IEC 60068-2-75:2014

(Main)Environmental testing - Part 2-75: Tests - Test Eh: Hammer tests

Environmental testing - Part 2-75: Tests - Test Eh: Hammer tests

IEC 60068-2-75:2014 provides three standardized and coordinated test methods for determining the ability of a specimen to withstand specified severities of impact. It is used, in particular, to demonstrate an acceptable level of robustness when assessing the safety of a product and is primarily intended for the testing of electrotechnical items. It consists of the application to the specimen of a prescribed number of impacts defined by their impact energy and applied in the prescribed directions. This part of IEC 60068 covers energy levels ranging from 0,14 J (joules) to 50 J (joules). This second edition cancels and replaces the first edition, published in 1997, and constitutes a technical revision. This edition includes the following significant technical change with respect to the previous edition:

- reconsideration of some values in Tables 1 and 2. Although some values are no longer recommended, they have been retained as alternatives for historical consistency purposes.

Essais d'environnement - Partie 2-75: Essais - Essai Eh: Essais au marteau

L'IEC 60068-2-75:2014 fournit trois méthodes d'essai normalisées et coordonnées pour déterminer l'aptitude d'un spécimen à supporter des sévérités spécifiées d'impact. Elle est utilisée en particulier pour démontrer un niveau acceptable de robustesse mécanique pour l'évaluation de la sécurité d'un produit; elle est destinée, en premier lieu, à l'essai de produits électrotechniques. Elle consiste à appliquer au spécimen un nombre prescrit d'impacts définis par leur énergie et appliqués dans des directions spécifiées. La présente partie de l'IEC 60068 couvre les niveaux d'énergie allant de 0,14 J (joules) à 50 J (joules). Cette deuxième édition annule et remplace la première édition, parue en 1997, et constitue une révision technique. Cette édition inclut la modification technique significative suivante par rapport à l'édition précédente:br /> - réexamen de certaines valeurs figurant dans les Tableaux 1 et 2. Bien qu'elles ne soient plus recommandées, certaines valeurs ont été conservées comme alternatives dans un but de cohérence avec la pratique antérieure.

General Information

- Status

- Published

- Publication Date

- 02-Sep-2014

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 17 - TC 104/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Sep-2014

- Completion Date

- 15-Sep-2014

Relations

- Effective Date

- 22-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60068-2-75:2014 (with AMD1:2025) defines standardized hammer tests (Test Eh) for environmental impact/robustness testing of electrotechnical items. The standard provides three coordinated methods - pendulum hammer (Eha), spring hammer (Ehb) and vertical hammer (Ehc) - to apply a prescribed number of impacts defined by their impact energy, direction and location. Energy levels covered range from 0.14 J to 50 J, and the second edition (replacing the 1997 edition) includes updated coordinate values in Tables 1 and 2, with some legacy values retained for historical comparison.

Key topics and technical requirements

- Three test methods: pendulum (Eha), spring (Ehb) and vertical (Ehc) hammer procedures with apparatus descriptions and mounting guidance.

- Severity definition: impact energy value, number of impacts and prescribed impact directions/locations.

- Test apparatus and calibration: requirements for striking elements, calibration procedures (Annex B for spring hammers) and coordinated striking element characteristics (Table 1; Annex A).

- Test procedure stages: preconditioning, initial measurements, testing (attitudes, preparation, operating mode and functional monitoring), recovery and final measurements.

- Measurement and documentation: prescribed measuring points, reporting of severities and detailed information to be provided in test specifications.

- Guidance and examples: informative annexes with guidance notes (Annex C) and example apparatus for pendulum and spring hammers (Annexes D and E).

- Coordination with system severity classes: severity levels are generally aligned with IEC 60721-1 for environmental classification.

Practical applications and who uses this standard

- Product manufacturers and design engineers use IEC 60068-2-75 to demonstrate mechanical robustness and to validate designs against impact-induced failures (e.g., switches, lamp holders, connectors and other electrotechnical components).

- Test laboratories and certification bodies implement the specified hammer tests to provide independent robustness verification and support compliance or safety assessments.

- Safety and compliance managers reference the standard when specifying test requirements in product specifications or when assessing field reliability related to mechanical shocks.

- R&D and QA teams apply the standard during development and production testing to detect weak points and to ensure repeatable impact testing across different hammer types.

Related standards

- IEC 60068 series - Environmental testing (general framework and complementary parts)

- IEC 60721-1 - Environmental conditions, classification and severity levels (used for coordinating severity definitions)

Keywords: IEC 60068-2-75, hammer tests, impact testing, pendulum hammer, spring hammer, vertical hammer, impact energy, robustness testing, electrotechnical equipment, environmental testing, calibration.

IEC 60068-2-75:2014+AMD1:2025 CSV - Environmental testing - Part 2-75: Tests - Test Eh: Hammer tests Released:21. 10. 2025 Isbn:9782832708033

IEC 60068-2-75:2014 - Environmental testing - Part 2-75: Tests - Test Eh: Hammer tests

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-75:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-75: Tests - Test Eh: Hammer tests". This standard covers: IEC 60068-2-75:2014 provides three standardized and coordinated test methods for determining the ability of a specimen to withstand specified severities of impact. It is used, in particular, to demonstrate an acceptable level of robustness when assessing the safety of a product and is primarily intended for the testing of electrotechnical items. It consists of the application to the specimen of a prescribed number of impacts defined by their impact energy and applied in the prescribed directions. This part of IEC 60068 covers energy levels ranging from 0,14 J (joules) to 50 J (joules). This second edition cancels and replaces the first edition, published in 1997, and constitutes a technical revision. This edition includes the following significant technical change with respect to the previous edition: - reconsideration of some values in Tables 1 and 2. Although some values are no longer recommended, they have been retained as alternatives for historical consistency purposes.

IEC 60068-2-75:2014 provides three standardized and coordinated test methods for determining the ability of a specimen to withstand specified severities of impact. It is used, in particular, to demonstrate an acceptable level of robustness when assessing the safety of a product and is primarily intended for the testing of electrotechnical items. It consists of the application to the specimen of a prescribed number of impacts defined by their impact energy and applied in the prescribed directions. This part of IEC 60068 covers energy levels ranging from 0,14 J (joules) to 50 J (joules). This second edition cancels and replaces the first edition, published in 1997, and constitutes a technical revision. This edition includes the following significant technical change with respect to the previous edition: - reconsideration of some values in Tables 1 and 2. Although some values are no longer recommended, they have been retained as alternatives for historical consistency purposes.

