IEC TR 62331:2005

(Main)Pulsed field magnetometry

Pulsed field magnetometry

Reviews methods for measuring magnetically hard materials using pulsed field magnetometers. The methods of measurement of the magnetic properties of magnetically hard materials have been specified in IEC 60404-5 for closed magnetic circuits and in IEC 60404-7 for open magnetic circuits. The measurement result of the magnetic properties of magnetically hard materials at elevated temperatures is given in IEC 61807. Pulsed field magnetometers have been developed to provide rapid measurement facilities to match high speed production rates with 100 % quality control. The object of this report is to describe the principles and practical implications of pulsed field magnetometry in order to enable the full potential of the technique to be considered, including its application using small and large magnets of varying geometries, to various magnetic field strengths and frequencies.

General Information

- Status

- Published

- Publication Date

- 22-Feb-2005

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 5 - TC 68/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Feb-2005

- Completion Date

- 15-May-2005

Overview - IEC TR 62331:2005 - Pulsed field magnetometry

IEC TR 62331:2005 is a Technical Report from the IEC that reviews methods for measuring magnetically hard (permanent) materials using pulsed field magnetometers (PFMs). The report describes the principles, instrumentation and practical implications of pulsed field magnetometry to enable rapid, production‑rate measurements - including application to small and large magnets of varying geometries, magnetic field strengths and frequencies. The document also outlines dynamic measurement effects and corrections needed for accurate magnetic characterization.

Key topics and technical requirements

- Scope and purpose: Reviews pulsed field techniques as a rapid alternative to slow static or superconducting magnet methods for full magnet characterization.

- PFM system components:

- Field generator: magnetizing solenoid and power supply (typically capacitive discharge systems) to generate short, intense field pulses (pulsed systems can reach very high fields - the report notes pulsed approaches can generate fields up to tens of tesla).

- Sensors (pick‑up coils): J coil (dΦ/dt coil used to derive sample polarization) and H coil (magnetic field strength sensor).

- Transient instrumentation & digitizing hardware: analogue integration, high‑rate digitization, numerical integration and filtering.

- Data processing: zero‑signal removal, M(H) loop positioning, self‑demagnetization correction, low‑pass filtering, calibration and eddy current correction.

- Measurement considerations: specimen size and geometry, temperature effects, magnetic viscosity and eddy current influences on transient signals.

- Practical recommendations: signal integration and calibration techniques, pulse waveform options, and comparison with other measurement methods.

Practical applications - who uses this standard

- Permanent magnet manufacturers and production engineers for 100% quality control at high throughput.

- Materials testing laboratories and calibration facilities requiring rapid magnetic characterization.

- R&D teams and magnet designers evaluating magnetic properties across geometries and temperatures.

- Standards bodies and test-house engineers integrating pulsed magnetometry into measurement protocols.

PFMs are especially valuable where fast, repeatable measurement of coercivity, remanence and full M(H) loops is required without the complexity or cost of superconducting magnets.

Related standards

- IEC 60404‑5 - Permanent magnet materials: methods of measurement (closed circuits)

- IEC 60404‑7 - Coercivity measurement in open circuits

- IEC 61807 - Magnetic properties at elevated temperatures

- IEC 60404‑14 - Magnetic moment measurement by withdrawal/rotation methods

Keywords: pulsed field magnetometry, pulsed field magnetometer, magnetically hard materials, permanent magnets, IEC TR 62331, J coil, H coil, eddy current correction, magnetizing solenoid, capacitive discharge, magnetic measurement, quality control.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62331:2005 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Pulsed field magnetometry". This standard covers: Reviews methods for measuring magnetically hard materials using pulsed field magnetometers. The methods of measurement of the magnetic properties of magnetically hard materials have been specified in IEC 60404-5 for closed magnetic circuits and in IEC 60404-7 for open magnetic circuits. The measurement result of the magnetic properties of magnetically hard materials at elevated temperatures is given in IEC 61807. Pulsed field magnetometers have been developed to provide rapid measurement facilities to match high speed production rates with 100 % quality control. The object of this report is to describe the principles and practical implications of pulsed field magnetometry in order to enable the full potential of the technique to be considered, including its application using small and large magnets of varying geometries, to various magnetic field strengths and frequencies.

Reviews methods for measuring magnetically hard materials using pulsed field magnetometers. The methods of measurement of the magnetic properties of magnetically hard materials have been specified in IEC 60404-5 for closed magnetic circuits and in IEC 60404-7 for open magnetic circuits. The measurement result of the magnetic properties of magnetically hard materials at elevated temperatures is given in IEC 61807. Pulsed field magnetometers have been developed to provide rapid measurement facilities to match high speed production rates with 100 % quality control. The object of this report is to describe the principles and practical implications of pulsed field magnetometry in order to enable the full potential of the technique to be considered, including its application using small and large magnets of varying geometries, to various magnetic field strengths and frequencies.

