IEC 62341-5-3:2019

(Main)Organic light emitting diode (OLED) displays - Part 5-3: Measuring methods of image sticking and lifetime

Organic light emitting diode (OLED) displays - Part 5-3: Measuring methods of image sticking and lifetime

IEC 62341-5-3:2019 specifies the standard measuring methods for determining the image sticking and lifetime of organic light emitting diode (OLED) display panels and modules, except finalized display products for end customers, such as TV sets, monitor sets and mobile phones. The measuring method for the lifetime mainly applies to modules.

This edition includes the following significant technical changes with respect to the previous edition:

a) the measurement vehicle for lifetime is only for the module;

b) the measurement method for monitor or TV devices is modified;

c) the digital signage display is included as an example of OLED devices;

d) the measurement method with HDR (high dynamic range) for image sticking is added;

e) the analysis method with CIEDE 2000 is added for image sticking;

f) the information method for evaluating image sticking is modified.

General Information

- Status

- Published

- Publication Date

- 08-Oct-2019

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 18 - TC 110/WG 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Oct-2019

- Completion Date

- 01-Nov-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62341-5-3:2019 specifies standard measuring methods for determining image sticking and luminance lifetime of organic light emitting diode (OLED) display panels and modules (excluding finalized consumer products such as TV sets, monitor sets and mobile phones). The second edition updates measurement vehicles and analysis methods and adds procedures for HDR displays and CIEDE2000 colour-difference analysis. The lifetime measurement mainly applies to modules, while modified methods address monitor/TV devices and include digital signage examples.

Key topics and technical requirements

- Scope and test objects

- Applies to OLED panels and modules (measurement for finalized products is excluded; monitor/TV measurement methods were updated).

- Lifetime measurement is focused on modules.

- Measuring configuration and conditions

- Defines the measuring system arrangement, required light measuring device (LMD) characteristics, and standard environmental/darkroom conditions.

- Standard setup covers DUT adjustments, starting conditions, and equipment calibration.

- Image sticking measurement

- Procedures for stress patterns, measuring areas, and post-stress evaluation.

- Includes both SDR and HDR test patterns and procedures to reflect modern content (HDR measurement method added in this edition).

- Analysis options include luminance and colour-difference evaluation using CIEDE2000 (newly introduced).

- Luminance lifetime measurement

- Specifies equipment, test procedures and lifetime estimation/extrapolation methods.

- Defines equivalent signal level (digital code 0–255 for 8-bit transforms) and equivalent current density concepts to normalize varying dynamic content - see Annex A for calculation methods.

- Reporting and analysis

- Standardized reporting formats for image-sticking metrics, target times, and lifetime thresholds.

- Annex B provides the CIEDE2000 colour-difference calculation procedure.

Practical applications and who uses this standard

- Display manufacturers and module developers - for product development, benchmarking and quality control of OLED panels and modules.

- Test and certification laboratories - to perform repeatable, internationally consistent image-sticking and lifetime tests.

- R&D teams and materials suppliers - to evaluate degradation behaviour under controlled stress and to compare materials/process variants.

- System integrators and digital signage vendors - to assess module suitability for continuous/static-content applications where image retention or long-term luminance is critical.

Benefits: consistent, repeatable measurements; valid comparisons across suppliers and designs; guidance for new HDR and colour-difference analysis in image-sticking evaluation.

Related standards

- IEC 62341 series (general OLED display standards)

- IEC 62341-1-2 (Terminology and letter symbols)

- IEC 62341-6-1 (Measuring methods of optical and electro‑optical parameters)

- ISO 11664-1 / CIE 15 (Colorimetry)

- IEC 60050-845 (IEV – Lighting)

Keywords: IEC 62341-5-3, OLED, image sticking, luminance lifetime, measuring methods, HDR, CIEDE2000, equivalent signal level, display testing.

Buy Documents

IEC 62341-5-3:2019 - Organic light emitting diode (OLED) displays - Part 5-3: Measuring methods of image sticking and lifetime Released:10/9/2019 Isbn:9782832274552

IEC 62341-5-3:2019 RLV - Organic light emitting diode (OLED) displays - Part 5-3: Measuring methods of image sticking and lifetime Released:10/9/2019 Isbn:9782832275061

Frequently Asked Questions

IEC 62341-5-3:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Organic light emitting diode (OLED) displays - Part 5-3: Measuring methods of image sticking and lifetime". This standard covers: IEC 62341-5-3:2019 specifies the standard measuring methods for determining the image sticking and lifetime of organic light emitting diode (OLED) display panels and modules, except finalized display products for end customers, such as TV sets, monitor sets and mobile phones. The measuring method for the lifetime mainly applies to modules. This edition includes the following significant technical changes with respect to the previous edition: a) the measurement vehicle for lifetime is only for the module; b) the measurement method for monitor or TV devices is modified; c) the digital signage display is included as an example of OLED devices; d) the measurement method with HDR (high dynamic range) for image sticking is added; e) the analysis method with CIEDE 2000 is added for image sticking; f) the information method for evaluating image sticking is modified.

IEC 62341-5-3:2019 specifies the standard measuring methods for determining the image sticking and lifetime of organic light emitting diode (OLED) display panels and modules, except finalized display products for end customers, such as TV sets, monitor sets and mobile phones. The measuring method for the lifetime mainly applies to modules. This edition includes the following significant technical changes with respect to the previous edition: a) the measurement vehicle for lifetime is only for the module; b) the measurement method for monitor or TV devices is modified; c) the digital signage display is included as an example of OLED devices; d) the measurement method with HDR (high dynamic range) for image sticking is added; e) the analysis method with CIEDE 2000 is added for image sticking; f) the information method for evaluating image sticking is modified.

