IEC TS 62647-4:2018

(Main)Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 4: Ball grid array (BGA) re-balling

Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 4: Ball grid array (BGA) re-balling

IEC TS 62647-4:2018(E) defines the requirements for replacing solder balls on ball grid array (BGA) component packages in the context of an electronic components management plan (ECMP) for aerospace, defence and high reliability products. The intent of this document is to provide re-balling companies (hereinafter referred to as the re-balling provider) with the administrative and technical requirements to be incorporated within existing processes or for establishing, implementing and maintaining a new set of processes or the creation of a stand-alone re-balling process.

General Information

- Status

- Published

- Publication Date

- 09-Apr-2018

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 1 - TC 107/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Apr-2018

- Completion Date

- 25-Apr-2018

Overview

IEC TS 62647-4:2018 - Process management for avionics: Part 4 - Ball grid array (BGA) re-balling defines administrative and technical requirements for replacing solder balls on Ball Grid Array (BGA) component packages within an Electronic Components Management Plan (ECMP) for aerospace, defence and other high‑reliability systems. The Technical Specification provides guidance for re-balling providers to establish, implement and maintain a re-balling process that supports lead‑free solder requirements and the stringent traceability, quality and configuration controls expected in avionics and defence electronics.

Key topics and technical requirements

This TS focuses on process control and traceability across the BGA re-balling lifecycle. Major topics include:

- Process approach and typical workflow for de‑balling and re‑balling operations, including flowcharts and process-awareness requirements.

- Customer and re‑balling provider responsibilities, including roles within an ECMP and order of precedence for contractual requirements.

- Inspection and incoming control for received BGA components and separate solder balls (acceptance, visual inspection, and documentation).

- De‑balling and re‑balling procedures: temperature control, preheat, flux and solder paste selection, ball placement (alignment and co‑planarity), reflow profiles, cooling, and post‑process cleaning.

- Environmental and handling controls: electrostatic discharge (ESD) protection, moisture/reflow sensitivity management, facility and personnel proficiency requirements.

- Quality, records and configuration management: lot records, process monitoring, failure handling, segregation and packaging/shipping of re‑balled BGAs.

- Qualification and testing: new part‑number qualification, similarity assessments, production lot tests and test methods (see Annex C), with templates for tailoring test plans (Annexes A, B, D).

- Counterfeit prevention and traceability obligations and procedures.

Practical applications

IEC TS 62647-4 is used to:

- Establish or audit a BGA re‑balling process for lead‑free solder environments in avionics/defence programs.

- Support obsolescence mitigation and component repair strategies for high‑reliability PCBs where replacement parts are unavailable.

- Ensure compliance with ECMPs and customer quality requirements for military, aerospace and other safety‑critical electronics.

- Define acceptance criteria, test plans and documentation standards for suppliers performing re‑balling as a subcontracted service.

Who should use this standard

- BGA re‑balling providers, repair centres and subcontractors

- Aerospace and defence OEMs, supply chain quality and procurement teams

- Engineering, reliability and obsolescence managers for high‑reliability electronics

- Quality auditors and certification assessors working to ECMP requirements

Related standards

- Other parts of the IEC 62647 series covering process management for avionics and lead‑free soldered systems.

- Referenced normative documents and test methods listed inside the TS for complete implementation and compliance.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC TS 62647-4:2018 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 4: Ball grid array (BGA) re-balling". This standard covers: IEC TS 62647-4:2018(E) defines the requirements for replacing solder balls on ball grid array (BGA) component packages in the context of an electronic components management plan (ECMP) for aerospace, defence and high reliability products. The intent of this document is to provide re-balling companies (hereinafter referred to as the re-balling provider) with the administrative and technical requirements to be incorporated within existing processes or for establishing, implementing and maintaining a new set of processes or the creation of a stand-alone re-balling process.

IEC TS 62647-4:2018(E) defines the requirements for replacing solder balls on ball grid array (BGA) component packages in the context of an electronic components management plan (ECMP) for aerospace, defence and high reliability products. The intent of this document is to provide re-balling companies (hereinafter referred to as the re-balling provider) with the administrative and technical requirements to be incorporated within existing processes or for establishing, implementing and maintaining a new set of processes or the creation of a stand-alone re-balling process.

