IEC 60393-6:2003

(Main)Potentiometers for use in electronic equipment - Part 6: Sectional specification: Surface mount preset potentiometers

Potentiometers for use in electronic equipment - Part 6: Sectional specification: Surface mount preset potentiometers

prescribes preferred ratings and characteristics and selects appropriate quality assessment procedures, tests and measuring methods from IEC 60393-1 and gives general performance requirements for this type of potentiometer.

General Information

- Status

- Published

- Publication Date

- 15-May-2003

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Drafting Committee

- MT 60393-6 - TC 40/MT 60393-6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 14-Dec-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60393-6:2003 - Potentiometers for use in electronic equipment, Part 6: Sectional specification: Surface mount preset potentiometers - prescribes preferred ratings and characteristics for surface mount preset potentiometers and selects applicable quality assessment procedures, tests and measuring methods from IEC 60393-1. The standard also gives general performance requirements and requires that any Detail Specification referencing this sectional specification meet equal or higher performance levels.

Key topics and technical requirements

- Scope and objective: Defines preferred ratings, characteristics and test severities for surface mount preset potentiometers used in electronic equipment.

- Preferred ratings & resistance range: Preferred values should follow IEC 60063 preferred number series (E-series or 1,2,5 series). Detail Specifications may list available ranges per style.

- Quality assessment procedures: Includes rules for structurally similar components, qualification approval, quality conformance inspection and handling of delayed deliveries (see IEC quality assessment references).

- Tests and measuring methods: Selects tests from IEC 60393-1 and references environmental and solderability tests from the IEC 60068 series (e.g., soldering, robustness of terminations, solvent immersion).

- Soldering and mounting guidance:

- Wave soldering example: preheat 80–100 °C; solder bath 260 °C ± 5 °C; solder time 5 s ± 0.5 s (two cycles); cleaning in solvent post‑solder.

- Reflow soldering example: silver-bearing eutectic Sn/Pb solder (≥ 2% silver) or typical 60/40/63/37 alternatives; unit temperature 215–260 °C until reflow but not longer than 10 s.

- Recommended substrates for mechanical/electrical tests and for electrical measurements are provided (epoxy glass and alumina examples).

- Marking and documentation: Detail Specifications must state marking requirements, outline drawings, dimensions (mm), land patterns, style codes and any special resistance-law measurements.

- Performance tests: Temperature coefficients, limits for change in resistance/output ratio, bump vs shock alternatives, and rated dissipation curves are specified or referenced.

Applications and who uses this standard

- Manufacturers of surface mount preset potentiometers use IEC 60393-6 to set product specifications, test schedules and production quality criteria.

- Design and electronics engineers rely on the standard for component selection, specifying mounting and soldering processes, and ensuring interoperability.

- Test labs and quality assurance teams use the defined tests, substrates and acceptance criteria to qualify parts and verify conformance.

- Procurement and compliance officers reference the standard in Detail Specifications and purchase contracts to ensure consistent performance and traceability.

Related standards (normative references)

- IEC 60393-1: Generic specification for potentiometers

- IEC 60063: Preferred number series for resistors and capacitors

- IEC 60068 series: Environmental testing (soldering, robustness, solvent immersion)

- IEC 60410: Sampling plans for inspection by attributes

- IEC QC 001001 / QC 001002-3: IEC Quality Assessment System (IECQ) procedures

Keywords: IEC 60393-6, surface mount preset potentiometers, potentiometers for use in electronic equipment, quality assessment, soldering, mounting, test severities, IEC 60393-1.

Frequently Asked Questions

IEC 60393-6:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Potentiometers for use in electronic equipment - Part 6: Sectional specification: Surface mount preset potentiometers". This standard covers: prescribes preferred ratings and characteristics and selects appropriate quality assessment procedures, tests and measuring methods from IEC 60393-1 and gives general performance requirements for this type of potentiometer.

prescribes preferred ratings and characteristics and selects appropriate quality assessment procedures, tests and measuring methods from IEC 60393-1 and gives general performance requirements for this type of potentiometer.