IEC 62341-5-3:2019 is classified under the following ICS (International Classification for Standards) categories: 31.120 - Electronic display devices; 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62341-5-3:2019 has the following relationships with other standards: It is inter standard links to IEC 62341-5-3:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62341-5-3:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62341-5-3 ®

Edition 2.0 2019-10

INTERNATIONAL

STANDARD

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-3: Measuring methods of image sticking and lifetime

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62341-5-3 ®

Edition 2.0 2019-10

INTERNATIONAL

STANDARD

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-3: Measuring methods of image sticking and lifetime

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.120; 31.260 ISBN 978-2-8322-7455-2

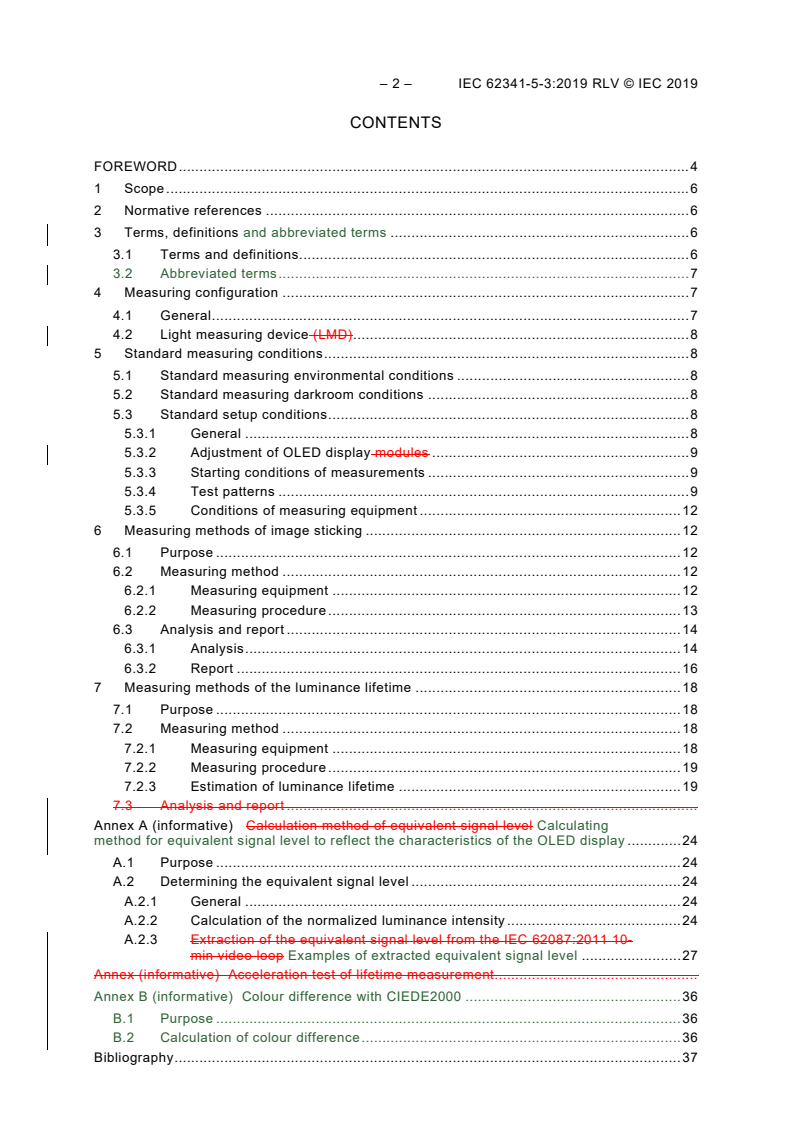

– 2 – IEC 62341-5-3:2019 © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 7

4 Measuring configuration . 7

4.1 General . 7

4.2 Light measuring device . 8

5 Standard measuring conditions . 8

5.1 Standard measuring environmental conditions . 8

5.2 Standard measuring darkroom conditions . 8

5.3 Standard setup conditions . 8

5.3.1 General . 8

5.3.2 Adjustment of OLED display . 8

5.3.3 Starting conditions of measurements . 9

5.3.4 Test patterns . 9

5.3.5 Conditions of measuring equipment . 11

6 Measuring methods of image sticking . 11

6.1 Purpose . 11

6.2 Measuring method . 11

6.2.1 Measuring equipment . 11

6.2.2 Measuring procedure . 11

6.3 Analysis and report . 12

6.3.1 Analysis . 12

6.3.2 Report . 14

7 Measuring methods of the luminance lifetime . 16

7.1 Purpose . 16

7.2 Measuring method . 16

7.2.1 Measuring equipment . 16

7.2.2 Measuring procedure . 16

7.2.3 Estimation of luminance lifetime . 17

Annex A (informative) Calculating method for equivalent signal level to reflect the

characteristics of the OLED display . 19

A.1 Purpose . 19

A.2 Determining the equivalent signal level . 19

A.2.1 General . 19

A.2.2 Calculation of the normalized luminance intensity . 19

A.2.3 Examples of extracted equivalent signal level . 22

Annex B (informative) Colour difference with CIEDE2000 . 25

B.1 Purpose . 25

B.2 Calculation of colour difference . 25

Bibliography . 26

Figure 1 – Measuring system and arrangement . 7

Figure 2 – Test pattern for SDR displays. 9

Figure 3 – Image sticking measuring area . 10

Figure 4 – Test pattern for HDR displays . 11

Figure 5 – Example of the resulting image after image stress . 12

Figure 6 – Example of luminance behavior in operation for an OLED display module . 16

Figure 7 – Example of lifetime estimation with the extrapolation method . 17

Figure 8 – Examples of estimated lifetime depending on the time elapsed . 18

2 2

Figure A.1 – Measured 10 mA/cm to 80 mA/cm OLED degradation values and

corresponding modelled functions with m = 1 / 1,7 . 20

Figure A.2 – Example of accumulated colour intensity of IEC 62087:2011 10-min video

loop in RGB subpixel format with equivalent signal distribution chart based on the left

images . 23

Figure A.3 – Example of accumulated colour intensity of the IEC 62087:2011 10-min

video loop in W, R, G, and B format, with equivalent signal distribution chart based on

the left images . 24

Table 1 – Examples of maximum and average code value extracted from video

samples . 10

Table 2 – Information on test pattern . 14

Table 3 – Example of typical value . 15

Table 4 – Reporting format of the image sticking data at target time . 15

Table 5 – Reporting format of the image sticking time with threshold . 15

Table A.1 – Examples of the maximum and the average equivalent signal

levels (8 bits) . 22

– 4 – IEC 62341-5-3:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-3: Measuring methods of image sticking and lifetime

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62341-5-3 has been prepared by IEC technical committee 110:

Electronic displays.

