IEC TS 61724-2:2025

(Main)Photovoltaic system performance - Part 2: Power performance index and capacity evaluation method

Photovoltaic system performance - Part 2: Power performance index and capacity evaluation method

IEC TS 61724-2:2025 applies to grid-connected PV systems comprising at least one inverter.

The test evaluates the PV system only in conditions where output is unconstrained by limitations in AC power output from the inverters. This document defines a test of a PV system's power performance index (PPI). PPI, defined in IEC 61724‑1, is the ratio of a system's measured power output under test conditions to its expected output at those conditions based on the system's design.

The test is intended to be performed over a short period of typically three to five days and is typically used to satisfy a contractual performance guarantee as part of the final completion of a PV power plant. This second edition cancels and replaces the first edition published in 2016. This edition includes the following significant technical changes with respect to the previous edition:

a) Adapting the document for bifacial PV systems, in accordance with the latest edition of IEC 61724‑1 and current industry practices.

b) Adapting the test procedure to account for the limited times of unconstrained system operation which are now common because of high DC-to-AC ratios (clipping) and interconnection limits (curtailment).

c) Adapting the test procedure to achieve a test that can be performed in a short time of three to five days during favourable conditions.

d) Focusing the document more heavily on the use of modern PV system modelling software to obtain the expected performance of the system under test.

e) Simplifying the mathematical procedure for calculating the test results.

f) Clearly identifying test elections (optional choices to be made in conducting the test) and providing a template for documenting these elections.

g) Clarifying the discussion of the test boundary that separates tested variables from untested variables.

h) Expanding and clarifying the discussion of data filtering.

General Information

- Status

- Published

- Publication Date

- 21-Sep-2025

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 3 - TC 82/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Sep-2025

- Completion Date

- 05-Sep-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 61724-2:2025 - "Photovoltaic system performance - Part 2: Power performance index and capacity evaluation method" defines a standardized short-duration test to determine a grid‑connected PV system’s Power Performance Index (PPI). PPI (defined in IEC 61724‑1) is the ratio of a system’s measured power output under test conditions to its expected output based on the system design. The test is intended for systems with at least one inverter and is performed over a short period (typically three to five days) using only periods when output is unconstrained by inverter clipping or curtailment.

This second edition (2025) updates the method for modern industry conditions - including bifacial PV, high DC/AC ratios (clipping), interconnection limits (curtailment), emphasis on modern PV modelling software, simplified calculations, explicit test elections, clearer test boundaries, and expanded data filtering guidance.

Key topics and technical requirements

- Scope and test boundary: Limits the test to times when inverters are maximum‑power‑point tracking and AC output is unconstrained.

- PPI calculation: Ratio of measured to expected power under the same conditions; procedure simplified in this edition.

- Short test schedule: Designed to be completed in 3–5 days during favourable conditions.

- Measurement equipment: Requirements and choices for POA irradiance sensors, PV cell temperature, and electrical power measurement.

- Performance models: Strong focus on modern PV system modelling software to predict expected power (multiple model options described).

- Bifacial systems: Adaptations for bifacial irradiance and rear-side contributions.

- Clipping and curtailment: Procedures to handle limited windows of unconstrained operation common with high DC/AC ratios and interconnection limits.

- Data filtering and quality control: Detailed criteria for data filtering, invalid readings, synchronization, non‑linear conditions, and multiple sensors.

- Other technical topics: Soiling assessment, tracker behavior, partial shading, plant modifications, multiple plant sections.

- Test elections & documentation: Clearly identified optional choices and a template for documenting them; standardized test reporting.

Practical applications and users

- Used primarily for capacity tests or contractual performance guarantees during final commissioning of PV power plants.

- Typical users:

- EPC contractors and plant developers validating handover performance

- Owners and operators assessing delivered capacity

- O&M teams and independent testing labs performing contract or warranty tests

- financiers and certifiers requiring standardized, short-term performance verification

- Benefits: provides a consistent, industry‑aligned method to validate delivered power capacity quickly and reproducibly using modern modelling tools.

Related standards

- IEC 61724‑1: Monitoring - defines PPI and monitoring terminology referenced by this TS.

- IEC TS 61724‑3: Energy performance evaluation method - for longer‑term or constrained operation energy assessments.