IEC TR 62331:2005 is classified under the following ICS (International Classification for Standards) categories: 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62331:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

REPORT TR 62331

First edition

2005-02

Pulsed field magnetometry

Reference number

IEC/TR 62331:2005(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

REPORT TR 62331

First edition

2005-02

Pulsed field magnetometry

IEC 2005 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

W

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – TR 62331 IEC:2005(E)

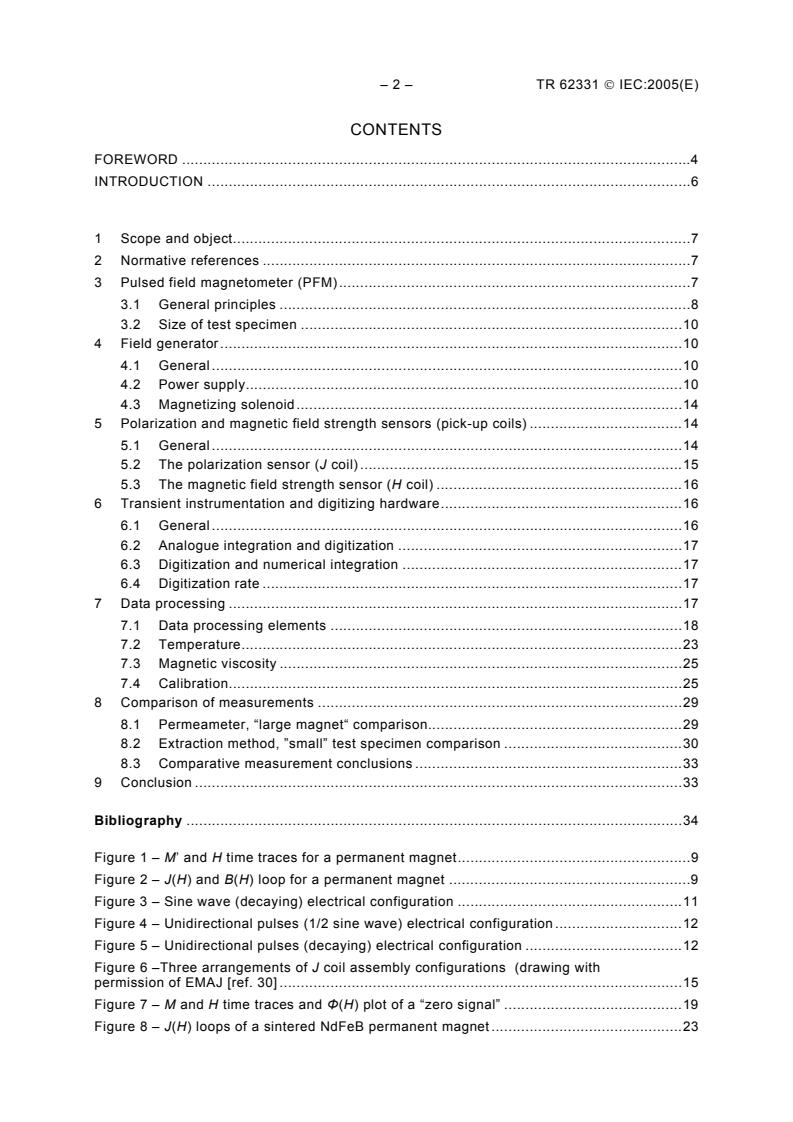

CONTENTS

FOREWORD .4

INTRODUCTION .6

1 Scope and object.7

2 Normative references .7

3 Pulsed field magnetometer (PFM).7

3.1 General principles .8

3.2 Size of test specimen .10

4 Field generator.10

4.1 General .10

4.2 Power supply.10

4.3 Magnetizing solenoid.14

5 Polarization and magnetic field strength sensors (pick-up coils) .14

5.1 General .14

5.2 The polarization sensor (J coil).15

5.3 The magnetic field strength sensor (H coil) .16

6 Transient instrumentation and digitizing hardware.16

6.1 General .16

6.2 Analogue integration and digitization .17

6.3 Digitization and numerical integration .17

6.4 Digitization rate .17

7 Data processing .17

7.1 Data processing elements .18

7.2 Temperature.23

7.3 Magnetic viscosity .25

7.4 Calibration.25

8 Comparison of measurements .29

8.1 Permeameter, “large magnet“ comparison.29

8.2 Extraction method, ”small” test specimen comparison .30

8.3 Comparative measurement conclusions .33

9 Conclusion .33

Bibliography .34

Figure 1 – M’ and H time traces for a permanent magnet.9

Figure 2 – J(H) and B(H) loop for a permanent magnet .9

Figure 3 – Sine wave (decaying) electrical configuration .11

Figure 4 – Unidirectional pulses (1/2 sine wave) electrical configuration .12

Figure 5 – Unidirectional pulses (decaying) electrical configuration .12

Figure 6 –Three arrangements of J coil assembly configurations (drawing with

permission of EMAJ [ref. 30] .15

Figure 7 – M and H time traces and Φ(H) plot of a “zero signal” .19

Figure 8 – J(H) loops of a sintered NdFeB permanent magnet .23

TR 62331 IEC:2005(E) – 3 –

Figure 9 – J(H) loop including eddy currents of a conductive bulk nickel specimen