IEC 60393-6:2003 is classified under the following ICS (International Classification for Standards) categories: 31.040.20 - Potentiometers, variable resistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60393-6:2003 has the following relationships with other standards: It is inter standard links to IEC 60393-6:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60393-6:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60393-6

First edition

2003-05

Potentiometers for use

in electronic equipment –

Part 6:

Sectional specification:

Surface mount preset potentiometers

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (http://www.iec.ch/searchpub/cur_fut.htm)

enables you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (http://www.iec.ch/online_news/

justpub/jp_entry.htm) is also available by email. Please contact the Customer

Service Centre (see below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60393-6

First edition

2003-05

Potentiometers for use

in electronic equipment –

Part 6:

Sectional specification:

Surface mount preset potentiometers

IEC 2003 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

U

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

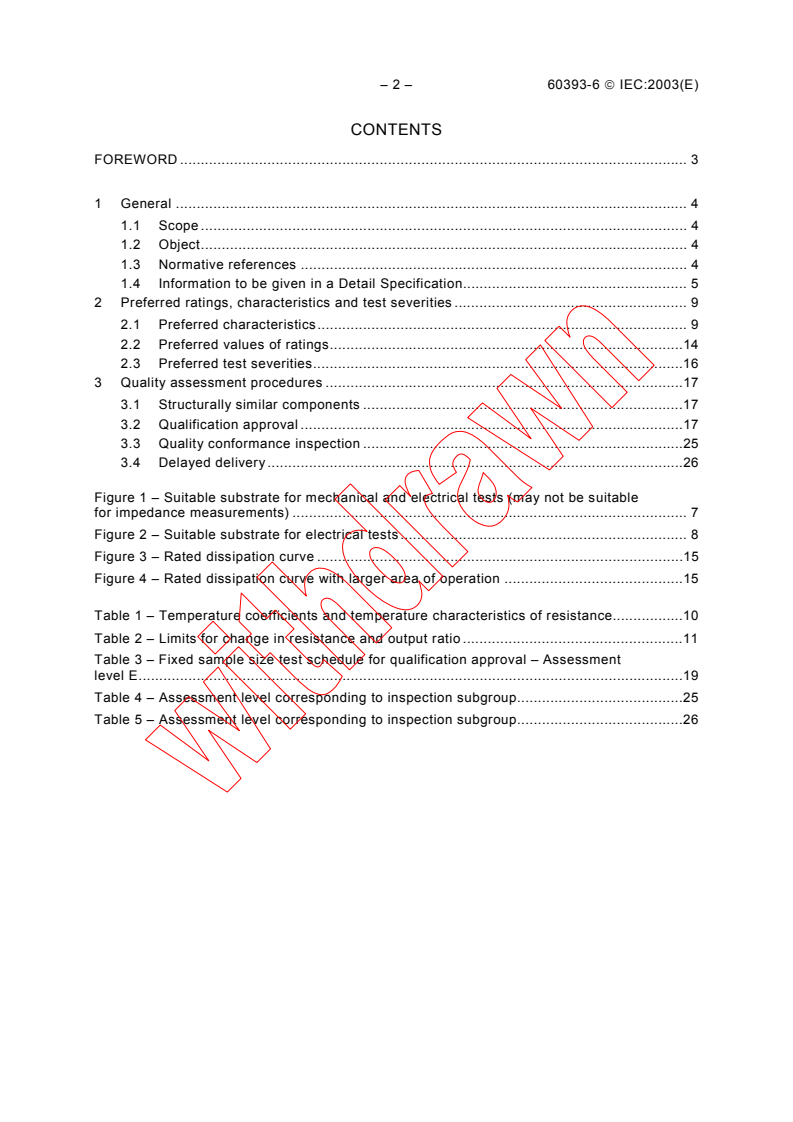

– 2 – 60393-6 IEC:2003(E)

CONTENTS

FOREWORD . 3

1 General . 4

1.1 Scope . 4

1.2 Object. 4

1.3 Normative references . 4

1.4 Information to be given in a Detail Specification. 5

2 Preferred ratings, characteristics and test severities . 9

2.1 Preferred characteristics. 9

2.2 Preferred values of ratings.14

2.3 Preferred test severities.16

3 Quality assessment procedures .17

3.1 Structurally similar components .17

3.2 Qualification approval .17

3.3 Quality conformance inspection .25

3.4 Delayed delivery.26

Figure 1 – Suitable substrate for mechanical and electrical tests (may not be suitable

for impedance measurements) . 7

Figure 2 – Suitable substrate for electrical tests. 8

Figure 3 – Rated dissipation curve .15

Figure 4 – Rated dissipation curve with larger area of operation .15

Table 1 – Temperature coefficients and temperature characteristics of resistance.10

