IEC 61730-2:2016

(Main)Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing

Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing

IEC 61730-2:2016 provides the testing sequence intended to verify the safety of PV modules whose construction has been assessed by IEC 61730-1. The test sequence and pass criteria are designed to detect the potential breakdown of internal and external components of PV modules that would result in fire, electric shock, and/or personal injury. The standard defines the basic safety test requirements and additional tests that are a function of the PV module end-use applications. Test categories include general inspection, electrical shock hazard, fire hazard, mechanical stress, and environmental stress. This new edition includes the following significant technical changes with respect to the previous edition:

- the test sequences have been rearranged;

- various tests have been detailed or added.

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) - Partie 2: Exigences pour les essais

L'IEC 61730-2:2016 fournit la séquence d'essais destinée à vérifier la sûreté des modules PV dont la construction a été évaluée par l'IEC 61730-1. La séquence d'essais et les critères d'acceptation sont conçus pour détecter le claquage éventuel de composants internes et externes des modules PV, qui entraînerait des incendies, des chocs électriques et/ou des dommages corporels. La norme définit les exigences de base relatives aux essais de sécurité, ainsi que des essais supplémentaires qui sont fonction des applications finales du module PV. Les catégories d'essais incluent un contrôle général, les risques de chocs électriques, le risque de feu, les contraintes mécaniques et les contraintes environnementales. Cette nouvelle édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- les séquences d'essai ont été réorganisées;

- certains essais ont été détaillés ou ajoutés.

General Information

- Status

- Published

- Publication Date

- 17-Aug-2016

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 12-Sep-2023

- Completion Date

- 01-Mar-2019

Relations

- Revises

IEC 61730-2:2004 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Revised

IEC 61730-2:2023 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing - Effective Date

- 05-Sep-2023

Overview

IEC 61730-2:2016 - Photovoltaic (PV) module safety qualification, Part 2 - defines the testing requirements and sequence to verify the electrical and fire safety of PV modules whose construction has been assessed under IEC 61730-1. The standard’s test sequence and pass criteria are intended to detect potential breakdowns of internal and external components that could lead to fire, electric shock, or personal injury. Edition 2.0 (2016) rearranged several test sequences and added or detailed multiple tests to reflect updated safety priorities.

Key technical topics and requirements

- Scope linkage: Applies where module construction has already been evaluated per IEC 61730-1; Part 2 provides the practical verification through testing.

- Test categories:

- General inspection (visual, markings, insulation thickness)

- Electrical shock hazard (impulse voltage, dielectric withstand, wet leakage, accessibility)

- Fire hazard (ignitability, flame propagation, fire tests)

- Mechanical stress (static mechanical load, module breakage, screw and termination robustness)

- Environmental stress (thermal cycling, humidity-freeze, damp heat, UV exposure, hot-spot endurance)

- Application classes: Defines different end‑use categories (e.g., Class A, B, C) with associated test needs and severity levels.

- Representative test procedures (described in standard): performance at STC, maximum power determination, bypass diode tests, ground continuity/equipotential bonding, impulse voltage, peel and lap-shear adhesion, robustness of terminations, and environmental conditioning.

- Pass criteria & sampling: Specifies sampling plans, sequence of stress tests, final measurements and clear pass/fail criteria for safety-relevant failures.

Practical applications - who uses IEC 61730-2

- PV module manufacturers - to design and qualify modules for safe field operation and to prepare product test plans.

- Independent test laboratories - to perform standardized safety tests and generate compliance reports.

- Certification bodies and regulators - to assess conformity for market access and safety approvals.

- System integrators, installers and safety engineers - to understand module safety limits and to specify products for projects requiring certified safety performance.

- R&D teams - for root-cause analysis of failures and improving module durability and safety.

Related standards

- IEC 61730-1 - Construction requirements (complements Part 2)

- IEC 61215 - (commonly used for PV design qualification/testing - see national/funder requirements for applicability)

By following IEC 61730-2:2016, stakeholders ensure PV modules are tested against recognized safety hazards - improving fire and shock protection and supporting reliable, certifiable photovoltaic deployments.

REDLINE IEC 61730-2:2016 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing Released:8/18/2016 Isbn:9782832236048

IEC 61730-2:2016 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 61730-2:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing". This standard covers: IEC 61730-2:2016 provides the testing sequence intended to verify the safety of PV modules whose construction has been assessed by IEC 61730-1. The test sequence and pass criteria are designed to detect the potential breakdown of internal and external components of PV modules that would result in fire, electric shock, and/or personal injury. The standard defines the basic safety test requirements and additional tests that are a function of the PV module end-use applications. Test categories include general inspection, electrical shock hazard, fire hazard, mechanical stress, and environmental stress. This new edition includes the following significant technical changes with respect to the previous edition: - the test sequences have been rearranged; - various tests have been detailed or added.

IEC 61730-2:2016 provides the testing sequence intended to verify the safety of PV modules whose construction has been assessed by IEC 61730-1. The test sequence and pass criteria are designed to detect the potential breakdown of internal and external components of PV modules that would result in fire, electric shock, and/or personal injury. The standard defines the basic safety test requirements and additional tests that are a function of the PV module end-use applications. Test categories include general inspection, electrical shock hazard, fire hazard, mechanical stress, and environmental stress. This new edition includes the following significant technical changes with respect to the previous edition: - the test sequences have been rearranged; - various tests have been detailed or added.