measurement result from a PFM system .27

Figure 10 – Copper specimen eddy current measurement result.27

Figure 11 – J(H) loop for eddy current “corrected” nickel specimen .28

Figure 12 – Results of a permeameter and a PFM measurement of a “large” specimen.29

st nd

Figure 13 – Detail of the 1 and 2 quadrants of the measurement results shown in

Figure 12 “large magnet” .29

Figure 14 – Comparison of a “small magnet” measured in a super-conducting,

extraction method magnetometer (EMM) compared with a PFM measurement result of

the same magnet [28] .30

Figure 15 – Measurement result of a NEOMAX 32EH NdFeB cylinder of diameter

10 mm length 7 mm on the TPM-2-10 system [34] .31

Figure 16 – Measurement result of a NEOMAX 32EH NdFeB cube of dimensions

7 mm × 7 mm × 7 mm [34].32

Figure 17 – Measurement result of a sintered Sm2Co17 cylinder of diameter 10 mm

and length 7 mm [34] .33

Table 1 – Comparison of methods of generating the magnetic field strength .13

Table 2 – Classification of the influences of eddy currents.21

Table 3 – A comparison of values taken from the measurement results presented in

Figure 11 and Figure 12.30

Table 4 – Comparison of values measured in Figure 14 above (see NOTE) .30

– 4 – TR 62331 IEC:2005(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PULSED FIELD MAGNETOMETRY

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated

in the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC 62331, which is a technical report, has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

68/299/DTR 68/303/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

TR 62331 IEC:2005(E) – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – TR 62331 IEC:2005(E)

INTRODUCTION

In order to measure the full magnetic characterization of magnetically hard (permanent

magnet) materials, it is necessary to apply a magnetic field sufficient to saturate the test

specimen of magnetic material.

The generation of this magnetic field can become a practical limiting factor and can

determine the appropriate measurement techniques.

Super-conducting magnets can generate very high static or slowly changing magnetic fields

but their complexity, high capital outlay and running costs, requiring cryogenic gases make

them far from ideal. It is necessary to change fields slowly to avoid “quenching” the super-

conducting magnet.

Conventionally wound electro-magnets with slowly changing magnetic fields have a

significant heat generation problem through I R loss. This can be alleviated through the use

of a high relative permeability “iron yoke”. However, saturation of the iron prevents maximum

characterization of the loop of rare earth permanent magnet materials to be determined.

A pulsed field system utilizing conventional conductors minimizes heating effects by limiting

field durations and by limiting heat generation to acceptable levels. Fields up to 40 Tesla (T)

can be generated in this way.

Careful consideration, however, must be given to the instrumentation and method to take

account of dynamic effects due to the short duration of the magnetic field.

While work on pulsed field magnetometry is carried out in many parts of the world, the two

main groups are MACCHARETEC [ref. 29] in Europe and EMAJ [ref. 30] in Japan. The

approach adopted in Japan is one of supporting a standard with fixed specimen sizes,

magnetic field strengths and frequencies in a limited number of configurations.

———————

References in square brackets refer to the bibliography.

TR 62331 IEC:2005(E) – 7 –

PULSED FIELD MAGNETOMETRY

1 Scope and object

This Technical Report reviews methods for measuring magnetically hard materials using

pulsed field magnetometers.

The methods of measurement of the magnetic properties of magnetically hard materials have

been specified in IEC 60404-5 for closed magnetic circuits and in IEC 60404-7 for open

magnetic circuits. The measurement result of the magnetic properties of magnetically hard

materials at elevated temperatures is given in IEC 61807.

Pulsed field magnetometers have been developed to provide rapid measurement facilities to

match high speed production rates with 100 % quality control.

