IEC TR 62354:2014

(Main)General testing procedures for medical electrical equipment

General testing procedures for medical electrical equipment

IEC TR 62354:2014 applies to medical electrical equipment. The object of this technical report is to provide guidance on general testing procedures according to IEC 60601-1:1988 (including the collateral provisions of IEC 60601-1-1:2000) and IEC 60601-1:2005 and IEC 60601-1:2005/AMD1:2012. This third edition cancels and replaces the second edition published in 2009. This edition constitutes a technical revision intended to align the guidance in this technical report with Amendment 1 to IEC 60601:2005. Several tests have been updated and additional test procedures added.

This technical report is to be read in conjunction with IEC 60601-1:1988, IEC 60601-1-1:2000 and IEC 60601-1:2005.

General Information

- Status

- Published

- Publication Date

- 24-Sep-2014

- Technical Committee

- SC 62A - Common aspects of medical equipment, software, and systems

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Sep-2014

- Completion Date

- 30-Nov-2014

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TR 62354:2014 - General testing procedures for medical electrical equipment is a technical report from the IEC that provides guidance on standardized safety and performance test methods for medical electrical (ME) equipment. Edition 3.0 (2014) updates and expands the second edition (2009) to align guidance with Amendment 1 to IEC 60601-1:2005 and to the collateral standard IEC 60601-1-1:2000. IEC TR 62354:2014 is intended to be read in conjunction with IEC 60601-1 series standards and clarifies general testing procedures, sequencing, laboratory conditions, measurement equipment, and practical test setups.

Key Topics and Requirements

This technical report covers a broad set of testing topics and procedural guidance for ME equipment, including:

- Test planning and sequence: Recommended order of tests, sample numbers, state of the ME equipment and special conditions for testing.

- Visual inspection and non-energized checks: Construction, protective parts, and access-related inspections prior to energized testing.

- Dielectric and insulation tests: Guidance on dielectric withstand (voltage-withstand) and assessment of creepage distances and air clearances (illustrated by multiple examples).

- Leakage and touch currents: Measurement circuits and measurement methods for earth leakage, touch current and patient leakage current, including configurations for applied parts.

- Defibrillation and patient-applied parts: Test setups for defibrillation-proof applied parts and energy reduction checks.

- Measurement and calibration: Requirements for test instruments, accuracy classes, traceability and calibration intervals.

- Laboratory power sources and test supplies: Guidance on laboratory mains, separate power sources and suitable measuring supply circuits.

- Production-line and preventive tests: Recommended production-line dielectric tests, grounding continuity, earth leakage checks and preventive maintenance.

- Annex guidance: Practical annexes on test probes, thermocouple preparation/attachment, safe laboratory practices, oxygen-rich environments, and indexes of tests.

Practical Applications and Users

IEC TR 62354:2014 is useful for:

- Medical device manufacturers - for design verification, safety testing and production-line quality control.

- Test laboratories and CB testing bodies - to establish consistent test procedures aligned with IEC 60601-1.

- Regulatory and compliance engineers - to interpret how to apply IEC 60601-1 test requirements in practice.

- R&D and QA teams - for product development, risk mitigation and maintenance planning.

Keywords: IEC TR 62354:2014, medical electrical equipment testing, IEC 60601-1 guidance, leakage current, dielectric test, creepage distance, production-line tests, calibration, safety testing.

Related Standards

- IEC 60601-1:1988 / 2005 (and Amendment 1:2012) - basic safety and essential performance for medical electrical equipment (primary normative reference).

- IEC 60601-1-1:2000 - collateral standard referenced in conjunction with IEC TR 62354:2014.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC TR 62354:2014 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "General testing procedures for medical electrical equipment". This standard covers: IEC TR 62354:2014 applies to medical electrical equipment. The object of this technical report is to provide guidance on general testing procedures according to IEC 60601-1:1988 (including the collateral provisions of IEC 60601-1-1:2000) and IEC 60601-1:2005 and IEC 60601-1:2005/AMD1:2012. This third edition cancels and replaces the second edition published in 2009. This edition constitutes a technical revision intended to align the guidance in this technical report with Amendment 1 to IEC 60601:2005. Several tests have been updated and additional test procedures added. This technical report is to be read in conjunction with IEC 60601-1:1988, IEC 60601-1-1:2000 and IEC 60601-1:2005.