Keywords: IEC TS 61724-2, PPI, power performance index, capacity test, photovoltaic system performance, bifacial PV, clipping, curtailment, PV modelling, data filtering.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 61724-2:2025 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic system performance - Part 2: Power performance index and capacity evaluation method". This standard covers: IEC TS 61724-2:2025 applies to grid-connected PV systems comprising at least one inverter. The test evaluates the PV system only in conditions where output is unconstrained by limitations in AC power output from the inverters. This document defines a test of a PV system's power performance index (PPI). PPI, defined in IEC 61724‑1, is the ratio of a system's measured power output under test conditions to its expected output at those conditions based on the system's design. The test is intended to be performed over a short period of typically three to five days and is typically used to satisfy a contractual performance guarantee as part of the final completion of a PV power plant. This second edition cancels and replaces the first edition published in 2016. This edition includes the following significant technical changes with respect to the previous edition: a) Adapting the document for bifacial PV systems, in accordance with the latest edition of IEC 61724‑1 and current industry practices. b) Adapting the test procedure to account for the limited times of unconstrained system operation which are now common because of high DC-to-AC ratios (clipping) and interconnection limits (curtailment). c) Adapting the test procedure to achieve a test that can be performed in a short time of three to five days during favourable conditions. d) Focusing the document more heavily on the use of modern PV system modelling software to obtain the expected performance of the system under test. e) Simplifying the mathematical procedure for calculating the test results. f) Clearly identifying test elections (optional choices to be made in conducting the test) and providing a template for documenting these elections. g) Clarifying the discussion of the test boundary that separates tested variables from untested variables. h) Expanding and clarifying the discussion of data filtering.

IEC TS 61724-2:2025 applies to grid-connected PV systems comprising at least one inverter. The test evaluates the PV system only in conditions where output is unconstrained by limitations in AC power output from the inverters. This document defines a test of a PV system's power performance index (PPI). PPI, defined in IEC 61724‑1, is the ratio of a system's measured power output under test conditions to its expected output at those conditions based on the system's design. The test is intended to be performed over a short period of typically three to five days and is typically used to satisfy a contractual performance guarantee as part of the final completion of a PV power plant. This second edition cancels and replaces the first edition published in 2016. This edition includes the following significant technical changes with respect to the previous edition: a) Adapting the document for bifacial PV systems, in accordance with the latest edition of IEC 61724‑1 and current industry practices. b) Adapting the test procedure to account for the limited times of unconstrained system operation which are now common because of high DC-to-AC ratios (clipping) and interconnection limits (curtailment). c) Adapting the test procedure to achieve a test that can be performed in a short time of three to five days during favourable conditions. d) Focusing the document more heavily on the use of modern PV system modelling software to obtain the expected performance of the system under test. e) Simplifying the mathematical procedure for calculating the test results. f) Clearly identifying test elections (optional choices to be made in conducting the test) and providing a template for documenting these elections. g) Clarifying the discussion of the test boundary that separates tested variables from untested variables. h) Expanding and clarifying the discussion of data filtering.

IEC TS 61724-2:2025 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 61724-2:2025 has the following relationships with other standards: It is inter standard links to IEC TS 61724-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 61724-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 61724-2 ®

