IEC TR 60695-1-21:2008

(Main)Fire hazard testing - Part 1-21: Guidance for assessing the fire hazard of electrotechnical products - Ignitability - Summary and relevance of test methods

Fire hazard testing - Part 1-21: Guidance for assessing the fire hazard of electrotechnical products - Ignitability - Summary and relevance of test methods

IEC/TR 60695-1-21:2008 provides a summary of test methods that are used to determine the ignitability of electrotechnical products or materials from which they are formed. It also includes test methods in which, by design, ignitability is a significant quantifiable characteristic. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

Essais relatifs aux risques du feu - Partie 1-21: Lignes directrices pour l'évaluation des risques du feu des produits électrotechniques - Allumabilité - Résumé et pertinence des méthodes d'essais

La CEI/TR 60695-1-21:2008 donne un résumé des méthodes d'essai qui sont utilisées pour déterminer l'allumabilité des produits électrotechniques ou des matériaux à partir desquels ils sont fabriqués. Il inclut aussi les méthodes d'essai dans lesquelles, par conception, l'allumabilité est une caractéristique. Cette publication fondamentale de sécurité est destinée à être utilisée par les comités d'études pour l'établissement de leurs normes conformément aux principes exposés dans le Guide 104 de la CEI et dans le Guide ISO/CEI 51.

General Information

- Status

- Replaced

- Publication Date

- 20-May-2008

- Technical Committee

- TC 89 - Fire hazard testing

- Drafting Committee

- WG 12 - TC 89/WG 12

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 07-Sep-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

Buy Documents

IEC TR 60695-1-21:2008 - Fire hazard testing - Part 1-21: Guidance for assessing the fire hazard of electrotechnical products - Ignitability - Summary and relevance of test methods Released:5/21/2008 Isbn:2831897920

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC TR 60695-1-21:2008 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Fire hazard testing - Part 1-21: Guidance for assessing the fire hazard of electrotechnical products - Ignitability - Summary and relevance of test methods". This standard covers: IEC/TR 60695-1-21:2008 provides a summary of test methods that are used to determine the ignitability of electrotechnical products or materials from which they are formed. It also includes test methods in which, by design, ignitability is a significant quantifiable characteristic. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

IEC/TR 60695-1-21:2008 provides a summary of test methods that are used to determine the ignitability of electrotechnical products or materials from which they are formed. It also includes test methods in which, by design, ignitability is a significant quantifiable characteristic. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

IEC TR 60695-1-21:2008 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 60695-1-21:2008 has the following relationships with other standards: It is inter standard links to IEC 60695-1-21:2016, EN 60695-1-11:2010, EN 60695-1-20:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 60695-1-21:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TR 60695-1-21

Edition 1.0 2008-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 1-21: Guidance for assessing the fire hazard of electrotechnical products –

Ignitability – Summary and relevance of test methods

Essais relatifs aux risques du feu –

Partie 1-21: Lignes directrices pour l'évaluation des risques du feu des produits

électrotechniques – Allumabilité – Résumé et pertinence des méthodes d'essais

IEC/TR 60695-1-21:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TR 60695-1-21

Edition 1.0 2008-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 1-21: Guidance for assessing the fire hazard of electrotechnical products –

Ignitability – Summary and relevance of test methods

Essais relatifs aux risques du feu –

Partie 1-21: Lignes directrices pour l'évaluation des risques du feu des produits

électrotechniques – Allumabilité – Résumé et pertinence des méthodes d'essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 13.220.40; 29.020 ISBN 2-8318-9792-0