IEC 60068-2-75:2014 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-75:2014 has the following relationships with other standards: It is inter standard links to IEC 60068-2-75:2014/AMD1:2025, IEC 60068-2-75:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-75:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-75 ®

Edition 2.1 2025-10

INTERNATIONAL

STANDARD

CONSOLIDATED VERSION

Environmental testing -

Part 2-75: Tests - Test Eh: Hammer tests

ICS 19.040 ISBN 978-2-8327-0803-3

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

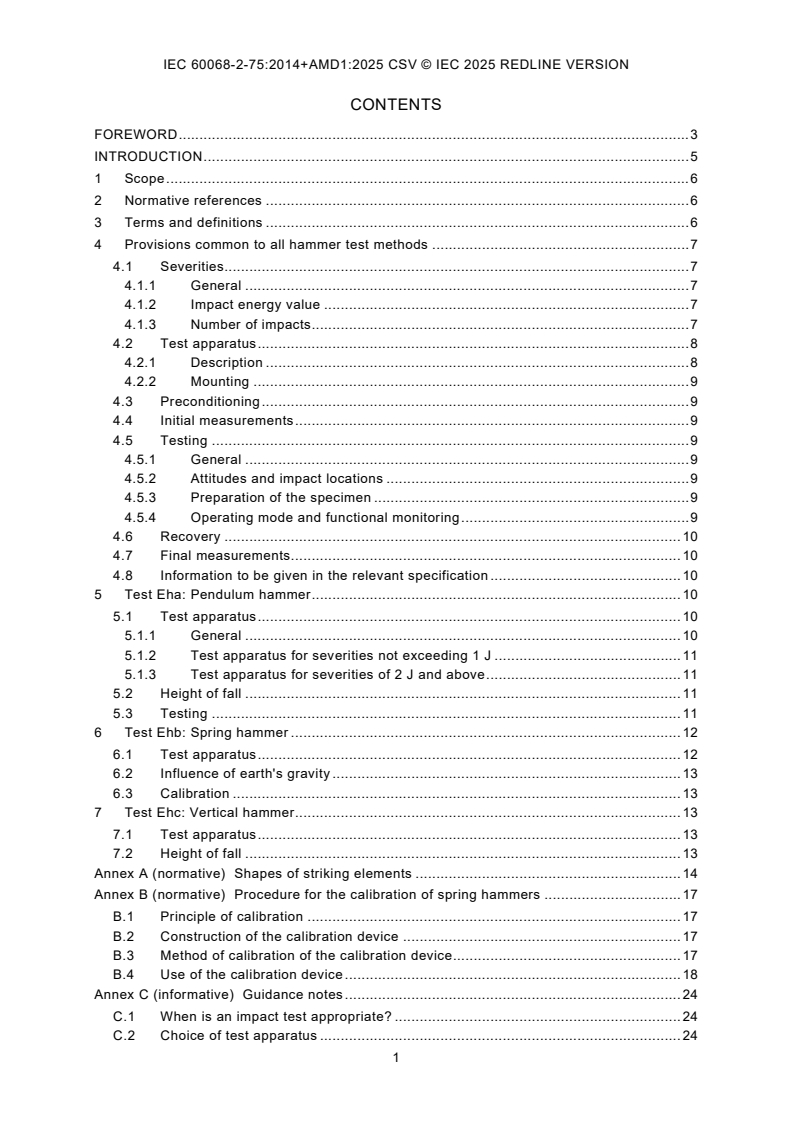

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Provisions common to all hammer test methods . 7

