IEC TS 62647-21:2013

(Main)Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 21: Program management - Systems engineering guidelines for managing the transition to lead-free electronics

Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 21: Program management - Systems engineering guidelines for managing the transition to lead-free electronics

IEC/TS 62647-21:2013(E) is designed to assist program management and/or systems engineering management in managing the transition to lead-free electronics to assure product reliability and performance. The basic principles delineated in this document can be used for program management and/or systems engineering management of any aerospace and/or high performance program. The annexes in the document describe tools that can be used in conjunction with this document. This document is designed to assist a program in assuring the performance, reliability, airworthiness, safety, and certifiability of product(s), in accordance with IEC/TS 62647-1.

General Information

- Status

- Published

- Publication Date

- 25-Jul-2013

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 1 - TC 107/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Jul-2013

- Completion Date

- 30-Nov-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62647-21:2013 - "Process management for avionics - Part 21: Program management" - provides systems engineering and program-management guidelines for managing the transition to lead-free electronics in aerospace and defence (avionics) systems. Its purpose is to help programs assure product reliability, performance, airworthiness, safety and certifiability while migrating from leaded to lead‑free solders, aligned with the broader IEC/TS 62647 series.

Key topics and requirements

The technical specification addresses program-level concerns and deliverables relevant to lead‑free transitions:

- Program decision criteria for adopting Pb‑free technologies and compliance to IEC/TS 62647-1.

- Requirements definition including customer, regulatory (e.g., RoHS/WEEE), and prime‑contractor expectations.

- Supplier lead‑free control plans: procurement controls, sub‑contractor oversight, producibility and schedule of Pb‑free implementation.

- Requalification and test planning: delta qualification, requalification, and acceptance methods (analysis, test, similarity).

- Rework/repair and maintenance guidelines and documentation/training needs for Pb‑free products.

- Risk management: identification, program‑level risk analyses and mitigation strategies specific to Pb‑free manufacturing and materials.

- Cost and schedule considerations associated with transition.

- Annex tools and templates (informative): tier‑risk matrix, links to EU directives and Executive Order 13148, program manager and manufacturing checklists, recommended contractual language, and supplier assessment checklists.

Practical applications and users

This specification is practical for organizations and roles responsible for managing lead‑free transitions in high‑reliability electronics:

- Program managers and systems engineering managers planning or overseeing Pb‑free adoption.

- Prime contractors and integrators in aerospace and defence evaluating supplier readiness and contractual language.

- Quality, procurement and supply‑chain engineers implementing supplier control plans and audits.

- Test and reliability engineers developing requalification and acceptance strategies.

- Regulatory and certification teams ensuring products remain airworthy, safe and certifiable during/material changes.

Use cases include program planning for phased Pb‑free implementation, supplier assessments, creation of requalification/test plans, and updating maintenance procedures and contractual requirements.

Related standards

- IEC/TS 62647-1 (framework and definitions for lead‑free avionics process management) - compliance reference within TS 62647-21.

- References and background: EU RoHS/WEEE directives and Executive Order 13148 are cited for regulatory context.

- Basis documents noted: IEC/PAS 62647-21 and GEIA-HB-0005-1.

Keywords: IEC TS 62647-21, lead-free electronics, avionics, aerospace, defence, program management, systems engineering, RoHS, WEEE, reliability, supplier control.

Buy Documents

IEC TS 62647-21:2013 - Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 21: Program management - Systems engineering guidelines for managing the transition to lead-free electronics

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC TS 62647-21:2013 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 21: Program management - Systems engineering guidelines for managing the transition to lead-free electronics". This standard covers: IEC/TS 62647-21:2013(E) is designed to assist program management and/or systems engineering management in managing the transition to lead-free electronics to assure product reliability and performance. The basic principles delineated in this document can be used for program management and/or systems engineering management of any aerospace and/or high performance program. The annexes in the document describe tools that can be used in conjunction with this document. This document is designed to assist a program in assuring the performance, reliability, airworthiness, safety, and certifiability of product(s), in accordance with IEC/TS 62647-1.