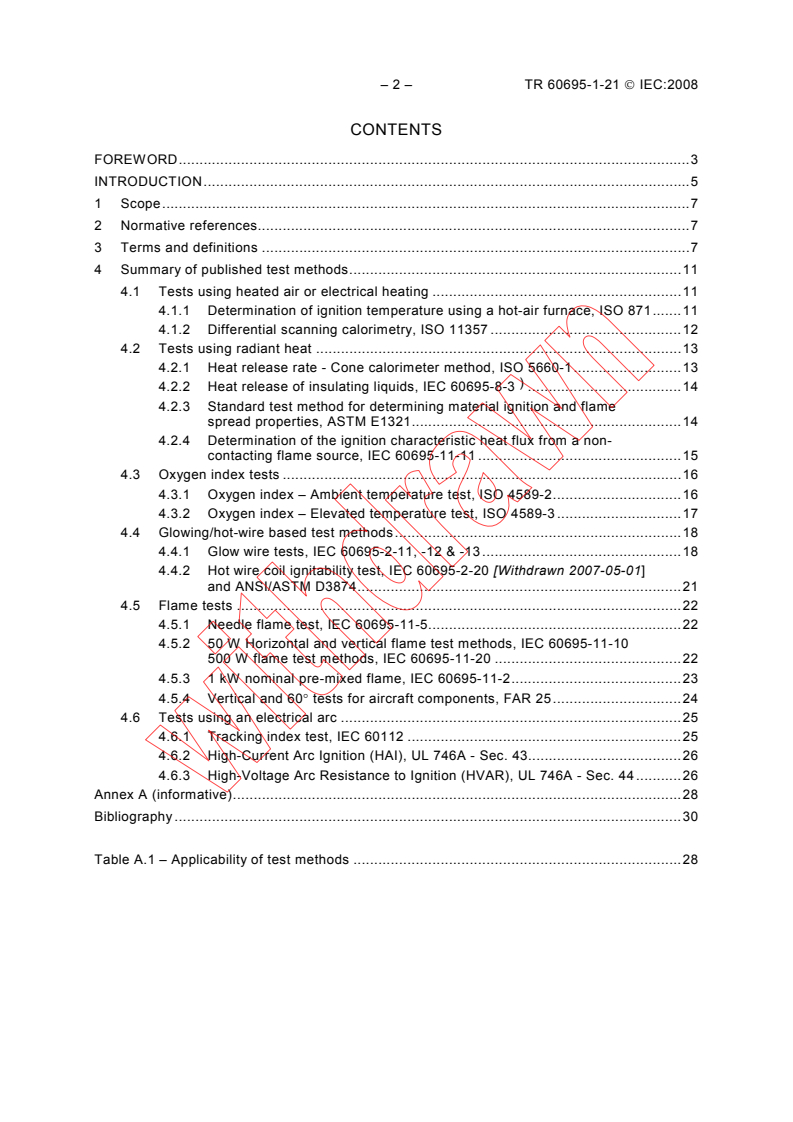

– 2 – TR 60695-1-21 © IEC:2008

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.7

2 Normative references.7

3 Terms and definitions .7

4 Summary of published test methods.11

4.1 Tests using heated air or electrical heating .11

4.1.1 Determination of ignition temperature using a hot-air furnace, ISO 871.11

4.1.2 Differential scanning calorimetry, ISO 11357 .12

4.2 Tests using radiant heat .13

4.2.1 Heat release rate - Cone calorimeter method, ISO 5660-1.13

)

4.2.2 Heat release of insulating liquids, IEC 60695-8-3 .14

4.2.3 Standard test method for determining material ignition and flame

spread properties, ASTM E1321.14

4.2.4 Determination of the ignition characteristic heat flux from a non-

contacting flame source, IEC 60695-11-11 .15

4.3 Oxygen index tests .16

4.3.1 Oxygen index – Ambient temperature test, ISO 4589-2.16

4.3.2 Oxygen index – Elevated temperature test, ISO 4589-3 .17

4.4 Glowing/hot-wire based test methods.18

4.4.1 Glow wire tests, IEC 60695-2-11, -12 & -13 .18

4.4.2 Hot wire coil ignitability test, IEC 60695-2-20 [Withdrawn 2007-05-01]

and ANSI/ASTM D3874.21

4.5 Flame tests .22

4.5.1 Needle flame test, IEC 60695-11-5.22

4.5.2 50 W Horizontal and vertical flame test methods, IEC 60695-11-10

500 W flame test methods, IEC 60695-11-20 .22

4.5.3 1 kW nominal pre-mixed flame, IEC 60695-11-2.23

4.5.4 Vertical and 60° tests for aircraft components, FAR 25.24

4.6 Tests using an electrical arc .25

4.6.1 Tracking index test, IEC 60112 .25

4.6.2 High-Current Arc Ignition (HAI), UL 746A - Sec. 43.26

4.6.3 High-Voltage Arc Resistance to Ignition (HVAR), UL 746A - Sec. 44.26

Annex A (informative).28

Bibliography .30

Table A.1 – Applicability of test methods .28

TR 60695-1-21 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 1-21: Guidance for assessing the fire hazard

of electrotechnical products –

Ignitability –

Summary and relevance of test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC/TR 60695-1-21, which is a technical report, has been prepared by IEC technical committee

89: Fire hazard testing.

