IEC 60352-5:2008

(Main)Solderless connections - Part 5: Press-in connections - General requirements, test methods and practical guidance

Solderless connections - Part 5: Press-in connections - General requirements, test methods and practical guidance

Determines the suitability of press-in connections under specified mechanical, electrical and atmospheric conditions. Is applicable to solderless press-in connections for use in telecommunication equipment and in electronic devices employing similar techniques. Changes with respect to the previous edition deal with: use of four layer test boards; sample tolerance range requirements; use of platings other than tin or tin/lead.

Connexions sans soudure - Partie 5: Connexions insérées à force - Exigences générales, méthodes d'essai et guide pratique

Détermine la conformité des connexions insérées à force dans des conditions mécaniques, électriques et atmosphériques spécifiées. Est applicable aux connexions insérées à force sans soudure utilisées dans les équipements de télécommunication et les systèmes électroniques employant des techniques similaires. Les modifications par rapport à l'édition précédente concernent: l'utilisation des cartes d'essai à quatre couches; les exigences des gammes de tolérances d'échantillons; l'utilisation de revêtements autres que ceux en étain ou étain/plomb.

General Information

- Status

- Published

- Publication Date

- 09-Jan-2008

- Technical Committee

- SC 48B - Electrical connectors

- Drafting Committee

- WG 6 - TC 48/SC 48B/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Feb-2012

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60352-5:2008 is an international standard developed by the International Electrotechnical Commission (IEC) that establishes the general requirements, test methods, and practical guidance for solderless press-in connections. This standard applies primarily to solderless press-in connections used in telecommunication equipment and similar electronic devices. It focuses on ensuring the suitability and reliability of press-in connections under various mechanical, electrical, and environmental conditions. The 2008 edition includes significant updates such as recommendations for using four-layer test boards, revised tolerance range requirements, and allowance for alternative plating materials beyond tin or tin/lead.

Key Topics

General Requirements

Defines essential criteria for manufacturing press-in connections to ensure mechanical strength, electrical performance, and resistance to atmospheric conditions.Materials and Design Features

Covers specifications for materials used in press-in terminations and printed circuit boards (PCBs), including dimensions of press-in zones, surface finishes, and plating alternatives.Test Methods

Outlines comprehensive testing procedures including mechanical tests (e.g., bending, push-out force), electrical tests, and climatic tests to qualify press-in connections for reliability and durability.Test Schedules

Provides structured test sequences for product qualification and application testing to confirm conformance with the standard.Practical Guidance

Offers insights on current-carrying capacity, tool selection (insertion, removal, support), repair methods, and considerations for combining press-in with soldered connections.

Applications

IEC 60352-5:2008 serves as a critical guideline for manufacturers, designers, and quality assurance engineers involved in:

Telecommunication Equipment

Ensuring reliable solderless press-in connections for high-performance communication devices.Electronic Devices

Implementing durable and efficient mechanical and electrical connections in consumer electronics, industrial controls, and other electronic assemblies.Printed Circuit Board Assembly

Applying appropriate materials, designs, and test protocols for PCBs with press-in connections to achieve optimum performance and longevity.Quality Control and Testing

Standardizing test regimes and acceptance criteria for press-in connections to maintain product integrity during manufacturing and field operation.Repair and Maintenance

Providing guidance on repairing press-in connections and understanding potential corrosion effects, especially in bimetallic combinations.

Related Standards

IEC 60352 is a multi-part series addressing solderless connections in various forms. Related parts complement the guidance provided in Part 5 by focusing on alternative connection techniques:

- IEC 60352-1: General requirements for solderless connections.

- IEC 60352-2: Press-fit connections.

- IEC 60352-3: Crimp connections.

- IEC 60352-4: Wire wrapping connections.

Additionally, IEC 60352-5 references relevant standards concerning printed circuit board materials and plating processes to ensure comprehensive quality control.

Keywords: IEC 60352-5, solderless connections, press-in connections, test methods, general requirements, telecommunication equipment, electronic devices, printed circuit boards, mechanical tests, electrical tests, climatic tests, solderless press-in, four-layer test boards, plating materials, quality standards.