4.1 Severities. 7

4.1.1 General . 7

4.1.2 Impact energy value . 7

4.1.3 Number of impacts. 7

4.2 Test apparatus . 8

4.2.1 Description . 8

4.2.2 Mounting . 9

4.3 Preconditioning . 9

4.4 Initial measurements . 9

4.5 Testing . 9

4.5.1 General . 9

4.5.2 Attitudes and impact locations . 9

4.5.3 Preparation of the specimen . 9

4.5.4 Operating mode and functional monitoring . 9

4.6 Recovery . 10

4.7 Final measurements. 10

4.8 Information to be given in the relevant specification . 10

5 Test Eha: Pendulum hammer . 10

5.1 Test apparatus . 10

5.1.1 General . 10

5.1.2 Test apparatus for severities not exceeding 1 J . 11

5.1.3 Test apparatus for severities of 2 J and above . 11

5.2 Height of fall . 11

5.3 Testing . 11

6 Test Ehb: Spring hammer . 12

6.1 Test apparatus . 12

6.2 Influence of earth's gravity . 13

6.3 Calibration . 13

7 Test Ehc: Vertical hammer . 13

7.1 Test apparatus . 13

7.2 Height of fall . 13

Annex A (normative) Shapes of striking elements . 14

Annex B (normative) Procedure for the calibration of spring hammers . 17

B.1 Principle of calibration . 17

B.2 Construction of the calibration device . 17

B.3 Method of calibration of the calibration device. 17

B.4 Use of the calibration device . 18

Annex C (informative) Guidance notes . 24

C.1 When is an impact test appropriate? . 24

C.2 Choice of test apparatus . 24

C.3 Choice of energy level . 24

C.4 Information for testing . 25

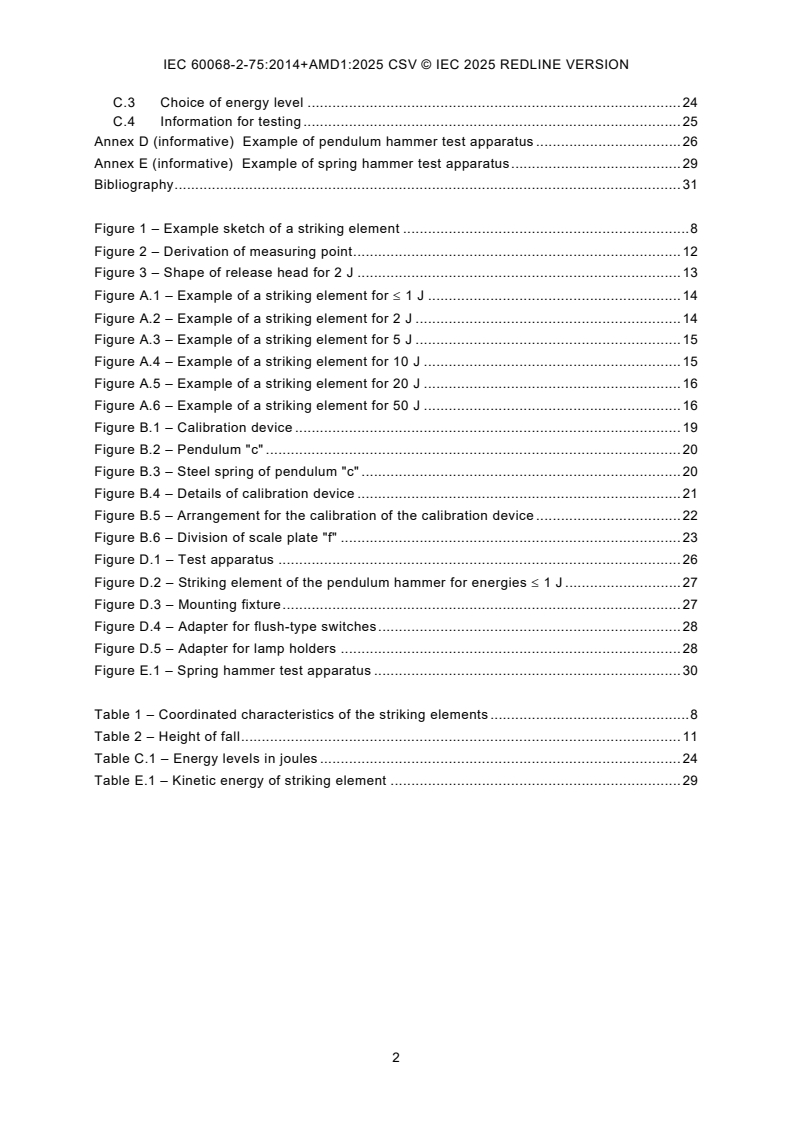

Annex D (informative) Example of pendulum hammer test apparatus . 26

Annex E (informative) Example of spring hammer test apparatus . 29

Bibliography . 31

Figure 1 – Example sketch of a striking element . 8

Figure 2 – Derivation of measuring point . 12

Figure 3 – Shape of release head for 2 J . 13

Figure A.1 – Example of a striking element for ≤ 1 J . 14

Figure A.2 – Example of a striking element for 2 J . 14

Figure A.3 – Example of a striking element for 5 J . 15

Figure A.4 – Example of a striking element for 10 J . 15

Figure A.5 – Example of a striking element for 20 J . 16

Figure A.6 – Example of a striking element for 50 J . 16

Figure B.1 – Calibration device . 19

Figure B.2 – Pendulum "c" . 20

Figure B.3 – Steel spring of pendulum "c" . 20

Figure B.4 – Details of calibration device . 21

Figure B.5 – Arrangement for the calibration of the calibration device . 22

Figure B.6 – Division of scale plate "f" . 23

Figure D.1 – Test apparatus . 26

Figure D.2 – Striking element of the pendulum hammer for energies ≤ 1 J . 27

Figure D.3 – Mounting fixture . 27

Figure D.4 – Adapter for flush-type switches . 28

Figure D.5 – Adapter for lamp holders . 28

Figure E.1 – Spring hammer test apparatus . 30

Table 1 – Coordinated characteristics of the striking elements . 8

Table 2 – Height of fall . 11

Table C.1 – Energy levels in joules . 24

Table E.1 – Kinetic energy of striking element . 29

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Environmental testing -

Part 2-75: Tests - Test Eh: Hammer tests

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s),

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60068-2-75 edition 2.1 contains the second edition (2014-09) [documents 104/635/FDIS

and 104/637/RVD] and its amendment 1 (2025-10) [documents 104/1106/FDIS and

104/1137/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text.

A separate Final version with all changes accepted is available in this publication.

International Standard IEC 60068-2-75 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This second edition cancels and replaces the first edition, published in 1997, and constitutes

a technical revision.

This edition includes the following significant technical change with respect to the previous

edition:

– reconsideration of some values in Tables 1 and 2. Although some values are no longer

recommended, they have been retained as alternatives for historical consistency

purposes.

It has the status of:a basic safety publication in accordance with IEC Guide 104.

The text of this standard is based on the following documents:

FDIS Report on voting

104/635/FDIS 104/637/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this document and its amendment will remain

unchanged until the stability date indicated on the IEC website under webstore.iec.ch in the

data related to the specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

Mechanical impacts likely to stress electrotechnical equipment in service can be generated by

hammers of various types. For standardization purposes, the results of such testing should

not depend on the type of testing apparatus and therefore, the characteristics of the various

types of test hammers described in this part of IEC 60068 are intended to be as close as

practicable for the same severity level.

It is important to note that both Clause 3 and the test method selected from Clauses 4, 5, and

6 need to be complied with in order to satisfy the requirements of this International Standard.

The severity levels are, in general, taken from IEC 60721-1.

For coordination purposes, it has been necessary to change certain fundamental parameters

of the previous tests Ef: Impact, pendulum hammer, and Eg: Impact, spring hammer. In all

cases, both sets of parameters are shown at the appropriate places in the text. Although

some values are no longer recommended, they have been retained as alternatives for

historical consistency purposes. This is because they have application in certain industries as

historic comparators.

1 Scope

This part of IEC 60068 provides three standardized and coordinated test methods for

determining the ability of a specimen to withstand specified severities of impact. It is used, in

particular, to demonstrate an acceptable level of robustness when assessing the safety of a

product and is primarily intended for the testing of electrotechnical items. It consists of the

application to the specimen of a prescribed number of impacts defined by their impact energy

and applied in the prescribed directions.

This part of IEC 60068 covers energy levels ranging from 0,14 J (joules) to 50 J (joules).

Three types of test apparatus are applicable to perform these tests. Annex C provides some

guidance as to this aspect.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60721-1, Classification of environmental conditions – Part 1: Environmental parameters

and their severities

IEC Guide 104, The preparation of safety publications and the use of basic safety publications

and group safety publications

IEC Guide 108, Guidelines for ensuring the coherency of IEC publications – Application of

horizontal standards

ISO 48-4, Rubber, vulcanized or thermoplastic - Determination of hardness

ISO 1052, Steels for general engineering purposes

ISO 2039-2, Plastics – Determination of hardness – Part 2: Rockwell hardness

ISO 2041, Vibration and shock and condition monitoring – Vocabulary

ISO 2768-1, General tolerances – Part 1: Tolerances for linear and angular dimensions

without individual tolerances indications

ISO 6508 (all parts), Metallic materials – Rockwell hardness test

ISO 6508-1, Metallic materials - Rockwell hardness test - Part 1: Test method

3 Terms and definitions

For the purposes of this document, the terms and definitions used in ISO 2041 or in

IEC 60068-1, together with the following, apply.

3.1

combined mass of the striking element

sum of the masses of the striking element and of the element's fixing system

3.2

fixing point

part of the specimen in contact with the mounting fixture at the point where the specimen is

normally fastened in service

3.3

equivalent mass

mass of the striking element and any relevant portions of the test apparatus which, combined

with its velocity, provides the impact energy

Note 1 to entry: For the particular application to the pendulum hammer apparatus, mass of the simple pendulum

hammer calculated from the measure of the vertical force (in newtons) to be applied in the axis of the striking

element to maintain the arm of the pendulum in a horizontal position, divided by the earth's gravity. When the mass

of the arm is evenly distributed, the equivalent mass is equal to the sum of the combined mass of the striking

element plus half the mass of the arm.

3.4

measuring point

point marked on the surface of the striking element where the line through the point of

intersection of the axes of the arms of both of the pendulum and of the striking element, and

perpendicular to the plane through both axes, meets the surface (see Figure 2).

Note 1 to entry: In some IEC standards which include a pendulum hammer test, the term "checking point" has

been used but it has not been used here in order to avoid confusion with "check point " in other parts of IEC 60068-2.

