IEC 62133:2012

(Main)Secondary cells and batteries containing alkaline or other non-acid electrolytes - Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications

Secondary cells and batteries containing alkaline or other non-acid electrolytes - Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications

IEC 62133:2012 specifies requirements and tests for the safe operation of portable sealed secondary cells and batteries (other than button) containing alkaline or other non-acid electrolyte, under intended use and reasonably foreseeable misuse. This edition includes the following significant technical changes with respect to the previous edition:

- update of assembly of cells into batteries (5.5);

- addition of design recommendations for lithium system only (5.6.2);

- separation of nickel systems and lithium systems (Clause 6);

- addition of specific requirements and tests for lithium systems (Clause 8);

- addition of charging of secondary lithium-ion cells for safe use (Annex A). The contents of the corrigendum of June 2013 have been included in this copy.

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide - Exigences de sécurité pour les accumulateurs portables étanches, et pour les batteries qui en sont constituées, destinés à l'utilisation dans des applications portables

IEC 62133:2012 spécifie les exigences et les essais pour le fonctionnement en sécurité des accumulateurs portables étanches, et accumulateurs (autre que boutons) contenant un électrolyte alcalin ou un autre électrolyte non acide dans des utilisations prévues et dans des utilisations abusives raisonnablement prévisibles. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- mise à jour du montage des éléments en batteries (5.5);

- recommandations complémentaires de conception uniquement pour les systèmes au lithium (5.6.2);

- séparation des systèmes au nickel et des systèmes au lithium (Article 6);

- addition d'exigences et d'essais spécifiques pour les systèmes au lithium (Article 8);

- addition des éléments d'accumulateurs lithium-ion pour un usage sûr (Annexe A). Le contenu du corrigendum de juin 2013 a été pris en considération dans cet exemplaire.

General Information

- Status

- Replaced

- Publication Date

- 05-Dec-2012

- Technical Committee

- SC 21A - Secondary cells and batteries containing alkaline or other non-acid electrolytes

- Drafting Committee

- WG 4 - TC 21/SC 21A/WG 4

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 07-Feb-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

REDLINE IEC 62133:2012 - Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications Released:12/7/2012 Isbn:9782832205051

IEC 62133:2012 - Secondary cells and batteries containing alkaline or other non-acid electrolytes - Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications Released:12/6/2012

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62133:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Secondary cells and batteries containing alkaline or other non-acid electrolytes - Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications". This standard covers: IEC 62133:2012 specifies requirements and tests for the safe operation of portable sealed secondary cells and batteries (other than button) containing alkaline or other non-acid electrolyte, under intended use and reasonably foreseeable misuse. This edition includes the following significant technical changes with respect to the previous edition: - update of assembly of cells into batteries (5.5); - addition of design recommendations for lithium system only (5.6.2); - separation of nickel systems and lithium systems (Clause 6); - addition of specific requirements and tests for lithium systems (Clause 8); - addition of charging of secondary lithium-ion cells for safe use (Annex A). The contents of the corrigendum of June 2013 have been included in this copy.

IEC 62133:2012 specifies requirements and tests for the safe operation of portable sealed secondary cells and batteries (other than button) containing alkaline or other non-acid electrolyte, under intended use and reasonably foreseeable misuse. This edition includes the following significant technical changes with respect to the previous edition: - update of assembly of cells into batteries (5.5); - addition of design recommendations for lithium system only (5.6.2); - separation of nickel systems and lithium systems (Clause 6); - addition of specific requirements and tests for lithium systems (Clause 8); - addition of charging of secondary lithium-ion cells for safe use (Annex A). The contents of the corrigendum of June 2013 have been included in this copy.

IEC 62133:2012 is classified under the following ICS (International Classification for Standards) categories: 29.220.30 - Alkaline secondary cells and batteries. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62133:2012 has the following relationships with other standards: It is inter standard links to IEC 62133-2:2017, IEC 62133-1:2017, IEC 62133:2012/COR1:2013, IEC 62133:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62133:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62133 ®

Edition 2.0 2012-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made

from them, for use in portable applications

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62133 ®

Edition 2.0 2012-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made

from them, for use in portable applications

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.220.30 ISBN 978-2-8322-0505-1

IEC 62133 ®

Edition 2.0 2012-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made

from them, for use in portable applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Exigences de sécurité pour les accumulateurs portables étanches, et pour les

batteries qui en sont constituées, destinés à l'utilisation dans des applications