Frequently Asked Questions

IEC 60352-5:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Solderless connections - Part 5: Press-in connections - General requirements, test methods and practical guidance". This standard covers: Determines the suitability of press-in connections under specified mechanical, electrical and atmospheric conditions. Is applicable to solderless press-in connections for use in telecommunication equipment and in electronic devices employing similar techniques. Changes with respect to the previous edition deal with: use of four layer test boards; sample tolerance range requirements; use of platings other than tin or tin/lead.

Determines the suitability of press-in connections under specified mechanical, electrical and atmospheric conditions. Is applicable to solderless press-in connections for use in telecommunication equipment and in electronic devices employing similar techniques. Changes with respect to the previous edition deal with: use of four layer test boards; sample tolerance range requirements; use of platings other than tin or tin/lead.

IEC 60352-5:2008 is classified under the following ICS (International Classification for Standards) categories: 31.220.10 - Plug-and-socket devices. Connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60352-5:2008 has the following relationships with other standards: It is inter standard links to IEC 60352-5:2001/AMD1:2003, IEC 60352-5:2001, IEC 60352-5:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60352-5:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60352-5

Edition 3.0 2008-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Solderless connections –

Part 5: Press-in connections – General requirements, test methods and practical

guidance

Connexions sans soudure –

Partie 5: Connexions insérées à force – Exigences générales, méthodes d’essai

et guide pratique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60352-5

Edition 3.0 2008-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Solderless connections –

Part 5: Press-in connections – General requirements, test methods and practical

guidance

Connexions sans soudure –

Partie 5: Connexions insérées à force – Exigences générales, méthodes d’essai

et guide pratique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 31.220.10 ISBN 2-8318-9522-7

