IEC 63137-1:2019

(Main)Standard test radio-frequency connectors - Part 1: Generic specification - General requirements and test methods

Standard test radio-frequency connectors - Part 1: Generic specification - General requirements and test methods

IEC 63137-1:2019 defines general requirements for standard test radio frequency (RF) connectors (grade 0), including terms and definitions, ratings and characteristics, general requirements, test methods, quality assessment procedures, and etc.

Standard test radio frequency (RF) connectors (grade 0) are intended to measure grade 1 and grade 2 RF connectors for electrical performances. Typically, a standard test radio frequency (RF) connector (grade 0) is an adapter with one end (normally a precision connector interface) which can be connected with measurement equipment and the other end (normally a standard test connector interface) which can be connected with grade 1 or grade 2 connectors.

This specification applies to grade 0 standard test connectors (called connector, hereinafter).

The corrigendum of January 2020 applies to the French language only.

Connecteurs d’essai normalisés pour fréquences radioélectriques - Partie 1: Spécification générique - Exigences générales et méthodes d’essai

l’IEC 63137-1:2019 définit les exigences générales relatives aux connecteurs d’essai normalisés pour fréquences radioélectriques (RF) (grade 0), y compris les termes et définitions, les valeurs assignées et caractéristiques, les exigences générales, les méthodes d’essai, les procédures d’évaluation de la qualité, etc.

Les connecteurs d’essai normalisés pour fréquences radioélectriques (RF) (grade 0) sont destinés à mesurer les performances électriques des connecteurs RF de grade 1 et de grade 2. Généralement, un connecteur d’essai normalisé pour fréquences radioélectriques (RF) (grade 0) consiste en un raccord dont une extrémité (normalement une interface de connecteur de précision) peut être reliée à un matériel de mesure et l’autre extrémité (normalement une interface de connecteur d’essai normalisé) peut être reliée à un connecteur de grade 1 ou de grade 2.

La présente spécification s’applique aux connecteurs d’essai normalisés de grade 0 (ci-après simplement dénommés «connecteur»).

Le contenu du corrigendum de janvier 2020 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 15-Aug-2019

- Technical Committee

- SC 46F - RF and microwave passive components

- Drafting Committee

- WG 1 - TC 46/SC 46F/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Aug-2019

- Completion Date

- 16-Aug-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

The IEC 63137-1:2019 standard, published by the International Electrotechnical Commission (IEC), provides the generic specification for standard test radio-frequency (RF) connectors-specifically grade 0 connectors. This standard outlines the general requirements and test methods crucial to ensuring performance, reliability, and quality of RF connectors used in measurement applications.

Primarily, these grade 0 standard test RF connectors serve as precise adapters designed to test grade 1 and grade 2 RF connectors. One end of the connector typically features a precision connector interface compatible with high-accuracy measurement equipment, while the other end connects to the connector under test. By adhering to IEC 63137-1:2019, manufacturers and testing laboratories ensure consistent electrical performance verification throughout the RF connector supply chain and testing processes.

Key Topics

Terms and Definitions

Provides clarity on RF connector classifications, key parameters, and terminology essential for uniform communication in testing and design.Design and Construction

Covers requirements related to materials, finishes, and dimensional aspects, ensuring interchangeability and mechanical integrity.Ratings and Characteristics

Specifies electrical and mechanical ratings such as voltage, current, impedance, and temperature ranges relevant for test connectors.Test Methods

Detailed procedures including:- Visual inspections for mechanical defects

- Dimensional measurements and gauge checking for interface compliance

- Electrical tests such as return loss, insertion loss, contact resistance, phase stability, and insulation resistance

- Mechanical evaluations including insertion force, coupling strength, contact captivation, and endurance tests

Quality Assessment

Defines protocols for first article inspection, lot-by-lot conformance checks, and handling of non-compliance to maintain consistent manufacturing quality.Marking and Packaging

Requirements for clear labeling on components and corresponding packaging to support traceability and identification.

Applications

IEC 63137-1:2019 is essential for industries and environments where accurate RF measurements are critical, such as:

- Telecommunications engineering – ensuring test connectors deliver precise measurement benchmarks for RF components in wireless and broadband communications.