IEC TR 62354:2014 applies to medical electrical equipment. The object of this technical report is to provide guidance on general testing procedures according to IEC 60601-1:1988 (including the collateral provisions of IEC 60601-1-1:2000) and IEC 60601-1:2005 and IEC 60601-1:2005/AMD1:2012. This third edition cancels and replaces the second edition published in 2009. This edition constitutes a technical revision intended to align the guidance in this technical report with Amendment 1 to IEC 60601:2005. Several tests have been updated and additional test procedures added. This technical report is to be read in conjunction with IEC 60601-1:1988, IEC 60601-1-1:2000 and IEC 60601-1:2005.

IEC TR 62354:2014 is classified under the following ICS (International Classification for Standards) categories: 11.040.01 - Medical equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62354:2014 has the following relationships with other standards: It is inter standard links to IEC TR 62354:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 62354:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62354 ®

Edition 3.0 2014-09

TECHNICAL

REPORT

General testing procedures for medical electrical equipment

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 62354 ®

Edition 3.0 2014-09

TECHNICAL

REPORT

General testing procedures for medical electrical equipment

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XH

ICS 11.040 ISBN 978-2-8322-1856-3

– 2 – IEC TR 62354:2014 © IEC 2014

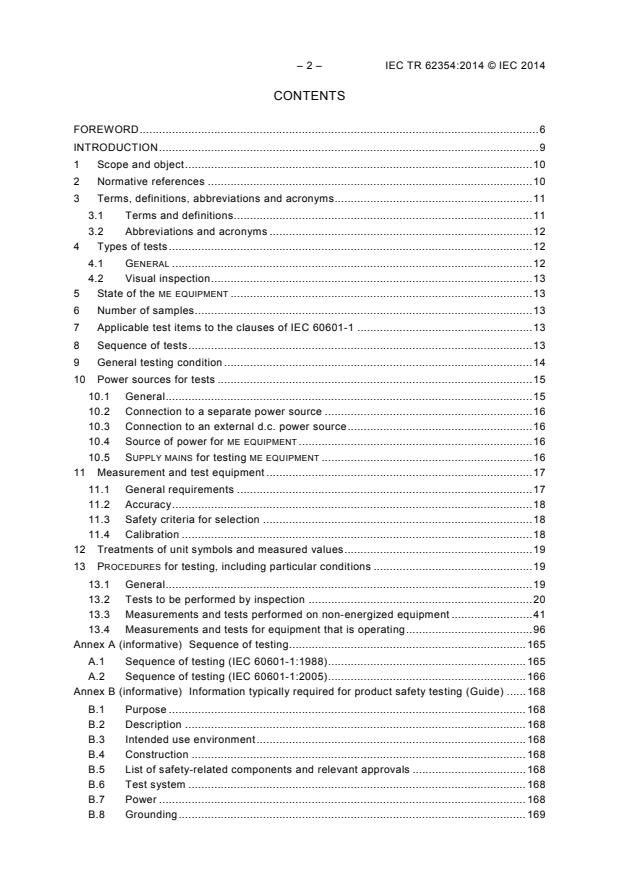

CONTENTS

FOREWORD . 6

INTRODUCTION . 9

1 Scope and object . 10

2 Normative references . 10

3 Terms, definitions, abbreviations and acronyms. 11

3.1 Terms and definitions . 11

3.2 Abbreviations and acronyms . 12

4 Types of tests . 12

4.1 GENERAL . 12

4.2 Visual inspection . 13

5 State of the ME EQUIPMENT . 13

6 Number of samples . 13

7 Applicable test items to the clauses of IEC 60601-1 . 13

8 Sequence of tests . 13

9 General testing condition . 14

10 Power sources for tests . 15

10.1 General . 15

10.2 Connection to a separate power source . 16

10.3 Connection to an external d.c. power source . 16

10.4 Source of power for ME EQUIPMENT . 16

10.5 SUPPLY MAINS for testing ME EQUIPMENT . 16

11 Measurement and test equipment . 17

11.1 General requirements . 17

11.2 Accuracy . 18