This second edition replaces the first edition published in 2013. This edition constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the measurement vehicle for lifetime is only for the module;

b) the measurement method for monitor or TV devices is modified;

c) the digital signage display is included as an example of OLED devices;

d) the measurement method with HDR (high dynamic range) for image sticking is added;

e) the analysis method with CIEDE 2000 is added for image sticking;

f) the information method for evaluating image sticking is modified.

The text of this standard is based on the following documents:

FDIS Report on voting

110/1134/FDIS 110/1154/RVD

Full information on the voting for the approval on this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62341 series, under the general title Organic light emitting

diode (OLED) displays, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

contains colours which are considered to be useful for the correct

that it

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62341-5-3:2019 © IEC 2019

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-3: Measuring methods of image sticking and lifetime

1 Scope

This part of IEC 62341 specifies the standard measuring methods for determining the image

sticking and lifetime of organic light emitting diode (OLED) display panels and modules,

except finalized display products for end customers, such as TV sets, monitor sets and mobile

phones. The measuring method for the lifetime mainly applies to modules.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-845, International Electrotechnical Vocabulary (IEV) – Part 845: Lighting

(available at )

IEC 62341-1-2, Organic light emitting diode (OLED) displays – Part 1-2: Terminology and

letter symbols

IEC 62341-6-1:2017, Organic light emitting diode (OLED) displays – Part 6-1: Measuring

methods of optical and electro-optical parameters

ISO 11664-1, Colorimetry – Part 1: CIE standard colorimetric observers

CIE 15, Colorimetry

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62341-1-2 and

IEC 60050-845 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

equivalent current density

average current density of a certain pixel calculated from a varying luminance per frame

image in a moving picture so that luminance degradation becomes similar at the same time

Note 1 to entry: See Annex A.

3.1.2

equivalent signal level

digital code value from 0 to 255 (in the case of 8 bits) transformed from the normalized

luminance of a certain pixel by a specified opto-electronic transfer function (OETF)

Note 1 to entry: See Annex A.

3.2 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

APL average picture level

CIELAB CIE 1976(L*a*b*) colour space

DUT devices under test

EOTF electro-optical transfer function

FWHM full-width-at-half-maximum

HDR high dynamic range

LMD light measuring device

OETF opto-electronic transfer function

OLED organic light emitting diode

PQ perceptual quantizer

SDR standard dynamic range

4 Measuring configuration

4.1 General

The system diagrams and/or operating conditions of the measuring equipment shall comply

with the structure specified in each item. The measuring system and its arrangement are

shown in Figure 1. The details are given in Clause 5.

Figure 1 – Measuring system and arrangement

– 8 – IEC 62341-5-3:2019 © IEC 2019

4.2 Light measuring device

The optical properties of displays shall generally be expressed in photometric or colorimetric

units using the CIE 1931 standard colorimetric two-degree observer (see ISO 11664-1).

Luminance can be measured by a photometer, and the CIE tristimulus values (X, Y, Z) or CIE

chromaticity coordinates by a colorimeter. A spectroradiometer can also obtain photometric

and colorimetric values through a numerical conversion of the measured spectral radiance

data (see, for example, [1] ). The following requirements are given for these instruments:

The LMD shall be a luminance meter, colorimeter, or a spectroradiometer. For DUTs that

have sharp spectral peak full-width-at-half-maximums (FWHMs) smaller than 20 nm, a

spectroradiometer should be used. A filter colorimeter should generally not be used for light

sources with sharp spectral peaks. If they are used, the colorimeter shall be calibrated with a

narrow bandwidth spectroradiometer to give the same results for the specific spectrum.

Report the characteristics of the spectroradiometer which is used for calibration. For light

sources with sharp spectral peaks, the maximum bandwidth of the spectroradiometer shall be

≤ 5 nm. The higher resolution spectroradiometer produces a more accurate colour

measurement. In those cases, the wavelength accuracy shall be within ±0,5 nm. The

spectroradiometer shall be capable of measuring spectral radiance over at least the 380 nm to

780 nm wavelength range, with a maximum bandwidth of 10 nm for smooth broadband

spectra (i.e. broad spectrum with no sharp spikes).

Care shall be taken to ensure that the LMD has enough sensitivity and dynamic range to

perform the required task. Before measuring the DUT, the LMD specification shall be checked.

5 Standard measuring conditions

5.1 Standard measuring environmental conditions

The standard measuring environmental conditions specified in IEC 62341-6-1:2017, 5.1, shall

be applied. For image sticking measurements, the environmental temperature shall be

controlled at 25 °C ± 3 °C, otherwise a temperature-controlled detector shall be used. (The

stability of the LMD shall be less than 1/5 of the intended detecting difference levels of

luminance and colour.)

5.2 Standard measuring darkroom conditions

The standard measuring darkroom conditions specified in IEC 62341-6-1:2017, 5.2, shall be

applied.

5.3 Standard setup conditions

5.3.1 General

Standard setup conditions are given below. Any deviations from these conditions shall be

recorded.

5.3.2 Adjustment of OLED display

The adjustment of the OLED display specified in IEC 62341-6-1:2017, 5.3.2, shall be applied.

____________

Numbers in square brackets refer to the Bibliography.

5.3.3 Starting conditions of measurements

Warm-up time is defined as the time elapsed from the moment of switching on the supply

voltage until repeated measurements of the display show a variation in luminance of less than

2 %/min. Repeated measurements shall be taken for a period of at least 15 min after starting.

The luminance variations shall also not exceed 5 % during the total measurement.

