IEC 60243-1:2013

(Main)Electric strength of insulating materials - Test methods - Part 1: Tests at power frequencies

Electric strength of insulating materials - Test methods - Part 1: Tests at power frequencies

IEC 60243-1:2013 provides test methods for the determination of short-time electric strength of solid insulating materials at power frequencies between 48 Hz and 62 Hz. This standard does not cover the testing of liquids and gases, although these are specified and used as impregnates or surrounding media for the solid insulating materials being tested. NOTE: Methods for the determination of breakdown voltages along the surfaces of solid insulating materials are included.

Rigidité diélectrique des matériaux isolants - Méthodes d'essai - Partie 1: Essais aux fréquences industrielles

La CEI 60243-1:2013 fournit les méthodes d'essai pour la détermination de la rigidité diélectrique de courte durée des matériaux isolants solides, aux fréquences industrielles comprises entre 48 Hz et 62 Hz. La présente norme ne couvre pas la manière d'effectuer l'essai des liquides ou des gaz bien que ceux-ci soient spécifiés et utilisés comme imprégnants ou comme milieu ambiant pour l'essai des matériaux isolants solides. NOTE: Les méthodes pour déterminer les tensions de claquage en surface des matériaux isolants solides sont indiquées.

General Information

- Status

- Published

- Publication Date

- 25-Mar-2013

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 3 - TC 112/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Mar-2013

- Completion Date

- 30-Apr-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60243-1:2013 is an internationally recognized standard developed by the International Electrotechnical Commission (IEC) that defines test methods for evaluating the electric strength of solid insulating materials at power frequencies ranging from 48 Hz to 62 Hz. This third edition focuses on the short-time electric strength determination to ensure material reliability in electrical equipment and systems. The standard excludes testing for liquids and gases directly, but it considers their role as impregnates or surrounding media for solid insulators.

The electric strength of insulating materials is critical as it determines the ability of materials to withstand electrical stresses without failure. IEC 60243-1:2013 provides detailed procedures for breakdown voltage testing, including tests perpendicular and parallel to material surfaces, ensuring robust and consistent evaluation of insulation performance under power frequency conditions.

Key Topics

Scope and Purpose

- Focuses on solid insulating materials under power frequencies (48-62 Hz).

- Includes surface breakdown voltage determination.

- Excludes direct testing of liquids and gases but accounts for their presence as impregnates or environmental media.

Test Setup and Specimen Preparation

- Standard specifies electrode arrangements for varying material shapes such as boards, sheets, tapes, tubes, and molded parts.

- Conditioning requirements before testing to ensure material stability.

- Details on electrode distances and geometries for reliable and repeatable results.

Electrical and Environmental Conditions

- Voltage source specifications for power frequency application.

- Measuring devices and procedures to accurately capture breakdown voltages.

- Guidelines for testing in different surrounding media-air, liquids, or other solid materials.

- Temperature considerations for tests conducted at elevated conditions.

Test Procedures

- Multiple test modes including short-time rapid-rise tests and step-by-step voltage application.

- Voltage increase schedules outlined (e.g., 20s, 60s, very slow rates of rise).

- Proof tests for verifying material electric strength.

Result Evaluation and Reporting

- Breakdown criteria and failure definitions.

- Statistical treatment and analysis of test data.

- Requirements for comprehensive test reporting to ensure traceability and conformity.

Applications

IEC 60243-1:2013 serves as a fundamental standard for quality assurance, research, and development related to electrical insulating materials used in:

- Electrical Equipment Manufacturing

- Transformers, switchgear, cables, and other power devices where insulation integrity is critical.

- Material Selection and Qualification

- Evaluation of new insulating materials and composites for power applications.

- Safety Testing and Compliance

- Ensuring insulation systems meet stringent safety and reliability standards.

- Research & Development

- Development of innovative insulation materials with improved dielectric properties.

- Maintenance and Diagnostics

- Assessing insulation degradation and service life predictions through controlled testing.

Related Standards

- IEC 60212 - Standard conditions for testing solid electrical insulating materials.

- IEC 60296 - Specifications for unused mineral insulating oils.

- IEC 60455-2 - Test methods for solventless polymerizable resinous compounds.

- IEC 60464-2 - Test methods for electrical varnishes.

- IEC 60684-2 - Test methods for flexible insulating sleeving.