Note 2 to entry: Theoretically, the centre of gravity of the striking element should be the measuring point. In

practice, the centre of gravity is either difficult to determine or inaccessible, and the measuring point is therefore

defined as above.

3.5

height of fall

vertical distance between the position of the measuring point when the pendulum is released

and its position at the moment of impact (see Figure D.1).

4 Provisions common to all hammer test methods

4.1 Severities

4.1.1 General

The severity is defined by the impact energy value chosen from 4.1.2, and the number of

impacts according to 4.1.3.

4.1.2 Impact energy value

The impact energy value shall be one of the following, as prescribed by the relevant

specification:

0,14 – 0,2 – (0,3) – 0,35 – (0,4) – 0,5 – 0,7 – 1 – 2 – 5 – 10 – 20 – 50 J (joules).

NOTE Figures in brackets appear in previous IEC 60068-2 standards, although no longer recommended, they

may be used for historic consistency.

4.1.3 Number of impacts

Unless otherwise prescribed by the relevant specification, the number of impacts shall be

three per location.

4.2 Test apparatus

4.2.1 Description

Three types of test apparatus are available to perform these tests:

– the pendulum hammer;

– the spring hammer;

– the vertical hammer.

The types of test apparatus are defined in Clauses 5, 6 and 7 as tests Eha, Ehb and Ehc,

respectively. The coordinated characteristics of the striking element are, in principle, similar in

all three cases and are stated in Table 1 in relation to the outline shown in Figure 1.

Dimensions are in millimetres. Tolerances are as per class m of ISO 2768-1, unless otherwise

stated.

Table 1 – Coordinated characteristics of the striking elements

≤1 2 5 10 20 50

Energy value

±10 % ±5 % ±5 % ±5 % ±5 % ±5 %

J

Equivalent

mass 0,25 (0,2) 0,5 1,7 5 5 10

±2 % kg

a b

Material Polyamide Steel

R mm 10 25 25 50 50 50

D mm 18,5 (20) 35 60 80 100 125

f mm 6,2(10) 7 10 20 20 25

r mm – – 6 – 10 17

l mm To be adjusted to match the equivalent mass, see Annex A.

a

85 ≤ HRR ≤100, Rockwell hardness according to ISO 2039-2 or 70 ≤ Shore D ≤ 85, Shore D hardness

according to ISO 48-4, for example Polyamide PA6.6.

b

Fe 490-2, according to ISO 1052: Rockwell hardness: HRE 80.85 according to ISO 6508-1 or

69 ≤ HRBW ≤ 91, Rockwell hardness according to ISO 6508-1, for example X6Cr17 (1.4016, AISI 430).

NOTE The values shown in brackets for the equivalent mass and the diameter of the striking element for the

energy value equal to or less than 1 J are those in the current test Ef. The values currently in test Eg are also

shown for these two parameters. Although, for coordination reasons, these values are no longer recommended,

they are used by some industries for historical comparison purposes.

Axis of

r

striking

element

R

f l

IEC

Figure 1 – Example sketch of a striking element

The striking surface shall be visually examined before each impact in order to ensure that

there is no damage that might affect the result of the test.

D

4.2.2 Mounting

As prescribed by the relevant specification, the specimen shall either

a) be mounted by its normal means on a rigid plane support, or

b) be placed against a rigid plane support.

In order to ensure that the specimen is rigidly supported, it may be necessary when

performing the test to place the specimen against a plane solid support, for example a wall or

a floor made of brick or concrete, covered by a sheet of polyamide which is tightly fixed to the

support.

Care shall be taken to ensure that there is no appreciable air gap between the sheet and the

support. The sheet shall have a Rockwell hardness of 85 ≤HRR ≤100 according to ISO 2039-

2, a thickness of approximately 8 mm and a surface area such that no parts of the specimen

are mechanically over-stressed due to the supporting area being insufficient.

The mounting arrangement is deemed to be sufficiently rigid if the displacement of the impact

surface of the plane support does not exceed 0,1 mm when struck by an impact applied

directly to it with the same level of energy as for the specimen.

NOTE 1 For specimens to be subjected to impact energies not exceeding 1 J, some examples of mounting and

support are shown in Figures D.3, D.4 and D.5.

NOTE 2 When the mass of the mounting is at least 20 times that of the specimen, the rigidity of the mounting is

likely to be sufficient.

4.3 Preconditioning

The relevant specification may call for preconditioning; it shall then prescribe the conditions.

4.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by the relevant specification.

4.5 Testing

4.5.1 General

Secondary impacts, i.e. rebounds, shall be avoided.

4.5.2 Attitudes and impact locations

The relevant specification shall prescribe the attitudes of the specimen and the locations on

the specimen corresponding to where damage is most likely to occur in practice and at which

the impacts are to be applied. Unless otherwise specified by the relevant specification, the

blows shall be applied perpendicularly to the tested surface.

4.5.3 Preparation of the specimen

The relevant specification shall state any requirements for the securing of bases, covers and

similar items before the specimen is subjected to the impacts.

NOTE Account may need to be taken of requirements for functional monitoring (see 4.5.4 b)).

4.5.4 Operating mode and functional monitoring

The relevant specification shall state:

a) whether the specimen is required to operate during impact;

b) whether any functional monitoring is required.

In both cases, the relevant specification shall provide the criteria upon which the acceptance

or rejection of the specimen is to be based.

NOTE Attention is drawn to the fact that, in case of breakage of the specimen, internal parts may become

hazardous.

4.6 Recovery

The relevant specification may call for recovery and shall then prescribe the conditions.

4.7 Final measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by the relevant specification.

The relevant specification shall prescribe the criteria upon which the acceptance or rejection

of the specimen is to be based.

4.8 Information to be given in the relevant specification

When one of the tests in this part of IEC 60068 is included in a relevant specification, the

following details shall be given as far as they are applicable, paying particular attention to the

items marked with an asterisk (*) as this information is always required:

Subclause

a) Impact energy * 4.1.2

b) Number of impacts, if other than three per location 4.1.3

c) Type(s) of test apparatus to be used 4.2.1

d) Method of mounting * 4.4.2

e) Preconditioning 4.3

f) Initial measurements* 4.4

g) Attitude and impact locations * 4.5.2

h) Securing of bases, covers and similar components 4.5.3

i) Operating mode and functional monitoring* 4.5.4

j) Acceptance and rejection criteria * 4.5.4 and 4.7

k) Conditions for recovery 4.6

l) Final measurements* 4.7

5 Test Eha: Pendulum hammer

5.1 Test apparatus

5.1.1 General

The test apparatus consists basically of a pendulum rotating at its upper end in such a way as

to be kept in a vertical plane. The axis of the pivot is at 1 000 mm above the measuring point.

The pendulum is composed of a nominally rigid arm and of a striking element complying with

the requirements of Table 1.