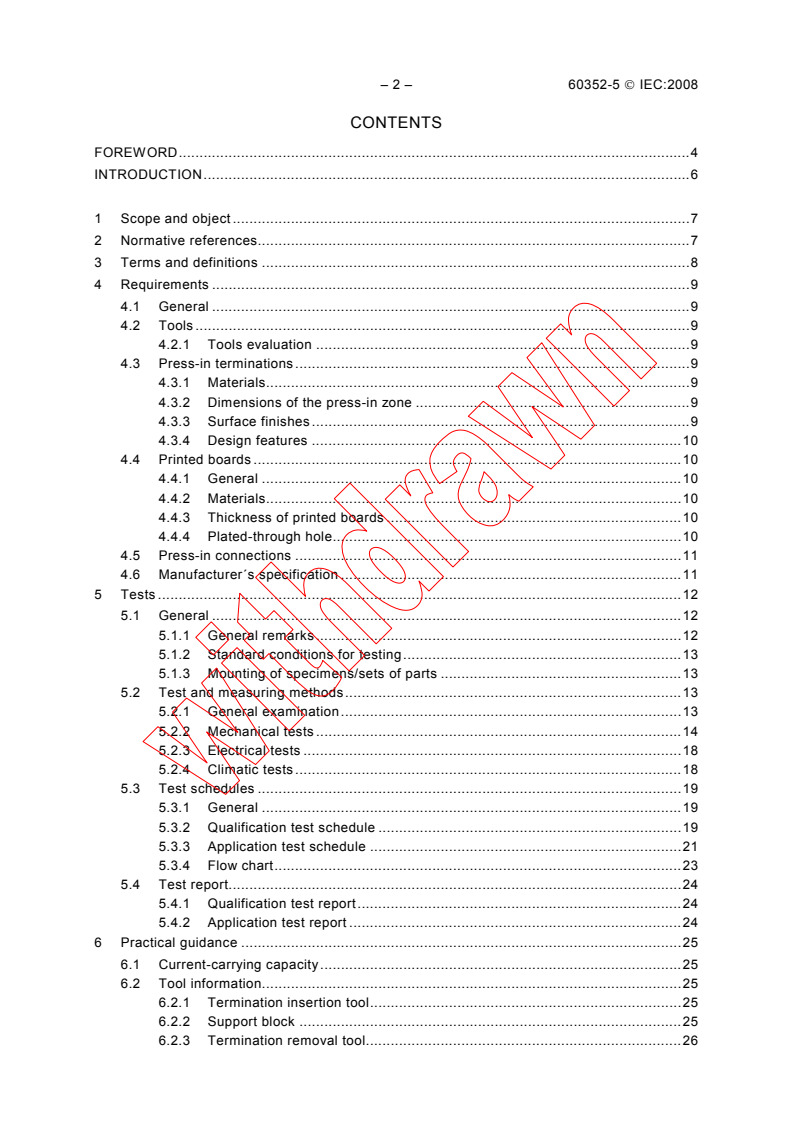

– 2 – 60352-5 © IEC:2008

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope and object .7

2 Normative references.7

3 Terms and definitions .8

4 Requirements .9

4.1 General .9

4.2 Tools .9

4.2.1 Tools evaluation .9

4.3 Press-in terminations.9

4.3.1 Materials.9

4.3.2 Dimensions of the press-in zone .9

4.3.3 Surface finishes .9

4.3.4 Design features .10

4.4 Printed boards .10

4.4.1 General .10

4.4.2 Materials.10

4.4.3 Thickness of printed boards .10

4.4.4 Plated-through hole.10

4.5 Press-in connections .11

4.6 Manufacturer´s specification .11

5 Tests .12

5.1 General .12

5.1.1 General remarks.12

5.1.2 Standard conditions for testing.13

5.1.3 Mounting of specimens/sets of parts .13

5.2 Test and measuring methods.13

5.2.1 General examination.13

5.2.2 Mechanical tests .14

5.2.3 Electrical tests .18

5.2.4 Climatic tests.18

5.3 Test schedules .19

5.3.1 General .19

5.3.2 Qualification test schedule .19

5.3.3 Application test schedule .21

5.3.4 Flow chart.23

5.4 Test report.24

5.4.1 Qualification test report.24

5.4.2 Application test report .24

6 Practical guidance .25

6.1 Current-carrying capacity.25

6.2 Tool information.25

6.2.1 Termination insertion tool.25

6.2.2 Support block .25

6.2.3 Termination removal tool.26

60352-5 © IEC:2008 – 3 –

6.3 Termination information .26

6.3.1 General .26

6.3.2 Design features .26

6.3.3 Materials and surface finishes.26

6.3.4 Press-in termination with wrap post.27

6.3.5 Press-in terminations with connector contact elements.27

6.4 Printed board information.28

6.4.1 General .28

6.4.2 Plated-through hole.28

6.5 Connection information .29

6.5.1 General .29

6.5.2 Repair of press-in connections .30

6.5.3 Combination of press-in connections and soldered connections.31

6.5.4 Bimetallic electrolytic corrosion effects.31

Annex A (normative) Solid press-in terminations.32

Annex B (informative) Plated through hole tolerance range .34

Bibliography .36

Figure 1 – Test arrangement, bending .14

Figure 2 – Test arrangement – push-out force .15

Figure 3 – Transverse section of a press-in connection .17

Figure 4 – Longitudinal section of a press-in connection .17

Figure 5 – Test arrangement for contact resistance .18

Figure 6 – Qualification test schedule .23

Figure 7 – Press-in connection made with a press-in termination, application level a).29

Figure 8 – Press-in connection made with a press-in termination, application level b).30

Figure 9 – Example of a termination removal tool .31

Figure A.1 – Parallelism of a solid press-in zone.33

Figure B.1 – Example of hole ranges .34

Table 1 – Finished plated-through holes .11

Table 2 – Vibration, preferred test severities.16

Table 3 – Push-out force for application level b) .29

Table A.1 – Plated-through holes for solid press-in zones .32

– 4 – 60352-5 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

SOLDERLESS CONNECTIONS –

Part 5: Press-in connections –

General requirements, test methods and practical guidance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60352-5 has been prepared by subcommittee 48B: Connectors, of

IEC technical committee 48: Electromechanical components and mechanical structures for

electronic equipment.

This third edition cancels and replaces the second edition published in 2001 and its

amendment 1 (2003). This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

1) A recommendation to use four layer test boards in 5.1.

2) Removal of sample tolerance range requirements in 5.3.2.1; they have been moved to

Annex B.

3) Subclause 6.4.2 has been modified to clarify that platings other than tin or tin/lead may be

used.

60352-5 © IEC:2008 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

48B/1805A/FDIS 48B/1830/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A list of all parts of the IEC 60352 series, under the general title Solderless connections, can

be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60352-5 © IEC:2008

INTRODUCTION

This part of IEC 60352 includes requirements, tests and practical guidance information.

