Tableau 4 – Temps de réponse pour les tensions alternatives-continues combinées . 56

Tableau A.1 – Tension nominale de déclenchement U . 64

Tn

Tableau A.2 – Tension instantanée de déclenchement U . 64

Ti

Tableau A.3 – Courant assigné I . 64

r

Tableau A.4 – Courant de courte durée admissible I . 65

W

Tableau A.5 – Courant de fuite I . 65

L

Tableau A.6 – Pouvoir de fermeture et de coupure . 65

Tableau A.7 – Choc de courant de foudre (8/20 µs) I . 65

imp-n

Tableau A.8 – Choc de fort courant 8/20 μs et 4/10 μs I . 66

imp-high

Tableau A.9 – Choc de forte charge I . 66

imp-hc

Tableau A.10 – Caractéristiques courant-temps pour court-circuiter les VLD de

classe 1 en toute sécurité . 66

Tableau A.11 – Paramètres préférentiels pour le choc de forte charge I . 66

imp-hc

Tableau A.12 – Tolérances applicables selon l'IEC 61643-11:2011 . 67

– 38 – IEC 62848-2:2019 © IEC 2019

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

APPLICATIONS FERROVIAIRES –

PARAFOUDRES ET APPAREILS LIMITEURS DE TENSION POUR RÉSEAUX

À COURANT CONTINU –

Partie 2: Appareils limiteurs de tension

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (IEC) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de l'IEC). L'IEC a pour

objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines

de l'électricité et de l'électronique. A cet effet, l'IEC – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de l'IEC"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec l'IEC, participent

également aux travaux. L'IEC collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de l'IEC concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de l'IEC

intéressés sont représentés dans chaque comité d'études.

3) Les Publications de l'IEC se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de l'IEC. Tous les efforts raisonnables sont entrepris afin que l'IEC

s'assure de l'exactitude du contenu technique de ses publications ; l'IEC ne peut pas être tenue responsable de

l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de l'IEC s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de l'IEC dans leurs publications nationales

et régionales. Toutes divergences entre toutes Publications de l'IEC et toutes publications nationales ou

régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) L'IEC elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de l'IEC. L'IEC n'est responsable d'aucun des services effectués par les organismes de certification

indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à l'IEC, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de l'IEC, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de l'IEC ou de

toute autre Publication de l'IEC, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L'attention est attirée sur le fait que certains des éléments de la présente Publication de l'IEC peuvent faire

l'objet de droits de brevet. L'IEC ne saurait être tenue pour responsable de ne pas avoir identifié de tels droits

de brevets et de ne pas avoir signalé leur existence.

La Norme internationale IEC 62848-2 a été établie par le comité d'études 9 de l'IEC :

Matériels et systèmes électriques ferroviaires.

Le présent document est basé sur l'EN 50526-2:2014.

La présente version bilingue (2025-11) correspond à la version anglaise monolingue publiée

en 2019-06.

La version française de cette norme n'a pas été soumise au vote.

Une liste de toutes les parties de la série IEC 62848, publiées sous le titre général

Applications ferroviaires — Parafoudres et appareils limiteurs de tension pour réseaux à

courant continu, peut être consultée sur le site web de l'IEC.

Ce document a été rédigé selon les Directives ISO/IEC, Partie 2.

Le comité a décidé que le contenu de ce document ne sera pas modifié avant la date de

stabilité indiquée sur le site web de l'IEC sous "http://webstore.iec.ch" dans les données

relatives au document recherché. A cette date, le document sera

• reconduit,

• supprimé,

• remplacé par une édition révisée, ou

• amendé.

– 40 – IEC 62848-2:2019 © IEC 2019

APPLICATIONS FERROVIAIRES –

PARAFOUDRES ET APPAREILS LIMITEURS DE TENSION POUR RÉSEAUX

À COURANT CONTINU –

Partie 2: Appareils limiteurs de tension

1 Domaine d'application

Le présent document concerne les appareils limiteurs de tension (VLD, Voltage Limiting

Device) destinés à être appliqués aux réseaux de traction en courant continu afin de satisfaire

aux dispositions de protection contre les chocs électriques dus aux tensions continues et aux

tensions alternatives-continues combinées, conformément à la série IEC 62128, en tenant

compte des mesures contre les courants vagabonds.

Les VLD fonctionnent de manière à raccorder le circuit de retour de voie des réseaux

ferroviaires en courant continu à un réseau de mise à la terre ou aux parties conductrices de

la zone de la ligne aérienne de contact ou de la zone de captage de courant.

2 Références normatives

Les documents suivants sont cités dans le texte de sorte qu'ils constituent, pour tout ou partie

de leur contenu, des exigences du présent document. Pour les références datées, seule

l'édition citée s'applique. Pour les références non datées, la dernière édition du document de

référence s'applique (y compris les éventuels amendements).