- IEC 60836 - Specifications for unused silicone insulating liquids.

- These referenced standards complement IEC 60243-1 by providing material-specific testing protocols ensuring comprehensive insulation system evaluation.

Keywords: IEC 60243-1, electric strength, insulating materials, power frequency testing, dielectric strength, breakdown voltage, electrical insulation testing, solid insulators, short-time electric strength, insulating material test methods, electrical safety standards, power equipment insulation.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60243-1:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric strength of insulating materials - Test methods - Part 1: Tests at power frequencies". This standard covers: IEC 60243-1:2013 provides test methods for the determination of short-time electric strength of solid insulating materials at power frequencies between 48 Hz and 62 Hz. This standard does not cover the testing of liquids and gases, although these are specified and used as impregnates or surrounding media for the solid insulating materials being tested. NOTE: Methods for the determination of breakdown voltages along the surfaces of solid insulating materials are included.

IEC 60243-1:2013 provides test methods for the determination of short-time electric strength of solid insulating materials at power frequencies between 48 Hz and 62 Hz. This standard does not cover the testing of liquids and gases, although these are specified and used as impregnates or surrounding media for the solid insulating materials being tested. NOTE: Methods for the determination of breakdown voltages along the surfaces of solid insulating materials are included.

IEC 60243-1:2013 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.035.01 - Insulating materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60243-1:2013 has the following relationships with other standards: It is inter standard links to IEC 60243-1:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60243-1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60243-1 ®

Edition 3.0 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric strength of insulating materials – Test methods –

Part 1: Tests at power frequencies

Rigidité diélectrique des matériaux isolants – Méthodes d'essai –

Partie 1: Essais aux fréquences industrielles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60243-1 ®

Edition 3.0 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric strength of insulating materials – Test methods –

Part 1: Tests at power frequencies

Rigidité diélectrique des matériaux isolants – Méthodes d'essai –

Partie 1: Essais aux fréquences industrielles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 17.220.99; 29.035.01 ISBN 978-2-83220-696-6

– 2 – 60243-1 © IEC:2013

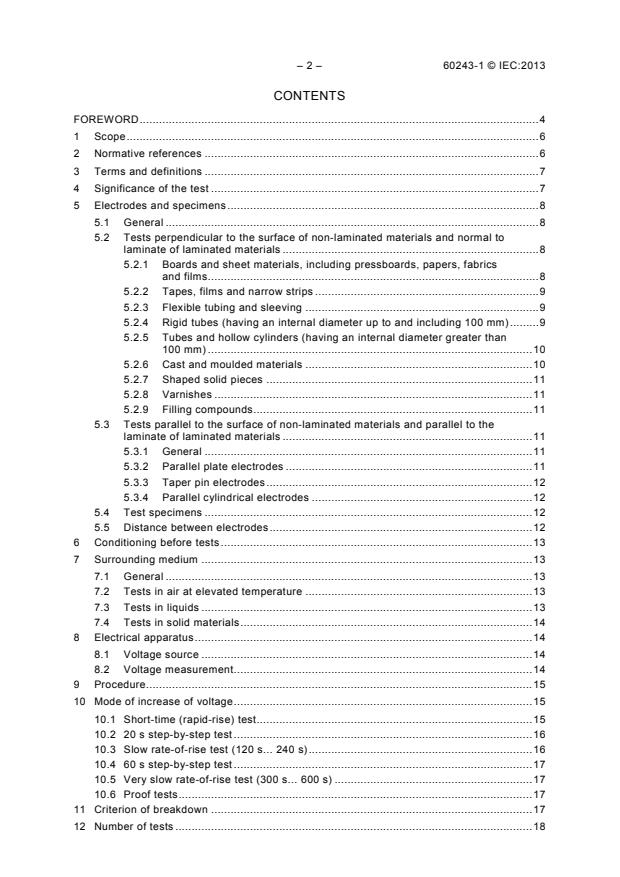

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Significance of the test . 7