The object of this report is to describe the principles and practical implications of pulsed field

magnetometry in order to enable the full potential of the technique to be considered,

including its application using small and large magnets of varying geometries, to various

magnetic field strengths and frequencies.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60404-5:1993, Magnetic materials – Part 5: Permanent magnet (magnetically hard)

materials – Methods of measurement of magnetic properties

IEC 60404-7:1982, Magnetic materials – Part 7: Method of measurement of coercivity of

magnetic materials in an open magnetic circuit

IEC 61807:1999, Magnetic properties of magnetically hard materials at elevated

temperatures – Methods of measurement

IEC 60404-14:2002, Magnetic materials – Part 14: Methods of measurement of the magnetic

moment of ferromagnetic material specimen by the withdrawal or rotation method

3 Pulsed field magnetometer (PFM)

A pulsed field magnetometer consists of the following parts:

a) The magnetic field strength generator consisting of

i) the power supply (usually a capacitive discharge system)

ii) magnetizing solenoid

b) Magnetization and magnetic field strength sensors (pick-up coils)

c) Instrumentation for transient processing and digitizing hardware

i) integration

ii) digitization

d) Data processing facilities to enable the processing of

– 8 – TR 62331 IEC:2005(E)

i) zero signal

ii) M(H) loop positioning

iii) self-demagnetization correction

iv) low band pass filtering

v) calibration factors

vi) eddy current correction.

3.1 General principles

The basic principle of operation of the pulsed field magnetometer depends upon an intense

transient magnetic field being generated by the magnetic field strength generator and being

applied to the test specimen to be measured. The magnetic field strength and resultant

magnetization of the test specimen are recorded and processed.

During a measurement cycle, the test specimen in the J coil increases flux. The output

voltage of this coil is the time derivative of the flux Φ coupled to that coil. This flux is due

largely to the magnetization of the specimen but also to the zero signal (see 7.1.1) and

possible eddy currents (see the eddy current correction techniques in 7.1.6) etc. As a

consequence the coil is usually referred to as the “Jcoil,” or on occasions the “M coil.” It is

however, truly a dΦ/dt coil. In this standard it will be referred to as the “J coil.”

In the case of the H coil, the output voltage is the time derivative of the magnetic flux that is

coupled to that coil and is largely the magnetic field strength applied to the specimen. This

coil is usually referred to as the “H coil,” although it is truly a dH/dt coil.

The outputs of these two coils are integrated (see 6.2). In the case of the integrated signal

from the Jcoil, the zero signal is removed and the result calibrated to generate an M’ signal,

that is, the magnetization of the specimen being measured in an open magnetic circuit. By

combining this with the H signal, an M’(H) hysteresis loop is obtained (see Clause 7).

If the M’(H) loop is corrected for the self-demagnetization of the open magnetic circuit

measurement, (see 7.1.3), the intrinsic M(H) or J(H) loop data can be obtained (or B(H) if

required) by the usual conversion.

The two signal channels, that is, from pick-up coil, through integration, digitization and data

collection and processing within the computer, are generally known as the “J” and “H"

channels.

TR 62331 IEC:2005(E) – 9 –

7 000

6 000

5 000

4 000

3 000

2 000

1 000

0,000 0,004 0,008 0,012 0,016 0,020 0,024

Time s

6 000

5 000

4 000

3 000

2 000

1 000

–1 000

–2 000

–3 000

–4 000

–5 000

0,000 0,004 0,008 0,012 0,016 0,020 0,024

Time s

IEC 321/05

Figure 1 – M’ and H time traces for a permanent magnet

The lower trace (above) is the time trace of the magnetic field strength (H) based upon the

field generator configuration discussed in 3.2.2.1. The upper trace represents the time trace

of the specimen magnetization; a specimen of sintered Neodymium Iron Boron; data obtained

after initial integration and digitization of the J and H coil outputs, in arbitrary units [ref. 32].

Remenance –:

–1,321 T

7 000

4,000

Remenance +:

6 000

1,321 T

Coercivity –:

5 000

1157 kA/m

3,000

Coercivity +:

4 000

–1157 kA/m

JHMax.:

3 000

1191,51 kJ/m

2,000

2 000

1 000

1,000

Loop ledgend

Neo27095 h.L_jhs

0,000 0,004 0,008 0,012 0,016 0,020 0,024 0,028

Neo27095 h.L_bhs

Time6 s 6 6 6

0,000

6 000

5 000

–1,000

4 000

3 000

2 000

–2,000

1 000

–1 000

–3,000

–2 000

–3 000

–4 000

–4,000

–5 000

0,000

–2 000 –1 500 –1 000 –500 0 500 1 000 1 500 2 000 2 500 3 000 0,004 0,008 0,012 0,016 0,020 0,024 0,028

Applied field kA/m 0 Time6 s 6 6 6

IEC 322/05

Figure 2 – J(H) and B(H) loop for a permanent magnet

Magnetization, AD counts

J and B T Applied field, AD counts

Applied field, AD counts Magnetization, AD counts

– 10 – TR 62331 IEC:2005(E)

The complete hysteresis loop is obtained by plotting the J data against the H data shown in

Figure 1, without using the time domain data. The time domain J and H data are again shown

to the right. [ref. 32]. The inner loop represents the B(H) loop.