portables

– 2 – 62133 © IEC:2012

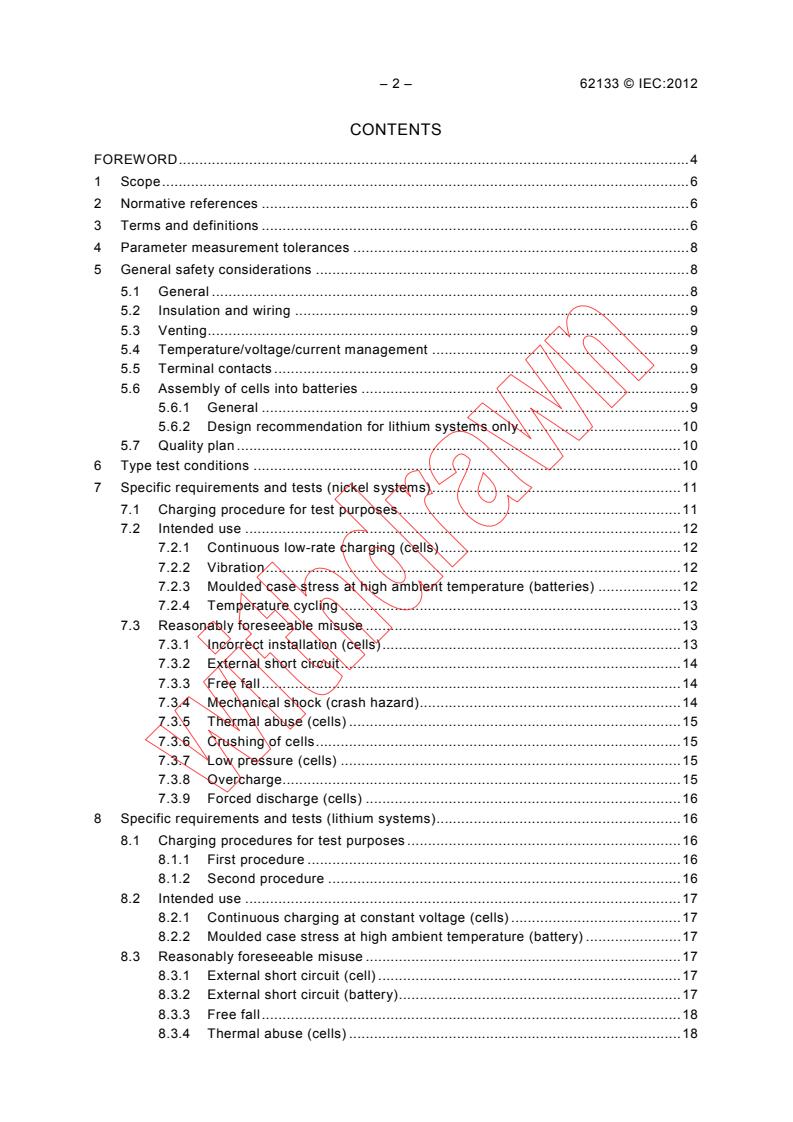

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Parameter measurement tolerances . 8

5 General safety considerations . 8

5.1 General . 8

5.2 Insulation and wiring . 9

5.3 Venting . 9

5.4 Temperature/voltage/current management . 9

5.5 Terminal contacts . 9

5.6 Assembly of cells into batteries . 9

5.6.1 General . 9

5.6.2 Design recommendation for lithium systems only . 10

5.7 Quality plan . 10

6 Type test conditions . 10

7 Specific requirements and tests (nickel systems) . 11

7.1 Charging procedure for test purposes . 11

7.2 Intended use . 12

7.2.1 Continuous low-rate charging (cells) . 12

7.2.2 Vibration . 12

7.2.3 Moulded case stress at high ambient temperature (batteries) . 12

7.2.4 Temperature cycling . 13

7.3 Reasonably foreseeable misuse . 13

7.3.1 Incorrect installation (cells) . 13

7.3.2 External short circuit . 14

7.3.3 Free fall . 14

7.3.4 Mechanical shock (crash hazard) . 14

7.3.5 Thermal abuse (cells) . 15

7.3.6 Crushing of cells . 15

7.3.7 Low pressure (cells) . 15

7.3.8 Overcharge. 15

7.3.9 Forced discharge (cells) . 16

8 Specific requirements and tests (lithium systems) . 16

8.1 Charging procedures for test purposes . 16

8.1.1 First procedure . 16

8.1.2 Second procedure . 16

8.2 Intended use . 17

8.2.1 Continuous charging at constant voltage (cells) . 17

8.2.2 Moulded case stress at high ambient temperature (battery) . 17

8.3 Reasonably foreseeable misuse . 17

8.3.1 External short circuit (cell) . 17

8.3.2 External short circuit (battery) . 17

8.3.3 Free fall . 18

8.3.4 Thermal abuse (cells) . 18

62133 © IEC:2012 – 3 –

8.3.5 Crush (cells) . 18

8.3.6 Over-charging of battery . 18

8.3.7 Forced discharge (cells) . 19

8.3.8 Transport tests . 19

8.3.9 Design evaluation – Forced internal short circuit (cells) . 19

9 Information for safety . 21

10 Marking . 21

10.1 Cell marking . 21

10.2 Battery marking . 22

10.3 Other information . 22

11 Packaging . 22

Annex A (normative) Charging range of secondary lithium ion cells for safe use . 23

Annex B (informative) Recommendations to equipment manufacturers and battery

assemblers . 34

Annex C (informative) Recommendations to the end-users . 35

Bibliography . 36

Figure 1 – Temperature profile for 7.2.4 – Temperature cycling test . 13

Figure 2 – Jig for pressing . 21

Figure A.1 – Typical of operating region of Li-ion cells with cobalt oxide cathode and

carbon anode . 24

Figure A.2 – Shape of nickel particle . 28

Figure A.3 – Nickel particle insertion position between positive and negative active

material coated area of cylindrical cell . 29

Figure A.4 – Nickel particle insertion position between positive aluminum foil and

negative active material coated area of cylindrical cell . 29

Figure A.5 – Disassembly of cylindrical cell . 30

Figure A.6 – Nickel particle insertion position between positive and negative (active

material) coated area of prismatic cell . 31

Figure A.7 – Nickel particle insertion position between positive aluminum foil and

negative (active material) coated area of prismatic cell . 32

Figure A.8 – Disassembly of prismatic cells . 33

Table 1 – Sample size for type tests (nickel systems) . 11

Table 2 – Sample size for type tests (lithium systems) . 11

Table 3 – Conditions for vibration test . 12

Table 4 – Condition of charging procedure . 16

a

Table 5 – Ambient temperature for cell test . 20

– 4 – 62133 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SECONDARY CELLS AND BATTERIES CONTAINING ALKALINE

OR OTHER NON-ACID ELECTROLYTES –

SAFETY REQUIREMENTS FOR PORTABLE SEALED

SECONDARY CELLS, AND FOR BATTERIES MADE FROM THEM,

FOR USE IN PORTABLE APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62133 has been prepared by subcommittee 21A: Secondary cells

and batteries containing alkaline or other non-acid electrolytes, of IEC technical committee 21:

Secondary cells and batteries.

This second edition cancels and replaces the first edition published in 2002. It constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– update of assembly of cells into batteries (5.5);

– addition of design recommendations for lithium system only (5.6.2);

– separation of nickel systems and lithium systems (Clause 6);

62133 © IEC:2012 – 5 –

– addition of specific requirements and tests for lithium systems (Clause 8);

– addition of charging of secondary lithium-ion cells for safe use (Annex A).

The text of this standard is based on the following documents:

FDIS Report on voting

21A/503/FDIS 21A/509/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The following difference exists in the countries indicated below:

Subclause 8.3.9: Design evaluation – Forced internal short circuit only applies to Korea,

Japan, Switzerland and France.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of June 2013 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication

indicates that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62133 © IEC:2012

SECONDARY CELLS AND BATTERIES CONTAINING ALKALINE

OR OTHER NON-ACID ELECTROLYTES –

SAFETY REQUIREMENTS FOR PORTABLE SEALED

SECONDARY CELLS, AND FOR BATTERIES MADE FROM THEM,

FOR USE IN PORTABLE APPLICATIONS

1 Scope

This International Standard specifies requirements and tests for the safe operation of portable

sealed secondary cells and batteries (other than button) containing alkaline or other non-acid

electrolyte, under intended use and reasonably foreseeable misuse.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-482, International Electrotechnical Vocabulary – Part 482: Primary and secondary

cells and batteries

IEC 61951-1, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 1: Nickel-cadmium

IEC 61951-2, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 2: Nickel-metal hydride

IEC 61960, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Secondary lithium cells and batteries for portable applications

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and

ISO/IEC Guide 51, as well as the following apply.