It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC

Guide 51.

– 4 – TR 60695-1-21 © IEC:2008

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

89/804/DTR 89/812A/RVC

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

)

This technical report is to be read in conjunction with IEC 60695-1-20 .

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60695 series, under the genral title Fire hazard testing, can be found

on the IEC website.

Part 1 consists of the following parts:

Part 1-10 : Guidance for assessing the fire hazard of electrotechnical products –

General guidelines

Part 1-11 : Guidance for assessing the fire hazard of electrotechnical products –

Fire hazard assessment

Part 1-20 : Guidance for assessing the fire hazard of electrotechnical products –

Ignitability – General guidance

Part 1-21: Guidance for assessing the fire hazard of electrotechnical products –

Ignitability – Summary and relevance of test methods

Part 1-30: Guidance for assessing the fire hazard of electrotechnical products –

Preselection testing procedures – General guidelines

Part 1-40: Guidance for assessing the fire hazard of electrotechnical products –

Insulating liquids

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the

data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

___________

)

Under consideration.

TR 60695-1-21 © IEC:2008 – 5 –

INTRODUCTION

Fires are responsible for creating hazards to life and property as a result of the generation of

heat (thermal hazard), and also as a result of the production of toxic effluent, corrosive effluent

and smoke (non-thermal hazard). Fires start with ignition and then can grow, leading in some

cases to flash-over and a fully developed fire. Ignition resistance is therefore one of the most

important parameters of a material to be considered in the assessment of fire hazard. If there

is no ignition, there is no fire.

For most materials (other than metals and some other elements), ignition occurs in the gas

phase. Ignition occurs when combustible vapour, mixed with air, reaches a high enough

temperature for exothermic oxidation reactions to rapidly propagate. The ease of ignition is a

function of the chemical nature of the vapour, the fuel/air ratio and the temperature.

In the case of liquids, the combustible vapour is produced by vaporization of the liquid, and the

vaporization process is dependent on the temperature and chemical composition of the liquid.

In the case of solids, the combustible vapour is produced by pyrolysis when the temperature of

the solid is sufficiently high. The vaporization process is dependent on the temperature and

chemical composition of the solid, and also on the thickness, density, specific heat, and

thermal conductivity of the solid.

The ease of ignition of a test specimen depends on many variables. Factors that need to be

considered for the assessment of ignitability are:

a) the geometry of the test specimen, including thickness and the presence of edges, corners

or joints;

b) the surface orientation;

c) the rate and direction of air flow;

d) the nature and position of the ignition source;

e) the magnitude and position of any external heat flux; and

f) whether the combustible material is a solid or a liquid.

In the design of any electrotechnical product the risk of fire and the potential hazards

associated with fire need to be considered. In this respect the objective of component, circuit

and equipment design as well as the choice of materials is to reduce to acceptable levels the

potential risks of fire even in the event of foreseeable abnormal use, malfunction or failure.

3) 2)

IEC 60695-1-10 , together with its companion, IEC 60695-1-11 , provide guidance on how

this is to be accomplished.

The primary aims are to prevent ignition caused by an electrically energized component part,

and in the event of ignition, to confine any resulting fire within the bounds of the enclosure of

the electrotechnical product.

Secondary aims include the minimization of any flame spread beyond the product’s enclosure

and the minimization of harmful effects of fire effluents including heat, smoke, and toxic or

corrosive combustion products.

Fires involving electrotechnical products can also be initiated from external non-electrical

sources. Considerations of this nature are dealt with in the overall risk assessment.

___________

2)

Under consideration.

– 6 – TR 60695-1-21 © IEC:2008

For these reasons there are many tests used to evaluate the ignitability of electrotechnical

products and of the materials used in their construction. This technical report describes

ignitability test methods in common use to assess electrotechnical products, or materials used

in electrotechnical products. It also includes test methods in which, by design, ignitability is a

significant quantifiable characteristic. It forms part of the IEC 60695-1 series, which gives

guidance to product committees wishing to incorporate fire hazard test methods in product

standards.