IEC 61730-2:2016 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61730-2:2016 has the following relationships with other standards: It is inter standard links to IEC 61730-2:2004, IEC 61730-2:2004/AMD1:2011, IEC 61730-2:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61730-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61730-2 ®

Edition 2.0 2016-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 61730-2 ®

Edition 2.0 2016-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-3604-8

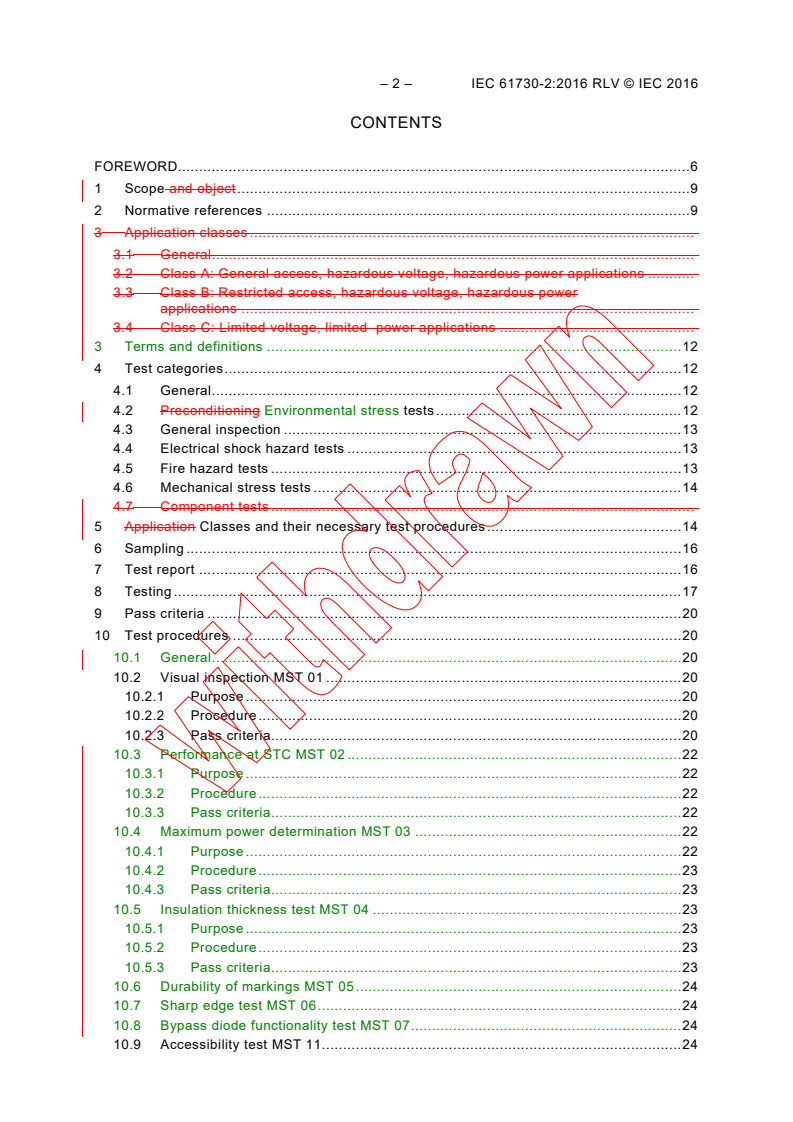

– 2 – IEC 61730-2:2016 RLV © IEC 2016

CONTENTS

FOREWORD. 6

1 Scope and object . 9

2 Normative references . 9

3 Application classes .

3.1 General .

3.2 Class A: General access, hazardous voltage, hazardous power applications .

3.3 Class B: Restricted access, hazardous voltage, hazardous power

applications .

