IEC 61730-2:2004

(Main)Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing

Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing

Describes the testing requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Outlines the requirements of testing and is to be used in conjunction with IEC 61215 or IEC 61646.

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) - Partie 2: Exigences pour les essais

Décrit les exigences d'essai pour les modules photovoltaïques afin de fournir un fonctionnement électrique et mécanique sûr au cours de leur durée de vie. Couvre la prévention contre les chocs électriques, les risques de feu et les accidents corporels dus à des contraintes mécaniques et environnementales. Présente les exigences d'essais et sera utilisée conjointement avec la CEI 61215 ou la CEI 61646.

General Information

- Status

- Published

- Publication Date

- 13-Oct-2004

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 18-Aug-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Revised

IEC 61730-2:2016 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing - Effective Date

- 05-Sep-2023

Overview

IEC 61730-2:2004 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies the testing requirements for photovoltaic (PV) modules to ensure their safe electrical and mechanical operation throughout their expected lifetime. This standard aims to prevent hazards related to electrical shock, fire, and injuries due to mechanical or environmental stresses. It complements IEC 61730-1, which addresses construction requirements, and is intended for use alongside performance standards such as IEC 61215 and IEC 61646 to enable a comprehensive assessment of PV modules.

This standard covers a wide range of safety tests, organized into a structured test sequence, facilitating the evaluation of PV modules for various application classes. IEC 61730-2 excludes modules with integrated AC inverters (AC modules) and does not cover specific requirements for marine or vehicle applications. Its test methods ensure modules meet stringent safety criteria, making them reliable and safe for use in general electrical systems.

Key Topics

Application Classes

IEC 61730-2 defines application classes based on access and voltage levels:- Class A: General access, hazardous voltage, and power

- Class B: Restricted access, hazardous voltage, and power

- Class C: Limited voltage and power

These classes guide the selection of appropriate test procedures for safety evaluation.

Test Categories and Procedures

The standard details different categories of tests to ensure module safety:- Preconditioning Tests: Prepare modules for environmental and mechanical testing.

- Electrical Shock Hazard Tests: Evaluate protection against electric shock through accessibility and dielectric tests.

- Fire Hazard Tests: Assess fire resistance, flame spread, and burning brand exposure.

- Mechanical Stress Tests: Include impact, bending, and breakage tests to confirm mechanical durability.

- Component Tests: Target specific elements such as terminal boxes and connectors.

Coordinated Testing with Performance Standards

The test sequence is optimized to align with IEC 61215 and IEC 61646, enabling simultaneous safety and performance testing on the same module samples, increasing testing efficiency and reliability.Pass Criteria and Reporting

The standard specifies clear criteria for test pass/fail outcomes and requires detailed test reports to document results and compliance for certification and quality assurance.

Applications

IEC 61730-2:2004 is essential for manufacturers, testing laboratories, and certification bodies involved in the development and assessment of photovoltaic modules. Key applications include:

- Ensuring safe installation of solar PV systems by minimizing risks of electrical shock and fire hazards.

- Protecting end users and maintenance personnel from injuries caused by mechanical failures or environmental stressors.

- Assisting manufacturers in product design validation and qualification to meet international safety benchmarks.

- Supporting certification processes and compliance for market acceptance worldwide.

- Acting as a reference for system designers to select modules suitable for different application environments and voltage classes.

Related Standards

- IEC 61730-1: Specifies the construction requirements for photovoltaic modules focused on safety aspects.

- IEC 61215: Defines performance testing and reliability qualification for crystalline silicon PV modules.

- IEC 61646: Applies to thin-film PV modules performance testing, complementary to IEC 61215.

- IEC 60060-1: Provides impulse voltage test methods referenced in electrical testing under IEC 61730-2.

- Other regional or national electrical safety and building codes may supplement this standard but should be used in conjunction with IEC 61730-2 for international consistency.

Implementing IEC 61730-2:2004 helps ensure photovoltaic modules adhere to rigorous safety requirements, promoting confidence in solar energy systems by safeguarding users and infrastructure against electrical, fire, and mechanical hazards over the operational lifetime.

IEC 61730-2:2004 - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing Released:10/14/2004 Isbn:2831876826

IEC 61730-2:2004+AMD1:2011 CSV - Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing Released:11/23/2012 Isbn:9782889128822

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 61730-2:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic (PV) module safety qualification - Part 2: Requirements for testing". This standard covers: Describes the testing requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Outlines the requirements of testing and is to be used in conjunction with IEC 61215 or IEC 61646.

Describes the testing requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Outlines the requirements of testing and is to be used in conjunction with IEC 61215 or IEC 61646.

IEC 61730-2:2004 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61730-2:2004 has the following relationships with other standards: It is inter standard links to IEC 61730-2:2004/AMD1:2011, IEC 61730-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61730-2:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61730-2

Edition 1.0 2004-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 2: Exigences pour les essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61730-2

Edition 1.0 2004-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 2: Exigences pour les essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 27.160 ISBN 2-8318-7682-6