TR 60695-1-21 © IEC:2008 – 7 –

FIRE HAZARD TESTING –

Part 1-21: Guidance for assessing the fire hazard

of electrotechnical products –

Ignitability –

Summary and relevance of test methods

1 Scope

This part of IEC 60695, which is a technical report, provides a summary of test methods that

are used to determine the ignitability of electrotechnical products or materials from which they

are formed. It also includes test methods in which, by design, ignitability is a significant

quantifiable characteristic.

It represents the current state of the art of the test methods and, where available, includes

special observations on their relevance and use. The list of test methods is not to be

considered exhaustive, and test methods which were not developed by IEC TC 89 are not to be

considered as endorsed by IEC TC 89 unless this is specifically stated.

This basic safety publication is intended for use by technical committees in the preparation of

standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications. The requirements, test methods

or test conditions of this basic safety publication will not apply unless specifically referred to or

included in the relevant publications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

3)

IEC 60695-1-20 , Fire hazard testing – Part 1-20: Guidance for assessing the fire hazard of

electrotechnical products – Ignitability – General guidance

IEC 60695-1-30, Fire hazard testing – Part 1-30: Guidance for assessing the fire hazard of

electrotechnical products – Use of preselection testing procedures

IEC Guide 104:1997, The preparation of safety publications and the use of basic safety

publications and group safety publications

ISO/IEC Guide 51:1999, Safety aspects – Guidelines for their inclusion in standards

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

___________

3)

Under consideration.

– 8 – TR 60695-1-21 © IEC:2008

3.1

combustion

exothermic reaction of a substance with an oxidiser

NOTE Combustion generally emits effluent accompanied by flames and/or visible light.

[ISO/IEC 13943, definition 23]

3.2

fire

a) process of combustion characterized by the emission of heat and effluent accompanied by

smoke, and/or flame, and/or glowing;

b) rapid combustion spreading uncontrolled in time and space

[IEC 60695-4, definition 3.19]

3.3

fire hazard

(cause of fire) physical object or condition with a potential for an undesirable consequence

from fire

3.4

fire point

minimum temperature at which a material ignites and continues to burn for a specified time

after a standardized small flame has been applied to its surface under specified conditions

NOTE 1 It is expressed in degrees Celsius.

NOTE 2 In some countries the term "fire point" has an additional meaning: a location where fire fighting equipment

is sited, which may also comprise a fire-alarm call point and fire instruction notices.

[ISO/IEC 13943, definition 53]

3.5

fire retardant (noun)

a substance added or a treatment applied to a material in order to suppress, reduce or delay

the combustion of the material

[IEC 60695-4, definition 3.31]

3.6

fire scenario

a detailed description of conditions, including environmental, of one or more of the stages from

before ignition to the completion of combustion in an actual fire at a specific location, or in a

full-scale simulation

[IEC 60695-4, definition 3.32]

3.7

flame (noun)

zone of combustion in the gaseous phase, usually with emission of light

[ISO/IEC 13943, definition 60]

3.8

flame retardant (noun)

substance added, or a treatment applied, to a material in order to suppress or delay the

appearance of a flame and/or reduce its propagation (spread) rate

NOTE The use of flame retardants does not necessarily suppress fire.

TR 60695-1-21 © IEC:2008 – 9 –

[ISO/IEC 13943, definition 65]

3.9

flaming combustion

combustion in gaseous phase, usually with emission of light

[ISO/IEC 13943, definition 72]

3.10

flash-ignition temperature (FIT)

the minimum temperature at which, under specified test conditions, sufficient flammable gases

are emitted to ignite momentarily on application of a pilot flame

[ISO 871, definition 3.1]

3.11

flash-over

the rapid transition to a state of total surface involvement in a fire of combustible materials

within an enclosure

[IEC 60695-4, definition 3.42]

3.12

flash point (ºC)

minimum temperature to which a material or product must be heated for the vapours emitted to

ignite momentarily in the presence of flame, under specified test conditions

NOTE It is expressed in degrees Celsius.

[ISO/IEC 13943, definition 76]

3.13

fully developed fire

state of total involvement of combustible materials in a fire

[ISO/IEC 13943, definition 80]

3.14

glowing combustion

combustion of a material in the solid phase without flame but with the emission of light from the

combustion zone

[ISO/IEC 13943, definition 84]

3.15

ignitability

measure of the ease with which an item can be ignited, under specified conditions

[ISO/IEC 13943, definition 91]

3.16

ignition

initiation of combustion

NOTE The term "ignition" in French has a very different meaning [state of body combustion].