IEC 60060-1:2010, Technique des essais à haute tension — Partie 1 : Définitions et

exigences générales

IEC 60085, Isolation électrique — Evaluation et désignation thermiques

IEC 60529:1989, Degrés de protection procurés par les enveloppes (code IP)

IEC 60850:2014, Applications ferroviaires — Tensions d'alimentation des réseaux de traction

IEC 61643-311, Composants pour parafoudres basse tension — Partie 311 : Exigences de

performance et circuits d'essai pour tubes à décharge de gaz (TDG)

IEC 61992-1:2006, Applications ferroviaires — Installations fixes — Appareillage à courant

continu — Partie 1 : Généralités

IEC 61992-1:2006/AMD1:2014

IEC 61992-7:2006 (toutes les parties), Applications ferroviaires — Installation fixes —

Appareillage à courant continu — Partie 7-x : Appareils de mesure, de contrôle et de

protection pour usage spécifique dans les systèmes de traction à courant continu

IEC 62128-1:2013, Applications ferroviaires — Installations fixes — Sécurité électrique, mise

à la terre et circuit de retour — Partie 1 : Mesures de protection contre les chocs électriques

IEC 62128-3:2013, Applications ferroviaires — Installations fixes — Sécurité électrique, mise

à la terre et circuit de retour — Partie 3 : Interactions mutuelles entre systèmes de traction en

courant alternatif et en courant continu

IEC 62497-1, Applications ferroviaires — Coordination de l'isolement — Partie 1 : Exigences

fondamentales — Distances d'isolement dans l'air et lignes de fuite pour tout matériel

électrique et électronique

IEC 62498-2, Applications ferroviaires — Conditions d'environnement pour le matériel —

Partie 2 : Installations électriques fixes

IEC 62848-1:2016, Applications ferroviaires — Parafoudres et appareils limiteurs de tension

pour réseaux à courant continu — Partie 1 : Parafoudres à oxyde métallique sans éclateur

EN ISO 4287, Spécification géométrique des produits (GPS) — Etat de surface : méthode du

profil — Termes, définitions et paramètres d'état de surface

ISO 4892-1, Plastiques — Méthodes d'exposition à des sources lumineuses de laboratoire —

Partie 1 : Lignes directrices générales

ISO 4892-2, Plastiques — Méthodes d'exposition à des sources lumineuses de laboratoire —

Partie 2 : Lampes à arc au xénon

ISO 4892-3, Plastiques — Méthodes d'exposition à des sources lumineuses de laboratoire —

Partie 3 : Lampes fluorescentes UV

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s'appliquent.

L'ISO et l'IEC tiennent à jour des bases de données terminologiques destinées à être utilisées

en normalisation, consultables aux adresses suivantes :

• IEC Electropedia : disponible à l'adresse http://www.electropedia.org/

• ISO Online browsing platform : disponible à l'adresse http://www.iso.org/obp

3.1

appareil limiteur de tension

VLD

dispositif de protection dont la fonction consiste à empêcher l'existence de toute tension de

contact élevée inadmissible

Note 1 à l'article: L'abréviation « VLD » est dérivée du terme anglais développé correspondant « Voltage-Limiting

Device ».

[SOURCE : IEC 60050-811:2017, 811-29-41]

3.2

VLD réarmable

VLD se réarmant après déclenchement

3.3

VLD non réarmable

VLD restant en permanence dans son état conducteur après déclenchement

3.4

éclateur à soudage

VLD qui est déclenché par décharge électrique dans un espace provoquant un court-circuit

permanent par soudage d'éléments métalliques

Note 1 à l'article: Parfois, ce type de VLD est appelé "fusible de tension".

3.5

courant assigné

I

r

valeur maximale du courant direct qui peut traverser le

VLD pendant la durée prolongée spécifiée dans les conditions environnementales spécifiées,

sans dépasser les limites d'échauffement

3.6

courant de courte durée admissible

I

W

courant que peut supporter un VLD dans la position de fermeture pendant un court intervalle

de temps spécifié et dans des conditions prescrites d'emploi et de comportement

– 42 – IEC 62848-2:2019 © IEC 2019

3.7

pouvoir de fermeture

I

NSS

valeur du courant présumé établi qu'un appareil

de connexion est capable d'établir sous une tension donnée et dans des conditions prescrites

d'emploi et de comportement

Note 1 à l'article: Les conditions à prescrire sont précisées dans les spécifications individuelles.

[SOURCE : IEC 60050-441:1984, 441-17-09, modifiée — Le début de la Note a été modifié.]