Table 2 – Limits for change in resistance and output ratio .11

Table 3 – Fixed sample size test schedule for qualification approval – Assessment

level E.19

Table 4 – Assessment level corresponding to inspection subgroup.25

Table 5 – Assessment level corresponding to inspection subgroup.26

60393-6 IEC:2003(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POTENTIOMETERS FOR USE IN ELECTRONIC EQUIPMENT –

Part 6: Sectional specification:

Surface mount preset potentiometers

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical Specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60393-6 has been prepared by IEC technical committee 40:

Capacitors and resistors for electronic equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

40/1288/FDIS 40/1324/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This Sectional Specification is to be used in conjunction with IEC 60393-1:1989.

The committee has decided that the contents of this publication will remain unchanged

until 2008. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended

A bilingual version of this publication may be issued at a later date.

– 4 – 60393-6 IEC:2003(E)

POTENTIOMETERS FOR USE IN ELECTRONIC EQUIPMENT –

Part 6: Sectional specification:

Surface mount preset potentiometers

1 General

1.1 Scope

This International Standard is applicable to surface mount preset potentiometers for use in

electronic equipment.

1.2 Object

The object of this standard is to prescribe preferred ratings and characteristics and to

select the appropriate quality assessment procedures, tests and measuring methods from

IEC 60393-1 and to give general performance requirements for this type of potentiometer.

Test severities and requirements prescribed in Detail Specifications referring to this Sectional

Specification shall be of equal or higher performance level, lower performance levels are not

permitted.

1.3 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60063:1963, Preferred number series for resistors and capacitors

Amendment 1 (1967)

Amendment 2 (1977)

IEC 60068-1, Environmental testing. Part 1: General and guidance

IEC 60068-2-20, Environmental testing. Part 2: Tests. Test T: Soldering

IEC 60068-2-21, Environmental testing – Part 2-21: Tests – Test U: Robustness of termin-

ations and integral mounting devices

IEC 60068-2-45, Environmental testing. Part 2: Tests. Test XA and guidance: Immersion in

cleaning solvents

IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td – Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60393-1:1989, Potentiometers for use in electronic equipment – Part 1: Generic

Specification

Amendment 1 (1992)

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

60393-6 IEC:2003(E) – 5 –

IEC QC 001001:2000, IEC Quality Assessment System for Electronic Components (IECQ) –

Basic rules

IEC QC 001002-3:1998, IEC Quality Assessment System for Electronic Components (IECQ) –

Rules of procedure – Part 3: Approval procedures

1.4 Information to be given in a Detail Specification

Detail Specifications shall be derived from the relevant Blank Detail Specification.

Detail Specifications shall not specify requirements inferior to those of the generic, sectional

or Blank Detail Specification.

When more severe requirements are included, they shall be listed in 1.8 of the Detail

Specification and indicated in the test schedules, for example by an asterisk.

NOTE The information given in 1.4.1 and 1.4.3 may, for convenience, be presented in tabular form.

The following information shall be given in each Detail Specification and the values quoted

shall preferably be selected from those given in the appropriate Clause of this Sectional

Specification.

1.4.1 Outline drawing and dimensions

The Detail Specification shall incorporate an illustration of the surface mount preset poten-

tiometer as aid to easy recognition and for comparison of the surface mount potentiometer

with others.

Dimensions and their associated tolerances, which affect interchangeability and mounting,

shall be given in the Detail Specification. All dimensions shall be stated in millimetres.

Normally the numerical values shall be given for the length, width and thickness of the body.

Where space is insufficient to show the detail dimensions required for inspection purposes,

such dimensions shall appear on the drawing forming an annex to the Detail Specification.

Recommended land patterns shall be given in Detail Specification.

When the outline drawing is other than described above, the Detail Specification shall state

such dimensional information as will adequately describe the surface mount potentiometer.

1.4.2 Mounting

The Detail Specification shall give guidance on methods of mounting for normal use.

Mounting for test and measurement purposes (when required) shall be in accordance with the

following Subclauses , unless otherwise specified.