Two test schedules are provided.

a) The qualification test schedule applies to individual press-in connections (press-in zone).

They are tested to the specification provided by the manufacturer of the press-in zone (see

4.6) taking into account the requirements of Clause 4.

The qualification is independent of the application of the press-in zone in a component.

b) The application test schedule applies to press-in connections which are part of a

component and are already qualified to the qualification test schedule.

Test sequences focus on the performance of the press-in connection which is affected by

the implementation in a component.

As the manufacturer of the press-in zone has to provide the main part of the information

needed for qualification, the use of the words "the manufacturer" is implemented throughout

this standard for simplicity.

IEC Guide 109 advocates the need to minimise the impact of a product on the natural

environment throughout the product life cycle.

It is understood that some of the materials permitted in this standard may have a negative

environmental impact.

As technological advances lead to acceptable alternatives for these materials, they will be

eliminated from the standard.

60352-5 © IEC:2008 – 7 –

SOLDERLESS CONNECTIONS –

Part 5: Press-in connections –

General requirements, test methods and practical guidance

1 Scope and object

This part of IEC 60352 is applicable to solderless press-in connections for use in tele-

communication equipment and in electronic devices employing similar techniques.

The press-in connection consists of a termination having a suitable press-in zone which is

inserted into a plated-through hole of a double-sided or multilayer printed board.

Information on materials and data from industrial experience is included in addition to the test

procedures to provide electrically stable connections under prescribed environmental

conditions.

The object of this part of IEC 60352 is to determine the suitability of press-in connections under

specified mechanical, electrical and atmospheric conditions.

Only compliant press-in zones can be qualified according to this part of IEC 60352.

Solid press-in zones are in use. Information about these is given in Annex A.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60050(581):1978, International Electrotechnical Vocabulary (IEV) – Chapter 581:

Electromechanical components for electronic equipment

Amendment 1 (1998)

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

Amendment 1 (1992)

IEC 61249 (all parts), Materials for printed boards and other interconnecting structures

IEC 60352-1:1997, Solderless connections – Part 1: Wrapped connections – General require-

ments, test methods and practical guidance

IEC 60512 (all parts), Connectors for electronic equipment – Tests and measurements

IEC 60512-1-100, Connectors for electronic equipment – Tests and measurements –

Part 1-100: General - Applicable publications

IEC 61188-5-1: Printed boards and printed board assemblies – Design and use – Part 5-1:

Attachment (land/joint) considerations – Generic requirements

– 8 – 60352-5 © IEC:2008

IEC 62326-4:1996, Printed boards – Part 4: Rigid multilayer printed boards with interlayer

connections – Sectional specification

3 Terms and definitions

For the purposes of this document, the terms and definitions of IEC 60050(581) and

IEC 60512-1 as well as the following apply.

3.1

press-in connection

solderless connection made by inserting a press-in termination into a plated-through hole of a

printed board

[IEV 581-03-46]

3.2

press-in termination (press-in post)

termination having a specially shaped zone suitable to provide for a solderless press-in

connection

[IEV 581-03-39]

3.2.1

solid press-in termination

press-in termination having a solid press-in zone

[IEV 581-03-40]

3.2.2

compliant press-in termination

press-in termination having a compliant press-in zone

[IEV 581-03-41]

3.3

press-in zone

specially shaped section of a press-in termination which is suitable to provide for the press-in

connection

[IEV 581-03-52]

3.4

termination insertion tool

device used to insert press-in terminations or components equipped with press-in terminations

into a printed board

[IEV 581-05-22]

3.5

termination removal tool

device for removing a press-in termination from a printed board

[IEV 581-05-23]

3.6

part

press-in terminations and a printed board with plated-through holes. The press-in terminations

are not inserted in the printed board.

60352-5 © IEC:2008 – 9 –

3.7

specimen

printed board, or a part of a printed board, with an inserted press-in termination, with or without

a component housing

4 Requirements

4.1 General

This Clause is applicable to compliant press-in zones only. For solid press-in zones, see

Annex A.

The connections shall be processed in a careful and workmanlike manner, in accordance with

good current practice.