5 Electrodes and specimens . 8

5.1 General . 8

5.2 Tests perpendicular to the surface of non-laminated materials and normal to

laminate of laminated materials . 8

5.2.1 Boards and sheet materials, including pressboards, papers, fabrics

and films . 8

5.2.2 Tapes, films and narrow strips . 9

5.2.3 Flexible tubing and sleeving . 9

5.2.4 Rigid tubes (having an internal diameter up to and including 100 mm) . 9

5.2.5 Tubes and hollow cylinders (having an internal diameter greater than

100 mm) . 10

5.2.6 Cast and moulded materials . 10

5.2.7 Shaped solid pieces . 11

5.2.8 Varnishes . 11

5.2.9 Filling compounds . 11

5.3 Tests parallel to the surface of non-laminated materials and parallel to the

laminate of laminated materials . 11

5.3.1 General . 11

5.3.2 Parallel plate electrodes . 11

5.3.3 Taper pin electrodes . 12

5.3.4 Parallel cylindrical electrodes . 12

5.4 Test specimens . 12

5.5 Distance between electrodes . 12

6 Conditioning before tests . 13

7 Surrounding medium . 13

7.1 General . 13

7.2 Tests in air at elevated temperature . 13

7.3 Tests in liquids . 13

7.4 Tests in solid materials . 14

8 Electrical apparatus . 14

8.1 Voltage source . 14

8.2 Voltage measurement . 14

9 Procedure. 15

10 Mode of increase of voltage . 15

10.1 Short-time (rapid-rise) test . 15

10.2 20 s step-by-step test . 16

10.3 Slow rate-of-rise test (120 s. 240 s) . 16

10.4 60 s step-by-step test . 17

10.5 Very slow rate-of-rise test (300 s. 600 s) . 17

10.6 Proof tests . 17

11 Criterion of breakdown . 17

12 Number of tests . 18

60243-1 © IEC:2013 – 3 –

13 Report . 18

Annex A (informative) Treatment of experimental data . 25

Bibliography . 26

Figure 1 – Electrode arrangements for tests on boards and sheets perpendicular to the

surface . 19

Figure 2 – Typical example of electrode arrangement for tests on tapes perpendicular

to the surface (see 5.2.2) . 20

Figure 3 – Electrode arrangement for tests perpendicular to the surface on tubes and

cylinders with internal diameter greater than 100 mm. 20

Figure 4 – Electrode arrangement for tests on casting and moulding materials

(diameter of the spherical electrodes: d = (20 ± 0,1) mm) . 21

Figure 5 – Electrode arrangement for test on shaped insulating parts (see 5.2.7) . 21

Figure 6 – Electrode arrangement for tests parallel to the surface (and along the

laminae, if present) . 22

Figure 7 – Electrode arrangement for tests parallel to the surface (and along the

laminae if present) . 23

Figure 8 – Arrangement for tests parallel to the laminae for boards more than 15 mm

thick with parallel cylindrical electrodes (see 5.3.4) . 24

Table 1 – Increments of voltage increase (kilovolts, peak / ) . 16

– 4 – 60243-1 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC STRENGTH OF INSULATING MATERIALS –

TEST METHODS –

Part 1: Tests at power frequencies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60243-1 has been prepared by technical committee 112:

Evaluation and qualification of electrical insulating materials and systems.

This third edition cancels and replaces the second edition, published in 1998, and constitutes

a technical revision.

The significant technical change with respect to the previous edition is that the current version

now includes an option for testing elastomeric materials.

The text of this standard is based on the following documents:

FDIS Report on voting

112/237/FDIS 112/248/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

60243-1 © IEC:2013 – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60243 series, published under the general title Electric

strength of insulating materials – Test methods, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60243-1 © IEC:2013

ELECTRIC STRENGTH OF INSULATING MATERIALS –

TEST METHODS –

Part 1: Tests at power frequencies

1 Scope

This part of IEC 60243 provides test methods for the determination of short-time electric

strength of solid insulating materials at power frequencies between 48 Hz and 62 Hz.

This standard does not cover the testing of liquids and gases, although these are specified

and used as impregnates or surrounding media for the solid insulating materials being tested.