3.2 Size of test specimen

As the test specimens are measured in an open magnetic circuit, there is no immediate limit

to the size of specimens that can be tested. Small and large test specimens can be measured

providing that eddy current considerations, and the practical considerations of the

instrumentation, are taken into account (see 7.1.6).

The results shown in this report are for cylinders of a maximum dimensions of 30 mm

diameter and 25 mm length and minimum dimensions of 5 mm diameter and 5 mm length,

although this is not a practical limitation for the PFM technique.

Cylindrical test specimens with diameters less than 3 mm and lengths of 3 mm have been

measured while cylinders of NdFeB of 40 mm diameter and 30 mm length have also been

measured.

The Japanese group EMAJ measure test specimens of a cylindrical shape of 10 mm diameter

and 7 mm length and a cube of 7 mm x 7 mm x 7 mm (see Figures 14–16).

4 Field generator

4.1 General

The field generator consists of a system that enables the magnetic field to be applied to the

test specimen.

This will consist of a power supply and a magnetizing solenoid. The power supply provides

the magnetizing current to the magnetizing solenoid in order to generate the applied

magnetic field.

4.2 Power supply

4.2.1 General

Power supplies normally have the capacity to apply an electrical potential (over the range of

400–10 000 V but more typically 1 000–3 000 V) at currents (with a current range of 1 000–

40 000 A but more typically 5 000–20 000 A), in both positive and negative polarities.

This can be accomplished by one of two methods:

a) capacitive discharge;

b) direct mains supply.

4.2.2 Capacitive discharge

The capacitive discharge arrangement enables electrical energy to be accumulated in

capacitors over an extended period of time, before being discharged in a short time period to

provide high currents from the low impedance source.

The energy storage:

E = ½ CU (1)

where

TR 62331 IEC:2005(E) – 11 –

E is the energy, in joules;

C is the capacitance, in farads;

U is the capacitor voltage, in volts.

For commercial PFM measurement systems, it is necessary to minimize costs and it is

therefore, normally necessary to achieve the required magnetic performance with the

minimum of capacitor energy. The capacitance and energy of the capacitive discharge

system is matched with the magnetizing solenoid to provide the required magnetizing

conditions of peak field strength, field volume, field homogeneity and period. The maximum

magnetic field strength achieved is proportional to the current density; the proportionality

factor being dependent on the geometry of the magnetising solenoid.

The discharge can be applied in the following forms:

a) sine wave (decaying);

b) unidirectional pulses (1/2 sine wave);

c) two unidirectional pulses (with decay).

4.2.2.1 Sine wave (decaying)

C

L

IEC 323/05

Figure 3 – Sine wave (decaying) electrical configuration

The current I(t), and therefore the magnetic field strength is determined by:

U

0 −βt

I(t) = .e sinωt (2)

ωL

1 R

where ω is given by ω = − (3)

LC

4L

and is given by β = R/2L (4)

Due to the resistive losses in the magnetizing solenoid, the peak field strength created in the

magnetizing solenoid in the reverse direction is reduced, depending on the damping factor β.

It is therefore necessary to apply a higher initial field, in order to achieve the necessary

reverse field.

The sine wave technique has the advantage of a continuous process to apply positive and

negative polarities and to avoid discontinuities. This is important in the testing of conductive

materials where eddy current effects are taken into consideration (see 7.1.6).

– 12 – TR 62331 IEC:2005(E)

4.2.2.2 Unidirectional pulses (1/2 sine wave)

C

L

IEC 324/05

Figure 4 – Unidirectional pulses (1/2 sine wave) electrical configuration

The current is determined by:

U

0 −βt

I(t) = .e sinωt (5)

ωL

1 R

where (6)

ω = −

LC

4L

and β = R/2L (7)

However, after the first half sine wave of the current, the reverse charge that is generated

across the capacitors is not permitted to discharge due to the diode characteristic of the

thyristor.

The resultant current waveform is a half sine wave (0–180°).

By applying an identical pulse with a reverse polarity, a maximum positive and negative field

can be applied with identical peak fields of positive and negative polarities.

The overall measurement is accomplished by two separate discharges. This approach does

have the advantage of achieving the same peak fields on positive and negative pulses.

However, two discrete pulses are applied with their inherent discontinuities of current.

4.2.2.3 Unidirectional pulses (decaying)

C

L

IEC 325/05

Figure 5 – Unidirectional pulses (decaying) electrical configuration

The current discharge is determined by:

U

−β(t - t )

I(t) = .e sinωt (8)

ωL

TR 62331 IEC:2005(E) – 13 –

where t is the time at the start of the discharge.