3.4 Class C: Limited voltage, limited power applications .

3 Terms and definitions . 12

4 Test categories . 12

4.1 General . 12

4.2 Preconditioning Environmental stress tests . 12

4.3 General inspection . 13

4.4 Electrical shock hazard tests . 13

4.5 Fire hazard tests . 13

4.6 Mechanical stress tests . 14

4.7 Component tests .

5 Application Classes and their necessary test procedures . 14

6 Sampling . 16

7 Test report . 16

8 Testing . 17

9 Pass criteria . 20

10 Test procedures . 20

10.1 General . 20

10.2 Visual inspection MST 01 . 20

10.2.1 Purpose . 20

10.2.2 Procedure . 20

10.2.3 Pass criteria . 20

10.3 Performance at STC MST 02 . 22

10.3.1 Purpose . 22

10.3.2 Procedure . 22

10.3.3 Pass criteria . 22

10.4 Maximum power determination MST 03 . 22

10.4.1 Purpose . 22

10.4.2 Procedure . 23

10.4.3 Pass criteria . 23

10.5 Insulation thickness test MST 04 . 23

10.5.1 Purpose . 23

10.5.2 Procedure . 23

10.5.3 Pass criteria . 23

10.6 Durability of markings MST 05 . 24

10.7 Sharp edge test MST 06 . 24

10.8 Bypass diode functionality test MST 07 . 24

10.9 Accessibility test MST 11 . 24

10.9.1 Purpose . 24

10.9.2 Apparatus . 24

10.9.3 Procedure . 24

10.9.4 Final measurements . 25

10.9.5 Pass criteria . 25

10.10 Cut susceptibility test MST 12 . 25

10.10.1 Purpose . 25

10.10.2 Apparatus . 25

10.10.3 Procedure . 25

10.10.4 Final measurements . 25

10.10.5 Pass criteria . 26

10.11 Ground Continuity test of equipotential bonding MST 13 . 27

10.11.1 Purpose . 27

10.11.2 Apparatus . 28

10.11.3 Procedure . 28

10.11.4 Final measurements . 28

10.11.5 Pass criteria . 28

10.12 Impulse voltage test MST 14 . 28

10.12.1 Purpose . 28

10.12.2 Apparatus . 28

10.12.3 Procedure . 29

10.12.4 Final measurement . 30

10.12.5 Pass criteria . 30

10.13 Dielectric withstand Insulation test MST 16 . 31

10.13.1 Purpose . 31

10.13.2 Procedure . 31

10.13.3 Pass criteria . 31

10.14 Wet leakage current test MST 17 . 31

10.15 Temperature test MST 21 . 31

10.15.1 Purpose . 31

10.15.2 Outdoor method . 33

10.15.3 Solar simulator method . 35

10.15.4 Pass criteria . 36

10.16 Hot-spot endurance test MST 22 . 36

10.17 Fire test MST 23 . 36

10.17.1 Purpose . 36

10.18 Ignitability test MST 24 . 37

10.18.1 Purpose . 37

10.18.2 Apparatus . 38

10.18.3 Test specimen . 38

10.18.4 Conditioning . 39

10.18.5 Procedure . 39

10.18.6 Duration of test . 40

10.18.7 Observations . 40

10.18.8 Pass criteria . 40

10.19 Bypass diode thermal test MST 25 . 40

10.20 Reverse current overload test MST 26 . 40

10.20.1 Purpose . 40

10.20.2 Procedure . 41

– 4 – IEC 61730-2:2016 RLV © IEC 2016

10.20.3 Pass criteria . 41

10.21 Module breakage test MST 32 . 42

10.21.1 Purpose . 42

10.21.2 Apparatus . 42

10.21.3 Procedure . 42

10.21.4 Pass criteria . 43

10.22 Screw connections test MST 33 . 49

10.22.1 Test for general screw connections MST 33a . 49

10.22.2 Test for locking screws MST 33b . 50

10.23 Static mechanical load test MST 34 . 51

10.24 Peel test MST 35 . 51

10.24.1 Purpose . 51

10.24.2 Sample requirements . 51

10.24.3 Apparatus . 52

10.24.4 Procedure . 52

10.24.5 Pass criteria . 54

10.25 Lap shear strength test MST 36 . 55

10.25.1 Purpose . 55

10.25.2 Test samples . 55

10.25.3 Apparatus . 56

10.25.4 Procedure . 56

10.25.5 Pass criteria . 57

10.26 Materials creep test MST 37 . 58

10.26.1 Purpose . 58

10.26.2 Apparatus . 58

10.26.3 Procedure . 58

10.26.4 Final measurements . 58

10.26.5 Pass criteria . 58

10.27 Robustness of terminations test MST 42 . 58

10.28 Thermal cycling test MST 51 . 59

10.29 Humidity freeze test MST 52 . 59

10.30 Damp heat test MST 53 . 59

10.31 UV test MST 54 . 59

10.32 Cold conditioning MST 55 . 59

10.32.1 Purpose . 59

10.32.2 Apparatus . 59

10.32.3 Procedure . 59

10.32.4 Pass criteria . 60

10.33 Dry heat conditioning MST 56 . 60

10.33.1 Purpose . 60

10.33.2 Apparatus . 60

10.33.3 Procedure . 60

10.33.4 Pass criteria . 60

11 Component tests .

11.1 Partial discharge-test MST 15 .

11.2 Conduit bending test MST 33 .

11.3 Terminal box knockout tests MST 44 .

Annex A (informative) Recommendations for testing of PV modules from production . 61

A.1 General . 61

A.2 Module output power . 61

A.3 Wet insulation test . 61

A.4 Visual inspection . 62

A.5 Bypass diodes . 62

A.6 Continuity test of equipotential bonding . 62

Annex B (normative informative) Fire tests, spread-of-flame and burning-brand tests

for PV modules . 63

B.1 General . 68

B.2 Fire test for PV modules based on ENV 1187. 68

B.2.1 General . 68

B.2.2 External fire exposure to roofs . 68

B.2.3 Classification according to ISO 13501-5 . 69

B.3 Fire test for PV modules based on ANSI/UL 1703 . 70

Bibliography .

Figure 1 – Test sequences . 19

Figure 2 – Assessment of bubbles in edge seals for cemented joints . 22

Figure 3 – Cut susceptibility test . 27

Figure 4 – Waveform of the impulse voltage following IEC 60060-1 . 29

Figure 5 – Impactor . 44

Figure 6 – Impact test frame 1 . 45

Figure 7 – Test fixture assembly .

Figure 7 – Impact test frame 2 . 46

Figure 8 – Sample preparation of cemented joints ≤ 10 mm using a release sheet . 52

Figure 9 – PV module with positions for peel samples on frontsheet or backsheet . 53

Figure 10 – Typical peel-off measurement curves . 54

Figure 11 – Lap shear test sample for proving cemented joint . 56

Figure 12 – Lap-shear test flow . 57

Figure A.1 – Test apparatus for fire test .

Figure A.2 – Burning brand construction .

Figure B.1 – Example of test set-up for fire test . 69

Table 1 – Preconditioning Environmental stress tests . 12

Table 2 – General inspection test. 13

Table 3 – Electrical shock hazard tests . 13

Table 4 – Fire hazard tests . 14

Table 5 – Mechanical stress tests . 14

Table 6 – Component tests .

Table 6 – Required tests, depending on the application Class. 15

Table 7 – Torque tests on screws per IEC 60598-1:2014, Table 4.1 . 50

Table 8 – Impulse voltage versus maximum system voltage .

Table 9 – Component temperature limits .

Table 10 – Bending loads .

– 6 – IEC 61730-2:2016 RLV © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61730-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This second edition cancels and replaces the first edition of IEC 61730-2, issued in 2004 and

its amendment 1 (2011), and constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Rearrange test sequences.

b) MST 01: Visual inspection: added nameplate requirement and modified pass criteria.

c) Added sharp edge test MST 06.

d) Added insulation thickness test MST 04.

e) MST 11: Accessibility test: defined force for test finger.

f) MST 12: Cut susceptibility test: defined blade radius for cut test.

g) MST 14: removed preconditioning requirement TC200 from Figure 1.

h) MST 15: Partial discharge test removed.

i) Renamed dielectric breakdown test MST 16 to insulation test.

j) MST 21: Temperature test: rewritten test procedure; removed short circuit mode; allow

alternative indoor test method.

k) MST 23: Fire test: subclause rewritten; fire test requirements related to national building

codes; moved optional test description to informative annex.

l) Added ignitability test MST 24.

m) MST 26: Reverse current overload test: changed specification of wooden board.