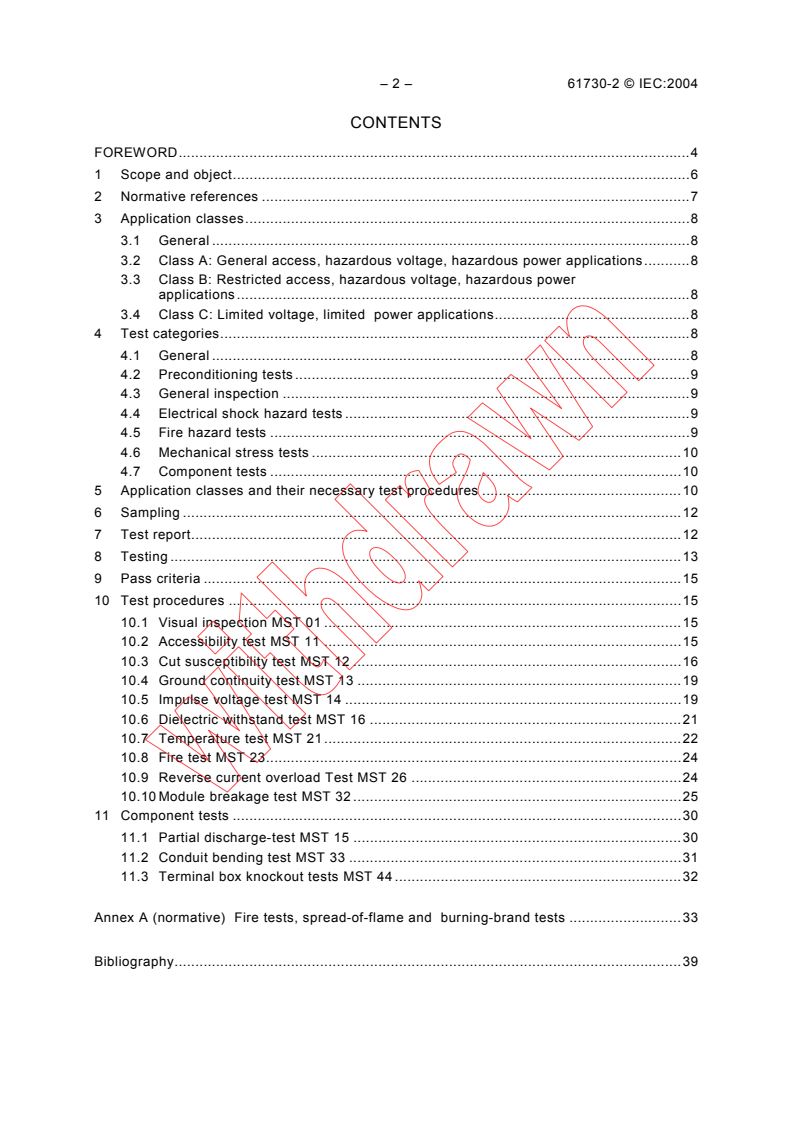

– 2 – 61730-2 © IEC:2004

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references .7

3 Application classes.8

3.1 General .8

3.2 Class A: General access, hazardous voltage, hazardous power applications.8

3.3 Class B: Restricted access, hazardous voltage, hazardous power

applications .8

3.4 Class C: Limited voltage, limited power applications.8

4 Test categories.8

4.1 General .8

4.2 Preconditioning tests .9

4.3 General inspection .9

4.4 Electrical shock hazard tests .9

4.5 Fire hazard tests .9

4.6 Mechanical stress tests .10

4.7 Component tests .10

5 Application classes and their necessary test procedures .10

6 Sampling .12

7 Test report.12

8 Testing .13

9 Pass criteria .15

10 Test procedures .15

10.1 Visual inspection MST 01 .15

10.2 Accessibility test MST 11 .15

10.3 Cut susceptibility test MST 12 .16

10.4 Ground continuity test MST 13 .19

10.5 Impulse voltage test MST 14 .19

10.6 Dielectric withstand test MST 16 .21

10.7 Temperature test MST 21.22

10.8 Fire test MST 23.24

10.9 Reverse current overload Test MST 26 .24

10.10 Module breakage test MST 32 .25

11 Component tests .30

11.1 Partial discharge-test MST 15 .30

11.2 Conduit bending test MST 33 .31

11.3 Terminal box knockout tests MST 44 .32

Annex A (normative) Fire tests, spread-of-flame and burning-brand tests .33

Bibliography.39

61730-2 © IEC:2004 – 3 –

Figure 1 – Test sequences.14

Figure 2 – Cut susceptibility test .18

Figure 3 – Wave-form of the impulse voltage according to IEC 60060-1.21

Figure 4 – Impactor.27

Figure 5 – Impact test frame 1 .28

Figure 6 – Impact test frame 2 .29

Figure 7 – Test fixture assembly .31

Figure A.1 – Test apparatus for fire test.34

Figure A.2 – Burning brand construction .37

Table 1 – Preconditioning tests.9

Table 2 – General inspection test.9

Table 3 – Electrical shock hazard tests .9

Table 4 – Fire hazard tests .10

Table 5 – Mechanical stress tests .10

Table 6 – Component tests .10

Table 7 – Required tests, depending on the application class .11

Table 8 – Impulse voltage versus maximum system voltage.20

Table 9 – Component temperature limits.23

Table 10 – Bending loads .31

– 4 – 61730-2 © IEC:2004

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61730-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

The text of this standard is based on the following documents:

FDIS Report on voting

82/357/FDIS 82/366/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

61730-2 © IEC:2004 – 5 –

IEC 61730 consists of the following parts, under the general title Photovoltaic (PV) module

safety qualification:

Part 1: Requirements for construction

Part 2: Requirements for testing

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 61730-2 © IEC:2004

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

1 Scope and object

This part of IEC 61730 describes the testing requirements for photovoltaic (PV) modules in

order to provide safe electrical and mechanical operation during their expected lifetime.

Specific topics are provided to assess the prevention of electrical shock, fire hazards, and

personal injury due to mechanical and environmental stresses. IEC 61730-1 pertains to the

particular requirements of construction. This part of IEC 61730 outlines the requirements of

testing.

This standard attempts to define the basic requirements for various application classes of

photovoltaic modules, but it cannot be considered to encompass all national or regional

building codes. The specific requirements for marine and vehicle applications are not covered.

This standard is not applicable to modules with integrated AC inverters (AC modules).

This standard is designed so that its test sequence can co-ordinate with those of IEC 61215

or IEC 61646, so that a single set of samples may be used to perform both the safety and

performance evaluation of a photovoltaic module design.

The test-sequences of this standard are arranged in an optimal way so that tests of

IEC 61215 or IEC 61646 can be used as basic preconditioning tests.

NOTE 1 The sequence of tests required in this standard may not test for all possible safety aspects associated

with the use of PV modules in all possible applications. This standard utilizes the best sequence of tests available

at the time of its writing. There are some issues, such as the potential danger of electric shock posed by a broken

module in a high voltage system, that should be addressed by the systems design, location, restrictions on access

and maintenance procedures.

The object of this document is to provide the testing sequence intended to verify the safety of

PV modules whose construction has been assessed by IEC 61730-1. The test sequence and

pass criteria are designed to detect the potential breakdown of internal and external

components of PV modules that would result in fire, electric shock and personal injury. The

standard defines the basic safety test requirements and additional tests that are a function of

the module end-use applications.

Test categories include general inspection, electrical shock hazard, fire hazard, mechanical

stress, and environmental stress.

NOTE 2 The additional testing requirements outlined in relevant ISO standards, or the national or local codes

which govern the installation and use of these modules in their intended locations, should be considered in addition

to the requirements contained within this document.