11.3 Safety criteria for selection . 18

11.4 Calibration . 18

12 Treatments of unit symbols and measured values . 19

13 PROCEDURES for testing, including particular conditions . 19

13.1 General . 19

13.2 Tests to be performed by inspection . 20

13.3 Measurements and tests performed on non-energized equipment . 41

13.4 Measurements and tests for equipment that is operating . 96

Annex A (informative) Sequence of testing. 165

A.1 Sequence of testing (IEC 60601-1:1988) . 165

A.2 Sequence of testing (IEC 60601-1:2005) . 166

Annex B (informative) Information typically required for product safety testing (Guide) . 168

B.1 Purpose . 168

B.2 Description . 168

B.3 Intended use environment . 168

B.4 Construction . 168

B.5 List of safety-related components and relevant approvals . 168

B.6 Test system . 168

B.7 Power . 168

B.8 Grounding . 169

B.9 Modes of operation; configurations . 169

B.10 Failure modes . 169

B.11 RISK ANALYSIS according with ISO 14971 . 169

B.12 Software . 169

B.13 Auxiliary equipment . 169

B.14 Transformers and chokes . 169

Annex C (informative) Testing and measuring equipment . 170

Annex D (informative) Suitable measuring supply circuits . 171

Annex E (informative) Preventive maintenance . 174

E.1 General . 174

E.2 Cleaning and disinfection . 174

E.3 Preventive maintenance checklist . 174

E.4 OPERATOR checks . 174

Annex F (informative) Test probes . 175

Annex G (informative) Index of tests (IEC 60601-1:2005 clauses order) . 177

Annex H (informative) Index of tests for an INTERNALLY POWERED EQUIPMENT – battery

only – (IEC 60601-1:2005 clauses order) . 179

Annex I (informative) Index of tests (IEC 60601-1:2005 alphabetic order) . 181

Annex J (informative) Index of tests for an INTERNALLY POWERED EQUIPMENT – battery

only – (IEC 60601-1:2005 alphabetic order) . 183

Annex K (informative) Production line tests . 185

K.1 Production-line dielectric voltage-withstand test . 185

K.2 Production-line grounding-continuity test . 186

K.3 Production-line EARTH LEAKAGE CURRENT test . 186

K.4 Recommended features for specific test equipment . 186

Annex L (informative) Evaluation of the laboratory power source characteristics . 189

L.1 Purpose . 189

L.2 Application . 189

L.3 Definitions. 190

L.4 Testing . 191

Annex M (informative) Traceability of calibrations and calibration intervals . 194

