IEC TS 62686-2:2019

(Main)Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 2: General requirements for passive components

Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 2: General requirements for passive components

IEC TS 62686-2:2019 defines the minimum requirements for general purpose "off-the-shelf" COTS (commercial off-the-shelf) passive components for aerospace, defence and high performance (ADHP) applications. This document applies to all passive components that can be operated in ADHP applications within the manufacturers’ publicly available data sheet limits in conjunction with IEC TS 62239-1. This document can be used by other high performance and high reliability industries, at their discretion.

ADHP application requirements are not necessarily fulfilled by this document alone. ADHP original equipment manufacturers (OEMs) could consider redesigning their products or conducting further testing to verify suitability in ADHP applications using their procedures for satisfying their electronic component management plan (ECMP) (see IEC TS 62239-1).

This first edition cancels and replaces IEC PAS 62686-2 published in 2016.

General Information

- Status

- Published

- Publication Date

- 29-Jan-2019

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 2 - TC 107/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Jan-2019

- Completion Date

- 09-Nov-2018

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62686-2:2019 - Process management for avionics: Part 2 defines general requirements for passive components intended for aerospace, defence and high performance (ADHP) applications. It specifies minimum process, documentation and verification expectations for commercial off-the-shelf (COTS) passive devices (resistors, capacitors, inductors, etc.) when used within manufacturers’ published datasheet limits and used in conjunction with IEC TS 62239-1 (electronic component management). This Technical Specification replaces IEC PAS 62686-2 (2016) and is intended to guide OEMs, suppliers and procurement teams in selecting and managing passive components for high-reliability systems.

Key topics and technical requirements

- Scope and applicability: Applies to general-purpose COTS passive components for ADHP; does not alone guarantee ADHP suitability - OEMs may require redesign or additional testing as part of their ECMP.

- Traceability & documentation: Requirements for traceability, date codes, unit packaging, labels, moisture sensitivity level (MSL) marking and lead‑free identification.

- Product/Process Change Notification (PCN): Required notification practices and minimum content for changes affecting component suitability.

- Shipment and handling controls: Unit pack, intermediate packing, ESD protection and shipment procedures to preserve component integrity.

- Electrical & mechanical controls: Baseline electrical testing, device marking, termination finish management and MSL controls.

- Qualification & testing: Qualification methodology, test samples, maintenance of qualification records; guidance includes a broad set of environmental and reliability tests (temperature cycling, moisture resistance/biased humidity, high temperature operating life, vibration, shock, solderability, tin‑whisker assessment, board flex, etc.) (see Annex A).

- Quality management & audit capability: Internal quality audits, subcontractor controls, sampling plans, outgoing quality and failure analysis support.

- Product monitoring & reporting: In-line monitoring, problem notification and data reporting to support production control.

- Environmental Health & Safety (EHS): Device handling, materials/substance requirements and regulatory compliance expectations.

Applications and practical value

- Ensures consistent procurement and acceptance of COTS passive components for avionics, defence and other high-performance systems.

- Guides suppliers in implementing process controls, documentation and qualification needed by ADHP OEMs.

- Helps OEMs integrate COTS passive parts into their Electronic Component Management Plans (ECMPs) - reducing supply-chain risk, improving traceability and supporting obsolescence/product discontinuance strategies.

- Useful for engineers performing component selection, reliability assessment, incoming inspection, and non-conformance management.

