IEC 60216-6:2022

(Main)Electrical insulating materials - Thermal endurance properties - Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating material using the fixed time frame method

Electrical insulating materials - Thermal endurance properties - Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating material using the fixed time frame method

IEC 60216-6:2022 specifies the experimental and calculation procedures for deriving the thermal endurance characteristics, temperature index (TI) and relative temperature index (RTI) of an electrical insulating material (EIM) using the “fixed time frame method (FTFM)”. In this protocol, the ageing takes place for a small number of fixed times, using the appropriate number of ageing temperatures throughout each time, the properties of the specimens being measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-1, where ageing is conducted at a small number of fixed temperatures, property measurement taking place after ageing times dependent on the progress of ageing. The diagnostic tests employed in the fixed time frame method are restricted to destructive tests. The method has not yet been applied to non-destructive or proof test procedures. This edition includes the following significant technical changes with respect to the previous edition:

- clarification of definition of index properties vs. endurance properties;

- complete rework of Annex G and the corresponding program.

Matériaux isolants électriques - Propriétés d'endurance thermique - Partie 6: Détermination des indices d’endurance thermique (IT et ITR) d’un matériau isolant en utilisant la méthode de trame de durées fixes

IEC 60216-6:2022 specifies the experimental and calculation procedures for deriving the thermal endurance characteristics, temperature index (TI) and relative temperature index (RTI) of an electrical insulating material (EIM) using the “fixed time frame method (FTFM)”. In this protocol, the ageing takes place for a small number of fixed times, using the appropriate number of ageing temperatures throughout each time, the properties of the specimens being measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-1, where ageing is conducted at a small number of fixed temperatures, property measurement taking place after ageing times dependent on the progress of ageing. The diagnostic tests employed in the fixed time frame method are restricted to destructive tests. The method has not yet been applied to non-destructive or proof test procedures. This edition includes the following significant technical changes with respect to the previous edition:

- clarification of definition of index properties vs. endurance properties;

- complete rework of Annex G and the corresponding program.

General Information

- Status

- Published

- Publication Date

- 27-Nov-2022

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 1 - TC 112/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Nov-2022

- Completion Date

- 02-Dec-2022

Overview

IEC 60216-6:2022 - part of the IEC 60216 series - defines the fixed time frame method (FTFM) for deriving thermal endurance indices of electrical insulating materials. It specifies experimental procedures and calculation methods to obtain the Temperature Index (TI) and Relative Temperature Index (RTI) based on thermal ageing at a set of fixed times and multiple temperatures. This third edition (2022) clarifies index vs. endurance property definitions, restricts diagnostic tests to destructive tests, and includes a complete rework of Annex G (computer program guidance).

Keywords: IEC 60216-6:2022, thermal endurance, TI, RTI, fixed time frame method, electrical insulating materials, thermal ageing.

Key topics and requirements

- FTFM protocol: Age specimens for a prescribed set of fixed times across multiple ageing temperatures; measure properties at the end of each time interval.

- Diagnostic tests: Limited to destructive tests (proof and non-destructive procedures not covered by this edition).

- Property selection: Distinguishes index properties (used for TI/RTI calculation) from endurance properties (properties that degrade during ageing).

- Statistical and calculation procedures: Regression analyses, equivalence of property values to temperatures, variance and linearity tests, confidence limits and extrapolation methods are specified.

- Reporting: Mandatory content for result reporting, including statistical test summaries and thermal endurance graphs.

- Supplementary material: Annexes provide decision flow charts, suggested ageing times/temperatures (e.g., TI correlation time guidance such as 20 000 h), statistical tables and a reworked Annex G with computer program examples for IEC 60216-6 calculations.

Keywords: thermal endurance calculation, regression analysis, destructive diagnostics, ageing temperatures.

Applications and users

IEC 60216-6:2022 is used by:

- Material manufacturers and R&D labs for material qualification and comparative performance assessment.

- Test laboratories performing thermal ageing and lifetime prediction for insulation materials.

- OEMs and design engineers selecting insulation materials to meet service temperature and lifetime requirements.

- Certification bodies and standards committees creating product specifications and compliance demonstrations.

Practical uses include predicting service life, determining TI/RTI for material datasheets, comparative screening of formulations, and supporting end-of-life or warranty assessments.

Keywords: insulation materials testing, lifetime prediction, service temperature rating, TI determination.

Related standards

- IEC 60216-1 - the companion method where ageing is done at fixed temperatures and property measurement is time-dependent (contrast to FTFM).

- Other parts of the IEC 60216 series covering definitions, general principles and alternative procedures for thermal endurance testing.

Use IEC 60216-6:2022 when applying the fixed time frame method to derive TI and RTI and when destructive diagnostic tests are acceptable for assessing thermal endurance.

REDLINE IEC 60216-6:2022 - Electrical insulating materials - Thermal endurance properties - Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating material using the fixed time frame method Released:11/28/2022 Isbn:9782832261736

IEC 60216-6:2022 - Electrical insulating materials - Thermal endurance properties - Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating material using the fixed time frame method Released:11/28/2022

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60216-6:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical insulating materials - Thermal endurance properties - Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating material using the fixed time frame method". This standard covers: IEC 60216-6:2022 specifies the experimental and calculation procedures for deriving the thermal endurance characteristics, temperature index (TI) and relative temperature index (RTI) of an electrical insulating material (EIM) using the “fixed time frame method (FTFM)”. In this protocol, the ageing takes place for a small number of fixed times, using the appropriate number of ageing temperatures throughout each time, the properties of the specimens being measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-1, where ageing is conducted at a small number of fixed temperatures, property measurement taking place after ageing times dependent on the progress of ageing. The diagnostic tests employed in the fixed time frame method are restricted to destructive tests. The method has not yet been applied to non-destructive or proof test procedures. This edition includes the following significant technical changes with respect to the previous edition: - clarification of definition of index properties vs. endurance properties; - complete rework of Annex G and the corresponding program.

