IEC 62108:2007

(Main)Concentrator photovoltaic (CPV) modules and assemblies - Design qualification and type approval

Concentrator photovoltaic (CPV) modules and assemblies - Design qualification and type approval

Specifies the minimum requirements for the design qualification and type approval of concentrator photovoltaic modules and assemblies suitable for long-term operation in general open-air climates. The test sequence is partially based on that specified in IEC 61215. Determines the electrical, mechanical, and thermal characteristics of the CPV modules and assemblies and shows that the CPV modules and assemblies are capable of withstanding prolonged exposure in climates described in the scope.

Modules et ensembles photovoltaïques à concentration - Qualification de la conception et homologation

Spécifie les exigences minimales pour la qualification de la conception et l'homologation des modules et ensembles photovoltaïques à concentration pour une utilisation de longue durée dans les climats généraux d'air libre. La séquence d'essais est issue partiellement de celle spécifiée dans la CEI 61215. Détermine les caractéristiques électriques, mécaniques et thermiques des modules et ensembles CPV et montre que les modules et ensembles CPV sont aptes à supporter une exposition prolongée aux climats définis dans le domaine d'application.

General Information

- Status

- Published

- Publication Date

- 06-Dec-2007

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 7 - TC 82/WG 7

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 26-Sep-2016

- Completion Date

- 25-Nov-2016

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62108:2007 is an international standard developed by the International Electrotechnical Commission (IEC) specifically for concentrator photovoltaic (CPV) modules and assemblies. This standard defines the minimum requirements for design qualification and type approval to ensure CPV products are suitable for long-term operation in various general open-air climates. The testing procedures established within IEC 62108 evaluate electrical, mechanical, and thermal durability to ensure CPV modules and assemblies can withstand prolonged exposure to environmental stressors. The tests are partly based on requirements found in IEC 61215, the standard for traditional flat-plate photovoltaic modules, but tailored to the unique characteristics of CPV technologies.

Key Topics

Design Qualification

IEC 62108 specifies comprehensive design qualification tests that verify CPV modules’ durability and long-term performance. These tests assess resistance to environmental factors such as thermal cycling, damp heat, humidity freeze, and ultraviolet exposure.Type Approval

The standard outlines type approval criteria ensuring CPV modules and assemblies meet performance and safety benchmarks before entering the market. Approval validates conformity with IEC requirements and promotes international market acceptance.Test Procedures

Detailed test methodologies are addressed, including:- Visual Inspection for identifying major defects

- Electrical Performance Measurement through outdoor and simulated I-V (current-voltage) characteristics

- Mechanical Load Testing to confirm structural integrity under wind and snow loads

- Thermal Cycling and Damp Heat Tests to simulate extreme temperature and humidity conditions

- Hail Impact and Water Spray Testing for physical resistance assessment

- Ground Path Continuity and Electrical Insulation Tests to verify safety compliance

Pass Criteria and Reporting

IEC 62108 defines clear pass/fail criteria for each test to ensure consistent assessment. Test reports document results, modifications, and any relevant observations, providing transparency and traceability.

Applications

IEC 62108:2007 is essential for manufacturers, testing laboratories, certification bodies, and purchasers involved in the CPV industry. Its applications include:

Product Development

Manufacturers leverage IEC 62108 during the design phase to ensure their CPV modules and assemblies meet durability and performance standards before mass production.Certification and Quality Assurance

Independent testing laboratories use the standard’s test sequences to provide credible type approval certificates, which can be prerequisites for regulatory approvals or financial incentives.Procurement Specifications

Project developers and investors reference IEC 62108 compliance to specify and procure reliable CPV systems capable of sustained outdoor performance.Market Harmonization

Adoption of this standard promotes harmonization of quality and safety benchmarks internationally, facilitating cross-border trade and industry growth.

Related Standards

- IEC 61215 – Design qualification and type approval for terrestrial photovoltaic (PV) modules (flat-plate)

- IEC 61730 – Photovoltaic module safety qualification

- IEC 60904 – Photovoltaic device measurement methods

- ISO 14001 – Environmental management standards relevant to sustainable CPV manufacturing practices

Keywords

Concentrator photovoltaic (CPV), CPV modules, CPV assemblies, IEC 62108, design qualification, type approval, photovoltaic standard, solar power module testing, electrical performance, mechanical reliability, thermal durability, environmental testing, renewable energy standards, photovoltaic module certification, international photovoltaic standards.