5.3.4 Test patterns

5.3.4.1 SDR displays

The test patterns for SDR display devices such as mobile phones, tablet PCs, monitors, TVs

and digital signage are shown in Figure 2. The test pattern for SDR displays is divided into

two groups.

1) Test pattern for mobiles and tablet PC displays

In the case of mobiles and tablet PCs, the measurement distance between the display and the

LMD depends on the size of the OLED display panels or modules. The measuring distance

and the aperture angle may be adjusted to achieve a measuring field greater than 500 pixels

if the setting of the measurement field angle is not applied. For display devices except

monitors, TVs and digital signage, the test pattern with a white level at the 4 % window box

located in the centre and a black level in the background, is used in Figure 2a).

2) Test pattern for monitors, TVs and digital signage displays

For monitors, TVs and digital signage, the test pattern is extracted by video analysis to reflect

the characteristics of the video sample. For the test pattern, the maximum code value is

allocated at the 4 % window box in the centre and the average code value is in the

background. The examples of the maximum and average gray code values are shown in

Table 1. The example of the test pattern is shown in Figure 2b). The maximum and average

code values between 0 and 255 (in the case of 8 bits) could be extracted from the

accumulating image for all frames of the video sample, which is converted as equivalent

grayscale from each colour channel.

NOTE 1 Image sticking is influenced by the characteristics of the OLED displays [5], [7]. Some manufacturers of

OLED displays apply various algorithms to optimize the quality of each device, and this also influences the image

sticking. To consider the characteristics of an OLED display, the method in Annex A is used for the test pattern

reflecting the characteristics of the OLED display.

a) Test pattern for mobiles b) Test pattern for monitors, TVs

and tablet PC displays and digital signage displays

Figure 2 – Test pattern for SDR displays

– 10 – IEC 62341-5-3:2019 © IEC 2019

Table 1 – Examples of maximum and average code value extracted from video samples

Examples of test video Maximum code value Average code value

IEC 62087:2011 107 84

Broadcast video sample 183 102

NOTE 2 For the test pattern, any video samples could be selected as needed. Table 1 shows two kinds of

representative examples. The broadcast video sample example is constructed by considering the viewing ratio of

the content of TV programmes based on the Korea broadcast media use environmental survey report:

entertainment (30,9%), news (20,2 %), drama (16,8 %), and so on [4]. The average gray level and test pattern size

are different between SDR and HDR in TVs. Depending on the purpose of the test, Figure 2b) or Figure 4a) would

apply.

3) Measuring area

In order to get repeatability of measurement, the measuring area from P to P for displays is

0 4

set to consider the uniformity of the OLED display panels or modules, as shown in Figure 3. If

the centre window size is changed, then it should be reported in Table 2.

Figure 3 – Image sticking measuring area

4) Checking the test pattern

For SDR displays, the output luminance can be different although they have the same digital

code value inputs. To check the brief information of the selected test pattern, the output

luminance for the test pattern should be measured and reported.

Apply the test pattern on OLED displays and measure the output luminance on t

...

IEC 62341-5-3 ®

Edition 2.0 2019-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-3: Measuring methods of image sticking and lifetime

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62341-5-3 ®

Edition 2.0 2019-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-3: Measuring methods of image sticking and lifetime

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.120; 31.260 ISBN 978-2-8322-7506-1

– 2 – IEC 62341-5-3:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 7

4 Measuring configuration . 7

4.1 General . 7

4.2 Light measuring device (LMD) . 8

5 Standard measuring conditions . 8

5.1 Standard measuring environmental conditions . 8

5.2 Standard measuring darkroom conditions . 8

5.3 Standard setup conditions . 8

5.3.1 General . 8

5.3.2 Adjustment of OLED display modules . 9

5.3.3 Starting conditions of measurements . 9

5.3.4 Test patterns . 9

5.3.5 Conditions of measuring equipment . 12

6 Measuring methods of image sticking . 12

6.1 Purpose . 12

6.2 Measuring method . 12

6.2.1 Measuring equipment . 12

6.2.2 Measuring procedure . 13

6.3 Analysis and report . 14

6.3.1 Analysis . 14

6.3.2 Report . 16

7 Measuring methods of the luminance lifetime . 18

7.1 Purpose . 18

7.2 Measuring method . 18

7.2.1 Measuring equipment . 18

7.2.2 Measuring procedure . 19

7.2.3 Estimation of luminance lifetime . 19

7.3 Analysis and report .

Annex A (informative) Calculation method of equivalent signal level Calculating

method for equivalent signal level to reflect the characteristics of the OLED display . 24

A.1 Purpose . 24

A.2 Determining the equivalent signal level . 24

A.2.1 General . 24

A.2.2 Calculation of the normalized luminance intensity . 24

A.2.3 Extraction of the equivalent signal level from the IEC 62087:2011 10-

min video loop Examples of extracted equivalent signal level . 27

Annex (informative) Acceleration test of lifetime measurement.

Annex B (informative) Colour difference with CIEDE2000 . 36

B.1 Purpose . 36

B.2 Calculation of colour difference . 36

Bibliography . 37

Figure – Test pattern for image sticking .

Figure – An example of the burn-in image .

Figure – An example of Weibull distribution of lifetime .

Figure – Accumulated colour intensity of IEC 62087:2011 10-min video loop in RGB

subpixel format with equivalent signal distribution chart based on the left images,

respectively .

Figure – Accumulated colour intensity of the IEC 62087:2011 10-min video loop in W,

R, G, and B format, with equivalent signal distribution chart based on the left images,

respectively .

Figure – Examples of Weibull distributions of accelerated lifetime test .