[ISO/IEC 13943, definition 96]

– 10 – TR 60695-1-21 © IEC:2008

3.17

ignition source

source of energy that initiates combustion

[ISO/IEC 13943, definition 97]

3.18

ignition temperature (minimum)

the (minimum) temperature of a material or of an ignition source at which sustained

combustion can be initiated under specified test conditions, as defined in the test method

NOTE Ignition requires a sufficient volume of flammable gas and oxidant (air). Sustained combustion requires a

sufficient rate of production of flammable gas. The minimum ignition temperature implies thermal stressing to

infinite time. For practical purposes, the standard should define the minimum ignition temperature appropriately.

[IEC 60695-4, definition 3.51]

3.19

lower flammability limit (LFL)

minimum concentration of fuel vapour in air below which propagation of a flame will not occur

in the presence of an ignition source

NOTE The concentration of a gas or vapour is usually expressed as a volume fraction (%) at a defined

temperature and pressure. The concentrations of solid and liquid aerosol, as well as mixtures of dust with air, are

usually expressed as a density (g⋅m ).

3.20

spontaneous-ignition temperature (SIT)

the minimum temperature at which ignition is obtained by heating, under specified test

conditions, in the absence of any additional flame ignition source.

[ISO 871, definition 3.2]

3.21

thermal inertia

product of thermal conductivity, density and specific heat capacity

NOTE 1 When a material is exposed to a heat flux, the rate of increase in surface temperature depends strongly

on the value of the thermal inertia of the material. The surface temperature of a material with a low thermal inertia

rises relatively quickly when it is heated, and vice versa.

2 -1 -4 -2

NOTE 2 The typical units are J ⋅s ⋅m ⋅K .

3.22

tracking

progressive formation of conducting paths, which are produced on the surface and/or within a

solid insulating material, due to the combined effects of electric stress and electrolytic

contamination

[IEC 60112, definition 3.1]

3.23

upper flammability limit (UFL)

highest concentration of a flammable substance in air within which a self-propagating flame

can occur

NOTE The concentration of a gas or vapour is usually expressed as a volume fraction (%) at a defined

temperature and pressure. The concentrations of solid and liquid aerosol, as well as mixtures of dust with air, are

usually expressed as a density (g⋅m ).

TR 60695-1-21 © IEC:2008 – 11 –

4 Summary of published test methods

This summary cannot be used in place of published standards which are the only valid

reference documents. It represents the current state of the art of the test methods and, where

available, includes special observations on their relevance and use. The list of test methods is

not to be considered exhaustive, and test methods which were not developed by IEC TC 89 are

not to be considered as endorsed by IEC TC 89 unless this is specifically stated.

Some test methods are material tests and some are end-product tests. Table A.1 in Annex A

lists the test methods described below and distinguishes between material tests and end-

product tests.

NOTE 1 Not all the following test methods are specifically ignition or ignitability tests, but some tests have been

included because ignition data are, or can be, measured.

NOTE 2 Where no repeatability and reproducibility data are known to be available, the reader is recommended to

contact the author/publisher of the relevant test method.

4.1 Tests using heated air or electrical heating

4.1.1 Determination of ignition temperature using a hot-air furnace, ISO 871

4.1.1.1 Purpose and principle

4)

ISO 871 [1] specifies a laboratory method for determining the flash-ignition temperature and

spontaneous-ignition temperature of plastics using a hot-air furnace.

A specimen of the material is heated in a hot-air ignition furnace using various temperatures

within the heated chamber, and the flash-ignition temperature is determined with a small pilot

flame directed at the opening in the top of the furnace to ignite evolved gases. The

spontaneous-ignition temperature is determined in the same manner as the flash-ignition

temperature, but without the ignition flame.

4.1.1.2 Test specimen

Materials supplied in any form, including composites, may be used. A 3 g sample is used if the

-3 -3

density is greater than 100 kg⋅m . For cellular materials having a density less than 100 kg⋅m ,

any outer skin is removed and a block of dimensions 20 mm × 20 mm × 50 mm is cut.