IEC/TS 62647-21:2013(E) is designed to assist program management and/or systems engineering management in managing the transition to lead-free electronics to assure product reliability and performance. The basic principles delineated in this document can be used for program management and/or systems engineering management of any aerospace and/or high performance program. The annexes in the document describe tools that can be used in conjunction with this document. This document is designed to assist a program in assuring the performance, reliability, airworthiness, safety, and certifiability of product(s), in accordance with IEC/TS 62647-1.

IEC TS 62647-21:2013 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62647-21:2013 has the following relationships with other standards: It is inter standard links to IEC PAS 62647-21:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62647-21:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62647-21 ®

Edition 1.0 2013-07

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 21: Program management – Systems engineering guidelines for managing

the transition to lead-free electronics

IEC/TS 62647-21:2013(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TS 62647-21 ®

Edition 1.0 2013-07

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 21: Program management – Systems engineering guidelines for managing

the transition to lead-free electronics

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

V

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-8322-1019-2

– 2 – TS 62647-21 © IEC:2013(E)

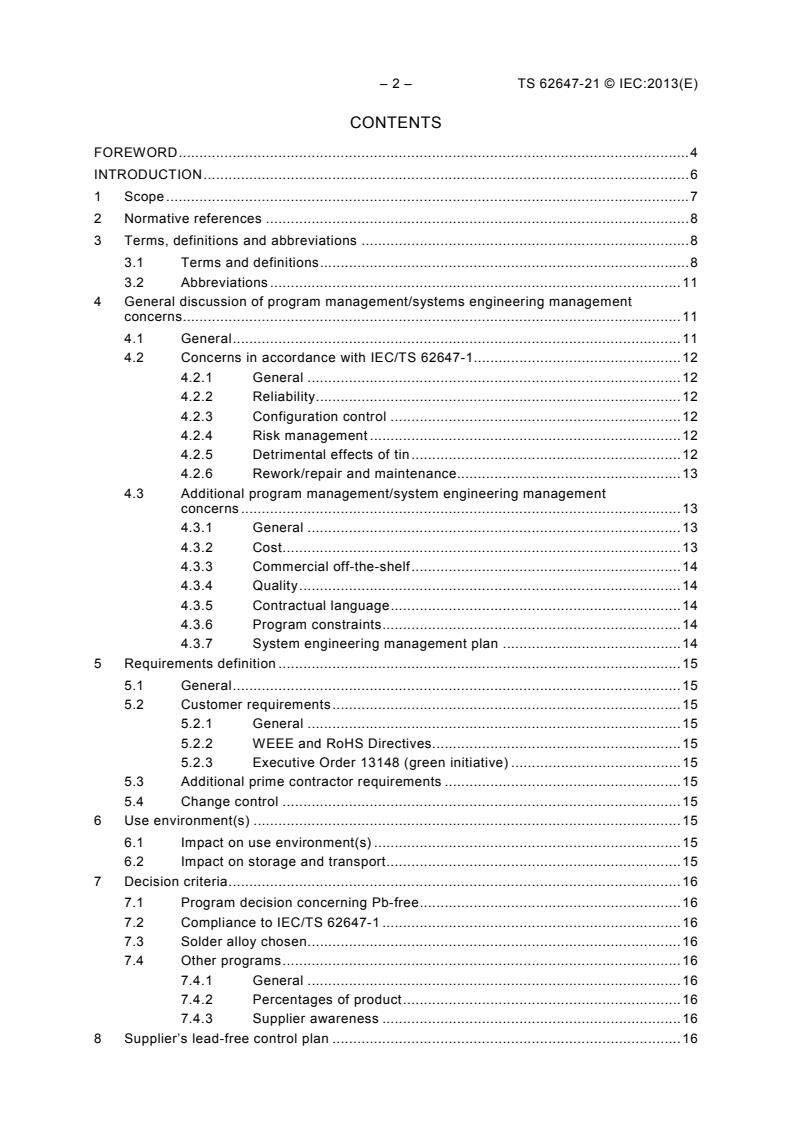

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 8

3 Terms, definitions and abbreviations . 8

3.1 Terms and definitions . 8

3.2 Abbreviations . 11

4 General discussion of program management/systems engineering management

concerns. 11

4.1 General . 11

4.2 Concerns in accordance with IEC/TS 62647-1. 12

4.2.1 General . 12

4.2.2 Reliability . 12

4.2.3 Configuration control . 12

4.2.4 Risk management . 12

4.2.5 Detrimental effects of tin . 12

4.2.6 Rework/repair and maintenance. 13

4.3 Additional program management/system engineering management

concerns . 13

4.3.1 General . 13

4.3.2 Cost . 13

4.3.3 Commercial off-the-shelf . 14

4.3.4 Quality . 14

4.3.5 Contractual language . 14

4.3.6 Program constraints . 14

4.3.7 System engineering management plan . 14

5 Requirements definition . 15

5.1 General . 15

5.2 Customer requirements . 15

5.2.1 General . 15

5.2.2 WEEE and RoHS Directives. 15

5.2.3 Executive Order 13148 (green initiative) . 15

5.3 Additional prime contractor requirements . 15

5.4 Change control . 15

6 Use environment(s) . 15

6.1 Impact on use environment(s) . 15

6.2 Impact on storage and transport . 15

7 Decision criteria . 16

7.1 Program decision concerning Pb-free . 16

7.2 Compliance to IEC/TS 62647-1 . 16

7.3 Solder alloy chosen. 16

7.4 Other programs . 16

7.4.1 General . 16

7.4.2 Percentages of product . 16

7.4.3 Supplier awareness . 16

8 Supplier’s lead-free control plan . 16

TS 62647-21 © IEC:2013(E) – 3 –

8.1 General . 16

8.2 Supplier procurement and sub-contractor control . 17

8.2.1 General . 17

8.2.2 Supplier procurement . 17