4.2 Tools

Tools shall be used and inspected according to the instructions and dimensions provided by

the manufacturer.

The tools shall be capable of making uniformly reliable connections during their useful life.

The tools shall be so designed that they do not damage the press-in termination or the printed

board when correctly operated.

4.2.1 Tools evaluation

Tools are evaluated for performance by testing the connections made by them and carrying out

tests according to 4.5 and 5.1.2. They shall meet the requirements of 4.6d) and 5.2.1.4.

4.3 Press-in terminations

4.3.1 Materials

Material used in the press-in zone shall be specified by the manufacturer.

For information on materials, see 6.3.3.

4.3.2 Dimensions of the press-in zone

The performance of a press-in connection depends on the dimensions of the specially shaped

press-in zone and the materials used for the press-in termination together with the dimensions

and materials of the plated-through hole in the printed board. The dimensions and shape

including the tolerances of the press-in zone shall be specified by the manufacturer.

NOTE For dimensions of plated-through holes, see 4.4.4.2.

4.3.3 Surface finishes

The press-in zone of the press-in termination shall be either unplated or plated. The surface

finish shall be specified by the manufacturer.

The surface shall be free of detrimental contamination or corrosion. For information on surface

finishes, see 6.3.3.

– 10 – 60352-5 © IEC:2008

4.3.4 Design features

For the shape of the press-in zone, a wide variety of designs can be used.

The press-in termination shall be so designed that a press-in connection is achieved by

inserting the press-in zone to a predetermined depth in a specified plated-through hole in the

board.

The press-in terminations and their press-in zones shall be so designed and manufactured that

damage to the plated-through hole in the printed board is avoided (see also 4.5).

Press-in terminations shall have insert features, for example a shoulder or suitable surface, to

facilitate the insertion operation.

4.4 Printed boards

4.4.1 General

Printed boards according to IEC 61188-5-1 and IEC 62326-4 or to a specification given by the

manufacturer shall be used.

4.4.2 Materials

The manufacturer shall specify the types of base material for which the press-in zone is

designed.

Examples of base materials may be found in IEC 61249.

4.4.3 Thickness of printed boards

The manufacturer shall specify for which range of board thicknesses the press-in zone is

designed.

4.4.4 Plated-through hole

4.4.4.1 Plating of the plated-through hole

The thickness of the plating of the plated-through hole shall be: copper ≥ 25 μm.

Further plating requirements shall be specified by the manufacturer.

4.4.4.2 Hole dimensions

The hole diameter prior to plating is of great importance in determining the reliability of a press-

in connection.

The tolerances on the hole diameters prior to and after plating are given in Table 1.

60352-5 © IEC:2008 – 11 –

Table 1 – Finished plated-through holes

All dimensions are in millimetres

Diameter of the finished Recommended diameter of

Nominal hole diameter

a b

plated-through hole the hole prior to plating

0,50 0,50 ± 0,05 0,60 ± 0,01

0,55

0,55 ± 0,05 0,64 ± 0,01

0,60 0,60 ± 0,05 0,70 ± 0,02

+0,07 +0

0,65 0,65 0,80

−0,04 −0,03

+0,07 +0,03

0,70 0,70 0,80

−0,05 −0,02

+0,05 +0,01

0,75 0,85

0,75

−0,07 −0,04

+0,09

0,80 0,80

0,90 ±0,025

−0,03

+0,10 +0,01

0,85 0,85 1,00

−0,05 −0,04

0,90

0,90 ± 0,07 1,00 ± 0,025

+0,09

1 1,00

1,15 ± 0,025

−0,06

+0,09

1,45 1,45 1,60 ± 0,025

−0,06

+0,09

1,60

1,60 1,75 ± 0,025

−0,06

a

These are typical values for the as-drilled pc board hole diameters for FR4

materials and do not necessarily apply to other pc board materials.

b

These values do not apply to moulded interconnection devices.