For testing heavy, voluminous or difficult-to-handle specimens, a portable pendulum may be

used. It shall comply with the above description but its pivot may be fixed directly on the

specimen or on a movable structure. In this case, it shall be ensured that, before the tests,

the axis of the pendulum is horizontal, that its fixing is sufficiently rigid and that the impact

point is in the vertical plane passing through the axis.

In all cases, when the pendulum is released, it shall be allowed to fall only under the influence

of gravitational force.

5.1.2 Test apparatus for severities not exceeding 1 J

The striking element comprises a steel body with a polyamide insert having a hemispherical

face. Its combined mass is 200 g (150 g) ± 1 g so that the equivalent mass complies with

Table 1. Annex D gives an example of a test apparatus.

5.1.3 Test apparatus for severities of 2 J and above

The ratio of the mass of the arm to the combined mass of the striking element shall not be

greater than 0,2 and the centre of gravity of the striking element shall be as close as is

practicable to the axis of the arm.

For some particular applications, the pendulum arm is replaced by a cord and the striking

element by a spherical steel ball. This is not recommended as the ball does not conform to

the geometry of the striking element specified in this part of IEC 60068.

5.2 Height of fall

To produce impacts of the required severity, the striking element shall be released from a

height depending on the equivalent mass of the pendulum, according to Table 2.

Table 2 – Height of fall

Energy

0,14 0,2 (0,3) 0,35 (0,4) 0,5 0,7 1 2 5 10 20 50

J

Equivalent

mass 0,25 (0,2) 0,25 (0,2) 0,25 (0,2) (0,2) 0,25 0,25 0,25 0,5 1,7 5 5 10

kg

Height

of fall 56 (100) 80 (150) 140 (200) (250) 200 280 400 400 300 200 400 500

mm ± 1 %

NOTE 1 Figures in brackets appear in previous IEC 60068-2 standards; although no longer recommended, they

may be used for historic consistency.

NOTE 2 In this part of IEC 60068, the energy, J, is calculated taking the standard acceleration due to the earth's

gravity (g ), rounded up to the nearest whole number, that is 10 m/s .

n

5.3 Testing

In order to avoid secondary impacts, i.e. rebounds, the hammer shall be retained after the

initial impact by grasping the striking element whilst avoiding the arm so that distortion is

prevented.

Vertical

Ai

Measuring point

Measuring point

Axis of striking element

IEC

Figure 2 – Derivation of measuring point

6 Test Ehb: Spring hammer

6.1 Test apparatus

The spring hammer consists of three principal parts: the body, the striking element and the

release system.

The body comprises the housing, the guide for the striking element, the release mechanism

and all rigidly fixed parts.

The striking element comprises the hammer head, the hammer shaft and the cocking knob.

The mass of this assembly is 250 g (200 g) for severities not exceeding 1 J, and 500 g for 2 J

(see Table 1 for tolerances).

The force to release the striking element shall not exceed 10 N.

The configuration of the hammer shaft, the hammer head and the means for the adjustment of

the hammer spring is such that the hammer spring has released all its stored energy

approximately 1 mm before the tip of the hammer head reaches the plane of impact. For the

last millimetre of its travel, prior to impact, the striking element is thus, apart from friction, a

freely moving mass having only kinetic energy and no stored energy. Moreover, after the tip of

the hammer head has passed the plane of impact, the striking element is free to travel,

without interference, over a further distance of between 8 mm and 12 mm. Annex E gives an

example of a test apparatus.

In order to comply with Table 1, the shape of the release head for 2 J shall be cylindrical for a

length of 23 mm with a diameter of 35 mm (see Figure 3).

Dimensions in millimetres

IEC

Figure 3 – Shape of release head for 2 J

6.2 Influence of earth's gravity

When the spring hammer is used in a position differing from the horizontal, the energy

actually delivered is modified by ∆E. This variation is positive when the blows are applied

downward, and negative when applied upward:

∆E = 10 × m × d × sin α

where

m is the mass of the striking element, in kilogrammes;

d is the travel of the striking element inside the spring hammer, in metres;

α is the angle of the axis of the striking element with the horizontal.

This variation shall be taken into account when establishing the actual energy delivered.

6.3 Calibration

The spring hammer shall be calibrated. Annex B gives a standardized preferred procedure

(see Clause B.2 in particular for 2 J). Other methods of calibration may also be used,

provided that evidence is available that they give equivalent accuracy.

7 Test Ehc: Vertical hammer

7.1 Test apparatus

The hammer consists basically of a striking element which falls freely from rest through a

vertical height, selected from Table 2, on to the specimen surface held in a horizontal plane.

The characteristics of the striking element shall comply with Table 1. The fall of the striking

element shall be along a guideway, for example three or four rails, with negligible braking.

This guideway shall not rest on the specimen and the striking element shall be free of the

guideway on striking the specimen. In order to reduce the friction, the length l of the striking

element shall not be smaller than its diameter D, and a small gap (for example 1 mm) shall be

provided between the striking element and the guideway.

7.2 Height of fall

The height of fall shall be as given in Table 2, the equivalent mass stated therein being equal

to the actual mass of the striking element.

Annex A

(normative)

Shapes of striking elements

The figures in this annex show the shape and characteristics of the striking elements

applicable to each of the six energy values defined in Table 1. For the purpose of these

figures, the lengths of the striking element are calculated for vertical hammers or for

pendulum hammers with arms of negligible mass. When the mass of the arms cannot be

neglected, the lengths of the striking element should be reduced so that the equivalent mass

meets the requirements of Table 1 (see 3.2).

Figure A.1 shows the striking element applicable to energy values of equal or less than 1 J. In

this case, the impact face should be made of polyamide with a hardness as specified in Table 1.

Figures A.2, A.3 and A.4 show the striking elements applicable to energy values of 2 J, 5 J

and 10 J, respectively. In these cases the impact face should be made of steel with

properties, including hardness, as specified in Table 1.

Figures A.5 and A.6 show the striking elements applicable to energy values of 20 J and 50 J,

respectively. In these cases, the impact face should be made of steel with properties,

including hardness, as specified in Table 1. In these cases, to comply with the other parameters

of Table 1, it is necessary to hollow out the end opposite to the striking face.

Every edge shall be smoothed.

The tolerances are as per class m of ISO 2768-1, unless otherwise stated.

Dimensions in millimetres

R 10

6,2

IEC

Figure A.1 – Example of a striking element for ≤ 1 J

Dimensions in millimetres

R 25

IEC

Figure A.2 – Example of a striking element for 2 J

Ø1

Ø3

Ø18,

Dimensions in millimetres

R 6

R 25

IEC

Figure A.3 – Example of a striking element for 5 J

Dimensions in millimetres

20 117

R 50

IEC

Figure A.4 – Example of a striking element for 10 J

Ø60

Ø80

Dimensions in millimetres

R 10

R

IEC

Figure A.5 – Example of a striking element for 20 J

Dimensions in millimetres

25 125

R 17

R 50

IEC

Figure A.6 – Example of a striking element for 50 J

Ø100

Ø125

Annex B

(normative)

Procedure for the calibration of spring hammers

B.1 Principle of calibration

The principle of this calibration procedure is to compare the energy provided by a spring

hammer, which is difficult to measure directly, to the energy of a pendulum, calculated from

its mass and height of fall.

