IEC TR 63192:2019

(Main)Nuclear power plants - Instrumentation and control systems important to safety - Hazard analysis: A review of current approaches

Nuclear power plants - Instrumentation and control systems important to safety - Hazard analysis: A review of current approaches

IEC TR 63192:2019 provides the comparison of the hazard analysis requirements between IAEA framework and NRC-IEEE framework of standards and guidance. The hazard analysis requirements in the different standards were compared with a set of comparison criteria, including the safety principle, the safety process, the definitions, the hazard analysis process, etc. This document includes the comparison results of the HA requirements of the safety control systems of other safety industries in Annex C.

For a nuclear power plant, the design safety and operation safety shall be analyzed, for example, to meet the IAEA Safety Requirements for Design (SSR-2/1) and Operation (SSR‑2/2). The scope of this document is to survey the state of the art in the hazard analysis for the design of I&C system of NPPs.

General Information

- Status

- Published

- Publication Date

- 28-Jan-2019

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Jan-2019

- Completion Date

- 14-Jan-2019

Overview

IEC TR 63192:2019 - "Nuclear power plants - Instrumentation and control systems important to safety - Hazard analysis: A review of current approaches" is an informative Technical Report that surveys the state of the art in hazard analysis (HA) approaches for digital I&C systems in nuclear power plants (NPPs). Rather than imposing requirements, it documents and compares HA requirements and guidance from major frameworks - principally the IAEA and the NRC/IEEE family - using a set of comparison criteria (safety principles, processes, definitions, HA process, independence, etc.). The report also summarizes HA guidance from other safety-critical industries in Annex C and practical HA techniques in Annex A.

Key topics and technical highlights

- Scope and purpose: Comparison of IAEA and NRC‑IEEE HA requirements for I&C systems important to safety, with emphasis on design-phase HA for meeting IAEA Safety Requirements for Design (SSR‑2/1) and Operation (SSR‑2/2).

- Terminology alignment: Mapping of definitions and terms used across IAEA, IEC and IEEE documents to clarify mismatches in HA language.

- Comparison criteria: Side‑by‑side evaluation using criteria such as safety principle, safety process, HA methods, HA process steps, independence of HA organization, and relationships to security and reliability.

- Framework survey: Coverage of specific standards and guidance including IAEA SSRs and SSG‑39, IEEE 603, IEEE 7‑4.3.2, IEEE 1228, IEEE 1012, and relevant NRC guidance.

- Cross‑industry review: Annex B/C compares HA practices from IEC 61508 (functional safety), DO‑178C (aerospace), ISO 26262 (automotive), IEC 60601 (medical), MIL‑STD‑882E (military), and others to identify transferable practices.

- Practical techniques: Annex A surveys practical HA methods for digital I&C (e.g., systematic hazard identification, analysis techniques) and discusses their applicability.

- Harmonization and future work: Discussion of MDEP common positions and needs for harmonized HA for system-of-systems (SoS), software, hardware and human factors, and integration with security/reliability activities.

Practical applications and users

IEC TR 63192 is useful for:

- NPP operators and utilities - to understand international HA expectations during design and licensing.

- System designers and I&C engineers - to inform HA planning for digital instrumentation and control systems.

- Safety analysts and assessors - for comparing HA approaches and selecting suitable methods.

- Regulators, licensors and reviewers - to align review criteria with international frameworks (IAEA, NRC/IEEE).

- Standards developers and project managers - to guide harmonization efforts across standards and industries.

Practical uses include informing design safety cases, supporting licensing submissions, selecting HA techniques, and benchmarking HA processes against international guidance.

Related standards and keywords

Related standards and documents referenced in the report include IAEA SSR‑2/1, IAEA SSR‑2/2, IAEA SSG‑39, IEC 61513, IEC 61508, IEEE 603, IEEE 7‑4.3.2, IEEE 1012, DO‑178C, ISO 26262, and relevant NRC guidance.

Keywords: hazard analysis, I&C systems, nuclear power plants, digital instrumentation and control, IAEA, NRC, IEEE, safety requirements, SSR‑2/1, SSR‑2/2, system safety, harmonization.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TR 63192:2019 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Nuclear power plants - Instrumentation and control systems important to safety - Hazard analysis: A review of current approaches". This standard covers: IEC TR 63192:2019 provides the comparison of the hazard analysis requirements between IAEA framework and NRC-IEEE framework of standards and guidance. The hazard analysis requirements in the different standards were compared with a set of comparison criteria, including the safety principle, the safety process, the definitions, the hazard analysis process, etc. This document includes the comparison results of the HA requirements of the safety control systems of other safety industries in Annex C. For a nuclear power plant, the design safety and operation safety shall be analyzed, for example, to meet the IAEA Safety Requirements for Design (SSR-2/1) and Operation (SSR‑2/2). The scope of this document is to survey the state of the art in the hazard analysis for the design of I&C system of NPPs.

