IEC 60404-2:1996

(Main)Magnetic materials - Part 2: Methods of measurement of the magneticproperties of electrical steel sheet and strip by means of anEpstein frame

Magnetic materials - Part 2: Methods of measurement of the magneticproperties of electrical steel sheet and strip by means of anEpstein frame

Applies to grain oriented and non-oriented electrical sheet and strip for a.c. measurements of magnetic properities at frequencies up to 400 Hz and for d.c. magnetic measurements. Defines the general principles and the technical details of the measurement of the magnetic properties of electrical steel sheet and strip by means of an Epstein frame. The a.c. magnetic characteristics are determined for sinusoidal induced voltages, for specified peak values of magnetic polarization and for a specified frequency.

Matériaux magnétiques - Partie 2: Méthodes de mesure des propriétésmagnétiques des tôles et bandes magnétiques au moyen d'un cadreEpstein

S'applique aux tôles et bandes magnétiques à grains orientés et non orientés, pour le mesurage des propriétés magnétiques en courant alternatif jusqu'à la fréquence de 400 Hz, et pour les mesures magnétiques en courant continu. Définit les principes généraux et les détails techniques du mesurage des propriétés magnétiques des tôles et bandes magnétiques au moyen d'un cadre Epstein. Les caractéristiques magnétiques en courant alternatif sont déterminées pour des tensions induites sinusoïdales, pour des valeurs crêtes particulières de la polarisation magnétique et pour une fréquence spécifiée.

General Information

- Status

- Published

- Publication Date

- 24-Jun-2008

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 2 - TC 68/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Mar-1996

- Completion Date

- 31-May-1996

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60404-2:1996 is an international standard established by the International Electrotechnical Commission (IEC) that defines standardized methods for measuring the magnetic properties of electrical steel sheets and strips. Specifically, it focuses on testing using the Epstein frame method for both grain-oriented and non-oriented electrical steel materials. The scope of this standard covers magnetic property measurements at frequencies up to 400 Hz for alternating current (AC) and direct current (DC) conditions. It ensures consistent and accurate characterization of magnetic materials essential in electrical engineering applications.

The standard applies to electrical steel used in critical components like transformers, motors, and generators, where magnetic performance influences energy efficiency and operational reliability. By standardizing measurement procedures, IEC 60404-2 facilitates product quality control, material comparison, and research development in magnetic materials technology.

Key Topics

Epstein Frame Method: The standard details the use of a 25 cm Epstein frame, a specialized test apparatus designed to measure magnetic characteristics of steel sheets and strips. This involves assembling standardized test specimens and applying sinusoidal induced voltages to determine magnetic polarization and other parameters.

AC Magnetic Measurements: IEC 60404-2 sets procedures for measuring AC magnetic properties, including specific total losses, peak magnetic polarization, and magnetic field strength values at frequencies up to 400 Hz. Measurements assume sinusoidal excitation and control ambient temperature to (23 ± 5) °C for accuracy.

DC Magnetic Measurements: It also covers techniques for DC magnetic property testing, involving magnetic polarization assessment and hysteresis loop determination using the Epstein frame under direct current magnetization.

Test Specimen Preparation: The standard specifies preparation instructions ensuring test specimens are correctly demagnetized and handled for reproducible and comparable results.

Measurement Procedures and Accuracy: Detailed protocols for power supply adjustment, voltage, frequency, and power measurements are provided, including guidelines for air flux compensation and reproducibility assessment.

Terminology and Definitions: The document aligns with IEC 60050-221 vocabulary relating to magnetic materials to maintain clarity and consistency in terms like "magnetic polarization".

Applications

IEC 60404-2:1996 is vital for manufacturers and researchers working with electrical steel materials used in electromagnetic devices. Its practical applications include:

Quality Control: Ensuring electrical steel sheets and strips meet predefined magnetic property requirements before they are incorporated into transformers, electric motors, generators, and inductors.

Material Development: Supporting R&D efforts by providing reliable magnetic measurements to evaluate the effects of processing techniques, alloying, and heat treatments on steel magnetic performance.

Standardized Testing: Facilitating international trade and regulatory compliance through harmonized test methods, enabling uniform quality assessment and material certification.

Performance Optimization: Assisting engineers in selecting electrical steel grades with optimal magnetic characteristics to maximize energy efficiency and reduce losses in electrical machines.

Related Standards

IEC 60404-2 references and complements other standards within the IEC 60404 series and related IEC documents for a comprehensive framework on magnetic materials:

IEC 60050-221: International Electrotechnical Vocabulary relating to magnetic materials and components, ensuring consistent terminology.