- Electronics manufacturing – validating RF connector performance during product development and quality control.

- Test and measurement laboratories – using standardized adapters to calibrate test setups and verify connector specifications.

- Aerospace and defense – where high-reliability RF connections must meet strict standards for performance under harsh conditions.

- Automotive electronics – supporting emerging RF-enabled vehicle systems by facilitating rigorous connector testing.

Using this standardized approach improves measurement repeatability, reduces uncertainty, and increases confidence in test results-vital for product development, certification, and compliance.

Related Standards

IEC 63137-1:2019 aligns with several other standards and documents within the RF and electrotechnical domain:

- IEC 63137 series – comprising additional parts covering detailed specifications or testing for other grades of standard test RF connectors.

- IEC 61169 series – focused on RF connector interfaces, providing comprehensive specifications for interface dimensions and testing.

- ISO/IEC Directives Part 2 – guiding standard preparation to ensure international reliability and consensus.

- Relevant electrotechnical vocabulary (IEV) defined by IEC to unify terminology across RF connector standards.

Adherence to IEC 63137-1:2019 together with associated standards facilitates robust and internationally recognized testing methodologies for RF connectors in multiple applications.

By implementing the IEC 63137-1:2019 requirements, professionals ensure their standard test RF connectors meet rigorous performance criteria, supporting high precision and quality in RF measurement fields worldwide.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 63137-1:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Standard test radio-frequency connectors - Part 1: Generic specification - General requirements and test methods". This standard covers: IEC 63137-1:2019 defines general requirements for standard test radio frequency (RF) connectors (grade 0), including terms and definitions, ratings and characteristics, general requirements, test methods, quality assessment procedures, and etc. Standard test radio frequency (RF) connectors (grade 0) are intended to measure grade 1 and grade 2 RF connectors for electrical performances. Typically, a standard test radio frequency (RF) connector (grade 0) is an adapter with one end (normally a precision connector interface) which can be connected with measurement equipment and the other end (normally a standard test connector interface) which can be connected with grade 1 or grade 2 connectors. This specification applies to grade 0 standard test connectors (called connector, hereinafter). The corrigendum of January 2020 applies to the French language only.

IEC 63137-1:2019 defines general requirements for standard test radio frequency (RF) connectors (grade 0), including terms and definitions, ratings and characteristics, general requirements, test methods, quality assessment procedures, and etc. Standard test radio frequency (RF) connectors (grade 0) are intended to measure grade 1 and grade 2 RF connectors for electrical performances. Typically, a standard test radio frequency (RF) connector (grade 0) is an adapter with one end (normally a precision connector interface) which can be connected with measurement equipment and the other end (normally a standard test connector interface) which can be connected with grade 1 or grade 2 connectors. This specification applies to grade 0 standard test connectors (called connector, hereinafter). The corrigendum of January 2020 applies to the French language only.

IEC 63137-1:2019 is classified under the following ICS (International Classification for Standards) categories: 33.120.30 - RF connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63137-1:2019 has the following relationships with other standards: It is inter standard links to IEC 63137-1:2019/COR1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 63137-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63137-1 ®

Edition 1.0 2019-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Standard test radio-frequency connectors –

Part 1: Generic specification – General requirements and test methods

Connecteurs d’essai normalisés pour fréquences radioélectriques –

Partie 1: Spécification générique – Exigences générales et méthodes d’essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63137-1 ®

Edition 1.0 2019-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Standard test radio-frequency connectors –

Part 1: Generic specification – General requirements and test methods

Connecteurs d’essai normalisés pour fréquences radioélectriques –

Partie 1: Spécification générique – Exigences générales et méthodes d’essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.120.30 ISBN 978-2-8322-7166-7