61730-2 © IEC:2004 – 7 –

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60410, Sampling plans and procedures for inspection by attributes

IEC 60664-1:1992, Insulation co-ordination for equipment within low-voltage systems – Part 1

Principles, requirements and tests

Amendment 2 (2002)

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for reference solar cells

IEC 60904-6, Photovoltaic devices – Part 6: Requirements for reference solar modules

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61140, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215:2004, Crystalline silicon terrestrial photovoltaic (PV) modules – Design

qualification and type approval

IEC 61646:1996, Thin-film terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61730-1:2004, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ANSI/UL 514C, Non-metallic outlet boxes, flush device boxes and covers

ANSI/UL 790, Tests for Fire Resistance of Roof Covering Materials

ANSI/UL 1703, Flat – Plate Photovoltaic Modules and Panels

ANSI Z97.1, American National Standard for Safety Glazing Materials Used in Buildings –

Safety Performance Specifications and Methods of Test

– 8 – 61730-2 © IEC:2004

3 Application classes

3.1 General

Photovoltaic modules may be installed in many different applications. Therefore, it is

important to evaluate the potential hazards associated with those applications and to evaluate

the construction of the module accordingly.

Relevant safety requirements and necessary tests shall be performed to verify the

conformance to the requirements of that application class. This clause defines those

application classes and construction qualities required for each class.

Application classes for PV-modules are defined as follows:

3.2 Class A: General access, hazardous voltage, hazardous power applications

Modules rated for use in this application class may be used in systems operating at greater

than 50 V DC or 240 W, where general contact access is anticipated. Modules qualified for

safety through IEC 61730-1 and this part of IEC 61730 within this application class are

considered to meet the requirements for safety class II.

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications

Modules rated for use in this application class are restricted to systems protected from public

access by fences, location, etc. Modules evaluated within this application class provide

protection by basic insulation, are considered to meet the requirements for safety class 0.

3.4 Class C: Limited voltage, limited power applications

Modules rated for use in this application class are restricted to systems operating at less than

50 V DC and 240 W, where general contact access is anticipated. Modules qualified for safety

through IEC 61730-1 and this part of IEC 61730 within this application class are considered to

meet the requirements for safety class III.

NOTE Safety classes are defined within IEC 61140.

4 Test categories

4.1 General

The following hazards might influence the lifetime and the safety of PV modules. In

accordance with these hazards, test procedures and criteria are described. The specific tests

to which a module will be subjected will depend on the end use application for which the

minimum tests are specified in Clause 5.

NOTE Module safety tests are labelled MST.

Tables 1 to 6 show the origin of the required tests. For some tests, the third column shows for

information the origin of the tests, but the appropriate test requirements are given in Clauses

10 and 11. The rest of the tests are based on or identical to IEC 61215/IEC 61646, and

references to the relevant Clauses are given in the last two columns. Some of the

IEC 61215/IEC 61646-based tests were modified for IEC 61730-2 and are included in Clauses

10 and 11.

61730-2 © IEC:2004 – 9 –

4.2 Preconditioning tests

Table 1 – Preconditioning tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 51 Thermal cycling (TC50 or TC200) 10.11 10.11

MST 52 Humidity freeze (HF10) 10.12 10.12

MST 53 Damp heat (DH1000) 10.13 10.13

MST 54 UV preconditioning test 10.10 10.10

4.3 General inspection

Table 2 – General inspection test

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 01 Visual inspection 10.1 10.1

4.4 Electrical shock hazard tests

These tests are designed to assess the risk to personnel due to shock or injury because of

contact with parts of a module that are electrically energised as a result of design,

construction, or faults caused by environment or operation.

Table 3 – Electrical shock hazard tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 11 Accessibility test ANSI/UL 1703

MST 12 Cut susceptibility test (not required for glass ANSI/UL 1703

surfaces)

MST 13 Ground continuity test ANSI/UL 1703

(not required unless metal framed)

MST 14 Impulse voltage test IEC 60664-1

MST 16 Dielectric withstand test 10.3* 10.3*

MST 17 Wet leakage current test 10.15 10.20

MST 42 Robustness of terminations test 10.14 10.14

* The pass/fail criteria differ from those given in IEC 61215 and IEC 61646.

4.5 Fire hazard tests

These tests assess the potential fire hazard due to the operation of a module or failure of its

components.

– 10 – 61730-2 © IEC:2004

Table 4 – Fire hazard tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 21 Temperature test ANSI/UL 1703

MST 22 Hot-spot test 10.9 10.9

MST 23 Fire test ANSI/UL 790

MST 25 Bypass diode thermal test 10.18

MST 26 Reverse current overload test ANSI/UL 1703

4.6 Mechanical stress tests

These tests are to minimise potential injury due to mechanical failure.

Table 5 – Mechanical stress tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 32 Module breakage test ANSI Z97.1

MST 34 Mechanical load test 10.16 10.16

4.7 Component tests

Table 6 – Component tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 15 Partial discharge test IEC 60664-1

MST 33 Conduit bending ANSI/UL 514C

MST 44 Terminal box knock out test ANSI/UL 514C

5 Application classes and their necessary test procedures

The specific tests to which a module will be subjected, depending on the application class

defined in IEC 61730-1, is described in Table 7. The order in which the tests are carried out

shall be in accordance with Figure 1.

Some tests shall be carried out as preconditioning tests.

NOTE This test sequence has been designed so that IEC 61730-2 can be performed in conjunction with

IEC 61215 or IEC 61646. In this way, the environmental stress tests in IEC 61215 or IEC 61646 can serve as the

preconditioning tests for IEC 61730-2.

61730-2 © IEC:2004 – 11 –

Table 7 – Required tests, depending on the application class

Application class

Tests

A B C

Preconditioning tests:

X X X MST 51 Thermal cycling (T50 or T200)

X X X MST 52 Humidity freeze (10HF)

X X X MST 53 Damp heat (DH1000)

X X X MST 54 UV resistance

General inspection test:

X X X MST 01 Visual inspection

Electrical shock hazard tests:

X X - MST 11 Accessibility test

X X - MST 12 Cut susceptibility test

X X X MST 13 Ground continuity test

X X* - MST 14 Impulse voltage test

X X* - MST 16 Dielectric withstand test

X X - MST 17 Wet leakage current test

X X X MST 42 Robustness of terminations test

Fire hazard tests:

X X X MST 21 Temperature test

X X X MST 22 Hot spot test

X** - - MST 23 Fire test

X X - MST 26 Reverse current overload test

Mechanical stress tests:

X - X MST 32 Module breakage test

X X X MST 34 Mechanical load test

Component tests:

X - - MST 15 Partial discharge test

X X - MST 33 Conduit bending

X X X MST 44 Terminal box knockout test

X Test required.