IEC 60404-4: Methods for measurement of DC magnetic properties of magnetically soft materials, expanding on the specific DC testing methods.

IEC 60404-8 Series: Specifications for individual electrical steel materials, including cold-rolled non-alloyed and alloyed steel sheets and strips.

IEC 60404-10: Guidelines for magnetic property measurements at frequencies higher than 400 Hz, where IEC 60404-2 is limited.

By adhering to IEC 60404-2 along with these associated standards, organizations can guarantee authoritative measurement methods and improve overall magnetic materials quality.

Keywords: IEC 60404-2, magnetic materials, electrical steel, Epstein frame, magnetic properties measurement, AC magnetic measurements, DC magnetic measurements, electrical steel testing, magnetic polarization, specific total loss, magnetic steel standards, IEC magnetic standards, electrical steel sheet and strip.

Buy Documents

IEC 60404-2:1996+AMD1:2008 CSV - Magnetic materials - Part 2: Methods of measurement of the magnetic properties of electrical steel strip and sheet by means of an Epstein frame Released:6/25/2008 Isbn:2831898358

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60404-2:1996 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Magnetic materials - Part 2: Methods of measurement of the magneticproperties of electrical steel sheet and strip by means of anEpstein frame". This standard covers: Applies to grain oriented and non-oriented electrical sheet and strip for a.c. measurements of magnetic properities at frequencies up to 400 Hz and for d.c. magnetic measurements. Defines the general principles and the technical details of the measurement of the magnetic properties of electrical steel sheet and strip by means of an Epstein frame. The a.c. magnetic characteristics are determined for sinusoidal induced voltages, for specified peak values of magnetic polarization and for a specified frequency.

Applies to grain oriented and non-oriented electrical sheet and strip for a.c. measurements of magnetic properities at frequencies up to 400 Hz and for d.c. magnetic measurements. Defines the general principles and the technical details of the measurement of the magnetic properties of electrical steel sheet and strip by means of an Epstein frame. The a.c. magnetic characteristics are determined for sinusoidal induced voltages, for specified peak values of magnetic polarization and for a specified frequency.

IEC 60404-2:1996 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60404-2:1996 has the following relationships with other standards: It is inter standard links to IEC 60404-2:1996/AMD1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60404-2:1996 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60404-2 ®

Edition 3.1 2008-06

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 2: Methods of measurement of the magnetic properties of electrical steel

strip and sheet by means of an Epstein frame

Matériaux magnétiques –

Partie 2: Méthodes de mesure des propriétés magnétiques des bandes et tôles

magnétiques en acier au moyen d'un cadre Epstein

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60404-2 ®

Edition 3.1 2008-06

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 2: Methods of measurement of the magnetic properties of electrical steel

strip and sheet by means of an Epstein frame

Matériaux magnétiques –

Partie 2: Méthodes de mesure des propriétés magnétiques des bandes et tôles

magnétiques en acier au moyen d'un cadre Epstein

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.20; 29.030 ISBN 2-8318-9835-8