4.5 Press-in connections

a) The combination of press-in termination, printed board and termination insertion tool shall

be compatible and specified by the manufacturer.

b) The press-in termination shall be correctly mounted in the plated-through hole of the printed

board as specified in the specification of the manufacturer of the press-in zone.

c) The press-in operation may result in deformation of the plated-through hole (visible by

microsectioning).

d) The press-in termination shall not be damaged (e.g. cracked or bent).

e) There shall be no deformation of the printed conductor and/or the plating of the

plated-through hole caused by the termination insertion tool or device.

f) There shall be no lands fractured or lifted.

g) There shall be no delamination, blistering or cracking of layers.

h) After the press-in operation, no detrimental plating particle chips shall be visible.

i) At the opposite side of the press-in direction, no plating of the plated-through hole shall be

loosened.

4.6 Manufacturer´s specification

The following information shall be supplied by the manufacturer of the press-in zone and/or the

component:

– 12 – 60352-5 © IEC:2008

a) Printed board and hole information

– printed board material;

– maximum number of conductive layers;

– printed board minimum and maximum thickness;

– printed board plating material;

– finished plated through holes dimension (Table 1);

– hole dimension prior to plating.

b) Press-in zone information

– material of the press-in termination;

– plating;

– dimensions, including tolerances.

c) Information on the application

– straight or right angle termination;

– rear plug up;

– wrapped connection;

– individual press-in termination;

– connector with pre-assembled press-in terminations.

d) Instruction and tools for the press-in operation

– tools to be used;

– numbers of repairs with or without a new press-in termination.

e) Press-in characteristics

– maximum press-in force per termination;

– minimum push-out force per termination.

f) Any other significant information

If this information cannot be disclosed, the qualification of the press-in connection will not take

place.

5 Tests

5.1 General remarks

5.1.1 General

As explained in the introduction, there are two test schedules which shall be applied according

to the following conditions.

a) Press-in connections, according to the requirements in Clause 4 and the requirements in

the manufacturer’s specification, shall be tested in accordance with the qualification test

schedule in 5.3.2.

This test schedule is intended to be applied on individual press-in terminations without

component housing.

b) Press-in connections which are part of a component and already qualified to the

qualification test schedule shall be tested in accordance with the application test schedule

in 5.3.3.

This test schedule is intended to be applied on complete components consisting of multiple

press-in terminations mounted in a component housing.

The application test schedule shall be implemented in the detail specification of the component

in such a way that the duplication of tests may be avoided.

60352-5 © IEC:2008 – 13 –

Therefore, the test phases in test group D (see 5.3.3.2) may be inserted in any test group of

the component specification, as long as the sequence, conditioning and environment comply

with the requirements of this standard.

Four layer printed circuit boards shall be used for testing unless otherwise specified in the

component specification or in the manufacturer’s specification.

5.1.2 Standard conditions for testing

5.1.2.1 General

Unless otherwise specified, all tests shall be carried out under standard conditions for testing

as specified in IEC 60512-1.

The ambient temperature and the relative humidity at which the measurements are made shall

be stated in the test report.

In case of dispute about test results, the test shall be repeated at one of the referee conditions

of IEC 60068-1.

5.1.2.2 Preconditioning

Where specified, the connections shall be preconditioned under standard conditions for testing

in accordance with the requirements of IEC 60512-1 for a minimum period of 24 h and no

longer than 25 h.

5.1.2.3 Recovery

Where specified, the specimens shall be allowed to recover under standard conditions for

testing for a period of a minimum of 2 h after conditioning.

5.1.3 Mounting of specimens/sets of parts

For the qualification test schedule, the sets of parts consist of press-in terminations and a

printed board with plated-through holes. When mounting is required in a test, the specimens

shall be mounted using the mounting method described in the manufacturer’s specification.

For the application test schedule, complete components shall be pressed on a printed board,

using the normal mounting method, unless otherwise specified in the component specification

or in the manufacturer’s specification.

NOTE For the definitions of part and specimen, see 3.6 and 3.7.

5.2 Test and measuring methods

NOTE As far as test methods are described in this subclause, it is intended that the description be replaced by a

reference to IEC 60512 as soon as the relevant test method is included in IEC 60512.

5.2.1 General examination

5.2.1.1 Visual examination of parts

The test shall be carried out in accordance with IEC 60512, test 1a. Magnification shall be five

times, and all parts shall be examined to ensure that the applicable requirements of 4.3 to 4.6

have been met.