1.4.2.1 Surface mount potentiometers shall be mounted on a suitable substrate; the method

of mounting will depend on the potentiometer construction. The Detail Specification shall

indicate which material is to be used for electrical measurements.

The substrate shall have metallized land areas of proper spacing to permit mounting of

surface mount potentiometers, and it shall provide electrical connection to the surface mount

potentiometer terminals. The details shall be specified in the Detail Specification.

___________

The text of 1.4.2 and its Subclauses will be integrated in a future edition of IEC 60393-1.

– 6 – 60393-6 IEC:2003(E)

Examples of test substrates for mechanical and electrical tests are shown in Figures 1 and 2

respectively. If another mounting method applies, the method should be clearly described in

the Detail Specification.

1.4.2.2 When the Detail Specification specifies wave soldering, a suitable glue, details of

which may be specified in the Detail Specification, shall be used to fasten the component to

the substrate before soldering is performed.

Small dots of glue shall be applied between the conductors of the substrate by means of a

suitable device securing repeatable results.

The surface mount potentiometers shall be placed on the dots using tweezers. In order to

ensure that no glue is applied to the conductors, the surface mount potentiometers shall not

be moved about.

The substrate with the surface mount potentiometers shall be heat-treated in an oven at

100 °C for 15 min.

The substrate shall be soldered in a wave soldering apparatus. The apparatus shall be

adjusted to have a pre-heating temperature of 80 °C to 100 °C, a solder bath at 260 °C

± 5 °C, and a soldering time of 5 s ± 0,5 s.

The soldering operation shall be repeated a second time (two cycles in total).

The substrate shall be cleaned for 3 min in a suitable solvent (see 3.1.2 of IEC 60068-2-45).

1.4.2.3 When the Detail Specification specifies reflow soldering, the following mounting

procedure applies:

a) The solder used, in preform or paste form, shall be silver bearing (2 % minimum) eutectic

Sn/Pb solder together with a non-activated flux, as stated in test T of IEC 60068-2-20.

Alternative solders, such as 60/40 or 63/37 may be used on surface mounts whose

construction includes solder leach barriers.

b) The surface mount potentiometer shall then be placed across the metallized land areas of

the test substrate so as to make contact between surface mount and substrate land areas.

c) The substrate shall then be placed in or on a suitable heating system (molten solder, hot

plate, tunnel oven, etc.). The temperature of the unit shall be maintained between 215 °C

and 260 °C, until the solder melts and reflows forming a homogeneous solder bond, but for

not longer than 10 s.

NOTE 1 The flux is removed by a suitable solvent (see 3.1.2 of IEC 60068-2-45). All subsequent handling is

such as to avoid contamination. Care is taken to maintain cleanliness in test chambers and during post test

measurements.

NOTE 2 The Detail Specification may require a more restricted temperature range.

NOTE 3 If vapour phase soldering is applied, the same method may be used with the temperatures adapted.

60393-6 IEC:2003(E) – 7 –

Dimensions in millimetres.

0,5 ± 0,1

0,5 ± 0,1

2 ± 0,1

3 ± 0,1

W

Note 3

Note 2

IEC 1420/03

Key

Solderable areas.

Areas which shall not be solderable (covered with non-solderable lacquer).

Dimensions not given should be chosen according to the design and size of the specimens to be tested.

NOTE 1 Material: Epoxide woven glass.

Thickness: 1,6 mm ± 0,1 mm.

NOTE 2 This conductor may be omitted or used as a guard electrode.

NOTE 3 Dimension W is dependent on the design of the test equipment.

Figure 1 – Suitable substrate for mechanical and electrical tests

(may not be suitable for impedance measurements)

– 8 – 60393-6 IEC:2003(E)

Dimensions in millimetres.

5 mm

Note 2

1 2 3 4 5 6

30 mm

IEC 1421/03

Key

Solderable areas.

Areas which shall not be solderable (covered with non-solderable lacquer).

Dimensions not given should be chosen according to the design and size of the specimens to be tested.

NOTE 1 Material: 90 % to 98 % alumina.

Thickness: 0,635 mm ± 0,05 mm.

NOTE 2 This conductor may be omitted or used as a guard electrode.

Figure 2 – Suitable substrate for electrical tests

1.4.3 Style (See 2.2.3 of IEC 60393-1)

The style shall be presented by a double letter code for example AB, which is arbitrarily

chosen for each Detail Specification.