− 2 − 60404-2 © IEC:1996+A1:2008

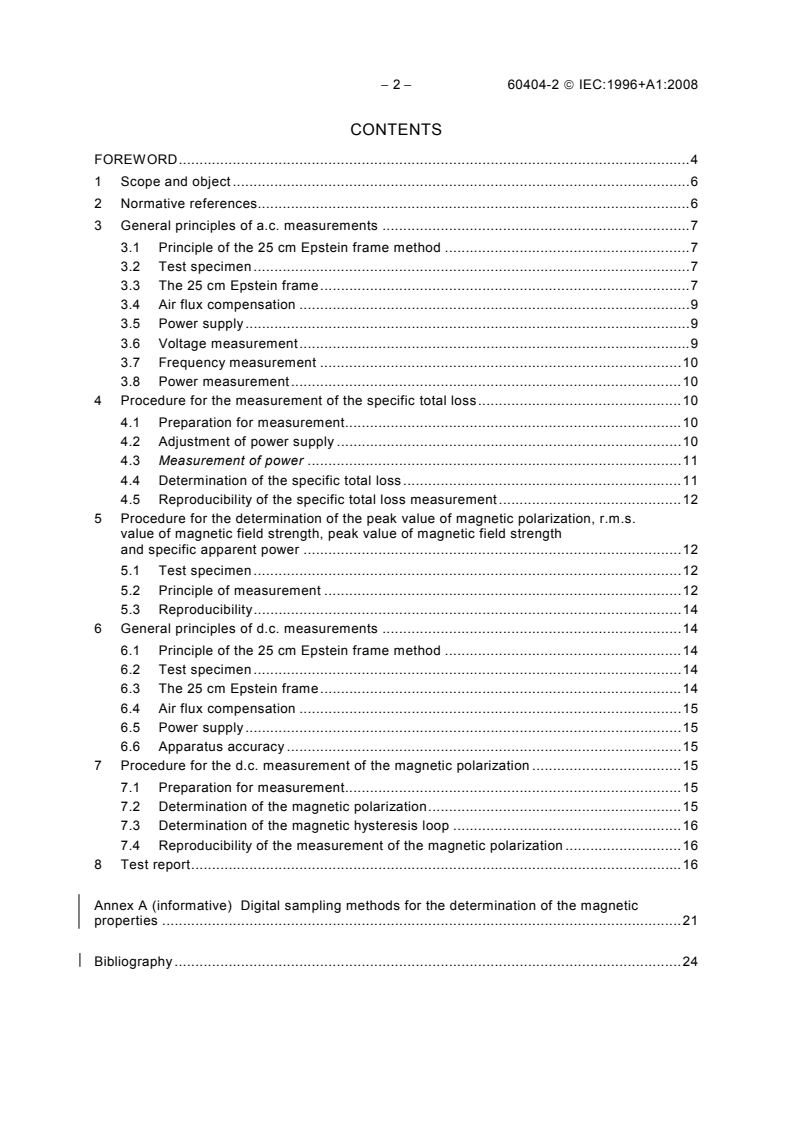

CONTENTS

FOREWORD.4

1 Scope and object .6

2 Normative references.6

3 General principles of a.c. measurements .7

3.1 Principle of the 25 cm Epstein frame method .7

3.2 Test specimen .7

3.3 The 25 cm Epstein frame.7

3.4 Air flux compensation .9

3.5 Power supply.9

3.6 Voltage measurement.9

3.7 Frequency measurement .10

3.8 Power measurement.10

4 Procedure for the measurement of the specific total loss.10

4.1 Preparation for measurement.10

4.2 Adjustment of power supply .10

4.3 Measurement of power .11

4.4 Determination of the specific total loss .11

4.5 Reproducibility of the specific total loss measurement.12

5 Procedure for the determination of the peak value of magnetic polarization, r.m.s.

value of magnetic field strength, peak value of magnetic field strength

and specific apparent power .12

5.1 Test specimen .12

5.2 Principle of measurement .12

5.3 Reproducibility.14

6 General principles of d.c. measurements .14

6.1 Principle of the 25 cm Epstein frame method .14

6.2 Test specimen .14

6.3 The 25 cm Epstein frame.14

6.4 Air flux compensation .15

6.5 Power supply.15

6.6 Apparatus accuracy .15

7 Procedure for the d.c. measurement of the magnetic polarization .15

7.1 Preparation for measurement.15

7.2 Determination of the magnetic polarization.15

7.3 Determination of the magnetic hysteresis loop .16

7.4 Reproducibility of the measurement of the magnetic polarization .16

8 Test report.16

Annex A (informative) Digital sampling methods for the determination of the magnetic

properties .21

Bibliography .24

60404-2 © IEC:1996+A1:2008 − 3 −

Figure 1 – Double-lapped joints .17

Figure 2 – The 25 cm Epstein frame.17

Figure 3 – Circuit for the wattmeter method .18

Figure 4 – Circuit for measuring the r.m.s. value of the magnetizing current.18

Figure 5 – Circuit for measuring the peak value of the magnetic field strength

using a peak voltmeter .19

Figure 6 – Circuit for measuring the peak value of magnetic field strength

using a mutual inductor M .19

D

Figure 7 – Circuit for d.c. testing: to obtain discrete values of magnetic polarization.20

Figure 8 – Circuit for d.c. testing: continuous recording method .20

− 4 − 60404-2 © IEC:1996+A1:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 2: Methods of measurement of the magnetic properties

of electrical steel strip and sheet by means of an Epstein frame

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 60404-2 edition 3.1 contains the third edition (2000) [documents 68/119/FDIS and

68/135/RVD] and its amendment 1 (2008) [documents 68/365/FDIS and 68/369/RVD].

A vertical line in the margin shows where the base publication has been modified by

amendment 1.

International Standard IEC 60404-2 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

60404-2 IEC:1996+A1:2008 − 5 −

This standard supersedes chapters I, II, IV and V of IEC 60404-2:1978.

The standard IEC 60404-11 supersedes chapter VIII of IEC 60404-2:1978.

The standard IEC 60404-13 supersedes chapters VI, VII and IX of IEC 60404-2:1978.

Chapter III of IEC 60404-2:1978 is cancelled.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of March 2018 have been included in this copy.