IEC 60216-6:2022 specifies the experimental and calculation procedures for deriving the thermal endurance characteristics, temperature index (TI) and relative temperature index (RTI) of an electrical insulating material (EIM) using the “fixed time frame method (FTFM)”. In this protocol, the ageing takes place for a small number of fixed times, using the appropriate number of ageing temperatures throughout each time, the properties of the specimens being measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-1, where ageing is conducted at a small number of fixed temperatures, property measurement taking place after ageing times dependent on the progress of ageing. The diagnostic tests employed in the fixed time frame method are restricted to destructive tests. The method has not yet been applied to non-destructive or proof test procedures. This edition includes the following significant technical changes with respect to the previous edition: - clarification of definition of index properties vs. endurance properties; - complete rework of Annex G and the corresponding program.

IEC 60216-6:2022 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.035.01 - Insulating materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60216-6:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60216-6 ®

Edition 3.0 2022-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical insulating materials – Thermal endurance properties –

Part 6: Determination of thermal endurance indices (TI and RTE RTI) of an

insulating material using the fixed time frame method

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60216-6 ®

Edition 3.0 2022-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical insulating materials – Thermal endurance properties –

Part 6: Determination of thermal endurance indices (TI and RTE RTI) of an

insulating material using the fixed time frame method

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.99; 29.035.01 ISBN 978-2-8322-6173-6