Utilizing IEC 62108 ensures that concentrator photovoltaic technology meets rigorous international protocols, which guarantees sustained energy production, durable field operation, and enhanced safety in diverse climatic conditions. This standard remains a critical foundation for advancing CPV innovation and market acceptance worldwide.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62108:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Concentrator photovoltaic (CPV) modules and assemblies - Design qualification and type approval". This standard covers: Specifies the minimum requirements for the design qualification and type approval of concentrator photovoltaic modules and assemblies suitable for long-term operation in general open-air climates. The test sequence is partially based on that specified in IEC 61215. Determines the electrical, mechanical, and thermal characteristics of the CPV modules and assemblies and shows that the CPV modules and assemblies are capable of withstanding prolonged exposure in climates described in the scope.

Specifies the minimum requirements for the design qualification and type approval of concentrator photovoltaic modules and assemblies suitable for long-term operation in general open-air climates. The test sequence is partially based on that specified in IEC 61215. Determines the electrical, mechanical, and thermal characteristics of the CPV modules and assemblies and shows that the CPV modules and assemblies are capable of withstanding prolonged exposure in climates described in the scope.

IEC 62108:2007 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62108:2007 has the following relationships with other standards: It is inter standard links to IEC 62108:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62108:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62108

Edition 1.0 2007-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Concentrator photovoltaic (CPV) modules and assemblies – Design qualification

and type approval

Modules et ensembles photovoltaïques à concentration – Qualification de la

conception et homologation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62108

Edition 1.0 2007-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Concentrator photovoltaic (CPV) modules and assemblies – Design qualification

and type approval

Modules et ensembles photovoltaïques à concentration – Qualification de la

conception et homologation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 27.160 ISBN 2-8318-9430-1