− 6 − 60404-2 © IEC:1996+A1:2008

MAGNETIC MATERIALS –

Part 2: Methods of measurement of the magnetic properties

of electrical steel strip and sheet by means of an Epstein frame

1 Scope and object

This part of IEC 60404 is applicable to grain oriented and non-oriented electrical sheet and

strip for a.c. measurements of magnetic properties at frequencies up to 400 Hz and for d.c.

magnetic measurements.

The object of this part is to define the general principles and the technical details of the

measurement of the magnetic properties of electrical steel sheet and strip by means of an

Epstein frame.

The Epstein frame is applicable to test specimens obtained from electrical steel sheets and

strips of any grade. The a.c. magnetic characteristics are determined for sinusoidal induced

voltages, for specified peak values of magnetic polarization and for a specified frequency.

The measurements are to be made at an ambient temperature of (23 ± 5) °C on test

specimens which have first been demagnetized.

Measurements at higher frequencies are to be made in accordance with IEC 60404-10.

NOTE Throughout this standard the term "magnetic polarization" is used as defined in IEC 60050(221). In some

standards of the IEC 60404 series, the term "magnetic flux density" was used.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60404-4, Magnetic materials – Part 4: Methods of measurement of d.c. magnetic properties

of magnetically soft materials

IEC 60404-8-3, Magnetic materials – Part 8-3: Specifications for individual materials – Cold-

rolled electrical non-alloyed and alloyed steel sheet and strip delivered in the semi-processed

state

IEC 60404-8-4, Magnetic materials – Part 8-4: Specifications for individual materials – Cold-

rolled non-oriented electrical steel sheet and strip delivered in the fully-processed state

IEC 60404-8-7, Magnetic materials – Part 8-7: Specifications for individual materials – Cold-

rolled grain-oriented electrical steel sheet and strip delivered in the fully-processed state

IEC 60404-10, Magnetic materials – Part 10: Methods of measurement of magnetic properties

of magnetic sheet and strip at medium frequencies

IEC 60404-13, Magnetic materials – Part 13: Methods of measurement of density, resistivity

and stacking factor of electrical steel sheet and strip

60404-2 © IEC:1996+A1:2008 − 7 −

3 General principles of a.c. measurements

3.1 Principle of the 25 cm Epstein frame method

The 25 cm Epstein frame which comprises a primary winding, a secondary winding and the

specimen to be tested as a core, forms an unloaded transformer whose characteristics are

measured by the method described in the following subclauses.

3.2 Test specimen

The strips to be tested are assembled in a square, having double-lapped joints (see figure 1),

thus forming four branches of equal length and equal cross-sectional area.

The strips shall be sampled in accordance with the appropriate product standard in the IEC

60404-8 series.

They shall be cut by a method which will produce substantially burr-free edges and, if so

specified, heat treated in accordance with the corresponding product standard. They shall have

the following dimensions:

− width b = 30 mm ± 0,2 mm;

− length 280 mm ≤ l ≤ 320 mm.

The lengths of the strips shall be equal within a tolerance of ±0,5 mm.

When strips are cut parallel or normal to the direction of rolling, the edge of the parent sheet

shall be taken as the reference direction.

The following tolerances shall apply for the angle between the specified and actual direction of

cutting:

±1° for grain oriented steel sheet;

±5° for non-oriented steel sheet.

Only flat strips shall be used. Measurements shall be made without additional insulation.

The number of strips comprising the test specimen shall be a multiple of four and is specified

in the corresponding product standard. However, the active mass of the test specimen (see

equation (1)) shall be at least 240 g for strips 280 mm long.

3.3 The 25 cm Epstein frame

The 25 cm Epstein frame (hereinafter referred to as the Epstein frame) shall consist of four

coils into which the strips making up the test specimen are inserted (see figure 2).

A mutual inductor for air flux compensation is included with the Epstein frame.

The winding formers supporting the coils are made of hard insulating material, such as

phenolic paper. They have a rectangular cross-section with 32 mm inner width. A height of

approximately 10 mm is recommended.

The coils shall be fixed to an insulating and non-magnetic base in such a way as to form a

square (see figure 2). The length of the sides of the square formed by the internal edges of the

+ 1

strips of the test specimen shall be 220 m m (see figure 2).

- 0

− 8 − 60404-2 © IEC:1996+A1:2008

Each of the four coils shall have two windings:

− a primary winding, on the outside (magnetizing winding);

− a secondary winding, on the inside (voltage winding).

NOTE An electrostatic screen may be provided between these windings.

The windings shall be distributed uniformly over a minimum length of 190 mm, each coil having

one quarter of the total number of turns.