n) MST 32: Module breakage test: defined new dimensions of impactor to allow other filling

compounds; consider variety of mounting techniques for glass breakage test; reduced

impact height to only 300 mm; corrected diameter of opening according to referenced

2 2

standard (65 cm instead of 6,5 cm ).

o) Added screw connection test MST 33.

p) Added peel test MST 35 for proof of cemented joints.

q) Added lap shear strength test MST 36 for proof of cemented joints.

r) Added materials creep test MST 37.

s) Added PV module test sequence with moisture and UV to stress polymers to Figure 1. The

new UV sequence was added as a response to the Kyoto meeting, where it was decided to

add a coupon test and a PV module test sequence. As it is not possible to perform the

ISO UV test on PV modules (no affordable equipment available) it was decided to rely on

already available PV module test equipment. R&D work has shown that cycling UV and HF

are best to age polymers in PV modules.

t) Added new sequence for Pollution Degree (PD) testing (sequence B1).

u) Added annex: Recommendations for testing of PV modules from production.

The text of this standard is based on the following documents:

FDIS Report on voting

82/1129/FDIS 82/1147/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 8 – IEC 61730-2:2016 RLV © IEC 2016

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

1 Scope and object

This part of IEC 61730 describes the testing requirements for photovoltaic (PV) modules in

order to provide safe electrical and mechanical operation during their expected lifetime.

Specific topics are provided to assess the prevention of electrical shock, fire hazards, and

personal injury due to mechanical and environmental stresses. IEC 61730-1 pertains to the

particular requirements of construction. This part of IEC 61730 outlines the requirements of

testing.

This standard attempts to define the basic requirements for various application classes of

photovoltaic modules, but it cannot be considered to encompass all national or regional

building codes. The specific requirements for marine and vehicle applications are not covered.

This standard is not applicable to modules with integrated AC inverters (AC modules).

This standard is designed so that its test sequence can co-ordinate with those of IEC 61215

or IEC 61646, so that a single set of samples may be used to perform both the safety and

performance evaluation of a photovoltaic module design.

The test-sequences of this standard are arranged in an optimal way so that tests of

IEC 61215 or IEC 61646 can be used as basic preconditioning tests.

The scope of IEC 61730-1 is also applicable to this part of IEC 61730. While IEC 61730-1

outlines the requirements of construction, this part of the standard lists the tests a PV module

is required to fulfill for safety qualification. IEC 61730-2 is applied for safety qualification only

in conjunction with IEC 61730-1.

NOTE 1 The sequence of tests required in this standard may not test for all possible safety

aspects associated with the use of PV modules in all possible applications. This standard

utilizes the best sequence of tests available at the time of its writing. There are some issues –

such as the potential danger of electric shock posed by a broken PV module in a high voltage

system – that should be addressed by the systems design, location, restrictions on access

and maintenance procedures.

The objective of this standard is to provide the testing sequence intended to verify the safety

of PV modules whose construction has been assessed by IEC 61730-1. The test sequence

and pass criteria are designed to detect the potential breakdown of internal and external

components of PV modules that would result in fire, electric shock, and/or personal injury.

The standard defines the basic safety test requirements and additional tests that are a

function of the PV module end-use applications. Test categories include general inspection,

electrical shock hazard, fire hazard, mechanical stress, and environmental stress.

NOTE 2 The additional testing requirements outlined in relevant ISO standards, or the national

or local codes which govern the installation and use of these PV modules in their intended

locations, should be considered in addition to the requirements contained within this standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

– 10 – IEC 61730-2:2016 RLV © IEC 2016

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068-1, Environmental testing – Part1: General and guidance

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60410, Sampling plans and procedures for inspection by attributes

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-3-5, Environmental testing – Part 3-5: Supporting documentation and guidance;

Confirmation of the performance of temperature chambers

IEC 60598-1:2014, Luminaires – Part 1: General requirements and tests

IEC 60664-1:1992 2007, Insulation co-ordination for equipment within low-voltage systems –

Part 1: Principles, requirements and tests

Amendment 2 (2002)

IEC 60695-2-10, Fire hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for photovoltaic reference solar

cells devices

IEC 60904-6, Photovoltaic devices – Part 6: Requirements for reference solar modules

IEC 60904-9, Photovoltaic devices – Part 9: Solar simulator performance requirements

IEC 60950-1:2005, Information technology equipment – Safety – Part 1: General requirements

IEC 61010-1, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61140, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215:2004 (all parts), Crystalline silicon Terrestrial photovoltaic (PV) modules – Design

qualification and type approval

IEC 61215-2, Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

IEC 61646:1996, Thin-film Terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61730-1:2004 2016, Photovoltaic (PV) module safety qualification – Part 1: Requirements

for construction

IEC 62790, Junction boxes for photovoltaic modules – Safety requirements and tests

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ISO 813, Rubber, vulcanized or thermoplastic – Determination of adhesion to a rigid substrate

– 90 degree peel method

ISO 4046-4, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper and board

grades and converted products

ISO 4587:2003, Adhesives – Determination of tensile lap-shear strength of rigid-to-rigid

bonded assemblies

ISO 5893, Rubber and plastics test equipment – Tensile, flexural and compression types

(constant rate of traverse) – Specification

ISO 8124-1, Safety of toys – Part 1: Safety aspects related to mechanical and physical

properties

ISO 11925-2:2010, Reaction to fire tests – Ignitability of products subjected to direct

impingement of flame – Part 2: Single-flame source test

ISO 23529, Rubber – General procedures for preparing and conditioning test pieces for

physical test methods

ANSI/UL 514C, Non-metallic outlet boxes, flush device boxes and covers

ANSI/UL 790, Tests for Fire Resistance of Roof Covering Materials

ANSI/UL 1703, Flat – Plate Photovoltaic Modules and Panels

ANSI Z97.1:2009, American National Standard – Safety Glazing Materials Used in Buildings

– Safety Performance Specifications and Methods of Test

ANSI/UL 1703:2015, Flat-plate photovoltaic modules and panels

3 Application classes

3.1 General

Photovoltaic modules may be installed in many different applications. Therefore, it is

important to evaluate the potential hazards associated with those applications and to evaluate

the construction of the module accordingly.