IEC TR 63192:2019 provides the comparison of the hazard analysis requirements between IAEA framework and NRC-IEEE framework of standards and guidance. The hazard analysis requirements in the different standards were compared with a set of comparison criteria, including the safety principle, the safety process, the definitions, the hazard analysis process, etc. This document includes the comparison results of the HA requirements of the safety control systems of other safety industries in Annex C. For a nuclear power plant, the design safety and operation safety shall be analyzed, for example, to meet the IAEA Safety Requirements for Design (SSR-2/1) and Operation (SSR‑2/2). The scope of this document is to survey the state of the art in the hazard analysis for the design of I&C system of NPPs.

IEC TR 63192:2019 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 63192:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 63192 ®

Edition 1.0 2019-01

TECHNICAL

REPORT

Nuclear power plants – Instrumentation and control systems important to

safety – Hazard analysis: a review of current approaches

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 63192 ®

Edition 1.0 2019-01

TECHNICAL

REPORT

Nuclear power plants – Instrumentation and control systems important to

safety – Hazard analysis: a review of current approaches

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-6408-9

– 2 – IEC TR 63192:2019 © IEC 2019

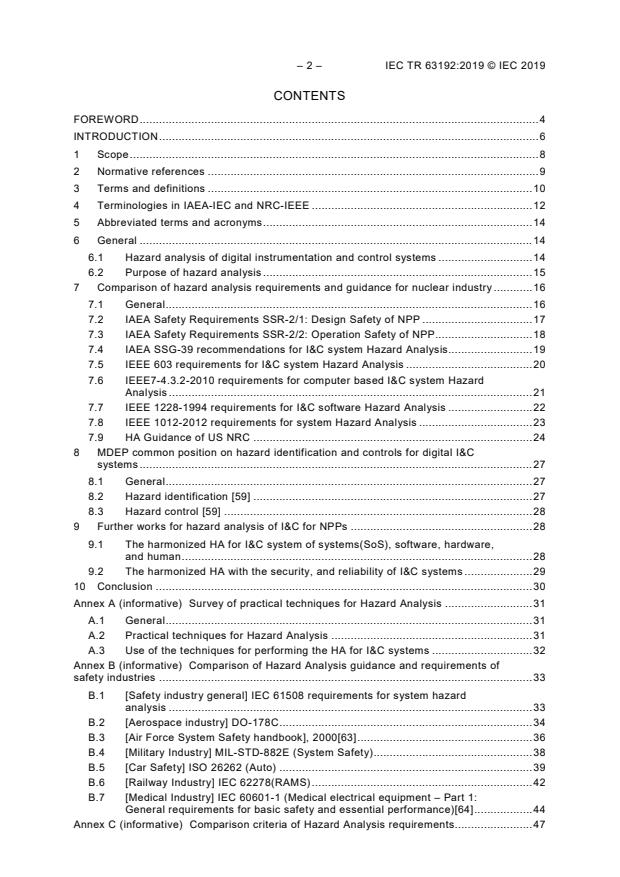

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 10

4 Terminologies in IAEA-IEC and NRC-IEEE . 12

5 Abbreviated terms and acronyms . 14

6 General . 14

6.1 Hazard analysis of digital instrumentation and control systems . 14

6.2 Purpose of hazard analysis . 15

7 Comparison of hazard analysis requirements and guidance for nuclear industry . 16

7.1 General . 16

7.2 IAEA Safety Requirements SSR-2/1: Design Safety of NPP . 17

7.3 IAEA Safety Requirements SSR-2/2: Operation Safety of NPP . 18

7.4 IAEA SSG-39 recommendations for I&C system Hazard Analysis. 19

7.5 IEEE 603 requirements for I&C system Hazard Analysis . 20

7.6 IEEE7-4.3.2-2010 requirements for computer based I&C system Hazard

Analysis . 21

7.7 IEEE 1228-1994 requirements for I&C software Hazard Analysis . 22

7.8 IEEE 1012-2012 requirements for system Hazard Analysis . 23

7.9 HA Guidance of US NRC . 24

8 MDEP common position on hazard identification and controls for digital I&C

systems . 27

8.1 General . 27

8.2 Hazard identification [59] . 27

8.3 Hazard control [59] . 28

9 Further works for hazard analysis of I&C for NPPs . 28

9.1 The harmonized HA for I&C system of systems(SoS), software, hardware,

and human . 28

9.2 The harmonized HA with the security, and reliability of I&C systems . 29

10 Conclusion . 30

Annex A (informative) Survey of practical techniques for Hazard Analysis . 31

A.1 General . 31

A.2 Practical techniques for Hazard Analysis . 31

A.3 Use of the techniques for performing the HA for I&C systems . 32

Annex B (informative) Comparison of Hazard Analysis guidance and requirements of

safety industries . 33

B.1 [Safety industry general] IEC 61508 requirements for system hazard

analysis . 33

B.2 [Aerospace industry] DO-178C . 34

B.3 [Air Force System Safety handbook], 2000[63] . 36

B.4 [Military Industry] MIL-STD-882E (System Safety) . 38