The individual primary windings of the four coils shall be connected in series, as shall be the

secondary windings. The number of primary and secondary turns may be adapted to the

particular conditions prevailing with regard to the power source, measuring equipment and

frequency.

NOTE The total number of turns generally used and recommended is 700 or 1 000.

In order to reduce the effect of the impedances of the windings as much as possible, the

following requirements shall be met:

R R

1 −6 2 −6

≤⋅1,25 10 Ω ≤⋅510 Ω

2 2

N N

1 2

L L

1 −9 2 −9

≤⋅2,5 10 H ≤⋅2,5 10 H

2 2

N N

1 2

where

R and R are the resistances of the primary and secondary windings, respectively, in ohms;

1 2

L and L are the inductances of the primary and secondary windings, respectively, in

1 2

henrys;

N and N are the total number of turns of the primary and secondary windings, respectively.

1 2

NOTE These requirements are satisfied, for example, if windings with the following characteristics are used:

− total number of turns: N = 700, N = 700;

1 2

− primary (outer) winding: each of the four coils carries 175 turns of two copper wires connected in parallel,

each with a nominal cross-sectional area of approximately 1,8 mm , wound side by side in three layers;

− secondary winding: each of the four coils carries 175 turns of one copper wire with a nominal cross-sectional

area of 0,8 mm wound in one layer.

The effective magnetic path length, l , of the magnetic circuit shall be conventionally assumed

m

to be equal to 0,94 m. Therefore, the active mass, m , that is the mass of the test specimen

a

which is magnetically active, is given by:

l

m

mm= (1)

a

4 l

where

l is the length of a test specimen strip, in metres;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

m is the total mass of the test specimen, in kilograms;

m is the active mass of the test specimen, in kilograms.

a

60404-2 © IEC:1996+A1:2008 − 9 −

3.4 Air flux compensation

The mutual inductor for air flux compensation shall be located in the centre of the space

enclosed by the four coils, its axis being directed normal to the plane of the axes of these coils.

The primary winding of the mutual inductor shall be connected in series with the primary

winding of the Epstein frame, and the secondary winding of the mutual inductor shall be

connected to the secondary winding of the Epstein frame in series opposition (see figure 3).

The adjustment of the value of the mutual inductance shall be made so that, when passing an

alternating current through the primary windings in the absence of the specimen in the

apparatus, the voltage measured between the non-common terminals of the secondary

windings shall be no more than 0,1 % of the voltage appearing across the secondary winding of

the test apparatus alone.

Thus the average value of the rectified voltage induced in the combined secondary windings is

proportional to the peak value of the magnetic polarization in the test specimen.

3.5 Power supply

The power supply shall have a low impedance and a high stability of voltage and frequency.

During measurements, the voltage and frequency variations shall not exceed ±0,2 % of the

required value.

For the determination of the specific total loss, the specific apparent power and the r.m.s. value

of the magnetic field strength, the form factor of the secondary voltage shall be 1,111 ± 1 %.

NOTE This is possible in several ways: for example by using an electronically controlled power supply or a

negative feedback power amplifier. The form factor of the secondary voltage is the ratio of its r.m.s. value to its

average rectified value.

Two voltmeters, one responsive to r.m.s. values and the other responsive to average rectified

values shall be used to determine the form factor.

NOTE The waveform of the secondary induced voltage should be checked with an oscilloscope to ensure that only

the fundamental component is present.

3.6 Voltage measurement

The secondary voltage of the Epstein frame shall be measured by means of appropriate

voltmeters having an input impedance greater than or equal to 1 000 Ω/V.

NOTE For the application of digital sampling methods, see Annex A.

3.6.1 Average type voltmeter

A voltmeter responsive to average rectified values having an accuracy of ±0,2 % or better shall

be used.

NOTE The preferred instrument is a digital voltmeter.

3.6.2 RMS voltmeter

A voltmeter responsive to r.m.s. values having an accuracy of ±0,2 % or better shall be used.

NOTE The preferred instrument is a digital voltmeter.

3.6.3 Peak voltmeter

A voltmeter responsive to peak values having an accuracy of ±0,5 % or better shall be used.

− 10 − 60404-2 © IEC:1996+A1:2008

3.7 Frequency measurement

A frequency meter having an accuracy of ±0,1 % or better shall be used.

NOTE For the application of digital sampling methods, see Annex A.

3.8 Power measurement

The power shall be measured by a wattmeter having an accuracy of ±0,5 % or better at the

actual power factor and crest factor.

NOTE For the application of digital sampling methods, see Annex A.