– 14 – 60352-5 © IEC:2008

5.2.1.2 Examination of dimensions

The test shall be carried out in accordance with IEC 60512, test 1b. All parts shall be examined

to ensure that the applicable requirements of 4.3 to 4.6 have been met.

5.2.1.3 Visual examination of specimens

The test shall be carried out in accordance with IEC 60512, test 1a. Magnification shall be five

times, and all specimens shall be examined to ensure that the applicable requirements of 4.3

to 4.6 have been met.

5.2.1.4 Inspection of tools

The tools shall be inspected and controlled according to the manufacturer’s instructions and

specifications to be sure that the applicable requirements of 4.2 and 4.6 have been met.

5.2.2 Mechanical tests

5.2.2.1 Bending

This test is only applicable to press-in terminations having a free post length of ≥10 mm

protruding from the board.

The object of this test is to assess the ability of a press-in connection to withstand the

mechanical stress caused by an unintentional bending of the free length of the termination and

following adjustment.

The test specimen shall consist of a printed board or a part of a printed board, with an inserted

press-in termination having a free post length of ≥10 mm for bending.

15°

15°

IEC 138/01

Figure 1 – Test arrangement, bending

The free end of one press-in termination shall be bent in one direction and the free end of a

second press-in termination shall be bent in the perpendicular direction. Bending over

distances 1, 2 and 3 shall be considered to be one cycle as shown in Figure 1.

Test severity: One cycle shall be carried out unless otherwise specified by the manufacturer.

5.2.2.2 Press-in force

The force necessary to insert a press-in termination into the plated-through hole of a printed

board is determined by

– the type of press-in zone;

– the type of printed board;

– the diameter of the plated-through hole;

– the surface material of the metal plating in the hole.

60352-5 © IEC:2008 – 15 –

The upper limit of the press-in force shall be specified by the manufacturer.

The recommended speed for application of the press-in force during measurement shall be

25 mm/min to 50 mm/min.

5.2.2.3 Push-out force

This test is only applicable in the qualification test schedule.

This test relates only to the press-in connection between the press-in zone and the metal

plating of a plated-through hole in a printed board. The minimum value given in the

manufacturer’s specification shall ensure a good electrical performance of the press-in

connection before and after mechanical, electrical and climatic conditioning according to the

test schedules.

The object of this test is to assess the ability of a press-in connection to withstand the

mechanical stress caused by a force acting along the longitudinal axis of the press-in

termination.

The test specimen shall consist of a printed board or a part of a printed board with a press-in

termination inserted as shown in Figure 2.

After the press-in operation and before carrying out the push-out test, the test specimens shall

be allowed to recover for a period of at least 24 h.

Printed board

Push-out device

Press-in termination

F

Push-out direction Press-in direction

IEC 2352/07

Figure 2 – Test arrangement – push-out force

A force F shall be applied to the press-in termination against the press-in direction.

A suitable device shall be used, for example a tensile testing machine. The head of the tensile

testing machine shall travel steadily at a speed <12 mm/min.

The specimen shall be tested until the press-in termination moves in the plated-through hole of

the printed board. The ultimate load shall be measured.

Requirement: The minimum and maximum push-out force shall be specified by the manu-

facturer of the press-in zone.

NOTE Where, for technical reasons, when carrying out the push-out test, the push-out operation cannot be

applied, a pull-out operation may be applied.

For information on additional mechanical stresses acting on the press-in termination due to the

application of the press-in connection, see 6.5.1.

– 16 – 60352-5 © IEC:2008

5.2.2.4 Vibration

This test is only applicable in the application test schedule.

The test shall be carried out in accordance with IEC 60512, test 6d.

The test specimens shall be firmly held on a vibration table.

A suitable test arrangement for testing press-in connections shall be defined in the component

specification.

Preferred severities are given in Table 2.

Contact disturbance shall be monitored during vibration test in accordance with IEC 60512,

test 2e.

Requirement: No contact disturbance exceeding 1 μs unless otherwise specified in the

applicable detail specification of the component.