M.1 Purpose . 194

M.2 Traceability of calibrations . 194

M.3 Calibration intervals for test equipment requiring calibration . 194

Annex N (informative) Guidance for preparation, attachment, extension, use of

thermocouples and acceptance of thermocouple wire . 196

N.1 General . 196

N.2 Preparation . 196

N.3 Placement . 196

N.4 Attachment . 197

N.5 Extension . 198

N.6 Use . 199

N.7 Acceptance of thermocouples wire . 199

Annex O (informative) Guideline for safe laboratory work . 201

O.1 BASIC SAFETY guidelines for working with test instruments . 201

O.2 Basic guidelines for performing safety tests . 203

O.3 Basic guidelines regarding test personnel and test areas . 205

– 4 – IEC TR 62354:2014 © IEC 2014

O.4 Contents of a documented safe environment for working in a testing

laboratory . 206

Bibliography . 207

Index of defined terms . 209

Figure 1 – Area of the bottom of an ENCLOSURE as specified in 11.3 b) 1) . 37

Figure 2 – Baffle . 37

Figure 3 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 1 . 51

Figure 4 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 2 . 51

Figure 5 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 3 . 52

Figure 6 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 4 . 52

Figure 7 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 5 . 52

Figure 8 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 6 . 52

Figure 9 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 7 . 53

Figure 10 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 8 . 53

Figure 11 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 9 . 54

Figure 12 – CREEPAGE DISTANCE and AIR CLEARANCE – Example 10 . 54

Figure 13 – Human body test mass . 73

Figure 14 – Application of test voltage to bridged PATIENT CONNECTIONS (common

mode) for DEFIBRILLATION-PROOF APPLIED PARTS . 103

Figure 15 – Application of test voltage to individual PATIENT CONNECTIONS (differential

mode) for DEFIBRILLATION-PROOF APPLIED PARTS . 104

Figure 16 – Application of test voltage to test the delivered defibrillation energy

(energy reduction test) . 108

Figure 17 – Example of a measuring device and its frequency characteristics . 110

Figure 18 – Measuring circuit for the EARTH LEAKAGE CURRENT of CLASS I equipment,

with or without APPLIED PARTS . 112

Figure 19 – Measuring circuit for the TOUCH CURRENT . 115

Figure 20 – Measuring circuit for the PATIENT LEAKAGE CURRENT from the PATIENT

CONNECTION to earth . 117

Figure 21 – Measuring circuit for the total PATIENT LEAKAGE CURRENT with all PATIENT

CONNECTIONS of all APPLIED PARTS of the same type (TYPE B APPLIED PARTS, TYPE BF

APPLIED PARTS or TYPE CF APPLIED PARTS) connected together . 118

Figure 22 – Measuring circuit for the PATIENT LEAKAGE CURRENT via the PATIENT

CONNECTION(S) of an F-TYPE APPLIED PART to earth caused by an external voltage on

the PATIENT CONNECTION(S) . 120

Figure 23 – Measuring circuit for the PATIENT LEAKAGE CURRENT from PATIENT

CONNECTION(S) to earth caused by an external voltage on a metal ACCESSIBLE PART

that is not PROTECTIVELY EARTHED . 121

Figure 24 – Measuring circuit for the PATIENT LEAKAGE CURRENT from PATIENT

CONNECTION(S) to earth caused by an external voltage on a SIGNAL INPUT/OUTPUT PART . 123

Figure 25 – Measuring circuit for the PATIENT AUXILIARY CURRENT . 125

Figure 26 – Ratio between hydraulic test pressure and maximum permissible working

pressure . 129

Figure 27 – Spark ignition test apparatus . 136

Figure 28 – Maximum allowable current I as a function of the maximum allowable

voltage U measured in a purely resistive circuit in an OXYGEN RICH ENVIRONMENT . 139

Figure 29 – Maximum allowable voltage U as a function of the capacitance C

measured in a capacitive circuit used in an OXYGEN RICH ENVIRONMENT . 139

Figure 30 – Maximum allowable current I as a function of the inductance L measured in

an inductive circuit in an OXYGEN RICH ENVIRONMENT . 140

Figure D.1 – Measuring supply circuit with one side of the SUPPLY MAINS at

approximately earth potential . 171

Figure D.2 – Measuring supply circuit with SUPPLY MAINS approximately symmetrical to

earth potential . 171

Figure D.3 – Measuring supply circuit for polyphase ME EQUIPMENT specified for

connection to a polyphase SUPPLY MAINS . 171

Figure D.4 – Measuring supply circuit for single-phase ME EQUIPMENT specified for

connection to a polyphase SUPPLY MAINS . 172

Figure D.5 – Measuring supply circuit for ME EQUIPMENT having a separate power

supply unit or intended to receive its power from another equipment in an ME SYSTEM . 172