Relevant safety requirements and necessary tests shall be performed to verify the

conformance to the requirements of that application class. This clause defines those

application classes and construction qualities required for each class.

Application classes for PV-modules are defined as follows:

3.2 Class A: General access, hazardous voltage, hazardous power applications

Modules rated for use in this application class may be used in systems operating at greater

than 50 V DC or 240 W, where general contact access is anticipated. Modules qualified for

safety through IEC 61730-1 and this part of IEC 61730 within this application class are

considered to meet the requirements for safety class II.

– 12 – IEC 61730-2:2016 RLV © IEC 2016

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications

Modules rated for use in this application class are restricted to systems protected from public

access by fences, location, etc. Modules evaluated within this application class provide

protection by basic insulation, are considered to meet the requirements for safety class 0.

3.4 Class C: Limited voltage, limited power applications

Modules rated for use in this application class are restricted to systems operating at less than

50 V DC and 240 W, where general contact access is anticipated. Modules qualified for safety

through IEC 61730-1 and this part of IEC 61730 within this application class are considered to

meet the requirements for safety class III.

NOTE Safety classes are defined within IEC 61140.

3 Terms and definitions

The Clause of Part 1 applies.

4 Test categories

4.1 General

The hazards described in the following subclause might influence the lifetime and the safety

of PV modules. In accordance with these hazards, test procedures and criteria are described.

The specific tests to which a PV module will be subjected will depend on the end-use

application for which the minimum tests are specified in Clause 5.

NOTE PV module safety tests are labelled MST.

Tables 1 to 5 show the origin of the required tests. For some tests the third column lists the

origin of the tests for information only; the appropriate test requirements are given in 10.1

through 10.32. The rest of the other tests are based on or are identical to the module

qualification tests MQT defined in the IEC 61215 series/IEC 61646. References to the

relevant Clauses tests are given in the last two columns. Some of the IEC 61215/IEC 61646-

based tests were modified for IEC 61730-2 and are included in 10.1 through 10.32.

4.2 Preconditioning Environmental stress tests

Table 1 – Preconditioning Environmental stress tests

Test Title Referenced According to Based on

standards

IEC 61215-2 IEC 61646

MST 51 Thermal cycling (TC50 or TC200) – 10.11 MQT 11 10.11

MST 52 Humidity freeze (HF10) – 10.12 MQT 12 10.12

MST 53 Damp heat (DH1000) – 10.13 MQT 13 10.13

MST 54 UV preconditioning test – 10.10 MQT 10 10.10

MST 55 Cold conditioning IEC 60068-2-1 –

MST 56 Dry hot conditioning IEC 60068-2-2 –

4.3 General inspection

Table 2 – General inspection test

Test Title Referenced According to Based on

standards

IEC 61215-2 IEC 61646

MST 01 Visual inspection – 10.1 MQT 01 10.1

MST 02 Performance at STC – MQT 6.1

MST 03 Maximum power determination – MQT 02

MST 04 Insulation thickness – –

MST 05 Durability of markings IEC 60950-1 –

MST 06 Sharp edge test ISO 8124-1 –

MST 07 Bypass diod

...

IEC 61730-2 ®

Edition 2.0 2016-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques

(PV) –

Partie 2: Exigences pour les essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61730-2 ®

Edition 2.0 2016-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques

(PV) –

Partie 2: Exigences pour les essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-3575-1