NOTE Methods for the determination of breakdown voltages along the surfaces of solid insulating materials are

included.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60212, Standard conditions for use prior to and during the testing of solid electical

insulating materials

IEC 60296, Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

IEC 60455-2, Specification for solventless polymerizable resinous compounds used for

electrical insulation – Part 2: Methods of test

IEC 60464-2, Varnishes used for electrical insulation – Part 2: Methods of test

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC 60836, Specifications for unused silicone insulating liquids for electrotechnical purposes

IEC 61099, Insulating liquids – Specifications for unused synthetic organic esters for electrical

purposes

ISO 293, Plastics – Compression moulding of test specimens of thermoplastic materials

ISO 294-1, Plastics – Injection moulding of test specimens of thermoplastic materials – Part 1:

General principles, and moulding of multipurpose and bar test specimens

ISO 294-3, Plastics – Injection moulding of test specimens of thermoplastic materials – Part 3:

Small plates

ISO 295, Plastics – Compression moulding of test specimens of thermosetting materials

60243-1 © IEC:2013 – 7 –

ISO 10724 (all parts), Plastics – Injection moulding of test specimens of thermosetting powder

moulding compounds (PMCs)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

electric breakdown

severe loss of the insulating properties of test specimens while exposed to electric stress,

which causes the current in the test circuit to operate an appropriate circuit-breaker

Note 1 to entry: Breakdown is often caused by partial discharges in the gas or liquid medium surrounding the test

specimen and the electrodes which puncture the specimen beyond the periphery of the smaller electrode (or of

both electrodes, if of equal diameter).

3.2

flashover

loss of the insulating properties of the gas or liquid medium surrounding a test specimen and

electrodes while exposed to electric stress, which causes the current in the test circuit to

operate an appropriate circuit-breaker

Note 1 to entry: The presence of carbonized channels or punctures through the specimen distinguishes tests

where breakdown occurred, from others where flashover occurred.

3.3

breakdown voltage

3.3.1

< tests with continuously rising voltage > voltage at which a specimen suffers breakdown

under the prescribed test conditions

3.3.2

< step-by-step tests > highest voltage which a specimen withstands without breakdown for the

duration of the time at that voltage level

3.4

electric strength

quotient of the breakdown voltage and the distance between the electrodes between which

the voltage is applied under the prescribed test conditions

Note 1 to entry: The distance between the test electrodes is determined as specified in 5.5, unless otherwise

specified.

4 Significance of the test

Electric strength test results obtained in accordance with this standard are useful for detecting

changes or deviations from normal characteristics resulting from processing variables, ageing

conditions or other manufacturing or environmental situations. However, they are not intended for

use in evaluating the behaviour of insulating materials in an actual application.

Measured values of the electric strength of a material may be affected by many factors,

including:

a) Condition of test specimens

1) the thickness and homogeneity of the specimen and the presence of mechanical strain;

2) previous conditioning of the specimens, in particular drying and impregnation

procedures;

– 8 – 60243-1 © IEC:2013

3) the presence of gaseous inclusions, moisture or other contamination.

b) Test conditions

1) the frequency, waveform and rate of rise or time of application of the voltage;

2) the ambient temperature, pressure and humidity;

3) the configuration, the dimensions, and thermal conductivity of the test electrodes;

4) the electrical and thermal characteristics of the surrounding medium.

The effects of all these factors shall be considered when investigating materials for which no

experience exists. This standard defines particular conditions which give rapid discrimination

between materials and which can be used for quality control and similar purposes.

The results given by different methods are not directly comparable but each may provide

information on relative electric strengths of materials. The electric strength of most materials

decreases as the thickness of the specimen between the electrodes increases and as the time

of voltage application increases.

The measured electric strength of most materials is significantly affected by the intensity and

the duration of surface discharges prior to breakdown. For designs which are free from partial

discharges up to the test voltage, it is very important to know the electric strength without

discharges prior to breakdown. However, the methods in this standard are generally not

suitable for providing this information.

Materials with high electric strength will not necessarily resist long-term degradation

processes such as heat, erosion or chemical deterioration by partial discharges, or

electrochemical deterioration in the presence of moisture, all of which may cause failure in

service at much lower stress.

5 Electrodes and specimens

5.1 General

The metal electrodes shall be maintained smooth, clean and free from defects at all times.

Electrode arrangements for tests on boards and sheets perpendicular to the surface are

shown in Figure 1.

NOTE This maintenance becomes more important when thin specimens are being tested. Stainless steel

electrodes e.g. minimize electrode damage at breakdown.

The leads to the electrodes shall not tilt or otherwise move the electrodes, nor affect the

pressure on the specimen, nor appreciably affect the electric field configuration in the

neighbourhood of the specimen.