– 2 – IEC 63137-1:2019 © IEC 2019

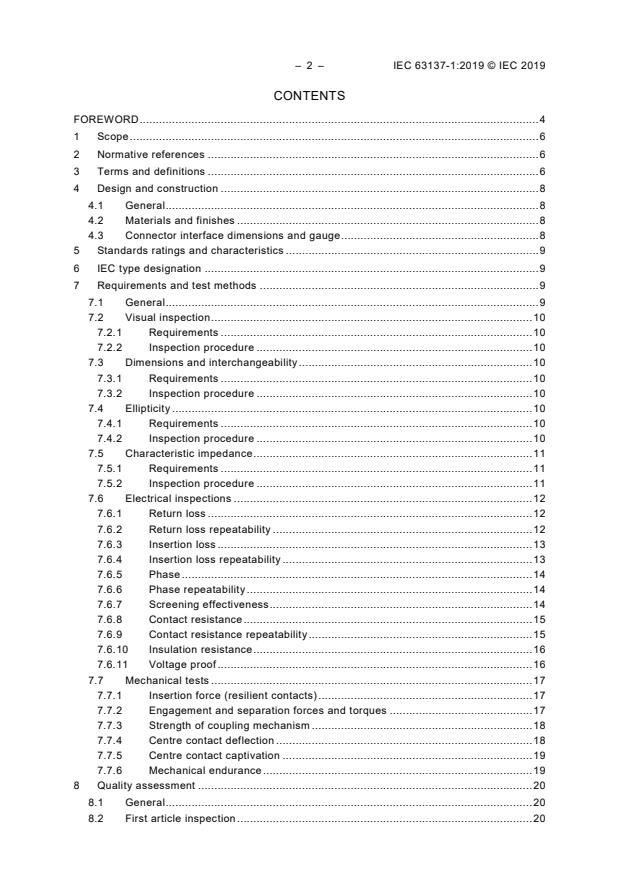

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Design and construction . 8

4.1 General . 8

4.2 Materials and finishes . 8

4.3 Connector interface dimensions and gauge . 8

5 Standards ratings and characteristics . 9

6 IEC type designation . 9

7 Requirements and test methods . 9

7.1 General . 9

7.2 Visual inspection . 10

7.2.1 Requirements . 10

7.2.2 Inspection procedure . 10

7.3 Dimensions and interchangeability . 10

7.3.1 Requirements . 10

7.3.2 Inspection procedure . 10

7.4 Ellipticity . 10

7.4.1 Requirements . 10

7.4.2 Inspection procedure . 10

7.5 Characteristic impedance . 11

7.5.1 Requirements . 11

7.5.2 Inspection procedure . 11

7.6 Electrical inspections . 12

7.6.1 Return loss . 12

7.6.2 Return loss repeatability . 12

7.6.3 Insertion loss . 13

7.6.4 Insertion loss repeatability . 13

7.6.5 Phase . 14

7.6.6 Phase repeatability . 14

7.6.7 Screening effectiveness . 14

7.6.8 Contact resistance . 15

7.6.9 Contact resistance repeatability . 15

7.6.10 Insulation resistance . 16

7.6.11 Voltage proof . 16

7.7 Mechanical tests . 17

7.7.1 Insertion force (resilient contacts) . 17

7.7.2 Engagement and separation forces and torques . 17

7.7.3 Strength of coupling mechanism . 18

7.7.4 Centre contact deflection . 18

7.7.5 Centre contact captivation . 19

7.7.6 Mechanical endurance . 19

8 Quality assessment . 20

8.1 General . 20

8.2 First article inspection . 20

8.2.1 First article test samples . 20

8.2.2 Inspection procedure . 20

8.2.3 Non-compliance . 21

8.2.4 Disposition of test samples . 21

8.3 Conformance inspection. 22

8.3.1 Lot-by-lot inspection . 22

8.4 Specifications . 22

8.4.1 Specification structures . 22

8.4.2 Sectional specification (SS) . 23

8.4.3 Detail specification (DS) . 23

9 Marking . 23

9.1 Marking of component . 23

9.2 Marking and contents of package . 23

Bibliography . 24

Table 1 – First article test program . 21

Table 2 – Group A inspection . 22

– 4 – IEC 63137-1:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

STANDARD TEST RADIO-FREQUENCY CONNECTORS –

Part 1: Generic specification – General requirements and test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and in

addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and expenses

arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 63137-1 has been prepared by subcommittee 46F: RF and

microwave passive components, of IEC technical committee 46: Cables, wires, waveguides, RF

connectors, RF and microwave passive components and accessories.