Figure 1 – Measuring system and arrangement . 7

Figure 2 – Test pattern for SDR displays. 11

Figure 3 – Image sticking measuring area . 11

Figure 4 – Test pattern for HDR displays . 12

Figure 5 – Example of the resulting image after image stress . 14

Figure 6 – Example of luminance behavior in operation for an OLED display panel or

module . 19

Figure 7 – Example of lifetime estimation with the extrapolation method . 21

Figure 8 – Examples of estimated lifetime depending on the time elapsed . 22

2 2

Figure A.1 – Measured 10 mA/cm to 80 mA/cm OLED degradation values and

corresponding modelled functions with m = 1 / 1,7 . 25

Figure A.2 – Example of accumulated colour intensity of IEC 62087:2011 10-min video

loop in RGB subpixel format with equivalent signal distribution chart based on the left

images . 30

Figure A.3 – Example of accumulated colour intensity of the IEC 62087:2011 10-min

video loop in W, R, G, and B format, with equivalent signal distribution chart based on

the left images . 32

Table – An example of measuring distance and radius size .

Table – An example of typical value .

Table – An example of the image sticking time with reference .

Table – An example of the image sticking data at target time .

Table – Examples of lifetime measurement .

Table – Summary of the acceleration test results in Figure B.1 .

Table – Statistical analysis results of the accelerated lifetime test in Figure B.1 .

Table 1 – Examples of maximum and average code value extracted from video

samples . 11

Table 2 – Information on test pattern . 17

Table 3 – Example of typical value . 17

Table 4 – Reporting format of the image sticking data at target time . 18

Table 5 – Reporting format of the image sticking time with threshold . 18

Table A.1 – Examples of the maximum and the minimum average equivalent signal

levels (8 bits) . 28

– 4 – IEC 62341-5-3:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-3: Measuring methods of image sticking and lifetime

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 62341-5-3 has been prepared by IEC technical committee 110:

Electronic displays.

This second edition replaces the first edition published in 2013. This edition constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the measurement vehicle for lifetime is only for the module;

b) the measurement method for monitor or TV devices is modified;

c) the digital signage display is included as an example of OLED devices;

d) the measurement method with HDR (high dynamic range) for image sticking is added;

e) the analysis method with CIEDE 2000 is added for image sticking;

f) the information method for evaluating image sticking is modified.

The text of this standard is based on the following documents:

FDIS Report on voting

110/1134/FDIS 110/1154/RVD

Full information on the voting for the approval on this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62341 series, under the general title Organic light emitting

diode (OLED) displays, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62341-5-3:2019 RLV © IEC 2019

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-3: Measuring methods of image sticking and lifetime

1 Scope

This part of IEC 62341 specifies the standard measurement conditions and measurement

measuring methods for determining the image sticking and lifetime of organic light emitting

diode (OLED) display panels and modules, except finalized display products for end

customers, such as TV sets, monitor sets and mobile phones. It The measuring method for

the lifetime mainly applies to modules.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (available at

)

IEC 60050-845, International Electrotechnical Vocabulary (IEV) – Part 845: Lighting

(available at )

IEC 62087:2011, Methods of measurement for the power consumption of audio, video and

related equipment

IEC 62341-1-2:2007, Organic light emitting diode (OLED) displays – Part 1-2: Terminology

and letter symbols

IEC 62341-6-1:20092017, Organic light emitting diode (OLED) displays – Part 6-1: Measuring

methods of optical and electro-optical parameters

IEC 61966-2-1:1999, Multimedia systems and equipment – Colour measurement and

management – Part 2-1: Colour management –Default RGB colour space – sRGB

ISO 11664-1, Colorimetry – Part 1: CIE standard colorimetric observers

CIE 15-2004, Colorimetry

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62341-1-2:2007 and

IEC 60050-845:1987 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

equivalent current density

average current density of a certain pixel calculated from a varying luminance per frame

image in a moving picture so that luminance degradation becomes similar at the same time

Note 1 to entry: See Annex A.

3.1.2

equivalent signal level

digital code value from 0 to 255 (in the case of 8 bits) transformed from the normalized

luminance of a certain pixel by a gamma specified opto-electronic transfer function (OETF)

Note 1 to entry: See Annex A.

3.2 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

APL average picture level

CIELAB CIE 1976(L*a*b*) colour space

DUT devices under test

EOTF electro-optical transfer function

FWHM full-width-at-half-maximum

HDR high dynamic range

LMD light measuring device

OETF opto-electronic transfer function

OLED organic light emitting diode

PQ perceptual quantizer

SDR standard dynamic range

4 Measuring configuration

4.1 General

The system diagrams and/or operating conditions of the measuring equipment shall comply

with the structure specified in each item. The measuring system and its arrangement are

shown in Figure 1. The details are given in Clause 5.

Figure 1 – Measuring system and arrangement

– 8 – IEC 62341-5-3:2019 RLV © IEC 2019

4.2 Light measuring device (LMD)

The LMD as defined in IEC 62341-6-1:2009 shall be used. Specifically, the accuracy of the

LMD at 1 degree of the measurement field angle is recommended as being ≤ ±3%, and with a

repeatability ≤ ±0,5%.

The optical properties of displays shall generally be expressed in photometric or colorimetric

units using the CIE 1931 standard colorimetric two-degree observer (see ISO 11664-1).

Luminance can be measured by a photometer, and the CIE tristimulus values (X, Y, Z) or CIE

chromaticity coordinates by a colorimeter. A spectroradiometer can also obtain photometric

and colorimetric values through a numerical conversion of the measured spectral radiance

data (see, for example, [1] ). The following requirements are given for these instruments:

The LMD shall be a luminance meter, colorimeter, or a spectroradiometer. For DUTs that

have sharp spectral peak full-width-at-half-maximums (FWHMs) smaller than 20 nm, a

spectroradiometer should be used. A filter colorimeter should generally not be used for light

sources with sharp spectral peaks. If they are used, the colorimeter shall be calibrated with a

narrow bandwidth spectroradiometer to give the same results for the specific spectrum.

Report the characteristics of the spectroradiometer which is used for calibration. For light

sources with sharp spectral peaks, the maximum bandwidth of the spectroradiometer shall be

≤ 5 nm. The higher resolution spectroradiometer produces a more accurate colour

measurement. In those cases, the wavelength accuracy shall be within ±0,5 nm. The

spectroradiometer shall be capable of measuring spectral radiance over at least the 380 nm to

780 nm wavelength range, with a maximum bandwidth of 10 nm for smooth broadband

spectra (i.e. broad spectrum with no sharp spikes).