Edition 2.0 2025-09

TECHNICAL

SPECIFICATION

Photovoltaic system performance -

Part 2: Power performance index and capacity evaluation method

ICS 27.160 ISBN 978-2-8327-0656-5

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

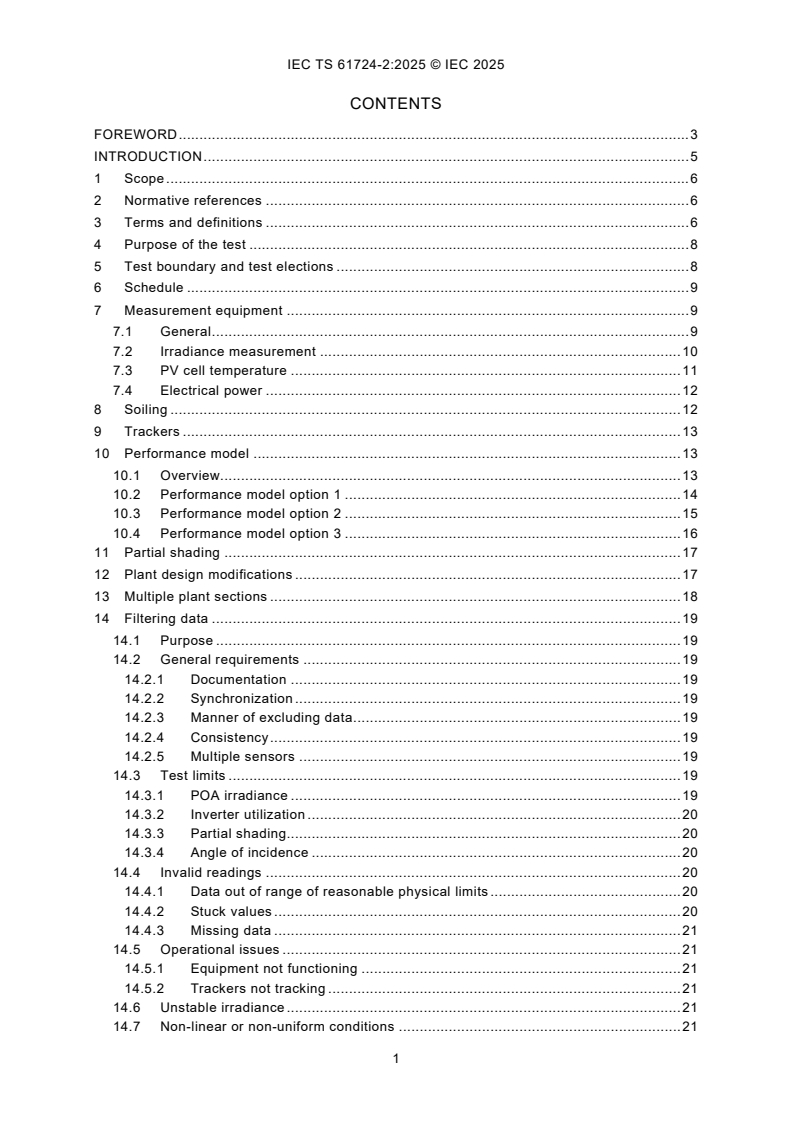

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Purpose of the test . 8

5 Test boundary and test elections . 8

6 Schedule . 9

7 Measurement equipment . 9

7.1 General . 9

7.2 Irradiance measurement . 10

7.3 PV cell temperature . 11

7.4 Electrical power . 12

8 Soiling . 12

9 Trackers . 13

10 Performance model . 13

10.1 Overview. 13

10.2 Performance model option 1 . 14

10.3 Performance model option 2 . 15

10.4 Performance model option 3 . 16

11 Partial shading . 17

12 Plant design modifications . 17

13 Multiple plant sections . 18

14 Filtering data . 19

14.1 Purpose . 19

14.2 General requirements . 19

14.2.1 Documentation . 19

14.2.2 Synchronization . 19

14.2.3 Manner of excluding data . 19

14.2.4 Consistency . 19

14.2.5 Multiple sensors . 19

14.3 Test limits . 19

14.3.1 POA irradiance . 19

14.3.2 Inverter utilization . 20

14.3.3 Partial shading. 20

14.3.4 Angle of incidence . 20

14.4 Invalid readings . 20

14.4.1 Data out of range of reasonable physical limits . 20

14.4.2 Stuck values . 20

14.4.3 Missing data . 21

14.5 Operational issues . 21

14.5.1 Equipment not functioning . 21

14.5.2 Trackers not tracking . 21

14.6 Unstable irradiance . 21

14.7 Non-linear or non-uniform conditions . 21

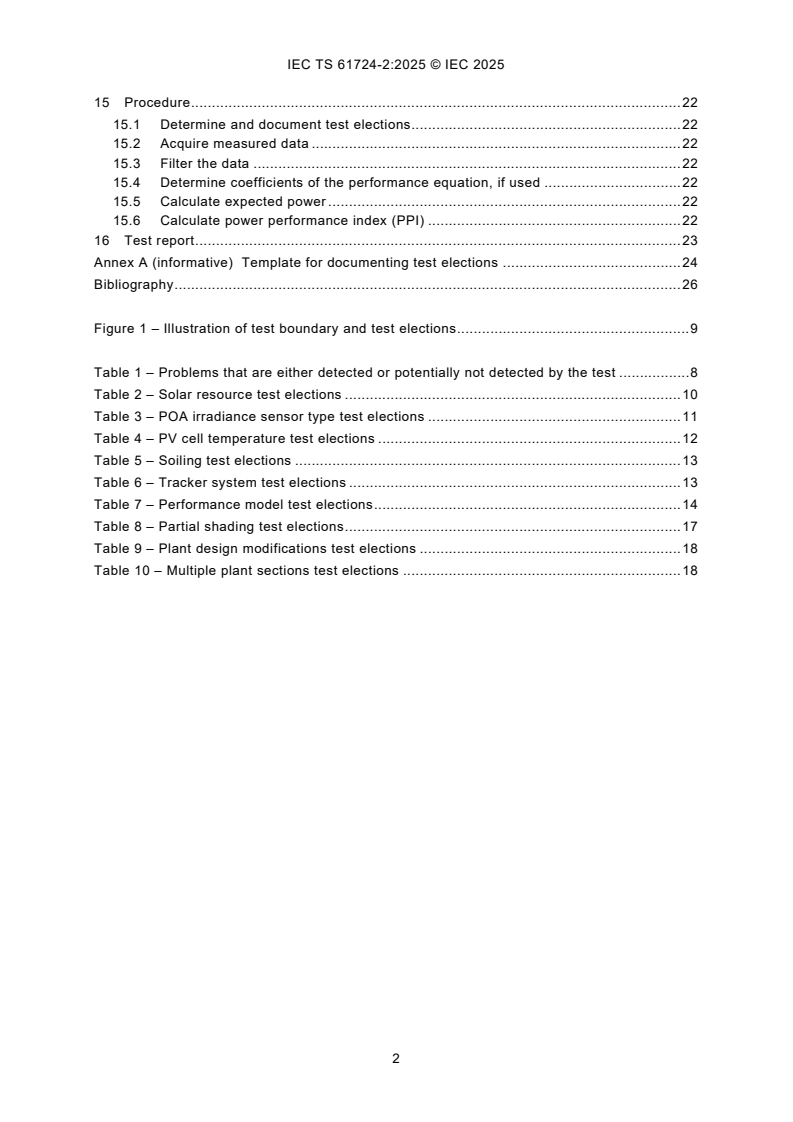

15 Procedure . 22

15.1 Determine and document test elections . 22

15.2 Acquire measured data . 22

15.3 Filter the data . 22

15.4 Determine coefficients of the performance equation, if used . 22

15.5 Calculate expected power . 22

15.6 Calculate power performance index (PPI) . 22

16 Test report . 23

Annex A (informative) Template for documenting test elections . 24

Bibliography . 26

Figure 1 – Illustration of test boundary and test elections . 9

Table 1 – Problems that are either detected or potentially not detected by the test . 8

Table 2 – Solar resource test elections . 10

Table 3 – POA irradiance sensor type test elections . 11

Table 4 – PV cell temperature test elections . 12

Table 5 – Soiling test elections . 13

Table 6 – Tracker system test elections . 13

Table 7 – Performance model test elections . 14

Table 8 – Partial shading test elections . 17

Table 9 – Plant design modifications test elections . 18

Table 10 – Multiple plant sections test elections . 18

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Photovoltaic system performance -

Part 2: Power performance index and capacity evaluation method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC TS 61724-2 has been prepared by IEC technical committee 82: Solar photovoltaic energy