8.2.3 Supplier sub-contractor control plan . 17

8.3 Productibility plan . 18

8.4 Manufacturing changes . 18

8.5 Manufacturing risk management . 18

8.6 Supplier schedule of Pb-free implementation . 18

9 Requalification/test plan . 18

9.1 General . 18

9.2 Delta qualification or requalification . 18

9.3 Acceptance by analysis/test . 18

9.4 Acceptance by similarity . 19

10 Rework/repair and maintenance . 19

10.1 General . 19

10.2 Supplier recommendations for rework/repair of Pb-free products . 19

10.3 Maintenance and training documentation . 19

11 Risk management . 19

11.1 General . 19

11.2 Program-level identification of program-level risks . 19

11.3 Risk analyses. 19

11.4 Risk mitigation . 19

12 Cost . 19

13 Presentation to customer . 20

13.1 General . 20

13.2 Compliance to IEC/TS 62647-1 . 20

13.3 System engineering management plan . 20

13.4 Other deliverables to the customer . 20

Annex A (informative) Matrix of tier level versus associated risk . 21

Annex B (informative) Links to the European Union Directives and Executive Order

13148 . 23

Annex C (informative) General program manager checklist for dealing with Pb-free

issues . 24

Annex D (informative) General manufacturing process assessment checklist for

assessing supplier compliance to IEC/TS 62647-1 . 26

Annex E (informative) Recommended program language (subject to contractual

agreements) . 33

Bibliography . 34

– 4 – TS 62647-21 © IEC:2013(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 21: Program management –

Systems engineering guidelines for managing

the transition to lead-free electronics

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

TS 62647-21 © IEC:2013(E) – 5 –

IEC/TS 62647-21, which is a technical specification, has been prepared by IEC technical

committee 107: Process management for avionics.

The text of this technical specification is based on the following documents: IEC/PAS 62647-

21 and GEIA-HB-0005-1.

This technical specification cancels and replaces IEC/PAS 62647-21, published in 2011. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Coherence with IEC/TS 62647-1 definitions.

b) Reference to IEC 62647 documents when already published.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

107/204/DTS 107/215/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62647 series, published under the general title Process

management for avionics – Aerospace and defence electronic systems containing lead-free

solder, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – TS 62647-21 © IEC:2013(E)

INTRODUCTION

Due to a variety of real and potential health issues, many constituent materials used in the

production of electronic products have come under scrutiny. The European Union (EU) has

started a process with two directives: 2002/95/EC Restriction of Hazardous Substances

(RoHS) and 2002/96/EC Waste Electrical and Electronic Equipment (WEEE) that restrict or

eliminate the use of various substances in a variety of products that are produced after July

2006. Directive 2011/65/EU on the restriction of the use of certain hazardous substances in

electrical and electronic equipment is an updated / recast version of the Directive 2002/95/EC.