B.5 [Car Safety] ISO 26262 (Auto) . 39

B.6 [Railway Industry] IEC 62278(RAMS) . 42

B.7 [Medical Industry] IEC 60601-1 (Medical electrical equipment – Part 1:

General requirements for basic safety and essential performance)[64] . 44

Annex C (informative) Comparison criteria of Hazard Analysis requirements . 47

C.1 Safety principles (safety model, safety culture) . 47

C.2 Safety processes . 47

C.3 Definition of HA . 47

C.4 Purpose of HA . 47

C.5 Method of HA . 47

C.6 HA process . 47

C.7 Independence of HA (HA organization) . 47

C.8 Harmonized HA of SoS . 48

C.9 Relationship with other requirements (security, reliability) . 48

Bibliography . 50

Figure 1 – I&C Layer and Defence-in-Depth Level . 9

Figure 2 – Internal or external hazards . 15

Figure 3 – IAEA-IEC framework of I&C standards . 16

Figure 4 – NRC-IEEE framework of I&C standards . 17

Figure 5 – Harmonization of HA requirements for I&C system of systems . 29

Figure 6 – Overall safety assessment . 30

Table 1 – Definitions of IAEA and IEEE nuclear standards . 13

Table 2 – Hazard Analysis in IAEA Safety Requirements SSR-2/1 . 18

Table 3 – HA requirements in IAEA SSG-39. 19

Table 4 – HA requirements in IEEE Standard 603-2009 . 20

Table 5 – HA requirements in IEEE7-4.3.2-2010 . 21

Table 6 – HA requirements in IEEE 1228-1994 . 23

Table 7 – HA requirements in IEEE 1012-2012 . 24

Table 8 – DSRS APPENDIX A. Hazard Analysis . 25

Table 9 – Research Information Letter of HA review (US NRC RIL 1101) . 26

Table B.1 – HA requirements in the functional safety standard IEC 61508 . 33

Table B.2 – HA requirements in the aerospace safety standards ARP 4761, DO-178C. 35

Table B.3 – HA requirements in Air Force System Safety handbook . 36

Table B.4 – HA requirements in the military safety standard MIL 882 E . 38

Table B.5 – HA requirements in the car safety standard ISO 26262 . 40

Table B.6 – HA requirements in the railway safety standard IEC 62278 . 43

Table B.7 – HA requirements in the medical safety standard . 45

Table C.1 – Comparison criteria . 48

– 4 – IEC TR 63192:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

NUCLEAR POWER PLANTS –

INSTRUMENTATION AND CONTROL SYSTEMS IMPORTANT TO SAFETY –

HAZARD ANALYSIS: A REVIEW OF CURRENT APPROACHES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as closely as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is are accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall be attached to IEC or its directors, employees, servants or agents including individual experts

and members of its technical committees and IEC National Committees for any personal injury, property

damage or other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees)

and expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 63192, which is a technical report, has been prepared by subcommittee 45A:

Instrumentation, control and electrical power systems of nuclear facilities, of IEC technical

committee 45: Nuclear instrumentation.

The text of this Technical Report is based on the following documents:

Draft TR Report on voting

45A/1197/DTR 45A/1231/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC TR 63192:2019 © IEC 2019

INTRODUCTION

a) Technical background, main issues and organisation of the document

The purpose of the TR is to identify the worldwide situation of HA requirements for digital I&C.