B.2 Construction of the calibration device

The assembled calibration device is shown in Figure B.1. Apart from the frame, the main parts

are a bearing "a", a drag pointer "b", a pendulum "c", a release base "d" and a release device

"e".

The main part of the calibration device is the pendulum “c” shown in Figure B.2. To the lower

end of this pendulum is fixed a steel spring with the details shown in Figure B.3. The spring is

of spring steel, requiring no special treatment, and is rigidly fixed to the pendulum “c”.

Figure B.4 shows some parts on a larger scale.

It should be noted that this spring is designed for calibrating spring hammers having

characteristics as defined in Table 1 for energy values equal to or less than 1 J. For

calibrating spring hammers having characteristics as defined for 2 J, the spring of the

pendulum of the calibrating device would need to be of a different design.

In order to obtain suitable friction characteristics of the pointer, a piece of thick woven cloth is

placed between the metal surfaces of the bearing, the piano wires being bent in such a way

that a small force is exerted against the cloth.

Because the release device is removed during the calibration of the calibration device, the

release device is fixed to the release base by means of screws.

B.3 Method of calibration of the calibration device

The calibration of the calibration device is effected by using a calibration striking element "g"

taken from a spring hammer, as shown in Figure B.5. Before calibration, the release device is

removed from the calibrating device.

The calibration striking element is suspended by four linen threads "h" from suspension points

situated in a horizontal plane, 2 000 mm above the point of contact between the pendulum

and the calibration striking element when the latter is in its rest position. The calibration

striking element is allowed to swing against the pendulum and the point of contact under

dynamic conditions, point “k”, shall be not more than 1 mm below the point of contact in the

rest position. The suspension points are then raised over a distance equal to the difference

between both contact points.

When the suspension system is adjusted, the axis of the calibration striking element “g” shall

be at right angles to the impact surface of the pendulum “c” and the calibration striking

element shall be horizontal at the moment of impact.

When the calibration striking element is in its rest position, the calibration device is placed so

that point “k” is positioned exactly at the head of the calibration striking element.

To obtain reliable results, the calibration device is rigidly fixed to a massive support, for

example to a structural part of a building.

The height of fall is measured at the centre of gravity of the calibration striking element and

the measurement can be facilitated by using a liquid level device consisting of two glass tubes

"j", which are interconnected by means of a flexible hose. One of the glass tubes is fixed and

provided with a scale "l".

The calibration striking element may be held in its upper position by means of a thin thread

"m" which, when ruptured, causes the release of the calibration striking element.

For scaling the calibration device, a circle is drawn on the scale plate, the centre of this circle

coinciding with the bearing of the pendulum and its radius being such that the circle extends

to the drag pointer. On this circle, the zero point 0 J shown in Figure B.6 is marked at the

point indicated by the drag pointer when the latter is brought into contact with the pendulum in

the rest position.

The calibration is made with an impact energy of 1 J, which is achieved with a height of fall

of 408 mm ± 1 mm, with a calibration striking element of 250 g.

The point on the scale plate corresponding to 1 J is obtained by allowing the suspended

calibration striking element to swing against point "k" on the spring of the pendulum. After

hitting the pendulum, the calibration striking element shall not move. The operation is

repeated at least 10 times and the 1 J point is the average of the indications of the drag

pointer.

The other points of the scale are then determined as follows:

a) a straight line is drawn through the centre of the circle a

...

IEC 60068-2-75 ®

Edition 2.0 2014-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-75: Tests – Test Eh: Hammer tests

Essais d’environnement –

Partie 2-75: Essais – Test Eh: Essais au marteau

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60068-2-75 ®

Edition 2.0 2014-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-75: Tests – Test Eh: Hammer tests

Essais d’environnement –

Partie 2-75: Essais – Test Eh: Essais au marteau

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX V

ICS 19.040 ISBN 978-2-8322-1842-6

– 2 – IEC 60068-2-75:2014 © IEC 2014

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions. 8

4 Provisions common to all hammer test methods . 8

4.1 Severities . 8

4.1.1 General . 8

4.1.2 Impact energy value . 8

4.1.3 Number of impacts . 9

4.2 Test apparatus . 9

4.2.1 Description . 9

4.2.2 Mounting . 10

4.3 Preconditioning . 10

4.4 Initial measurements . 10

4.5 Testing . 10

4.5.1 General . 10

4.5.2 Attitudes and impact locations . 11

4.5.3 Preparation of the specimen . 11

4.5.4 Operating mode and functional monitoring . 11

4.6 Recovery . 11

4.7 Final measurements . 11

4.8 Information to be given in the relevant specification . 11

5 Test Eha: Pendulum hammer . 12

5.1 Test apparatus . 12

5.1.1 General . 12

5.1.2 Test apparatus for severities not exceeding 1 J . 12

5.1.3 Test apparatus for severities of 2 J and above. 12

5.2 Height of fall . 12

5.3 Testing . 13

6 Test Ehb: Spring hammer . 13

6.1 Test apparatus . 13

6.2 Influence of earth's gravity . 14

6.3 Calibration . 14

7 Test Ehc: Vertical hammer . 14

7.1 Test apparatus . 14

7.2 Height of fall . 14

Annex A (normative) Shapes of striking elements . 15

Annex B (normative) Procedure for the calibration of spring hammers. 18

B.1 Principle of calibration . 18

B.2 Construction of the calibration device . 18

B.3 Method of calibration of the calibration device . 18

B.4 Use of the calibration device. 19

Annex C (informative) Guidance notes. 25

C.1 When is an impact test appropriate? . 25

C.2 Choice of test apparatus. 25

C.3 Choice of energy level . 25

C.4 Information for testing . 26

Annex D (informative) Example of pendulum hammer test apparatus . 27

Annex E (informative) Example of spring hammer test apparatus . 30

Bibliography . 32

Figure 1 – Example sketch of a striking element . 10

Figure 2 – Derivation of measuring point . 13

Figure 3 – Shape of release head for 2 J . 14

Figure A.1 – Example of a striking element for ≤ 1 J . 15

Figure A.2 – Example of a striking element for 2 J . 15

Figure A.3 – Example of a striking element for 5 J . 16

Figure A.4 – Example of a striking element for 10 J . 16

Figure A.5 – Example of a striking element for 20 J . 17

Figure A.6 – Example of a striking element for 50 J . 17

Figure B.1 – Calibration device . 20

Figure B.2 – Pendulum "c" . 21

Figure B.3 – Steel spring of pendulum "c" . 21

Figure B.4 – Details of calibration device . 22

Figure B.5 – Arrangement for the calibration of the calibration device . 23

Figure B.6 – Division of scale plate "f" . 24

Figure D.1 – Test apparatus . 27

Figure D.2 – Striking element of the pendulum hammer for energies ≤ 1 J . 28

Figure D.3 – Mounting fixture . 28

Figure D.4 – Adapter for flush-type switches . 29

Figure D.5 – Adapter for lamp holders . 29

Figure E.1 – Spring hammer test apparatus . 31

Table 1 – Coordinated characteristics of the striking elements . 9

Table 2 – Height of fall . 12

Table C.1 – Energy levels in joules . 25

Table E.1 – Kinetic energy of striking element . 30

– 4 – IEC 60068-2-75:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-75: Tests –

Test Eh: Hammer tests

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-75 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This second edition cancels and replaces the first edition, published in 1997, and constitutes a

technical revision.