– 2 – IEC 60216-6:2022 RLV © IEC 2022

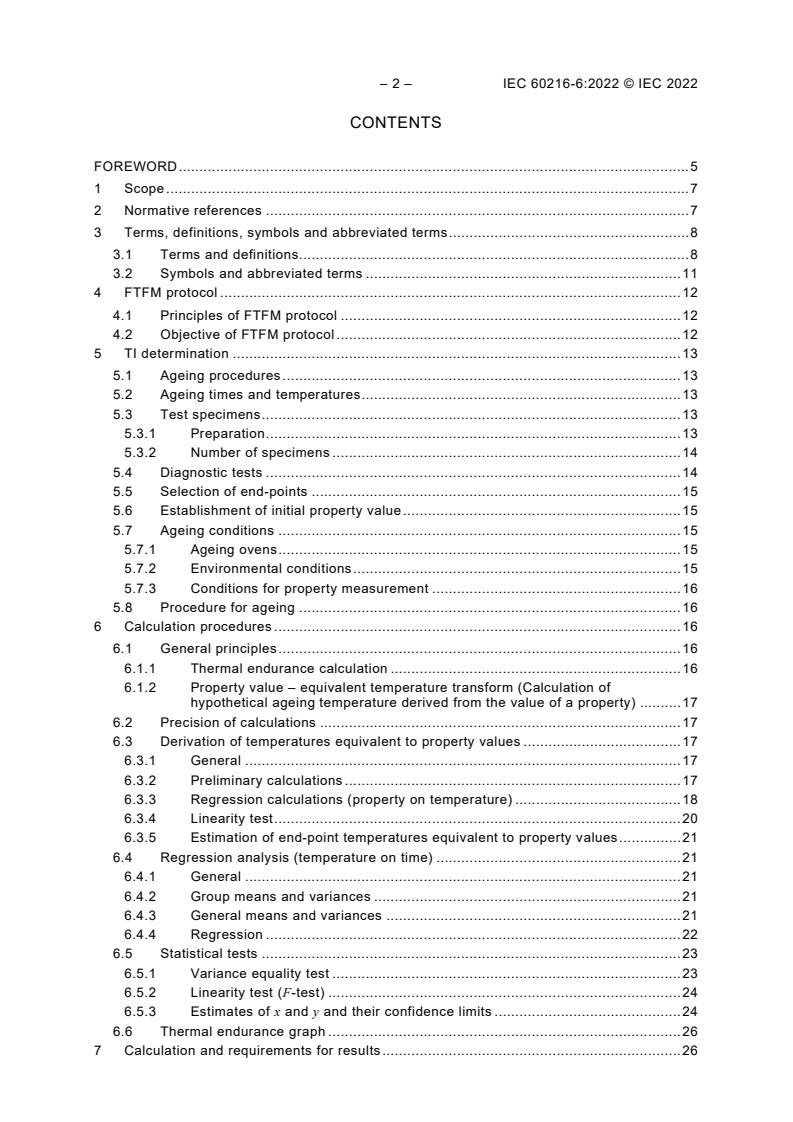

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviated terms . 8

3.1 Terms and definitions. 8

3.2 Symbols and abbreviated terms . 11

4 FTFM protocol . 13

4.1 Principles of FTFM protocol . 13

4.2 Objective of FTFM protocol . 13

5 TI determination . 13

5.1 Ageing procedures . 13

5.2 Ageing times and temperatures . 14

5.3 Test specimens . 14

5.3.1 Preparation . 14

5.3.2 Number of specimens . 14

5.4 Diagnostic tests . 15

5.5 Selection of end-points . 15

5.6 Establishment of initial property value . 15

5.7 Ageing conditions . 16

5.7.1 Ageing ovens . 16

5.7.2 Environmental conditions . 16

5.7.3 Conditions for property measurement . 16

5.8 Procedure for ageing . 16

6 Calculation procedures . 17

6.1 General principles . 17

6.1.1 Thermal endurance calculation . 17

6.1.2 Property value – equivalent temperature transform (Calculation of

hypothetical ageing temperature derived from the value of a property) . 17

6.2 Precision of calculations . 18

6.3 Derivation of temperatures equivalent to property values . 18

6.3.1 General . 18

6.3.2 Preliminary calculations . 18

6.3.3 Regression calculations (property on temperature) . 18

6.3.4 Linearity test . 20

6.3.5 Estimation of end-point temperatures equivalent to property values . 21

6.4 Regression analysis (temperature on time) . 21

6.4.1 General . 21

6.4.2 Group means and variances . 22

6.4.3 General means and variances . 22

6.4.4 Regression . 23

6.5 Statistical tests . 23

6.5.1 Variance equality test . 23

6.5.2 Linearity test (F-test) . 24

6.5.3 Estimates of x and y and their confidence limits . 25

6.6 Thermal endurance graph . 26

7 Calculation and requirements for results . 26

– 3 – IEC 60216-6:2022 RLV © IEC 2022

7.1 Calculation of thermal endurance characteristics . 26

7.2 Reporting of results. 27

7.2.1 Summary of statistical tests and reporting . 27

7.2.2 Report format . 27

8 Report . 28

9 RTE RTI determination . 28

10 Additional symbols . 28

11 Experimental procedures . 29

11.1 Selection of control material reference EIM . 29

11.2 Selection of diagnostic test for extent of ageing . 29

11.3 Ageing procedures . 29

12 Calculation procedures . 30

12.1 General principles . 30

12.2 Input data . 30

12.3 RTE RTI. 30

12.4 Confidence limits . 31

12.5 Extrapolation . 33

13 Results and report . 33

13.1 Results of statistical and numerical tests . 33

13.2 Result . 33

13.3 Report . 33

Annex A (normative) Decision flow chart . 34

Annex B (normative) Decision table . 36

Annex C (informative) Statistical tables . 37

Annex D (informative) Suggested ageing times and temperatures . 41

D.1 TI determination . 41

D.1.1 Correlation time (TI) = 20 000 h . 41

D.1.2 Other correlation times for TI calculation (see 12.3) . 41

D.2 RTE RTI determination . 41

Annex E (informative) Figures . 43

Annex F (normative) Statistical significance of the difference between two regression

estimates . 46

Annex G (informative) Computer programs for IEC 60216-6 . 47

G.1 General . 54

G.1.1 Overview . 54

G.1.2 Convenience program execution . 55

G.2 Data files . 56

G.2.1 Content of file Control6.ftd . 57

G.2.2 Report . 59

G.2.3 Thermal endurance graph . 61

Figure A.1 – Decision flow chart . 35

Figure E.1 – Property-temperature graph with regression line . 43

Figure E.2 – Thermal endurance graph . 43

Figure E.3 – Ageing times and temperatures in relation to thermal endurance graph . 44

Figure E.4 – Ageing times and temperatures in relation to thermal endurance graph . 44

Figure E.5 – Ageing times and temperatures in relation to thermal endurance graph . 45

– 4 – IEC 60216-6:2022 RLV © IEC 2022

Figure G.1 – Shortcut property dialog for program launch . 56

Figure G.2 – Thermal endurance graph . 61

Table 1 – Intermediate data values . 30

Table B.1 – Decision table . 36

Table C.1 – χ -function . 37

Table C.2 – t-function . 37

Table C.3 – F-function, P = 0,05 . 38

Table C.4 – F-function, P = 0,005. 39

Table D.1 – Ageing temperatures and times. 41

– 5 – IEC 60216-6:2022 RLV © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSULATING MATERIALS –

THERMAL ENDURANCE PROPERTIES –

Part 6: Determination of thermal endurance indices (TI and RTE RTI)

of an insulating material using the fixed time frame method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60216-6:2006. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60216-6:2022 RLV © IEC 2022

IEC 60216-6 has been prepared by IEC technical committee 112: Evaluation and qualification

of electrical insulating materials and systems. It is an International Standard.

This third edition cancels and replaces the second edition published in 2006. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) clarification of definition of index properties vs. endurance properties;

b) complete rework of Annex G and the corresponding program.

The text of this International Standard is based on the following documents:

Draft Report on voting

112/583/FDIS 112/589/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60216 series, published under the general title Electrical insulating

materials – Thermal endurance properties, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 7 – IEC 60216-6:2022 RLV © IEC 2022

ELECTRICAL INSULATING MATERIALS –

THERMAL ENDURANCE PROPERTIES –

Part 6: Determination of thermal endurance indices (TI and RTE RTI)

of an insulating material using the fixed time frame method

1 Scope

This part of IEC 60216 specifies the experimental and calculation procedures for deriving the

thermal endurance characteristics, temperature index (TI) and relative thermal endurance index

(RTE) relative temperature index (RTI) of an electrical insulating material (EIM) using the “fixed

time frame method (FTFM)”.

In this protocol, the ageing takes place for a small number of fixed times, using the appropriate

number of ageing temperatures throughout each time, the properties of the specimens being

measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-

1, where ageing is conducted at a small number of fixed temperatures, property measurement

taking place after ageing times dependent on the progress of ageing.

The diagnostic tests employed in the fixed time frame method are restricted to destructive tests.

The method has not yet been applied to non-destructive or proof test procedures.

Both the TI and the RTE RTI determined according to the FTFM protocol are derived from

experimental data obtained in accordance with the instructions of IEC 60216-1 and IEC 60216-2

as modified in this part of IEC 60216. The calculation procedures and statistical tests are

modified from those of IEC 60216-3 and IEC 60216-5.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60212, Standard conditions for use prior to and during the testing of solid electrical

insulating materials

IEC 60216-1:20012013, Electrical insulating materials – Thermal endurance properties – Part

1: Ageing procedures and evaluation of test results

IEC 60216-2, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of test

criteria

IEC 60216-3:20022021, Electrical insulating materials – Thermal endurance properties – Part

3: Instructions for calculating thermal endurance characteristics

IEC 60216-4-1, Electrical insulating materials – Thermal endurance properties – Part 4-1:

Ageing ovens – Single-chamber ovens

IEC 60216-4-2, Electrical insulating materials – Thermal endurance properties – Part 4-2:

Ageing ovens – Precision ovens for use up to 300 °C

– 8 – IEC 60216-6:2022 RLV © IEC 2022

IEC 60216-4-3, Electrical insulating materials – Thermal endurance properties – Part 4-3:

Ageing ovens – Multi-chamber ovens

IEC 60216-5:2022, Electrical insulating materials – Thermal endurance properties – Part 5:

Determination of relative thermal endurance index (RTE) relative temperature index (RTI) of

an insulating material

IEC 60493-1:1974, Guide for the statistical analysis of ageing test data – Part 1: Methods based

on mean values of normally distributed test results

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

electrical insulating material

EIM

material of low electric conductivity, used to separate conducting parts at different electric

potentials or to isolate such parts from the surroundings

3.1.2

assessed thermal endurance index

ATE

numerical value of the temperature in degrees Celsius, up to which the control material

possesses known, satisfactory service performance in the specified application

NOTE 1 The ATE of a specific material may vary between different applications of the material.

NOTE 2 ATE is sometimes referred to as “absolute” thermal endurance index.