– 2 – IEC 61730-2:2016 © IEC 2016

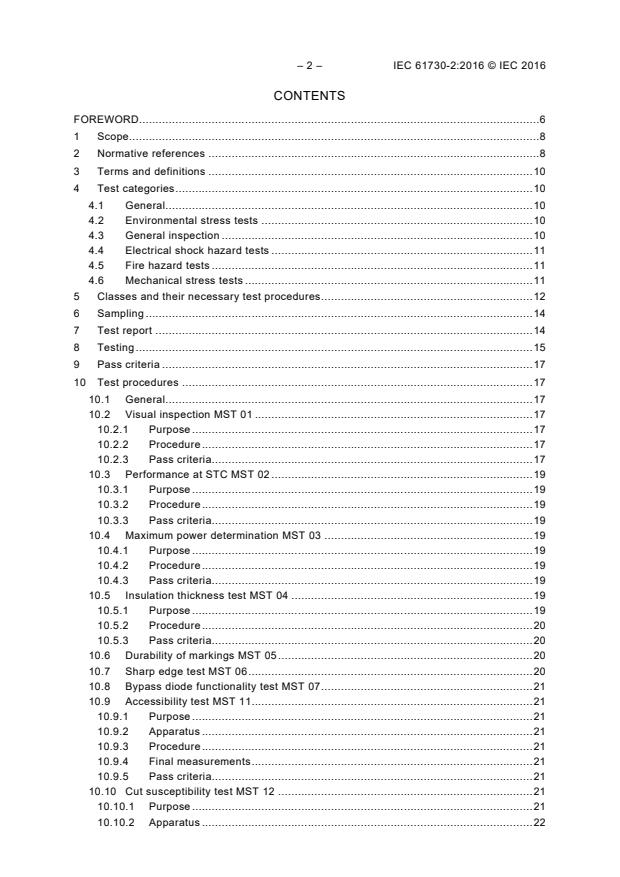

CONTENTS

FOREWORD. 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 10

4 Test categories . 10

4.1 General . 10

4.2 Environmental stress tests . 10

4.3 General inspection . 10

4.4 Electrical shock hazard tests . 11

4.5 Fire hazard tests . 11

4.6 Mechanical stress tests . 11

5 Classes and their necessary test procedures . 12

6 Sampling . 14

7 Test report . 14

8 Testing . 15

9 Pass criteria . 17

10 Test procedures . 17

10.1 General . 17

10.2 Visual inspection MST 01 . 17

10.2.1 Purpose . 17

10.2.2 Procedure . 17

10.2.3 Pass criteria . 17

10.3 Performance at STC MST 02 . 19

10.3.1 Purpose . 19

10.3.2 Procedure . 19

10.3.3 Pass criteria . 19

10.4 Maximum power determination MST 03 . 19

10.4.1 Purpose . 19

10.4.2 Procedure . 19

10.4.3 Pass criteria . 19

10.5 Insulation thickness test MST 04 . 19

10.5.1 Purpose . 19

10.5.2 Procedure . 20

10.5.3 Pass criteria . 20

10.6 Durability of markings MST 05 . 20

10.7 Sharp edge test MST 06 . 20

10.8 Bypass diode functionality test MST 07 . 21

10.9 Accessibility test MST 11 . 21

10.9.1 Purpose . 21

10.9.2 Apparatus . 21

10.9.3 Procedure . 21

10.9.4 Final measurements . 21

10.9.5 Pass criteria . 21

10.10 Cut susceptibility test MST 12 . 21

10.10.1 Purpose . 21

10.10.2 Apparatus . 22

10.10.3 Procedure . 22

10.10.4 Final measurements . 22

10.10.5 Pass criteria . 22

10.11 Continuity test of equipotential bonding MST 13 . 23

10.11.1 Purpose . 23

10.11.2 Apparatus . 23

10.11.3 Procedure . 24

10.11.4 Final measurements . 24

10.11.5 Pass criteria . 24

10.12 Impulse voltage test MST 14 . 24

10.12.1 Purpose . 24

10.12.2 Apparatus . 24

10.12.3 Procedure . 25

10.12.4 Final measurement . 26

10.12.5 Pass criteria . 26

10.13 Insulation test MST 16 . 26

10.13.1 Purpose . 26

10.13.2 Procedure . 26

10.13.3 Pass criteria . 26

10.14 Wet leakage current test MST 17 . 26

10.15 Temperature test MST 21 . 27

10.15.1 Purpose . 27

10.15.2 Outdoor method . 27

10.15.3 Solar simulator method . 28

10.15.4 Pass criteria . 30

10.16 Hot-spot endurance test MST 22 . 30

10.17 Fire test MST 23 . 30

10.17.1 Purpose . 30

10.18 Ignitability test MST 24 . 31

10.18.1 Purpose . 31

10.18.2 Apparatus . 31

10.18.3 Test specimen . 32

10.18.4 Conditioning . 32

10.18.5 Procedure . 32

10.18.6 Duration of test . 33

10.18.7 Observations . 33

10.18.8 Pass criteria . 33

10.19 Bypass diode thermal test MST 25 . 34

10.20 Reverse current overload test MST 26 . 34

10.20.1 Purpose . 34

10.20.2 Procedure . 34

10.20.3 Pass criteria . 34

10.21 Module breakage test MST 32 . 35

10.21.1 Purpose . 35

10.21.2 Apparatus . 35

10.21.3 Procedure . 35

10.21.4 Pass criteria . 35

10.22 Screw connections test MST 33 . 38

10.22.1 Test for general screw connections MST 33a . 38

– 4 – IEC 61730-2:2016 © IEC 2016

10.22.2 Test for locking screws MST 33b . 40

10.23 Static mechanical load test MST 34 . 40

10.24 Peel test MST 35 . 40

10.24.1 Purpose . 40

10.24.2 Sample requirements . 40

10.24.3 Apparatus . 41

10.24.4 Procedure . 41

10.24.5 Pass criteria . 44

10.25 Lap shear strength test MST 36 . 44

10.25.1 Purpose . 44

10.25.2 Test samples . 44

10.25.3 Apparatus . 45

10.25.4 Procedure . 45

10.25.5 Pass criteria . 46

10.26 Materials creep test MST 37 . 47

10.26.1 Purpose . 47

10.26.2 Apparatus . 47

10.26.3 Procedure . 47

10.26.4 Final measurements . 47

10.26.5 Pass criteria . 47

10.27 Robustness of terminations test MST 42 . 47

10.28 Thermal cycling test MST 51 . 48

10.29 Humidity freeze test MST 52 . 48

10.30 Damp heat test MST 53 . 48

10.31 UV test MST 54 . 48

10.32 Cold conditioning MST 55 . 48

10.32.1 Purpose . 48

10.32.2 Apparatus . 48

10.32.3 Procedure . 48

10.32.4 Pass criteria . 49

10.33 Dry heat conditioning MST 56 . 49

10.33.1 Purpose . 49

10.33.2 Apparatus . 49

10.33.3 Procedure . 49

10.33.4 Pass criteria . 49

Annex A (informative) Recommendations for testing of PV modules from production . 50

A.1 General . 50

A.2 Module output power . 50

A.3 Wet insulation test . 50

A.4 Visual inspection . 51

A.5 Bypass diodes . 51

A.6 Continuity test of equipotential bonding . 51

Annex B (informative) Fire tests, spread-of-flame and burning-brand tests for PV

modules . 52

B.1 General . 52

B.2 Fire test for PV modules based on ENV 1187 . 52

B.2.1 General . 52

B.2.2 External fire exposure to roofs . 52

B.2.3 Classification according to ISO 13501-5 . 53

B.3 Fire test for PV modules based on ANSI/UL 1703 . 54

Figure 1 – Test sequences . 16

Figure 2 – Assessment of bubbles in edge seals for cemented joints. 18

Figure 3 – Cut susceptibility test . 23

Figure 4 – Waveform of the impulse voltage following IEC 60060-1 . 25

Figure 5 – Impactor . 36

Figure 6 – Impact test frame 1 . 37

Figure 7 – Impact test frame 2 . 38

Figure 8 – Sample preparation of cemented joints ≤ 10 mm using a release sheet . 41