One of the key materials restricted is lead (Pb), which is widely used in electronic solder and

electronic piece part terminations. While these regulations may appear to only affect products

for sale in the EU, due to the reduced market share of the Aerospace, Defence and High

Performance (ADHP) electronics industry, many of the lower tier suppliers have changed their

products because their primary market is consumer electronics. Additionally, several U.S.

states have enacted similar “green” laws and many Asian electronics manufacturers have

recently announced completely green product lines.

Since the ADHP electronics industry is one of the few major industrial sectors that still repair

circuit card assemblies (CCAs) and since Pb-free materials and processes are relatively

immature and poorly understood, an aerospace-wide approach to the transition was deemed

to be highly valuable.

TS 62647-21 © IEC:2013(E) – 7 –

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 21: Program management –

Systems engineering guidelines for managing

the transition to lead-free electronics

1 Scope

This part of IEC 62647 is designed to assist program management and/or systems

engineering management in managing the transition to lead-free (Pb-free) electronics to

assure product reliability and performance.

Manufacturers of Aerospace, Defence and High Performance (ADHP) electronics may

inadvertently introduce Pb-free elements (including piece part finish, printed wiring board

(PWB) or printed circuit board (PCB) finish, or assembly solder) if careful coordination

between buyer and supplier is not exercised. For example, piece part manufacturers may not

always change part numbers to identify Pb-free finishes, especially if the previous tin-lead

(Sn-Pb) finished piece part has been discontinued. Detailed examination of piece parts and

documents at receiving inspection, while crucial, may not be sufficient to identify Pb-free

piece parts.

NOTE 1 Pb-free technology can impact any program regardless of whether the program itself is exempt or bound

by environmental regulations. The industry conversion to Pb-free solder technology may affect an ADHP program

in one or both of the following ways:

1) if the program is required to implement Pb-free technology (contract requirement, environmental regulation,

etc), then the program manager/lead systems engineer will need to assess the impact of in-house transition

with respect to design (performance of products using Pb-free) and process (processes to build Pb-free

products);

2) if the program purchases COTS (commercial-off-the-shelf) items for its products/systems, then there is a very

good chance that these items will contain Pb-free solder or Pb-free finishes on parts, printed wiring boards

(PWBs), printed circuit boards (PCB), or circuit cards assemblies (CCA).

The basic principles delineated in this document can be used for program management and/or

systems engineering management of any aerospace and/or high performance program. The

annexes in the document describe tools that can be used in conjunction with this document.

1) Annex A describes a matrix of product tier level versus associated risks with respect to a

Pb-free transition.

2) Annex B contains links to the European Union Directives and Executive Order 13148.

3) Annex C contains a general program manager checklist for dealing with Pb-free issues

that summarizes the content of this document.

4) Annex D contains a general manufacturing process assessment checklist to assess

supplier compliance to IEC/TS 62647-1.

5) Annex E describes a recommended program language to assure performance, reliability,

airworthiness, safety, and certifiability of Pb-free product(s).

This document is designed to assist a program in assuring the performance, reliability,

airworthiness, safety, and certifiability of product(s), in accordance with IEC/TS 62647-1.

Please note that the program manager and systems engineer (along with their respective

organizations), and the appropriate enterprise authority work together in ensuring that all

impacts of Pb-free technology insertion are understood and risks mitigated accordingly.

– 8 – TS 62647-21 © IEC:2013(E)

For the purposes of this document, “program management (or manager) and/or systems

engineering management (or manager) and/or the appropriate enterprise authority” are

defined as “program manager”.

NOTE 2 The implications are that the program manager and systems engineering manager (along with their

respective organizations) and the appropriate enterprise authority work together in ensuring that all impacts of Pb-

free technology insertion are understood and risks mitigated accordingly.