When very thin films (for example <5 μm thick) are to be tested, the standards for those

materials shall specify the electrodes and special procedures for handling and specimen

preparation.

5.2 Tests perpendicular to the surface of non-laminated materials and normal to

laminate of laminated materials

5.2.1 Boards and sheet materials, including pressboards, papers, fabrics and films

5.2.1.1 Unequal electrodes

The electrodes shall consist of two metal cylinders with the edges rounded to give a radius of

(3 ± 0,2) mm. One electrode shall be (25 ± 1) mm in diameter and approximately 25 mm high.

The other electrode shall be (75 ± 1) mm in diameter and approximately 15 mm high. These

two electrodes shall be arranged coaxially within 2 mm as in Figure 1a.

60243-1 © IEC:2013 – 9 –

NOTE Radii for surface not in contact with the electrode are not critical with respect to test results but should

avoid partial discharges in the surrounding medium.

5.2.1.2 Equal diameter electrodes

If a fixture is employed, which accurately aligns upper and lower electrodes within 1,0 mm,

the diameter of the lower electrode may be reduced to (25 ± 1) mm, the diameters of the two

electrodes differing by no more than 0,2 mm. The results obtained will not necessarily be the

same as those obtained with the unequal electrodes of 5.2.1.1.

5.2.1.3 Sphere and plate electrodes

The electrodes shall consist of a metal sphere and a metal plate (see Figure 1c). The upper

electrode shall be a sphere of (20 ± 1) mm in diameter and the lower one is a metal plate of

(25 ± 1) mm in diameter with the edge rounded to give a radius of 2.5 mm. The discrepancy of

the central axes between upper and lower electrodes shall be within 1 mm.

5.2.1.4 Tests on thick sample

When specified, boards and sheets over 3 mm thick shall be reduced by machining on one

side to (3 ± 0,2) mm and then tested with the high-potential electrode on the non-machined

surface.

When it is necessary in order to avoid flashover or because of limitations of available

equipment, specimens may be prepared by machining to smaller thicknesses as needed.

5.2.2 Tapes, films and narrow strips

The electrodes shall consist of two metal rods, each (6 ± 0,1) mm in diameter, mounted

vertically one above the other in a jig so that the specimen is held between the faces of the

ends of the rods.

The upper and lower electrodes shall be coaxial within 0,1 mm. The ends of the electrodes

shall form planes at right angles to their axes, with edge radii of (1 ± 0,2) mm. The upper

electrode shall have a mass of (50 ± 2) g and shall move freely in the vertical direction in

the jig.

Figure 2 shows an appropriate arrangement. If specimens are to be tested while extended,

they shall be clamped in a frame holding them in the required position relative to the

assembly shown in Figure 2. Wrapping one end of the specimen around a rotatable rod is one

convenient way of achieving the required extension.

To prevent flashover around the edges of narrow tapes, the test specimen may be clamped

using strips of film or other thin dielectric material overlapping the edges of the tape.

Alternatively, gaskets that surround the electrodes may be used, provided that there is an

annular space between electrode and gasket of 1 mm to 2 mm. The distance between the

bottom electrode and the specimen (before the top electrode comes in contact with the

specimen) shall be less than 0,1 mm.

NOTE For testing films see IEC 60674-2.

5.2.3 Flexible tubing and sleeving

To be tested according to IEC 60684-2.

5.2.4 Rigid tubes (having an internal diameter up to and including 100 mm)

The outer electrode shall consist of a band of metal foil (25 ± 1) mm wide. The inner electrode

is a closely fitting internal conductor, e.g. rod, tube, metal foil or a packing of metal spheres

– 10 – 60243-1 © IEC:2013

0,75 mm to 2 mm in diameter, making good contact with the inner surface. In each case, the

ends of the inner electrode shall extend for at least 25 mm beyond the ends of the outer

electrode.

Where no adverse effect will result, petroleum jelly may be used for attaching the foil to the

inner and outer surfaces.

5.2.5 Tubes and hollow cylinders (having an internal diameter greater than 100 mm)

The outer electrode shall be a band of metal foil (75 ± 1) mm wide and the inner electrode, a

disk of metal foil (25 ± 1) mm in diameter, flexible enough to conform with the curvature of the

cylinder. The arrangement is shown in Figure 3.