Figure F.1 – Standard test finger . 175

Figure F.2 – Test hook . 176

Figure F.3 – Test pin . 176

Figure F.4 – Ball-pressure test apparatus . 176

Figure N.1 – Thermocouple preparation . 196

Figure N.2 – Securing of thermocouples . 197

Figure N.3 – Example of confinement of a thermocouple . 198

Figure N.4 – Example where thermocouple connectors need not be used . 199

Table 1 – Units outside the SI units system that may be used . 19

Table 2 – Tests to be performed by inspection . 20

Table 3 – NOMINAL cross-sectional area of conductors of a POWER SUPPLY CORD . 31

Table 4 – Acceptable perforation of the bottom of an ENCLOSURE . 38

Table 5 – Measurements and tests performed on non-energized equipment . 41

Table 6 – Testing of cord anchorages . 56

a

Table 7 – Acceptable gaps . 62

Table 8 – Drop height . 87

Table 9 – Test torques for rotating controls . 93

Table 10 – Measurements and tests for equipment that is operating . 96

Table 11 – Allowable maximum temperatures for skin contact with ME EQUIPMENT

APPLIED PARTS . 147

Table 12 – Allowable maximum temperatures for ME EQUIPMENT parts that are likely to

be touched . 147

Table 13 – Allowable maximum temperatures of parts . 148

Table 14 – Temperature limits of motor windings . 148

Table 15 – Maximum motor winding steady-state temperature . 149

Table 16 – Maximum allowable temperatures of transformer windings under overload

and short-circuit conditions at 25 °C (± 5 °C) ambient temperature . 149

Table 17 – Test current for transformers . 162

Table C.1 – IEC 60601-1:1988+AMD 1:1991 and AMD 2:1995 . 170

Table D.1 – Legends of symbols for Figure D.1 to Figure D.5 . 173

Table L.1 – Method for testing a single phase laboratory power source. 191

– 6 – IEC TR 62354:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GENERAL TESTING PROCEDURES

FOR MEDICAL ELECTRICAL EQUIPMENT

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC 62354, which is a technical report, has been prepared by subcommittee 62A: Common

aspects of electrical equipment used in medical practice, of IEC technical committee 62:

Electrical equipment in medical practice.

This third edition cancels and replaces the second edition published in 2009. This edition

constitutes a technical revision intended to align the guidance in this technical report with

Amendment 1 to IEC 60601:2005. Several tests have been updated and additional test

procedures added. The following tests have been added or significantly revised:

13.2.1 RISK MANAGEMENT PROCESS

13.2.4 Durability and legibility of marking

13.2.5 Battery markings

13.2.8 POTENTIAL EQUALIZATION TERMINAL

13.2.14 USABILITY of ME EQUIPMENT

13.3.1 Humidity preconditioning

13.3.2 Impedance of PE connection

13.3.7 CREEPAGE DISTANCES and AIR CLEARANCES

13.3.12 Instability (in transport position; excluding transport; from horizontal and vertical

forces and from unwanted lateral movement)

13.3.13 Castors and wheels (Force for propulsion, movement over a threshold)

13.3.14 Safety catch evaluation

13.3.17 Overflow

13.3.18 Spillage

13.3.23 Impact

13.3.14 Drop impact

13.3.25 Rough handling

13.3.27 Actuating parts of controls

13.3.28 Construction of transformers

13.4.1 ESSENTIAL PERFORMANCE – Functional

13.4.3 Voltage mismatch

13.4.4 Limitation of voltage, current or energy

13.4.5 DEFIBRILLATION-PROOF APPLIED PART protection

13.4.6 Energy reduction

13.4.7 EARTH LEAKAGE CURRENT

13.4.9 PATIENT LEAKAGE CURRENT

13.4.14 Sound pressure level measurements

13.4.16 X-radiation (ionizing radiation) measurement

13.4.20 Interruption of power supply

13.4.28 Rechargeable battery overcharge/discharge

13.4.29 Mains transformers

This technical report is intended to be read in conjunction with IEC 60601-1:1988 (including

the collateral provisions of IEC 60601-1-1:2000) and IEC 60601-1:2005 and

IEC 60601-1:2005/AMD1:2012.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

62A/936/DTR 62A/947/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

In this technical report, the terms defined in Clause 2 of IEC 60601-1:1988 or Clause 3 of