systems. It is a Technical Specification.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Adapting the document for bifacial PV systems, in accordance with the latest edition of

IEC 61724-1 and current industry practices.

b) Adapting the test procedure to account for the limited times of unconstrained system

operation which are now common because of high DC-to-AC ratios (clipping) and

interconnection limits (curtailment).

c) Adapting the test procedure to achieve a test that can be performed in a short time of three

to five days during favorable conditions.

d) Focusing the document more heavily on the use of modern PV system modeling software to

obtain the expected performance of the system under test.

e) Simplifying the mathematical procedure for calculating the test results.

f) Clearly identifying test elections (optional choices to be made in conducting the test) and

providing a template for documenting these elections.

g) Clarifying the discussion of the test boundary that separates tested variables from untested

variables.

h) Expanding and clarifying the discussion of data filtering.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

82/2386/DTS 82/2484/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61724 series, published under the general title Photovoltaic system

performance, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

INTRODUCTION

This document defines a test of a PV system's power performance index (PPI). PPI, defined in

IEC 61724-1, is the ratio of a system's measured power output under test conditions to its

expected output at those conditions based on the system's design.

NOTE This type of test is sometimes referred to as a capacity test, whose result is a capacity test ratio, which is

equivalent to PPI.

The test is intended to be performed over a short period of typically three to five days and is

typically used to satisfy a contractual performance guarantee as part of the final completion of

a PV power plant.

1 Scope

The test applies to grid-connected PV systems comprising at least one inverter.

The test evaluates the PV system only in conditions where output is unconstrained by limitations

in AC power output from the inverters. Accordingly:

• Data used for the test is limited to times when inverters are maximum-power-point tracking,

so that PV system output power is unconstrained by inverter limitations (clipping) or

interconnection limits (curtailment).

• The maximum operational capacity of the system can ultimately be determined by maximum

inverter output.

Results of a performance test can be affected by various choices made in the procedure.

Therefore, this document clarifies how test choices ("test elections") affect the boundary

between external variables and the part of the system being tested.