This edition includes the following significant technical change with respect to the previous

edition:

– reconsideration of some values in Tables 1 and 2. Although some values are no longer

recommended, they have been retained as alternatives for historical consistency purposes.

It has the status of:a basic safety publication in accordance with IEC Guide 104.

The text of this standard is based on the following documents:

FDIS Report on voting

104/635/FDIS 104/637/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60068-2-75:2014 © IEC 2014

INTRODUCTION

Mechanical impacts likely to stress electrotechnical equipment in service can be generated by

hammers of various types. For standardization purposes, the results of such testing should not

depend on the type of testing apparatus and therefore, the characteristics of the various types

of test hammers described in this part of IEC 60068 are intended to be as close as practicable

for the same severity level.

It is important to note that both Clause 3 and the test method selected from Clauses 4, 5, and 6

need to be complied with in order to satisfy the requirements of this International Standard.

The severity levels are, in general, taken from IEC 60721-1.

For coordination purposes, it has been necessary to change certain fundamental parameters of

the previous tests Ef: Impact, pendulum hammer, and Eg: Impact, spring hammer. In all cases,

both sets of parameters are shown at the appropriate places in the text. Although some values

are no longer recommended, they have been retained as alternatives for historical consistency

purposes. This is because they have application in certain industries as historic comparators.

ENVIRONMENTAL TESTING –

Part 2-75: Tests –

Test Eh: Hammer tests

1 Scope

This part of IEC 60068 provides three standardized and coordinated test methods for

determining the ability of a specimen to withstand specified severities of impact. It is used, in

particular, to demonstrate an acceptable level of robustness when assessing the safety of a

product and is primarily intended for the testing of electrotechnical items. It consists of the

application to the specimen of a prescribed number of impacts defined by their impact energy

and applied in the prescribed directions.

This part of IEC 60068 covers energy levels ranging from 0,14 J (joules) to 50 J (joules).

Three types of test apparatus are applicable to perform these tests. Annex C provides some

guidance as to this aspect.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60721-1, Classification of environmental conditions – Part 1: Environmental parameters

and their severities

IEC Guide 104, The preparation of safety publications and the use of basic safety publications

and group safety publications

IEC Guide 108, Guidelines for ensuring the coherency of IEC publications – Application of

horizontal standards

ISO 1052, Steels for general engineering purposes

ISO 2039-2, Plastics – Determination of hardness – Part 2: Rockwell hardness

ISO 2041, Vibration and shock and condition monitoring – Vocabulary

ISO 2768-1, General tolerances – Part 1: Tolerances for linear and angular dimensions without

individual tolerances indications

ISO 6508 (all parts), Metallic materials – Rockwell hardness test

– 8 – IEC 60068-2-75:2014 © IEC 2014

3 Terms and definitions

For the purposes of this document, the terms and definitions used in ISO 2041 or in

IEC 60068-1, together with the following, apply.

3.1

combined mass of the striking element

sum of the masses of the striking element and of the element's fixing system

3.2

fixing point

part of the specimen in contact with the mounting fixture at the point where the specimen is

normally fastened in service

3.3

equivalent mass

mass of the striking element and any relevant portions of the test apparatus which, combined

with its velocity, provides the impact energy

Note 1 to entry: For the particular application to the pendulum hammer apparatus, mass of the simple pendulum

hammer calculated from the measure of the vertical force (in newtons) to be applied in the axis of the striking

element to maintain the arm of the pendulum in a horizontal position, divided by the earth's gravity. When the mass

of the arm is evenly distributed, the equivalent mass is equal to the sum of the combined mass of the striking

element plus half the mass of the arm.

3.4

measuring point

point marked on the surface of the striking element where the line through the point of

intersection of the axes of the arms of both of the pendulum and of the striking element, and

perpendicular to the plane through both axes, meets the surface (see Figure 2).

Note 1 to entry: In some IEC standards which include a pendulum hammer test, the term "checking point" has

been used but it has not been used here in order to avoid confusion with "check point " in other parts of IEC 60068-2.

Note 2 to entry: Theoretically, the centre of gravity of the striking element should be the measuring point. In

practice, the centre of gravity is either difficult to determine or inaccessible, and the measuring point is therefore

defined as above.

3.5

height of fall

vertical distance between the position of the measuring point when the pendulum is released

and its position at the moment of impact (see Figure D.1).

4 Provisions common to all hammer test methods

4.1 Severities

4.1.1 General

The severity is defined by the impact energy value chosen from 4.1.2, and the number of

impacts according to 4.1.3.

4.1.2 Impact energy value

The impact energy value shall be one of the following, as prescribed by the relevant

specification:

0,14 – 0,2 – (0,3) – 0,35 – (0,4) – 0,5 – 0,7 – 1 – 2 – 5 – 10 – 20 – 50 J (joules).

NOTE Figures in brackets appear in previous IEC 60068-2 standards, although no longer recommended, they may

be used for historic consistency.

4.1.3 Number of impacts

Unless otherwise prescribed by the relevant specification, the number of impacts shall be three

per location.

4.2 Test apparatus

4.2.1 Description

Three types of test apparatus are available to perform these tests:

– the pendulum hammer;

– the spring hammer;

– the vertical hammer.

The types of test apparatus are defined in Clauses 5, 6 and 7 as tests Eha, Ehb and Ehc,

respectively. The coordinated characteristics of the striking element are, in principle, similar in

all three cases and are stated in Table 1 in relation to the outline shown in Figure 1.

Dimensions are in millimetres. Tolerances are as per class m of ISO 2768-1, unless otherwise

stated.

Table 1 – Coordinated characteristics of the striking elements

≤1 2 5 10 20 50

Energy value

±10 % ±5 % ±5 % ±5 % ±5 % ±5 %

J

Equivalent

0,25 (0,2) 0,5 1,7 5 5 10

mass

±2 % kg

a b

Polyamide Steel

Material

10 25 25 50 50 50

R mm

D mm 18,5 (20) 35 60 80 100 125

f mm 6,2(10) 7 10 20 20 25

r mm – – 6 – 10 17

l mm To be adjusted to match the equivalent mass, see Annex A.

a

85 ≤ HRR ≤100, Rockwell hardness according to ISO 2039-2.

b

Fe 490-2, according to ISO 1052: Rockwell hardness: HRE 80.85 according to ISO 6508.