Figure 9 – PV module with positions for peel samples on frontsheet or backsheet . 42

Figure 10 – Typical peel-off measurement curves . 43

Figure 11 – Lap shear test sample for proving cemented joint . 45

Figure 12 – Lap-shear test flow . 46

Figure B.1 – Example of test set-up for fire test . 53

Table 1 – Environmental stress tests . 10

Table 2 – General inspection test . 10

Table 3 – Electrical shock hazard tests . 11

Table 4 – Fire hazard tests . 11

Table 5 – Mechanical stress tests . 12

Table 6 – Required tests, depending on the Class . 13

Table 7 – Torque tests on screws per IEC 60598-1:2014, Table 4.1 . 39

– 6 – IEC 61730-2:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61730-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This second edition cancels and replaces the first edition of IEC 61730-2, issued in 2004 and

its amendment 1 (2011), and constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Rearrange test sequences.

b) MST 01: Visual inspection: added nameplate requirement and modified pass criteria.

c) Added sharp edge test MST 06.

d) Added insulation thickness test MST 04.

e) MST 11: Accessibility test: defined force for test finger.

f) MST 12: Cut susceptibility test: defined blade radius for cut test.

g) MST 14: removed preconditioning requirement TC200 from Figure 1.

h) MST 15: Partial discharge test removed.

i) Renamed dielectric breakdown test MST 16 to insulation test.

j) MST 21: Temperature test: rewritten test procedure; removed short circuit mode; allow

alternative indoor test method.

k) MST 23: Fire test: subclause rewritten; fire test requirements related to national building

codes; moved optional test description to informative annex.

l) Added ignitability test MST 24.

m) MST 26: Reverse current overload test: changed specification of wooden board.

n) MST 32: Module breakage test: defined new dimensions of impactor to allow other filling

compounds; consider variety of mounting techniques for glass breakage test; reduced

impact height to only 300 mm; corrected diameter of opening according to referenced

2 2

standard (65 cm instead of 6,5 cm ).

o) Added screw connection test MST 33.

p) Added peel test MST 35 for proof of cemented joints.

q) Added lap shear strength test MST 36 for proof of cemented joints.

r) Added materials creep test MST 37.

s) Added PV module test sequence with moisture and UV to stress polymers to Figure 1. The

new UV sequence was added as a response to the Kyoto meeting, where it was decided to

add a coupon test and a PV module test sequence. As it is not possible to perform the

ISO UV test on PV modules (no affordable equipment available) it was decided to rely on

already available PV module test equipment. R&D work has shown that cycling UV and HF

are best to age polymers in PV modules.

t) Added new sequence for Pollution Degree (PD) testing (sequence B1).

u) Added annex: Recommendations for testing of PV modules from production.

The text of this standard is based on the following documents:

FDIS Report on voting

82/1129/FDIS 82/1147/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 61730-2:2016 © IEC 2016

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

1 Scope

The scope of IEC 61730-1 is also applicable to this part of IEC 61730. While IEC 61730-1

outlines the requirements of construction, this part of the standard lists the tests a PV module

is required to fulfill for safety qualification. IEC 61730-2 is applied for safety qualification only

in conjunction with IEC 61730-1.

The sequence of tests required in this standard may not test for all possible safety aspects

associated with the use of PV modules in all possible applications. This standard utilizes the

best sequence of tests available at the time of its writing. There are some issues – such as

the potential danger of electric shock posed by a broken PV module in a high voltage system

– that should be addressed by the system design, location, restrictions on access and

maintenance procedures.

The objective of this standard is to provide the testing sequence intended to verify the safety

of PV modules whose construction has been assessed by IEC 61730-1. The test sequence

and pass criteria are designed to detect the potential breakdown of internal and external

components of PV modules that would result in fire, electric shock, and/or personal injury.

The standard defines the basic safety test requirements and additional tests that are a

function of the PV module end-use applications. Test categories include general inspection,

electrical shock hazard, fire hazard, mechanical stress, and environmental stress.

The additional testing requirements outlined in relevant ISO standards, or the national or local

codes which govern the installation and use of these PV modules in their intended locations,

should be considered in addition to the requirements contained within this standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-3-5, Environmental testing – Part 3-5: Supporting documentation and guidance;

Confirmation of the performance of temperature chambers

IEC 60598-1:2014, Luminaires – Part 1: General requirements and tests

IEC 60664-1:2007, Insulation co-ordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 60695-2-10, Fire hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for photovoltaic reference devices

IEC 60904-9, Photovoltaic devices – Part 9: Solar simulator performance requirements

IEC 60950-1:2005, Information technology equipment – Safety – Part 1: General requirements

IEC 61010-1, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61140, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215 (all parts), Terrestrial photovoltaic (PV) modules – Design qualification and type

approval

IEC 61215-2, Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

IEC 61730-1:2016, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

IEC 62790, Junction boxes for photovoltaic modules – Safety requirements and tests

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ISO 813, Rubber, vulcanized or thermoplastic – Determination of adhesion to a rigid substrate

– 90 degree peel method

ISO 4046-4, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper and board

grades and converted products

ISO 4587:2003, Adhesives – Determination of tensile lap-shear strength of rigid-to-rigid

bonded assemblies

ISO 5893, Rubber and plastics test equipment – Tensile, flexural and compression types

(constant rate of traverse) – Specification

ISO 8124-1, Safety of toys – Part 1: Safety aspects related to mechanical and physical

properties

ISO 11925-2:2010, Reaction to fire tests – Ignitability of products subjected to direct

impingement of flame – Part 2: Single-flame source test

ISO 23529, Rubber – General procedures for preparing and conditioning test pieces for

physical test methods

ANSI Z97.1:2009, Standard – Safety Glazing Materials Used in Buildings – Safety

Performance Specifications and Methods of Test

ANSI/UL 1703:2015, Flat-plate photovoltaic modules and panels

– 10 – IEC 61730-2:2016 © IEC 2016

3 Terms and definitions

The Clause of Part 1 applies.