IEC TS 62647-4:2018 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62647-4:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62647-4 ®

Edition 1.0 2018-04

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 4: Ball grid array (BGA) re-balling

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62647-4 ®

Edition 1.0 2018-04

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 4: Ball grid array (BGA) re-balling

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-8322-5530-8

– 2 – IEC TS 62647-4:2018 © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 9

4 Process approach . 12

4.1 Typical process . 12

4.2 Awareness . 14

5 General requirements . 14

5.1 Process control at the customer level . 14

5.1.1 Customer’s responsibilities . 14

5.1.2 Electronic components classes . 14

5.2 Process control at re-balling provider level . 15

5.2.1 Re-balling provider’s responsibilities . 15

5.2.2 Electronic component classes . 15

5.2.3 Counterfeit prevention and traceability management . 15

5.2.4 Quality . 16

5.2.5 Records . 16

5.2.6 Facility requirements . 16

5.2.7 Electrostatic discharge (ESD) . 16

5.2.8 Physical handling of BGA components . 16

5.2.9 Moisture/reflow sensitivity . 16

5.2.10 Configuration management . 17

5.2.11 Personnel proficiency . 17

5.2.12 Order of precedence . 17

5.3 Customer and re-balling provider relationship . 17

6 Technical requirements . 17

6.1 Receipt of BGA components and separate balls . 17

6.1.1 General . 17

6.1.2 Incoming inspection of BGA components . 17

6.1.3 Incoming inspection of separate solder balls . 19

6.2 Specific analysis based on component balls alloy . 19

6.3 BGA component de-balling. 20

6.3.1 General . 20

6.3.2 Temperature excursions . 20

6.3.3 Flux . 20

6.3.4 Preheat. 20

6.3.5 Solder balls removal (de-balling) . 20

6.3.6 Cool down . 21

6.3.7 Cleaning (post de-balling) . 21

6.3.8 Complete removal and cleanliness verification . 21

6.4 BGA component re-balling . 21

6.4.1 General . 21

6.4.2 Capability . 21

6.4.3 Solder paste . 22

6.4.4 Flux . 22

6.4.5 Ball placement (alignment and co-planarity) . 22

6.4.6 Preheating . 22

6.4.7 Reflow temperature profile . 22

6.4.8 Cooling down . 22

6.4.9 Cleaning (post re-balling) . 23

6.5 Post-process inspection of re-balled BGA components . 23

6.5.1 General . 23

6.5.2 Production lot tests . 23

6.5.3 Process monitoring and control . 23

6.5.4 Case of failures . 24

6.5.5 Records . 24

6.6 Rework . 24

6.6.1 General . 24

6.6.2 Rework if authorized by the customer . 24

6.7 New BGA component part number qualification . 24

6.7.1 General . 24

6.7.2 New BGA component part number qualification by similarity . 25

6.7.3 New BGA component part number qualification . 25

6.7.4 Records . 26

6.7.5 Customer’s approval . 26

6.7.6 Cases of BGA component re-qualification . 26

6.8 Physical marking . 27

6.9 Packaging and shipping . 27

6.10 Re-balled BGA components segregation . 27

Annex A (informative) Template for tailoring the requirements of IEC TS 62647-4. 28

Annex B (informative) Requirement matrix for IEC TS 62647-4 . 29

Annex C (normative) Test methods . 37

Annex D (informative) Template for test methods tailoring in the frame of a BGA

component production lot test plan or a new BGA component part number qualification

test plan . 39

Bibliography . 40

Figure 1 – Typical flowchart of de-balling/re-balling operations . 13

Table 1 – Electronic component class . 14

Table 2 – Typical control and inspection test methods . 19

Table 3 – Typical production lot test methods . 23

Table 4 – Typical test methods for process monitoring and control . 24

Table 5 – Typical test methods used for inspection of re-balled BGA components

within the framework of new BGA component part number qualification . 25

Table 6 – Typical optional additional tests for new BGA component part number

qualification . 26

Table A.1 – Template for tailoring of requirements . 28

Table B.1 – Requirement matrix . 29

Table C.1 – Test methods . 37

Table D.1 – Template for requirements tailoring . 39

– 4 – IEC TS 62647-4:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 4: Ball grid array (BGA) re-balling

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62647-4, which is a Technical Specification, has been prepared by IEC technical

committee 107: Process management for avionics.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

107/314/DTS 107/331/RVDTS

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62647 series, published under the general title Process

management for avionics – Aerospace and defence electronic systems containing lead-free

solder, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC TS 62647-4:2018 © IEC 2018

INTRODUCTION

As the result of RoHS directives, soldering assembly processes have migrated predominantly

from tin-lead to Pb-free, and a majority of BGA components manufacturers have converted

from tin-lead solder balls to Pb-free solder balls. This has introduced well documented

reliability concerns. In the case of a leaded soldering process, a solution can be to replace the

Pb-free solder balls on the BGA components with tin-lead solder balls. This will prevent

mixing solder alloys.