5.2.6 Cast and moulded materials

5.2.6.1 Cast materials

Make test pieces and test according to IEC 60455-2.

5.2.6.2 Moulded materials

5.2.6.2.1 General

Use a pair of spherical electrodes, each (20 ± 0,1) mm in diameter, arranged on a common

axis which is normal to the plane of the test specimen (see Figure 4) or, in case of

elastomers, unequal electrodes according to 5.2.1.3 (see Figure 1c) .

5.2.6.2.2 Thermosets

Use test specimens of (1,0 ± 0,1) mm thickness, compression moulded in accordance with

ISO 295; or injection moulded in accordance with the ISO 10724 series with lateral

dimensions which are sufficient to prevent flashover (see 5.4).

If it is not possible to use specimens of (1,0 ± 0,1) mm thickness, specimens with a thickness

of (2,0 ± 0,2) mm shall be used.

5.2.6.2.3 Thermoplastics

Use test specimens injection moulded in accordance with ISO 294-1 and ISO 294-3,

ISO mould type D1 60 mm × 60 mm × 1 mm. If these dimensions are insufficient to prevent

flashover (see 5.4) or if compression moulded test specimens are stipulated by the standard

for the relevant material, use plates at least 100 mm in diameter and (1,0 ± 0,1) mm thick,

compression moulded in accordance with ISO 293.

For the conditions of injection or compression moulding, see the standard for the relevant

material. If there is no applicable material standard, the conditions shall be agreed between

the interested parties.

5.2.6.2.4 Elastomers

Use test specimens of (1,0 ± 0,1) mm thickness with sufficient lateral dimensions to prevent

flashover (see 5.4), moulded under standard conditions. If there is no effective standard the

processing conditions shall be agreed between the interested parties.

As electrode arrangement, unequal electrodes according 5.2.1.3 (see Figure 1c) shall be

used. In the case of elastomers of low hardness, e.g. silicone rubbers, a suitable casting

material shall be used as embedding material or surrounding medium, respectively.

60243-1 © IEC:2013 – 11 –

5.2.7 Shaped solid pieces

For shaped insulating specimens which do not have sufficient contact with the electrode’s flat contact

surface, the opposing identical spherical electrodes shall be used (see Figure 5). Commonly used

electrodes for tests of this nature have diameters of 12,5 mm or 20 mm.

5.2.8 Varnishes

To be tested according to IEC 60464-2.

5.2.9 Filling compounds

The electrodes shall consist of two metal spheres, each 12,5 mm to 13 mm in diameter,

arranged horizontally along the same axis (1 ± 0,1) mm apart, unless otherwise specified, and

embedded in the compound. Care shall be taken to avoid cavities, particularly between the

electrodes. As values obtained with the different electrode spacing are not directly

comparable, the gap length shall be detailed in the specification for the compound and

mentioned in the test report.

5.3 Tests parallel to the surface of non-laminated materials and parallel to the

laminate of laminated materials

5.3.1 General

If it is not necessary to differentiate between failure by puncture of the specimen and failure

across its surface, the electrodes of 5.3.2 or 5.3.3 may be used, those of 5.3.2 being

preferred.

When the prevention of surface failure is required, the electrodes of 5.3.3 shall be used.

5.3.2 Parallel plate electrodes

5.3.2.1 Boards and sheets

For tests on boards and sheets, the test specimen shall be of the thickness of the material to

be tested and rectangular, (100 ± 2) mm long and (25 ± 0,2) mm wide. The long edges shall

be cut as parallel planes at right angles to the surface of the material. The test specimen is

placed with the 25 mm width between parallel metal plates, not less than 10 mm thick, forming

the electrodes between which the voltage shall be applied. For thin materials, two or three

test specimens are used suitably placed (i.e. with their long edges at a convenient angle) to

support the upper electrode. The electrodes shall be of sufficient size to overlap the edges of

the test specimens by not less than 15 mm and care shall be taken to ensure good contact

over the whole area of those edges. The edges of the electrodes shall be suitably rounded

(3 mm to 5 mm) to avoid breakdown from edge to edge of the electrodes (see Figure 6).

If breakdown cannot be obtained with available equipment, the width of the specimens may be

reduced to (15 ± 0,2) mm or (10 ± 0,2) mm. Such reduction of specimen width shall be

specifically recorded in the test report.