When the capacitor is completely discharged, the diode becomes conducting and prevents

the capacitor from becoming charged reversely. From this point in time the current is

determined by:

−R.(t +t )

L

I(t) = I .e (9)

where

t occurs when U = 0

1 0

I is the current at the instant in time when the clamping diode becomes forward biased.

As with method 4.2.2.2 a complete positive and negative magnetic field strength period can

be achieved by applying two pulses, one of reverse polarity.

While this technique suffers from the necessity of applying two pulses, it also has two very

different dynamic responses on the rising and falling current waveforms, thereby offering a

lower dH/dt during the period after peak field.

Table 1 – Comparison of methods of generating the magnetic field strength

Fixed Identical positive

Single wave

frequency Continuous and negative

function

fields

Sine wave (decaying)

YES YES YES NO

4.2.2.1

Unidirectional ½ wave

YES NO YES YES

4.2.2.2

Unidirectional pulse

NO NO NO YES

(decaying) 4.2.2.3

The preferred approach is the sine wave (decaying) as described in 4.2.2.1, particularly in

consideration of possible eddy currents in conductive specimens as the resulting applied

magnetic field strength is of a continuous waveform in the case of 4.2.2.1 as opposed to the

discontinuities created by the discrete positive and negative periods required by 4.2.2.2 and

4.2.2.3.

It should be noted that the preferred approach of EMAJ [ref. 30] is 4.2.2.2, unidirectional

pulse (1/2) sine wave.

4.2.2.4 The repeatability of the applied voltage

The repeatability of the voltage applied to the capacitor of the capacitor bank is relatively

unimportant provided that the energy is sufficient to saturate the magnet material of the test

specimen. The repeatability is, however, very important for correcting the zero signal. A

repeatability of ±1 % can be easily achieved and is adequate. A repeatability of ±0,1 % is

more typically available.

The magnetic field strength is dependent upon the resistance of the magnetizing solenoid.

The temperature variation of the magnetizing solenoid can have a small influence on the

result and must be considered.

– 14 – TR 62331 IEC:2005(E)

4.2.3 Direct mains supply

Some high field facilities around the world utilize power supplies that are directly coupled to

mains supplies. These systems are able to create high fields (20–40 T) for periods of around

1 s.

Although these facilities offer a valuable resource, they will not be considered in this report.

It is also possible to construct power supplies of this type on a much smaller scale. The

difficulty with this type of equipment is that it is directly coupled to a mains supply and cannot

comply with mains supply power demand regulations, and therefore is not likely to be of great

significance.

4.3 Magnetizing solenoid

The magnetizing solenoid can be considered as a conventional solenoid.

The design of the solenoid must take into account the following factors:

4.3.1 Peak magnetic field strength

The peak value of magnetic field strength must be sufficiently large to saturate the test

specimen in both positive and negative directions. This should include a margin of +10 %

overshoot.

The required magnetic field strength depends upon the material, the orientation and the

demagnetization factor of the test specimen.

4.3.2 Volume to be magnetized

The volume of the magnetizing solenoid must be sufficiently large to enclose the test

specimen and the pick-up coil system.

4.3.3 Field homogeneity across the volume of the specimen under test

The field homogeneity throughout the entire test specimen volume should be within ±1 %.

4.3.4 Field frequency

Rate of change of field with time, dH/dt, should be kept as low as possible either to avoid

inducing significant eddy currents in conductive specimens, or to be suitable for eddy current

correction.

It should be noted that the preferred approach of EMAS [ref. 31]) is to avoid eddy currents.

5 Polarization and magnetic field strength sensors (pick-up coils)

5.1 General

It is necessary to measure correlated values of polarization J of the test specimen and the

magnetic field strength H during that test.

This is usually achieved using pick-up coils. While it is feasible that other forms of detectors

could be used, such as Hall sensors, such alternative detectors are not considered in this

report.

TR 62331 IEC:2005(E) – 15 –

It may be considered reasonable to utilize a single channel system and measure J and H

transients on successive magnetizing pulses. Apply a field pulse while recording J and when

the magnetizing solenoid has regained its original temperature, apply a second (and

hopefully identical) pulse and measure H. This, however, seems an unnecessary

complication and can be a source of procedural error. Two channels and simultaneous

recording of both channels are required.

Pick-up coils can be configured in a variety of geometries, however all have common

features.

Thus, what is needed is, in principle:

a) the polarization sensor (J coil);

b) the magnetic field strength sensor (H coil).

5.2 The polarization sensor (J coil)

The polarization sensor or J coil assembly consists of two (or more) coils connected in series

opposition. The coils have equal area turns products but different coupling to the test

specimen and so measure only the magnetization of the test specimen and not the applied

magnetic field.