This document was prepared to standardize the requirements and guidelines for replacing the

solder balls on applicable BGA components. The requirements within this document are

derived from existing industry standards and a collaboration of service providers and

customers, typically avionics original equipment manufacturers (OEMs).

This document is intended to be used by de-balling/re-balling providers and customers to

incorporate these requirements into their operations to provide a consistent and well-

controlled process, or to create a de-balling/re-balling plan that augments their existing

processes.

There are two major reasons to de-ball/re-ball BGA components: alloy compatibility and

replacement of damaged balls.

The customer should understand the potential risks of the BGA de-balling/re-balling process

for a specific package.

To avoid reliability problems, the BGA de-balling/re-balling process should be qualified and

carefully controlled to prevent the possibility of BGA failure after re-balling. Generally,

automated processes contribute positively to this objective and are encouraged in the

electronic industry.

This document does not guarantee a particular yield or reliability of BGA components going

through the de-balling/re-balling process. BGA component construction and materials used

should be evaluated for compatibility with the solder re-balling process to ensure that BGA

component reliability and integrity are maintained.

Because of the dynamic nature of the transition to lead-free (Pb-free) electronics, this and

other similar documents are based on the best information and expertise available; its update

will be considered as future knowledge and data are obtained.

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 4: Ball grid array (BGA) re-balling

1 Scope

This part of IEC 62647, which is a Technical Specification, defines the requirements for

replacing solder balls on ball grid array (BGA) component packages in the context of an

electronic components management plan (ECMP) for aerospace, defence and high reliability

products.

NOTE 1 IEC TS 62239-1 and EIA-STD-4899 describe the electronic components management program (ECMP).

It does not apply to column grid array (CGA) components or chip scale components.

This re-balling document addresses two types of configurations. For other configuration types,

see Annex A for tailoring.

• Configuration 1: A BGA package that will be de-balled and then re-balled with tin-lead

balls compatible with a tin-lead soldering assembly process.

• Configuration 2: A BGA package that will be de-balled and then re-balled with Pb-free

balls compatible with a Pb-free soldering assembly process.

The intent of this document is to provide re-balling companies (hereinafter referred to as the

re-balling provider) with the administrative and technical requirements to be incorporated

within existing processes or for establishing, implementing and maintaining a new set of

processes or the creation of a stand-alone re-balling process.

This document is intended to be used by de-balling/re-balling providers and customers,

typically avionics original equipment manufacturers (OEM); it defines the requirements for re-

balling providers who are providing services to the aerospace, defence, high performance and

high reliability electronics industry.

Requirements for new BGA component part number qualification are also included. This

document identifies the need for the creation of new part numbers for re-balled BGA

components, covers process and testing requirements for the de-balling/re-balling process

and encourages the automated processes due to the ability to control the process.

Companies engaged in re-balling are supposed to have the necessary knowledge, experience

and tools, and to customize if needed their own methods for defining a de-balling/re-balling

process that meets the requirements in this document.

Each customer determines the applicability of this document and the need for full replacement

of the existing solder balls. Some applications can have unique requirements that exceed the

scope of this document and are therefore specified separately.

This document is not intended to address all procedures and processes associated with a de-

balling/re-balling facility; it is assumed there are management, quality, manufacturing, safety,

calibration and training processes/procedures in place as well as all the necessary tools and

equipment to accomplish the work.

NOTE 2 For the purposes of this document, if the term “BGA” is used alone, it is stated as “BGA component".

– 8 – IEC TS 62647-4:2018 © IEC 2018

NOTE 3 The replacement, for example, of damaged tin-lead balls by new tin-lead balls or damaged Pb-free balls

by new Pb-free balls is not specifically addressed in this document but some parts of the document and the table

for tailoring the requirements (see Annex A) can be used for supporting the operations.