– 2 – 62108 © IEC:2007

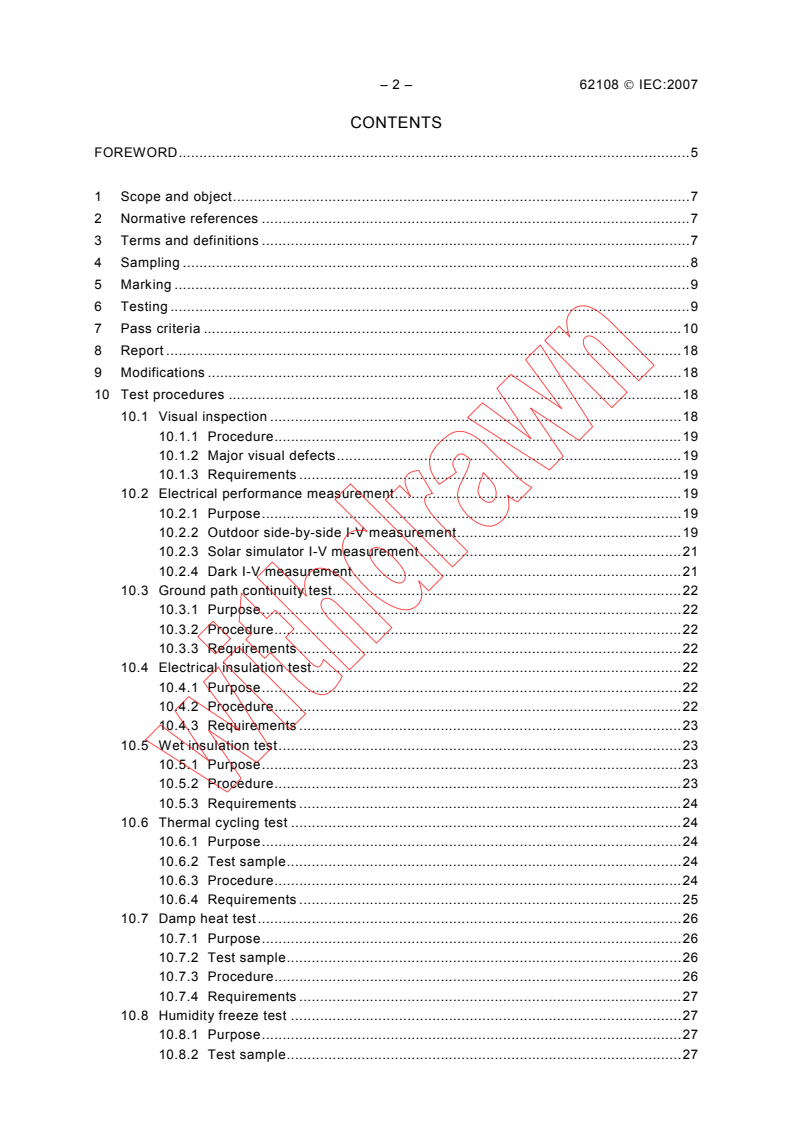

CONTENTS

FOREWORD.5

1 Scope and object.7

2 Normative references .7

3 Terms and definitions .7

4 Sampling .8

5 Marking .9

6 Testing .9

7 Pass criteria .10

8 Report .18

9 Modifications .18

10 Test procedures .18

10.1 Visual inspection .18

10.1.1 Procedure.19

10.1.2 Major visual defects.19

10.1.3 Requirements .19

10.2 Electrical performance measurement.19

10.2.1 Purpose.19

10.2.2 Outdoor side-by-side I-V measurement.19

10.2.3 Solar simulator I-V measurement.21

10.2.4 Dark I-V measurement.21

10.3 Ground path continuity test.22

10.3.1 Purpose.22

10.3.2 Procedure.22

10.3.3 Requirements .22

10.4 Electrical insulation test.22

10.4.1 Purpose.22

10.4.2 Procedure.22

10.4.3 Requirements .23

10.5 Wet insulation test.23

10.5.1 Purpose.23

10.5.2 Procedure.23

10.5.3 Requirements .24

10.6 Thermal cycling test .24

10.6.1 Purpose.24

10.6.2 Test sample.24

10.6.3 Procedure.24

10.6.4 Requirements .25

10.7 Damp heat test.26

10.7.1 Purpose.26

10.7.2 Test sample.26

10.7.3 Procedure.26

10.7.4 Requirements .27

10.8 Humidity freeze test .27

10.8.1 Purpose.27

10.8.2 Test sample.27

62108 © IEC:2007 – 3 –

10.8.3 Procedure.27

10.8.4 Requirements .27

10.9 Hail impact test .28

10.9.1 Purpose.28

10.9.2 Apparatus.28

10.9.3 Procedure.28

10.9.4 Requirements .29

10.10 Water spray test .29

10.10.1 Purpose .29

10.10.2 Procedure.29

10.10.3 Requirements .30

10.11 Bypass/blocking diode thermal test.30

10.11.1 Purpose .30

10.11.2 Test sample .30

10.11.3 Apparatus .30

10.11.4 Procedure.30

10.11.5 Requirements .31

10.12 Robustness of terminations test.31

10.12.1 Purpose .31

10.12.2 Types of terminations .31

10.12.3 Procedure.31

10.12.4 Requirements .32

10.13 Mechanical load test.32

10.13.1 Purpose .32

10.13.2 Procedure.32

10.13.3 Requirements .33

10.14 Off-axis beam damage test.33

10.14.1 Purpose .33

10.14.2 Special case .33

10.14.3 Procedure.33

10.14.4 Requirements .34

10.15 Ultraviolet conditioning test .34

10.15.1 Purpose .34

10.15.2 Procedure.34

10.16 Outdoor exposure test .34

10.16.1 Purpose .34

10.16.2 Procedure.34

10.16.3 Requirements .35

10.17 Hot-spot endurance test .35

Annex A (informative) Summary of test conditions and requirements .36

Bibliography.38

Figure 1 – Schematic of point-focus dish PV concentrator.11

Figure 2 – Schematic of linear-focus trough PV concentrator .12

Figure 3 – Schematic of point-focus Fresnel lens PV concentrator .13

Figure 4 – Schematic of linear-focus Fresnel lens PV concentrator .14

– 4 – 62108 © IEC:2007

Figure 5 – Schematic of a heliostat CPV .15

Figure 6 – Qualification test sequence for CPV modules .16

Figure 7 – Qualification test sequence for CPV assemblies.17

Figure 8 – Temperature and current profile of thermal cycle test (not to scale) .26