3.1.2

assessed temperature index

ATI

numerical value of the temperature index in degrees Celsius of the reference EIM

Note 1 to entry: The ATI of a specific material may vary between different applications of the material.

3.1.3

ageing temperature

temperature in degrees Celsius at which a group of specimens is thermally aged

3.1.4

end-point temperature

temperature in degrees Celsius at which a specimen is considered to have reached end-point

after ageing for a specified time

– 9 – IEC 60216-6:2022 RLV © IEC 2022

3.1.5

candidate material EIM

material for which an estimate of the thermal endurance is required to be determined

Note 1 to entry: The determination is made by simultaneous thermal ageing of the material and a control material

reference EIM.

3.1.6

central second moment of a data group

sum of the squares of the differences between the data values and the value of the group mean

divided by the number of data items in the group

3.1.7

95 % confidence limit

statistical parameter, calculated from test data, which with 95 % confidence constitutes an

upper or lower limit for the true value of a quantity estimated by statistical analysis

Note 1 to entry: This implies that there is only 5 % probability that the true value of the quantity estimated is actually

larger (or smaller) than the upper (or lower) confidence limit.

Note 2 to entry: In other connections, confidence values other than 95 % may sometimes be used, e.g. in the

linearity test for destructive test data.

3.1.8

control material reference EIM

material with known assessed thermal endurance index (ATE), preferably derived from service

experience, used as a reference for comparative tests with the candidate material EIM

3.1.9

correlation coefficient

number expressing the completeness of the relation between members of two data sets, equal

to the covariance divided by the square root of the product of the variances of the sets

Note 1 to entry: The value of its square is between 0 (no correlation) and 1 (complete correlation).

Note 2 to entry: In this standard, the two data sets are the values of the independent variable and the means of the

corresponding dependent variable groups.

3.1.10

correlation time (RTE) for RTI

estimated time to end-point of the control material reference EIM at a temperature equal to its

ATE ATI in degrees Celsius

τ

Note 1 to entry: In this document, it is expressed by symbol , see Clause 10.

c

3.1.11

correlation time for TI

hypothetical time to end-point used to calculate TI

Note 1 to entry: Its usual value is 20 000 h, see Clause D.1.

3.1.12

covariance,

for two sets of data with equal numbers of elements where each element in one set corresponds

to one in the other, sum of the products of the deviations of the corresponding members from

their set means, divided by the number of degrees of freedom

3.1.13

degrees of freedom

number of data values minus the number of parameter values

– 10 – IEC 60216-6:2022 RLV © IEC 2022

3.1.14

destructive test

diagnostic property test, where the test specimen is irreversibly changed by the property

measurement, in a way which precludes a repeated measurement on the same specimen

Note 1 to entry: An example of a destructive test is the measurement of electric strength. An example of a non-

destructive test is the measurement of tg dissipation factor tan δ.

3.1.15

end-point line

line parallel to the temperature axis intercepting the property axis at the end-point value

3.1.16

halving interval

HIC

numerical value of the temperature interval in Kelvin which expresses the halving of the time to

end-point taken at a time equal to TI

3.1.17

regression analysis

process of deducing the best fit line expressing the relation of corresponding members of two

data groups by minimizing the sum of squares of deviations of members of one of the groups

from the line

3.1.18

regression coefficients

coefficients of the equation of the best fit line derived by regression analysis

3.1.18

relative thermal endurance index

RTE

estimate of the thermal endurance of a candidate material, made by thermal ageing

simultaneously with the control material, as described in this standard

NOTE The value of RTE is the value of the temperature in degrees Celsius at which the estimated time to end-point

of the candidate material is the same as the estimated time to end-point of the control material at a temperature

equal to its ATE.

3.1.19

relative temperature index

RTI

determined by test in relation to the thermal performance of a known reference EIM

3.1.20

significance

probability of a value of a statistical function greater than a specified value

Note 1 to entry: The value is equal to (1–p) where p is the cumulative distribution function value. Significance is

conventionally printed in upper case (P).

3.1.21

standard deviation

square root of the variance of a data group or sub-group

3.1.22

standard error of an estimate of the true value of a data group property

value of the standard deviation of the hypothetical sampling population of which the group

property may be considered to be a member

Note 1 to entry: For an estimate of the group mean, the standard error is equal to the group standard deviation

divided by the square root of the number of data items in the group, and indicates the uncertainty in the estimate of

the true value of the mean. This standard is concerned only with means and the difference between two means.

– 11 – IEC 60216-6:2022 RLV © IEC 2022

3.1.23

temperature index

TI

numerical value of the temperature in degrees Celsius derived from the thermal endurance

relationship at a time of 20 000 h (or other specified time) determined by test by itself

Note 1 to entry: This rating is based on 20 000 h life, unless otherwise specified, based on one of the end-of-life

criteria listed in IEC 60216-2.

3.1.24

temperature group,

number of specimens being exposed together to thermal ageing at the same temperature in the

same oven

Note 1 to entry: Where there is no risk of ambiguity, either temperature groups or test groups may be referred to

simply as “groups”.

3.1.25

test group,

number of specimens removed together from a temperature group for destructive testing

Note 1 to entry: Where there is no risk of ambiguity, either temperature groups or test groups may be referred to

simply as “groups”.

3.1.26

thermal endurance graph

graph in which the logarithm of the time to reach a specified end-point in a thermal endurance

test is plotted against the reciprocal thermodynamic (absolute) test temperature

3.1.27

thermal endurance graph paper

graph paper having a logarithmic time scale as the ordinate and values proportional to the

reciprocal of the thermodynamic (absolute) temperature as the abscissa

Note 1 to entry: The ordinate is usually graduated in powers of ten (from 10 h to 100 000 h is often a convenient

range). The abscissa is usually graduated in a non-linear (Celsius) temperature scale oriented with temperature

increasing from left to right.

3.1.28

time group,

all test groups removed for testing at the same time

3.1.29

variance of a data group

sum of the squares of the deviations of the data from a reference level defined by one or more

parameters divided by the number of degrees of freedom

Note 1 to entry: The reference level may can, for example be a mean value (1 parameter) or a line (2 parameters,

here intercept on the axis of the independent variable and slope).