It is not the purpose of this technical report to reconcile the hazards analysis techniques and

to harmonise the use of hazards analysis terminology between the many different approaches

used by standards bodies (e.g. between the IEEE and IAEA), but rather to document the

different approaches. The information provided can then be used to further the development

of a consistent approach to hazards analysis within the IEC.

It is intended that this document be used by operators of NPPs (utilities), systems evaluators

and by licensors.

b) Situation of the current document in the structure of the IEC SC 45A standard

series

IEC 63192 as a Technical Report is a fourth level IEC/SC 45A document.

For more details on the structure of the IEC SC 45A standard series, see item d) of this

introduction.

c) Recommendations and limitations regarding the application of the document

It is important to note that a technical report is entirely informative in nature. It gathers data

collected from different origins and it establishes no requirements.

d) Description of the structure of the IEC SC 45A standard series and relationships

with other IEC documents and other bodies documents (IAEA, ISO)

The top-level documents of the IEC SC 45A standard series are IEC 61513 and IEC 63046.

IEC 61513 provides general requirements for I&C systems and equipment that are used to

perform functions important to safety in NPPs. IEC 63046 provides general requirements for

electrical power systems of NPPs; it covers power supply systems including the supply

systems of the I&C systems. IEC 61513 and IEC 63046 are to be considered in conjunction

and at the same level. IEC 61513 and IEC 63046 structure the IEC SC 45A standard series

and shape a complete framework establishing general requirements for instrumentation,

control and electrical systems for nuclear power plants.

IEC 61513 and IEC 63046 refer directly to other IEC SC 45A standards for general topics

related to categorization of functions and classification of systems, qualification, separation,

defence against common cause failure, control room design, electromagnetic compatibility,

security, software and hardware aspects for programmable digital systems, coordination of

safety and security requirements and management of ageing. The standards referenced

directly at this second level should be considered together with IEC 61513 and IEC 63046 as

a consistent document set.

At a third level, IEC SC 45A standards not directly referenced by IEC 61513 or by IEC 63046

are standards related to specific equipment, technical methods, or specific activities. Usually

these documents, which make reference to second-level documents for general topics, can be

used on their own. IEC 63096 refers in detail to a distinct version of ISO/IEC 27002. A later

modification of ISO/IEC 27002 must not automatically influence the modifications, detailing

and completions given by IEC 63096 without analysing the consequences from the nuclear

I&C perspective.

A fourth level extending the IEC SC 45 standard series, corresponds to the Technical Reports

which are not normative.

The IEC SC 45A standards series consistently implements and details the safety and security

principles and basic aspects provided in the relevant IAEA safety standards and in the

relevant documents of the IAEA nuclear security series (NSS). In particular this includes the

IAEA requirements SSR-2/1, establishing safety requirements related to the design of nuclear

power plants (NPPs), the IAEA safety guide SSG-30 dealing with the safety classification of

structures, systems and components in NPPs, the IAEA safety guide SSG-39 dealing with the

design of instrumentation and control systems for NPPs, the IAEA safety guide SSG-34

dealing with the design of electrical power systems for NPPs and the implementing guide

NSS17 for computer security at nuclear facilities. The safety and security terminology and

definitions used by SC 45A standards are consistent with those used by the IAEA.

IEC 61513 and IEC 63046 have adopted a presentation format similar to the basic safety

publication IEC 61508 with an overall life-cycle framework and a system life-cycle framework.

Regarding nuclear safety, IEC 61513 and IEC 63046 provide the interpretation of the general

requirements of IEC 61508-1, IEC 61508-2 and IEC 61508-4, for the nuclear application

sector. In this framework IEC 60880, IEC 62138 and IEC 62566 correspond to IEC 61508-3

for the nuclear application sector. IEC 61513 and IEC 63046 refer to ISO as well as to IAEA

GS-R part 2 and IAEA GS-G-3.1 and IAEA GS-G-3.5 for topics related to quality assurance

(QA). At level 2, regarding nuclear security, IEC 62645 is the entry document for the

IEC/SC 45A security standards. It builds upon the valid high level principles and main

concepts of the generic security standards, in particular ISO/IEC 27001 and ISO/IEC 27002; it

adapts them and completes them to fit the nuclear context and coordinates with the

IEC 62443 series. At level 2, IEC 60964 is the entry document for the IEC/SC 45A control

room standards and IEC 62342 is the entry document for the ageing management standards.