IEC 60601-1:2005 are printed in SMALL CAPITALS.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 8 – IEC TR 62354:2014 © IEC 2014

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

INTRODUCTION

IEC/TR 60513, Fundamental aspects of safety standards for medical electrical equipment

published by IEC sub-committee 62A provided the basis for inclusion of the test methods for

ME EQUIPMENT in the safety standards.

"Technical requirements and test methods are interrelated elements of product standards and

should always be considered together.

Product standards should identify where medically informed judgements are required in

deciding whether a particular requirement applies.

Wherever possible, the standards should contain test specifications for completely and clearly

checking compliance with the technical requirements. In some cases, a compliance statement

such as 'visual inspection', 'manual testing' or similar is adequate for this purpose if such a

method gives an accurate assessment.

It should be easy to recognize which test methods apply to each technical requirement.

Appropriate headings should designate the appropriate test and a reference should be made

to the clause containing the requirement. This also applies for references which are made to

other relevant test standards."

It was deemed necessary to support IEC 60601-1 with guidelines for general testing

PROCEDURES for MEDICAL ELECTRICAL EQUIPMENT.

In developing the test PROCEDURES, the advice given in IEC/TR 60513 and ISO/IEC Guide 51

was considered as follows:

a) test results should be reproducible within defined limits. When considered necessary, the

test method should incorporate a statement as to its limit of uncertainty;

b) where the sequence of tests can influence the results, the correct sequence should be

specified.

There is also growing support for the idea that all the test PROCEDURES for ME EQUIPMENT

should be found within one international standard.

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories, highlights the need for a single series of requirements covering test

PROCEDURES.

IEC/TR 60513 includes a major new principle referring to testing:

“In specifying minimum safety requirements, provision is made for assessing the

adequacy of the design PROCESS where this provides an appropriate alternative to the

application of laboratory testing with specific pass/fail criteria, (e.g. in assessing the

safety of new technologies such as programmable electronic systems).”

– 10 – IEC TR 62354:2014 © IEC 2014

GENERAL TESTING PROCEDURES

FOR MEDICAL ELECTRICAL EQUIPMENT

1 Scope and object

This technical report applies to MEDICAL ELECTRICAL EQUIPMENT (as defined in Subclauses 3.63

of IEC 60601-1:2005 and 2.2.15 of IEC 60601-1:1988), hereinafter referred to as

ME EQUIPMENT.

The object of this technical report is to provide guidance on general testing PROCEDURES

according to IEC 60601-1:1988 (including the collateral provisions of IEC 60601-1-1:2000)

and IEC 60601-1:2005 and IEC 60601-1:2005/AMD1:2012.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60086-4, Primary batteries – Part 4: Safety of lithium batteries

IEC 60127-1, Miniature fuses – Part 1: Definitions for miniature fuses and general

requirements for miniature fuse-links

IEC 60252-1, AC motor capacitors – Part 1: General – Performance, testing and rating –

Safety requirements – Guide for installation and operation

IEC 60364-4-41, Low voltage electrical installations – Part 4-41: Protection for safety –

Protection against electric shock

IEC 60417, Graphical symbols for use on equipment. Available from: http://www.graphical-

symbols.info/equipment

IEC/TR 60513, Fundamental aspects of safety standards for medical electrical equipment

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60529:1989/AMD1:1999

IEC 60601-1:1988, Medical electrical equipment – Part 1: General requirements for safety

IEC 60601-1:1998/AMD1:1991

IEC 60601-1:1998/AMD2:1995

IEC 60601-1:2005, Medical electrical equipment – Part 1: General requirements for basic

safety and essential performance

IEC 60601-1:2005/AMD1:2012

—————————

A consolidated version 2.1 (2001) exists that includes IEC 60529:1989 and its Amendment 1:1999.