Who should use this standard

- Avionics and defence OEMs, system integrators and design engineers

- Passive component manufacturers and contract manufacturers

- Procurement, quality and reliability professionals in ADHP and other high-reliability industries

- Certification and supply-chain managers requiring structured PCN, traceability and qualification documentation

Related standards

- IEC TS 62239-1 - Electronic component management plan (ECMP) for ADHP applications (referenced for full ADHP requirements)

- Relevant IEC passive component and environmental test standards referenced within IEC TS 62686-2 (see annexes for test mappings)

Keywords: IEC TS 62686-2:2019, passive components, ADHP, avionics, COTS, ECMP, qualification, traceability, ESD, moisture sensitivity, PCN, quality assurance.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC TS 62686-2:2019 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 2: General requirements for passive components". This standard covers: IEC TS 62686-2:2019 defines the minimum requirements for general purpose "off-the-shelf" COTS (commercial off-the-shelf) passive components for aerospace, defence and high performance (ADHP) applications. This document applies to all passive components that can be operated in ADHP applications within the manufacturers’ publicly available data sheet limits in conjunction with IEC TS 62239-1. This document can be used by other high performance and high reliability industries, at their discretion. ADHP application requirements are not necessarily fulfilled by this document alone. ADHP original equipment manufacturers (OEMs) could consider redesigning their products or conducting further testing to verify suitability in ADHP applications using their procedures for satisfying their electronic component management plan (ECMP) (see IEC TS 62239-1). This first edition cancels and replaces IEC PAS 62686-2 published in 2016.

IEC TS 62686-2:2019 defines the minimum requirements for general purpose "off-the-shelf" COTS (commercial off-the-shelf) passive components for aerospace, defence and high performance (ADHP) applications. This document applies to all passive components that can be operated in ADHP applications within the manufacturers’ publicly available data sheet limits in conjunction with IEC TS 62239-1. This document can be used by other high performance and high reliability industries, at their discretion. ADHP application requirements are not necessarily fulfilled by this document alone. ADHP original equipment manufacturers (OEMs) could consider redesigning their products or conducting further testing to verify suitability in ADHP applications using their procedures for satisfying their electronic component management plan (ECMP) (see IEC TS 62239-1). This first edition cancels and replaces IEC PAS 62686-2 published in 2016.

IEC TS 62686-2:2019 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62686-2:2019 has the following relationships with other standards: It is inter standard links to IEC PAS 62686-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62686-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62686-2 ®