4.1.1.3 Test method

-1

An air velocity of 25 mm⋅s is set and an initial test temperature is chosen. At the end of

10 min the temperature is lowered or raised by 50 °C, depending on whether ignition has or

has not occurred and a fresh sample is tested. When the range within which the ignition

temperature lies has been determined, tests are begun 10 °C below the highest temperature

within this range and continued by dropping the temperature in 10 °C steps until the

temperature is reached at which there is no ignition during a 10 min period. The ignition

temperature is recorded as the lowest test temperature at which ignition is observed.

4.1.1.4 Repeatability and reproducibility

Data are available in Annex A of ISO 871.

4.1.1.5 Relevance of test data

Tests made under the conditions of this method can be of considerable value in comparing the

relative ignition characteristics of different materials. Values obtained represent the lowest

___________

4)

Figures in square brackets refer to the bibliography.

– 12 – TR 60695-1-21 © IEC:2008

ambient air temperature that will cause ignition of the material under the conditions of this test.

Test values are expected to rank materials according to ignition susceptibility under actual use

conditions.

4.1.2 Differential scanning calorimetry (DSC), ISO 11357

4.1.2.1 Introduction

Differential scanning calorimetry (DSC) is one of a number of thermal methods of analysis

which are not used to directly measure ignition, but which are used to measure a number of

properties which affect ignitability and which can be used in fire safety engineering studies and

in fire modelling.

NOTE Other useful techniques include thermogravimetric analysis (TGA), differential thermal analysis (DTA),

thermomechanical analysis (TMA), dynamic mechanical thermal analysis (DMTA), and pyrolysis gas

chromatography [2], [3].

4.1.2.2 Purpose and principle

ISO 11357 [4] consists of seven parts, and describes methods using DSC to measure the

following properties of polymeric materials such as thermoplastics and thermosetting plastics,

including moulding materials and composite materials:

• Glass transition temperature

• Temperature and enthalpy of melting and crystallization

• Specific heat capacity

• Polymerization temperatures and/or times and polymerization kinetics

• Oxidation induction time

• Crystallization kinetics

The DSC method involves the measurement of the difference between the heat flow into a test

specimen and that into a reference specimen as a function of temperature and/or time, while

the test specimen and the reference specimen are subjected to a controlled temperature

programme under a specified atmosphere.

4.1.2.3 Test specimen

Test specimens may be liquid or solid. The optimum test specimen mass varies depending on

what parameter is being studied, but will typically be in the range 5 mg to 50 mg. The test

specimen is placed in a sample pan which, if required, is sealed with a lid. The reference

specimen is usually an identical empty sample pan.

4.1.2.4 Test method

The instrument is first calibrated, then the sample pans are inserted and the instrument is

programmed to carry out the desired thermal cycle. Control operations and data analysis are

according to the manufacturer’s instructions.

4.1.2.5 Repeatability and reproducibility

Data are given in annexes to the various parts of ISO 11357.

4.1.2.6 Relevance of test data

DSC enables the measurement of two important parameters which are needed in fire models of

ignition. These are a) specific heat capacity as a function of temperature, and b) the heat of

gasification.

TR 60695-1-21 © IEC:2008 – 13 –

4.2 Tests using radiant heat

4.2.1 Heat release rate - Cone calorimeter method, ISO 5660-1

4.2.1.1 Purpose and principle

ISO 5660-1 [5] specifies a method for assessing the heat release rate of a test specimen

exposed in the horizontal orientation to a controlled level of irradiance in the presence of a

-2 -2

spark ignition source. The irradiance is within the range of 0 kW⋅m to 100 kW⋅m . The heat

release rate is determined by measurement of the oxygen consumption derived from the

oxygen concentration and the flow rate in the combustion product stream. The time to ignition

(sustained flaming) is also measured in the test. The test specimen is mounted on a load cell

so that the mass is measured during the test.

The test method is based on the observation that, generally, the net heat of combustion is

proportional to the amount of oxygen required for combustion. The relationship is that

approximately 13,1 kJ of heat are released per gram of oxygen consumed.

4.2.1.2 Test specimen

The test specimen is square (100 mm × 100 mm) and not more than 50 mm thick. It is wrapped

in aluminium foil so that the bottom and sides are covered and the top surface is exposed. The

wrapped test specimen is placed in a retainer frame. A substrate is used if appropriate.