3.1

safety

freedom from unacceptable risk

3.2

risk

a combination of the probability of occurrence of harm and the severity of that harm

3.3

harm

physical injury or damage to the health of people or damage to property or to the environment

62133 © IEC:2012 – 7 –

3.4

hazard

potential source of harm

3.5

intended use

use of a product, process or service in accordance with specifications, instructions and

information provided by the supplier

3.6

reasonably foreseeable misuse

use of a product, process or service in a way which is not intended by the supplier, but which

may result from readily predictable human behaviour

3.7

secondary cell

basic manufactured unit providing a source of electrical energy by direct conversion of

chemical energy, that consists of electrodes, separators, electrolyte, container and terminals,

and that is designed to be charged electrically

3.8

secondary battery

assembly of secondary cell(s) ready for use as a source of electrical energy characterized by

its voltage, size, terminal arrangement, capacity and rate capability

3.9

leakage

visible escape of liquid electrolyte

3.10

venting

release of excessive internal pressure from a cell/battery in a manner intended by design to

preclude rupture or explosion

3.11

rupture

mechanical failure of a cell container or battery case induced by an internal or external cause,

resulting in exposure or spillage but not ejection of materials

3.12

explosion

failure that occurs when a cell container or battery case opens violently and major

components are forcibly expelled

3.13

fire

the emission of flames from a cell or battery

3.14

portable battery

a battery for use in a device or appliance which is conveniently hand carried

3.15

portable cell

a cell intended for assembly in a portable battery

– 8 – 62133 © IEC:2012

3.16

polymer cell

cell using gel polymer electrolyte or solid polymer electrolyte, not liquid electrolyte

3.17

rated capacity

quantity of electricity C Ah (ampere-hours) declared by the manufacturer which a single cell

can deliver when discharged at the reference test current of 0,2 I A to a specified final

t

voltage, after charging, storing and discharging under specified conditions

3.18

upper limit charging voltage

the highest charging voltage in the cell operating region specified by the cell manufacturer

3.19

maximum charging current

the maximum charging current in the cell operating region which is specified by the cell

manufacturer

4 Parameter measurement tolerances

The overall accuracy of controlled or measured values, relative to the specified or actual

parameters, shall be within these tolerances.

a) ± 1 % for voltage;

b) ± 1 % for current;

c) ± 2 °C for temperature;

d) ± 0,1 % for time;

e) ± 1 % for dimension;

f) ± 1 % for capacity.

These tolerances comprise the combined accuracy of the measuring instruments, the

measurement techniques used, and all other sources of error in the test procedure.

For assistance in selecting instrumentation see IEC 60051 series for analogue instruments

and IEC 60485 for digital instruments. The details of the instrumentation used shall be

provided in any report of results.

5 General safety considerations

5.1 General

The safety of secondary cells and batteries requires the consideration of two sets of applied

conditions:

• intended use;

• reasonably foreseeable misuse.

Cells and batteries shall be so designed and constructed that they are safe under conditions

of both intended use and reasonably foreseeable misuse. It is expected that cells or batteries

subjected to misuse may fail to function following such experience. They shall not however

present significant hazards. It may also be expected that cells and batteries subjected to

intended use shall not only be safe but shall continue to be functional in all respects.

Potential hazards which are the subject of this standard are:

62133 © IEC:2012 – 9 –

a) fire,

b) burst/explosion,

c) leakage of cell electrolyte,

d) venting,

e) burns from excessively high external temperatures,

f) rupture of battery case with exposure of internal components.

Conformity with 5.2 to 5.7 is checked by inspection, by the tests of Clauses 7 and 8, and in

accordance with the appropriate standard (see Clause 2).

5.2 Insulation and wiring

The insulation resistance between the positive terminal and externally exposed metal surfaces

of the battery excluding electrical contact surfaces shall be not less than 5 MΩ at 500 V d. c.

when measured 60 s after applying the voltage.

Internal wiring and its insulation shall be sufficient to withstand the maximum anticipated

current, voltage and temperature requirements. The orientation of wiring shall be such that

adequate clearances and creepage distances are maintained between connectors. The

mechanical integrity of internal connections shall be sufficient to accommodate conditions of

reasonably foreseeable misuse.

5.3 Venting

Battery cases and cells shall incorporate a pressure relief mechanism or shall be so

constructed that they will relieve excessive internal pressure at a value and rate that will

preclude rupture, explosion and self-ignition. If encapsulation is used to support cells within

an outer case, the type of encapsulant and the method of encapsulation shall neither cause

the battery to overheat during normal operation nor inhibit pressure relief.

5.4 Temperature/voltage/current management

The design of batteries shall be such that abnormal temperature-rise conditions are

prevented. Batteries shall be designed to be within temperature, voltage and current limits

specified by the cell manufacturer. Batteries shall be provided with specifications and

charging instructions for equipment manufacturers so that associated chargers are

designed to maintain charging within the temperature, voltage and current limits specified.

NOTE Where necessary, means can be provided to limit current to safe levels during charge and discharge.

5.5 Terminal contacts

Terminals shall have clear polarity marking on the external surface of the battery. The size

and shape of the terminal contacts shall ensure that they can carry the maximum anticipated

current. External terminal contact surfaces shall be formed from conductive materials with

good mechanical strength and corrosion resistance. Terminal contacts shall be arranged so

as to minimize the risk of short circuits.

NOTE Exception: Battery packs with keyed external connectors designed for connection to specific end products

need not be marked with polarity markings if the design of the external connector prevents reverse polarity

connections.