Edition 1.0 2019-01

TECHNICAL

SPECIFICATION

Process management for avionics – Electronic components for aerospace,

defence and high performance (ADHP) applications –

Part 2: General requirements for passive components

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62686-2 ®

Edition 1.0 2019-01

TECHNICAL

SPECIFICATION

Process management for avionics – Electronic components for aerospace,

defence and high performance (ADHP) applications –

Part 2: General requirements for passive components

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-8322-6247-4

– 2 – IEC TS 62686-2:2019 © IEC 2019

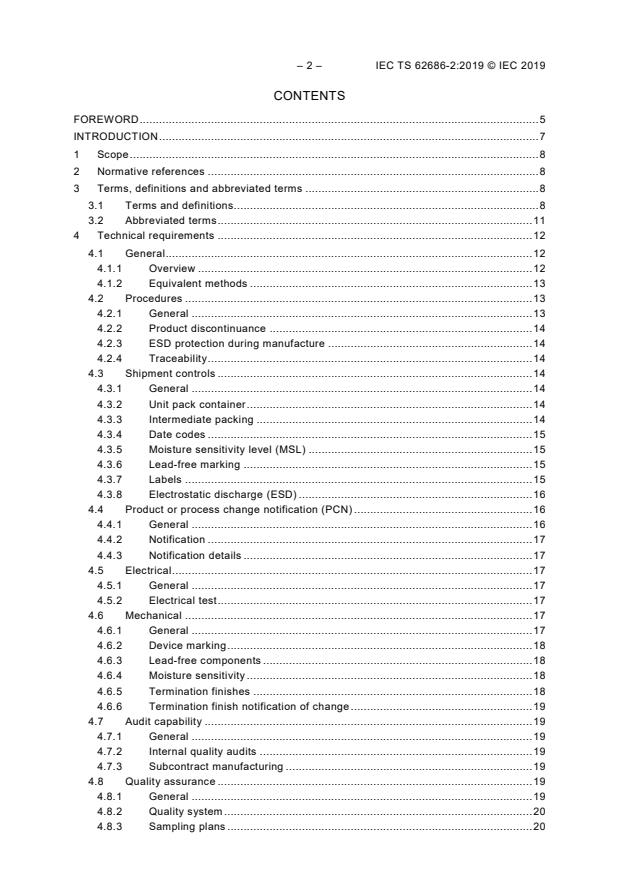

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Abbreviated terms . 11

4 Technical requirements . 12

4.1 General . 12

4.1.1 Overview . 12

4.1.2 Equivalent methods . 13

4.2 Procedures . 13

4.2.1 General . 13

4.2.2 Product discontinuance . 14

4.2.3 ESD protection during manufacture . 14

4.2.4 Traceability . 14

4.3 Shipment controls . 14

4.3.1 General . 14

4.3.2 Unit pack container . 14

4.3.3 Intermediate packing . 14

4.3.4 Date codes . 15

4.3.5 Moisture sensitivity level (MSL) . 15

4.3.6 Lead-free marking . 15

4.3.7 Labels . 15

4.3.8 Electrostatic discharge (ESD) . 16

4.4 Product or process change notification (PCN) . 16

4.4.1 General . 16

4.4.2 Notification . 17

4.4.3 Notification details . 17

4.5 Electrical . 17

4.5.1 General . 17

4.5.2 Electrical test . 17

4.6 Mechanical . 17

4.6.1 General . 17

4.6.2 Device marking . 18

4.6.3 Lead-free components . 18

4.6.4 Moisture sensitivity . 18

4.6.5 Termination finishes . 18

4.6.6 Termination finish notification of change . 19

4.7 Audit capability . 19

4.7.1 General . 19

4.7.2 Internal quality audits . 19

4.7.3 Subcontract manufacturing . 19

4.8 Quality assurance . 19

4.8.1 General . 19

4.8.2 Quality system . 20

4.8.3 Sampling plans . 20

4.8.4 Failure analysis support . 20

4.8.5 Outgoing quality . 20

4.9 Qualification . 20

4.9.1 General . 20

4.9.2 Methodology . 21

4.9.3 Test samples . 24

4.9.4 Qualification categories . 24

4.9.5 Maintenance of qualification standard . 24

4.9.6 In-process test results . 25

4.9.7 Test references . 25

4.9.8 Qualification report . 25

4.9.9 Archiving . 25

4.9.10 Qualification of device changes . 25

4.9.11 Similarity assessment . 25

4.10 Product monitoring in the production line . 26

4.10.1 General . 26

4.10.2 Monitoring programme . 26

4.10.3 Problem notification . 26

4.10.4 Data reporting. 26

4.11 Environmental health and safety (EHS) . 26

4.11.1 General . 26

4.11.2 General EHS compliance . 27

4.11.3 Device handling . 27

4.11.4 Device materials and substances . 27

Annex A (informative) Test code (TC) information for guidance . 28

A.1 General . 28

A.2 TC1 – Electrical test. 28

A.3 TC2 – External visual . 28

A.4 TC3 – Package dimensions . 29

A.5 TC4 – High temperature exposure (storage) . 30

A.6 TC5 – Temperature cycling . 30

A.7 TC6 – Moisture resistance . 30

A.8 TC7 – Biased humidity . 30

A.9 TC8 – High temperature operating life. 30

A.10 TC9 – Terminal strength (leaded) . 31

A.11 TC10-Resistance to solvents . 31

A.12 TC11 – Mechanical shock . 31

A.13 TC12 – Vibration . 31

A.14 TC13 – Resistance to heat . 31

A.15 TC14 – Thermal shock . 32

A.16 TC15 – Board flex (SMD) . 32

A.17 TC16 – Beam load . 32

A.18 TC17 – Solderability . 32

A.19 TC18 – Electrostatic discharge . 32

A.20 TC19 – Flammability . 32

A.21 TC20 – Terminal strength (SMD) . 32

A.22 TC21 – Surge voltage . 32

A.23 TC22 – Hermeticity . 33

A.24 TC23 – Tin whisker . 33

– 4 – IEC TS 62686-2:2019 © IEC 2019

Annex B (informative) Typical IECQ-CECC approved components . 34

Annex C (informative) Typical USA military specified passive components. 36

Annex D (informative) Typical automotive components . 37

Annex E (informative) Typical IEC specified passive components . 39

E.1 Typical IEC passive component specifications . 39