For a procedure that evaluates system performance over an extended period, including during

constrained operation, refer to IEC TS 61724-3, Photovoltaic system performance – Part 3:

Energy performance evaluation method.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61724-1:2021, Photovoltaic system performance - Part 1: Monitoring

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC TS 61836 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

maximum-power-point tracking

inverter is maximizing the DC array's output power

3.2

unconstrained operation

operation when all inverters are freely performing maximum-power-point tracking

3.3

constrained operation

operation when output of inverter(s) is limited below the maximum possible by maximum-power-

point tracking, due to either inverter maximum output capacity (clipping) or grid interconnection

limits (curtailment)

3.4

weather conditions

environmental conditions including solar irradiance, ambient temperature, wind speed, and

precipitation

3.5

test conditions

conditions at which the test is performed, including weather conditions

3.6

performance model

simulation model used to calculate the predicted or expected PV power generation based on

the design parameters of the system and specific weather conditions

3.7

performance model software

software package used to implement the performance model

3.8

performance equation

simplified equation that captures the behavior of the performance model over a limited range of

conditions

3.9

measured power

measured AC electric power that is generated by the PV system at time point index i

3.10

expected power

power generation of a PV system that is expected at the test conditions based on the

performance model at time point index i

3.11

power performance index

PPI

ratio of the measured power to the expected power at the test conditions

3.12

test boundary

differentiation between the part of the system under test versus external variables

3.13

DC-to-AC ratio

ratio of total module DC power ratings to total inverter AC output ratings

3.14

inverter utilization

fraction of inverter AC output power relative to the inverter's AC power rating

3.15

test election

choice made regarding the test procedure which can significantly affect which aspects of the

system are within the test boundary, which models are used, or how results are determined,

and which should be documented for the parties to the test

4 Purpose of the test

This test is intended to be used to demonstrate that the system operation matches the design

expectations, typically during commissioning, for unconstrained operation only.

Table 1 summarizes potential system problems that the test is capable of detecting or

potentially not detecting.

Table 1 – Problems that are either detected or potentially not detected by the test

Problems which can be detected Problems which might not be detected

• Strings offline • Inverter maximum output below ratings

• Inverters offline • Pre-construction resource assessment errors

• Trackers offline • Module or system degradation

• Module underperformance • Long-term operational issues

• Inverter underperformance • Low availability

• Irradiance transposition modeling errors • Under-estimation of auxiliary loads with seasonal

variability

• DC performance modeling errors

• Higher than expected cable losses

• Higher than expected soiling

• Tilt angle not matching the design

• Deviations from original design

• Tracker performance deviations

NOTE 1 Test elections can modify which of these NOTE 2 Many of the problems which might not be

problems are detected by the test. detected can be evaluated using IEC TS 61724-3.

5 Test boundary and test elections

Many choices regarding measured parameters, model selection, and site maintenance can

affect the results of the test. These choices are called test elections.

As illustrated in Figure 1:

• When test elections cause the effect of a particular factor to affect the final test result, the

factor is inside the test boundary. This means that the factor is part of the system that is

being tested.

• When test elections cause the effect of a particular factor to be expected not to affect the

test result, the factor is outside the test boundary. This means that although the factor can

affect system performance, it is expected that it does not affect the test result, typically

because the factor will affect measured and expected power in the same way.

Possible test elections are addressed throughout this document with an indication of how these

elections affect the test boundary, where relevant.

In some cases, making a particular test election to address one problem can have the

unintended consequence of removing a different test factor from inside the test boundary even

though that factor is desired to be tested. In these cases, a separate test may be performed to

assess whether the excluded factor is within design expectations.

NOTE For example, as provided in Table 6, fixing trackers at horizontal tilt to mitigate constrained operation

(clipping) during the test means that tracker behaviour is not tested. In this case, a separate test of tracker behaviour

could be performed.

Test elections should be agreed in advance by parties to the test, if possible, and should be

documented in the test report.

Annex A lists all test elections in this document and provides a template for documenting test

elections.

Figure 1 – Illustration of test boundary and test elections

6 Schedule

Data collection for the test is intended to be performed over a short period of less than one

week, if possible, although the user can elect to use a longer period.

Acquiring sufficient data in unconstrained operation within a short period can require specific

test elections, including modifications of the system operation, as discussed below. For

example, see the note in Table 6.

The test may be completed at any time of year when acceptable test values can be reliably

generated. Deviation from target conditions and the effects of variable angle of incidence can

increase the uncertainty at some times of the year. Systems at high latitudes should be tested

during a time of year that allows the data requirements outlined in Clause 14 and Clause 15 to

be fulfilled during the test period.

Some PV modules show measurable performance changes within hours or days of being

installed in the field, including light-induced degradation or metastability, while others do not.

The test should be performed after any initial module performance degradation is complete.

7 Measurement equipment

7.1 General

To perform the test, input to the PV system (weather conditions) and output from the PV system

(power delivered to the grid or a load) shall be measured.