(a) (b) (c)

IEC 326/05

Figure 6 –Three arrangements of J coil assembly configurations

(drawing with permission of EMAJ [ref. 30]

As discussed earlier, during a measurement cycle, flux is increased by the presence of the

specimen in the J coil assembly. The output voltage of this coil is the time derivative of the

flux Φ coupled to that coil. This flux signal is due largely to the magnetization of the

specimen but also to the zero signal (see 7.1.1) and possible eddy currents (see 7.1.6) etc.

Considering the J coil assembly in Case 6(a), often known as an “n+n coil,” the two

constituent coils have identical cross-sectional area and numbers of turns (equal area turns

product). The coils are connected in opposition so no coil output results from applying a

pulsed homogeneous field (H) to both coils.

– 16 – TR 62331 IEC:2005(E)

When a test specimen is located in one of the two coils, it will be coupled strongly to that coil

(the test specimen coil) and coupled weakly to the neighbouring coil (the compensation coil).

When a pulsed homogeneous field is applied to the coil assembly, the output will be

proportional to the time derivatives of the magnetization of the test specimen (see NOTE

below).

In the case of J coil assembly, Case 6(b) often known as a “½ n+n+½ n coil,” the

compensation coil is divided into two smaller coils at each end of the J coil assembly. These

two coils each have half the area turns product of the specimen coil that is positioned

between them. The compensation coils are connected in opposition to the specimen coil.

The test specimen is located in the specimen coil and is strongly coupled to it, while only

weakly coupled to the compensation coils. Again, the output will be proportional to the time

derivatives of the magnetization of the test specimen.

In the case of J coil assembly, Case 6(c) often known as a “coaxial coil,” the compensation

coil has a much larger cross-sectional area, but correspondingly fewer turns in order to equal

the area turns product of the specimen coil which is positioned coaxially, inside the

compensation coil. The compensation coil is connected in opposition to the specimen coil.

The test specimen is positioned within the specimen coil and is strongly coupled to it. Due to

the weaker coupling of the test specimen to the compensation coil, once again, the output will

be proportional to the time derivatives of the magnetization of the test specimen. Variations

of these pick-up coil geometries and other geometries are possible.

Ideally, the J coil assembly signal should be uniform over the maximum expected test

volume, i.e. with a homogeneous test specimen material, the response signal should be

strictly proportional to the volume of the test specimen.

Such arrangements permit the measurement of magnetization so that the response, in the

ideal case, is not dependent upon test specimen shape or position. However, systems that do

not have such a pick-up homogeneity must be calibrated with a sample of an identical

geometry to that of the test specimen to be measured.

A value of homogeneity of the pick-up coil of ±1 % or better is typical.

NOTE As the area turns of the two coils are never exactly equal, a suitable correction must be provided. This

may prove to be a mechanical adjustment or additional electronic components. In either case, careful

consideration must be made to avoid compromising the integrity of the coil output during a measurement cycle.

5.3 The magnetic field strength sensor (H coil)

The magnetic field strength sensor may consist of one or more, coils which are coupled to the

magnetic field strength in the region of the test specimen, but not significantly coupled to the

test specimen. These coils are often positioned on the same structure as the J coil.

Also as discussed earlier, the H coil output is the time derivative of the magnetic flux that is

coupled to that coil and is largely due to the magnetic field strength. This coil is usually

referred to as the “H coil,” although it is truly a dH/dt coil.

6 Transient instrumentation and digitizing hardware

6.1 General

The outputs of the pick-up coils are proportional to the time derivatives of magnetic flux.

The magnetic field strength pick-up coil (H) the coil output voltage is:

TR 62331 IEC:2005(E) – 17 –

dH

U ∝ (10)

H

dt

The polarization, J pick-up coil output voltage is:

dJ

U ∝ (11)

J

dt

It is necessary to obtain the integrals of these signals in order to obtain J and H signals.

Two approaches may be used for integration:

a) analogue integration and digitization;

b) digitization and numerical integration.

6.2 Analogue integration and digitization

The signals from the pick-up coils are fed to the input of an analogue integrator and are

incorporated. The output of the integrator is then fed to an analogue-to-digital converter

(ADC) and digitized.

The advantage of this approach is that the analogue integrators have a very wide input

dynamic range and can inherently cope with magnetization time derivatives, from a given test

specimen across a wide range of magnetic field strengths.

6.3 Digitization and numerical integration

The signals from the pick-up coils are fed to the input of an analogue-to-digital converter and

are digitized. A numerical approach is then used to integrate the data.

The disadvantage of this approach is that the ADC must have a very wide input range and

higher resolution than in 6.2 when dealing with the dΦ/dt signals.