E.2 IEC passive component environmental test methods . 39

Annex F (informative) Verification requirements matrix for IEC TS 62686-2 . 46

Bibliography . 55

Table 1 – Label requirements. 16

Table 2 – Internal quality audit areas . 19

Table 3 – Technology/family qualification and device qualification . 22

Table 4 – Qualification tests for device types . 23

Table D.1 – AEC-Q200 temperature grades . 37

Table E.1 – IEC passive specifications' environmental test methods compared to

those specified in Table 3 . 40

Table F.1 – Verification requirements matrix for IEC TS 62686-2 . 46

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS – ELECTRONIC

COMPONENTS FOR AEROSPACE, DEFENCE AND

HIGH PERFORMANCE (ADHP) APPLICATIONS –

Part 2: General requirements for passive components

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62686-2 which is a technical specification, has been prepared by IEC technical

committee 107: Process management for avionics.

– 6 – IEC TS 62686-2:2019 © IEC 2019

This first edition cancels and replaces the first edition of IEC PAS 62686-2 published in 2016.

This edition constitutes a technical revision.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

107/302/DTS 107/343/RVDTS

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62686 series, published under the general title Process

management for avionics – Electronic components for aerospace, defence and high

performance (ADHP) applications, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

INTRODUCTION

This part IEC 62686 includes all the requirements of the obsolete STACK Specification

S/0003 issue 2 related to passive components and contains revisions for alternative

qualification test methods and additional test information for the aerosapace, defence and

high performance (ADHP) industries. This document is typically used in conjunction with

IEC TS 62239-1.

NOTE With the addition of alternative methods, it is possible for manufacturers to be audited by IECQ under the

new IECQ automotive scheme or IECQ approved component scheme.

– 8 – IEC TS 62686-2:2019 © IEC 2019

PROCESS MANAGEMENT FOR AVIONICS – ELECTRONIC

COMPONENTS FOR AEROSPACE, DEFENCE AND

HIGH PERFORMANCE (ADHP) APPLICATIONS –

Part 2: General requirements for passive components

1 Scope

This part of IEC 62686 defines the minimum requirements for general purpose "off-the-shelf"

COTS (commercial off-the-shelf) passive components for aerospace, defence and high

performance (ADHP) applications.

This document applies to all passive components that can be operated in ADHP applications

within the manufacturers’ publicly available data sheet limits in conjunction with

IEC TS 62239-1. This document can be used by other high performance and high reliability

industries, at their discretion.

ADHP application requirements are not necessarily fulfilled by this document alone. ADHP

original equipment manufacturers (OEMs) could consider redesigning their products or

conducting further testing to verify suitability in ADHP applications using their procedures for

satisfying their electronic component management plan (ECMP) (see IEC TS 62239-1).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

JESD48, Product discontinuance

J-STD-609B, Marking, symbols, and labels of leaded and lead-free terminal finished materials

used in electronic assembly

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp.

3.1.1

calendar days, pl.

continuous days, including weekends and holidays

3.1.2

container

outer shipping container consisting of one or more inner containers

3.1.3

data sheet

document prepared by the manufacturer that describes the electrical, mechanical, and

environmental characteristics of the component

3.1.4

deviation

user agreement to allow the delivery of a shipping lot which does not fully meet the

requirements of this document

Note 1 to entry: This is considered equivalent to concession for the purposes of this document.