This document may be used by other high performance and high reliability industries at their

discretion.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC/TS 62647-1:2012, Process management for avionics – Aerospace and defence electronic

systems containing lead free solder – Part 1: Preparation for a lead-free control plan

IEC/TS 62647-2, Process management for avionics – Aerospace and defence electronic

systems containing lead-free solder – Part 2: Mitigation of deleterious effects of tin

3 Terms, definitions and abbreviations

For the purposes of this document, the following terms, definitions and abbreviations apply.

3.1 Terms and definitions

3.1.1

assemblies

electronic items that require electrical attachments, including soldering of wires or component

terminations

EXAMPLE Circuit cards and wire harnesses.

[SOURCE: IEC/TS 62647-1:2012, 3.1]

3.1.2

COTS

commercial-off-the-shelf

item whose design and configuration is controlled by the manufacturer and on which the user

has no control as to design and configuration

Note 1 to entry: An item may be a component, a subassembly, an assembly, a system.

[SOURCE: IEC/TS 62647-1:2012, 3.3]

3.1.3

critical

state of an item or function, which if defective, will result in the system’s inability to retain

operational capability, meet primary objective, or affect safety

[SOURCE: IEC/TS 62647-1:2012, 3.2]

TS 62647-21 © IEC:2013(E) – 9 –

3.1.4

customer

entity or organization that (a) integrates a piece part, soldered assembly, unit, or system into

a higher control level system, (b) operates the higher control level system, or (c) certifies the

system for use

EXAMPLE This may include end item users, integrators, regulatory agencies, operators, original equipment

manufacturers (OEMs), and sub-contractors.

[SOURCE: IEC/TS 62647-1:2012, 3.5]

3.1.5

high performance

continued performance or performance on demand where an application (product, equipment,

electronics, system, program) down time cannot be tolerated in an end-use environment

which can be uncommonly harsh, and the application must function when required

EXAMPLE: Examples of high performance applications are life support or other critical systems.

[SOURCE: IEC/TS 62647-1:2012, 3.7]

3.1.6

lead-free

Pb-free

less than 0,1 % by weight of lead (Pb) in accordance with reduction of hazardous substances

(RoHS) guidelines

[SOURCE: IEC/TS 62647-1:2012, 3.8]

3.1.7

Lead-free control plan

LFCP

aerospace or military system supplier’s document that defines the processes that assure the

Plan owners, their customers and all other stakeholders that aerospace, defence and high

performance high-reliability electronics systems containing Pb-free solder and Pb-free piece

part and PWB finishes will continue to be reliable, safe, producible, affordable, and

supportable

[SOURCE: IEC/TS 62647-1:2012, 3.9]

3.1.8

Pb-free tin

pure tin or any tin alloy with < 3 % lead (Pb) content by weight

Note 1 to entry: Some Pb-free finishes other than pure tin, such as tin-bismuth and tin-copper are considered to

be “tin” for the purposes of this specification. Many of these alloys have not been assessed for whiskering

behaviour.

[SOURCE: IEC/TS 62647-1:2012, 3.11]

3.1.9

Pb-free tin finish

final finishes or underplates either external or internal to a device, board or other hardware,

including all leads and surfaces, even those coated, encapsulated, or otherwise not exposed

Note 1 to entry: It may include finishes on electrical piece parts, mechanical piece parts, and boards. It does not

include Pb-free bulk solders, assembly materials, solder balls, or those devices where the Pb-free tin finish has

been completely replaced (consistent with GEIA-STD-0006).

[SOURCE: IEC/TS 62647-1:2012, 3.12]

– 10 – TS 62647-21 © IEC:2013(E)

3.1.10

PCB

printed circuit board

PWB

printed wiring board

substrate using conductive pathways, tracks or signal traces etched from copper sheets

laminated, and allowing to connect electrically a set of electronic components to realize a

circuit card

3.1.11

piece part

electronic component that is not normally disassembled without destruction and is normally

attached to a printed wiring board to perform an electrical function

[SOURCE: IEC/TS 62647-1:2012, 3.14]

3.1.12

repair

act of restoring the functional capability of a defective article in a manner that precludes

compliance of the article with applicable drawings or specifications

[SOURCE: IEC/TS 62647-1:2012, 3.17]

3.1.13

rework

action taken to return a unit (SRU/LRU/system) to a state meeting all requirements of the

engineering drawing, including both functionality and physical configuration by making repairs

Note 1 to entry: Also used to define the act of reprocessing non-complying articles, through the use of original or

equivalent processing in a manner that assures full compliance of the article with applicable drawings or

specifications.