Measurement equipment and procedures shall conform to IEC 61724-1, which specifies all

parameters to be measured and the number and types of sensors to be used. For utility-scale

systems, the equipment used shall conform to Class A of IEC 61724-1. Class B of IEC 61724-1

might not support all options of this document.

All parameters required by IEC 61724-1 shall be measured, including parameters not explicitly

mentioned in this document.

Details of all measurement equipment and sensors, including number and type of sensors and

dates of calibration, cleaning, and inspection shall be documented.

The recommended data aggregation recording interval (see IEC 61724-1) for all parameters is

one minute. Longer intervals are not recommended.

NOTE Longer aggregation intervals can adversely affect the ability to collect sufficient data for high DC-to-AC ratio

systems in sunny conditions when inverters can frequently experience constrained operation (clipping) or, depending

on test elections, introduce bias by masking periods of constrained inverter operation.

7.2 Irradiance measurement

Two options are provided for the source of solar resource measurements as listed in Table 2.

The choice between these options affects the test boundary, as described in Table 2, and the

method of performing model calculations, as described in Clause 10.

Table 2 – Solar resource test elections

Test election Procedure Impacts

Solar resource option 1 – outside Measurements used for the test Irradiance transposition model is

the plane of array include global horizontal irradiance inside the test boundary: any

(GHI) and albedo (for bifacial inaccuracies of the irradiance

systems), and optionally either transposition model used by the PV

diffuse horizontal irradiance (DHI) performance model software (e.g.

or direct-normal irradiance (DNI), prediction of rear irradiance) will

or both. contribute to the test result by

modifying the expected power.

For bifacial systems, requires

IEC 61724-1 bifacial option 1. If neither DHI or DNI, are

measured: irradiance

decomposition inaccuracies are

inside the test boundary and can

affect the test result.

Solar resource option 2: inside the Measurements used for the test Irradiance transposition model is

plane of array include front-side and (for bifacial outside* the test boundary:

systems) rear-side plane-of-array expected power is derived from

(POA) irradiance. POA measurements

For bifacial systems, requires *Except during periods of partial

IEC 61724-1 bifacial option 2. shading, when the performance

model can use irradiance

transposition from POA to estimate

module performance in

performance model option 2.

POA irradiance measurement may be performed with either pyranometers, PV reference cells,

or PV reference modules as provided in Table 3.

For bifacial systems, the ground albedo and shading conditions of the area near either rear-

side irradiance sensors or reference modules, or both, should be representative of conditions

throughout the array.

Rear POA measurements may be performed with either pyranometers or reference cells with

no difference in performance modelling procedure.

When using a reference module, total front plus rear POA irradiance is directly obtained. See

Clause 10.

Table 3 – POA irradiance sensor type test elections

Test election Procedure Impacts

Pyranometer – Use a pyranometer which provides broadband (spectrally Performance model

broadband with global flat) measurement response and global angular software spectral and

angular response response. angular corrections can

be inside the test

Set options in the performance model software to

boundary: inaccuracy in

account for the PV modules' angular response (incidence

the performance model

angle modifier, IAM) and, optionally and recommended,

software spectral and

the spectral response, when estimating power.

angular correction

affects the test result by

Environmental data (e.g. ambient temperature and

modifying the expected

humidity) can be needed for spectral correction.

power.

PV reference cell – Use PV reference cells that provide a spectral response Irradiance measurement

spectral and angular accounts for spectral

and angular response similar to that of the PV modules.

response similar to response of modules.

Set options in the performance model software to ignore

modules

spectral correction. Set options in the performance

model software to ignore the module's angular response

(incidence angle modifier (IAM)) or filter the data to

exclude time points when the solar angle of incidence

(AOI) causes the IAM of the cells or the modules to be

< 0,99, e.g. AOI > 30°.

PV reference module Use calibrated PV reference modules (see notes) Irradiance measurement

identical to those in the PV array, therefore providing a accounts for spectral

spectral response and angular response exactly response of modules.

matching the PV array.

For bifacial systems,

Set options in the performance model software to ignore total front plus rear POA

spectral correction. Set options in the performance irradiance is directly

model software to ignore the module's angular response provided.

(incidence angle modifier (IAM)) OR filter the data to

exclude time points when the solar angle of incidence

(AOI) causes the IAM of the cells or the modules to be

< 0,99, e.g. AOI > 30°.

NOTE 1 Rear-side irradiance sensors and reference modules should be placed interior to the array, at least 5 m

from the end of a row and avoiding array borders, to avoid edge-brightening end effects that can result in rear-

side irradiance non-representative of the conditions throughout the array.

NOTE 2 PV reference modules can be either standalone (not connected to the array) or in-situ (within the array,

for example measured with in-situ I-V tracers).