- Test needs not be carried out.

* Different test levels for application classes A and B.

** Minimum fire resistance class C is necessary for building roof-mounted modules.

– 12 – 61730-2 © IEC:2004

6 Sampling

Six modules and a laminate (a module without frame) for safety testing (plus spares as

desired) and additional modules as required for the fire-test shall be taken at random from a

production batch or batches, in accordance with the procedure given in IEC 60410. The

modules shall have been manufactured from specified materials and components in

accordance with the relevant drawings and process sheets and have been subjected to the

manufacturer's normal inspection, quality control and production acceptance procedures. The

modules shall be complete in every detail and shall be accompanied by the manufacturer's

handling, mounting and connection instructions, including the maximum permissible system

voltage.

When the modules to be tested are prototypes of a new design and not from production, this

fact shall be noted in the test report (see Clause 7).

7 Test report

The results shall be laid down in a test report according to ISO/IEC 17025. The results shall

be reported, normally in a test report and shall include all the information requested by the

client and necessary to the interpretation of the test and all information required by the

method used:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page;

d) name and address of client, where appropriate;

e) description and identification of the item tested;

f) characterization and condition of the test item;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to or exclusions from the test method, and any other

information relevant to a specific tests, such as environmental conditions;

k) measurements, examinations and derived results supported by tables, graphs, sketches

and photographs as appropriate including maximum systems voltage, safety class,

mounting technique and any failures observed;

l) a statement indicating whether the impulse voltage test was performed on module or

laminate;

m) a statement of the estimated uncertainty of the test results (where relevant);

n) a signature and title, or equivalent identification of the person(s) accepting responsibility

for the content of the certificate or report, and the date of issue;

o) where relevant, a statement to the effect that the results relate only to the items tested;

p) a statement that the certificate or report shall not be reproduced except in full, without the

written approval of the laboratory.

A copy of this report shall be kept by the manufacturer for reference purposes.

—————————

If the module is only used with frame and the frame is an essential part to fulfil the isolation requirement, the

laminate can be replaced by a module.

61730-2 © IEC:2004 – 13 –

8 Testing

The modules shall be divided into groups and subjected to the safety tests shown in Figure 1,

carried out in the order specified. The modules shall be selected such that the preconditioning

tests of 4.2 are met. Each box in Figure 1 refers to the corresponding subclause in this part of

IEC 61730.

NOTE Spare modules may be included in the safety test program provided that they have been appropriately

environmentally tested to meet the necessary prerequisites.

Test procedures and criteria, including initial and final measurements where necessary, are

detailed in Clauses 10 and 11. Some tests are identical to tests in IEC 61215/IEC 61646 and

are detailed in Clause 4 instead. In carrying out these tests, the tester shall strictly observe

the manufacturer's handling, mounting, and connection instructions.

– 14 – 61730-2 © IEC:2004

Module safety test MST

IEC 61730

7 modules or

6 modules and 1 laminate

IEC 61215

Module performance test MPT

IEC 61646

The numbers in each box are references to final

Visual inspection

10.2 17

measurements, that are to be performed after

MST 01

MST or MPT (if required). In this example:

01 = Module safety test MST 01

10.2 = Performance test (IEC 61215, IEC 61646)

Component tests

17 = Module safety test MST 17 Performance test

10.2 (IEC 61215,

IEC 61646)

11 pieces

of foil

1 module 1 module 3 modules

Number of 1 module

1 laminate

modules depends

1 piece

on the module size

of

Dielectric withstand

junction

Control

test

box

MST 16

Test on

Ground continuity 6 knock

test

outs

MST 13

Partial discharge

test

Fire test Module breakage test

Accessibility

MSTMST 1 155

MST 23

MST 32

test

MST 11

Conduit bending

test

Wet leakage current

MSTMST 3 333

test

MST 17

Terminal box

knock out test

1 m1 modulodulee 1 m1 modulodulee

1 module

MSTMST 4 444

1 laminate (module)

DDamamp heatp Heat t Teestst Thermal cycling test

UV-resistance test

1000 h1 000 h 200 cycles

MST 54

MSTMST 5 533 MST 51a

01 10.2 16

01 10.2 16 01 10.2 16

Thermal cycling test Wet leakage current

Bypass diode

test

50 cycles

thermal test

MST 17

MST 51b

MST 25

01 10.2 16

17 17

0101 1616

Mechanical load

Humidity freeze test laminate

Temperature

test (module)

MST 52

MST 34 test

MSTMST 2 211

01 10.2 17

01 10.2 16

Robustness of Hot-spot Impulse voltage Reverse current

terminations test test overload test

test

MST 42

MST 22 MSTMST 1 144 MSTMST 2 266

01 10.2 16 17 01 16 17

01 16

Cut susceptibility

test

MST 12

01 13 17

Accessibility test

MST 11

Visual inspection

MST 01

IEC 1357/04

Figure 1 – Test sequences

61730-2 © IEC:2004 – 15 –

9 Pass criteria

The module product under evaluation shall be judged to have passed the safety qualification

test, if the test samples meet all of the criteria of each individual test.

If any module does not meet these test criteria, the module product under evaluation shall be

deemed not to have met the safety test requirements.

NOTE The nature of the failure will determine the extent of re-testing requirements.

10 Test procedures

10.1 Visual inspection MST 01

10.1.1 Purpose

To detect any visual defects in the module.

10.1.2 Procedure

This test is identical with 10.1 from IEC 61215/IEC 61646 with the additional inspection

criteria of

– any other conditions which may affect safety;

– markings not consistent with Clause 11 of IEC 61730-1.

Make note of and/or photograph the nature and position of any cracks, bubbles or

delaminations, etc. which may worsen and adversely affect the module safety in subsequent

tests. Visual conditions other than the major defects listed below are acceptable for the

purpose of safety test approval.