[SOURCE: IEC/TS 62647-1:2012, 3.16]

3.1.14

sub-contractor

organization, within the given high-reliability industry, that supplies, maintains, repairs, or

supports electronic systems, and is not the direct supplier to the customer or user of those

systems

[SOURCE: IEC/TS 62647-1:2012, 3.22]

3.1.15

supplier

entity or organization that designs, manufactures, repairs, or maintains a piece part, unit, or

system

Note 1 to entry: This includes original equipment manufacturers (OEMs), repair facilities, sub-contractors, and

piece part manufacturers.

[SOURCE: IEC/TS 62647-1:2012, 3.23]

3.1.16

system

one or more units that perform electrical function(s)

[SOURCE: IEC/TS 62647-1:2012, 3.24]

TS 62647-21 © IEC:2013(E) – 11 –

3.1.17

tin whisker

spontaneous crystal growth that emanates from a tin (Sn) surface and which may be

cylindrical, kinked, or twisted

Note 1 to entry: Typically tin whiskers have an aspect ratio (length/width) greater than two, with shorter growths

referred to as nodules or odd-shaped eruptions (OSEs).

[SOURCE: IEC/TS 62647-1:2012, 3.26]

3.1.18

unit

one or more assemblies within a chassis or higher level system to perform electrical

function(s)

[SOURCE: IEC/TS 62647-1:2012, 3.27]

3.2 Abbreviations

ADHP Aerospace, defence and high performance

ATP Acceptance test procedure

CCA Circuit card assembly

COTS Commercial off-the-shelf

ENIG Electroless nickel/gold

EU European Union

FMECA Failure mode effects and criticality analysis

GEIA Government Electronics and Information Technology Association

IR Infra-red

LFCP Lead-free control plan

OEM Original equipment manufacturer

OSP Organic solderability preservative

Pb-free Lead-free

PMP Parts, materials, and processes

PWB Printed wiring board

PCB Printed circuit board

SEMP System engineering management plan

Sn-Pb Tin/lead (e.g. 63 % tin/37 % lead)

4 General discussion of program management/systems engineering

management concerns

4.1 General

A program manager’s role is to be aware of how changes will affect the program, whether the

program is on the system level, unit level, assembly level, or piece part level. The change

from Sn-Pb solder to Pb-free solder will affect all electronics programs, regardless of level or

size. The program manager also needs to understand where Pb-free is being introduced in

the program (piece part finishes only, assembly soldering, etc.). Annex A differentiates the

various tier levels and the associated risk to consider. The concerns described in 4.2 and 4.3

need to be considered for a successful transition.

– 12 – TS 62647-21 © IEC:2013(E)

4.2 Concerns in accordance with IEC/TS 62647-1

4.2.1 General

In accordance with IEC/TS 62647-1, program concerns include reliability, configuration

control, risk management, effects of tin in the system, and rework/repair and maintenance.

4.2.2 Reliability

The program manager should understand how the transition to Pb-free may affect the

reliability of the program. The program manager or a designee should understand the effects

of mixing Sn-Pb and Pb-free solder, the effects on package types/geometry, how Pb-free may

react to the program’s use environment, if units and/or systems will include Sn-Pb and Pb-free

assemblies, piece parts, etc. In addition, the program manager should consider a common

reliability data collection during all phases of the program to facilitate systems performance

improvement.

4.2.3 Configuration control

The need for configuration control is paramount to the Pb-free transition. Studies have shown

that mixing Sn-Pb and Pb-free solders or the mixing of Pb-free solders of different alloys

and/or piece parts (solders or finishes of different alloys) may have detrimental impact on the

long-term reliability under high stress (e.g., defence, commercial aerospace, or space)

environments. The program manager should understand the appropriate configuration

controls (e.g., traceability) that are necessary for the program’s environment. Note that the

program manager shall decide the configuration control measures that shall be taken for the

various levels (i.e., piece part, assembly, unit, system).