Care shall be taken to ensure that the LMD has enough sensitivity and dynamic range to

perform the required task. Before measuring the DUT, the LMD specification shall be checked.

5 Standard measuring conditions

5.1 Standard measuring environmental conditions

The standard measuring environmental conditions specified in IEC 62341-6-1:20092017, 5.1,

shall be applied. For image sticking measurements, the environmental temperature shall be

controlled at 25 °C ± 2 3 °C, otherwise a temperature-controlled detector shall be used. (The

stability of the LMD shall be less than 1/5 of the intended detecting difference levels of

luminance and colour.)

5.2 Standard measuring darkroom conditions

The standard measuring darkroom conditions specified in IEC 62341-6-1:20092017, 5.2, shall

be applied.

5.3 Standard setup conditions

5.3.1 General

For the measurement area, the minimum radius for measurement with the distance and

aperture angle is explained in Table 1.

____________

Numbers in square brackets refer to the Bibliography.

Table 1 – An example of measuring distance and radius size

Radius of measurement

Distance Aperture angle

field

(mm) (degree)

(mm)

2 10

1 5

0,2 1

0,1 0,5

Standard setup conditions are given below. Any deviations from these conditions shall be

recorded.

5.3.2 Adjustment of OLED display modules

The adjustment of the OLED display modules specified in IEC 62341-6-1:20092017, 5.3.12,

shall be applied.

5.3.3 Starting conditions of measurements

Warm-up time is defined as the time elapsed from the moment of switching on the supply

voltage until repeated measurements of the display show a variation in luminance of less than

2 %/min. Repeated measurements shall be taken for a period of at least 15 min after starting.

The luminance variations shall also not exceed 5 % during the total measurement.

5.3.4 Test patterns

The test patterns for display devices such as mobile phones, table PCs, monitors and TVs are

shown in Figure 2. In the case of mobiles and tablet PCs, depending on the size of the OLED

display panels or modules and measurement distance between the display and the LMD, if the

pattern size is a smaller area than a 10 mm radius at a 500 mm measurement distance with a

2-degree aperture angle of the LMD, then the aperture angle of the LMD should be set to

cover the pattern area as set in Table 1. The measuring distance and the aperture angle may

be adjusted to achieve a measuring field greater than 500 pixels if the setting of the aperture

angle is difficult. For all applications, the test pattern is used in Figure 2a), and usage method

case for monitors and TVs such as Figure 2b) may be used. In order to get repeatability of

measurement, the measuring location from P to P for TVs type as shown in Figure 2c) are

0 4

set, considering the uniformity of the OLED display panels or modules.

– 10 – IEC 62341-5-3:2019 RLV © IEC 2019

IEC 2152/13 IEC 2153/13

a) – The test pattern for display b) – The test pattern for monitor

devices except monitors and TV devices

and TVs

IEC 215413

c) – Image sticking measuring location

Figure 2 – Test pattern for image sticking

5.3.4.1 SDR displays

The test patterns for SDR display devices such as mobile phones, tablet PCs, monitors, TVs

and digital signage are shown in Figure 2. The test pattern for SDR displays is divided into

two groups.

1) Test pattern for mobiles and tablet PC displays

In the case of mobiles and tablet PCs, the measurement distance between the display and the

LMD depends on the size of the OLED display panels or modules. The measuring distance

and the aperture angle may be adjusted to achieve a measuring field greater than 500 pixels

if the setting of the measurement field angle is not applied. For display devices except

monitors, TVs and digital signage, the test pattern with a white level at the 4 % window box

located in the centre and a black level in the background, is used in Figure 2a).

2) Test pattern for monitors, TVs and digital signage displays

For monitors, TVs and digital signage, the test pattern is extracted by video analysis to reflect

the characteristics of the video sample. For the test pattern, the maximum code value is

allocated at the 4 % window box in the centre and the average code value is in the

background. The examples of the maximum and average gray code values are shown in

Table 1. The example of the test pattern is shown in Figure 2b). The maximum and average

code values between 0 and 255 (in the case of 8 bits) could be extracted from the

accumulating image for all frames of the video sample, which is converted as equivalent

grayscale from each colour channel.

NOTE 1 Image sticking is influenced by the characteristics of the OLED displays [5], [7]. Some manufacturers of

OLED displays apply various algorithms to optimize the quality of each device, and this also influences the image

sticking. To consider the characteristics of an OLED display, the method in Annex A is used for the test pattern

reflecting the characteristics of the OLED display.

a) Test pattern for mobiles b) Test pattern for monitors, TVs

and tablet PC displays and digital signage displays

Figure 2 – Test pattern for SDR displays

Table 1 – Examples of maximum and average code value extracted from video samples

Examples of test video Maximum code value Average code value

IEC 62087:2011 107 84

Broadcast video sample 183 102

NOTE 2 For the test pattern, any video samples could be selected as needed. Table 1 shows two kinds of

representative examples. The broadcast video sample example is constructed by considering the viewing ratio of

the content of TV programmes based on the Korea broadcast media use environmental survey report:

entertainment (30,9%), news (20,2 %), drama (16,8 %), and so on [4]. The average gray level and test pattern size

are different between SDR and HDR in TVs. Depending on the purpose of the test, Figure 2b) or Figure 4a) would

apply.

3) Measuring area

In order to get repeatability of measurement, the measuring area from P to P for displays is

0 4

set to consider the uniformity of the OLED display panels or modules, as shown in Figure 3. If

the centre window size is changed, then it should be reported in Table 2.

Figure 3 – Image sticking measuring area

4) Checking the test pattern

For SDR displays, the output luminance can be different although they have the same digital

code value inputs. To check the brief information of the selected test pattern, the output

luminance for the test pattern should be measured and reported.

– 12 – IEC 62341-5-3:2019 RLV © IEC 2019

Apply the test pattern on OLED displays and measure the output luminance on the measuring

area from P to P as shown in Figure 3. The results of the output luminance of the test

0 4

pattern should be reported in Table 2.