The resistance of the voltage circuit of the wattmeter shall be at least 5 000 times its

reactance, unless the wattmeter is compensated for its reactance.

If a current measuring device is included in the circuit it shall be short-circuited when the

secondary voltage has been adjusted and the loss is being measured.

4 Procedure for the measurement of the specific total loss

NOTE For the application of digital sampling methods, see Annex A.

4.1 Preparation for measurement

The Epstein frame and measuring equipment shall be connected as shown in figure 3.

The test specimen shall be weighed and its mass determined to within ±0,1 %. After weighing,

the strips shall be stacked into the coils of the Epstein frame with double lapped joints at the

corners and with the same number of strips in each branch of the frame such that the length of

+1

the internal side of the square so formed is 220 mm. Where strips are cut half parallel and

−0

half perpendicular to the direction of rolling, the strips cut in the direction of rolling shall be

inserted in two opposite branches of the frame and those cut perpendicular to the direction of

rolling inserted in the other two branches. Care shall be taken to ensure that the air gap

between the strips in the overlapping portions is as small as possible. It is permissible to apply

a force of about 1 N to each corner, normal to the plane of the overlapping strips.

The test specimen shall then be demagnetized in a decreasing alternating magnetic field of an

initial level higher than used in previous measurements.

4.2 Adjustment of power supply

The power supply output shall be slowly increased, whilst observing the ammeter in the primary

circuit to ensure that the wattmeter current circuit is not overloaded, until the average rectified

value of the secondary voltage U of the Epstein frame has reached the required value. This

is calculated from the desired value of magnetic polarization by means of:

R

i

$

Uf= 4N AJ (2)

RR+

it

60404-2 © IEC:1996+A1:2008 − 11 −

where

U is the average value of the rectified voltage induced in the secondary winding, in volts;

A is the cross-sectional area of the test specimen, in square metres;

f is the frequency, in hertz;

$

J is the peak value of magnetic polarization, in teslas;

N is the total number of turns of the secondary winding;

R is the total resistance of the instruments in the secondary circuit, in ohms;

i

R is the series resistance of the secondary windings and mutual inductor, in ohms.

t

The cross-sectional area of the test specimen is given by the equation:

m

A = (3)

4 l ρ

m

where

A is the cross-sectional area of the test specimen, in square metres;

m is the total mass of the test specimen, in kilograms;

l is the length of a test specimen strip, in metres;

ρ is the conventional density, or the value determined in accordance with IEC 60404-13, of

m

the test material, in kilograms per cubic metre.

4.3 Measurement of power

The ammeter in the primary circuit shall be short circuited and the secondary voltage

readjusted if necessary. The form factor of the secondary voltage shall be determined in

accordance with 3.5 and then the wattmeter reading shall be recorded.

4.4 Determination of the specific total loss

The power, P , measured by the wattmeter includes the power consumed by the instruments in

m

the secondary circuit. The total loss, P , of the test specimen shall therefore be calculated

c

using the equation:

⎛ ⎞

1,111 U

⎜ ⎟

N

⎝ ⎠

P=−P (4)

c m

R

i

N

where

P is the calculated total loss of the test specimen, in watts;

c

N is the total number of turns of the primary winding;

N is the total number of turns of the secondary winding;

P is the power measured by the wattmeter, in watts;

m

R is the total resistance of the instruments in the secondary circuit, in ohms;

i

U is the average value of the rectified voltage induced in the secondary winding, in volts.

The measured specific total loss, P , is obtained by dividing P by the active mass m of the

s c a

test specimen.

P P 4 l

c c

P== (5)

s

m m l

a m

− 12 − 60404-2 © IEC:1996+A1:2008

where

P is the specific total loss of the test specimen, in watts per kilogram;

s

l is the length of a test specimen strip, in metres;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

m is the total mass of the test specimen, in kilograms;

m is the active mass of the test specimen, in kilograms;

a

P is the calculated total loss of the test specimen, in watts.

c

4.5 Reproducibility of the specific total loss measurement

The reproducibility of the results obtained from the procedures described in this subclause is

characterized by a relative standard deviation of 1,5 % for measurements on grain oriented

material at magnetic polarizations up to 1,7 T and for measurements on non-oriented material

up to 1,5 T.

For measurements at higher magnetic polarizations, it is expected that the relative standard

deviation will be increased.

5 Procedure for the determination of the peak value of magnetic polarization,

r.m.s. value of magnetic field strength, peak value of magnetic field strength

and specific apparent power

This clause describes measuring methods for the determination of the following characteristics:

$

− peak value of magnetic polarization J ;

~

− r.m.s. value of magnetic field strength H ;

$

− peak value of magnetic field strength H ;

− specific apparent power S .

s

5.1 Test specimen

The test specimen shall comply with 3.2.