NOTE 3 PV reference module short-circuit current shall be calibrated at a reference condition of irradiance and

temperature. Modules should be pre-conditioned prior to calibration. Calibration can be performed in a laboratory

according to IEC 60904-1 or IEC 60904-1-2 or in the field using emerging methods (for an example, see "Irradiance

Monitoring for Bifacial PV Systems' Performance and Capacity Testing", Chris Deline et al, IEEE Journal of

Photovoltaics, 2024.)

NOTE 4 To calculate the effective irradiance measured by a PV reference module, measure the module's short-

circuit current I and temperature and calculate the irradiance

T GG⋅I⋅ 1/−αT⋅(−T ) I

( )

sc ref sc ref sc,ref

where G is the irradiance at the calibration reference condition (e.g. 1 000 W/m for STC), α is the module's

ref

temperature coefficient at short-circuit, T is the temperature at the reference condition (e.g. 25 °C at STC),

ref

and I is the module's calibrated short-circuit current at the reference condition.

sc,ref

7.3 PV cell temperature

The performance of a PV system can be corrected for PV cell temperature. The PV cell

temperature estimated by a performance model can be based on various measurements as well

as mathematical treatment in the model. The more general term "PV temperature" is used for

the temperature as used in the model.

=

PV temperature can either be directly measured using back-of-module temperature sensors or

estimated from ambient temperature and wind speed. This choice affects the test boundary, as

described in Table 4, and the method of performing model calculations, as described in

Clause 10.

Table 4 – PV cell temperature test elections

Test election Procedure Impacts

Estimate PV cell temperature Estimate PV cell temperature at PV cell temperature estimation

each time point from based on the performance model is

measurements of ambient inside the test boundary: any

temperature, irradiance and wind inaccuracies in the PV cell

temperature estimation used by the

speed.

performance model, including

This estimation should be

differences between modelled and

performed by the performance

actual temperatures caused by

model software.

thermal inertia of the modules,

racking systems and other impacts

to air flow, will contribute to the

uncertainty of the test result by

modifying the expected power.

Measure PV temperature with Use direct measurements of PV PV cell temperature estimation

back-of-module temperature module temperature at each time based on the performance model is

sensors point. outside the test boundary: the

expected power is based on

Optionally, correct the offset

measured PV temperatures,

between PV cell temperature and

therefore any inaccuracies in the

measured back-of-module

performance model's estimation of

temperature based on thermal

temperature are not tested.

resistance of the module, POA

irradiance, reflection losses and Results could be affected by

electrical yield. See comments sensor placement due to

below. temperature non-uniformity,

installation method, and response

time vs. irradiance.

NOTE 1 Internal PV cell temperatures are typically up to ~ 1 °C higher than temperatures on the back of the PV

module, due to heat transport between the cells and the module's exterior surfaces. The magnitude of this

difference depends on the module construction. In addition, the temperature on the module surface can be up to

~ 1 °C higher than that measured by a back-of-module temperature sensor, due to heat transport through the

adhesive layer used to bond the sensor. Follow provisions in IEC 61724-1 regarding back-of-module temperature

sensors to minimize this error. Thus, total offsets between cell temperature and measured back-of-module

temperature could be up to ~ 2 °C. Optionally, a correction can be made to account for this difference; however,

note that performing or not performing the correction moves details of the module thermal performance and the

sensor attachment method inside or outside the test boundary.

NOTE 2 Corrections can also be made to account for small temporal differences between actual module

temperature, which changes rapidly, and measured module temperature with back-of-module temperature

sensors, which will lag the module temperature changes in time. Corrections can be made by comparing the

irradiance and back-of-module temperature profiles during the day to determine the amount of temperature shift.

NOTE 3 For more information on temporal effects in temperature estimation, see the paper "Comparative Study

for Time-specific Ross Coefficient and Overall Ross Coefficient for Estimation of Photovoltaic Module

Temperature" (10.1109/CSUDET47057.2019.9214602).

7.4 Electrical power

Electrical power measurements used in the final test result for PPI should be from high-accuracy

plant-level measurements (IEC 61724-1:2021, 11.2 and Table 6), not from lower-accuracy

inverter-level measurements (IEC 61724-1:2021, 11.1 and Table 5). Lower-accuracy

inverter-level measurements may be used for troubleshooting and filtering purposes.

8 Soiling

Table 5 lists test elections related to PV module soiling.

Table 5 – Soiling test elections

Test election Procedure Impacts

Evaluate system cleaning as part of Clean irradiance sensors prior to System cleanliness is inside the

the test and during* the test, but do not test boundary: any losses due to

clean modules. soiling on the modules contributes

negatively to system performance

evaluation.