3.1.5

device specification

document written by a user and agreed by the supplier

3.1.6

form

shape, size, dimensions, and other physically measurable parameters that uniquely

characterize a product

[SOURCE: IEC TS 62239-2:2017, 3.1.23]

3.1.7

fit

ability to physically interface or connect with

3.1.8

function

action or actions that a product is designed to perform

[SOURCE: IEC TS 62239-2:2017, 3.1.25]

3.1.9

incoming lot

one or more shipments of a device, grouped together for the purpose of incoming inspection

3.1.10

inner container

box or bag containing devices, either in magazines or bulk packaged

3.1.11

magazine

shipping container that feeds into automatic placement machines

EXAMPLE: Sticks, tubes, matrix trays, tape/reel, etc.

3.1.12

component

device

electrical or electronic device that is not subject to disassembly without destruction or

impairment of design use and is a small circuit having a high equivalent circuit element

density

– 10 – IEC TS 62686-2:2019 © IEC 2019

Note 1 to entry: It is considered as a single part composed of interconnected elements on or within a single

substrate to perform an electronic circuit function.

Note 2 to entry: This excludes printed wiring boards/printed circuit boards, circuit card assemblies and modules

composed exclusively of discrete electronic components.

3.1.13

manufacturing lot

definite quantity of devices tracked at each manufacturing operation

Note 1 to entry: A manufacturing lot is associated with a travel log and constitutes a group homogeneously

processed through all manufacturing operations under uniform manufacturing conditions.

3.1.14

moisture sensitivity level

MSL

rating indicating a component’s susceptibility to damage due to absorbed moisture when

subjected to reflow soldering

3.1.15

original component manufacturer

OCM

company specifying and manufacturing the electronic component

[SOURCE: IEC TS 62668-1:2016, 3.1.13]

3.1.16

OEM

original equipment manufacturer

manufacturer which defines the electronic subassembly that includes the electronic

components or defines the components used in an assembly and/or test specification

[SOURCE: IEC TS 62668-1:2016, 3.1.14]

3.1.17

passive component

component that does not require electrical power to operate (for example not capable of

power gain)

Note 1 to entry: For the purposes of this document, the term ’passive’ is restricted to capacitors and resistors.

3.1.18

room temperature

temperature identified at 25 °C ± 5 °C in a room

3.1.19

shipping lot

single lot of one or more containers received by a user

3.1.20

supplier

company which provides to another an electronic component which is identified by the logo or

name marked on the device

Note 1 to entry: A supplier can be the OCM, a franchised distributor or agent, a non-franchised distributor,

broker, reseller, OEM, CEM and EMS etc.

[SOURCE: IEC TS 62686-1:2015, 3.1.19]

3.1.21

termination

element of a component that connects it electrically and mechanically to the next level of

assembly

3.2 Abbreviated terms

AC alternating current

ADHP aerospace, defence and high performance

AEC Automotive Electronics Council

AOQ average out-going quality

AQEC aerospace qualified electronic component

AQL acceptable quality level

CB certification body

CECC CENELEC electronic components committee

CFC chlorofluorocarbon

COTS commercial off-the-shelf

DC direct current

DFMEA design failure modes and effect analysis

DLA Defense Logistics Agency (see http://www.dscc.dla.mil/)

DPM defects per million

DVP&R design verification plan and report

ECMP electronic component management plan

EHS environmental health and safety

EMAS Eco-Management and Audit Scheme (established by the European Union)