3.2 Symbols and abbreviated terms

The following symbols are used in the calculations of Clauses 6, 7, 12 and Annex A, Annex B

and Annex C.

Symbol Description Clause

a Regression coefficient: intercept of regression line with x-axis 6.4.4

b Regression coefficient: slope of regression line relative to y-axis 6.4.4

6.5.3

ˆ

b

r

Y

Parameter derived from b for calculation of

c

b

p Regression coefficient for destructive test calculations 6.3.5

– 12 – IEC 60216-6:2022 RLV © IEC 2022

Symbol Description Clause

6.5.1

c

Parameter in calculation of χ

6.3.4,

F F-distributed variance ratio for linearity test

6.5.2

g, h, i, j Indexing parameters for regression calculations 6.3, 6.4

HIC Halving interval 7.1

k Number of ageing times 6.1.1

Total number of x values 6.4.3

N

ij

n Number of x values in time group i 6.1.1

i ij

Annex A,

Annex B

P Significance of the value of a statistical test function

and

Annex C

p 6.3

End-point property value

e

p 6.3

Property value h in temperature group g (time group i implied)

gh

6.3

p

Mean property value in temperature group g (time group i implied)

g

6.5.1

q Base of logarithms in calculation of χ

r Number of temperature groups selected in time group i 6.3.3

6.4.4

r Square of correlation coefficient

6.5.2

Total (non-regression) variance of x-values

s

2 Variance of property values in temperature group g (time group i 6.3.3

s

1g

implied)

6.5.2

Value of s adjusted to allow for acceptable non-linearity

s

a

6.5.3

2 ˆ

Y

Parameter derived from s for calculation of

s

c

r

t Student's t-distributed stochastic variable 6.5.3

7.1

TC, TC

a s

Lower confidence limit of TI or TI (see above)

a

a

t 6.5.3

Value of t with probability p and N degrees of freedom

p,N

x 6.3.5

Value of x, index number j, in time group i

ij

x

General mean of x-values 6.4.3

6.5.3

ˆˆ

XX, Estimate of x, and its confidence limit

c

y 6.1.1

Value of y for time group i

i

y

General mean of y-values 6.4.3

ˆˆ 6.5.3

YY,

Estimate of y, and its confidence limit

c

Reciprocal kelvin temperature for 6.1.1

z

ϑ

ij ij

nd

µ (y)

6.4.3

2 Central 2 moment of y values

Total number of property values in time group (i implied) 6.3.3

ν

2 2

6.5.1

χ χ distributed variable for variance equality (Bartlett's) test

ϑ

ij

Ageing temperature for specimen group j in time group i 6.1.1

– 13 – IEC 60216-6:2022 RLV © IEC 2022

Symbol Description Clause

Θ

6.1.1

0 273,15 K (corresponding to 0 °C)

τ

Ageing time for time group i 6.1.1

i

4 FTFM protocol

4.1 Principles of FTFM protocol

The FTFM (fixed time frame method) protocol is based upon the principle that thermal ageing

for determination of thermal endurance characteristics is carried out over a small number of

fixed times, with a sufficient range of ageing temperatures at each time to ensure that the

property values determined reach the end-point in a satisfactory manner.

In this it differs from the fixed temperature frame procedure of IEC 60216-1, where a small

number of ageing temperatures is employed, with ageing being carried out with testing at

intervals, until the end-point has been reached.

4.2 Objective of FTFM protocol

The objective of The protocol is to shall achieve the following advantages:

The determination of thermal endurance characteristics is completed in a fixed, predetermined

time.

This enables much more efficient planning of the determination and will often have substantial

commercial advantage. A simple TI determination will can be completed in 5 kh, whereas by

the fixed temperature frame procedure, it may can be necessary for ageing to be considerably

prolonged past this time to achieve the end-point at the lowest chosen ageing temperature.

Each temperature to end-point (i.e. time-group mean) in the thermal endurance regression is

based on the temperatures selected in a time group. The number of temperatures selected may

be any number between three and the number of temperature groups in a time group.

Since the largest source of systematic error in the fixed temperature frame procedure is

temperature error (actual indication error or temperature distribution error), systematic errors

can be considerably reduced. Errors from this source can lead to results which are either

inaccurate or invalid through incorrect assessment of linearity.

5 TI determination

5.1 Ageing procedures

Each test procedure shall specify the shape, dimensions and number of the test specimens, the

times of exposure, the property to which TI is related, the methods of its determination, the end-

point, and the derivation of the thermal endurance characteristics from the experimental data.

The chosen property should, if possible, reflect in a significant fashion a function of the material

EIM in practical use. A choice of properties is given in IEC 60216-2.

To provide uniform conditions, the conditioning of specimens after removal from the oven and

before measurement may need to should be specified.

– 14 – IEC 60216-6:2022 RLV © IEC 2022

5.2 Ageing times and temperatures

In the majority of cases, the required thermal endurance characteristics are for a projected

duration of 20 000 h. However, there is often a need for such information related to other, longer

or shorter times. In cases of longer times, the times given as requirements or recommendations

in the text of this standard (e.g. 5 kh for the minimum value of the longest ageing time) shall be

increased in the ratio of the actual specification time to 20 kh.

In cases of shorter specification times, the related times may be decreased in the same ratio if

necessary.

Particular care will be needed for very short specification times, since the higher ageing

temperatures may can lead into temperature regions which include transition points, e.g. glass

transition temperature or partial melting, with consequent non-linearity. Very long specification

times may can also lead to non-linearity.

Recommendations for ageing times and temperatures are given in Annex D and illustrated in

Figure E.3 to Figure E.5.

5.3 Test specimens

5.3.1 Preparation

The specimens used for the ageing test shall constitute a random sample from the population

investigated and shall be treated uniformly.

Since processing conditions may significantly affect the ageing characteristics of some

materials EIMs, it shall be ensured that, for example, sampling, cutting sheet from the supply

roll, cutting of anisotropic material in a given direction, moulding, curing, preconditioning, are

performed in the same manner for all specimens.

The material specifications or the standards for the diagnostic test methods will contain all

necessary instructions for the preparation of specimens.