5.3.4.2 HDR displays

In 5.3.4.1, the test pattern for SDR displays is described. The test pattern for HDR displays is

shown in Figure 4a). It is based on the PQ curve and 10 bits. The test pattern for HDR

displays is proposed separately because the characteristics of the contents of the SDR and

HDR are different. The test pattern for SDR or HDR can be used as needed. The background

code value should be 510. The size of the box window should be 10 %, which is located in the

centre. The code value of the 10 % box window should be 710. The measured luminance of

the box window and the background luminance should be reported. To get repeatability of the

measurement data, the measuring area from P to P is the centre of the boxes, as shown in

0 4

Figure 4b). The measurement data should be reported in Table 2.

a) HDR test pattern b) Measurement area

Figure 4 – Test pattern for HDR displays

NOTE The code value of the 10 % box window and background is the result of the analysed data of HDR contents

which are HDR games, drama and documentary.

5.3.5 Conditions of measuring equipment

The general conditions in IEC 62341-6-1:20092017, Clause 5, shall be applied.

6 Measuring methods of image sticking

6.1 Purpose

The purpose of this method is to measure the image sticking of an OLED display panels or

modules.

6.2 Measuring method

6.2.1 Measuring equipment

The following equipment defined in IEC 62341-6-1:20092017, 6.1.2 5.3.4, shall be used:

a) power supplies and signal sources for driving,

b) LMD.

6.2.2 Measuring procedure

The OLED display modules shall be set in darkroom conditions for measurement.

a) Initial measurements on full screen pattern

Apply a full white screen driving signal to the OLED display modules over the full screen, and

set all power supplies to the standard operation conditions. However, for some display

applications, the full screen luminance can be reduced, according to 7.3.1 of IEC 62341-6-

1:2009.

Measure the initial spectral radiance or tristimulus values of white at P to P as shown in

0 4

Figure 2c) 3. The initial spectra radiance or tristrimulus values of the primary colours may also

be measured individually.

b) Image burn-in stress using the test pattern

For the test pattern for display devices (except monitors and TVs), set the test input signal

to the OLED display modules to generate a 0 % luminance level over the full screen and a

peak luminance at the test pattern which is located at the centre of the display as shown in

Figure 2a). For monitor and TV, set the peak luminance level over the 4 % window pattern

located in the centre of the display with a 15 % luminance level of the peak luminance

over the background area. For information about guidance, see Annex C of

IEC 62087:2011. If the other pattern is used, it should be based on Annex A of this

document and reported.

For image stress, the test pattern based on 5.3.4 for display devices should be applied to the

OLED display.

Keep the test pattern until the specified time, considering the luminance degradation curve.

For example, the measurement time can be every 1 h during the first 6 h, and every 24 h

during the first 120 h, then every 72 h until the target time in the standard measurement

condition. Alternatively keep the test pattern until the target time in the standard measurement

condition.

c) Measurements on full screen pattern after image stress

Before the measurement, turn off the OLED display and stabilize it to the standard operation

condition. Then turn on the OLED display again and apply a full white screen driving signal to

the OLED display modules over the full screen. Set all power supplies also to the standard

operation conditions. Measure the spectral radiance or the tristimulus values at the same

measuring location as the initial measurement. The initial and final spectra radiance or

tristrimulus values of the individual primary colours may also be measured and reported.

For the measurement method, only white tone is considered. For the other primary colours

such as red, green and blue, each test pattern should be designed following the methods of

5.3.4, and each full primary colour screen pattern should be used for measurement.

All measurements shall be done at the target time of 400 and 500 h and shall be reported. In

Figure 3 5, an example of the burn-in image stress is shown.

– 14 – IEC 62341-5-3:2019 RLV © IEC 2019

IEC 2155/13

Figure 3 – An example of the burn-in image

Figure 5 – Example of the resulting image after image stress

6.3 Analysis and report

6.3.1 Analysis

6.3.1.1 Luminance and chromatic deviation method

Image sticking can be characterized by luminance and chromatic deviation.

The image sticking of luminance IS(t) for white is calculated as follows:

{ Lt()}/L ()t

∑ i 0

i=1

(1)

IS()t =1−×100 (%)

{ Lt()}/L ()t

∑

i 0 00

i=1

where

t is the specified measurement time;

t is the initial measurement time;

L is the luminance of the measurement location from P .

i i

Chromatic deviation Δu’v’(t) caused by image sticking at P over time for white is calculated

0 0

as follows:

∆u 'vt'( ) {u '(t)− u '(t )}+−{vt'( ) vt'( )} (2)

00 0

where

=

t is the specified measurement time;

t is the initial measurement time;

(u’(t), v’(t)) is the white chromaticity value at the specified time;

(u’(t ), v’(t )) is the white chromaticity value at the initial time.

0 0

The average of the chromatic deviation Δu’v’(t) caused by image sticking between

AVG

different measuring locations from P to P for white is calculated as follows:

1 4

∆uv' '()t ( {u ' ()t− u ' ()t }+−{v ' ()t v ' ()t } ) / 4 (3)

AVG ∑ ii0 0

i=1

where

t is the specified measurement time;

(u’ (t), v’ (t)) are the chromaticity coordinates of the measuring locations of P (i = 1, 2, 3, 4).

i i i

The value of u' and v' can be calculated from the tristimulus value X, Y, and Z using the

following formula:

u ' 4XX/(++15Y 3Z)

(4)

v ' 9YX/(++15Y 3Z)

6.3.1.2 Colour difference method

6.3.1.2.1 General

The image sticking shall be analyzed with ∆E* of the three-dimensional, CIE 1976 L*a*b*

ab

colour space (see CIE 15-2004) following the procedure in 6.2.2. Additional three-dimensional

uniform colour spaces and colour spaces may also be used and identified in the test report.