NOTE 1 It is assumed that for the design of I&C systems in NPPs that implement conventional safety functions

(e.g. to address worker safety, asset protection, chemical hazards, process energy hazards) international or

national standards would be applied.

NOTE 2 IEC/SC 45A domain was extended in 2013 to cover electrical systems. In 2014 and 2015 discussions

were held in IEC/SC 45A to decide how and where general requirements for the design of electrical systems were

to be considered. IEC/SC 45A experts recommended that an independent standard be developed at the same level

as IEC 61513 to establish general requirements for electrical systems. Project IEC 63046 is now launched to cover

this objective. When IEC 63046 is published this NOTE 2 of the introduction of IEC/SC 45A standards will be

suppressed.

– 8 – IEC TR 63192:2019 © IEC 2019

NUCLEAR POWER PLANTS –

INSTRUMENTATION AND CONTROL SYSTEMS IMPORTANT TO SAFETY –

HAZARD ANALYSIS: A REVIEW OF CURRENT APPROACHES

1 Scope

This document provides the comparison of the hazard analysis requirements between IAEA

framework and NRC-IEEE framework of standards and guidance. The hazard analysis

requirements in the different standards were compared with a set of comparison criteria,

including the safety principle, the safety process, the definitions, the hazard analysis process,

etc. This document includes the comparison results of the HA requirements of the safety

control systems of other safety industries in Annex C.

For a nuclear power plant, the design safety and operation safety shall be analyzed, for

example, to meet the IAEA Safety Requirements for Design (SSR-2/1) and Operation

(SSR-2/2). The scope of this document is to survey the state of the art in the hazard analysis

for the design of I&C system of NPPs.

Figure 1 illustrates the scope of I&C systems important to safety which have hazard analysis

requirements, in the form of a three by three matrix which is in IEEE 603-2009. This document

covers the hazard analysis for the sense and command features of digital systems. This

document also considers the requirements for hazard analysis of the system of systems(SoS),

including the software, hardware and human for the digital systems.

Figure 1 – I&C Layer and Defence-in-Depth Level

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60880:2006, Nuclear power plants – Instrumentation and control systems important to

safety – Software aspects for computer-based systems performing category A functions

IEC 61226:2009, Nuclear power plants – Instrumentation and control important to safety –

Classification of instrumentation and control functions

IEC 61508 (all parts), Functional Safety of electrical/electronic/programmable electronic

safety-related systems

– 10 – IEC TR 63192:2019 © IEC 2019

IEC TR 61508-0, Functional safety of electrical/electronic/programmable electronic safety-

related systems – Part 0: Functional safety and IEC 61508

IEC 61508-4, Functional safety of electrical/electronic/programmable electronic safety-related

systems – Part 4: Definitions and abbreviations

IEC 61513:2011, Nuclear power plants – Instrumentation and control important to safety –

General requirements for systems

IAEA Safety Standards Specific Safety Requirements SSR-2/1:2012, Safety of Nuclear Power

Plants: Design

IAEA Safety Standards, Specific Safety Requirements SSR-2/2:2012, Safety of Nuclear Power

Plants: Commissioning and Operation

IAEA Safety Standards, Safety Guide SSG-39:2016, Design of Instrumentation and Control

Systems for Nuclear Power Plants

IEEE Standard 7-4.3.2-2010, IEEE standard criteria for Digital Computers in safety systems

for nuclear power generating stations

IEEE Standard 603-2009, IEEE standard criteria for safety systems for nuclear power

generating stations

IEEE Standard 1012-2012, IEEE standard for system and software verification and validation

IEEE Standard 1228-1994, IEEE standard for Software Safety Plans

Research Information Letter (RIL) 1101: Technical basis to review hazard analysis of digital

safety systems, US NRC, August, 2013

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

safety analysis

evaluation of the potential hazards associated with the conduct of an activity

Note 1 to entry: Safety analysis is often used interchangeably with safety assessment. However, when the

distinction is important, safety analysis should be used for the study of safety, and safety assessment for the

valuation of safety — for example, evaluation of the magnitude of hazards, evaluation of the performance of safety

measures and judgment of their adequacy, or quantification of the overall radiological impact or safety of a facility

or activity.

[SOURCE: IAEA Safety Glossary, edition 2007]

3.2

assessment

the process, and the result, of analyzing systematically and evaluating the hazards associated

with sources and practices, and associated protection and safety measures. Assessment is

often aimed at quantifying performance measures for comparison with criteria.