The text of this International Standard is based on the following documents:

FDIS Report on voting

46F/459/FDIS 46F/470/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 63137 series, published under the general title Standard test

radio-frequency connectors, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of January 2020 have been included in this copy.

– 6 – IEC 63137-1:2019 © IEC 2019

STANDARD TEST RADIO-FREQUENCY CONNECTORS –

Part 1: Generic specification – General requirements and test methods

1 Scope

This part of IEC 63137 defines general requirements for standard test radio frequency (RF)

connectors (grade 0), including terms and definitions, ratings and characteristics, general

requirements, test methods, quality assessment procedures, and etc.

Standard test radio frequency (RF) connectors (grade 0) are intended to measure grade 1 and

grade 2 RF connectors for electrical performances. Typically, a standard test radio frequency

(RF) connector (grade 0) is an adapter with one end (normally a precision connector interface)

which can be connected with measurement equipment and the other end (normally a standard

test connector interface) which can be connected with grade 1 or grade 2 connectors.

This specification applies to grade 0 standard test connectors (called connector, hereinafter).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60457-1, Rigid precision coaxial lines and their associated precision connectors – Part 1:

General requirements and measuring methods

IEC 60617, Graphical symbols for diagrams

IEC 61169-1-2 , Radio frequency connectors – Part 1-2: Electrical test methods – Insertion loss

IEC 61169-1-4:__ , Radio-frequency connectors – Part 1-4: Electrical test methods – voltage

standing wave ratio, return loss and reflection coefficient

IEC 62153-4-4 Metallic communication cable test methods – Part 4-4: Electromagnetic

compatibility (EMC) – Test method for measuring of the screening attenuation as up to and

above 3 GHz, triaxial method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

___________

Under preparation. Stage at the time of publication: IEC/FDIS 61169-1-2:2019.

Under preparation. Stage at the time of publication: IEC/CDV 61169-1-4:2019.

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

standard test connector: Grade 0

precisely made connector of a particular type used to carry out return loss measurements on

Grade 1 and Grade 2 connectors, contributing only negligible errors to the measuring result

Note 1 to entry: The standard test connector is often part of an inner-type adaptor which allows connection with a

precision connector forming part of the measuring equipment.

3.2

precision connector

connector that has coincident mechanical and electrical reference planes, air dielectric, and

has the property of making connections with a high degree of repeatability without introducing

significant reflections, loss or leakage

Note 1 to entry: It is intended for mounting on air-lines and instruments. Precision connectors can be of the

hermaphroditic type, flange type or of the pin and socket type as stated in IEC 60457-1.

3.3

within-type adaptor

adaptor for use between two or more connectors all of the same type

3.4

inter-type adaptor

adaptor for use between two or more connectors of different types

3.5

ellipticity

ratio of the difference between the maximum inner diameter of outer conductor or the maximum

outer diameter of inner conductor and the minimum inner diameter of outer conductor or

minimum outer diameter of inner conductor, to the nominal inner diameter of outer conductor, or

outer diameter of inner conductor, expressed as a percentage

Use Formula (1):

DD–

max min

E × %100 (1)

( )

D

nom

where

E is the ellipticity of inner or outer conductor;

D is nominal inner diameter of outer conductor, or outer diameter of inner conductor, in

nom

mm;

D is the measured maximum inner diameter of outer conductor, or maximum outer

max

diameter of inner conductor, in mm;

D is the measured minimum inner diameter of outer conductor, or minimum outer

min

diameter of inner conductor, in mm.

Note 1 to entry: The measurements for D and D should be made at the same cross section.

max min

3.6

eccentricity

ratio of the axial deviation between outer diameter of an inner conductor and inner diameter of

an outer conductor to the nominal inner diameter value of the outer conductor, expressed as a

percentage

=

– 8 – IEC 63137-1:2019 © IEC 2019

Use Formula (2):

e

E ×100()% (2)

D

where

E is inner to outer conductor eccentricity;

e is axial deviation between outer diameter of inner conductor and inner diameter of

outer conductor, in mm;

D is nominal inner diameter value of outer conductor, in mm.