This type of electrode is suitable only for tests on rigid materials at least 1,5 mm thick.

5.3.2.2 Tubes and cylinders

For tests on tubes and cylinders, the test specimen shall be a complete ring or a 100 mm

circumferential portion of a ring of (25 ± 0,2)mm axial length. Both edges of the specimen

shall be finished as parallel planes at right angles to the axis of the tube or cylinder. The

specimen is tested between parallel plates as described in 5.3.2.1 for boards and sheets.

Where necessary to support the upper electrode, two or three specimens are used. The

electrodes shall be of sufficient size to overlap the edges of the specimens by not less than

– 12 – 60243-1 © IEC:2013

15 mm and care shall be taken to ensure good contact over the whole area of the edges of

the specimens.

5.3.3 Taper pin electrodes

Two parallel holes are drilled perpendicularly to the surface, with centres (25 ± 1) mm apart

and of such a diameter that, after reaming with a reamer having a taper of approximately 2 %,

the diameter of each hole at the larger end is not less than 4,5 mm and not greater than

5,5 mm.

The holes shall be drilled completely through the specimen or, in the case of large tubes,

through one wall only, and shall be reamed throughout their full length.

When the specimens are drilled and reamed, the material adjacent to the holes shall not be

damaged, e.g. split, broken or charred, in any way.

The taper pins used as electrodes shall have a taper of (2 ± 0,02) % and shall be pressed, not

hammered into the holes so that they fit tightly and extend on each side of the test specimen

by not less than 2 mm (see Figure 7, 7a and 7b).

This type of electrode is suitable only for tests on rigid materials at least 1,5 mm thick.

5.3.4 Parallel cylindrical electrodes

For tests on specimens of high electric strength and which are more than 15 mm thick,

specimens 100 mm × 50 mm shall be cut and two holes drilled as shown in Figure 8 so that

each is not more than 0,1 mm greater in diameter than each cylindrical electrode which shall

be (6 ± 0,1) mm in diameter and have hemispherical ends. The base of each hole is

hemispherical to mate with the end of the electrode, so that the gap between the end of the

electrode and the base of the hole will not exceed 0,05 mm at any point. If not otherwise

specified in the material specification, the holes shall be (10 ± 1) mm apart, edge-to-edge,

throughout their length and extend to within (2,25 ± 0,25) mm of the surface opposite that

through which they are drilled. Two alternative forms of vented electrodes are shown in

Figure 8. When electrodes with slots are used, these slots shall be diametrically opposed to

the gap between the electrodes.

5.4 Test specimens

In addition to the information concerning specimens given in the preceding subclauses, the

following general points shall be noted.

In the preparation of test specimens from solid materials, care shall be taken that the surfaces

in contact with the electrodes are parallel and as flat and smooth as the material allows.

For tests made perpendicularly to the surface of the material, test specimens need only be of

sufficient area to prevent flashover under the conditions of test.

In tests made perpendicularly to the surface of the material, the results on specimens of

different thicknesses are not directly comparable (see Clause 4).

5.5 Distance between electrodes

The value to be used in calculating the electric strength shall be one of the following, as

specified for the material under test:

a) nominal thickness or distance between electrodes (use this value unless otherwise

specified);

60243-1 © IEC:2013 – 13 –

b) average thickness of the test specimen or distance between electrodes for tests parallel to

the surface;

c) thickness or distance between electrodes measured immediately adjacent to the

breakdown on each test specimen.

6 Conditioning before tests

The electric strength of insulating materials varies with temperature and moisture content.

Where a specification is available for the material to be tested, this shall be followed.

Otherwise, specimens shall be conditioned for not less than 24 h at (23 ± 2) °C, (50 ± 5) %

relative humidity, that is, the standard ambient atmosphere of IEC 60212, unless other

conditions are agreed upon.

7 Surrounding medium

7.1 General

Materials shall be tested in a surrounding medium selected to prevent flashover. Suitable

materials may be transformer oil according to IEC 60296, silicone fluid according to

IEC 60836 or ester fluid according to IEC 61099 or appropriate casting material. The

surrounding medium shall not have significant interaction with the material under test, e.g. by

causing swelling, during the time of testing.