Note 1 to entry: In IAEA publications, assessment should be distinguished from analysis. Assessment is aimed at

providing information that forms the basis of a decision on whether or not something is satisfactory. Various kinds

of analysis may be used as tools in doing this. Hence an assessment may include a number of analyses.

[SOURCE: IAEA Safety Glossary, edition 2007]

3.3

safety assessment

a) assessment of all aspects of a practice that are relevant to protection and safety; for an

authorized facility, this includes siting, design and operation of the facility. This will

normally include risk assessment.

b) analysis to predict the performance of an overall system and its impact, where the

performance measure is the radiological impact or some other global measure of the

impact on safety

c) the systematic process that is carried out throughout the design process to ensure that all

the relevant safety requirements are met by the proposed (or actual) design. Safety

assessment includes, but is not limited to, the formal safety analysis

[SOURCE: IAEA Safety Glossary, edition 2007]

3.4

hazard

a) potential source of harm

[SOURCE: ISO/IEC Guide 51:2014, 3.2]

b) intrinsic property or condition that has the potential to cause harm or damage. (B) A

source of potential harm or a situation with a potential for harm in terms of human injury,

damage to health, property, or the environment, or some combination of these

[SOURCE: IEEE 1012-2012]

3.5

hazard identification

process of recognizing that a hazard exists and defining its characteristics

[SOURCE: IEEE 1012-2012]

3.6

contributory hazard

factor contributing to potential for harm

[SOURCE: AviationGlossary.com, “Contributory Hazard,”

, October 15, 2012]

3.7

hazard analysis

a) process of examining a system throughout its lifecycle to identify inherent hazards and

contributory hazards, and requirements and constraints to eliminate, prevent, or control

them

[SOURCE: US NRC RIL 1101]

– 12 – IEC TR 63192:2019 © IEC 2019

b) systematic qualitative or quantitative evaluation of software for undesirable outcomes

resulting from the development or operation of a system

these outcomes may include injury, illness, death, mission failure, economic loss,

property loss, environmental loss, or adverse social impact. This evaluation may include

screening or analysis methods to categorize, eliminate, reduce, or mitigate hazards

[SOURCE: IEEE 1012-1998]

c) process of examining a system throughout its lifecycle to identify inherent hazards and

contributory hazards, and requirements and constraints to eliminate, prevent, or control

them

Note 1 to entry: The scope of hazard analysis extends beyond design basis accidents for the plant by including

abnormal events and plant operations with degraded equipment and plant systems.

[SOURCE: IAEA SSG-39, 2016]

d) process that explores and identifies conditions that are not identified by the normal

design review and testing process

the scope of hazard analysis extends beyond plant design basis events by including

abnormal events and plant operations with degraded equipment and plant systems.

Hazard analysis focuses on system failure mechanisms rather than verifying correct

system operation

[SOURCE: IEEE Std 7-4.3.2-2003 and 2010]

e) a hazard analysis (HA) is a process for examining an instrumentation and control (I&C)

system throughout its development lifecycle to identify hazards (i.e., factors and causes),

and system requirements and constraints to eliminate, prevent, or control them. Hazard

analyses examine safety related I&C systems, subsystems, and components, their

interrelationships and their interactions with other systems, subsystems, and components

to identify unintended or unwanted I&C system operation including the impairment or loss

of the ability to perform a safety function

[SOURCE: US NRC DSRS App A]

4 Terminologies in IAEA-IEC and NRC-IEEE

There are some differences in the concept, definitions and principles of the safety aspects

between IAEA and IEEE communities. Table 1 shows the differences as a summary.

Table 1 – Definitions of IAEA and IEEE nuclear standards

IAEA IEEE

1 Framework IAEA-IEC NRC-IEEE

Risk based Graded application of quality and

2 No graded application

qualification reliability features

SIL in IEC 61508, Categories in IEC

3 Classification Class IE, Non1E

4 Safety view Safety requirements specification is the Safety Analysis in all phases of the lifecycle

main activity in the lifecycle.