3.7

repeatability without rotation

maximum measured difference in the specified parameter of a connector pair between the

extreme values of measurements of this parameter during the specified number of

connect/disconnect cycles at fixed angular orientation (i.e. without rotation)

Note 1 to entry: For example, the repeatability shall not exceed the specified values for return loss , insertion

S

loss , phase , etc.

S ∆arg S

21 11

3.8

repeatability with rotation

maximum measured difference for return loss magnitude and insertion loss magnitude with

rotation

Note 1 to entry: Determine the extreme values during rotation of connector orientation of 16 approximately 45°

increments over two complete 360° cycles.

4 Design and construction

4.1 General

The connectors shall be designed and constructed to ensure these features including adequate

accuracy, uniform impedance, long mechanical durability, and good repeatability. The relevant

specification is not intended to restrict those designs and dimensions for details of construction

which do not influence interchangeability or performance, nor are they to be used as

manufacturing drawings.

All of mechanical drawings shall be made as specified in IEC 60617. The dimensions and

tolerances shall be given in metric units. During conversion of dimensions given in inches into

millimetres, they shall, in principle, be rounded to the nearest 0,000 1 mm or 0,000 05 in.

4.2 Materials and finishes

The materials and finishes used for the connectors shall be as specified in the safety,

environmental regulations and the relevant specifications. Dissimilar metals between which an

electromotive couple may exist shall not be placed in contact with each other.

4.3 Connector interface dimensions and gauge

The interface dimensions and gauge for the connectors shall be as specified in the relevant

specifications.

=

5 Standards ratings and characteristics

The ratings and characteristics applicable to each connector type and style shall be specified in

the specification. They should normally include:

a) the return loss as a function of frequency;

b) any other rating or characteristic, as applicable.

6 IEC type designation

The purpose of the IEC type designation is to identify a particular connector within the scope of

IEC RF connector standardization. It is not intended to include information in excess of this.

In practice, it is usually necessary to identify a manufacturer's product because, although

complying with the IEC standard, there may be features not covered by the standard.

The connectors complying with the relevant specification shall be designated by the following

information:

a) the number of the specification;

b) the letters "IEC";

c) the series codes of both interface ends of the connector (series code-polarity code). For

example:

1) for inter-type adapters, “2.4-F/SMP-M” denotes that one end is 2.4 series female

connector interface, and the other end is SMP series male connector interface;

2) for within-type adapters, “2.4-F/M” denotes that one end is 2.4 series female connector

interface, and the other end is 2.4 series male connector interface;

d) additional indication method as specified in the relevant specification.

NOTE When an IEC type designation is used, either for the marking of the product or in a description of the product,

it is the responsibility of the manufacturer to ensure that the item meets the requirements of the relevant specification.

7 Requirements and test methods

7.1 General

Unless otherwise specified, the following conditions shall be applied.

Measurements for mechanical and electrical performances shall be carried out under these

ambient conditions: at 20 °C to 30 °C temperature, 20% to 80% relative humidity, and

86 kPa to 106 kPa atmospheric pressure.

The connectors shall be preconditioned under the ambient conditions, as specified above, to

reach thermal stability before measurements are made.

When a nominal value only is given for an applied stress and/or the duration of application, the

specified value shall be taken to indicate the minimum test severity to be applied.

The test shall be carried out with connectors – as received from the supplier. In no case shall the

contact parts be cleaned or otherwise prepared prior to tests, unless explicitly specified in the

specification.

Nominal coupling torque value shall be specified for screw-coupled connectors in the relevant

specification.

– 10 – IEC 63137-1:2019 © IEC 2019

7.2 Visual inspection

7.2.1 Requirements

a) Workmanship

The connectors shall be manufactured in a precise manner. Connectors and associated

fittings shall be processed in such a manner as to be uniform in quality and shall be free from

visible sharp edges, burrs and other defects that will affect life, serviceability or appearance.

b) Deterioration after electrical and mechanical tests

Unless otherwise specified, there shall be no visible deterioration likely to influence the

performance.

c) Marking

It shall be correct in accordance with 9.1, and be legible after any of the specified tests.

d) Marking on the package

It shall be in accordance with 9.2.