Although developed for the avionics industry, this process can be applied by other industrial

sectors at their discretion.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 61340-5-1, Electrostatics – Part 5-1: Protection of electronic devices from electrostatic

phenomena – General requirements

IEC TR 61340-5-2, Electrostatics – Part 5-2: Protection of electronic devices from

electrostatic phenomena – User guide

IEC 62090, Product package labels for electronic components using bar code and two-

dimensional symbologies

IEC 62668 (all parts), Process management for avionics – Counterfeit prevention

AEC-Q100-010, Solder ball shear test

ANSI/ESD S20.20, Protection of Electrical and Electronic Parts, Assemblies and Equipment

(Excluding Electrically Initiated Explosive Devices)

ECA/IPC/JEDEC J-STD-075, Classification of Non-IC Electronic Components for Assembly

Processes

IPC J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies

IPC J-STD-001xS , Space Applications Electronic Hardware Addendum to IPC J-STD-001x

Requirements for Soldered Electrical and Electronic Assemblies

IPC J-STD-002, Solderability Tests for Component Leads, Terminations, Lugs, Terminals and

Wires

IPC J-STD-004, Requirements for Soldering Fluxes

IPC J-STD-005, Requirements for Soldering Pastes

IPC/JEDEC J-STD-020, Moisture/Reflow Sensitivity Classification for Non-hermetic Solid

State Surface Mount Devices

IPC/JEDEC J-STD-033, Handling, Packing Shipping and Use of Moisture/Reflow Sensitive

Surface Mount Devices

IPC/JEDEC J-STD-035, Acoustic Microscopy for Non-Hermetic. Encapsulated. Electronic.

Components

___________

In « IPC J-STD-001xS » the « x » refers to the issue of the IPC J-STD-001 document ; for exemple « IPC J-

STD-001FS » refers to « IPC JST-001F » (issue F).

IPC-TM-650 number 2.3.25, Test Methods Manual – Detection and Measurement of Ionizable

Surface Contaminants by Resistivity of Solvent Extract (ROSE)

JEDEC J-STD-046, Customer Notification of Product/Process Changes by Electronic Product

Suppliers

JEDEC JESD625, Requirements for Handling Electrostatic-Discharge-Sensitive (ESDS)

Devices

JEDEC JESD22-A101, Steady State Temperature Humidity Bias Life Test

JEDEC JESD22-B101, External visual

JEDEC JESD22-B107, Mark Permanency

JEDEC JESD22-B117, Solder Ball Shear

JEDEC JESD213, Standard Test Method Utilizing X-ray Fluorescence (XRF) for Analyzing

Component Finishes and Solder Alloys to Determine Tin (Sn) – Lead (Pb) Content

MIL-STD-883, Test Method Standard: Microcircuits

SAE AS5553, Counterfeit Electronic Parts; Avoidance, Detection, Mitigation, and Disposition

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

AM

acoustic microscopy

microscopy that employs very high or ultra-high frequency ultrasound

Note 1 to entry: Acoustic microscopy is a technical field where the acoustic microscope operates non-

destructively and penetrates most solid materials to make visible images of internal features, including defects

such as cracks, delaminations and voids; the acoustic microscope is generally called “scanning acoustic

microscope (SAM)”.

3.2

approved supplier

organization selling or supplying materiel, parts, products or provision of a service, which has

been determined capable by a procuring organization to deliver throughout the lifetime of a

contract

3.3

BGA

ball grid array

surface mount package wherein the balls for terminations are formed in a grid on the bottom

of a package

Note 1 to entry: There are different varieties of BGA packages and solder ball technologies such as CBGA,

PBGA, TBGA packages.

– 10 – IEC TS 62647-4:2018 © IEC 2018

3.4

CBGA

ceramic ball grid array

BGA package with a ceramic body

3.5

declaration of conformance

document certified by a competent authority that the supplied good or service meets the

required specifications

Note 1 to entry: Declaration of conformance can also be called certificate of conformance; the competent

authority can be the original manufacturer of the supplied good or service.

3.6

CTE

coefficient of thermal expansion

degree of expansion of a material divided by the change in temperature

Note 1 to entry: PCB/PWB CTE (x-y) is measured in the direction in the plane of the piece part mounting surface

and is used to quantify the stresses in the solder joint arising from the differences in CTE between the piece parts

and the PCB/PWB during thermal cycling. CTE (z axis) is measured in the “thickness” direction and is typically

used to quantify plated through hole stress

Note 2 to entry: The term “piece part” can be used in lieu of “component”.

[SOURCE: IEC TS 62647-22:2013, 3.1.8, modified – Note 2 has been added.]