The second edition of IEC 60601-1, cancelled and replaced by the third edition in 2005.

A consolidated version 3.1 (2012) exists that includes IEC 60601-1:2005 and its Amendment 1:2012.

IEC 60601-1-2, Medical electrical equipment – Part 1-2: General requirements for basic safety

and essential performance – Collateral Standard: Electromagnetic disturbances –

Requirements and tests

IEC 61010 (all parts), Safety requirements for electrical equipment for measurement, control,

and laboratory use

IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

IEC 61672-1, Electroacoustics – Sound level meters – Part 1: Specifications

IEC 61672-2, Electroacoustics – Sound level meters – Part 2: Pattern evaluation tests

IEC 62133, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made from them,

for use in portable applications

ISO 17665-1, Sterilization of health care products – Moist heat – Part 1: Requirements for the

development, validation and routine control of a sterilization process for medical devices

ISO 11135-1, Medical devices – Validation and routine control of ethylene oxide sterilization

ISO 11137-1, Sterilization of health care products – Radiation – Part 1: Requirements for

development, validation and routine control of a sterilization process for medical devices

ISO 14971:2007, Medical devices – Application of risk management to medical devices

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ISO 80000-1, Quantities and units – Part 1: General

3 Terms, definitions, abbreviations and acronyms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60601-1:1988 and

IEC 60601-1:2005 apply.

NOTE 1 Where the terms “voltage” and “current” are used in this document, they mean the r.m.s. values of an

alternating, direct or composite voltage or current unless stated otherwise.

NOTE 2 An index of defined terms is found beginning on page 209.

NOTE 3 When used in the body of this document, N/A means “Not applicable”.

—————————

Withdrawn and replaced by ISO 11135:2014.

– 12 – IEC TR 62354:2014 © IEC 2014

3.2 Abbreviations and acronyms

Abbreviation Term

a.c. Alternating current

d.c. Direct current

DUT Device under test

MAR Mean angle resolvable

MD Measuring device

ME MEDICAL ELECTRICAL

RH Relative humidity

r.m.s. Root mean square

SI System international

SIP/SOP SIGNAL INPUT/OUTPUT PART

4 Types of tests

4.1 GENERAL

“TYPE TESTS” are required for verifying the BASIC SAFETY and ESSENTIAL PERFORMANCE of the

product design.

NOTE 1 The tests described in this technical report can also be used by the MANUFACTURER to ensure the quality

of the product and the manufacturing PROCESS. See Annex I.

A test need not be carried out if analysis shows that the condition being tested has been

adequately evaluated by other tests or methods.

The results of the RISK ANALYSIS should additionally be used to determine which

combination(s) of simultaneous faults should be tested.

NOTE 2 The test results might render it necessary to revise the RISK ANALYSIS.

When testing the ME EQUIPMENT, relevant information provided by the MANUFACTURER in the

instruction for use should be taken into account.

Before commencing testing, the ME EQUIPMENT under test (the device under test or DUT)

should be disconnected from the SUPPLY MAINS. If not possible, special precautions should be

taken to prevent HARM to the personnel performing the tests and measurements or other

individuals who might be affected.

Connections such as data lines or functional earth conductors can act like PROTECTIVE EARTH

CONNECTIONS. Such additional, but unintentional, PROTECTIVE EARTH CONNECTIONS can create

measurement errors.

Unless otherwise specified in IEC 60601-1, ME EQUIPMENT is to be tested under the least

favourable working conditions. The working conditions are specified in the ACCOMPANYING

DOCUMENTS. The least favourable working conditions are to be documented for every test

where they apply.