10.1.3 Pass criteria

For the purpose of the safety test approval, the following are considered to be major visual

defects:

a) broken, cracked, or torn external surfaces;

b) bent or misaligned external surfaces, including superstrates, substrates, frames and

junction boxes to the extent that the safety of the module would be impaired;

c) bubbles or delaminations forming a continuous path between any part of the electrical

circuit and the edge of the module, or which exhibited significant growth during the testing

and would, if testing were continued, reach such a condition;

d) evidence of any molten or burned encapsulant, back sheet, diode or active PV component;

e) loss of mechanical integrity to the extent that the safety of the installation and operation of

the module would be impaired;

f) markings not complying with Clause 12 of IEC 61730-1.

10.2 Accessibility test MST 11

10.2.1 Purpose

To determine if uninsulated electrical connections represent a shock hazard to personnel.

– 16 – 61730-2 © IEC:2004

10.2.2 Apparatus

The apparatus is as follows:

a) A cylindrical test fixture Type 11 according to Figure 7 of IEC 61032.

b) An ohmmeter or continuity tester.

10.2.3 Procedure

The procedure is as follows:

a) Mount and wire the test module as recommended by the manufacturer.

b) Attach the ohmmeter or continuity tester to the module electric circuit and to the test

fixture.

c) Remove all covers, plugs and connections from the module that can be removed without

using a tool.

d) Probe with the test fixture in and around all electrical connectors, plugs, junction boxes

and any other areas where the electrical circuit of the module may be accessible.

e) Monitor the ohmmeter or continuity tester during the probing to determine if the test fixture

makes electrical contact to the module electric circuitry.

10.2.4 Final measurements

None.

10.2.5 Requirements

At no time during the test shall there be less than 1 MΩ resistance between the test fixture

and the module electric circuit.

10.2.6 Pass criteria

At no time during the test shall the probe contact any live electrical part. This test is

performed at the beginning and the end of the sequence according to Figure 1, but also can

be used at any time during the test sequence if there is any reason to believe that active

electric circuitry has been exposed by one of the other tests.

10.3 Cut susceptibility test MST 12

10.3.1 Purpose

To determine whether any front and rear surfaces of the module made of polymeric materials

are capable of withstanding routine handling during installation and maintenance without

exposing personnel to the danger of electric shock. This test is derived from ANSI/UL 1703.

10.3.2 Apparatus

A test fixture as shown in Figure 2, designed to draw a defined shaped object, a 0,64 mm ±

0,05 mm thick carbon steel blade (for example the back of a hacksaw blade) over the surface

of the module with an applied force of 8,9 N ± 0,5 N.

61730-2 © IEC:2004 – 17 –

10.3.3 Procedure

The procedure is as follows:

a) Position the module horizontally with the front surface facing upward.

b) The test fixture is to be placed on the surface for 1 min and then drawn across the surface

of the module at a speed of (150 ± 30) mm/s.

Repeat the procedure five times in different directions.

c) Repeat a) and b) for the rear surface of the module.

10.3.4 Final measurements

Repeat MST 01, MST 13, MST 16 and MST 17.

10.3.5 Pass criteria

The pass criteria are as follows:

a) No visual evidence that the superstrate or substrate surfaces have been cut, exposing the

active circuitry of the module.

b) MST 13, MST 16, MST 17 shall meet the same requirements as for the initial

measurements.

– 18 – 61730-2 © IEC:2004

A

140°

B

Q

Test point

carbon steel strip

(i.e. hacksaw

blade)

90°

C

IEC 1358/04

Key

A 150 mm from axis to center of weight.

B 170 mm from axis to test point.

C Test point – 0,64 mm thick steel strip.

Q Total force exerted at test point Q: 8,9 N

Figure 2 – Cut susceptibility test

61730-2 © IEC:2004 – 19 –

10.4 Ground continuity test MST 13

10.4.1 Purpose

To demonstrate that there is a conductive path between all exposed conductive surfaces of

the module, so that the exposed conductive surfaces can be adequately grounded in a PV

system. This test is required only if the module has exposed conductive parts such as a metal

frame or a metallic junction box.

10.4.2 Apparatus

The apparatus is as follows:

a) A constant current supply capable of producing a current that is 2,5 times the maximum

over-current protection rating of the module under test. See MST 26.

b) A suitable voltmeter.

NOTE According to IEC 61730-1 the maximum over-current protection rating has to be provided by the

manufacturer.

10.4.3 Procedure

The procedure is as follows:

a) Select the manufacturer’s designated grounding point and recommended grounding

connection. Attach to one terminal of the constant current supply.

b) Select an adjacent (connected) exposed conductive component with the greatest physical

displacement from the grounding point, and attach to the other terminal of the current

supply.

c) Attach the voltmeter to the two conductive components attached to the current supply in

proximity to the current leads.

d) Apply a current 2,5 times ± 10 % of the maximum over-current protection rating of the

module for a minimum of 2 min.

e) Measure the applied current and the resultant voltage drop.

f) Reduce the current to zero.

g) Repeat the test on one additional frame component.

10.4.4 Final measurements

None.

10.4.5 Pass criteria

The resistance between the selected exposed conductive component and each other

conductive component of the module shall be less than 0,1 Ω.

10.5 Impulse voltage test MST 14

10.5.1 Purpose

To verify the capability of the solid insulation of the module to withstand over-voltages of

atmospheric origin. It also covers over-voltages due to switching of low-voltage equipment.

NOTE If the PV module is not going to be sold without frame, the impulse voltage test should be done with the

module framed.

– 20 – 61730-2 © IEC:2004

10.5.2 Apparatus

The apparatus is as follows:

a) Impulse voltage generator.

b) Oscilloscope.

10.5.3 Procedures

For the purposes of test reproducibility, this test is conducted under the conditions of room

temperature and relative humidity of less than 75 %. The procedure is as follows:

a) Cover the whole module with a copper foil. Connect the foil to the negative terminal of the

impulse voltage generator.

b) Connect the shorted output terminals of the module to the positive terminal of the impulse

voltage generator.

Specification of the foil:

1) Thickness copper 0,03 mm to 0,05 mm.

2) Conducting glue (conductivity <1 Ω, measuring area: 625 mm ).

3) Total thickness 0,05 mm to 0,07 mm.

c) With no illumination, apply the surge impulse voltage given in Table 8 with a waveform as

shown in Figure 3 by the impulse voltage generator. The waveform of the pulse shall be

observed by an oscilloscope and the rise time and the pulse duration shall be checked for

each test.