Specimens having relatively low breakdown values may be tested in air, particularly if the

tests are to be made at elevated temperature. Even at moderate test voltages, discharges at

the edges of the electrodes may have significant effects on the test values.

If it is intended that the tests evaluate the behaviour of a material in another medium, that

medium may be used.

Select a medium which has minimum deleterious effect on the material under test.

The effect of the ambient medium on the results may be great, particularly in the case of

absorbent materials such as paper and pressboard, and it is essential that procedures for

specimen preparation define fully all necessary steps (e.g. drying and impregnation), and the

condition of the ambient medium during test.

Sufficient time shall be allowed for the specimen and the electrodes to attain the required

temperature, but some materials may be affected by prolonged exposure to high

temperatures.

7.2 Tests in air at elevated temperature

Tests in air at elevated temperature may be made in any well-designed oven of sufficient size

to accommodate the test specimen and the electrodes without flashover occurring during the

tests. Some means of circulating the air within the oven shall be provided so that a

substantially uniform temperature within ±2 K of the specified temperature is maintained

around the test specimen, and with a thermometer, thermocouple or other means for

measuring the temperature as near the point of test as practicable.

7.3 Tests in liquids

When tests are conducted in an insulating liquid, it is necessary to ensure adequate electric

strength of the liquid to avoid flashover. Specimens tested in liquids which have a higher

relative permittivity than transformer oil may show a higher dielectric strength than when

tested in transformer oil. Contamination which reduces the electric strength of the oil or other

liquid may also increase the measured electric strength of test specimens.

– 14 – 60243-1 © IEC:2013

Tests at elevated temperature may be made either in a container of liquid in an oven (see 7.1)

or in a thermostatically controlled bath using the insulating liquid for heat transfer. In this

case, suitable means for circulating the liquid, so that the temperature is substantially uniform

and maintained within ±2 K of the specified temperature around the test specimen, shall be

provided.

7.4 Tests in solid materials

For plate-shaped specimens of soft elastomers, a suitable casting material shall be used,

which preferably cures at room temperature and has a permittivity similar to the tested

elastomer. During the casting, voids shall be avoided, particularly in the volume between the

cylindrical electrode and test plate by a vacuum treatment. The casting material shall have a

sufficient adhesion at the electrodes and the surface of the test plate.

For silicone elastomers this can be silicone rubber of low viscosity (room temperature

vulcanizing two components)

8 Electrical apparatus

8.1 Voltage source

The test voltage shall be obtained from a step-up transformer supplied from a variable

sinusoidal low-voltage source. The transformer, its voltage source and the associated controls

shall have the following properties.

The ratio of crest to root-mean-square (r.m.s.) test voltage shall be equal to ±5 %

(1,34.1,48), with the test specimen in the circuit, at all voltages up to and including the

breakdown voltage.

The power rating of the source shall be sufficient to meet the requirements above until electric

breakdown occurs. For most materials, using electrodes as recommended, an output current

capacity of 40 mA is usually adequate. The power rating for most tests will vary from 0,5 kVA,

for testing low-capacitance specimens at voltages up to 10 kV, to 5 kVA for voltages up to 100

kV.

The controls on the variable low-voltage source shall be capable of varying the test voltage

smoothly, uniformly and without overshoots. When applying voltage in accordance with

Clause 8, the incremental increase produced, e.g. by a variable autotransformer, shall not

exceed 2 % of the expected breakdown voltage.

Motor-driven controls are preferable for making short-time or rapid-rise tests.

To protect the voltage source from damage, it shall be equipped with a device which

disconnects the power supply within a few cycles on breakdown of the specimen. It may

consist of a current-sensitive element in the HV supply to the electrodes.

To restrict damage by current or voltage surges at breakdown, it is desirable to include a

resistor with a suitable value in series with the electrodes. The value of the resistor will

depend on the damage which can be tolerated on the electrodes.

The use of a very high valued resistor may result in breakdown voltages which are higher than

those obtained with a lower valued resistor.

8.2 Voltage measurement

The voltage values are recorded in equivalent r.m.s. values. It is preferable to use a peak-

reading voltmeter and divide the reading by . The overall error of the voltage-measuring

60243-1 © IEC:2013 – 15 –

circuit shall not exceed 5 % of the measured value, including the error due to the response

time of the voltmeter. The response-time induced error shall not b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...