5.2 Principle of measurement

$

5.2.1 Peak value of magnetic polarization J

The peak value of magnetic polarization shall be determined from the average value of the

secondary rectified voltage measured as described in clause 4 and calculated from equation 2.

5.2.2 RMS value of magnetic field strength

The r.m.s. value of the magnetic field strength shall be calculated from the r.m.s. value of the

current, measured by an r.m.s. ammeter in the circuit shown in figure 4. Alternatively a

precision resistor, of value typically in the range 0,1 Ω to 1 Ω of an accuracy of 0,1 %, shall be

connected in place of the ammeter and the voltage developed across this resistor shall be

measured using a voltmeter responsive to r.m.s. values conforming to the requirements of 3.6.

The frequency shall be set to the desired value. The peak value of the magnetic polarization

shall be set by adjusting the secondary voltage of the Epstein frame to the required value

calculated from equation 2. The r.m.s. value of the current shall then be determined and

recorded. The r.m.s. value of the magnetic field strength shall be calculated from the equation:

N

~~

H = I (6)

l

m

60404-2 © IEC:1996+A1:2008 − 13 −

where

~

H is the r.m.s. value of magnetic field strength, in amperes per metre;

~

I is the r.m.s. value of magnetizing current, in amperes;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

N is the total number of turns of the primary winding.

5.2.3 Peak value of magnetic field strength

The peak value of the magnetic field strength shall be derived from the peak value of the

magnetizing current Î which is obtained by measuring the voltage drop across a known

precision resistor R of an accuracy of 0,1 %, using a peak voltmeter as shown in figure 5. For

this measurement, the form factor of the secondary voltage is allowed to exceed the specified

value (see 3.5).

The peak magnetic field strength shall be calculated from the equation:

N

$$

H = I (7)

l

m

where

$

H is the peak value of magnetic field strength, in amperes per metre;

$

⎛ ⎞

U

$

Î is the peak value of magnetizing current ⎜I = ⎟ in amperes;

1 1

R

⎝ ⎠

l is the conventional effective magnetic path length of test specimen (l = 0,94 m);

m m

N is the total number of turns of the primary winding of the Epstein frame.

Alternatively, the peak value of the magnetizing current Î can be determined by measuring the

average rectified value of the voltage appearing across the secondary winding of a mutual

inductor M of an accuracy of 0,5 %, the primary winding of which is connected in series with

D

the primary winding of the Epstein frame. With this method it is necessary to ensure (e.g. by

observing the waveform on an oscilloscope) that there are no more than two zero crossings per

cycle of the voltage waveform of the secondary winding of the mutual inductor. The circuit is

given in figure 6. The voltmeter can be the same instrument as is used for measuring the

secondary voltage of the Epstein frame. With this method, the peak value of the magnetic field

strength shall be calculated from the equation:

N RR+

1 vm

$

H=⋅ ⋅ U (7a)

m

4fM l R

Dm v

where

M is the mutual inductance in the circuit given in figure 6, page 35, in henrys;

D

R is the resistance of the secondary winding of M , in ohms;

m D

R is the internal resistance of the average type voltmeter, in ohms;

v

U is the average rectified value of the voltage induced in the secondary winding of M ,

m D

in volts.

− 14 − 60404-2 © IEC:1996+A1:2008

5.2.4 Determination of the specific apparent power

For a given value of magnetic polarization and frequency, the corresponding r.m.s. values of

the magnetizing current (see 5.2.2) and the r.m.s. value of the secondary voltage of the Epstein

frame shall be measured. The r.m.s. value of the voltage shall be measured by connecting a

voltmeter complying with the requirements of 3.6 across the secondary winding of the Epstein

frame.

The specific apparent power is given by the following relationship:

N N 4 l

~~ ~~

1 1

SI==U IU (8)

s1 2 12

mN mNl

a2 m2

where

S is the specific apparent power, in voltamperes per kilogram;

s

~

I is the r.m.s. value of the magnetizing current in amperes;

l is the conventional effective magnetic path length, in metres (l = 0,94m);

m

m

l is the length of a test specimen strip, in metres;

m is the total mass of the test specimen, in kilograms;

m is the active mass of the test specimen, in kilograms;

a

N is the total number of turns of the primary winding of the Epstein frame;

N is the total number of turns of the secondary winding of the Epstein frame;

~

U is the r.m.s. value of the voltage induced in the secondary winding, in volts.