NOTE 1 According to 2.2.2.1.1 of IEC 60664-1, modules belong to the over-voltage category III. The test-

level has been reduced by one step because systems are normally equipped with over-voltage protection

devices. On the other hand, to verify reinforced insulation (as required for application class A and safety class

II), the level for application class A has been increased by one step.

Table 8 – Impulse voltage versus maximum system voltage

Impulse voltage

Maximum system voltage

Application class A Application class B

V

V V

100 1 500 800

150 2 500 1 500

300 4 000 2 500

600 6 000 4 000

1 000 8 000 6 000

NOTE 2 Linear interpolation is allowed for intermediate values of maximum system voltage.

d) Three successive pulses shall be applied.

e) Change the polarity of the terminals of the pulse generator and apply three successive

pulses.

61730-2 © IEC:2004 – 21 –

10.5.4 Final measurement

Repeat MST 01 visual inspection.

10.5.5 Pass criteria

The pass criteria are as follows:

a) No evidence of dielectric breakdown or surface tracking of the module is observed during

the test.

b) No evidence of major visual defects as defined in 10.1.

Voltage

1,0

B

0,9

0,5

0,3

A

Time

T’

T

T

T

T = 1,2 μs ± 30 %

T = 50 μs ± 20 %

IEC 1359/04

NOTE The parameter 0 is the start point of the impulse voltage. In a diagram with linear time scale this is the

intersection point of the time axis and the line defined by points A and B.

Figure 3 – Wave-form of the impulse voltage according to IEC 60060-1

10.6 Dielectric withstand test MST 16

10.6.1 Purpose

To determine whether or not the module is sufficiently well insu

...

IEC 61730-2 ®

Edition 1.1 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 2: Exigences pour les essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 61730-2 ®

Edition 1.1 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 2: Requirements for testing

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 2: Exigences pour les essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-88912-882-2