5.6 Assembly of cells into batteries

5.6.1 General

If there is more than one battery housed in a single battery case, cells used in the assembly

of each battery shall have closely matched capacities, be of the same design, be of the same

– 10 – 62133 © IEC:2012

chemistry and be from the same manufacturer. Each battery shall have an independent

control and protection. Manufacturers of cells shall make recommendations about current,

voltage and temperature limits so that the battery manufacturer/designer may ensure proper

design and assembly. Batteries that are designed for the selective discharge of a portion of

their series connected cells shall incorporate separate circuitry to prevent the cell reversal

caused by uneven discharges. Protective circuit components should be added as appropriate

and consideration given to the end-device application. When testing a battery, the

manufacturer of the battery shall provide a test report confirming the compliance according to

this standard. Conformity shall be checked by inspection.

5.6.2 Design recommendation for lithium systems only

The voltage of each cell, or each cellblock consisting of parallel-connected plural cells, should

not exceed the upper limit of the charging voltage specified in Table 4, excepting the case

where the portable electronic devices or the likes have the equivalent function.

The following should be considered at the battery pack level and by the device designer:

• for the battery consisting of a single cell or a single cellblock, it is recommended that the

charging voltage of the cell does not exceed the upper limit of the charging voltage

specified in Table 4;

• for the battery consisting of series-connected plural single cells or series-connected plural

cellblocks, it is recommended that the voltages of any one of the single cells or single

cellblocks does not exceed the upper limit of the charging voltage, specified in Table 4, by

monitoring the voltage of every single cell or the single cellblocks;

• for the battery consisting of series-connected plural single cells or series-connected plural

cellblocks, it is recommended that charging is stopped when the upper limit of the

charging voltage is exceeded for any one of the single cells or single cellblocks by

measuring the voltage of every single cell or the single cellblocks.

5.7 Quality plan

The manufacturer shall prepare and implement a quality plan that defines procedures for the

inspection of materials, components, cells and batteries and which covers the whole process

of producing each type of cell or battery. Manufacturers should understand their process

capabilities and should institute the necessary process controls as they relate to product

safety.

6 Type test conditions

Tests are made with the number of cells or batteries specified in Table 1 for nickel-cadmium

and nickel-metal hydride systems and Table 2 for lithium systems, using cells or batteries that

are not more than six months old. Unless otherwise specified, tests are carried out in an

ambient temperature of 20 °C ± 5 °C.

NOTE Test conditions are for type tests only and do not imply that intended use includes operation under these

conditions. Similarly, the limit of six months is introduced for consistency and does not imply that battery safety is

reduced after six months.

62133 © IEC:2012 – 11 –

Table 1 – Sample size for type tests (nickel systems)

Test Cell Battery

7.2.1 Low rate charging 5 –

7.2.2 Vibration 5 5

7.2.3 Moulded case stress – 3

7.2.4 Temperature cycling 5 5

7.3.1 Incorrect Installation 5 sets of 4 –

7.3.2 External short circuit 5 /Temperature 5 /Temperature

7.3.3 Free fall 3 3

7.3.4 Mechanical shock 5 5

7.3.5 Thermal abuse 5 –

7.3.6 Crush 5 (10 for prismatic) –

7.3.7 Low pressure 3 –

7.3.8 Overcharge 5 5

7.3.9 Forced discharge 5 –

Table 2 – Sample size for type tests (lithium systems)

Test Cell Battery

8.1.2 Charge (Procedure 2) 5/Temp/Condition 5/Temp/Condition

8.2.1 Continuous charge 5 -

8.2.2 Moulded case stress - 3

8.3.1 External short circuit 5/Temp -

8.3.2 External short circuit – 5/Temp

8.3.3 Free fall 3 3

8.3.4 Thermal abuse 5/Temp -

8.3.5 Crush 5/Temp -

8.3.6 Overcharge - 5

8.3.7 Forced Discharge 5 -

8.3.8 Transport (20) -

a

8.3.9 Forced Internal Short 10 -

a

Country specific test : only required for listed countries.

7 Specific requirements and tests (nickel systems)

7.1 Charging procedure for test purposes

Unless otherwise stated in this standard, the charging procedure for test purposes is carried

out in an ambient temperature of 20 °C ± 5 °C, using the method declared by the

manufacturer.

Prior to charging, the battery shall have been discharged at 20 °C ± 5 °C at a constant current

of 0,2 I A down to a specified final voltage.

t

– 12 – 62133 © IEC:2012

Warning: THESE TESTS USE PROCEDURES WHICH MAY RESULT IN HARM IF ADEQUATE PRECAUTIONS

ARE NOT TAKEN. TESTS SHOULD ONLY BE PERFORMED BY QUALIFIED AND EXPERIENCED

TECHNICIANS USING ADEQUATE PROTECTION. TO PREVENT BURNS, CAUTION SHOULD BE

TAKEN FOR THOSE CELLS OR BATTERIES WHOSE CASINGS MAY EXCEED 75 °C AS A

RESULT OF TESTING.

7.2 Intended use

7.2.1 Continuous low-rate charging (cells)

a) Requirement

A continuous low-rate charge shall not cause fire or explosion.

b) Test

Fully charged cells are subjected for 28 days to a charge as specified by the

manufacturer.

c) Acceptance criteria

No fire, no explosion.

7.2.2 Vibration

a) Requirements

Vibration encountered during transportation shall not cause leakage, fire or explosion.

b) Test

Fully charged cells or batteries are vibration-tested under the following test conditions and

the sequence in Table 3. A simple harmonic motion is applied to the cells or batteries with

an amplitude of 0,76 mm, and a total maximum excursion of 1,52 mm. The frequency is

varied at the rate of 1 Hz/min between the limits of 10 Hz and 55 Hz. The entire range of

frequencies (10 Hz to 55 Hz) and return (55 Hz to 10 Hz) is traversed in 90 min ± 5 min for

each mounting position (direction of vibration). The vibration is applied in each of three

mutually perpendicular directions, in the sequence specified below.

Step 1: Verify that the measured voltage is typical of the charged product being tested.

Steps 2-4: Apply the vibration as specified in Table 3.

Step 5: Rest cell for 1 h, and then make a visual inspection.

c) Acceptance criteria

No fire, no explosion, no leakage.

Table 3 – Conditions for vibration test

Rest time Vibration time

Step Visual examination

h min

1 – – Pre-test

2 – 90 ± 5 –

3 – 90 ± 5 –

4 – –

90 ± 5

5 1 – Post-test

7.2.3 Moulded case stress at high ambient temperature (batteries)

a) Requirement

Internal components of batteries shall not be exposed during use at high temperature.