3.7

customer

one who pays for the service or the services provided by another

3.8

de-balling

process operation that consists in removing the solder balls from a BGA

3.9

HIC

humidity indicator card

card on which a moisture-sensitive chemical is applied such that it will make a significant,

perceptible change in color (hue), typically from blue (dry) to pink (wet) when the indicated

relative humidity is exceeded

3.10

Pb-free

lead-free

less than 0,1 % by weight of lead (Pb) in accordance with reduction of hazardous substances

(RoHS) guidelines

[SOURCE: IEC TS 62647-1:2012, 3.8, modified – "lead-free" has been added as a second

term.]

3.11

MSL

moisture sensitivity level

alphanumeric rating indicating a plastic electronic device’s susceptibility to damage due to

absorbed moisture when subjected to reflow soldering as determined by IPC/JEDEC J-STD-

3.12

OCM

original component manufacturer

company specifying and manufacturing the electronic component

[SOURCE: IEC TS 62668-1:2016, 3.1.13]

3.13

part number

unambiguous identifier

Note 1 to entry: A part number unambiguously identifies for example an electronic component, a design, or an

equipment.

3.14

PCB

printed circuit board

PWB

printed wiring board

substrate using conductive pathways, tracks or signal traces etched from copper sheets

laminated, and allowing to connect electrically a set of electronic components to realize a

circuit card

[SOURCE: IEC TS 62647-21:2013, 3.1.10]

3.15

PBGA

plastic ball grid array

BGA with a plastic body

3.16

qualification by similarity

act of qualifying a product part number based on already available testing results which have

been used to deliver the qualification to another product part number whose technical

characteristics are considered similar or practically similar

Note 1 to entry: Qualification by similarity may apply to a component part number when the component has

package and die sizes, construction and materials which are considered to be insignificantly different from an

already ”qualified” component part number.

3.17

re-balling

process operation that consists in putting back a solder ball in replacement of the previous

one on a ball grid array (BGA) package

3.18

re-balling provider

company offering de-balling and re-balling service

3.19

RoHS

European directive dealing with the restriction of the use of certain hazardous substances

Note 1 to entry: The RoHS directive is a European Union directive on the restriction of the use of certain

hazardous substances in electrical and electronic equipment.

– 12 – IEC TS 62647-4:2018 © IEC 2018

3.20

solder ball technology

technology employing solder balls or bumps at the component package level to make

mechanical and electrical connections between the component package and the PCB/PWB

EXAMPLE 1 Ball grid arrays (BGAs), flip chips and chip scale interconnections.

3.21

tin-lead

solder bearing the elements tin and lead, and corresponding to 63 % by weight of tin and

37 % by weight of lead unless otherwise specified

[SOURCE: IEC TS 62647-3:2014, 3.1.6]

3.22

TBGA

taped ball grid array

BGA on a tape substrate

Note 1 to entry: The tape is generally a polyimide film.

3.23

qualification

process for confirming and approving that a product or service meets the needs or

requirements of its user

Note 1 to entry: For the purposes of this document, the qualification process applies to manufacturing and

production operations and processes. It is generally based on objective evidence (for example tests results,

process parameters) demonstrating that the product requirements and the quality demands are met.

3.24

XRF

X-ray fluorescence

method for material composition analysis

[SOURCE: IEC TS 62647-2:2012, 3.1.28]