Considering the ambient temperature, humidity and pressure described in the technical

description, tests should be performed at the worst-case extremes depending on the test and

the effects of these parameters on the test results. If the test is not impacted by these

parameters, then test can be conducted anywhere within the specified range.

4.2 Visual inspection

Covers and housings should be opened only:

– if required in the instructions for use for the ME EQUIPMENT, or

– if specified in this technical report, or

– if there is an indication of a HAZARD or HAZARDOUS SITUATION.

Special attention should be paid to the following:

– all fuses accessible from the outside should be marked (type, ratings) on the

ME EQUIPMENT or marked by reference and specified in the ACCOMPANYING DOCUMENTS;

– the markings are legible and complete;

– any damage;

– relevant ACCESSORIES should be assessed together with the ME EQUIPMENT (e.g.

DETACHABLE or FIXED POWER SUPPLY CORDS, PATIENT leads, tubing etc.);

– all required documentation, such as instructions for use, is present and complete and

reflects the current revision of the ME EQUIPMENT.

5 State of the ME EQUIPMENT

Some tests specified in this document are conducted in the NORMAL CONDITION whilst others

are conducted in SINGLE FAULT CONDITIONS.

NORMAL CONDITION and SINGLE FAULT CONDITIONS are described in both IEC 60601-1:1988 and

IEC 60601-1:2005.

6 Number of samples

TYPE TESTS are performed on a representative sample of the item being assessed.

Multiple samples can be utilized simultaneously if the validity of the results is not significantly

affected.

7 Applicable test items to the clauses of IEC 60601-1

Table 2, Table 5 and Table 10 relate the test PROCEDURES described in this technical report to

the relevant subclauses of IEC 60601-1:2005. When applicable, these tables also provide a

cross reference to the relevant subclauses of IEC 60601-1:1988.

Annex G and Annex H contain an index of the tests in this technical report sorted by the

relevant subclause in IEC 60601-1:2005. Annex I and Annex J contain the lists sorted in

alphabetical order by test title.

8 Sequence of tests

Unless stated otherwise, the tests in this technical report are to be sequenced in such a way

so that the results of any test do not influence the results of other tests. Tests should, if

applicable, be performed in the sequence indicated in Annex A, unless otherwise stated by

particular standards.

However, this does not preclude the possibility of conducting a test that preliminary inspection

suggests might cause failure.

– 14 – IEC TR 62354:2014 © IEC 2014

The tests for radiation HAZARDS, biocompatibility, USABILITY, alarm systems, PEMS and

electromagnetic compatibility can be performed independently from the tests specified in the

present document.

The tests specified for ME SYSTEMS should be performed in the same sequence as the tests

for ME EQUIPMENT.

9 General testing condition

The following general testing conditions should be applied:

NORMAL USE, tests are carried out under the least

a) After the DUT has been set up for

favourable working conditions which are specified in the ACCOMPANYING DOCUMENTS.

b) The DUT is to be shielded from other influences (for example, draughts) that might affect

the validity of the tests.

c) In cases where ambient temperatures cannot be maintained, the test conditions are to be

consequently modified and results adjusted accordingly.

d) Qualified personnel are to perform these tests. Qualifications include training on the

subject, knowledge, experience, and acquaintance with the relevant technologies and

regulations. The personnel should be able to assess safety and should be able to

recognize possible consequences and HAZARDS arising from non-conforming

ME EQUIPMENT

e) ACCESSORIES for the ME EQUIPMENT, which can affect the safety of the DUT or the results

of the measurements, should be included in the tests. ACCESSORIES included in the tests

are to be documented.

RISK arises for testing

f) All tests are to be performed in such a manner that no unacceptable

personnel, PATIENTS or other individuals.

g) If not otherwise stated, all values for current and voltage are effective values (r.m.s.) or

d.c. values as appropriate.

h) All tests performed should be comprehensively documented. The documentation should

contain as a minimum the following data:

– identification of the testing body (e. g. company, department);

– names of the persons, who performed the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...