4 Test categories

4.1 General

The hazards described in the following subclause might influence the safety of PV modules.

In accordance with these hazards, test procedures and criteria are described. The specific

tests to which a PV module will be subjected will depend on the end-use application for which

the minimum tests are specified in Clause 5.

NOTE PV module safety tests are labelled MST.

Tables 1 to 5 show the origin of the required tests. For some tests the third column lists the

origin of the tests for information only; the appropriate test requirements are given in 10.1

through 10.32. The other tests are based on or are identical to the module qualification tests

MQT defined in the IEC 61215 series. References to the relevant tests are given in the last

column. Some of the IEC 61215-based tests were modified for IEC 61730-2 and are included

in 10.1 through 10.32.

4.2 Environmental stress tests

Table 1 – Environmental stress tests

Test Title Referenced Based on

standards

IEC 61215-2

MST 51 Thermal cycling (TC50 or TC200) – MQT 11

MST 52 Humidity freeze (HF10) – MQT 12

MST 53 Damp heat (DH1000) – MQT 13

MST 54 UV preconditioning – MQT 10

MST 55 Cold conditioning IEC 60068-2-1 –

MST 56 Dry hot conditioning IEC 60068-2-2 –

4.3 General inspection

Table 2 – General inspection test

Test Title Referenced Based on

standards

IEC 61215-2

MST 01 Visual inspection – MQT 01

MST 02 Performance at STC – MQT 6.1

MST 03 Maximum power determination – MQT 02

MST 04 Insulation thickness – –

MST 05 Durability of markings IEC 60950-1 –

MST 06 Sharp edge test ISO 8124-1 –

MST 07 Bypass diode functionality test – –

4.4 Electrical shock hazard tests

These tests are designed to assess the risk to persons due to shock or injury from contact

with parts of a PV module that are electrically energised as a result of design, construction, or

faults caused by environment or operation.

Table 3 – Electrical shock hazard tests

Test Title Referenced standards Based on

IEC 61215-2

MST 11 Accessibility test IEC 61032 –

MST 12 Cut susceptibility test ANSI/UL 1703:2015 –

MST 13 Continuity test for equipotential bonding ANSI/UL 1703:2015 –

MST 14 Impulse voltage test IEC 60664-1 –

MST 16 Insulation test – MQT 03

MST 17 Wet leakage current test – MQT 15

MST 42 Robustness of terminations test IEC 62790 MQT 14

4.5 Fire hazard tests

These tests assess the potential fire hazard due to the operation of a PV module or failure of

its components.

Table 4 – Fire hazard tests

Test Title Referenced standards Based on

IEC 61215-2

MST 21 Temperature test ANSI/UL 1703:2015 –

MST 22 Hot-spot endurance test – MQT 09

MST 23* Fire test – National/Local code

MST 24 Ignitability test ISO 11925-2 –

MST 25 Bypass diode thermal test – MQT 18

MST 26 Reverse current overload test ANSI/UL 1703:2015 –

* Fire tests are locally regulated and typically only required for building integrated or building added products,

typically to verify their ability to resist fire from external sources.

4.6 Mechanical stress tests

These tests are to minimise potential injury due to mechanical failure.

– 12 – IEC 61730-2:2016 © IEC 2016

Table 5 – Mechanical stress tests

Test Title Referenced standards Based on

IEC 61215-2

MST 32 Module breakage test ANSI Z97.1 –

MST 33 Screw connection test IEC 60598-1 –

MST 34 Mechanical load test – MQT 16

MST 35 Peel test ISO 5893 –

MST 36 Lap shear strength test ISO 4587:2003 –

MST 37 Materials creep test – –

MST 42 Robustness of terminations test MQT 14

5 Classes and their necessary test procedures

The specific tests to which a PV module will be subjected, depending on the Class defined in

IEC 61730-1 referring to IEC 61140, are described in Table 6. The order in which the tests are

carried out shall be in accordance with Figure 1. Some tests shall be carried out as

preconditioning tests.

Table 6 – Required tests, depending on the Class

Class according to Tests

IEC 61140

II 0 III

Environmental stress tests:

X X X MST 51 Thermal cycling (T50 or T200)

X X X MST 52 Humidity freeze (HF10)

X X X MST 53 Damp heat (DH200 or DH1000)

2 2

X X X MST 54 UV pre-conditioning (15 kWh/m or 60 kWh/m )

1 1 1

X X X MST 55 Cold conditioning

1 1 1

X X X MST 56 Dry hot conditioning

General inspection test:

X X X MST 01 Visual Inspection

X X X MST 02 Performance at STC

X X X MST 03 Maximum power determination

X X - MST 04 Insulation thickness

X X X MST 05 Durability of markings

X X X MST 06 Sharp edge test

Electrical shock hazard tests:

X X - MST 11 Accessibility test

X X - MST 12 Cut susceptibility test

X X - MST 13 Continuity test for equipotential bonding

X X - MST 14 Impulse voltage test

X X X MST 16 Insulation test

X X - MST 17 Wet leakage current test

X X X MST 42 Robustness of terminations test

Fire hazard tests:

X X X MST 21 Temperature test

X X X MST 22 Hot-spot endurance test

2 2 2

X X X MST 23 Fire test

X X X MST 24 Ignitability test

X X X MST 25 Bypass diode thermal test

X X - MST 26 Reverse current overload test

Mechanical stress tests:

X X X MST 32 Module breakage test

X X X MST 33 Screw connection test

X X X MST 34 Mechanical load test

3,5 3,5 3,5

X X X MST 35 Peel test

4,5 4,5 4,5

X X X MST 36 Lap shear strength test

X X X MST 37 Materials creep test

X Test required.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...