4 Process approach

4.1 Typical process

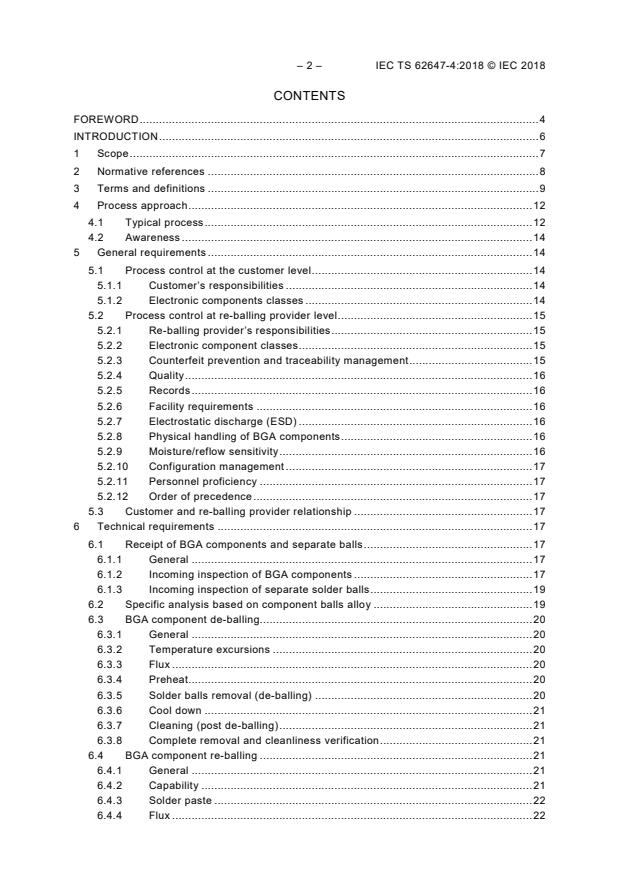

Figure 1 provides a typical flowchart for BGA de-balling/re-balling processes and operations

in accordance with the configurations 1 and 2 mentioned in Clause 1.

The process step 12a of Figure 1 addresses a new BGA component part number qualification

which is performed using the de-balling/re-balling process before launching production lots of

this new BGA component part number in a “production lot” mode; the process steps 4 to 11 of

Figure 1 apply and the customer’s approval of the qualification is based on results provided

by the re-balling provider (see 6.7).

The process step 12b addresses the inspection and control of re-balled BGA components in a

“production lot” mode.

1 – Start

No

2 – Is re-balling

3 – Approved re-balling provider

provider on approved

suppliers list

Yes

4 – Identify received base

component (BGA)

5 – Base component (BGA)

incoming inspection

No

Passed

16 – Stop

Yes

Alternative

6 – Base component (BGA)

ball composition

Configuration 2

Sn-Pb balls

Configuration 1

Pb-free balls

12a – New BGA

component part number

qualification

7 – Check if

10 – De-balling

base part can survive

the Pb-free reflow

temperature

Yes

No

Or Or

12b – Inspection,

11 – Re-balling for

8 – De-balling

marking and control

Sn-Pb balls

17 – Stop

or other

alternative Stop

14 – Packing

9 – Re-balling

13 – Marking 15 – End

and shipping

18 – Stop

for Pb-free balls

IEC

Figure 1 – Typical flowchart of de-balling/re-balling operations

Table B.1 provides a requirements matrix that may be used to document the accomplishments

of the requirements for IEC TS 62647-4.

The requirements of this document may be tailored to address the customer’s unique/specific

program needs. If tailoring is performed, the re-balling provider shall obtain the documented

customer’s approval. The customer is cautioned that tailoring the test plan by reducing the

sample sizes, eliminating the tests, or relaxing the acceptance criteria can result in

compromised reliability of the processed components. Annex A provides a tailoring template

that may be used.

– 14 – IEC TS 62647-4:2018 © IEC 2018

4.2 Awareness

As a reminder, BGA de-balling/re-balling process and operations can degrade the

performance and reliability of the electronic components as determined in the original

component manufacturer's (OCM) datasheet and/or technical data and lead to the loss of any

regular or extended warranty which is normally provided by the original component

manufacturer (OCM) regarding the electronic component use and storage. Consulting with the

OCM is recommended to determine if there are potential limitations concerning additional

reflow and re-processing of the BGA terminations.

5 General requirements

5.1 Process control at the customer level

5.1.1 Customer’s responsibilities

The re-balling provider shall be on the approved suppliers' list with an approved de-balling/re-

balling process.

If the re-balling provider is not on the approved suppliers' list the re-balling provider can assist

in gaining approval by demonstrating how its de-balling/re-balling process complies with the

requirements contained herein by mapping its demonstration data to the compliance

verification matrix contained in Annex B which can depend on the class assigned to the BGA

components (see 5.2.2) and any tailoring.

NOTE 1 Some customers might require for approval additional information that can include:

• process capability definition and description (including process flow chart);

• process monitoring definition and description;

• acceptance criteria definition for re-balled BGA component (for example co-planarity, ball size and shape, ball

shear strength and cleaning contamination level).

NOTE 2 Subclause 5.1 addresses the process steps 2 and 3 identified in Figure 1.

5.1.2 Electronic components classes

Electronic components are divided into four classes which define the levels of requirements.

Descriptions are provided in Table 1.