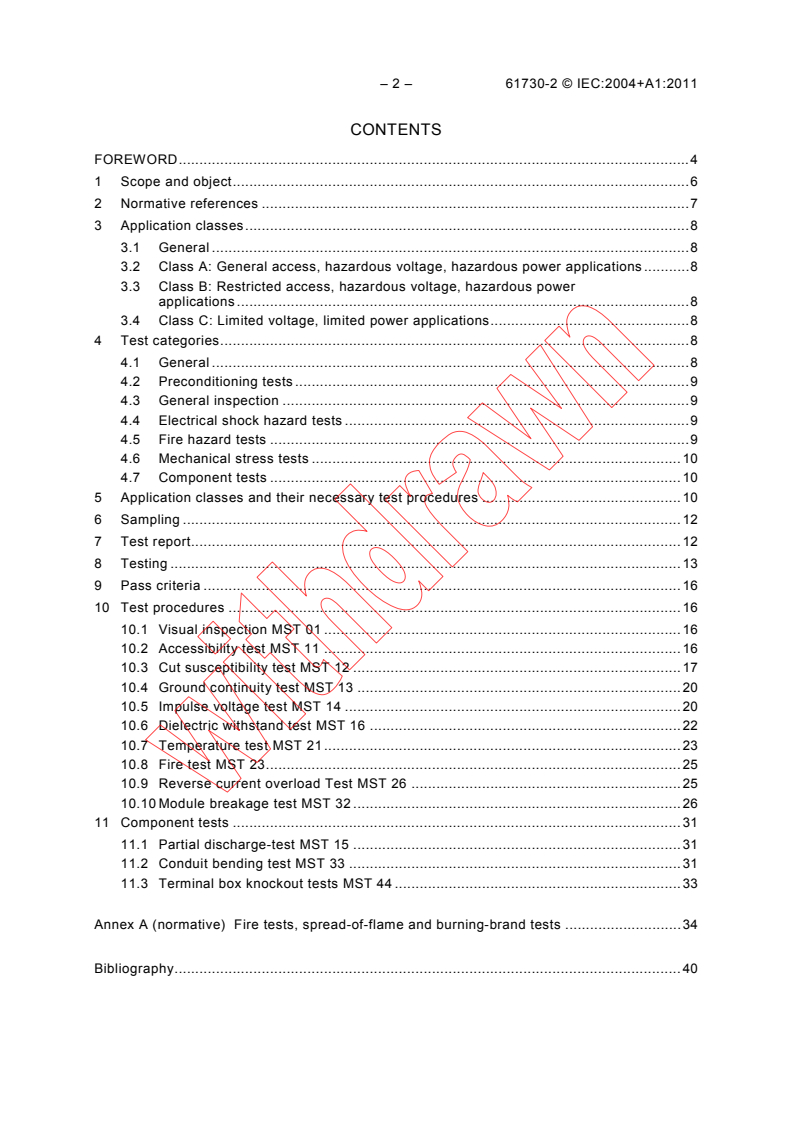

– 2 – 61730-2 © IEC:2004+A1:2011

CONTENTS

FOREWORD . 4

1 Scope and object . 6

2 Normative references . 7

3 Application classes . 8

3.1 General . 8

3.2 Class A: General access, hazardous voltage, hazardous power applications . 8

3.3 Class B: Restricted access, hazardous voltage, hazardous power

applications . 8

3.4 Class C: Limited voltage, limited power applications . 8

4 Test categories . 8

4.1 General . 8

4.2 Preconditioning tests . 9

4.3 General inspection . 9

4.4 Electrical shock hazard tests . 9

4.5 Fire hazard tests . 9

4.6 Mechanical stress tests . 10

4.7 Component tests . 10

5 Application classes and their necessary test procedures . 10

6 Sampling . 12

7 Test report. 12

8 Testing . 13

9 Pass criteria . 16

10 Test procedures . 16

10.1 Visual inspection MST 01 . 16

10.2 Accessibility test MST 11 . 16

10.3 Cut susceptibility test MST 12 . 17

10.4 Ground continuity test MST 13 . 20

10.5 Impulse voltage test MST 14 . 20

10.6 Dielectric withstand test MST 16 . 22

10.7 Temperature test MST 21 . 23

10.8 Fire test MST 23 . 25

10.9 Reverse current overload Test MST 26 . 25

10.10 Module breakage test MST 32 . 26

11 Component tests . 31

11.1 Partial discharge-test MST 15 . 31

11.2 Conduit bending test MST 33 . 31

11.3 Terminal box knockout tests MST 44 . 33

Annex A (normative) Fire tests, spread-of-flame and burning-brand tests . 34

Bibliography . 40

61730-2 © IEC:2004+A1:2011 – 3 –

Figure 1 – Test sequences . 15

Figure 2 – Cut susceptibility test . 19

Figure 3 – Wave-form of the impulse voltage according to IEC 60060-1 . 22

Figure 4 – Impactor . 28

Figure 5 – Impact test frame 1 . 29

Figure 6 – Impact test frame 2 . 30

Figure 7 – Test fixture assembly . 32

Figure A.1 – Test apparatus for fire test . 35

Figure A.2 – Burning brand construction . 38

Table 1 – Preconditioning tests . 9

Table 2 – General inspection test. 9

Table 3 – Electrical shock hazard tests . 9

Table 4 – Fire hazard tests . 10

Table 5 – Mechanical stress tests . 10

Table 6 – Component tests . 10

Table 7 – Required tests, depending on the application class . 11

Table 8 – Impulse voltage versus maximum system voltage . 21

Table 9 – Component temperature limits . 24

Table 10 – Bending loads . 32

– 4 – 61730-2 © IEC:2004+A1:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 61730-2 consists of the first edition (2004) [documents

82/357/FDIS and 82/366/RVD] and its amendment 1 (2011) [documents 82/660/FDIS and

82/678/RVD]. It bears the edition number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

61730-2 © IEC:2004+A1:2011 – 5 –

International Standard IEC 61730-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61730 consists of the following parts, under the general title Photovoltaic (PV) module

safety qualification:

Part 1: Requirements for construction

Part 2: Requirements for testing

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – 61730-2 © IEC:2004+A1:2011

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 2: Requirements for testing

1 Scope and object

This part of IEC 61730 describes the testing requirements for photovoltaic (PV) modules in

order to provide safe electrical and mechanical operation during their expected lifetime.

Specific topics are provided to assess the prevention of electrical shock, fire hazards, and

personal injury due to mechanical and environmental stresses. IEC 61730-1 pertains to the

particular requirements of construction. This part of IEC 61730 outlines the requirements of

testing.

This standard attempts to define the basic requirements for various application classes of

photovoltaic modules, but it cannot be considered to encompass all national or regional

building codes. The specific requirements for marine and vehicle applications are not covered.

This standard is not applicable to modules with integrated AC inverters (AC modules).

This standard is designed so that its test sequence can co-ordinate with those of IEC 61215

or IEC 61646, so that a single set of samples may be used to perform both the safety and

performance evaluation of a photovoltaic module design.

The test-sequences of this standard are arranged in an optimal way so that tests of

IEC 61215 or IEC 61646 can be used as basic preconditioning tests.

NOTE 1 The sequence of tests required in this standard may not test for all possible safety aspects associated

with the use of PV modules in all possible applications. This standard utilizes the best sequence of tests available

at the time of its writing. There are some issues, such as the potential danger of electric shock posed by a broken

module in a high voltage system, that should be addressed by the systems design, location, restrictions on access

and maintenance procedures.

The object of this document is to provide the testing sequence intended to verify the safety of

PV modules whose construction has been assessed by IEC 61730-1. The test sequence and

pass criteria are designed to detect the potential breakdown of internal and external

components of PV modules that would result in fire, electric shock and personal injury. The

standard defines the basic safety test requirements and additional tests that are a function of

the module end-use applications.

Test categories include general inspection, electrical shock hazard, fire hazard, mechanical

stress, and environmental stress.

NOTE 2 The additional testing requirements outlined in relevant ISO standards, or the national or local codes

which govern the installation and use of these modules in their intended locations, should be considered in addition

to the requirements contained within this document.

61730-2 © IEC:2004+A1:2011 – 7 –

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60410, Sampling plans and procedures for inspection by attributes

IEC 60664-1:1992, Insulation co-ordination for equipment within low-voltage systems – Part 1

Principles, requirements and tests

Amendment 2 (2002)

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for reference solar cells devices

IEC 60904-6, Photovoltaic devices – Part 6: Requirements for reference solar modules

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61140, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215:2004, Crystalline silicon terrestrial photovoltaic (PV) modules – Design

qualification and type approval

IEC 61646:1996, Thin-film terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61730-1:2004, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ANSI/UL 514C, Non-metallic outlet boxes, flush device boxes and covers

ANSI/UL 790, Tests for Fire Resistance of Roof Covering Materials

ANSI/UL 1703, Flat – Plate Photovoltaic Modules and Panels

ANSI Z97.1, American National Standard for Safety Glazing Materials Used in Buildings –

Safety Performance Specifications and Methods of Test

– 8 – 61730-2 © IEC:2004+A1:2011

3 Application classes

3.1 General

Photovoltaic modules may be installed in many different applications. Therefore, it is

important to evaluate the potential hazards associated with those applications and to evaluate

the construction of the module accordingly.

Relevant safety requirements and necessary tests shall be performed to verify the

conformance to the requirements of that application class. This clause defines those

application classes and construction qualities required for each class.

Application classes for PV-modules are defined as follows:

3.2 Class A: General access, hazardous voltage, hazardous power applications

Modules rated for use in this application class may be used in systems operating at greater

than 50 V DC or 240 W, where general contact access is anticipated. Modules qualified for

safety through IEC 61730-1 and this part of IEC 61730 within this application class are

considered to meet the requirements for safety class II.

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications

Modules rated for use in this application class are restricted to systems protected from public

access by fences, location, etc. Modules evaluated within this application class provide

protection by basic insulation, are considered to meet the requirements for safety class 0.

3.4 Class C: Limited voltage, limited power applications

Modules rated for use in this application class are restricted to systems operating at less than

50 V DC and 240 W, where general contact access is anticipated. Modules qualified for safety

through IEC 61730-1 and this part of IEC 61730 within this application class are considered to

meet the requirements for safety class III.

NOTE Safety classes are defined within IEC 61140.

4 Test categories

4.1 General

The following hazards might influence the lifetime and the safety of PV modules. In

accordance with these hazards, test procedures and criteria are described. The specific tests

to which a module will be subjected will depend on the end use application for which the

minimum tests are specified in Clause 5.