Table 2 – Vibration, preferred test severities

Range of frequency 10 Hz to 55 Hz 10 Hz to 500 Hz 10 Hz to 2 000 Hz

Full duration 2 h + 5 min/– 0 min 6 h+ 5 min/– 0 min 6 h+ 5 min/– 0 min

Displacement amplitude below 0,35 mm 0,35 mm 1,5 mm

the cross-over frequency

2 2

Acceleration amplitude above – 50 m/s 200 m/s

the cross-over frequency

Directions Three axes Three axes Three axes

Number of sweep cycles per direction 8 10 8

Unless otherwise specified in the relevant component detail specification, the 10 Hz to 500 Hz

range shall be carried out.

5.2.2.5 Microsectioning

5.2.2.5.1 General

The test shall be carried out in accordance with IEC 61188-5-1.

5.2.2.5.2 Transverse sectioning

The deformation "a" of the drilled hole contour in the plated-through hole shall be smaller than

70 μm.

The minimum remaining thickness "b" of the plating shall be more than 8 μm. There shall be no

cracks in the plating of the through hole. See Figure 3. Compliance is checked by inspection

and measurement.

60352-5 © IEC:2008 – 17 –

Press-in

b

direction

Measurement of

the deformation

Location of the

microsection

a

Original hole

contour

IEC 140/01

Dimensions in millimetres

Figure 3 – Transverse section of a press-in connection

5.2.2.5.3 Longitudinal sectioning

The deformation "c" of the connected pattern to the plated-through hole shall be not more than

50 μm (see Figure 4).

Neither the plating of the plated-through hole nor the conductor may have cracks ("d"). For

double-sided printed boards, these requirements are applicable to the outer layers. Compliance

is checked by inspection, measurement and visual examination according to 5.2.1.3. The

measurement shall be recorded.

Press-in zone

d

Printed board

IEC 2353/07

Figure 4 – Longitudinal section of a press-in connection

The area of contact between the press-in zone and the hole shall be appropriate to carry the

specified current.

5.2.2.6 Replacement (repairing)

The manufacturer shall specify if replacement is allowed and, if so, the number of replace-

ments allowed. The test of the ability of a press-in zone to withstand replacement and its

possibility to show equal performance is made by having a part of the press-in zone replaced.

+0,2

0,3

–0,1

c

– 18 – 60352-5 © IEC:2008

Replacement is always carried out with new press-in terminations, using the tools specified by

the manufacturer. All requirements are identical to those applicable to the first press-in cycle.

The repaired sets of parts shall be inspected. No loose parts of metal or cracks in the board

layer or conductors shall be visible.

If the component allows the replacement of the press-in termination, the operation and the

tools shall be specified by the manufacturer of the component or a detail specification.

5.2.3 Electrical tests

5.2.3.1 Contact resistance

The contact resistance test shall be carried out in accordance with IEC 60512, test 2a. Care

shall be taken regarding the resolution of the micro-voltmeter as well as corrections for thermo-

electrical voltage. The measuring points should be made as close as possible to minimize the

bulk resistance.

Figure 5 shows an example of the test arrangement.

Printed board

Press-in zone

μV

mA

IEC 2354/07

Figure 5 – Test arrangement for contact resistance

Requirements after mechanical, electrical or climatic conditioning:

a) qualification test schedule: The maximum change of contact resistance shall be less than

0,5 mΩ for each test phase.

b) application test schedule: The maximum change of contact resistance shall be specified

in the component detail specification, if any, or in the

manufacturer’s specification.

If necessary, when direct measurement of press-in connection is not possible, an overall

measurement of contact resistance shall be specified and the requirement for the press-in

connection shall be included in the value required for the component.

5.2.4 Climatic tests

5.2.4.1 General

The detail specification of the component, if any, or the manufacturer’s specification shall

prescribe the upper category temperature (UCT) and the lower category temperature (LCT)

which shall be used in the following tests.

When the printed board associated with this component has a different temperature category,

the climatic test shall be carried out with the temperature category either of the component, or

the printed board, whichever is the less severe.

NOTE The maximum operating temperature of the printed board is the limiting value.

60352-5 © IEC:2008 – 19 –

5.2.4.2 Rapid change of temperature

The test shall be carried out in accordance with IEC 60512, test 11d. Unless otherwise

specified by the manufacturer of the component or a detail specification, the following details

shall apply:

– low temperature T –40 °C (LCT)

A

– high temperature T 85 °C (UCT)

B

– duration of exposure t 30 min

– number o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...