5 Software Safety goal and requirements shall be Same approach, but different in direct hazard

qualification met through good engineering. analysis

principle

1 Simple, separate safety systems 1 Simple, separate safety systems design

design

2 System quality

2 System quality

– Complete and correct safety

– Complete and correct safety requirements

requirements

– Correct implementation

– Correct implementation

– Producing quality products

– Producing quality products

3 Defense-in-depth and diversity

3 Defense-in-depth and diversity

4 Hazard avoidance / identification /

resolution

6 Accident Deviations from normal operation (IEEE 1228) An unplanned event or series of

events that results in death, injury, illness,

environmental damage, or damage to or loss of

equipment or property

7 Hazard (IEC 61508-4) Potential source of harm (IEEE 7-4.3.2) A condition that is a prerequisite

to an accident. Hazards include external events

as well as conditions internal to computer

hardware or software

8 Risk (IEEE 1228) A measure that combines both the

(IEC 61508-4) Combination of the

likelihood that a system hazard will cause an

probability of occurrence of harm and

accident and the severity of that accident

severity of that harm

9 Safety

(IEC 61508-4) Freedom from

unacceptable risk

10 Software (IEEE 1228) A software condition that is a

hazard prerequisite to an accident

11 System (IEEE 1228) A system condition that is a

hazard prerequisite to an accident

12 Software (IEEE 1228) Freedom from software hazards

safety

13 System (IEEE 1228) Freedom from system hazards

safety

14 Hazard (IEEE 7-4.3.2) Hazard Analysis: A process that

(IEC 61508-0) Hazard Analysis derives

analysis explores and identifies conditions that are not

Safety Function Requirements

identified by the normal design review and

testing process. Hazard analysis focuses on

system failure mechanisms rather than

verifying correct system operation.

(NUREG-CR 6430)[50] Hazard Analysis is the

process of identifying and evaluating the

hazards of a system, and then either

eliminating the hazard or reducing its risk to an

acceptable level.

15 Risk (IEC 61508-0) Risk assessment derives No definition

assessment

safety integrity requirements

—————————

Numbers in square brackets refer to the Bibliography.

– 14 – IEC TR 63192:2019 © IEC 2019

16 Functional (IEC 61508-0) Functional safety: is part No definition

safety

of the overall safety that depends on a

system or equipment operating correctly

in response to its inputs.

17 Functional (IEEE 7-4.3.2) Hazard Analysis: A process that

(IEC 61508-4) Functional safety

safety explores and identifies conditions that are not

assessment: investigation, based on

assessment identified by the normal design review and

evidence, to judge the functional safety

testing process. The scope of hazard analysis

achieved by one or more E/E/PE (See

extends beyond plant design basis events by

Table B.1) safety-related systems, other

including abnormal events and plant operations

technology safety-related systems or

with degraded equipment and plant systems.

external risk reduction facilities

5 Abbreviated terms and acronyms

ASIC Application Specific Integrated Circuit

CCF Common Cause Failure

COTS Commercial Off-The-Shelf

DSRS Design Specific Review Standard

ESF Engineered Safety Features

FPGA Field Programmable Gate Array

HDL Hardware Description Language

HA Hazard Analysis

HVAC Heating, Ventilation, Air Conditioning

IAEA International Atomic Energy Agency

I&C Instrumentation and Control

NPP Nuclear Power Plant

NRC Nuclear Regulatory Commission

PLC Programmable Logic Controller

QA Quality Assurance

RAMS Reliability, Availability, Maintainability, and Safety

RTS Reactor Trip System

SIL Safety Integrity Level

SoS System of Systems

SSR Specific Safety Requirements

V&V Verification & Validation

6 General

6.1 Hazard analysis of digital instrumentation and control systems

A hazard, in general, is defined as “potential for harm.” In this document, the scope of “harm”

is limited to the loss of a safety function in a Nuclear Power Plant (NPP). Furthermore, the

unintended or spurious action of a safety function can cause harm or in some cases

contravene the safety function needed in that particular situation.

In the context of ensuring a safety system of the highest criticality, a hazard (potential for

harm, in brief) is the potential to degrade the system’s capability to perform its allocated

safety function (henceforth, potential to degrade the system). The hazard may be external or

internal to the system. (There may be multiple levels of integration of a system, i.e., there may

be systems within systems; then the internal-external boundary shifts in accordance with the

level of integration in focus.)

The Hazard Analysis (HA) of an Instrumentation and Control (I&C) system is to identify the

relationship of the logical faults, error, and failure of I&C systems to the physical harm of the

nuclear power plant, and also to find the impact of the external hazard, e.g., tsunami, of the

nuclear power plant to the I&C systems.

Hazards analysis, a systems engineering activity, is the application of systematic and

replicable methods to identify hazards, their potential adverse effects, their causes, and the

changes in system concept or safety requirements needed to meet the overall safety goals of

the system.