Figure 9 – Profile of humidity-freeze test conditions.28

Table 1 – Terms used for CPVs .8

Table 2 – Allocation of test samples to typical test sequences .10

Table 3 – Thermal cycle test options for sequence A .25

Table 4 – Pre-thermal cycle test options for sequence B.27

Table 5 – Humidity freeze test options for sequence B.27

62108 © IEC:2007 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

CONCENTRATOR PHOTOVOLTAIC (CPV) MODULES AND ASSEMBLIES –

DESIGN QUALIFICATION AND TYPE APPROVAL

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62108 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

The text of this standard is based on the following documents:

FDIS Report on voting

82/494/FDIS 82/504/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 62108 © IEC:2007

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

62108 © IEC:2007 – 7 –

CONCENTRATOR PHOTOVOLTAIC (CPV) MODULES AND ASSEMBLIES –

DESIGN QUALIFICATION AND TYPE APPROVAL

1 Scope and object

This International Standard specifies the minimum requirements for the design qualification

and type approval of concentrator photovoltaic (CPV) modules and assemblies suitable for

long-term operation in general open-air climates as defined in IEC 60721-2-1. The test

sequence is partially based on that specified in IEC 61215 for the design qualification and

type approval of flat-plate terrestrial crystalline silicon PV modules. However, some changes

have been made to account for the special features of CPV receivers and modules,

particularly with regard to the separation of on-site and in-lab tests, effects of tracking

alignment, high current density, and rapid temperature changes, which have resulted in the

formulation of some new test procedures or new requirements.

The object of this test standard is to determine the electrical, mechanical, and thermal

characteristics of the CPV modules and assemblies and to show, as far as possible within

reasonable constraints of cost and time, that the CPV modules and assemblies are capable of

withstanding prolonged exposure in climates described in the scope. The actual life of CPV

modules and assemblies so qualified will depend on their design, production, environment,

and the conditions under which they are operated.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 61215:2005, Crystalline silicon terrestrial photovoltaic (PV) modules – Design

qualification and type approval

ISO/IEC 17025:2005, General requirements for the competence of testing and calibration

laboratories

ANSI/UL 1703 ed.3 March 15, 2002: Flat-Plate Photovoltaic Modules and Panels

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

concentrator

term associated with photovoltaic devices that use concentrated sunlight

3.2

concentrator cell

basic photovoltaic device that is used under the illumination of concentrated sunlight

3.3

concentrator optics

optical device that performs one or more of the following functions from its input to output:

increasing the light intensity, filtering the spectrum, modifying light intensity distribution, or

changing light direction. Typically, it is a lens or a mirror. A primary optics receives

unconcentrated sunlight directly from the sun. A secondary optics receives concentrated or

modified sunlight from another optical device, such as primary optics or another secondary

optics.

– 8 – 62108 © IEC:2007

3.4

concentrator receiver

group of one or more concentrator cells and secondary optics (if present) that accepts

concentrated sunlight and incorporates the means for thermal and electric energy transfer. A

receiver could be made of several sub-receivers. The sub-receiver is a physically stand-

alone, smaller portion of the full-size receiver.

3.5

concentrator module

group of receivers, optics, and other related components, such as interconnection and

mounting, that accepts unconcentrated sunlight. All of the above components are usually

prefabricated as one unit, and the focus point is not field adjustable. A module could be made

of several sub-modules. The sub-module is a physically stand-alone, smaller portion of the

full-size module.

3.6

concentrator assembly

group of receivers, optics, and other related components, such as interconnection and

mounting, that accepts unconcentrated sunlight. All of the above components would usually

be shipped separately and need some field installation, and the focus point is field adjustable.

An assembly could be made of several sub-assemblies. The sub-assembly is a physically

stand-alone, smaller portion of the full-size assembly.