The thickness of specimens is in some cases specified in the list of property measurements for

the determination of thermal endurance. See IEC 60216-2. If not, the thickness shall be

reported. Some physical properties are sensitive even to minor variations of specimen

thickness. In such cases the thickness after each ageing period may need to be determined

and reported if required in the relevant specification.

The thickness is also important because the rate of ageing may can vary with thickness. Ageing

data of materials EIMs with different thicknesses are not always comparable. Consequently, a

material may an EIM can be assigned more than one thermal endurance characteristic derived

from the measurement of properties at different thicknesses.

The tolerances of specimen dimensions shall be the same as those normally used for general

testing. Where specimen dimensions need smaller tolerances than those normally used, these

special tolerances shall be given.

Screening measurements ensure that specimens are of uniform quality and typical of the

material EIM to be tested.

5.3.2 Number of specimens

The accuracy of endurance test results depends largely on the number of specimens aged at

each temperature.

The total number of specimens (N) is derived as follows:

– 15 – IEC 60216-6:2022 RLV © IEC 2022

N = a × b × c + d

where

a is the number of specimens in a test group undergoing identical treatment at one

temperature and discarded after determination of the property (usually five);

b is the number of treatments, i.e. total number of exposure temperatures, at one time;

c is the number of ageing time levels;

d is the number of specimens in the group used to establish the initial value of the property.

Normal practice is to select d = 2a when the diagnostic criterion is a percentage change of

the property from its initial level. When the criterion is an absolute property level, d is usually

given the value of zero, unless reporting of the initial value is required.

It is good practice to prepare additional specimens, or at least to provide a reserve from the

original material batch from which such specimens may can subsequently be prepared. In this

way any required ageing of additional specimens in case of unforeseen complications will

introduce a minimum risk of producing systematic differences between groups of specimens.

Such complications may can arise, for example, if the thermal endurance relationship turns out

to be non-linear, or if specimens are lost due to thermal runaway of an oven.

5.4 Diagnostic tests

If IEC material specifications are available, property requirements in terms of acceptable lower

limits of TI values are usually given. If such material specifications are not available, a selection

of properties and methods for the evaluation of thermal endurance is given in IEC 60216-2.

If such a method cannot be found, an international, national or institution standard or a specially

devised method should be used in that order of preference. In this case, the diagnostic test

shall be stated in the report, including the property, measurement procedure and end-point.

5.5 Selection of end-points

The thermal endurance of materials may need to EIMs can be characterized by different

endurance data (derived using different properties and/or end-points), in order to facilitate the

adequate selection of the material in respect of its particular application. See IEC 60216-2.

There are two alternative ways in which the end-point may can be defined:

a) as a percentage increase or decrease in the measured value of the property from the original

level. This approach will provide comparisons among materials EIMs but bears a poorer

relationship than item b) to the property values required in normal service. For the

determination of the initial value, see 5.6;

b) as a fixed value of the property. This value might be selected with respect to usual service

requirements. End-points of proof tests are predominantly given in the form of fixed values

of the property.

The end-point should be selected to indicate a deg

...

IEC 60216-6 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electrical insulating materials – Thermal endurance properties –

Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating

material using the fixed time frame method

Matériaux isolants électriques – Propriétés d'endurance thermique –

Partie 6: Détermination des indices d’endurance thermique (IT et ITR) d’un

matériau isolant en utilisant la méthode de trame de durées fixes

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 60216-6 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electrical insulating materials – Thermal endurance properties –

Part 6: Determination of thermal endurance indices (TI and RTI) of an insulating

material using the fixed time frame method

Matériaux isolants électriques – Propriétés d'endurance thermique –

Partie 6: Détermination des indices d’endurance thermique (IT et ITR) d’un

matériau isolant en utilisant la méthode de trame de durées fixes

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.99; 29.035.01 ISBN 978-2-8322-6022-7

– 2 – IEC 60216-6:2022 © IEC 2022

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Symbols and abbreviated terms . 11

4 FTFM protocol . 12

4.1 Principles of FTFM protocol . 12

4.2 Objective of FTFM protocol . 12

5 TI determination . 13

5.1 Ageing procedures . 13

5.2 Ageing times and temperatures . 13

5.3 Test specimens . 13

5.3.1 Preparation . 13

5.3.2 Number of specimens . 14

5.4 Diagnostic tests . 14

5.5 Selection of end-points . 15

5.6 Establishment of initial property value . 15

5.7 Ageing conditions . 15

5.7.1 Ageing ovens . 15

5.7.2 Environmental conditions . 15

5.7.3 Conditions for property measurement . 16

5.8 Procedure for ageing . 16

6 Calculation procedures . 16

6.1 General principles . 16

6.1.1 Thermal endurance calculation . 16

6.1.2 Property value – equivalent temperature transform (Calculation of

hypothetical ageing temperature derived from the value of a property) . 17

6.2 Precision of calculations . 17

6.3 Derivation of temperatures equivalent to property values . 17

6.3.1 General . 17

6.3.2 Preliminary calculations . 17

6.3.3 Regression calculations (property on temperature) . 18

6.3.4 Linearity test . 20

6.3.5 Estimation of end-point temperatures equivalent to property values . 21

6.4 Regression analysis (temperature on time) . 21

6.4.1 General . 21

6.4.2 Group means and variances . 21

6.4.3 General means and variances . 21

6.4.4 Regression . 22

6.5 Statistical tests . 23

6.5.1 Variance equality test . 23

6.5.2 Linearity test (F-test) . 24

6.5.3 Estimates of x and y and their confidence limits . 24

6.6 Thermal endurance graph . 26

7 Calculation and requirements for results . 26

7.1 Calculation of thermal endurance characteristics . 26

7.2 Reporting of results . 27

7.2.1 Summary of statistical tests and reporting . 27

7.2.2 Report format . 27

8 Report . 27

9 RTI determination . 28

10 Additional symbols. 28

11 Experimental procedures . 29

11.1 Selection of reference EIM . 29

11.2 Selection of diagnostic test for extent of ageing . 29

11.3 Ageing procedures . 29

12 Calculation procedures . 29

12.1 General principles . 29

12.2 Input data . 29

12.3 RTI . 30

12.4 Confidence limits . 31

12.5 Extrapolation. 32

13 Results and report . 33

13.1 Results of statistical and numerical tests. 33

13.2 Result . 33

13.3 Report. 33

Annex A (normative) Decision flow chart . 34

Annex B (normative) Decision table . 36

Annex C (informative) Statistical tables . 37

Annex D (informative) Suggested ageing times and temperatures . 41

D.1 TI determination . 41

D.1.1 Correlation time (TI) = 20 000 h . 41

D.1.2 Other correlation times for TI calculation (see 12.3) . 41

D.2 RTI determination . 42

Annex E (informative) Figures . 43

Annex F (normative) Statistical significance of the difference between two regression