Although the term “hazard analysis” has been defined in many different ways as shown in 3.7,

in this document the comparison scope of HA requirements is related to identify all internal

and external hazards of I&C systems boundary shown in Figure 2, leading to the loss or

spurious activation of safety functions of the NPP.

Figure 2 – Internal or external hazards

The hazard analysis is the analysis of internal and external hazards at the boundary of I&C

system as shown in Figure 2. Internal hazards include the inherent hazards from software

faults introduced throughout the software lifecycle, interaction faults between software and

human, and between software and hardware, functional interaction and multiple functional

failures such as a common cause failure. External hazards include a loss of power, EMI, RFI,

flood, earthquake, and their cascaded events.

6.2 Purpose of hazard analysis

The purpose of HA should be:

a) to identify the hazard and the contributory hazards of I&C system of systems (SoS;.

b) to validate the hazardous aspects of I&C system, software, hardware, and human

throughout the lifecycle;

c) to provide solutions for the elimination, control, and mitigation of the hazards.

– 16 – IEC TR 63192:2019 © IEC 2019

7 Comparison of hazard analysis requirements and guidance for nuclear

industry

7.1 General

There are two major groups of standardization communities in the nuclear industry, the IAEA

community and the IEEE community. Each community has developed safety standards and

regulatory criteria as shown in Figure 3 and Figure 4. The box in bold in Figures 3 and 4 has

some requirements related to the hazard analysis. In this clause, those HA requirements are

compared by a template which is defined in Annex C of this document.

Figure 3 – IAEA-IEC framework of I&C standards

Figure 4 – NRC-IEEE framework of I&C standards

7.2 IAEA Safety Requirements SSR-2/1: Design Safety of NPP:2012

Table 2 presents Hazard Analysis in IAEA Safety Requirements SSR-2/1:2012.

– 18 – IEC TR 63192:2019 © IEC 2019

Table 2 – Hazard Analysis in IAEA Safety Requirements SSR-2/1:2012

Comparison criteria of HA HA requirements in the safety standard of

requirements IAEA SSR-2/1: Design Safety of NPP

1 Safety principles

Requirement 17: Internal and external hazards. All foreseeable internal

hazards and external hazards, including the potential for human induced

(safety model or safety

events directly or indirectly to affect the safety of the nuclear power plant,

culture)

shall be identified and their effects shall be evaluated. Hazards shall be

considered for determination of the postulated initiating events and

generated loadings for use in the design of relevant items important to

safety for the plant.

2 Safety processes None

3 Definition of HA Internal hazards

5.16. The design shall take due account of internal hazards such as fire,

explosion, flooding, missile generation, collapse of structures and falling

objects, pipe whip, jet impact and release of fluid from failed systems or

from other installations on the site. Appropriate features for prevention and

mitigation shall be provided to ensure that safety is not compromised.

External hazards

5.17. The design shall include due consideration of those natural and

human induced external events (i.e. events of origin external to the plant)

that have been identified in the site evaluation process. Natural external

events shall be addressed, including meteorological, hydrological,

geological and seismic events. Human induced external events arising from

nearby industries and transport routes shall be addressed. In the short

term, the safety of the plant shall not be permitted to be dependent on the

availability of off-site services such as electricity supply and firefighting

services. The design shall take due account of site specific conditions to

determine the maximum delay time by which off-site services need to be

available.

4 Purpose of HA None

5 Method of HA None

6 HA process None

7 Independence of HA (HA None

organization)

8 Harmonized HA of SoS None

9 Relationship with other None

requirements (security,

reliability)

10 Discussion [Terminology Issue]

There are only the top level requirements of the internal and external

hazards in IAEA SSR-2/1 without the definitions of the internal and external

hazards.

There are informal explanations of the internal and external hazards:

Internal hazard such as fire, explosion, flooding, missile generation,

collapse of structures and falling objects, pipe whips, jet impacts, and

release of fluid from failed systems or from other installations on the site.

natural and human induced external events (i.e., events of origin external

to the plant)

In IAEA Safety Glossary, there is no definition of internal and external

hazards.

The internal and external hazards should be decided according to the

boundaries of the appropriate systems, such as the plant system, an I&S

system, a platform, an operating system, a device, and so on.

7.3 IAEA Safety Requirements SSR-2/2: Operation Safety of NPP:2012

No explicit requirements for operational hazards. There are many implicit requirements of

hazards.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...