ESD electrostatic discharge

FFF form, fit and function

FIT failures in time

GR&R gage repeatability and reproducibility analysis

h hour

HAST highly accelerated stress test

HBM human body model

HTOL high temperature operating life

IATF International Automotive Task Force

IECQ International Electrotechnical Commission Quality Assessment System for

Electronic Components

I/O input and output

IR infra-red

LTB last time buy

LTPD lot tolerance percent defective

min minute

MSA measurements system analysis

MSL moisture sensitivity level

OCM original component manufacturer

OEM original equipment manufacturer

PC preconditioning

– 12 – IEC TS 62686-2:2019 © IEC 2019

PCB printed circuit board

PCN product or process change notification

PFMEA process failure modes and effects analysis

Pkg package

PPAP part production approval process

QA quality assurance

QPL qualified parts list

REACh registration, evaluation, authorization and restriction of substances

RoHS restriction of hazardous substances

SMD surface mount device

SPC statistical process control

T ambient temperature

amb

TC test code

T minimum operating temperature

opmin

T maximum operating temperature

opmax

UCT upper category temperature

4 Technical requirements

4.1 General

4.1.1 Overview

The supplier, preferably the franchised distributor or original component manufacturer (OCM),

as defined in 3.1.20 and 3.1.15, shall have an appropriate quality management system and

shall provide the following minimum technical requirements. Other proposed equivalent test

methods, rationale and supporting data shall be reviewed and shall achieve the same end

objectives as specified herein (see 4.4.4). The supplier or OCM shall provide a high-level

statement summarising how compliance to the specification is achieved including the use of

equivalent test methods (see 4.1.2), when they are used.

NOTE 1 ISO 9001 or AS/EN/JISQ 9100 can assist with compliance to this clause.

NOTE 2 In case the COTS passive components cannot be procured directly from the OCM (for example if too

small a quantity), the franchised distribution network is usually privileged with regard to potential risks (for example

lack of traceability and counterfeiting).

Informative annexes are provided at the end of this document and their contents are subject

to change. Users of this document are encouraged to review the latest data available

whenever referencing the content of these annexes:

• Informative Annex A: Test code (TC) information;

• Informative Annex B: Typical IECQ-CECC approved passive components;

• Informative Annex C: Typical USA military specified passive components;

• Informative Annex D: Typical automotive component;

• Informative Annex E: Typical IEC specified passive components;

• Informative Annex F: Verification requirements matrix for IEC TS 62686-2.

4.1.2 Equivalent methods

4.1.2.1 General

Use of such equivalent tests shall not be considered to be deviations or waivers to the

requirements of this document and are based on:

• IECQ-CECC approved components, see 4.1.2.2;

• automotive components see 4.1.2.3;

• IEC passive components see 4.1.2.4.

4.1.2.2 IECQ-CECC approved components

IECQ approved components to CECC specifications meet the requirements of this

specification, see the guidance in Annex C.

NOTE 1 The IECQ assesses and approves manufacturers to CECC specifications, which are listed on the IECQ

on-line certificate system for ‘Approved Component’ under the ‘Component’ section.

NOTE 2 USA military specified components are considered equivalent to the IECQ-CECC approved components

where the DLA assesses and approves manufacturers which are listed on qualified parts lists (QPLs), see annex A

for more guidance.

4.1.2.3 Automotive components

Automotive components which are typically manufactured on IATF 16949 certified

manufacturing lines and qualified to AEC-Q200, for temperature grades 0, 1, 2, and 3, with

the outgoing quality requirements typically included in a production part approval process

(PPAP) process and with the obsolescence and product change notification as specified

herein may meet the requirements of this specification, see Annex D for guidance.

NOTE 1 The IECQ automotive qualification programme can be expanded to cover this category of automotive

component.

NOTE 2 The VDA 6 series assessment, particularly VDA 6.3, Process audit, can be used for the PPAP element of

the IECQ assessment process.

4.1.2.4 IEC passive component specifications

Passive components specified by IEC meet most of the qualification requirements of this

specification, see the guidance in Annex E. However, the qualification test method durations

and sample sizes may be different and the other requirements of Clause 4 may not always be

met. An assessment and closure of any gaps in requirements will be required before claiming

compliance to this specification.

NOTE 1 These components are controlled by zero defect test schedules and are 100 % tested as finished

components.