3.8

pouvoir de coupure

courant maximal qu'un VLD réarmable peut interrompre à

une tension donnée

3.9

courant de fuite

I

L

courant parcourant les bornes du VLD lorsque celui-ci est

en position ouverte

3.10

choc de courant de foudre

I

imp-n

choc de courant 8/20 µs ; les limites de réglage sont telles que l'on mesure des valeurs

comprises entre 7 µs et 9 µs pour la durée conventionnelle de front et entre 18 µs et 22 µs

pour la durée jusqu'à mi-valeur sur la queue

Note 1 à l'article: La durée jusqu'à mi-valeur sur la queue n'est pas un paramètre critique et aucune tolérance

n'est imposée lors des essais de type à la tension résiduelle.

[SOURCE : IEC 60099-4:2014, 3.31]

3.11

choc de fort courant

I

imp-high

valeur de crête d'un courant de décharge présentant une forme de choc de 4/10 µs ou

8/20 µs, utilisée pour évaluer l'aptitude du VLD à supporter les coups de foudre directs du

point de vue diélectrique

3.12

choc de forte charge

I

imp-hc

valeur de crête d'un choc de forte charge parcourant le VLD avec le transfert de charge

spécifié Q et l'énergie spécifiée W/R pendant le temps spécifié

Note 1 à l'article: La valeur de crête d'un choc de forte charge présentant une forme de 10/350 µs est également

une expression généralement admise.

3.13

tension de déclenchement

U

T

tension à laquelle un VLD devient conducteur

3.14

tension nominale de déclenchement

U

Tn

tension à laquelle le VLD devient conducteur lorsqu'une tension continue est appliquée

pendant une longue durée

Note 1 à l'article: Cette tension est utilisée pour identifier le VLD.

3.15

tension instantanée de déclenchement

U

Ti

tension de déclenchement minimale à laquelle le VLD devient conducteur immédiatement

après son application

Note 1 à l'article: Un délai maximal de 5 ms est appliqué dans le présent document.

3.16

tension de non-déclenchement

U

W

tension maximale au-dessous de laquelle le VLD ne se déclenche pas, quelle que soit la

durée d'application de la tension

3.17

tension résiduelle d'un VLD

U

res

valeur de tension apparaissant aux bornes du VLD

pendant le passage d'un courant spécifié

3.18

tension combinée

tension ayant des composantes importantes en courant alternatif et en courant continu

3.19

temps de réponse

T

R

temps compris entre l'application d'une tension et le

moment où le VLD devient conducteur

3.20

degré de protection

niveau de protection procuré par une enveloppe contre l'accès aux parties dangereuses,

contre la pénétration de corps solides étrangers et/ou contre la pénétration de l'eau et vérifié

par des méthodes d'essai normalisées

[SOURCE : IEC 60529:1989, 3.3]

3.21

code IP

système de codification pour indiquer les degrés de protection procurés par une enveloppe

contre l'accès aux parties dangereuses, la pénétration de corps solides étrangers, la

pénétration de l'eau et pour donner une information additionnelle liée à une telle protection

[SOURCE : IEC 60529:1989, 3.4]

4 Classes de VLD

Le présent document identifie les propriétés et la technologie d'un VLD en utilisant les classes de VLD

qui sont définies dans le Tableau 1.

– 44 – IEC 62848-2:2019 © IEC 2019

Tableau 1 – Classes d'appareils limiteurs de tension

Alimentation Aptitude

Méthode de

auxiliaire à couper

commutation Réarmable

Temps de réponse T

nécessaire le

R

Classe entre les états de Polarité ou non

pour un courant

maximal

forte et de faible réarmable

fonctionneme dans le

résistance

nt normal VLD

Peut être

réarmable

Soudage

dans

1 d'éléments Non Bidirectionnel 5 ms Non

certaines

métalliques

a

conditions

Passif au

5 ms

passage

Déclenchement de (pour des tensions naturel

2.1 Non Unidirectionnel oui

thyristors supérieures ou égales à par zéro

U ) du

Ti

courant

Passif au

5 ms

passage

Déclenchement de (pour des tensions naturel

2.2 Non Bidirectionnel oui

thyristors supérieures ou égales à par zéro

U ) du

Ti

courant

Dépend de la tension et

ne dépassant pas les

limites indiquées dans

Contacteur

3.1 oui Bidirectionnel l'IEC 62128-1:2013, oui oui

seulement

9.3.2.2 ou

l'IEC 62128-3:2013, 7.2

à 7.5

Dépend de la tension et

ne dépassant pas les

Contacteur limites indiquées dans

3.2 oui Bidirectionnel oui oui

seulement l'IEC 62128-1:2013,

9.3.2.3,

l'IEC 62128-3:2013, 7.6

Contacteur Spécifié par le fabricant

3.3 oui Bidirectionnel oui oui

seulement ou l'acheteur

Pour les tensions allant

jusqu'à U , dépend de la

Ti

tension et ne dépassant

pas les limites indiquées

dans l'IEC 62128-1:2013,

Combinaison de

9.3.2.2 ou

4.1 thyristors et d'un oui Bidirectionnel oui oui

l'IEC 62128-3:2013, 7.2

contacteur

à 7.5.