NOTE Module safety tests are labelled MST.

Tables 1 to 6 show the origin of the required tests. For some tests, the third column shows for

information the origin of the tests, but the appropriate test requirements are given in Clauses

10 and 11. The rest of the tests are based on or identical to IEC 61215/IEC 61646, and

references to the relevant Clauses are given in the last two columns. Some of the

IEC 61215/IEC 61646-based tests were modified for IEC 61730-2 and are included in Clauses

10 and 11.

61730-2 © IEC:2004+A1:2011 – 9 –

4.2 Preconditioning tests

Table 1 – Preconditioning tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 51 Thermal cycling (TC50 or TC200) 10.11 10.11

MST 52 Humidity freeze (HF10) 10.12 10.12

MST 53 Damp heat (DH1000) 10.13 10.13

MST 54 UV preconditioning test 10.10 10.10

4.3 General inspection

Table 2 – General inspection test

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 01 Visual inspection 10.1 10.1

4.4 Electrical shock hazard tests

These tests are designed to assess the risk to personnel due to shock or injury because of

contact with parts of a module that are electrically energised as a result of design,

construction, or faults caused by environment or operation.

Table 3 – Electrical shock hazard tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 11 Accessibility test ANSI/UL 1703

MST 12 Cut susceptibility test (not required for glass ANSI/UL 1703

surfaces)

MST 13 Ground continuity test ANSI/UL 1703

(not required unless metal framed)

MST 14 Impulse voltage test IEC 60664-1

MST 16 Dielectric withstand test 10.3* 10.3*

MST 17 Wet leakage current test 10.15 10.20

MST 42 Robustness of terminations test 10.14 10.14

* The pass/fail criteria differ from those given in IEC 61215 and IEC 61646.

4.5 Fire hazard tests

These tests assess the potential fire hazard due to the operation of a module or failure of its

components.

– 10 – 61730-2 © IEC:2004+A1:2011

Table 4 – Fire hazard tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 21 Temperature test ANSI/UL 1703

MST 22 Hot-spot test 10.9 10.9

MST 23 Fire test ANSI/UL 790

MST 25 Bypass diode thermal test 10.18 10.18

MST 26 Reverse current overload test ANSI/UL 1703

4.6 Mechanical stress tests

These tests are to minimise potential injury due to mechanical failure.

Table 5 – Mechanical stress tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 32 Module breakage test ANSI Z97.1

MST 34 Mechanical load test 10.16 10.16

4.7 Component tests

Table 6 – Component tests

According to

References in

Test Title

Standards

IEC 61215 IEC 61646

MST 15 Partial discharge test IEC 60664-1

MST 33 Conduit bending ANSI/UL 514C

MST 44 Terminal box knock out test ANSI/UL 514C

5 Application classes and their necessary test procedures

The specific tests to which a module will be subjected, depending on the application class

defined in IEC 61730-1, is described in Table 7. The order in which the tests are carried out

shall be in accordance with Figure 1.

Some tests shall be carried out as preconditioning tests.

NOTE This test sequence has been designed so that IEC 61730-2 can be performed in conjunction with

IEC 61215 or IEC 61646. In this way, the environmental stress tests in IEC 61215 or IEC 61646 can serve as the

preconditioning tests for IEC 61730-2.

61730-2 © IEC:2004+A1:2011 – 11 –

Table 7 – Required tests, depending on the application class

Application class

Tests

A B C

Preconditioning tests:

X X X MST 51 Thermal cycling (T50 or T200)

X X X MST 52 Humidity freeze (10HF)

X X X MST 53 Damp heat (DH1000)

X X X MST 54 UV resistance pre-conditioning

General inspection test:

X X X MST 01 Visual inspection

Electrical shock hazard tests:

X X - MST 11 Accessibility test

X X - MST 12 Cut susceptibility test

X X X MST 13 Ground continuity test

X X* - MST 14 Impulse voltage test

X X* - MST 16 Dielectric withstand test

X X - MST 17 Wet leakage current test

X X X MST 42 Robustness of terminations test

Fire hazard tests:

X X X MST 21 Temperature test

X X X MST 22 Hot spot test

X** - - MST 23 Fire test

X X - MST 26 Reverse current overload test

Mechanical stress tests:

X - X MST 32 Module breakage test

X X X MST 34 Mechanical load test

Component tests:

X - - MST 15 Partial discharge test

X X - MST 33 Conduit bending

X X X MST 44 Terminal box knockout test

X Test required.

- Test needs not be carried out.

* Different test levels for application classes A and B.

** Minimum fire resistance class C is necessary for building roof-mounted modules.

– 12 – 61730-2 © IEC:2004+A1:2011

6 Sampling

Six modules and a laminate (a module without frame) for safety testing (plus spares as

desired) and additional modules as required for the fire-test shall be taken at random from a

production batch or batches, in accordance with the procedure given in IEC 60410. The

modules shall have been manufactured from specified materials and components in

accordance with the relevant drawings and process sheets and have been subjected to the

manufacturer's normal inspection, quality control and production acceptance procedures. The

modules shall be complete in every detail and shall be accompanied by the manufacturer's

handling, mounting and connection instructions, including the maximum permissible system

voltage.

When the modules to be tested are prototypes of a new design and not from production, this

fact shall be noted in the test report (see Clause 7).

7 Test report

The results shall be laid down in a test report according to ISO/IEC 17025. The results shall

be reported, normally in a test report and shall include all the information requested by the

client and necessary to the interpretation of the test and all information required by the

method used:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page;

d) name and address of client, where appropriate;

e) description and identification of the item tested;

f) characterization and condition of the test item;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to or exclusions from the test method, and any other

information relevant to a specific tests, such as environmental conditions;

k) measurements, examinations and derived results supported by tables, graphs, sketches

and photographs as appropriate including maximum systems voltage, safety class,

mounting technique and any failures observed;

l) a statement indicating whether the impulse voltage test was performed on module or

laminate;

m) a statement of the estimated uncertainty of the test results (where relevant);

n) a signature and title, or equivalent identification of the person(s) accepting responsibility

for the content of the certificate or report, and the date of issue;

o) where relevant, a statement to the effect that the results relate only to the items tested;

p) a statement that the certificate or report shall not be reproduced except in full, without the

written approval of the laboratory.

A copy of this report shall be kept by the manufacturer for reference purposes.

—————————