estimates . 46

Annex G (informative) Computer program . 47

G.1 General . 47

G.1.1 Overview . 47

G.1.2 Convenience program execution . 48

G.2.1 Content of file Control6.ftd . 50

G.2.2 Report . 52

G.2.3 Thermal endurance graph . 54

Figure A.1 – Decision flow chart . 35

Figure E.1 – Property-temperature graph with regression line . 43

Figure E.2 – Thermal endurance graph . 43

Figure E.3 – Ageing times and temperatures in relation to thermal endurance graph. 44

Figure E.4 – Ageing times and temperatures in relation to thermal endurance graph. 44

Figure E.5 – Ageing times and temperatures in relation to thermal endurance graph. 45

– 4 – IEC 60216-6:2022 © IEC 2022

Figure G.1 – Shortcut property dialog for program launch . 49

Figure G.2 – Thermal endurance graph . 54

Table 1 – Intermediate data values . 30

Table B.1 – Decision table . 36

Table C.1 – χ -function . 37

Table C.2 – t-function . 37

Table C.3 – F-function, P = 0,05 . 38

Table C.4 – F-function, P = 0,005 . 39

Table D.1 – Ageing temperatures and times . 41

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSULATING MATERIALS –

THERMAL ENDURANCE PROPERTIES –

Part 6: Determination of thermal endurance indices (TI and RTI)

of an insulating material using the fixed time frame method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60216-6 has been prepared by IEC technical committee 112: Evaluation and qualification

of electrical insulating materials and systems. It is an International Standard.

This third edition cancels and replaces the second edition published in 2006. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) clarification of definition of index properties vs. endurance properties;

b) complete rework of Annex G and the corresponding program.

– 6 – IEC 60216-6:2022 © IEC 2022

The text of this International Standard is based on the following documents:

Draft Report on voting

112/583/FDIS 112/589/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60216 series, published under the general title Electrical insulating

materials – Thermal endurance properties, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

ELECTRICAL INSULATING MATERIALS –

THERMAL ENDURANCE PROPERTIES –

Part 6: Determination of thermal endurance indices (TI and RTI)

of an insulating material using the fixed time frame method

1 Scope

This part of IEC 60216 specifies the experimental and calculation procedures for deriving the

thermal endurance characteristics, temperature index (TI) and relative temperature index (RTI)

of an electrical insulating material (EIM) using the “fixed time frame method (FTFM)”.

In this protocol, the ageing takes place for a small number of fixed times, using the appropriate

number of ageing temperatures throughout each time, the properties of the specimens being

measured at the end of the relevant time interval. This differs from the procedure of IEC 60216-

1, where ageing is conducted at a small number of fixed temperatures, property measurement

taking place after ageing times dependent on the progress of ageing.

The diagnostic tests employed in the fixed time frame method are restricted to destructive tests.

The method has not yet been applied to non-destructive or proof test procedures.

Both the TI and the RTI determined according to the FTFM protocol are derived from

experimental data obtained in accordance with the instructions of IEC 60216-1 and IEC 60216-2

as modified in this part of IEC 60216. The calculation procedures and statistical tests are

modified from those of IEC 60216-3 and IEC 60216-5.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60212, Standard conditions for use prior to and during the testing of solid electrical

insulating materials

IEC 60216-1:2013, Electrical insulating materials –Thermal endurance properties – Part 1:

Ageing procedures and evaluation of test results

IEC 60216-2, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of test

criteria

IEC 60216-3:2021, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60216-4-1, Electrical insulating materials – Thermal endurance properties – Part 4-1:

Ageing ovens – Single-chamber ovens

IEC 60216-4-2, Electrical insulating materials – Thermal endurance properties – Part 4-2:

Ageing ovens – Precision ovens for use up to 300 °C

– 8 – IEC 60216-6:2022 © IEC 2022

IEC 60216-4-3, Electrical insulating materials – Thermal endurance properties – Part 4-3:

Ageing ovens – Multi-chamber ovens

IEC 60216-5:2022, Electrical insulating materials – Thermal endurance properties – Part 5:

Determination of relative temperature index (RTI) of an insulating material

IEC 60493-1, Guide for the statistical analysis of ageing test data – Part 1: Methods based on

mean values of normally distributed test results

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

electrical insulating material

EIM

material of low electric conductivity, used to separate conducting parts at different electric

potentials or to isolate such parts from the surroundings

3.1.2

assessed temperature index

ATI

numerical value of the temperature index in degrees Celsius of the reference EIM

Note 1 to entry: The ATI of a specific material may vary between different applications of the material.

3.1.3

ageing temperature

temperature in degrees Celsius at which a group of specimens is thermally aged

3.1.4

end-point temperature

temperature in degrees Celsius at which a specimen is considered to have reached end-point

after ageing for a specified time

3.1.5

candidate EIM

material for which an estimate of the thermal endurance is required to be determined

Note 1 to entry: The determination is made by simultaneous thermal ageing of the material and a reference EIM.

3.1.6

central second moment of a data group

sum of the squares of the differences between the data values and the value of the group mean

divided by the number of data items in the group

3.1.7

95 % confidence limit

statistical parameter, calculated from test data, which with 95 % confidence constitutes an

upper or lower limit for the true value of a quantity estimated by statistical analysis

Note 1 to entry: This implies that there is only 5 % probability that the true value of the quantity estimated is actually

larger (or smaller) than the upper (or lower) confidence limit.

Note 2 to entry: In other connections, confidence values other than 95 % may sometimes be used, e.g. in the

linearity test for destructive test data.