62133 © IEC:2012 – 13 –

b) Test

Fully charged batteries are exposed to a moderately high temperature to evaluate case

integrity. The battery is placed in an air circulating oven at a temperature of 70 °C ± 2 °C.

The batteries remain in the oven for 7 h, after which they are removed and allowed to

return to room temperature.

c) Acceptance criteria

No physical distortion of the battery case resulting in exposure of internal components.

7.2.4 Temperature cycling

a) Requirements

Repeated exposure to high and low temperatures shall not cause fire or explosion.

b) Test according to the following procedure and the profile shown in Figure 1.

Fully charged cells or batteries are subjected to temperature cycling (–20 °C, +75 °C),

in forced draught chambers, according to the following procedure.

Step 1: Place the cells or batteries in an ambient temperature of 75 °C ± 2 °C for 4 h.

Step 2: Change the ambient temperature to 20 °C ± 5 °C within 30 min and maintain

at this temperature for a minimum of 2 h.

Step 3: Change the ambient temperature to –20 °C ± 2 °C within 30 min and maintain

at this temperature for 4 h.

Step 4: Change the ambient temperature to 20 °C ± 5 °C within 30 min and maintain

at this temperature for a minimum of 2 h.

Step 5: Repeat steps 1 to 4 for a further four cycles.

Step 6: After the fifth cycle, store the cells or batteries and check after a rest period of

at least 24 h.

NOTE This test can be performed in a single chamber whose temperature is changed or in three separate

chambers at three different test temperatures.

c) Acceptance criteria

No fire, no explosion, no leakage.

–20

–40

–60

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Time (h)

IEC 2194/12

Figure 1 – Temperature profile for 7.2.4 –

Temperature cycling test

7.3 Reasonably foreseeable misuse

7.3.1 Incorrect installation (cells)

a) Requirements

The incorrect installation of a single cell in a multi-cell application shall not cause fire or

explosion.

b) Test

Temperature (°C)

– 14 – 62133 © IEC:2012

Fully charged cells are evaluated under conditions in which one of the cells is incorrectly

installed. Four fully charged single cells of the same brand, type, size and age are

connected in series with one of the four cells reversed. The resultant assembly is

connected across a resistor of 1 Ω until the vent opens or until the temperature of the

reversed cell returns to ambient temperature. Alternatively, a stabilized d.c. power supply

can be used to simulate the conditions imposed on the reversed cell.

c) Acceptance criteria

No fire, no explosion.

7.3.2 External short circuit

a) Requirements

Short-circuiting of the positive and negative terminals shall not cause fire or explosion.

b) Test

Two sets of fully charged cells or batteries are stored in an ambient temperature

of 20 °C ± 5 °C and +55 °C ± 5 °C respectively. Each cell or battery is then short-circuited

by connecting the positive and negative terminals with a total external resistance

of 80 mΩ ± 20 mΩ. The cells or batteries remain on test for 24 h or until the case

temperature declines by 20 % of the maximum temperature rise, whichever is the sooner.

c) Acceptance criteria

No fire, no explosion.

7.3.3 Free fall

a) Requirements

Dropping a cell or battery (for example, from a bench top) shall not cause fire or

explosion.

b) Test

Each fully charged cell or battery is dropped three times from a height of 1,0 m onto a

concrete floor. The cells or batteries are dropped so as to obtain impacts in random

orientations. After the test, the sample shall be put on rest for a minimum of one hour and

then a visual inspection shall be performed.

c) Acceptance criteria

No fire, no explosion.

7.3.4 Mechanical shock (crash hazard)

a) Requirements

Shocks encountered during handling or transportation shall not cause fire, explosion or

leakage.

b) Test

The fully charged cell or battery is secured to the testing machine by means of a rigid

mount which will support all mounting surfaces of the cell or battery. The cell or battery is

subjected to a total of three shocks of equal magnitude. The shocks are applied in each of

three mutually perpendicular directions. At least one of them shall be perpendicular to a

flat face.

For each shock the cell or battery is accelerated in such a manner that during the initial

. The peak acceleration shall be between

3 ms the minimum average acceleration is 75 g

n

125 g and 175 g . Cells or batteries are tested in an ambient temperature

n n

of 20 °C ± 5 °C. After the test, the sample shall be put on rest for a minimum of one hour

and then a visual inspection shall be performed.

c) Acceptance criteria

No fire, no explosion, no leakage.

62133 © IEC:2012 – 15 –

7.3.5 Thermal abuse (cells)

a) Requirements

An extremely high temperature shall not cause fire or explosion.

b) Test

Each fully charged cell, stabilized at room temperature, is placed in a gravity or circulating

air-convection oven. The oven temperature is raised at a rate of 5 °C/min ± 2 °C/min to a

temperature of 130 °C ± 2 °C. The cell remains at this temperature for 10 min before the

test is discontinued.

c) Acceptance criteria

No fire, no explosion.

7.3.6 Crushing of cells

a) Requirements

Severe crushing of a cell (for example, during disposal in a waste compactor) shall not

cause fire or explosion.

b) Test

Each fully charged cell is crushed between two flat surfaces. The force for the crushing is

applied by a hydraulic ram exerting a force of 13 kN ± 1 kN. The crushing is performed in

a manner that will cause the most adverse result. Once the maximum force has been

applied, or an abrupt voltage drop of one-third of the original voltage has been obtained,

the force is released.

A cylindrical or prismatic cell is crushed with its longitudinal axis parallel to the flat

surfaces of the crushing apparatus. To test both wide and narrow sides of prismatic cells,

a second set of cells is tested, rotated 90° around their longitudinal axes compared to the

first set.

c) Acceptance criteria

No fire, no explosion.

7.3.7 Low pressure (cells)

a) Requirements

Low pressure (for example, during transportation in an aircraft cargo hold) shall not cause

fire or explosion.

b) Test

Each fully charged cell is placed in a vacuum chamber, in an ambient temperature

of 20 °C ± 5 °C. Once the chamber has been sealed, its internal pressure is gradually

reduced to a pressure equal to or less than 11,6 kPa (this simulates an altitude of

15 240 m) held at that value for 6 h.

c) Acceptance criteria

No fire, no explosion, no leakage.

7.3.8 Overcharge

a) Requirements

Charging for longer periods and at a higher rate than specified by the manufacturer shall

not cause fire or explosion.

b) Test

A discharged cell or battery is subjected to a high-rate charge of 2,5 times the

recommended charging current for a time that produces a 250 % charge input (250 % of

rated capacity).

c) Acceptance criteria

No fire, no explosion.