The style designation therefore has no meaning unless the number of the Detail Specification

is also given.

1.4.4 Resistance law

The resistance law is generally not verified. If required, the Detail Specification shall prescribe

the measuring points and the associated limits for the output ratio and shall specify the

position of the corresponding tests in the test schedules.

1.4.5 Ratings and characteristics

The ratings and characteristics shall be in accordance with the relevant Clauses of this

Sectional Specification together with the following:

1.4.5.1 Rated resistance range

See 2.2.1. The preferred values are those of the E-series of IEC 60063 and/or the 1,

2, 5 series.

NOTE When products approved to the Detail Specification have different ranges, the following statement should

be added: “The range of values available in each style is given in the register of approvals”.

1.4.5.2 Bump and shock

The bump and shock tests are considered to be alternatives. The Detail Specification shall

indicate which test has been selected.

60393-6 IEC:2003(E) – 9 –

1.4.6 Marking

The Detail Specification shall specify the content of the marking on the surface mount preset

potentiometer and on the body.

Surface mount preset potentiometers are generally not marked on the body. If some marking

can be applied, the surface mount preset potentiometer shall be clearly marked with the rated

resistance and many of the remaining items in 2.4 of IEC 60393-1.

All items shall be marked on the package. Deviations from the above mentioned requirements

shall be specifically stated.

2 Preferred ratings, characteristics and test severities

2.1 Preferred characteristics

The values given in the Detail Specification shall preferably be selected from the following:

2.1.1 Preferred climatic categories

The surface mount preset potentiometers covered by this Sectional Specification are

classified into climatic categories according to the general rules given in IEC 60068-1.

The lower and upper category temperature and the duration of the damp heat, steady state

test shall be chosen from the following:

Lower category temperature: −65 °C, -55 °C, −40 °C and −25 °C

Upper category temperature: +70 °C, +85 °C, +100 °C, +125 °C and +155 °C

Duration of the damp heat, steady state test: 4, 10, 21 and 56 days.

The severities for the cold and dry heat tests are the lower and upper category temperatures

respectively. Because of the construction of some surface mount preset potentiometers, these

temperatures will occur between two of the preferred temperatures given in the IEC 60068-2

series. In this case, the nearest preferred temperature within the actual temperature range of

the surface mount preset potentiometer shall be chosen for this severity.

2.1.2 Temperature coefficients and temperature characteristics of resistance

The preferred limits of change in resistance for the temperature characteristic of resistance

are given in Table 1.

Each line in the Table gives the preferred temperature coefficient and corresponding

temperature characteristics for 20 °C to 70 °C and limits of change in resistance for the

measurement of the temperature characteristic of resistance (see 4.14 of IEC 60393-1) on

the basis of the category temperature ranges of 2.1.1 of this Sectional Specification.

– 10 – 60393-6 IEC:2003(E)

Table 1 – Temperature coefficients and temperature characteristics of resistance

Temper- Temper- Temperature characteristic of resistance

ature ature (limits of percentage change in resistance)

coeffi- charac-

Reference temperature/ Reference temperature/

cient teristic

lower category temperature upper category temperature

20/70 °C

−6

10 /K % +20/−65 +20/−55 +20/−40 +20/−25 +20/+85 +20/+100 +20/+125 +20/+155

±1 000 ±5 ±8,5 ±7,5 ±6 ±4,5 ±6,5 ±8 ±10,5 ±13,5

± 750 ±3,75 ±6,4 ±5,63 ±4,5 ±3,38 ±4,88 ±6 ±7,88 ±10,13

±3,75 ±3 ±2,25 ±3,25 ±4 ±5,25 ±6,75

± 500 ±2,5 ±4,3

± 250 ±1,25 ±2,15 ±1,88 ±1,5 ±1,13 ±1,62 ±2 ±2,62 ±3,38

± 150 ±0,75 ±1,3 ±1,15 ±0,9 ±0,68 ±0,98 ±1,2 ±1,6 ±2,05

± 100 ±0,5 ±0,85 ±0,75 ±0,6 ±0,45 ±0,65 ±0,8 ±1,05 ±1,35

± 50 ±0,25 ±0,43 ±0,375 ±0,3 ±0,23 ±0,325 ±0,4 ±0,525 ±0,675

± 25 ±0,125 ±0,215 ±0,188 ±0,15 ±0,113 ±0,162 ±0,2 ±0,262 ±0,34

NOTE 1 Potentiometers having an upper category temperature of +85 °C need not be measured between 20 °C

and 70 °C.