NOTE The values shown in brackets for the equivalent mass and the diameter of the striking element for the

energy value equal to or less than 1 J are those in the current test Ef. The values currently in test Eg are also

shown for these two parameters. Although, for coordination reasons, these values are no longer recommended,

they are used by some industries for historical comparison purposes.

– 10 – IEC 60068-2-75:2014 © IEC 2014

Axis of

r

striking

element

R

f l

IEC

Figure 1 – Example sketch of a striking element

The striking surface shall be visually examined before each impact in order to ensure that there

is no damage that might affect the result of the test.

4.2.2 Mounting

As prescribed by the relevant specification, the specimen shall either

a) be mounted by its normal means on a rigid plane support, or

b) be placed against a rigid plane support.

In order to ensure that the specimen is rigidly supported, it may be necessary when performing

the test to place the specimen against a plane solid support, for example a wall or a floor

made of brick or concrete, covered by a sheet of polyamide which is tightly fixed to the support.

Care shall be taken to ensure that there is no appreciable air gap between the sheet and the

support. The sheet shall have a Rockwell hardness of 85 ≤HRR ≤100 according to ISO 2039-2,

a thickness of approximately 8 mm and a surface area such that no parts of the specimen are

mechanically over-stressed due to the supporting area being insufficient.

The mounting arrangement is deemed to be sufficiently rigid if the displacement of the impact

surface of the plane support does not exceed 0,1 mm when struck by an impact applied directly

to it with the same level of energy as for the specimen.

NOTE 1 For specimens to be subjected to impact energies not exceeding 1 J, some examples of mounting and

support are shown in Figures D.3, D.4 and D.5.

NOTE 2 When the mass of the mounting is at least 20 times that of the specimen, the rigidity of the mounting is

likely to be sufficient.

4.3 Preconditioning

The relevant specification may call for preconditioning; it shall then prescribe the conditions.

4.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by the relevant specification.

4.5 Testing

4.5.1 General

Secondary impacts, i.e. rebounds, shall be avoided.

D

4.5.2 Attitudes and impact locations

The relevant specification shall prescribe the attitudes of the specimen and the locations on the

specimen corresponding to where damage is most likely to occur in practice and at which the

impacts are to be applied. Unless otherwise specified by the relevant specification, the blows

shall be applied perpendicularly to the tested surface.

4.5.3 Preparation of the specimen

The relevant specification shall state any requirements for the securing of bases, covers and

similar items before the specimen is subjected to the impacts.

NOTE Account may need to be taken of requirements for functional monitoring (see 4.5.4 b)).

4.5.4 Operating mode and functional monitoring

The relevant specification shall state:

a) whether the specimen is required to operate during impact;

b) whether any functional monitoring is required.

In both cases, the relevant specification shall provide the criteria upon which the acceptance or

rejection of the specimen is to be based.

NOTE Attention is drawn to the fact that, in case of breakage of the specimen, internal parts may become

hazardous.

4.6 Recovery

The relevant specification may call for recovery and shall then prescribe the conditions.

4.7 Final measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by the relevant specification.

The relevant specification shall prescribe the criteria upon which the acceptance or rejection of

the specimen is to be based.

4.8 Information to be given in the relevant specification

When one of the tests in this part of IEC 60068 is included in a relevant specification, the

following details shall be given as far as they are applicable, paying particular attention to the

items marked with an asterisk (*) as this information is always required:

Subclause

a) Impact energy * 4.1.2

b) Number of impacts, if other than three per location 4.1.3

c) Type(s) of test apparatus to be used 4.2.1

d) Method of mounting * 4.4.2

e) Preconditioning 4.3

f) Initial measurements* 4.4

g) Attitude and impact locations * 4.5.2

h) Securing of bases, covers and similar components 4.5.3

i) Operating mode and functional monitoring* 4.5.4

j) Acceptance and rejection criteria * 4.5.4 and 4.7

k) Conditions for recovery 4.6

– 12 – IEC 60068-2-75:2014 © IEC 2014

l) Final measurements* 4.7

5 Test Eha: Pendulum hammer

5.1 Test apparatus

5.1.1 General

The test apparatus consists basically of a pendulum rotating at its upper end in such a way as

to be kept in a vertical plane. The axis of the pivot is at 1 000 mm above the measuring point.

The pendulum is composed of a nominally rigid arm and of a striking element complying with

the requirements of Table 1.

For testing heavy, voluminous or difficult-to-handle specimens, a portable pendulum may be

used. It shall comply with the above description but its pivot may be fixed directly on the

specimen or on a movable structure. In this case, it shall be ensured that, before the tests, the

axis of the pendulum is horizontal, that its fixing is sufficiently rigid and that the impact point is

in the vertical plane passing through the axis.

In all cases, when the pendulum is released, it shall be allowed to fall only under the influence

of gravitational force.

5.1.2 Test apparatus for severities not exceeding 1 J

The striking element comprises a steel body with a polyamide insert having a hemispherical

face. Its combined mass is 200 g (150 g) ± 1 g so that the equivalent mass complies with

Table 1. Annex D gives an example of a test apparatus.

5.1.3 Test apparatus for severities of 2 J and above

The ratio of the mass of the arm to the combined mass of the striking element shall not be

greater than 0,2 and the centre of gravity of the striking element shall be as close as is

practicable to the axis of the arm.

For some particular applications, the pendulum arm is replaced by a cord and the striking

element by a spherical steel ball. This is not recommended as the ball does not conform to the

geometry of the striking element specified in this part of IEC 60068.

5.2 Height of fall

To produce impacts of the required severity, the striking element shall be released from a

height depending on the equivalent mass of the pendulum, according to Table 2.

Table 2 – Height of fall

Energy

0,14 0,2 (0,3) 0,35 (0,4) 0,5 0,7 1 2 5 10 20 50

J

Equivalent

mass 0,25 (0,2) 0,25 (0,2) 0,25 (0,2) (0,2) 0,25 0,25 0,25 0,5 1,7 5 5 10

kg

Height

of fall 56 (100) 80 (150) 140 (200) (250) 200 280 400 400 300 200 400 500

mm ± 1 %

NOTE 1 Figures in brackets appear in previous IEC 60068-2 standards; although no longer recommended, they

may be used for historic consistency.

NOTE 2 In this part of IEC 60068, the energy, J, is calculated taking the standard acceleration due to the earth's

gravity (g ), rounded up to the nearest whole number, that is 10 m/s .

n

5.3 Testing

In order to avoid secondary impacts, i.e. rebounds, the hammer shall be retained after the

initial impact by grasping the striking element whilst avoiding the arm so that distortion is

prevented.