3.1.8

reference EIM

material with known thermal endurance, preferably derived from service experience, used as a

reference for comparative tests with the candidate EIM

3.1.9

correlation coefficient

number expressing the completeness of the relation between members of two data sets, equal

to the covariance divided by the square root of the product of the variances of the sets

Note 1 to entry: The value of its square is between 0 (no correlation) and 1 (complete correlation).

Note 2 to entry: In this standard, the two data sets are the values of the independent variable and the means of the

corresponding dependent variable groups.

3.1.10

correlation time for RTI

estimated time to end-point of the reference EIM at a temperature equal to its ATI in degrees

Celsius

Note 1 to entry: In this document, it is expressed by symbol τ , see Clause 10.

c

3.1.11

correlation time for TI

hypothetical time to end-point used to calculate TI

Note 1 to entry: Its usual value is 20 000 h, see Clause D.1.

3.1.12

covariance,

for two sets of data with equal numbers of elements where each element in one set corresponds

to one in the other, sum of the products of the deviations of the corresponding members from

their set means, divided by the number of degrees of freedom

3.1.13

degrees of freedom

number of data values minus the number of parameter values

3.1.14

destructive test

diagnostic property test, where the test specimen is irreversibly changed by the property

measurement, in a way which precludes a repeated measurement on the same specimen

Note 1 to entry: An example of a destructive test is the measurement of electric strength. An example of a non-

destructive test is the measurement of dissipation factor tan δ.

3.1.15

end-point line

line parallel to the temperature axis intercepting the property axis at the end-point value

3.1.16

halving interval

HIC

numerical value of the temperature interval in Kelvin which expresses the halving of the time to

end-point taken at a time equal to TI

– 10 – IEC 60216-6:2022 © IEC 2022

3.1.17

regression analysis

process of deducing the best fit line expressing the relation of corresponding members of two

data groups by minimizing the sum of squares of deviations of members of one of the groups

from the line

3.1.18

regression coefficients

coefficients of the equation of the best fit line derived by regression analysis

3.1.19

relative temperature index

RTI

determined by test in relation to the thermal performance of a known reference EIM

3.1.20

significance

probability of a value of a statistical function greater than a specified value

Note 1 to entry: The value is equal to (1–p) where p is the cumulative distribution function value. Significance is

conventionally printed in upper case (P).

3.1.21

standard deviation

square root of the variance of a data group or sub-group

3.1.22

standard error of an estimate of the true value of a data group property

value of the standard deviation of the hypothetical sampling population of which the group

property may be a member

Note 1 to entry: For an estimate of the group mean, the standard error is equal to the group standard deviation

divided by the square root of the number of data items in the group, and indicates the uncertainty in the estimate of

the true value of the mean. This standard is concerned only with means and the difference between two means.

3.1.23

temperature index

TI

numerical value of the temperature in degrees Celsius determined by test by itself

Note 1 to entry: This rating is based on 20 000 h life, unless otherwise specified, based on one of the end-of-life

criteria listed in IEC 60216-2.

3.1.24

temperature group,

number of specimens being exposed together to thermal ageing at the same temperature in the

same oven

Note 1 to entry: Where there is no risk of ambiguity, either temperature groups or test groups may be referred to

simply as “groups”.

3.1.25

test group,

number of specimens removed together from a temperature group for destructive testing

Note 1 to entry: Where there is no risk of ambiguity, either temperature groups or test groups may be referred to

simply as “groups”.

3.1.26

thermal endurance graph

graph in which the logarithm of the time to reach a specified end-point in a thermal endurance

test is plotted against the reciprocal thermodynamic (absolute) test temperature

3.1.27

thermal endurance graph paper

graph paper having a logarithmic time scale as the ordinate and values proportional to the

reciprocal of the thermodynamic (absolute) temperature as the abscissa

Note 1 to entry: The ordinate is usually graduated in powers of ten (from 10 h to 100 000 h is often a convenient

range). The abscissa is usually graduated in a non-linear (Celsius) temperature scale oriented with temperature

increasing from left to right.

3.1.28

time group,

all test groups removed for testing at the same time

3.1.29

variance of a data group

sum of the squares of the deviations of the data from a reference level defined by one or more

parameters divided by the number of degrees of freedom

Note 1 to entry: The reference level can, for example be a mean value (1 parameter) or a line (2 parameters, here

intercept on the axis of the independent variable and slope).

3.2 Symbols and abbreviated terms

The following symbols are used in the calculations of Clauses 6, 7, 12 and Annex A, Annex B

and Annex C.

Symbol Description Clause

a Regression coefficient: intercept of regression line with x-axis 6.4.4

b Regression coefficient: slope of regression line relative to y-axis 6.4.4

6.5.3

ˆ

b

r

Y

Parameter derived from b for calculation of

c

b

p Regression coefficient for destructive test calculations 6.3.5

c 6.5.1

Parameter in calculation of χ

6.3.4,

F F-distributed variance ratio for linearity test

6.5.2

g, h, i, j Indexing parameters for regression calculations 6.3, 6.4

HIC Halving interval 7.1

k Number of ageing times 6.1.1

Total number of x values 6.4.3

N

ij

n Number of x values in time group i 6.1.1

i ij

Annex A,

Annex B

P Significance of the value of a statistical test function

and

Annex C

p 6.3

End-point property value

e

p 6.3

Property value h in temperature group g (time group i implied)

gh

6.3

p

Mean property value in temperature group g (time group i implied)

g

q 6.5.1

Base of logarithms in calculation of χ

r Number of temperature groups selected in time group i 6.3.3

Square of correlation coefficient 6.4.4

r

– 12 – IEC 60216-6:2022 © IEC 2022

Symbol Description Clause

6.5.2

Total (non-regression) variance of x-values

s

Variance of property values in temperature group g (time group i 6.3.3

s

1g

implied)

6.5.2

Value of s adjusted to allow for acceptable non-linearity

s

a

6.5.3

ˆ

Y

Parameter derived from s for calculation of

s

c

r

t Student's t-distributed stochastic variable 6.5.3

7.1

TC, TC

a s

Lower confidence limit of TI or TI (see above)

a

a

t 6.5.3

Value of t with probability p and N degrees of freedom

p,N