– 16 – 62133 © IEC:2012

7.3.9 Forced discharge (cells)

a) Requirements

A cell in a multi-cell application shall withstand polarity reversal without causing fire or

explosion.

b) Test

A discharged cell is subjected to a reverse charge at 1 I A for 90 min.

t

c) Acceptance criteria

No fire, no explosion.

8 Specific requirements and tests (lithium systems)

8.1 Charging procedures for test purposes

8.1.1 First procedure

(This charging

...

IEC 62133 ®

Edition 2.0 2012-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made

from them, for use in portable applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Exigences de sécurité pour les accumulateurs portables étanches, et pour les

batteries qui en sont constituées, destinés à l'utilisation dans des applications

portables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62133 ®

Edition 2.0 2012-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made

from them, for use in portable applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Exigences de sécurité pour les accumulateurs portables étanches, et pour les

batteries qui en sont constituées, destinés à l'utilisation dans des applications

portables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX W

ICS 29.220.30 ISBN 978-2-83220-505-1

– 2 – 62133 © IEC:2012

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Parameter measurement tolerances . 8

5 General safety considerations . 8

5.1 General . 8

5.2 Insulation and wiring . 9

5.3 Venting . 9

5.4 Temperature/voltage/current management . 9

5.5 Terminal contacts . 9

5.6 Assembly of cells into batteries . 9

5.6.1 General . 9

5.6.2 Design recommendation for lithium systems only . 10

5.7 Quality plan . 10

6 Type test conditions . 10

7 Specific requirements and tests (nickel systems) . 11

7.1 Charging procedure for test purposes . 11

7.2 Intended use . 12

7.2.1 Continuous low-rate charging (cells) . 12

7.2.2 Vibration . 12

7.2.3 Moulded case stress at high ambient temperature (batteries) . 12

7.2.4 Temperature cycling . 13

7.3 Reasonably foreseeable misuse . 13

7.3.1 Incorrect installation (cells) . 13

7.3.2 External short circuit . 14

7.3.3 Free fall . 14

7.3.4 Mechanical shock (crash hazard) . 14

7.3.5 Thermal abuse (cells) . 15

7.3.6 Crushing of cells . 15

7.3.7 Low pressure (cells) . 15

7.3.8 Overcharge. 15

7.3.9 Forced discharge (cells) . 16

8 Specific requirements and tests (lithium systems) . 16

8.1 Charging procedures for test purposes . 16

8.1.1 First procedure . 16

8.1.2 Second procedure . 16

8.2 Intended use . 17

8.2.1 Continuous charging at constant voltage (cells) . 17

8.2.2 Moulded case stress at high ambient temperature (battery) . 17

8.3 Reasonably foreseeable misuse . 17

8.3.1 External short circuit (cell) . 17

8.3.2 External short circuit (battery) . 17

8.3.3 Free fall . 18

8.3.4 Thermal abuse (cells) . 18

62133 © IEC:2012 – 3 –

8.3.5 Crush (cells) . 18

8.3.6 Over-charging of battery . 18

8.3.7 Forced discharge (cells) . 19

8.3.8 Transport tests . 19

8.3.9 Design evaluation – Forced internal short circuit (cells) . 19

9 Information for safety . 21

10 Marking . 21

10.1 Cell marking . 21

10.2 Battery marking . 22

10.3 Other information . 22

11 Packaging . 22

Annex A (normative) Charging range of secondary lithium ion cells for safe use . 23

Annex B (informative) Recommendations to equipment manufacturers and battery

assemblers . 34

Annex C (informative) Recommendations to the end-users . 35

Bibliography . 36

Figure 1 – Temperature profile for 7.2.4 – Temperature cycling test . 13

Figure 2 – Jig for pressing . 21

Figure A.1 – Typical of operating region of Li-ion cells with cobalt oxide cathode and

carbon anode . 24

Figure A.2 – Shape of nickel particle . 28

Figure A.3 – Nickel particle insertion position between positive and negative active

material coated area of cylindrical cell . 29

Figure A.4 – Nickel particle insertion position between positive aluminum foil and

negative active material coated area of cylindrical cell . 29

Figure A.5 – Disassembly of cylindrical cell . 30

Figure A.6 – Nickel particle insertion position between positive and negative (active

material) coated area of prismatic cell . 31

Figure A.7 – Nickel particle insertion position between positive aluminum foil and

negative (active material) coated area of prismatic cell . 32

Figure A.8 – Disassembly of prismatic cells . 33

Table 1 – Sample size for type tests (nickel systems) . 11

Table 2 – Sample size for type tests (lithium systems) . 11

Table 3 – Conditions for vibration test . 12

Table 4 – Condition of charging procedure . 16

a

Table 5 – Ambient temperature for cell test . 20

– 4 – 62133 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SECONDARY CELLS AND BATTERIES CONTAINING ALKALINE

OR OTHER NON-ACID ELECTROLYTES –

SAFETY REQUIREMENTS FOR PORTABLE SEALED

SECONDARY CELLS, AND FOR BATTERIES MADE FROM THEM,

FOR USE IN PORTABLE APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62133 has been prepared by subcommittee 21A: Secondary cells

and batteries containing alkaline or other non-acid electrolytes, of IEC technical committee 21:

Secondary cells and batteries.

This second edition cancels and replaces the first edition published in 2002. It constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– update of assembly of cells into batteries (5.5);

– addition of design recommendations for lithium system only (5.6.2);

– separation of nickel systems and lithium systems (Clause 6);

62133 © IEC:2012 – 5 –

– addition of specific requirements and tests for lithium systems (Clause 8);

– addition of charging of secondary lithium-ion cells for safe use (Annex A).

The text of this standard is based on the following documents:

FDIS Report on voting

21A/503/FDIS 21A/509/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The following difference exists in the countries indicated below:

Subclause 8.3.9: Design evaluation – Forced internal short circuit only applies to Korea,

Japan, Switzerland and France.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of June 2013 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication

indicates that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62133 © IEC:2012

SECONDARY CELLS AND BATTERIES CONTAINING ALKALINE

OR OTHER NON-ACID ELECTROLYTES –

SAFETY REQUIREMENTS FOR PORTABLE SEALED

SECONDARY CELLS, AND FOR BATTERIES MADE FROM THEM,

FOR USE IN PORTABLE APPLICATIONS

1 Scope

This International Standard specifies requirements and tests for the safe operation of portable

sealed secondary cells and batteries (other than button) containing alkaline or other non-acid

electrolyte, under intended use and reasonably foreseeable misuse.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-482, International Electrotechnical Vocabulary – Part 482: Primary and secondary

cells and batteries

IEC 61951-1, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 1: Nickel-cadmium

IEC 61951-2, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 2: Nickel-metal hydride

IEC 61960, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Secondary lithium cells and batteries for portable applications

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and

ISO/IEC Guide 51, as well as the following apply.