The material content of the terminations (component leads) is critical in assuring adequate

reliability and performance of the finished product. The program manager should ensure that

appropriate and demonstrated processes are in place at the suppliers’ that will accurately

identify the material content of piece parts used in soldered assemblies and that the material

content is compatible with the supplier’s soldering processes.

The program manager may require a parts, materials, and processes plan to be in place at

the supplier’s which reflects appropriate quality control procedures. The plan should include

sub-contractor controls that affect the reliability of the end product.

4.2.4 Risk management

Risk identification and risk assessment need to be performed for the Pb-free transition for the

particular environmental conditions of the program. Risks need to be identified early and a

mitigation strategy engaged. The program manager has a responsibility to conduct a complete

risk management plan.

4.2.5 Detrimental effects of tin

Pb-free tin finishes in an avionics or high performance system can have detrimental effects on

functionality of the system as tin whiskers can spontaneously grow from the surfaces. Piece

parts with Pb-free tin finishes have already been introduced into ADHP systems with minimal

understanding of the effects that they will have. Program managers need to have a plan for

either eliminating the use of Pb-free tin in their product, through life-time buys or re-finishing

piece parts, or a plan for addressing and mitigating the risks.

IEC/TS 62647-2 provides standard methods for controlling and mitigating the use of Pb-free

tin finished piece parts. It defines three basic levels, with additional sublevels, for controlling

and mitigating the use of Pb-free tin finishes with accurate regard to tin whiskers. These

levels can be summarized as follows.

Level 1: No restrictions on Pb-free tin finish use.

TS 62647-21 © IEC:2013(E) – 13 –

Level 2: Pb-free tin finish is allowed under some circumstances.

– Level 2A. Use of Pb-free tin finish without explicit controls is acceptable under

most circumstances but the likelihood of whiskers and the methods used to

estimate their impact and mitigation strategies will be documented. Pb-free tin

finish may be prohibited in some specific circumstances called out in

contractual documents.

– Level 2B. Pb-free tin finishes may be used but only with customer approved and

specified control measures. These Pb-free tin finish approvals may be blanket

approvals for multiple piece parts and applications within the system. Pb-free

tin finish may be prohibited in some specific circumstances called out in

contractual documents.

– Level 2C. Restricted use of Pb-free tin finish. Pb-free tin finish is prohibited

unless an exception with customer approval is made. Specific instruction on use

of Pb-free tin finish and required control measures are to be provided and

reviewed on a case-by-case basis.

Level 3: Use of Pb-free tin finish is prohibited and measures shall be taken to verify

compliance.

These levels are designed to be used in requests for proposals and control documents. The

customers should determine the appropriate control level or levels for their product, based on

criticality, their comfort with the risk, and other mitigating features of their program, such as

redundancy and repairability. For many larger programs, different subsystems or units may

need different control levels that can be based on customer and supplier discussions and

agreement regarding both application and supplier mitigation solution knowledge.

In most cases, it would be appropriate for OEMs to have general policies that aid in the

selection of the appropriate control level. Program managers should work with their

companies to develop the policy to aid in consistent requirements across programs.

Program managers also need to be prepared for handling errors in finish determination or

mitigation application. This may simply be a variation in the program's normal process waiver

process or may require a more in-depth risk assessment, depending on the criticality level.

4.2.6 Rework/repair and maintenance

Rework/repair and maintenance becomes a concern if Sn-Pb and Pb-free solders and/or piece

parts are used on the same assemblies. As stated before, studies have shown that reliability

of the joints/junctions of mixed lead and Pb-free solder may decrease in high stress

environments. A program manager should make the customer aware of the higher risks

associated with field rework/repair and maintenance when standard solder materials (i.e.

60 % tin/40 % lead or 63 % tin/37 % lead) are used on Pb-free assemblies and/or piece parts.

4.3 Additional program management/system engineering management concerns

4.3.1 General

The program manager also has additional concerns from a programmatic point of view. These

include cost, parts obsolescence, COTS, quality, contract language, other existing program

constraints, and updating of the program system engineering management plan (SEMP).

Other concerns can be addressed based on specific program needs.