Exclude soiling from the test, by Clean both irradiance sensors and System cleanliness is outside the

cleaning modules prior to and during* the test boundary: the system is clean

test. during the test.

Exclude soiling from the test, by Clean irradiance sensors prior to System cleanliness is outside the

compensating and during* the test, but do not test boundary: the system power is

clean modules. compensated for soiling. Some

uncertainty is introduced.

Measure the soiling loss during the

test.

Run the performance model using

measured soiling loss.

NOTE It is not recommended to assume that irradiance sensors and modules are equally dirty.

* Frequency of cleaning during the test is at the discretion of the parties performing the test and depends on

rate of soiling accumulation.

9 Trackers

Table 6 lists test elections related to tracker systems.

Table 6 – Tracker system test elections

Test election Procedure Impacts

Trackers operate normally Allow trackers to operate as Tracker operation is inside the test

boundary: any deviation of tracker

designed.

operation from the design

expectations may affect the test

result.

Modify tracker operation to mitigate Fix trackers at a horizontal angle or Tracker operation is outside the

clipping for high DC-to-AC ratio other non-sun-tracking angle to test boundary: normal tracker

systems eliminate clipping and obtain operation is not tested. Tracker

unconstrained operation during a operation should be evaluated

greater portion of the day. separately.

Adjust the performance model to Uncertainty can be increased

match the fixed tracker position. because reflection losses (incident

angle modifier effects) are not

considered as in normal operation.

10 Performance model

10.1 Overview

Performing the test requires running the system performance model using measured weather

data to determine the expected power at the test conditions. This is done by inputting measured

weather data into the performance model.

However, inputting weather data to performance model software can be complicated by various

factors, including the software's ability to process different irradiance input types and its ability

to process sub-hourly inputs.

Therefore, this document provides three performance model options which are summarised in

Table 7 and defined further below. Each option can have further variations depending on other

test elections, such as the election for modelled vs. measured PV cell temperature (Table 4).

Table 7 – Performance model test elections

Test election Test procedure Impacts

Performance model option 1 • Use solar resource option 1, See test boundary impacts of solar

solar resource outside the resource option 1 in Table 2.

plane of array, per Table 2.

• See details in 10.2.

Performance model option 2 • Use solar resource option 2, See test boundary impacts of solar

solar resource in the plane of resource option 2 in Table 2.

array, per Table 2.

• See details in 10.3.

Performance model option 3 • Approximate the software-

derived performance model by

regression to a simpler

performance equation.

• Decouples software limitations

from the test.

• See details in 10.4.

10.2 Performance model option 1

For this option, as shown in Table 7, use solar resource option 1 per Table 2, corresponding to

irradiance measured outside the plane of array, and directly input the measured weather into

the performance model software when calculating the expected power in Clause 15.

Observe additional requirements of Table 3 according to irradiance sensor type.

This option requires at least the following capabilities from the performance model software:

• Input sub-hourly data with at least one-minute resolution.

• Input GHI and, optionally, DHI or DNI values.

• Calculate PV cell temperature from measured ambient temperature and wind speed, if using

this test election (see Table 4).

• Input measured PV temperature from back-of-module temperature sensors, if using this test

election (Table 4).

• Calculate spectral correction factors for PV modules, in particular thin film modules, from

input environmental data such as either relative humidity or precipitable water vapor

content.

• Upload measured tracker angles for each timestep or default to backtracking or true tracking

models.

• Upload measured soiling and albedo data for each timestep.

Document the exact modelling software version used when performing this test. Preferably the

software version should be the same as that used for any predicted performance during the

system design phase.

For this option, measurement of diffuse irradiance is recommended (see Table 2), especially if

the test conditions include any shading of the modules, including row-to-row shading.

10.3 Performance model option 2

For this option, as shown in Table 7, use solar resource option 2 per Table 2, corresponding to

irradiance measured within the plane of array, and directly input the measured weather into the

performance model software when calculating the expected power in Clause 15.

Observe additional requirements of Table 3 according to irradiance sensor type.

This option requires at least the following capabilities from the performance model software:

• Input sub-hourly data with at least one-minute resolution.

• Predict system performance based on inputting POA irradiance, including rear POA

irradiance when applicable.

• Calculate PV cell temperature from ambient temperature and wind speed, if using this test

election (see Table 4).

• Input measured PV temperature from back-of-module temperature sensors, if using this test

election (Table 4).

• Calculate spectral correction factors for PV modules, in particular thin film modules, from

input environmental data such as either relative humidity or precipitable water vapor

content, or ability to turn off spectral and incidence angle modifier models when using

reference cells or modules for irradiance measuremen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...