4.2.1.3 Test method

The apparatus is first calibrated, and then the exhaust flow and irradiance levels are set. The

test specimen is placed in position under a radiation shield, and then the test is started when

the shield is removed and the spark igniter is inserted and powered.

Data are collected for typically 32 min after sustained flaming has occurred. Three specimens

are tested.

NOTE ISO 5660-1 describes the measurement of heat release, mass, and ignition time. However, many cone

calorimeters also additionally allow the measurement of CO, CO and smoke production. ISO 5660-2 [6] describes

the measurement of smoke production.

4.2.1.4 Repeatability and reproducibility

Data are available in Annex B of ISO 5660-1.

4.2.1.5 Relevance of test data

Heat release rate is one of the most important variables in determining the hazard from a fire.

In a typical fire, many items composed of many surfaces contribute to the development of a

fire, thus making its evaluation quite complex. A determination must first be made of when

each separate surface will ignite, if at all, and this bench scale test gives this information.

The size of the fire from any items already burning must be determined in order to calculate its

contribution to the external irradiance on nearby items. Flame spread over each surface must

also be evaluated. The heat release rate from the whole surface is then determined knowing

the heat release rate per unit area for a given irradiance, as a function of time, as evaluated

using this bench scale test. The total fire output then involves a summation over all surfaces

for all materials.

Ignition time data as a function of irradiance can also be used to calculate useful ignition

related parameters such as the thermal inertia of materials.

– 14 – TR 60695-1-21 © IEC:2008

)

4.2.2 Heat release of insulating liquids, IEC 60695-8-3

4.2.2.1 Purpose and principle

This technical report specifies test methods for determining the heat release and smoke

production from insulating liquids of electrotechnical products when exposed to a defined heat

flux. The standard may also be applicable to other liquid specimens.

The principle of the method is the same as that described in 4.2.1.1. In addition a laser, shining

through the exhaust effluent, is used to measure smoke production, as described in

ISO 5660-2.

4.2.2.2 Test specimen

3 3

For preliminary tests 20 cm of liquid are used. 50 cm of liquid are used for the main tests.

The liquid is placed in a square, stainless steel sample holder which is 100 mm × 100 mm and

15 mm deep.

4.2.2.3 Test method

The apparatus is calibrated in accordance with Parts 1 and 2 of ISO 5660 and preliminary tests

are carried out to find the minimum heat flux (critical ignition flux) at which the test specimen

ignites in less than 1 200 s. The main tests are then carried out at this critical ignition flux. Data

analysis is in accordance with Parts 1 and 2 of ISO 5660.

4.2.2.4 Repeatability and reproducibility

No data are currently available.

4.2.2.5 Relevance of test data

From this test it is possible to obtain a quantitative assessment of the relative ease, or

difficulty, of the ignition of liquids used for electrotechnical purposes. Quantitative heat release

and smoke production data are also obtained. All these data can be used in fire safety

engineering studies including fire hazard assessments.

4.2.3 Standard test method for determining material ignition and flame spread

properties, ASTM E1321

4.2.3.1 Purpose and principle

ASTM E1321 [7] determines material properties related to piloted ignition of a vertically

oriented sample under a constant and uniform heat flux and to lateral flame spread on a

vertical surface due to an externally applied radiant-heat flux.

4.2.3.2 Test specimen

Test specimens are tested in the form of intended use. For the ignition test, specimens are

155 mm × 155 mm. For the flame spread test, specimens are 800 mm × 155 mm. For both

tests, materials and composites of normal thickness 50 mm or less are tested using their full

thickness. The test method is restricted to thermally thick test specimens (i.e. when the

exposed surface has ignited, the back surface will not have become significantly heated above

the ambient temperature).

___________

)

Under consideration.

TR 60695-1-21 © IEC:2008 – 15 –

4.2.3.3 Test method

The test method consists of two procedures; one to measure ignition and one to measure

lateral flame spread. Vertically mounted specimens are exposed to the heat from a vertical

air/gas fuelled radiant-heat energy source inclined at 15° to the test specimen.

-2

For the ignition test, a test specimen is exposed to a heat flux of 30 kW⋅m and the time of

ignition, if it occurs within 20 min, is noted. The test is repeated until a minimum flux for

-2

ignition, with a tolerance of ± 2 kW⋅m , has been obtained. Tests are then repeated at higher

-2

heat fluxes (using increments of about 10 kW⋅m ), until an ignition time / heat flux profile has

-2

been determined for heat fluxes between the minimum heat flux for ignition and 65 kW⋅m .