Table 1 – Electronic component class

Class Class description Class definition

a

1 General electronic products Products suitable for applications where the major requirement is

function of the complete assembly.

a

2 Dedicated service electronic Products where continued performance and extended life are

products required, and for which uninterrupted service is desired but not

critical. Typically the end-use environment would not cause

failures.

a

3 High performance/harsh Products where continued high performance or performance-on-

environment electronic products demand is critical, equipment downtime cannot be tolerated, end-

use environment can be uncommonly harsh, and the equipment

must function when required, such as life support or other critical

systems.

b

Space High performance/extremely Products where performance is required for surviving the vibration

severe environment electronic and thermal cyclic environments getting to and operating in space.

products

a

See IPC J-STD-001.

b

See IPC J-STD-001xS (Space Applications Electronic Hardware Addendum)

5.2 Process control at re-balling provider level

5.2.1 Re-balling provider’s responsibilities

The re-balling provider is responsible for the development and implementation of

requirements and procedures necessary to prevent damage and to control conditions for

passing the production tests (see 6.5) and to satisfy customer requirements (see 5.3).

If the re-balling provider plans to subcontract activities, it shall:

• inform the customer, consider subcontractor(s) which is(are) in its own approved suppliers

list, or in the customer-approved suppliers list if any, and request customer’s approval

with regard to the intended subcontracted activities;

• if approved by the customer, cascade all the requirements with regard to the potential

subcontractor(s) and subcontracted activities, and verify the implementation of

requirements.

5.2.2 Electronic component classes

Prior to processing, the re-balling provider shall obtain the component class from the

customer (see 5.1.2).

5.2.3 Counterfeit prevention and traceability management

5.2.3.1 Electronic component counterfeit prevention

If the re-balling provider is engaged in the procurement of BGA components

• the re-balling provider shall only purchase BGA components:

– direct from the original component manufacturers; or

– from franchised or authorized distributors with full traceability through the supply chain

to the original component manufacturer;

• if this is not possible, the re-balling provider shall:

– advise the customer;

– ask the customer where it purchases the BGA components in accordance with its anti-

counterfeit management plan or any other decision with regard to BGA components

procurement source;

• the re-balling provider shall, in any case, have a counterfeit electronic components

management plan/process which satisfies the requirements of IEC 62668 (all parts) and/or

SAE AS5553 or equivalent.

5.2.3.2 Materials, chemicals, components, and process tools and equipment

traceability

5.2.3.2.1 Materials and chemicals

All process materials and chemicals (balls, solder alloys, cleaning fluids, de-ionized water,

fluxes, etc.) shall be traceable to their original manufacturers.

5.2.3.2.2 BGA components

Changing solder ball metallurgy composition is considered a major change according to

JEDEC J-STD-046. New part numbers shall be created. Process lot traceability shall be

maintained and documented on all relevant paperwork and the smallest unit container. The

re-balling provider shall label the containers and shipping documentation of processed piece

parts in accordance with marking standard IEC 62090 or equivalent.

– 16 – IEC TS 62647-4:2018 © IEC 2018

5.2.3.2.3 Process tools and equipment

All tools and equipment used in the de-balling/re-balling process shall be identified and

traceable.

5.2.4 Quality

5.2.4.1 Quality standards

The re-balling provider shall have a documented quality system registered to an

internationally recognized quality management system. In addition, the de-balling and re-

balling process shall satisfy the applicable requirements of IPC J-STD-001.

NOTE 1 An internationally recognized quality management system can be the relevant parts of AS/EN/JISQ 9100

or equivalent.

NOTE 2 Usually the documented quality system includes technical operation procedures, non-conformance and

corrective actions aspects and configuration management, for example of materials, chemicals, tools and

equipment or processes.

5.2.4.2 Declaration of conformity

The re-balling provider shall have a process to provide at products deliveries a declaration of

conformity stating that the specified requirements (see 5.2.12) are met.

NOTE ISO/IEC 17050-1 can be a relevant document to assist the declaration of conformity process.

5.2.5 Records

Quality records, technical records (for example component qualification test results, control

results, process monitoring), lot travellers, change notices and all other documentation

generated during the de-balling/re-balling process shall be retained for a minimum period of

ten years unless otherwise required by the customer, and made available to the customer

upon request within five business days.

5.2.6 Facility requirements

In addition to having the tools and equipment necessary and maintained (for example

calibration) for de-balling and re-balling, the re-balling provider’s f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...