7.2.2 Inspection procedure

The inspection will be performed visually or under a magnification as specified in the relevant

specification.

7.3 Dimensions and interchangeability

7.3.1 Requirements

7.3.1.1 Dimensions

Interface dimensions and outline dimensions for the connectors shall be as specified in the

relevant specification.

7.3.1.2 Interchangeability

The connectors shall be connected and disconnected normally with their mating counterparts.

7.3.2 Inspection procedure

The connectors shall be inspected as follows:

a) inspection for interface dimensions shall be performed by mating the gauge specified in the

relevant specification with the connector;

b) inspection for outline dimensions shall be performed using measuring tool with adequate

accuracy;

c) inspection for interchangeability shall be performed by mating the connector with at least

three counterparts, respectively.

7.4 Ellipticity

7.4.1 Requirements

The ellipticity of inner and outer conductor of the connector shall not exceed limit value, as given

in the relevant specification.

7.4.2 Inspection procedure

The diameters of inner and outer conductors of connectors shall be measured using a measuring

tool with adequate accuracy. Then calculate the ellipticities from Formula (1).

7.5 Characteristic impedance

7.5.1 Requirements

Unless otherwise specified in the relevant specification, an error in the characteristic impedance

caused by the most adverse combination of diameter tolerances and eccentricity of the inner

and outer conductors used in constructing a standard test connector shall not more than the

value specified in the relevant specification.

7.5.2 Inspection procedure

The diameters of inner and outer conductor of the connector as well as axial deviation between

outer diameter of inner conductor and inner diameter of outer conductor shall be measured

using a measuring tool with adequate accuracy.

Then calculate the eccentricities from Formula (2).

The characteristic impedance shall be calculated from Formula (3).

60 DD138

Z= ×=ln ×log (3)

dd

ε ε

rr

where

ε is relative permittivity of the dielectric;

r

D is effective inner diameter of the outer conductor, in mm;

D is effective outer diameter of the inner conductor, in mm;

Z is characteristic impedance, in Ω.

Variation of the characteristic impedance due to diameter tolerances of the inner and outer

conductors shall be calculated from Formula (4).

60 ∆∆Dd

∆Z − (4)

0

Dd

ε

r

where

Δd is diameter tolerances of the outer diameter of the inner conductor, in mm;

ΔD is diameter tolerances of the inner diameter of the outer conductor, in mm;

ΔZ is variation of the characteristic impedance, in Ω.

Variation of the characteristic impedance due to inner to outer conductor eccentricity shall be

calculated from Formula (5).

e

∆Z ≈−240 (5)

0

Dd−

When the characteristic impedance is 50 Ω, Formula (5) may be simplified as the following:

=

– 12 – IEC 63137-1:2019 © IEC 2019

e

∆ZE≈−296 =−296 (6)

0

D

where

Z is impedance, in Ω;

E is inner to outer conductor eccentricity;

e is axial deviation between outer diameter of inner conductor and inner diameter of outer

conductor, in mm.

7.6 Electrical inspections

7.6.1 Return loss

7.6.1.1 Requirements

Return loss of connectors shall be in accordance with the value specified in the relevant

specification over the whole frequency range.

7.6.1.2 Test procedure

The test shall be performed using time domain method as specified in 7.2 in IEC 61169-1-4:__ .

7.6.1.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) frequency range to be measured;

b) minimum return loss value;

c) details of the connector to be mated to the connector under test (or detail drawing);

d) necessary characteristics of the appropriate precision terminal load;

e) any deviation from the standard test method.

7.6.2 Return loss repeatability

7.6.2.1 Requirements

The maximum differences for the return loss of connectors shall not exceed the value specified

in the relevant specification over the whole frequency range.