NOTE 2 If measurements are required at additional temperatures, these shall be specified in the Detail

Specification.

60393-6 IEC:2003(E) – 11 –

2.1.3 Limits for change in resistance and output ratio

For each stability class, the preferred limits for change in resistance and output ratio for each

of the tests listed in the heading of Table 2 are as indicated.

Table 2 – Limits for change in resistance and output ratio

Stability 4.38 4.34 2.1.3.1 of this 4.43.2 4.22 4.35

Electrical Thrust and Vibration

class Climatic sequence Change of Sectional

temperature Specification endurance pull on

4.39

Shear at 70 °C spindle

Damp heat,

steady state 2.1.3.2 of this 4.43.3

Sectional Electrical

4.40

Specification endurance at

Mechanical

Substrate upper category

endurance

bending test temperature

4.43.2

2.1.3.3 of this

Electrical

Sectional

endurance at 70 °C

Specification

Resistance to

4.43.3

soldering heat

Electrical

endurance at

4.35

upper category

Vibration

temperature

4.36

Bump

4.37

Shock

U

ab

Δ

ΔΔΔΔR between terminals a and c ΔΔΔΔR between

U

ac

terminals a and

b

(See NOTE 2)

10 ±5 % ±7,5 %

±(10 % R+0,5 Ω) ±(5 % R+0,1 Ω) ±(5 % R+0,1 Ω) ±(15 % R+0,5 Ω)

5 ±2 % ±3 %

±(5 % R+0,1 Ω) ±(3 % R+0,1 Ω) ±(2 % R+0,1 Ω) ±(7,5 % R+0,1 Ω)

3 ±1 % ±2 %

±(3 % R+0,1 Ω) ±(2 % R+0,1 Ω) ±(1 % R+0,05 Ω) ±(5 % R+0,1 Ω)

2 ±1 % ±2 %

±(2 % R+0,1 Ω) ±(2 % R+0,1 Ω) ±(1 % R+0,05 Ω) ±(3 % R+0,1 Ω)

NOTE 1 The clause numbers in the heading of the Table refer to IEC 60393-1, unless otherwise specified.

U

ab

NOTE 2 The change in the output voltage ratio Δ shall be expressed in percent of the total applied voltage.

U

ac

2.1.3.1 Shear (adhesion) test

2.1.3.1.1 Test conditions: the surface mount potentiometer shall be mounted as described

in 1.4.2.

The potentiometer shall be subjected to test Ue of IEC 60068-2-21, under the following

condition.

A force of 5 N shall be applied to the surface mount potentiometer body progressively, without

shock, and shall be maintained for a period of 10 s ± 1 s.

2.1.3.1.2 Requirements: the surface mount potentiometer shall be visually examined in the

mounted state. There shall be no visible damage.

___________

The text of 2.1.3.1, 2.1.3.2, 2.1.3.3 and 2.1.3.4 and their Subclauses will be integrated in a future edition of

IEC 60393-1.

– 12 – 60393-6 IEC:2003(E)

2.1.3.2 Substrate bending test (formerly bond strength of the end face plating)

2.1.3.2.1 The surface mount potentiometer shall be mounted on an epoxide woven glass

printed board, as described in 1.4.2.

2.1.3.2.2 The resistance of the surface mount potentiometer shall be measured as specified

in 4.6 of IEC 60393-1.

2.1.3.2.3 The potentiometer shall be subjected to test Ue of IEC 60068-2-21 using the

conditions as prescribed in the relevant Specification for deflection D and the number of

bends.

2.1.3.2.4 The resistance of the surface mount potentiometer shall be measured as specified

in 4.6 of IEC 60393-1, with the board in the bent position. The change in resistance compared

with that measured in 2.1.3.2.2 shall not exceed the value specified in the Detail

Specification.

2.1.3.2.5 The printed board shall be allowed to recover from the bent position and then

removed from the test jig.

2.1.3.2.6 Final inspection and requirements: the surface mount potentiometers shall be

visually examined and there shall be no visible damage.

2.1.3.3 Resistan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...