Each colour point can be plotted on the L*, a*, and b* axes of the CIE L*a*b* colour space by

referencing the peak white tristimulus value (X , Y , Z ) in the measuring location P at the

n n n 0

initial time t and using the following transformation formula:

L* ()t=116×−f (Y ()t / Y ) 16

i in

a* ()t=500×−[ f (X ()t / X ) f (Y ()t / Y )] (5)

i i n in

b* ()t=200×−[ f (Y ()t / Y ) f (Z ()t / Z )]

i in i n

where

1/3 3

xx > (/6 29)

fx() =

1 29 4

() x + otherwise

3 6 29

t is the specified measurement time;

L*a*b* L* a* b* is the CIELAB colour coordinates of the measuring locations of P

i i i I i

(i = 0, 1, 2, 3, 4);

(X , Y , Z ) is the tristimulus value of the reference white in the measuring location P at

n n n 0

the initial time t .

6.3.1.2.2 CIE 1976

The colour difference formula ΔE* (t) caused by image sticking at P over time for white is

ab 0 0

calculated as follows:

=

=

=

– 16 – IEC 62341-5-3:2019 RLV © IEC 2019

2 22

(6)

∆E * (t) {L* (t)− L* (t )}+{a* (t)− a* (t )}+−{bt* ( ) bt* ( )}

ab 0 0 0 0 0 00 0 00

where

t is the specified measurement time;

t is the initial measurement time;

L*a*b* L* a* b* are the CIELAB colour coordinates of the measuring locations of P .

0 0 0 0 0

The average of the colour difference formula ΔE* (t) caused by image sticking between

ab AVG

different measuring locations from P to P for white is calculated as follows:

1 4

2 22

(7)

∆E * ()t {L* ()t− L* (t )}+{a * ()t− a * (t )}+{b* ()tb− * (t )} / 4

∑

ab AVG i 0 0 ii00 0 0

i=1

where

t is the specified measurement time;

L*a*b* L* a* b* are the chromaticity coordinates of the measuring locations of P (i = 1,

i i i i i

2, 3, 4).

6.3.2 Report

6.3.2.1 General

The typical value of image sticking can be reported with specified time, as shown in Table 2.

If other primary colours are used such as red, green and blue, it should be reported.

Table 2 – An example of typical value

Measurement data

time

P Average of P ~ P

Colour

0 1 4

(hour)

X Y Z X Y Z

0 White

1 White

6.3.2.2 Image sticking time

The estimated time of image sticking can be reported with the result of the comparison

between the reference luminance ratio, the chromatic deviation, and the colour difference, as

shown in Table 3.

Table 3 – An example of the image sticking time with reference

Factor Threshold Estimated time

Luminance ratio (IS) 3 %

Chromatic deviation ∆u’v’(t) at P

0 0

0,004

Average of chromatic deviation ∆u’v’(t)

AVG

Colour difference ∆E* (t) at P

ab 0 0

Average of colour difference ∆E* (t)

ab AVG

=

=

…

6.3.2.3 Image sticking data

The image sticking can be reported after target time, as shown in Table 4.

Table 4 – An example of the image sticking data at target time

Time

Factor Result data

(hours)

Luminance ratio (IS)

Chromatic deviation ∆u’v’(t) at P

0 0

Average of chromatic deviation ∆u’v’(t)

AVG

Colour difference ∆E* (t) at P

ab 0 0

Average of colour difference ∆E* (t)

ab AVG

6.3.2.1 Information of test pattern

Before reporting the measurement data, information on the used test pattern should be

reported, as shown in Table 2. It includes the type of test pattern, the size of the window box,

the allocated code values located at the centre and background, and the output luminance of

OLED displays for the test pattern. If other test patterns not listed in 5.3.4 are used, they

should be reported in accordance with Table 2.

Table 2 – Information on test pattern

Types of test pattern (SDR, HDR, etc.)

Size of window box - %

Centre – (based on 8 or 10 bits)

Code value

Background – (based on 8 or 10 bits)

Centre (P )

Output

luminance

Background (average of from P to P )

1 4

6.3.2.2 Measurement data record

The typical value of image sticking can be reported following the format shown in Table 3. For

the typical value, the initial data should be reported and other data at the specified time can

be selected following the measuring procedure of image stress.

Table 3 – Example of typical value

Measurement data

Time

Colour P Average of P to P

0 1 4

(hour)

X Y Z X Y Z

0 White

1 White

White

6.3.2.3 Image sticking data

Image sticking should be reported with the result of the comparison between the reference

luminance ratio, the chromatic deviation, and the colour difference, following the format

shown in Table 4. Each result data should be calculated from Formulae (1) to (7), and should

– 18 – IEC 62341-5-3:2019 RLV © IEC 2019

be reported in Table 4. The designated time is 500 h. If the time is changed, it should be

reported.

Table 4 – Reporting format of the image sticking data at target time

Time

Factor Result data

(hours)

Luminance ratio (IS)

Chromatic deviation Δu’v’(t) at P

0 0

Average of chromatic deviation Δu’v’(t)

AVG

Colour difference ΔE* (t) at P

ab 0 0

Average of colour difference ΔE* (t)

ab AVG

It is recommended to refer to ΔE* using the method in Annex B, if it is necessary to

calculate the colour difference with CIEDE2000 instead of ΔE* .

ab

6.3.2.4 Image sticking time

Image sticking can also be reported as the estimated time with the thresholds as shown in

Table 5. The thresholds of the image sticking can be set depending on the display size, peak

luminance and so on. They can be selected as needed and should be reported.

Table 5 – Reporting format of the image sticking time with threshold

Factor Threshold Estimated time

Luminance ratio (IS) -

Chromatic deviation Δu’v’(t) at P

0 0

-

Average of chromatic deviation Δu’v’(t)

AVG

Colour difference ΔE* (t ) at P

ab 0 0

-

Average of colour difference ΔE* (t)

ab AVG

It is recommended to refer to ΔE* using the method in Annex B, if it is necessary to

calculate colour difference with CIEDE2000 instead of ΔE* .

ab

7 Measuring methods of the luminance lifetime

7.1 Purpose

The purpose of this met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...