7.6.2.2 Test procedure

a) Test without rotation:

The connector to be tested shall be connected into the test system, and tested as specified

in 7.6.1. The following details shall be applied:

1) calibration: calibrate measurement system by using an open/short/load (termination) at

the end of precision airline;

2) connect the connector to be tested and behind parts to the end of precision airline, and

the resulting return loss S is observed and stored;

3) disconnect the connector to be tested, and then connect it again. The resulting return

loss S is observed and stored again;

4) repeat step 3), and do five times;

___________

Under preparation. Stage at the time of publication: IEC/CDV 61169-1-4:2019.

5) calculate the maximum difference among six test results at any frequency point.

b) Test with rotation:

The connector to be tested shall be connected into the test system, and tested as specified

in 7.6.1. The following details shall be applied:

1) calibration: calibrate measurement system by using an open/short/load (termination) at

the end of precision airline;

2) connect the connector to be tested and behind parts to the end of precision airline, and

the resulting return loss S is observed and stored;

3) disconnect the connector to be tested and then connect it gain. Rotate it with 45°

increments. The resulting return loss S is observed and stored again;

4) repeat step 3), and do sixteen times; and obtain sixteen test results over two complete

360° cycles.

5) Calculate the maximum difference among all test results at any frequency point.

7.6.2.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) test frequency range;

b) requirements for return loss repeatability;

c) details of the connector to be mated to the connector under test (or detail drawing);

d) necessary characteristics of the appropriate precision terminal load;

e) any deviation from the standard test method.

7.6.3 Insertion loss

7.6.3.1 Requirements

Insertion loss of connectors shall not exceed the value specified in the relevant specification

over the whole frequency range.

7.6.3.2 Test procedure

The test shall be performed as specified in IEC 61169-1-2.

7.6.3.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) test frequency range;

b) limit value of insertion loss;

c) details of the connector to be mated to the connector under test (or detail drawing);

d) any deviation from the standard test method.

7.6.4 Insertion loss repeatability

7.6.4.1 Requirements

Numeric differences for the insertion loss of connectors shall not exceed the value specified in

the relevant specification over the whole frequency range.

7.6.4.2 Test procedure

a) Test without rotation

Perform measurement of insertion loss as in 7.6.3. The following details shall be applied:

– 14 – IEC 63137-1:2019 © IEC 2019

1) calibrate the system;

2) perform initial measurement of the insertion loss by connecting the connector under test

to both end faces of the reference airlines. S parameter for insertion loss is observed,

and stored;

3) the connection is broken and then reconnected. The measurement values are obtained

and stored;

4) repeat step 3), and do five times;

5) calculate the maximum numeric difference at any frequency point for six test results.

b) Test with rotation

Perform measurement of insertion loss as in 7.6.3. The following details shall be applied:

1) calibrate the system;

2) perform initial measurement of the insertion loss by connecting the connector under test

parameter for insertion loss is observed,

to both end faces of the reference airlines. S

and stored;

3) when the connection is broken and then reconnected. Rotate the connector with 45°

increments over two complete 360° cycles. The measurement values are obtained and

stored;

4) calculate the maximum numeric difference at any frequency point for test results.

7.6.4.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) test frequency range;

b) requirements for insertion loss repeatability;

c) details of the connector to be mated to the connector under test (or detail drawing);

d) any deviation from the standard test method.

7.6.5 Phase

Requirements and procedures are same as in 7.6.3, except that the test parameter is set into

phase option when setting parameters for the instrument.

7.6.6 Phase repeatability

The requirements and procedures are same as in 7.6.4, except that test parameter is set into

phase option when setting parameters on the instrument.

7.6.7 Screening effectiveness

7.6.7.1 Requirements

It shall be in accordance with the value specified in the relevant specification.

7.6.7.2 Test procedure

The measurement will be performed using triaxial method as specified in IEC 62153-4-4.

7.6.7.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) appropriate frequency range;

b) details of the connector to be mated to the connector under test (or detail drawing);

c) any deviation from the standard test method.

7.6.8 Contact resistance

7.6.8.1 Requirements

The contact resistance shall not exceed the value specified in the relevant specification.

The changes in resistance of the centre conductor and outer conductor of a mated connector

pair shall not deviate, after conditioning, by more than the appropriate maximum permitted

values specified in the relevant specification.