Pour des tensions

supérieures ou égales à

U 5 ms.

Ti

Pour les tensions allant

jusqu'à U , dépend de

Ti

la tension et ne

dépassant pas les limites

indiquées dans

Combinaison de

l'IEC 62128-1:2013,

4.2 thyristors et d'un oui Bidirectionnel oui oui

9.3.2.3 ou

contacteur

l'IEC 62128-3:2013, 7.6.

Pour des tensions

supérieures ou égales à

U 5 ms

Ti

Combinaison de

Spécifié par le fabricant

4.3 thyristors et d'un oui Bidirectionnel oui oui

ou l'acheteur

contacteur

NOTE L'IEC 62128-1 définit deux fonctionnalités pour les VLD, VLD-O et VLD-F. Dans le présent document,

aucune discrimination n'est nécessaire.

a

Pour les faibles courants transitoires associés à une faible dissipation d'énergie, aucun soudage ne peut se produire.

5 Caractéristiques et exigences des VLD

5.1 Marquage

Les VLD doivent être identifiés par les informations minimales suivantes, qui doivent être

apposées sur la plaque signalétique :

– nom du fabricant ou marque et désignation du type de fabrication ;

– classe de VLD selon l'IEC 62848-2 (facultatif) ;

– courant assigné I en A ;

r

– courant de courte durée admissible I en kA ;

w

– tension nominale de déclenchement U ;

Tn

– année de fabrication ;

– numéro de série.

Les bornes des appareils unidirectionnels doivent être marquées par les symboles + et -.

Pour les VLD de petite taille dont la plaque signalétique est trop petite pour contenir

l'ensemble des informations, les appareils doivent être marqués du nom du fabricant ou de la

marque, de la désignation du type ainsi que de la tension nominale de déclenchement. Les

autres informations doivent être fournies dans une fiche technique.

5.2 Exigences de fonctionnement en service

5.2.1 Conditions de service normales à l'extérieur

Les VLD conformes au présent document doivent être adaptés pour fonctionner dans les

conditions de service normales suivantes :

– température ambiante entre -40 °C et +40 °C ;

– rayonnement solaire inférieur à 1 120 W/m , comme spécifié dans l'IEC 62498-2 ;

– altitude ne dépassant pas 1 400 m (selon l'Annexe B de l'IEC 61992-1:2006) ;

– pollution ne dépassant pas PD 4, comme spécifié dans l'IEC 62497-1.

Le matériel doit être adapté à une installation au voisinage d'une voie ferrée sur des

fondations conçues pour amortir les principaux effets du passage des trains. Cependant, une

vibration ou des chocs restreints peuvent affecter le matériel qui doit être capable de

fonctionner de façon satisfaisante lorsqu'il est exposé aux accélérations classiques suivantes

appliquées séparément :

– g : accélération verticale : 5 m/s ;

v

– g : accélération horizontale : 5 m/s .

h

5.2.2 Conditions de service normales à l'intérieur

Les VLD conformes au présent document doivent être adaptés pour fonctionner dans les

conditions de service normales suivantes :

– température ambiante entre -5 °C et +40 °C (selon l'Annexe B de l'IEC 61992-1:2006) ;

– altitude ne dépassant pas 1 400 m (selon l'Annexe B de l'IEC 61992-1:2006) ;

– pollution ne dépassant pas PD 3, comme spécifié dans l'IEC 62497-1.

5.2.3 Conditions de service anormales

La liste suivante répertorie des exemples de conditions de service anormales types qui

exigent des considérations particulières de fabrication ou d'application de VLD et pour

lesquels il convient de les rappeler à l'attention du fournisseur :

– température supérieure à +40 °C ou inférieure à -5 °C pour les installations en intérieur ou

inférieure à -40 °C pour les installations en extérieur ;

– 46 – IEC 62848-2:2019 © IEC 2019

– application à des altitudes supérieures à 1 400 m. Dans ce cas, les essais d'échauffement

et les essais diélectriques (pour les VLD contenus dans un coffret), réalisés dans des

laboratoires à des altitudes inférieures, doivent appliquer une correction des valeurs des

essais d'échauffement et diélectriques à convenir entre les parties prenantes ;

– toutes conditions d'environnement excessives susceptibles de dégrader la surface

isolante ou les accessoires de montage : fumées, poussière de vapeur, brouillard salin ou

autres matériaux conducteurs ; humidité, eau ou vapeur ;

– mélanges explosifs de poussières, gaz ou fumées ;

– exigences mécaniques particulières (séismes, vibrations, charges de glace importantes,

contraintes importantes de porte-à-faux) ;

– conditions anormales de transport ou de stockage ;