3.1

safety

freedom from unacceptable risk

3.2

risk

a combination of the probability of occurrence of harm and the severity of that harm

3.3

harm

physical injury or damage to the health of people or damage to property or to the environment

62133 © IEC:2012 – 7 –

3.4

hazard

potential source of harm

3.5

intended use

use of a product, process or service in accordance with specifications, instructions and

information provided by the supplier

3.6

reasonably foreseeable misuse

use of a product, process or service in a way which is not intended by the supplier, but which

may result from readily predictable human behaviour

3.7

secondary cell

basic manufactured unit providing a source of electrical energy by direct conversion of

chemical energy, that consists of electrodes, separators, electrolyte, container and terminals,

and that is designed to be charged electrically

3.8

secondary battery

assembly of secondary cell(s) ready for use as a source of electrical energy characterized by

its voltage, size, terminal arrangement, capacity and rate capability

3.9

leakage

visible escape of liquid electrolyte

3.10

venting

release of excessive internal pressure from a cell/battery in a manner intended by design to

preclude rupture or explosion

3.11

rupture

mechanical failure of a cell container or battery case induced by an internal or external cause,

resulting in exposure or spillage but not ejection of materials

3.12

explosion

failure that occurs when a cell container or battery case opens violently and major

components are forcibly expelled

3.13

fire

the emission of flames from a cell or battery

3.14

portable battery

a battery for use in a device or appliance which is conveniently hand carried

3.15

portable cell

a cell intended for assembly in a portable battery

– 8 – 62133 © IEC:2012

3.16

polymer cell

cell using gel polymer electrolyte or solid polymer electrolyte, not liquid electrolyte

3.17

rated capacity

quantity of electricity C Ah (ampere-hours) declared by the manufacturer which a single cell

can deliver when discharged at the reference test current of 0,2 I A to a specified final

t

voltage, after charging, storing and discharging under specified conditions

3.18

upper limit charging voltage

the highest charging voltage in the cell operating region specified by the cell manufacturer

3.19

maximum charging current

the maximum charging current in the cell operating region which is specified by the cell

manufacturer

4 Parameter measurement tolerances

The overall accuracy of controlled or measured values, relative to the specified or actual

parameters, shall be within these tolerances.

a) ± 1 % for voltage;

b) ± 1 % for current;

c) ± 2 °C for temperature;

d) ± 0,1 % for time;

e) ± 1 % for dimension;

f) ± 1 % for capacity.

These tolerances comprise the combined accuracy of the measuring instruments, the

measurement techniques used, and all other sources of error in the test procedure.

For assistance in selecting instrumentation see IEC 60051 series for analogue instruments

and IEC 60485 for digital instruments. The details of the instrumentation used shall be

provided in any report of results.

5 General safety considerations

5.1 General

The safety of secondary cells and batteries requires the consideration of two sets of applied

conditions:

• intended use;

• reasonably foreseeable misuse.

Cells and batteries shall be so designed and constructed that they are safe under conditions

of both intended use and reasonably foreseeable misuse. It is expected that cells or batteries

subjected to misuse may fail to function following such experience. They shall not however

present significant hazards. It may also be expected that cells and batteries subjected to

intended use shall not only be safe but shall continue to be functional in all respects.

Potential hazards which are the subject of this standard are:

62133 © IEC:2012 – 9 –

a) fire,

b) burst/explosion,

c) leakage of cell electrolyte,

d) venting,

e) burns from excessively high external temperatures,

f) rupture of battery case with exposure of internal components.

Conformity with 5.2 to 5.7 is checked by inspection, by the tests of Clauses 7 and 8, and in

accordance with the appropriate standard (see Clause 2).

5.2 Insulation and wiring

The insulation resistance between the positive terminal and externally exposed metal surfaces

of the battery excluding electrical contact surfaces shall be not less than 5 MΩ at 500 V d. c.

when measured 60 s after applying the voltage.

Internal wiring and its insulation shall be sufficient to withstand the maximum anticipated

current, voltage and temperature requirements. The orientation of wiring shall be such that

adequate clearances and creepage distances are maintained between connectors. The

mechanical integrity of internal connections shall be sufficient to accommodate conditions of

reasonably foreseeable misuse.

5.3 Venting

Battery cases and cells shall incorporate a pressure relief mechanism or shall be so

constructed that they will relieve excessive internal pressure at a value and rate that will

preclude rupture, explosion and self-ignition. If encapsulation is used to support cells within

an outer case, the type of encapsulant and the method of encapsulation shall neither cause

the battery to overheat during normal operation nor inhibit pressure relief.

5.4 Temperature/voltage/current management

The design of batteries shall be such that abnormal temperature-rise conditions are

prevented. Batteries shall be designed to be within temperature, voltage and current limits

specified by the cell manufacturer. Batteries shall be provided with specifications and

charging instructions for equipment manufacturers so that associated chargers are

designed to maintain charging within the temperature, voltage and current limits specified.

NOTE Where necessary, means can be provided to limit current to safe levels during charge and discharge.

5.5 Terminal contacts

Terminals shall have clear polarity marking on the external surface of the battery. The size

and shape of the terminal contacts shall ensure that they can carry the maximum anticipated

current. External terminal contact surfaces shall be formed from conductive materials with

good mechanical strength and corrosion resistance. Terminal contacts shall be arranged so

as to minimize the risk of short circuits.

NOTE Exception: Battery packs with keyed external connectors designed for connection to specific end products

need not be marked with polarity markings if the design of the external connector prevents reverse polarity

connections.