7.6.8.2 Test procedure

Measurements will be carried out with alternating current (AC). In case of dispute, however, the

measurement with direct current shall govern.

The contact resistance shall be calculated from the potential difference measured between the

points intended for inner conductor and outer conductor contact of mated pairs. The contact

shall be made before the current is switched on. Both end faces of the connector shall be tested

separately.

The measuring set-up shall be such as to ensure that the result is within ± 10 % of the

resistance to be measured, unless another accuracy is given in the relevant specification.

of a pair of

In general, the resistances of the centre contact and the outer contact R

o

connectors shall be measured separately. The relevant specification shall state explicitly if the

total resistance R of the two contacts in series is to be determined by a direct measurement.

tot

The relevant value of the contact resistance is the mean value calculated from five consecutive

measuring cycles. No individual value shall exceed twice the mean value.

One measuring cycle consists of:

1) making the contact (engaging the connectors);

2) connection of voltage source;

3) measurement;

4) disconnection of voltage source;

5) breaking the contact (disengaging the connectors).

7.6.8.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) the upper limit values of contact resistance of the centre contact and outer contact (the upper

limit value of total resistance shall also be given when necessary);

b) any deviation from the standard test method.

7.6.9 Contact resistance repeatability

7.6.9.1 Requirements

The changes in resistance of the centre conductor and outer conductor of a mated connector

pair shall not deviate by more than the appropriate maximum permitted values specified in the

relevant specification.

– 16 – IEC 63137-1:2019 © IEC 2019

7.6.9.2 Test procedure

Perform the initial measurement of contact resistance as in 7.6.8.2. Then the connection is

broken and reconnected, and then the measured value is compared with the initial measurement.

Repeat in such manner five times.

7.6.9.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) the allowable maximum numeric difference;

b) any deviation from the standard test method.

7.6.10 Insulation resistance

7.6.10.1 Requirements

The value of insulation resistance shall be not less than the value specified in the relevant

specification.

7.6.10.2 Test procedure

The insulation resistance shall be measured between the contacts with a DC voltage

of 500 V ± 50 V or with the rated voltage of the connector, whichever is less.

The test equipment shall have a suitable range to cover the resistance being measured.

The insulation resistance shall be measured after an electrification time of 1 min ± 5 s.

7.6.10.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) value of the test voltage if other than 500 V;

b) minimum value of insulation resistance;

c) test arrangement (mated or unmated connector);

d) any deviation from the standard test method.

7.6.11 Voltage proof

7.6.11.1 Requirements

Connectors shall withstand the voltage specified in the relevant specification, without

breakdown or flashover.

7.6.11.2 Test procedure

When applicable, the connectors shall be tested both mated and unmated.

An AC voltage at a frequency between 40 Hz and 65 Hz shall be applied for 60 s for qualification

approval and for 5 s for quality conformance inspection unless otherwise prescribed in the

relevant specification.

The relation between the rated voltage U and the test voltage E (RMS values) is given by:

E = 3 U for connectors having a rated voltage up to and including 1 kV, and

E = 1,5 U with a minimum of 3 kV, for connectors having a rated voltage exceeding 1 kV.

NOTE If the cable capacitance does not allow the AC test to be performed, a DC voltage proof is done at 1,414 times

the RMS value of the AC voltage.

7.6.11.3 Information to be given in the relevant specification

The following information shall be given in the relevant specification:

a) test voltage value;

b) maximum leakage current;

c) any deviation from the standard test method.

7.7 Mechanical tests

7.7.1 Insertion force (resilient contacts)

7.7.1.1 Requirements

The values of insertion force shall not exceed those specified in the relevant specification.

7.7.1.2 Test procedure

Resilient contacts, either female (socket) or male (pin) shall be tested in the following manner

using the specified gauges.

a) The gauge causing the maximum deformation shall be applied to the contact and

withdrawn three times. For a centre female contact, the diameter of the gauge shall be the

maximum specified diameter of the mating male contact. For the outer male contact, the

inner diameter of the gauge shall be the minimum specified diameter of the female body.

b) The gauge causing minimum deformation shall then be engaged with the contact. The

contact shall support the gauge when the gauge is hanging from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...