The data are correlated with defined theories of ignition for the derivation of material

flammability properties.

For the flame spread test, a test specimen is exposed to a graduated heat flux that is

-2

higher at the hotter end than the minimum heat flux necessary for

approximately 5 kW⋅m

ignition; this heat flux being determined from the ignition test. The test specimen is preheated

to thermal equilibrium; the preheat time also being determined from the ignition test. After

ignition, the flame front progression along the horizontal length of the test specimen is tracked

as a function of time. The data are correlated with defined theories of ignition and flame spread

for the derivation of material flammability properties.

4.2.3.4 Repeatability and reproducibility

No data are currently available.

4.2.3.5 Relevance of test data

The results of this test method provide a minimum surface flux and temperature necessary for

ignition and for lateral spread, an effective material thermal inertia value, and a flame-heating

parameter pertinent to lateral flame spread. The results are potentially useful to predict the

time to ignition and the velocity of lateral flame spread on a vertical surface under a specified

external flux without forced lateral airflow. Data can be used in fire growth models.

4.2.4 Determination of the ignition characteristic heat flux from a non-contacting

flame source, IEC 60695-11-11

4.2.4.1 Purpose and principle

IEC 60695-11-11 [8] describes a test method used to obtain the ignition characteristic heat flux

(ICHF) of electrotechnical products, sub-assemblies and materials. The heat flux originates

from a non-contacting flame. The test method measures ignition time as a function of incident

heat flux.

4.2.4.2 Test specimen

Test specimens are cut from a representative sample of the material taken from an end-

product. Where this is not possible, the test specimen is produced using the same fabrication

process and the same thickness as would be normally used to make a part of a product. The

size of each test specimen is 75 mm ± 1 mm long by 75 mm ± 1 mm wide for both end-product

testing and materials testing. Preferred thicknesses are 0,75 mm ± 0,1 mm, 1,5 mm ± 0,1 mm

and 3,0 mm ± 0,2 mm.

4.2.4.3 Test method

The first step is to use a heat flux meter to determine the incident heat fluxes generated at

-2

several different distances vertically above the flame. These are in the range 30 kW⋅m to

-2

75 kW⋅m .

– 16 – TR 60695-1-21 © IEC:2008

Tests are then carried out on test specimens at heat flux levels which are a multiple of

-2 -2 -2

5 kW⋅m and which are in the range 30 kW⋅m to 75 kW⋅m , such that one of the heat fluxes

is the highest at which the average ignition time is greater than 120 s.

For the purposes of this test method, ignition of the test specimen is considered to be a

sustained and continuous flaming combustion for at least 5 s.

4.2.4.4 Repeatability and reproducibility

No data are available. An interlaboratory series of tests is currently underway.

4.2.4.5 Relevance of test data

This test method simulates the fire behaviour of products, assemblies and materials in those

cases where a flame source exists close to, but does not make contact with these items. An

example is a candle flame near an electrotechnical product.

4.3 Oxygen index tests

4.3.1 Oxygen index – Ambient temperature test, ISO 4589-2

4.3.1.1 Purpose and principle

ISO 4589-2 [9] is used to determine the minimum volume fraction of oxygen, in a mixture with

nitrogen, that will support combustion of small vertical test specimens under specified test

conditions. The results, reported as percentages, are defined as oxygen index values.

4.3.1.2 Test specimen

For moulding materials the test specimen dimensions are 80 mm to 150 mm in length, 10 mm

in width and 4 mm in thickness. The dimensions for other materials are detailed in Table 2 of

ISO 4589-2.

4.3.1.3 Test method

A small test specimen is supported vertically in a mixture of oxygen and nitrogen flowing

upwards through a transparent chimney. The upper end of the specimen is ignited and the

subsequent burning behaviour of the specimen is observed to compare the period for which

burning continues, or the length of specimen burnt, with specified limits for such burning. By

testing a series of specimens in different oxygen concentrations, the minimum oxygen

concentration is estimated for the required burning behaviour.

4.3.1.4 Repeatability and reproducibility

Data are given in 9.4 and Annex D of ISO 4589-2.

4.3.1.5 Relevance of test data

The oxygen index (OI) test at ambient temperature was first described by Fenimore and Mart

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...