3.7

representative samples for CPV

see details in Clause 4

Figures from Figures 1 to 5 are schematics of cells, receivers, modules, and assemblies.

Table 1 – Terms used for CPVs

Primary optics

Secondary optics

CPV Module – prefabricated and

the focus point is not field

CPV cells

adjustable, similar to most

CPV

Fresnel lens systems.

Electric energy

receiver

transfer means

CPV Assembly – needs some

Thermal energy

field installation and the focus

transfer means

point is field adjustable, similar to

most reflective systems.

Interconnection

Mounting

4 Sampling

For non-field-adjustable focus-point CPV systems or modules, 7 modules and 2 receivers are

required to complete all the specified tests, plus one receiver for the bypass/blocking diode

thermal test (intrusive or non-intrusive). For details, see Figure 6. For field-adjustable focus-

point CPV systems or assemblies, 9 receivers (including secondary optics sections, if

applicable) and 7 primary optics sections are required to complete all the specified tests, plus

one receiver for the bypass/blocking diode thermal test (intrusive or non-intrusive). For details,

see Figure 7.

In the case that a full-size module or assembly is too large to fit into available testing

equipment, such as environmental chambers, or a full-size module or assembly is too

expensive (e.g., for a 20 kW reflective dish concentrator system, 9 receiver samples account

for 180 kW of PV cells), a smaller representative sample may be used. However, even if

representative samples are used for the other test, a full-size module or assembly should be

installed and tested for outdoor exposure. This can be conducted either in the testing lab, or

through on-site witness.

62108 © IEC:2007 – 9 –

Representative samples should include all components, except some repeated parts. If

possible, the representative samples should use sub-receivers, sub-modules, or sub-

assemblies. During the design and manufacturing of the representative samples, much

attention should be paid to reach the maximum similarity to the full-size component in all

electrical, mechanical, and thermal characteristics related to quality and reliability.

Specifically, the cell string in representative samples should be long enough to include at

least two bypass diodes, but in no case less than ten cells. The encapsulations, interconnects,

terminations, and the clearance distances around all edges should be the same as on the

actual full-size products. Other representative components, including lens/housing joints,

receiver/housing joints, and end plate/lens should also be included and tested.

Test samples should be taken at random from a production batch or batches. When the

samples to be tested are prototypes of a new design and not from production, or

representative samples are used, these facts should be noted in the test report (see Clause 8).

The test samples should have been manufactured from specified materials and components in

accordance with the relevant drawings and process instructions and should have been

subjected to the manufacturer’s normal inspection, quality control, and production acceptance

procedures. They should be complete in every detail and should be accompanied by the

manufacturer’s handling, mounting, connection, and operation manuals. Samples should not

be subjected to other special procedures that are not a part of standard production.

If the intrusive bypass/blocking diode thermal test is to be performed, an additional specially

manufactured receiver is required with extra electrical and thermal detector leads so that each

individual diode can be accessed separately.

5 Marking

Each receiver or module section should carry the following clear and indelible markings:

– name, monogram, or symbol of manufacturer;

– type or model number;

– serial number;

– polarity of terminals or leads (color coding is permissible);

– maximum system voltage for which the module or assembly is suitable;

– nominal maximum output power and its tolerance at specified condition;

– the date, place of manufacture, and cell materials should be marked, or be traceable from

the serial number.

If representative samples are used, the same markings as on full-size products should be

included for all tests, and the marking should be capable of surviving all test sequences.

6 Testing

Before beginning the testing, all testing samples, including the control module and control

receiver, should be exposed to the direct normal irradiation (DNI) of sunlight (either natural or

simulated) for a total of 5 to 5,5 kWh/m while open-circuited. This procedure is designed to

reduce the initial photon degradation effects.

In this standard, short-circuit current I , open-circuit voltage V , maximum output power P ,

sc oc m

and other measures are all based on DNI 900 W/m , cell temperature 25 °C, spectrum at Air

Mass 1,5D (under consideration), and wind speed 3 m/s. A formal Concentrator Standard Test

Condition (CSTC) definition will be given in a future IEC CPV standard, which is under

consideration.