4.3.2 Cost

The costs of the Pb-free transition need to be quantified and decisions need to be made as to

who will assume the costs. The program manager should be aware that the situation is likely

to be dynamic over the next several years. Added costs may come from additional risk

management determination, configuration controls, rework/repair and maintenance changes,

drawing changes, possible redesign, requalifying/delta qualifying, etc.

– 14 – TS 62647-21 © IEC:2013(E)

4.3.3 Commercial off-the-shelf

4.3.3.1 General

Commercial-off-the-shelf (COTS) is always a critical concern for a program manager. The

very nature of COTS may allow Pb-free substitution irrespective of program requirements.

4.3.3.2 COTS piece parts and parts obsolescence or COTS piece parts

The supplier may request substitution of Pb-free finished piece parts on a program. This

occurs not only because of the piece part supplier obsolescing standard Sn-Pb-finishes, but

also due to a COTS piece part substitution. The program manager or a designee should have

controls in place and understand IEC/TS 62647-2, to mitigate the risks associated with Pb-

free finished piece parts and COTS. The program manager needs to ensure that the parts,

materials, and processes (PMP) control plan for the program is updated and addresses how

lead-free piece parts will be identified and tracked. If a PMP control plan is not available for

the program, the program manager should ensure that the PMP functional group is aware of

each parts substitution and is adequately addressing the issue of lead-free piece parts.

4.3.3.3 COTS assemblies

The product may contain COTS assemblies, as well. The program manager should be aware

of the possible risks due to COTS assemblies containing either Pb-free piece parts and/or Pb-

free soldered assemblies. The program manager needs to ensure that the parts, materials,

and processes (PMP) control plan for the program is updated and addresses how lead-free

assemblies will be identified and tracked. If a PMP control plan is not available for the

program, the program manager should ensure that the PMP functional group is aware of each

parts substitution and is adequately addressing the issue of lead-free assemblies.

4.3.4 Quality

Quality is a critical consideration in the transition to Pb-free and the program manager needs

to be assured that the final product meets the technical and operational requirements with the

specified reliability at all levels. This includes the flow of requirements, implementation and

documentation through and to sub-contractors.

4.3.5 Contractual language

Appropriate contractual language needs to be included in new contracts that describe the

customer requirements regarding Pb-free parts. An example contractual language is included

in Annex E.

4.3.6 Program constraints

The program manager needs to be proactive in understanding all of the impacts to the

program schedule (including all integrated master schedule line items). Consideration needs

to be particularly paid to changes in the delivery schedule due to requalification/delta

qualification of Pb-free parts and additional reliability testing. Also, if risk mitigation plans

include lifetime buys of long-lead Sn-Pb-finish parts (due to obsolescence), the updated

schedule needs to reflect the changes appropriately.

4.3.7 System engineering management plan

The program manager should reassess the program’s system engineering management plan,

if one exists, and update to include the Pb-free transition controls for the program.

TS 62647-21 © IEC:2013(E) – 15 –

5 Requirements definition

5.1 General

A re-evaluation of the program requirements should be performed to determine the impact of

the Pb-free transition.

5.2 Customer requirements

5.2.1 General

The program manager should include all of the Pb-free transitions in a thorough risk

assessment/mitigation plan and present it to the customer. The purpose of the plan is to help

the customer understand the risks associated with the transition.

5.2.2 WEEE and RoHS Directives

The program manager should understand the implications of the WEEE and RoHS Directives

(Annex B).

5.2.3 Executive Order 13148 (green initiative)

Even though this generally applies only to facility operations issues, weapon system

maintenance by the customer may come under this category. The program manager should

be aware of the customer’s requirements in this area (Annex B).

5.3 Additional prime contractor requirements

Additional prime contractor requirements need to be re-assessed with regard to a possible

Pb-free transition.

5.4 Change control

The program manager should determine if any change from Sn-Pb to Pb-free constitutes a

change for which customer approval is needed. The purpose is to assure that configuration

control, traceability, and marking are properly controlled.

6 Use environment(s)

6.1 Impact on use environment(s)

The use environment(s) is(are) defined by the program requirements. The program manager

needs assurance from the supplier that the tr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...