This approach does not require an analogue integrator although analogue amplifiers or

attenuators may be required.

6.4 Digitization rate

The digitization process must occur on a rate that is high enough to obtain sufficient points

over the minimum data density region, i.e. close to the coercivity of the test specimen.

This will occur when dΦ/dt is at maximum and the rate will be determined by the applied

dH/dt and the characteristic of the test specimen.

A minimum sample rate of 2 × 10 samples/s for a magnetic field strength with sine wave

period of 50 ms is recommended.

The resolution of measurements should be a minimum of 12 bits.

7 Data processing

The H coil output is proportional to dH/dt. In order to process this data to obtain valid H data

(applied magnetic field strength), it is necessary to integrate the signal and apply an H

channel calibration factor. The H channel calibration factor is specific to the H coil and H

channel integrator arrangement of the individual PFM system.

– 18 – TR 62331 IEC:2005(E)

The J channel signal processing involves more steps:

The J pick-up coil output is proportional to dΦ/dt plus the derivative of the zero signal.

(Where Φ is the flux produced by the magnetization of the test specimen.)

This signal is first integrated and the zero signal (see 7.1.1) removed to obtain an M’ signal,

that is, a signal proportional to Φ. The M’ signal is then multiplied by the J channel calibration

factor and divided by the test specimen volume consideration, in order to obtain M*, that is,

the intrinsic open magnetic circuit magnetization of the test specimen material. By applying a

self demagnetization factor to the M* signal the intrinsic J signal can be obtained (see 7.1.3).

The J calibration factor is specific to the J coil and J channel integrator arrangement of the

individual PFM system. (see 7.1.5).

As the initial magnetization of the test specimen is unknown, it may be necessary to position

the M* signal in the M* domain (see 7.1.2).

The synchronized J and H signals can now be combined to obtain a J(H) hysteresis loop. It is

not uncommon to carry out many or all of the J channel processing steps in the J (H) domain

(i.e. the M’(H), M*(H) or J(H) domains).

The B(H) loop can be obtained by the usual conversion.

In the event that eddy currents have occurred in the test specimen during the measurement

process, eddy current correction may need to be considered (see 7.1.6).

7.1 Data processing elements

The following must be taken into consideration when carrying out data processing:

– zero signal;

– loop positioning;

– self-demagnetization;

– filtering;

– calibration factors/scaling;

– eddy currents.

In order to convert the raw data (“J” and “H”) from the measurement, into a J(H) and/or B(H)

data set, it is necessary to process the data with respect to the following elements:

7.1.1 Zero signal

When a measurement is made on a PFM system, without a test specimen, a signal is

observed. For a well designed and constructed system, this signal will be small compared to

the size of the measured test specimen signal, and very repeatable. This signal is generally

known as the “zero signal.”

The zero signal is caused by eddy currents in conductive materials and other effects in the

region of the applied magnetizing field.

This signal can be expected to change in magnitude, and possible shape, for different

magnetic field strengths.

It is necessary to numerically subtract the zero signal obtained from a prior measurement

without a test specimen, from the real measurement data. The amplitude of the zero signal

can limit the minimum size of the test specimen to be measured.

TR 62331 IEC:2005(E) – 19 –

While a zero signal of say 5 % (compared to the overall measurement signal) might be

acceptable, a variation (from measurement to measurement) in the zero signal of, say 10 %,

will offer a single source of error of 0,5 % in the M measurement process.

A resulting error of 0,1 % should be considered acceptable.

0,005 40

0,003

0,000

–0,002

–10

–0,005

–20

–0,007

–30

0,000 0,004 0,008 0,012 0,016 0,020 0,024 0,028

–0,010 Time s

–0,012

1 000

–0,015

–0,017

–0,020

–1 000

–0,022

–1 000 –750 –500 –250 0 250 500 750 1 000 1 250 1 500 1 750

0,000 0,004 0,008 0,012 0,016 0,020 0,024 0,028

Applied field kA/m

Time s

IEC 327/05

NOTE See Figure 10 for an explanation of “apparent polarization”.

Figure 7 – M and H time traces and Φ(H) plot of a “zero signal”

The measurement result is obtained after the integration and digitization of the J and H coil

signals in arbitrary units (counts). The zero signal recorded above (top right) represents a

peak value of ± 30 counts in a system with a ± 8 192 count range. The time trace, bottom

right, represents the magnetic field strength. The loop (left) represents the zero signal in the

Φ(H) domain [ref. 32] .

7.1.2 Loop positioning

As the pick-up coil sensors are AC coupled systems, the DC portion of the measured signals

is unknown. It is necessary to position the M(H) loop within the M(H) domain.

While the magnetic field strength can be expected to start and end at zero, the magnetization

signal can be related to a magnetic specimen of unknown

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...