The test samples should be randomly divided into groups and subjected to the qualification

test sequences in Figure 6 or Figure 7. Test procedures and requirements are detailed in

Clause 10, and summarized in Annex A. The allocation of test samples to typical test

sequences is given in Table 2.

– 10 – 62108 © IEC:2007

After initial tests and inspections, one module or one receiver/mirror section should be

removed from the test sequence as a control unit. Preferably, the control unit should be

stored in the dark at room temperature to reduce the electrical performance degradation, but

it may be kept outdoors with a dark cover. As shown in Figure 6 for modules or in Figure 7 for

assemblies, the test sequence is performed both in-lab and on-site. If the distance between

these two locations is considerable or public shipping companies are involved, a dark current-

voltage (I-V) curve measurement before and after the shipping should be performed to

evaluate any possible changes on testing samples.

If a particular manufacturer produces only specific components, such as receivers, lenses, or

mirrors, the design qualification and type approval testing may be conducted only on

applicable test sequences, and a partial certification can be issued independently.

If some test procedures in this standard are not applicable to a specific design configuration,

the manufacturer should discuss this with the certifying body and testing agency to develop a

comparable test program, based on the principles described in this standard. Any changes

and deviations shall be recorded and reported in details, as required in Clause 8, item j).

Table 2 – Allocation of test samples to typical test sequences

Module Assembly

Test

sequence

receiver module receiver mirror

Control 1 1 1

A 2 2

B 2 2 2

C 2 2 2

D 1 1 1

E 1 (full-size) 1 (full-size) 1 (full-size)

F 1 1

Total 3 7 10 7

7 Pass criteria

A concentrator photovoltaic module or assembly design should be judged to have passed the

qualification tests, and therefore to be IEC 62108 type approved, if each test sample meets all

the following criteria:

a) the relative power degradation in sequences A to D does not exceed 13 % if the I-V

measurement is under outdoor natural sunlight, or 8 % if the I-V measurement is under

solar simulator;

b) the relative power degradation in sequence E does not exceed 7 % for natural sunlight I-V

measurement, or 5 % for solar simulator I-V measurement, because the 1 000 kWh/m DNI

outdoor exposure and 50 kWh/m ultraviolet (UV) tests are not an accelerated stress test;

c) no sample has exhibited any open circuit during the tests;

d) there is no visual evidence of a major defect, as defined in 10.1.2;

e) the insulation test requirements are met at the beginning and the end of each sequence;

f) the wet leakage current test requirements are met at the beginning and the end of each

sequence;

g) specific requirements of the individual tests are met.

If there are some failures observed during the test, the following judgment and re-test

procedure should apply:

h) if two or more test samples do not meet pass criteria, the design shall be deemed not to

have met the qualification requirements;

62108 © IEC:2007 – 11 –

i) should one sample fail any test, another two samples meeting the requirements of

Clause 4 could be subjected to the whole of the relevant test sequence from the beginning;

j) in case i), if both samples pass the test sequence, the design should be judged to have

met the qualification requirements;

k) in case i), if one or both of these samples also fail, the design shall be deemed not to

have met the qualification requirements;

l) in case h) or k), the entire test program illustrated in Figure 6 or Figure 7 should be re-

performed, usually after some design or processing improvement.

Assembly

Primary

optics

Cooling

tubes

Receiver

Secondary

optics mirrors

Solar

Sub-receiver

cell

IEC 2263/07

Figure 1 – Schematic of point-focus dish PV concentrator

– 12 – 62108 © IEC:2007

Assembly

Heat sink

Receiver

Solar cell

IEC 2264/07

Figure 2 – Schematic of linear-focus trough PV concentrator

62108 © IEC:2007 – 13 –

Modules

Array

Tracker

mechanism

Rear view

Fresnel lens

parquets

Module

Primary (300X)

Fresnel lens

Solar cell

Reflective

Insulated

secondary

electrode

Solar cell

Receiver

Module

back

Heat

spreader

IEC 2265/07

Figure 3 – Schematic of point-focus Fresnel lens PV concentrator

– 14 – 62108 © IEC:2007

Module

Fresnel

lens

Cross-section

Solar cell

Heat

spreader

Receiver

Solar cell

receiver

IEC 2266/07

Figure 4 – Schematic of linear-focus Fresnel lens PV concentrator

62108 © IEC:2007 – 15 –

Cooling fins

and fans

Receiver

Solar cells

Assembly

Primary

optics

IEC 2267/07

Figure 5 – Schematic of a heliostat CPV

– 16 – 62108 IEC:2007

©

START

Visual 10.1 7 modules (labelled as "m") and 2 receivers "r", at least one in full size, are required;

7m +2r 1 receiver specially constructed for intrusive bypass/blocking diode thermal test, when required.