NOTE 2 Currently there is no IECQ assessment scheme for these components.

4.2 Procedures

4.2.1 General

The OCM shall have the following procedures:

• product discontinuance (4.2.2);

• ESD protection during manufacture (4.2.3);

• specification control (4.2.4);

• traceability including anti-counterfeit measures (4.2.5).

– 14 – IEC TS 62686-2:2019 © IEC 2019

4.2.2 Product discontinuance

Notification shall be made for example in accordance with JESD48 or equivalent, with the

exception of timing as described in a) and b) below:

a) the OCM or supplier shall provide to the user a notice of last order dates:

• a minimum of 12 months before these dates for single-source devices, and

• a minimum of 6 months before these dates for multi-sourced devices;

b) the OCM or supplier may give less than the specified notice period provided a mutually

acceptable extension (up to the specification limit) is negotiated with any user needing a

different period.

4.2.3 ESD protection during manufacture

Many passive components are considered to be sensitive to static and shall be protected

through the OCM’s manufacturing operation. The OCM and supplier shall ensure that devices

are not exposed to static damage and are not degraded or damaged due to static discharge.

IEC 61340-3-1, IEC 61340-5-1, IEC TR 61340-5-2, JESD625 or AEC-Q200-002 are examples

of suitable documents for ESD precautions. OCMs and suppliers holding current certification

for compliance with IEC 61340-5-1 are deemed to have satisfied this requirement.

4.2.4 Traceability

Traceability shall be managed as follows:

a) the OCM and supplier shall have traceability for any device in a shipping lot through a

route code, lot code or other marking on the device or magazine or inner container to

identify the manufacturing route, for example manufacturing location, assembly location,

test location, date code and lot code;

b) the information needed to interpret the code shall be available for example according to

IEC 60062;

c) the procedure shall be available for inspection during audit.

The OCMs and suppliers shall use anti-counterfeit measures to protect their intellectual

property, such as use of registered trademarks, logos, patents, etc. The OCM and supplier

shall also assist the user in determining if the product is genuine when requested and in

identifying the franchised distributors.

4.3 Shipment controls

4.3.1 General

The OCM‘s name, logo and trademark shall be marked on the shipping container where it is

practical to do so.

4.3.2 Unit pack container

The packing for shipment needs to preserve the integrity of goods inside:

a) unit pack container configurations should be in accordance with existing industry

practices;

b) components should be oriented in the same direction, in all unit pack containers.

NOTE Industry standards such as EIA-481, EIA-468, EIA-296, EIA-948, EIA-960 can be used to provide guidance

for 4.3.2.

4.3.3 Intermediate packing

An intermediate container packing process should be designed to eliminate the presence of

partial quantities.

4.3.4 Date codes

4.3.4.1 Mixing

As a preferred methodology, there should be no more than one date code per unit pack

container. If this is not possible, then there should be no more than two date codes in one unit

pack container. If two date codes are used, the unit pack container should be clearly labelled

as having mixed date codes and labels need to indicate the quantity for each date code.

If possible, there should be no more than three date codes per sealed intermediate by date

code. The label on the intermediate container should list all date codes and quantities by date

code.

4.3.4.2 Remarking

If the date of assembly and test are both marked, the test date can be remarked if the device

is re-tested at a later date. If only one date is marked to represent the manufacturing date and

initial electrical test it shall not be changed unless it is necessary to correct poor quality

marking or incorrect information and provided that the time delta between the original mark

and the remark in less than 6 weeks.

4.3.4.3 Age on delivery

Date code age on delivery shall be as follows where shipped directly from the OCM or

supplier:

a) the date codes of devices shall not be older than 48 months upon users’ receipt date;

b) the exception is for aluminium electrolytic capacitors which shall not be older than

24 months.

4.3.5 Moisture sensitivity level (MSL)

The labelling and inner container, used for example for shipping, shall be in accordance with

IEC 61760-4 or J-STD-033 or equivalent standard.