5.6 Assembly of cells into batteries

5.6.1 General

If there is more than one battery housed in a single battery case, cells used in the assembly

of each battery shall have closely matched capacities, be of the same design, be of the same

– 10 – 62133 © IEC:2012

chemistry and be from the same manufacturer. Each battery shall have an independent

control and protection. Manufacturers of cells shall make recommendations about current,

voltage and temperature limits so that the battery manufacturer/designer may ensure proper

design and assembly. Batteries that are designed for the selective discharge of a portion of

their series connected cells shall incorporate separate circuitry to prevent the cell reversal

caused by uneven discharges. Protective circuit components should be added as appropriate

and consideration given to the end-device application. When testing a battery, the

manufacturer of the battery shall provide a test report confirming the compliance according to

this standard. Conformity shall be checked by inspection.

5.6.2 Design recommendation for lithium systems only

The voltage of each cell, or each cellblock consisting of parallel-connected plural cells, should

not exceed the upper limit of the charging voltage specified in Table 4, excepting the case

where the portable electronic devices or the likes have the equivalent function.

The following should be considered at the battery pack level and by the device designer:

• for the battery consisting of a single cell or a single cellblock, it is recommended that the

charging voltage of the cell does not exceed the upper limit of the charging voltage

specified in Table 4;

• for the battery consisting of series-connected plural single cells or series-connected plural

cellblocks, it is recommended that the voltages of any one of the single cells or single

cellblocks does not exceed the upper limit of the charging voltage, specified in Table 4, by

monitoring the voltage of every single cell or the single cellblocks;

• for the battery consisting of series-connected plural single cells or series-connected plural

cellblocks, it is recommended that charging is stopped when the upper limit of the

charging voltage is exceeded for any one of the single cells or single cellblocks by

measuring the voltage of every single cell or the single cellblocks.

5.7 Quality plan

The manufacturer shall prepare and implement a quality plan that defines procedures for the

inspection of materials, components, cells and batteries and which covers the whole process

of producing each type of cell or battery. Manufacturers should understand their process

capabilities and should institute the necessary process controls as they relate to product

safety.

6 Type test conditions

Tests are made with the number of cells or batteries specified in Table 1 for nickel-cadmium

and nickel-metal hydride systems and Table 2 for lithium systems, using cells or batteries that

are not more than six months old. Unless otherwise specified, tests are carried out in an

ambient temperature of 20 °C ± 5 °C.

NOTE Test conditions are for type tests only and do not imply that intended use includes operation under these

conditions. Similarly, the limit of six months is introduced for consistency and does not imply that battery safety is

reduced after six months.

62133 © IEC:2012 – 11 –

Table 1 – Sample size for type tests (nickel systems)

Test Cell Battery

7.2.1 Low rate charging 5 –

7.2.2 Vibration 5 5

7.2.3 Moulded case stress – 3

7.2.4 Temperature cycling 5 5

7.3.1 Incorrect Installation 5 sets of 4 –

7.3.2 External short circuit 5 /Temperature 5 /Temperature

7.3.3 Free fall 3 3

7.3.4 Mechanical shock 5 5

7.3.5 Thermal abuse 5 –

7.3.6 Crush 5 (10 for prismatic) –

7.3.7 Low pressure 3 –

7.3.8 Overcharge 5 5

7.3.9 Forced discharge 5 –

Table 2 – Sample size for type tests (lithium systems)

Test Cell Battery

8.1.2 Charge (Procedure 2) 5/Temp/Condition 5/Temp/Condition

8.2.1 Continuous charge 5 -

8.2.2 Moulded case stress - 3

8.3.1 External short circuit 5/Temp -

8.3.2 External short circuit – 5/Temp

8.3.3 Free fall 3 3

8.3.4 Thermal abuse 5/Temp -

8.3.5 Crush 5/Temp -

8.3.6 Overcharge - 5

8.3.7 Forced Discharge 5 -

8.3.8 Transport (20) -

a

8.3.9 Forced Internal Short 10 -

a

Country specific test : only required for listed countries.

7 Specific requirements and tests (nickel systems)

7.1 Charging procedure for test purposes

Unless otherwise stated in this standard, the charging procedure for test purposes is carried

out in an ambient temperature of 20 °C ± 5 °C, using the method declared by the

manufacturer.

Prior to charging, the battery shall have been discharged at 20 °C ± 5 °C at a constant current

of 0,2 I A down to a specified final voltage.

t

– 12 – 62133 © IEC:2012

Warning: THESE TESTS USE PROCEDURES WHICH MAY RESULT IN HARM IF ADEQUATE PRECAUTIONS

ARE NOT TAKEN. TESTS SHOULD ONLY BE PERFORMED BY QUALIFIED AND EXPERIENCED

TECHNICIANS USING ADEQUATE PROTECTION. TO PREVENT BURNS, CAUTION SHOULD BE

TAKEN FOR THOSE CELLS OR BATTERIES WHOSE CASINGS MAY EXCEED 75 °C AS A

RESULT OF TESTING.

7.2 Intended use

7.2.1 Continuous low-rate charging (cells)

a) Requirement

A continuous low-rate charge shall not cause fire or explosion.

b) Test

Fully charged cells are subjected for 28 days to a charge as specified by the

manufacturer.

c) Acceptance criteria

No fire, no explosion.

7.2.2 Vibration

a) Requirements

Vibration encountered during transportation shall not cause leakage, fire or explosion.

b) Test

Fully charged cells or batteries are vibration-tested under the following test conditions and

the sequence in Table 3. A simple harmonic motion is applied to the cells or batteries with

an amplitude of 0,76 mm, and a total maximum excursion of 1,52 mm. The frequency is

varied at the rate of 1 Hz/min between the limits of 10 Hz and 55 Hz. The entire range of

frequencies (10 Hz to 55 Hz) and return (55 Hz to 10 Hz) is traversed in 90 min ± 5 min for

each mounting position (direction of vibration). The vibration is applied in each of three

mutually perpendicular directions, in the sequence specified below.

Step 1: Verify that the measured voltage is typical of the charged product being tested.

Steps 2-4: Apply the vibration as specified in Table 3.

Step 5: Rest cell for 1 h, and then make a visual inspection.

c) Acceptance criteria

No fire, no explosion, no leakage.

Table 3 – Conditions for vibration test

Rest time Vibration time

Step Visual examination

h min

1 – – Pre-test

2 – 90 ± 5 –

3 – 90 ± 5 –

4 – –

90 ± 5

5 1 – Post-test

7.2.3 Moulded case stress at high ambient temperature (batteries)

a) Requirement

Internal components of batteries shall not be exposed during use at high temperature.