Elec. Perf. SBS 10.2

On-site testing In-lab testing Sequence F

7m +2r 1r

Elec. Perf. Dark 10.2 If long distance shipping is involved, Elec. Perf. Dark 10.2

5m + 2r use dark IV to evaluate any changes 5m + 2r Bypass/blocking

Ground continuity 10.3 Diode 1r 10.11

2m Ground continuity 10.3

5m + 2r

Dry/Wet Insul 10.4

2m 10.5 Dry/Wet Insul 10.4

Control 5m + 2r 10.5

1m Sequence D

Sequence E 1m

1m (full size)

Mechanical Load 10.13

Outdoor/UV 10.16 1m

1m 10.15

Sequence A Sequence B Sequence C Terminations 10.12

Water Spray 10.10 2r 2m 2m 1m

1m

Thermal Cycle 10.6 Pre-thermal cycle 10.6 Damp Heat 10.7 Hail Impact 10.9

Off-Axis Beam 10.14 2r 2m 2m 1m

1m

Bypass Diode 10.11 Humidity Freeze 10.8 Hot-Spot 10.17

Ground continuity 10.3 non-intrusive, 1r 2m 1m

1m

Elec. Perf. Dark 10.2 If long distance shipping is involved, Ground continuity 10.3

5m + 2r use dark IV to evaluate any changes 5m + 2r

Elec. Perf. SBS

7m +2r 10.2 Elec. Perf. Dark 10.2

5m + 2r

Visual On-site testing In-lab testing

7m +2r 10.1

IEC 2268/07

END

Figure 6 – Qualification test sequence for CPV modules

62108 IEC:2007 – 17

©

START

Visual 10.1 9 receivers (labelled as "r") and 7 mirrors (labelled as "mir"), at least 1 pair in full size, are required;

9r + 7mir 1 receiver specially constructed for intrusive bypass diode thermal test, when required.

Elec. Perf. SBS 10.2 On-site testing In-lab testing Sequence F

9r + 7mir 1r

Elec. Perf. Dark 10.2 If long distance shipping is involved, Elec. Perf. Dark 10.2

7r + 5mir use dark IV to evaluate any changes 7r + 5mir Bypass/blocking

Ground continuity 10.3 Diode 1r 10.11

2r + 2mir Ground continuity 10.3

7r + 5mir

Dry/Wet Insul 10.4

2r + 2mir 10.5 Dry/Wet Insul 10.4

Control 7r + 5mir 10.5

1r + 1mir Sequence D

Sequence E 1r + 1mir

1r + 1mir (full size)

Mechanical Load 10.13

Outdoor/UV 10.16 1r + 1mir

1r + 1mir 10.15

Sequence A Sequence B Sequence C Terminations 10.12

Water Spray 10.10 2r 2r + 2mir 2r + 2mir 1r + 1mir

1r + 1mir

Thermal Cycle 10.6 Pre-thermal cycle 10.6 Damp Heat 10.7 Hail Impact 10.9

Off-Axis Beam 10.14 2r 2r + 2mir 2r + 2mir 1r + 1mir

1r + 1mir

Bypass Diode 10.11 Humidity Freeze 10.8 Hot-Spot 10.17

Ground continuity 10.3 non-intrusive, 1r 2r + 2mir 1r + 1mir

1r + 1mir

Elec. Perf. Dark 10.2 If long distance shipping is involved, Ground continuity 10.3