5.3 Reproducibility

The reproducibility of the results obtained from the procedures described in this clause

depends essentially upon the accuracy of the instruments used for the measurement and

careful attention to the physical details of the test equipment. When using instruments having

an accuracy of ±0,5 % or better, the reproducibility of the measurements is characterized by a

standard deviation of the order of 2 % except for the specific apparent power where the

reproducibility is characterized by a standard deviation of between 2 % (for values of magnetic

polarization below the knee of the magnetization curve) to 7 % (for values of magnetic

polarization approaching saturation).

6 General principles of d.c. measurements

6.1 Principle of the 25 cm Epstein frame method

The 25 cm Epstein frame which comprises a primary winding, a secondary winding and the

specimen to be tested as a core, forms an unloaded transformer whose d.c. characteristics are

measured by the method described in the following subclauses.

6.2 Test specimen

The test specimen shall comply with 3.2.

6.3 The 25 cm Epstein frame

The 25 cm Epstein frame shall be constructed in accordance with 3.3.

60404-2 © IEC:1996+A1:2008 − 15 −

6.4 Air flux compensation

The effect of the air flux shall be compensated by means of a mutual inductor as described

in 3.4.

6.5 Power supply

The power supply shall have a current rating sufficient to produce the maximum magnetic field

strength required. The ripple content shall be less than 1 % and the current stability shall be

such that the resultant relative magnetic flux variations are not more than 0,2 %.

6.6 Apparatus accuracy

The accuracy of the measuring apparatus shall be as follows:

6.6.1 Magnetic flux integrator

A magnetic flux integrator having an accuracy of ±0,3 % or better shall be used.

NOTE The magnetic flux integrator may be calibrated by one of the methods described in annex B of IEC 60404-4.

6.6.2 Ammeter

An ammeter having an accuracy of ±0,2 % or better shall be used.

7 Procedure for the d.c. measurement of the magnetic polarization

7.1 Preparation for measurement

The Epstein frame and measuring equipment shall be connected as shown in figure 7.

The test specimen shall be weighed and assembled into the Epstein frame as described in 4.1.

The test specimen shall then be demagnetized either in a decreasing alternating magnetic field

or by a series of reversals of a gradually reducing direct current flowing in the primary winding

of the Epstein frame, the frequency of the reversals being about two per second. The initial

value of the magnetic field strength produced by the demagnetizing current shall be of a level

higher than that used in previous measurements.

The cross-sectional area A of the test specimen shall be calculated from equation 3.

7.2 Determination of the magnetic polarization

Discrete values of magnetic polarization can be determined for corresponding values of

magnetic field strength using a circuit as shown in figure 7, or a normal magnetization curve

can be obtained from a series of discrete values. Alternatively, a continuous recording method

may be used. A calibrated four terminal resistor is connected in series with the magnetizing

winding of the Epstein frame. The potential terminals are connected to the X input of an X-Y

recorder and the output of the flux integrator is connected to the Y input of the X-Y recorder as

shown in figure 8. A plotter or computer interface can be used in place of the X-Y recorder.

The magnetic field strength shall be determined by measuring the magnetizing current in the

primary winding of the Epstein frame using the following equation:

NI

H = (9)

l

m

− 16 − 60404-2 © IEC:1996+A1:2008

where

H is the magnetic field strength, in amperes per metre;

I is the magnetizing current, in amperes;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

N is the total number of turns of the primary winding of the Epstein frame.

To obtain discrete values of magnetic polarization, the magnetic flux integrator shall be zeroed

and the current through the primary winding shall be increased until the desired value of

magnetic field strength is reached.

The magnetizing current and the change in fluxmeter reading shall be recorded. The value of

the magnetic polarization shall be calculated from the change in fluxmeter reading and the

calibration constant of the flux integrator using the following equation:

K α

jj

ΔJ = (10)

NA

where

ΔJ is the measured change of magnetic polarization, in tesla;

A is the cross-sectional area of the test specimen, in square metres;

α is the reading of the flux integrator;

j

K is the calibration constant of the flux integrator, in volt seconds;

j

N is the total number of turns of the secondary winding of the Epstein frame.

7.3 Determination of the magnetic hysteresis loop

If required, the magnetic hysteresis loop shall be determined in accordance with IEC 60404-4

except that the ring shall be replaced by the Epstein frame and test specimen.

7.4 Reproducibility of the measurement of the magnetic polarization

The reproducibility of the results obtained from the procedure described in this clause is

characterized by a relative standard deviation of 1,0 %.

8 Test report

The test report shall include the following, as applicable:

a) type and identity of test specimen;

b) density of material (conventional, or as measured in accordance with IEC 60404-13);

c) length of test specimen strips;

d) number of strips;

e) ambient temperature during the measurements;

f)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...