4.3.6 Lead-free marking

The shipping container and date code marking shall be in accordance with J-STD-609B or

equivalent.

4.3.7 Labels

In general, labels shall include the requirements mentioned in Table 1 and exhibit:

a) human readable content: the content shown for each label shall be available in human

readable form on the outside of the relevant package;

b) machine readable content: bar codes for those items specified shall be included in 3 of

9 codes (bar code 39) according to IEC 62090 or ANSI/EIA-556 or equivalent compatible

standard;

c) warning notice: any necessary warning notices or symbols to ensure the safety of the

contents shall be included as appropriate.

– 16 – IEC TS 62686-2:2019 © IEC 2019

Table 1 – Label requirements

Dry pack label: Bar

code

• Date of sealing and sealed life or expiration date.

• Time and storage condition limits after opening.

• Bake conditions if usage conditions after opening are violated.

• Moisture sensitivity classification according to IEC 61760-4 or J-STD-020.

Outer container label: this label is typically implemented as a shipping note or packing list attached

to the outer container:

• Delivery address.

• Purchase order number. *

*

• User part number.

a

*

• OCM’s device type number .

a

• OCM’s name .

b

• Export Control Certification number and controlling authority . *

a

• Quantities enclosed of each device type .

Inner container label:

• OCM’s device type number. *

b

• User part number . *

b

*

• Purchase order number .

• Quantity of devices. *

• Date code. *

*

• Lot number.

b

• Assembly location .

b

• Test location .

a

For security reasons, can be omitted by agreement of the user.

b

Preferred but not mandatory.

4.3.8 Electrostatic discharge (ESD)

The symbols and labelling used for marking shall be in accordance with IEC 61340-5-3 or

ANSI/EIA-471 or equivalent standard.

For their ESD protection, all devices shall be supplied in suitable protective packaging with

electrostatic properties meeting the requirements of IEC 61340-5-3 or ANSI/EIA-541.

All packaging should be static safe (non-generative as a minimum) to safeguard sensitive

products occupying the same manufacturing areas.

4.4 Product or process change notification (PCN)

4.4.1 General

The OCM shall provide the following:

• notification (4.4.2);

• notification details (4.4.3).

4.4.2 Notification

In the event of the OCM proposing or making a change to a device, then:

a) the OCM and/or supplier shall give at least 90 calendar days' written notice prior to

shipping the changed product. The user will respond to confirm the date on which the

changed product shipments can begin (this could be less than 90 calendar days), advise

that the changed product is not acceptable, or request further information;

b) where an event beyond the control of the OCM occurs, where the 90 calendar days’ notice

cannot be given, the OCM or supplier shall reach a mutually agreed lesser notice period

with any user affected by the change

NOTE AEC-Q200 process change notification satisfies this requirement.

4.4.3 Notification details

The PCN shall include the following items:

a) title of change;

b) OCM’s type number(s) affected;

c) OCM’s notification identification number;

d) estimated last order and shipment dates for unchanged devices to be supplied on request;

e) estimated earliest shipment date of changed devices;

f) manufacturing location and product line affected;

g) thorough description of the proposed change;

h) means of distinguishing changed devices from unchanged devices. This may be a date

code, lot code, date code range or distinguishing marking or feature that is visible to the

user at point of receipt of shipment;

i) sufficient engineering and/or qualification test data, including details of any qualification

test vehicle used and its applicability to the product change. These shall be available on

request to demonstrate that the change will not adversely affect device form, fit, function,

quality or reliability, and that the changed product will continue to meet the specified

requirements;

j) user part number of the affected device (preferred item but not mandatory).

4.5 Electrical

4.5.1 General

Operating conditions shall be as defined in the device specification or data sheet, as

explained in 4.5.2.

4.5.2 Electrical test

All shipped packaged devices shall have passed a production electrical test progra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...