7r + 5mir use dark IV to evaluate any changes 7r + 5mir

Elec. Perf. SBS

9r + 7mir 10.2 Elec. Perf. Dark 10.2

7r + 5mir

Visual On-site testing In-lab testing

9r + 7mir 10.1

IEC 2269/07

END

Figure 7 – Qualification test sequence for CPV assemblies

– 18 – 62108 © IEC:2007

8 Report

Following type approval, a certified report of the qualification tests, with measured

performance characteristics and details of any failures and re-tests, should be prepared by

the test agency in accordance with ISO/IEC 17025. Each test report should include at least the

following information:

a) a title;

b) the name and address of the laboratory, and the location where the tests were carried out,

if different from the address of the laboratory (such as on-site location);

c) unique identification of the test report (such as the serial number), and on each page an

identification to ensure that the page is recognized as a part of the test report, and a clear

identification of the end of the test report;

d) name and address of client, where appropriate;

e) description and identification of the item tested;

f) characterization and condition of the test item;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to, or exclusions from the test method, and any other

information relevant to a specific tests, such as environmental conditions;

k) measurements, examinations, and derived results supported by tables, graphs, sketches,

and photographs as appropriate, including short-circuit current, open-circuit voltage,

maximum output power, maximum power loss observed after all of the tests, and any

failures observed;

l) a statement of the estimated uncertainty of the test results, where relevant;

m) a signature and title, or equivalent identification, of the person(s) accepting responsibility

for the content of the report, and the date of issue;

n) where relevant, a statement to the effect that the results relate only to the items tested;

o) a statement that to maintain the qualification and type approval, the manufacturer shall

report to and discuss with the certifying body and testing agency every change they made;

p) a statement that the report shall not be reproduced except in full, without the written

approval of the laboratory.

A copy of this report should be kept by the manufacturer for reference purposes.

9 Modifications

Any changes in design, materials, components, or processing of the modules and assemblies

may require a repetition of some or all of the qualification tests to maintain type approval.

Manufacturers shall report to and discuss with the certifying body and testing agency every

change they made.

10 Test procedures

10.1 Visual inspection

This procedure provides the requirements for obtaining baseline, intermediate, and final visual

inspections to identify and determine any physical changes or defects in module or assembly

construction at the beginning and after the completion of each required test.

Any hardware showing initial damage not due to the manufacturing process should be

rejected if it may worsen and lead to failure during the subsequent environmental tests. A new

module or assembly may then be substituted before beginning the test sequence.

62108 © IEC:2007 – 19 –

10.1.1 Procedure

All test samples should be thoroughly inspected and photographed when necessary. All

defects or abnormalities (including initial defects related to the quality of solder joints such as

inadequate or excessive solder, solder balls, bent interconnects, or misalignment of parts)

should be documented with appropriate sketches or photographs to show the locations of the

defects. Components, such as the lens, mirror, secondary optical elements, heat spreaders,

and encapsulants, should also be inspected for defects. Specifically, inspect for:

a) bubbles, delamination, or any kind of similar defect on the cell and around its edges;

b) damage incurred during shipping and handling, such as cracked lenses, cracked or bent

housings, and bent terminals or mounting brackets;

c) integrity of the seal around the lens and housing joints. Any crack or gap in sealant

materials should be noted;

d) any ventilation hole or breather must not be clogged;

e) provision for grounding all accessible conductive parts;

f) broken, cracked, bent, misaligned, or torn external surfaces;

g) faulty interconnections or joints;

h) visible corrosion of output connections, interconnections, and bus bars;

i) failure of adhesive bonds;

j) tacky surfaces of plastic materials;

k) faulty terminations, or exposed live electrical parts;

l) any other conditions that may affect reliability or performance.

10.1.2 Major visual defects

For the purpose of design qualification and type approval, the following are considered to be

major visual defects:

a) broken, cracked, bent, misaligned, or torn external surfaces, including lens, mirror,

receiver body, frame, and junction box;

b) broken or cracked cells;

c) bubbles or delamination forming a continuous path between any part of the electrical

circuit and the edge of the receiver;

d) visible corrosion of any of the active circuitry of the sample;

e) adhesive or sealant failures;

f) loss of mechanical integrity, to the extent that the installation and/or operation of the

modules or assemblies would be impaired.

10.1.3 Requirements

No major visual defects.

10.2 Electrical performance measurement

10.2.1 Purpose

The purpos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...